Study on Protective Coal Pillar Size Design for Ultra High Voltage Line Tower Mining in Mountain Areas

Abstract

:1. Introduction

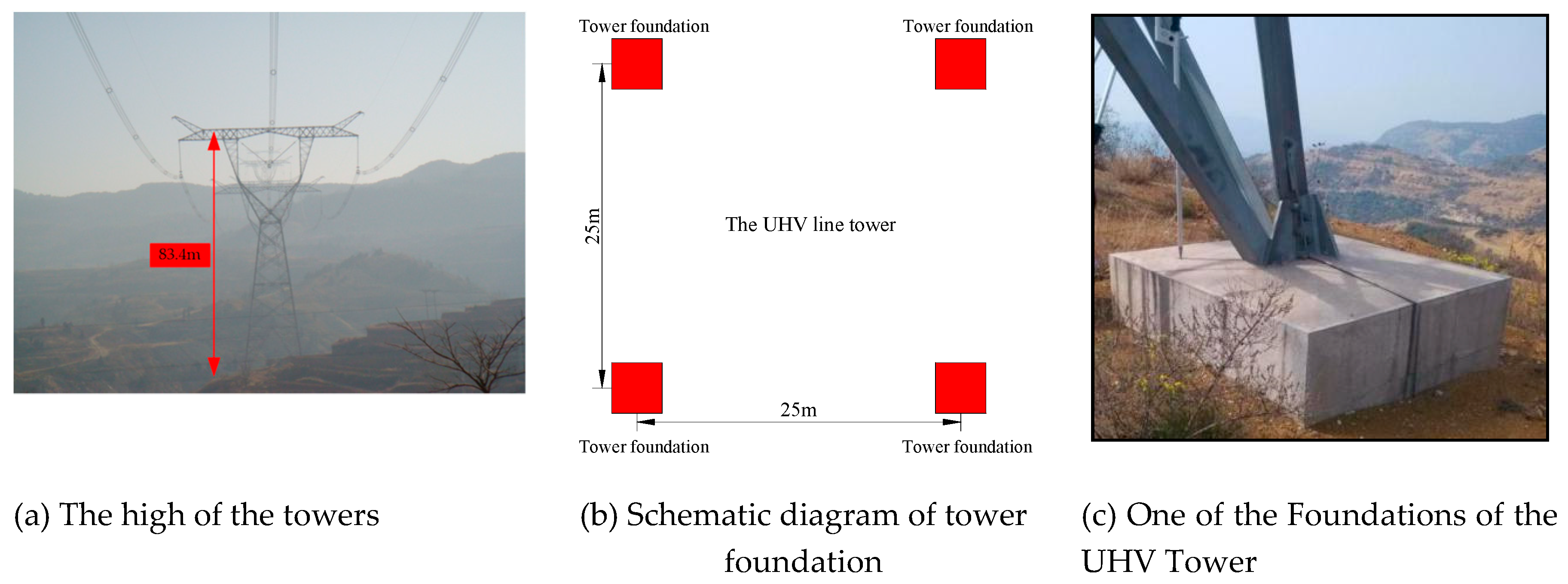

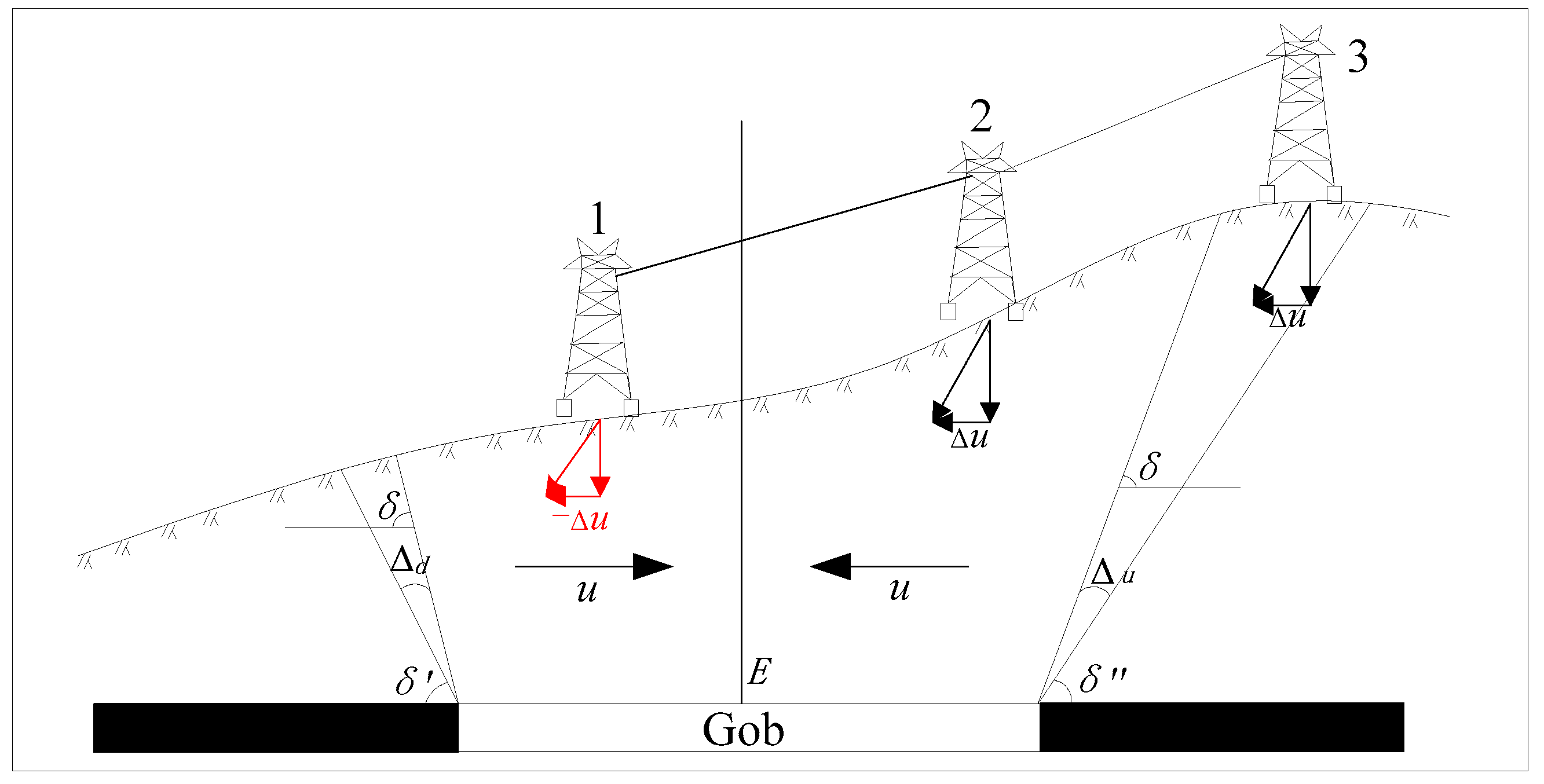

2. Geological Mining Conditions and the Ultra High Voltage Towers

3. Selection and Analysis of the Angle of Critical Deformation of Strata

3.1. Selection of the Angle of Critical Deformation by P Coefficient Method

3.2. Selection of the Angle of Critical Deformation by Repeated Mining

3.3. Analysis of the Angle of Critical Deformation by Considering Additional Influence of Slippage Mining in Mountain Area

4. Analysis of the Protective Coal Pillar Size

4.1. The Method of Protective Coal Pillar Design

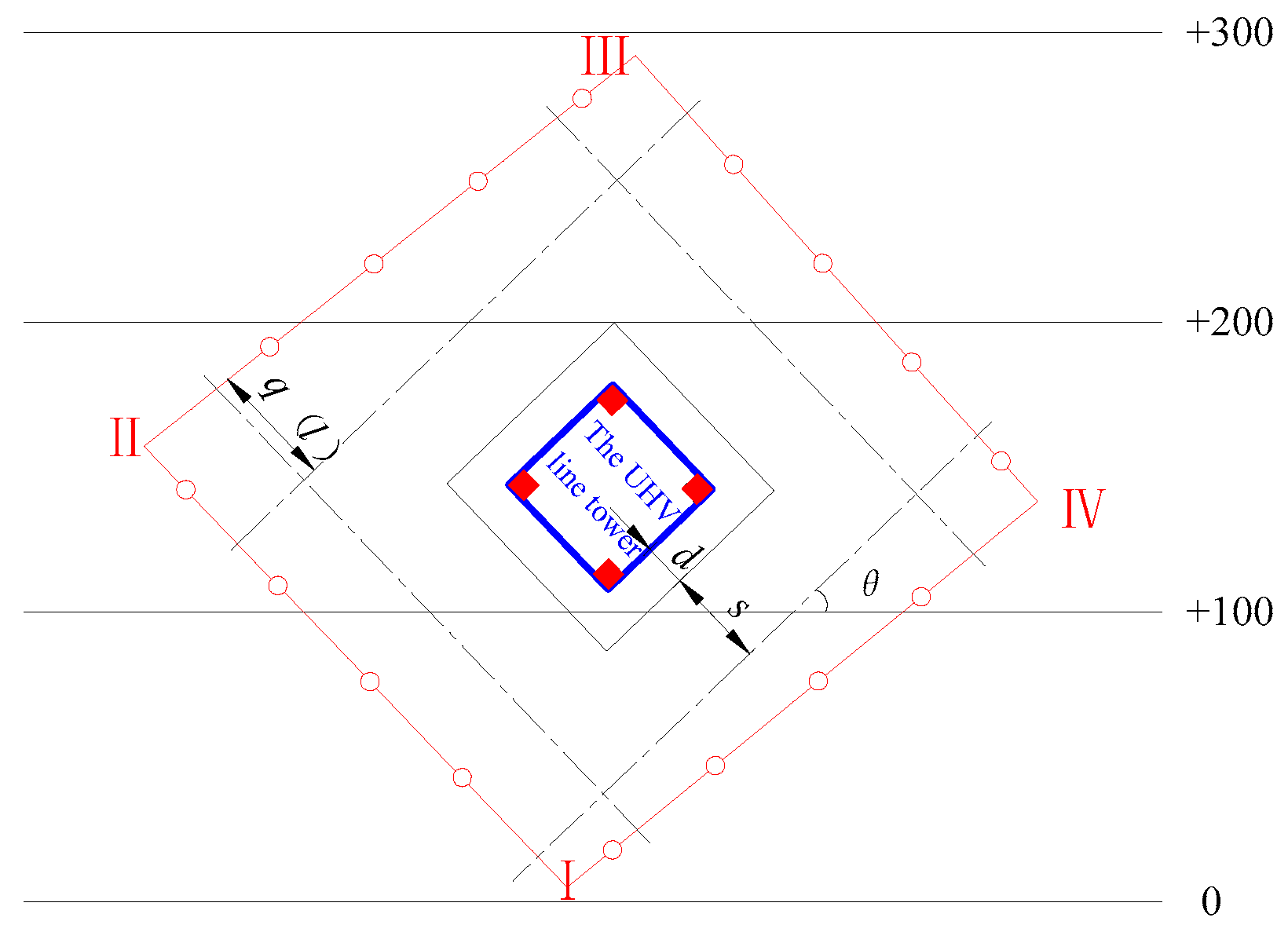

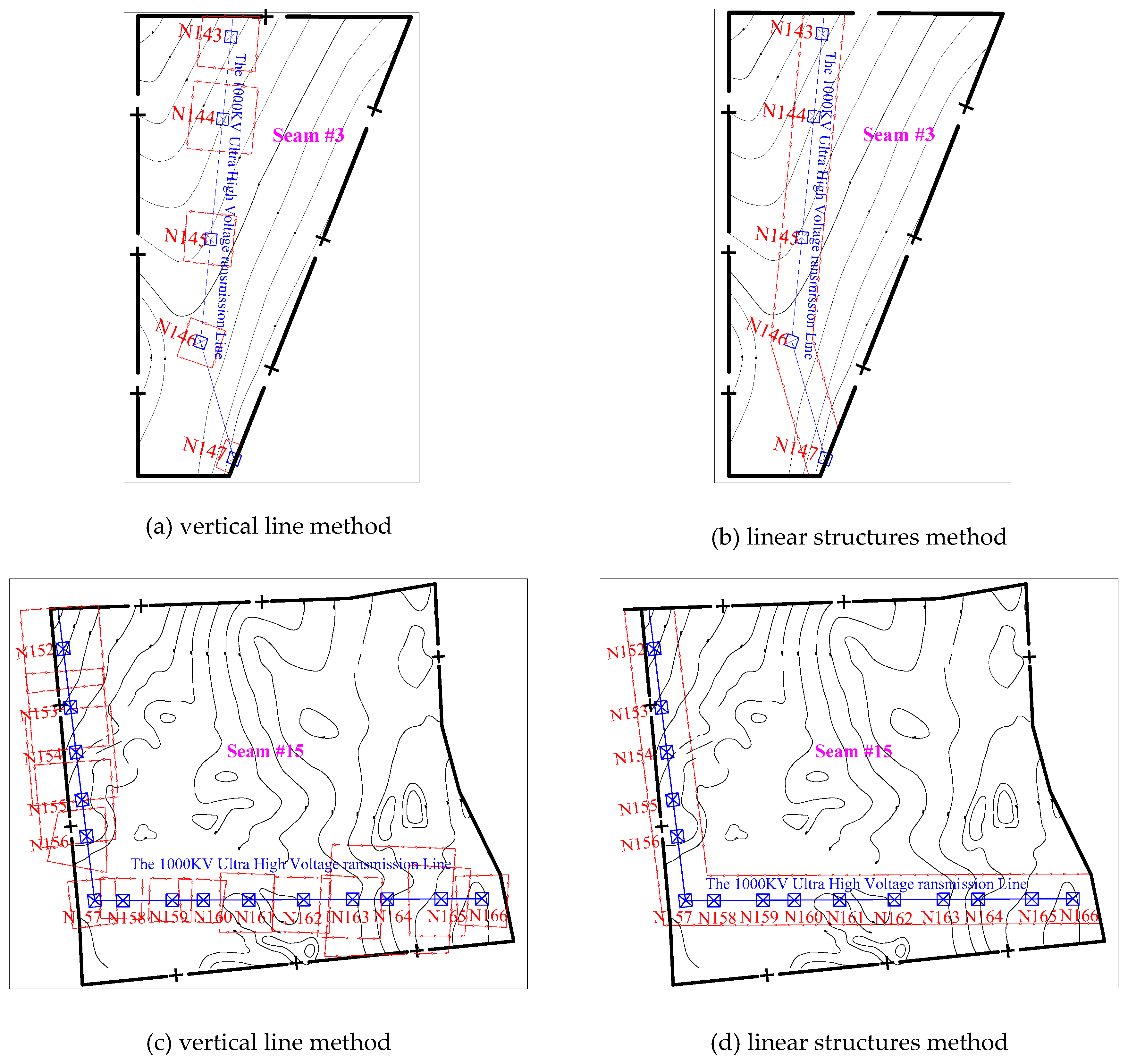

4.1.1. The Vertical Line Method

Determination of the Boundary of Protected Area

Determination of Protective Boundary of Unconsolidated Formation

Determination of Protective Coal Pillar Boundary

Determination of the Range of Protective Coal Pillar

Determination of the Protective Coal Pillar Size

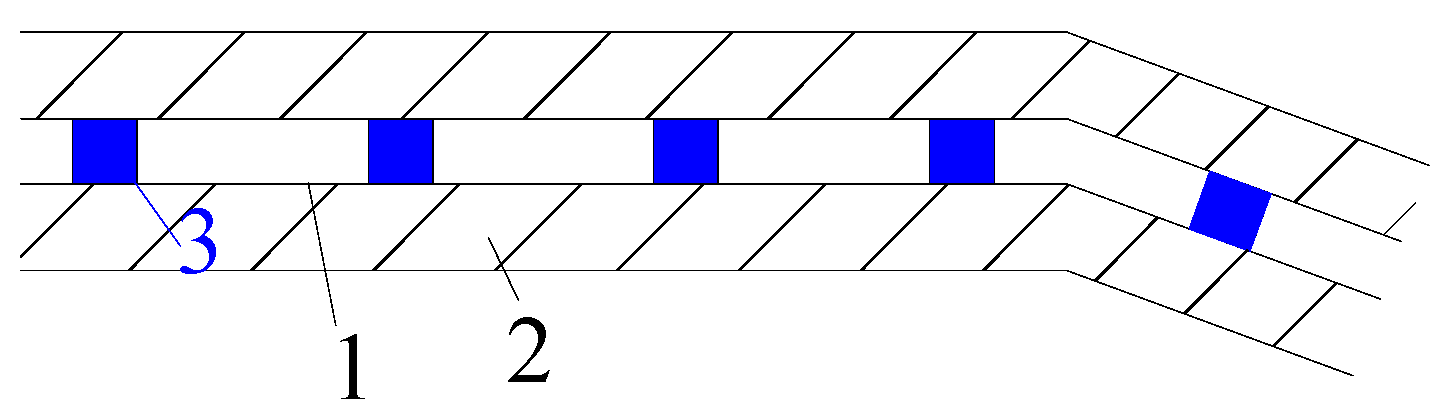

4.1.2. The Linear Structure Method

4.2. Result of Protective Coal Pillar Design

4.2.1. Result of Protective Coal Pillar Size

4.2.2. Result of the Protective Coal Pillar Amount

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- The Ministry of Coal Industry of China. Standard of Coal Pillar Design and Mining under Buildings, Water Bodies, Railways and Main Wells and Roadways; Coal Industry Press: Beijing, China, 2017; pp. 100–179. ISBN 978-7-5020-6050-3.

- Guo, W.B. Coal Mining Damages and Protection; Coal Industry Press: Beijing, China, 2013; pp. 1–6. ISBN 978-7-5020-4287-5. [Google Scholar]

- Guo, W.B.; Yang, Z.G.; Zhan, M. Research and Application of Mining Subsidence Law of “Three Soft” Coal Seam; Science Press: Beijing, China, 2013; pp. 234–237. ISBN 978-7-03-037255-0. [Google Scholar]

- Wei, F.Y.; Chen, J.J.; Zou, Y.F. Analytical model of protective coal pillar design for vertical section method. J. China Coal Soc. 2008, 3, 256–258. [Google Scholar] [CrossRef]

- Liu, Y.; Cai, L.; Wang, S.; Yang, W. High-voltage line tower deformation monitoring based on feature line. Sci. Surv. Mapp. 2016, 41, 212–216. [Google Scholar] [CrossRef]

- Li, J.F.; Hu, H.F.; Li, W. Effect Analysis of Slippage Caused by Underground Mining on Surface Movement and Deformation. Coal Mine Saf. 2014, 45, 204–207. [Google Scholar] [CrossRef]

- Shu, Q.; Yuan, G.; Guo, G.; Zhang, Y. Limits to foundation displacement of an extra high voltage transmission tower in a mining subsidence area. Int. J. Min. Sci. Technol. 2012, 22, 13–18. [Google Scholar] [CrossRef]

- Yuan, G.-L.; Li, S.-M.; Xu, G.-A.; Si, W.; Zhang, Y.-F.; Shu, Q.-J. The anti-deformation performance of composite foundation of transmission tower in mining subsidence area. Procedia Earth Planet. Sci. 2009, 1, 571–576. [Google Scholar] [CrossRef] [Green Version]

- Kwinta, A.; Gawronek, P. Prediction of Linear Objects Deformation Caused by Underground Mining Exploitation. Procedia Eng. 2016, 161, 150–156. [Google Scholar] [CrossRef] [Green Version]

- Xu, P.; Mao, X.; Zhang, M.; Zhou, Y.; Yu, B. Safety analysis of building foundations over old goaf under additional stress from building load and seismic actions. Int. J. Min. Sci. Technol. 2014, 24, 713–718. [Google Scholar] [CrossRef]

- Lian, X.G.; Hu, H.F. Terrestrial laser scanning monitoring and spatial analysis of ground disaster in Gaoyang coal mine in Shanxi, China: A technical note. Environ. Earth Sci. 2017, 76, 287. [Google Scholar] [CrossRef]

- Yang, F.; Yang, J.; Han, J.; Zhang, Z. Study on the Limited Values of Foundation Deformation for a Typical UHV Transmission Tower. IEEE Trans. Power Deliv. 2010, 25, 2752–2758. [Google Scholar] [CrossRef]

- Bernett, T.W. Structural of 345kV overhead transmission structures emdash Brunot Island-Collier. Minutes Meet. Pa. Electr. Assoc. Eng. Sect. 1978, 16–18. [Google Scholar]

- Bruhn, R.W.; Ferrell, J.R.; Luxbacher, G.W. The Structural Response of a Steel-Lattice Transmission Tower to Mining-Related Ground Movements. In Proceedings of the 10th International Conference on Ground Control in Mining, Morgantown, WV, USA, 10–12 June 1991. [Google Scholar]

- Guo, W.B.; Yong, Q. Study on the synergy acting model of high voltage power transmission lines tower, groundwork and foundation influenced by mining. J. China Coal Soc. 2011, 36, 1075–1080. [Google Scholar] [CrossRef]

- Guo, W.B.; Zheng, B. Study of Coal Caving Mining Under High-Voltage Transmission Line the Steel Tower of and Its Safety. J. Min. Saf. Eng. 2011, 28, 267–272. [Google Scholar] [CrossRef]

- Guo, W.B.; Yuan, L.H.; Zheng, B. Study of the effect on high-voltage transmission line tower of surface slope. J. Henan Polytech. Univ. (Nat. Sci.) 2012, 31, 285–290. [Google Scholar] [CrossRef]

- Liu, Z.A.; Gao, W.L.; Que, J.S. Numerical analysis of transmission tower foundation stability at various zones affected by coal seam mining. J. Eng. Geol. 2011, 19, 922–927. [Google Scholar] [CrossRef]

- Yan, Y.G.; Dai, H.Y.; Fan, Z.D.; Zou, B.; Jin, R.Q.; Han, C.Y. Location Optimization of Open-off Cut in Steeply-inclined and Extremely-thick Coal-seam under High-voltage Line Tower. Coal Min. Technol. 2015, 20, 66–69. [Google Scholar] [CrossRef]

- He, W.L.; Kang, J.R. Study on the law of surface movement and deformation in mountainous area. J. China Coal Soc. 1992, 1–15. [Google Scholar] [CrossRef]

- Han, K.F.; Kang, J.R.; Wang, Z.S.; Wu, K. Uniform prediction parameters for ground movement model in mountain area caused by coal mining. J. Min. Saf. Eng. 2014, 31, 896–900. [Google Scholar] [CrossRef]

- Qin, S.F. The Impact of Mountainous Terrain on Buildings and Protective Coal Pillar Design in Mining Area. Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2015. [Google Scholar]

- Feng, J. Study on Regularity and Application of Surface Subsidence Due to Mountain Mining. Master’s Thesis, China University of Mining and Technology (Beijing), Beijing, China, 2016. [Google Scholar]

- Peng, S.S.; Zhang, J.X. English Writing Method & Vocabulary in Coal Mine Ground Control; China University of Mining and Technology Press: Xuzhou, China, 2017; pp. 301–302. ISBN 978-7-5646-3562-6. [Google Scholar]

- Guo, W.B.; Bai, E.H.; Ma, X.C. Surface Subsidence Characteristics and Indices for Mining in “Three-Soft” Coal Seams. In Proceedings of the ICGCM China 2014 Proceedings (English volume), Beijing, China, 24 October 2014; China University of Mining and Technology Press: Beijing, China, 2014. [Google Scholar]

- Wang, D.; Jiang, J.Y.; Han, X.P.; Nan, C.Q.; He, X.G.T. Stability of supporting coal pillar for slope highwall mined in lignite surface mine. China Saf. Sci. J. 2017, 27, 62–67. [Google Scholar] [CrossRef]

- Guo, W.B.; Deng, K.Z.; Zou, Y.F. Study on Artificial Neural Network Method for Calculation of Displacement Angle of Strata. China Saf. Sci. J. 2003, 72–76. [Google Scholar] [CrossRef]

| Stratum | Coalsea (m) | Coal Seam Thickness Minimum–Maximum Average (m) | Seam Spacing Minimum–Maximum Average (m) | Workability | Roof and Floor | |

|---|---|---|---|---|---|---|

| Roof | Floor | |||||

| Shanxi Formation | 3 | 5.74–7.45 6.31 | 43.00–59.28 47.57 | Workable | Siltstone Sandy mudstone | Black mudstone Sandy mudstone Siltstone |

| Taiyuan Formation | 9 | 0–2.37 1.34 | 24.15–2.15 36.38 | Most were workable. | Siltstone | Mudstone Siltstone |

| 15 | 2.02–5.45 2.69 | Workable | Limestone | Mudstone | ||

| Protection Level | Structures | Safety Berm Width/m |

|---|---|---|

| I | Expressways, UHV transmission towers, large tunnels, trunk line of oil (gas) pipeline, main ventilator rooms in mines, etc. | 20 |

| The Lithology of Overlying Strata | The Angle of Critical Deformation/(°) | ||

|---|---|---|---|

| Strike Direction (δ) | Head End (γ) | Tail End (β) | |

| Hard | 75~80 | 75~80 | δ – (0.7~0.8) × α |

| Medium hard | 70~75 | 70~75 | δ – (0.6~0.7) × α |

| Weak | 60~70 | 60~70 | δ – (0.3~0.5) × α |

| Coal Seam | #3 | #15 (Repeated Mining) | ||||

|---|---|---|---|---|---|---|

| The angle of critical deformation | Additional influence of slippage caused by mining in mountain area | Additional influence of slippage caused by mining in mountain area | ||||

| The uphill direction | The downhill direction | The uphill direction | The downhill direction | |||

| The strike direction (°) | 65 | 60 | 63 | 60 | 55 | 58 |

| The tail end direction (°) | 63 | 58 | 61 | 58 | 53 | 56 |

| The head end direction (°) | 65 | 60 | 63 | 60 | 55 | 58 |

| Coalseam | No. of the UHV Line Tower | Protective Coal Pillar Size(m) | |

|---|---|---|---|

| The Vertical Line Method | The Linear Structure Method | ||

| #3 | N143 | 361.6 | 334.6 |

| N144 | 341.9 | 350.0 | |

| N145 | 233.5 | 228.7 | |

| N146 | 230.9 | 214.6 | |

| N147 | 166.4 | 187.3 | |

| #15 | N152 | 347.2 | 358.2 |

| N153 | 337.0 | 332.6 | |

| N154 | 348.3 | 314.3 | |

| N155 | 329.6 | 330.3 | |

| N156 | 223.2 | 236.5 | |

| N157 | 182.9 | 201.3 | |

| N158 | 163.7 | 171.6 | |

| N159 | 166.7 | 168.5 | |

| N160 | 175.2 | 185.6 | |

| N161 | 229.1 | 225.6 | |

| N162 | 232.3 | 214.9 | |

| N163 | 259.2 | 265.3 | |

| N164 | 494.6 | 359.3 | |

| N165 | 250.8 | 236.9 | |

| N166 | 208.4 | 201.6 | |

| Coal Seam | Thickness of Coal Seam (m) | Bulk Density of Coal (t/m3) | Linear Structure Method | The Vertical Line Method | ||

|---|---|---|---|---|---|---|

| The Area of Protective Coal Pillars (m2) | The Amount of Protective Coal Pillars (t) | The Area of Protective Coal Pillars (m2) | The Amount of Protective Coal Pillars (t) | |||

| #3 | 6.31 | 1.46 | 3,878,231.9 | 35,728,600 | 3,248,604.3 | 29,928,100 |

| #15 | 2.69 | 1.49 | 5,172,020.7 | 20,729,976 | 4,440,632.7 | 17,798,500 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, F.; Guo, W.; Li, J. Study on Protective Coal Pillar Size Design for Ultra High Voltage Line Tower Mining in Mountain Areas. Designs 2019, 3, 20. https://doi.org/10.3390/designs3020020

Xu F, Guo W, Li J. Study on Protective Coal Pillar Size Design for Ultra High Voltage Line Tower Mining in Mountain Areas. Designs. 2019; 3(2):20. https://doi.org/10.3390/designs3020020

Chicago/Turabian StyleXu, Feiya, Wenbing Guo, and Jianli Li. 2019. "Study on Protective Coal Pillar Size Design for Ultra High Voltage Line Tower Mining in Mountain Areas" Designs 3, no. 2: 20. https://doi.org/10.3390/designs3020020

APA StyleXu, F., Guo, W., & Li, J. (2019). Study on Protective Coal Pillar Size Design for Ultra High Voltage Line Tower Mining in Mountain Areas. Designs, 3(2), 20. https://doi.org/10.3390/designs3020020