Establishing Flow Stress and Elongation Relationships as a Function of Microstructural Features of Ti6Al4V Alloy Processed using SLM

Abstract

1. Introduction

2. Background

3. Results and Discussion

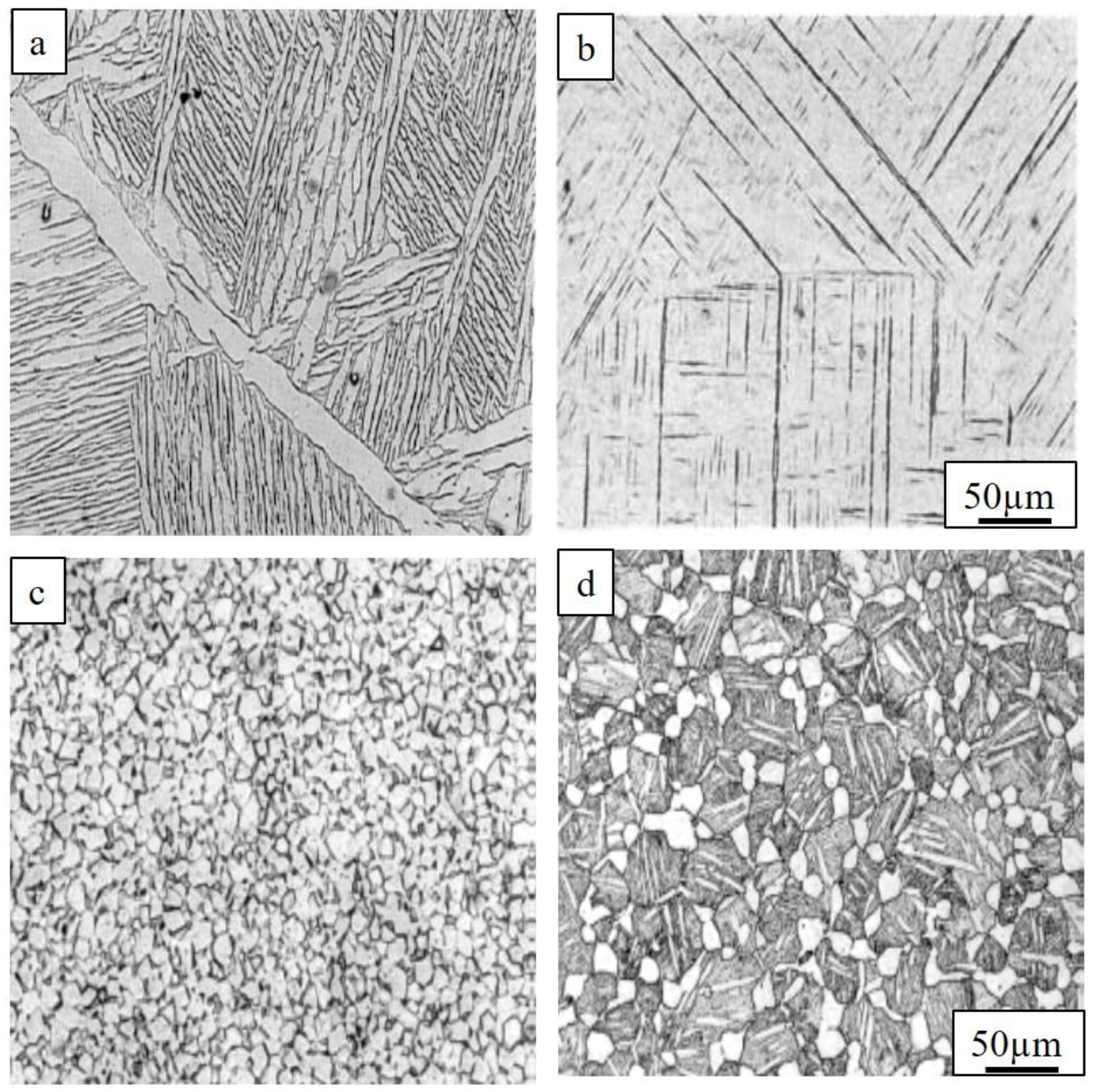

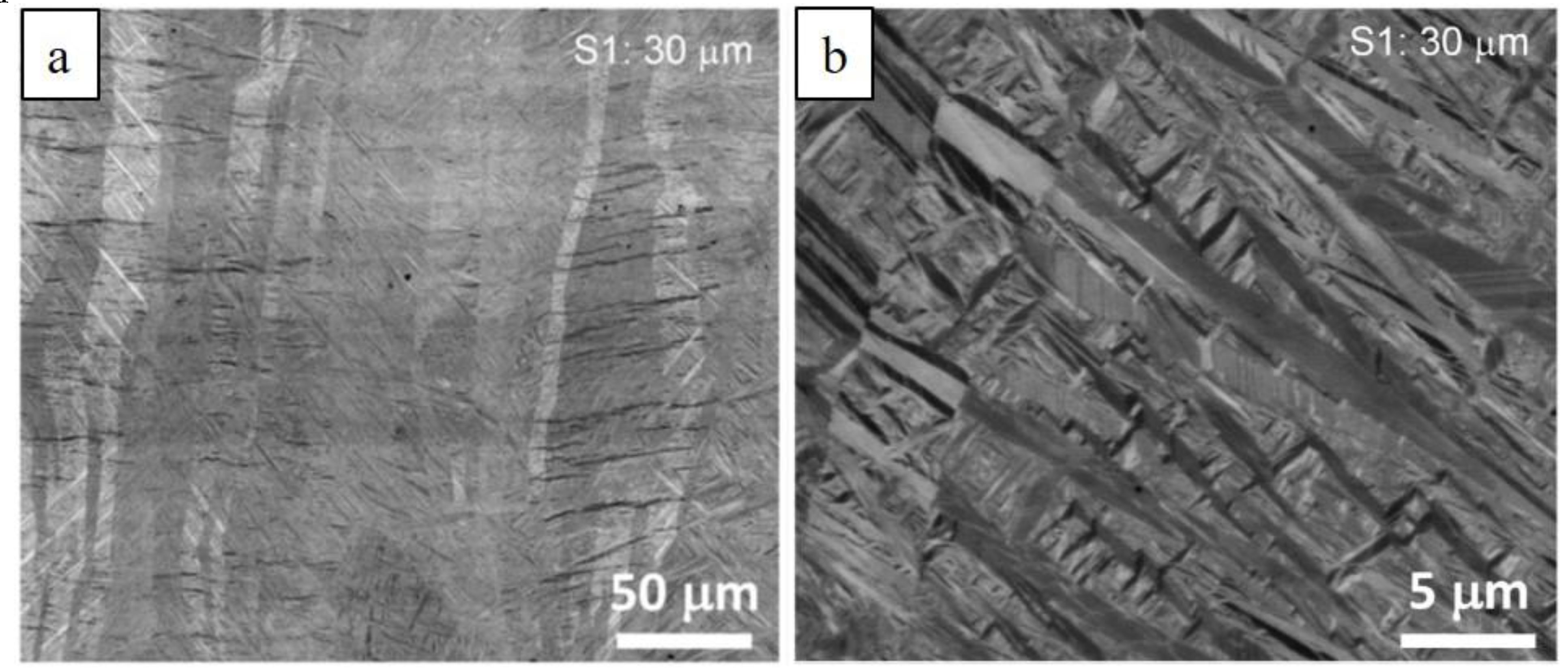

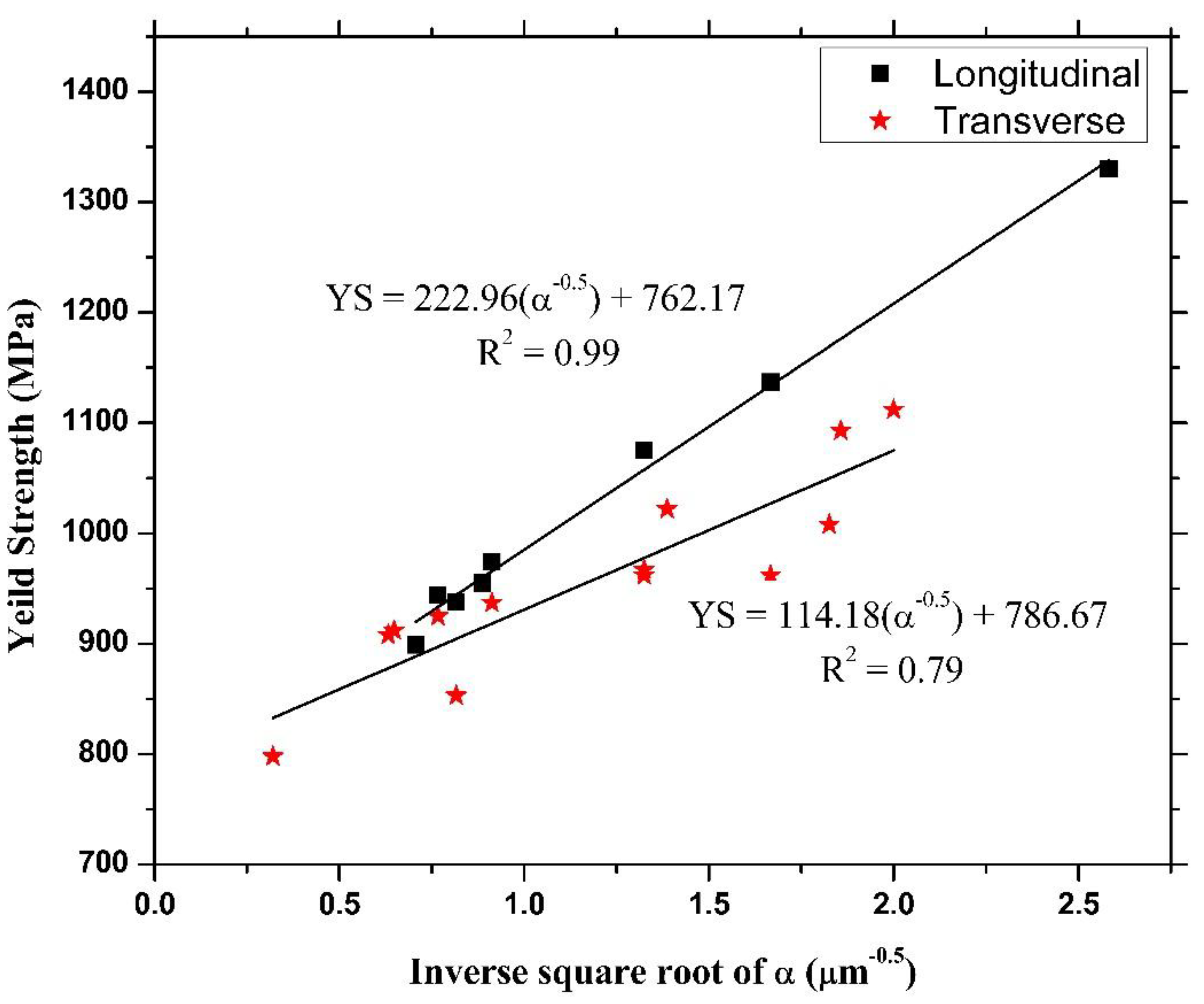

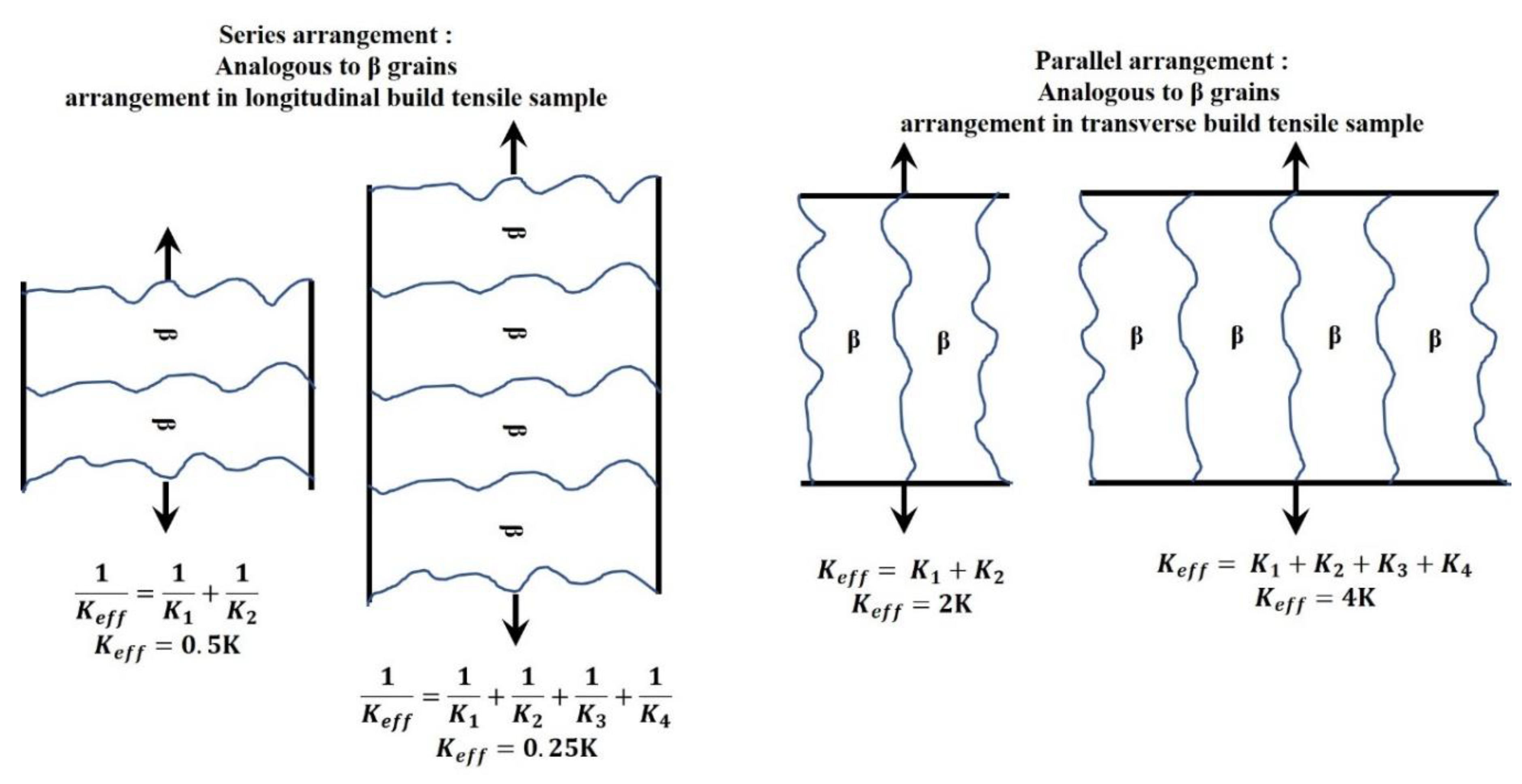

3.1. Correlation between As-Built and Heat-Treated Yield Strength and α/β Feature Sizes

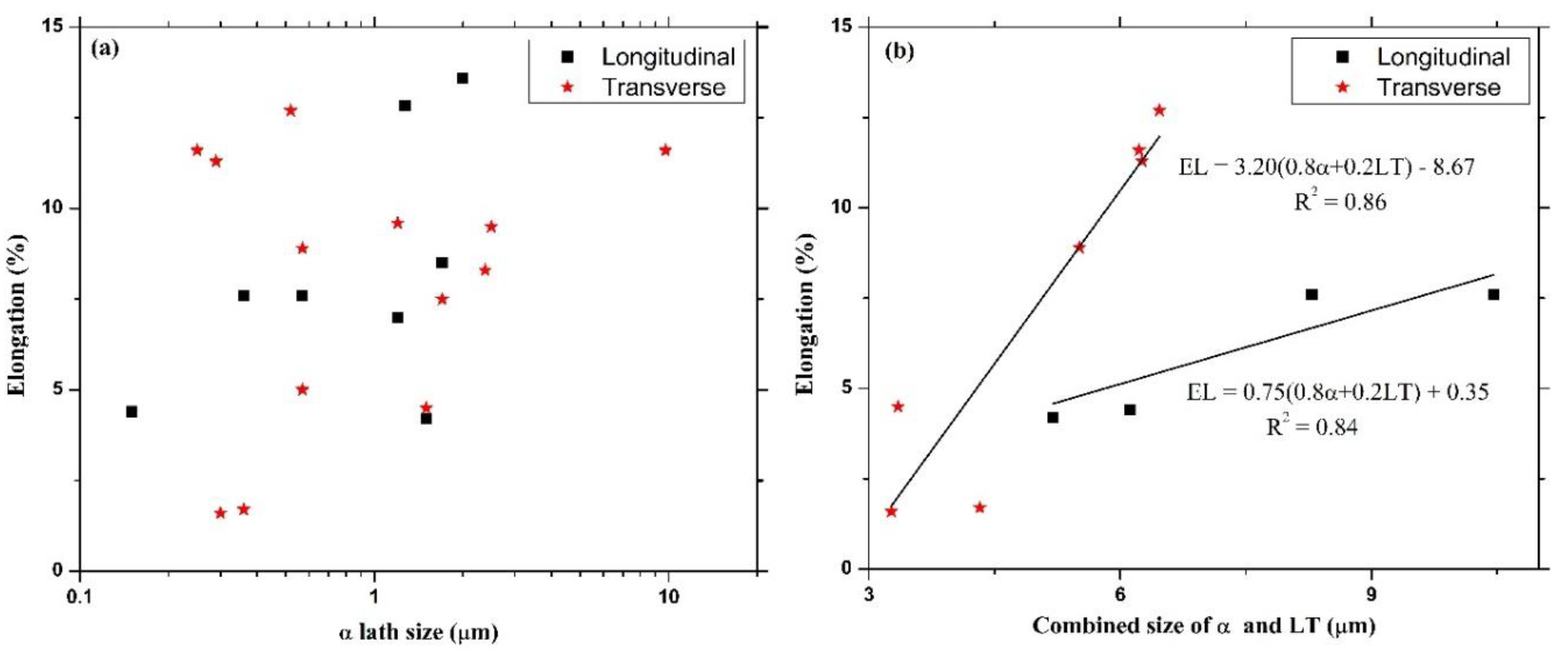

3.2. Correlation between As-Built Elongation and α/β Feature Sizes

3.3. Correlation between Heat-Treated Elongation and α/β Feature Sizes

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer: Berlin, Germany, 2010; Volume 238. [Google Scholar]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Kumar, P.; Farah, J.; Akram, J.; Teng, C.; Ginn, J.; Misra, M. Influence of laser processing parameters on porosity in Inconel 718 during additive manufacturing. Int. J. Adv. Manuf. Technol. 2019. [Google Scholar] [CrossRef]

- Peters, M.; Hemptenmacher, J.; Kumpfert, J.; Leyens, C. Structure and Properties of Titanium and Titanium Alloys. In Titanium and Titanium Alloys: Fundamentals and Applications; Wiley: Hoboken, NJ, USA, 2003; pp. 1–36. [Google Scholar]

- Ramosoeu, M.; Chikwanda, H.; Bolokang, A.; Booysen, G.; Ngonda, T. Additive manufacturing: Characterization of TI-6AI-4V alloy intended for biomedical application. In Proceedings of the The Southern African Institute of Mining and Metallurgy Advanced Metals Initiative, Light Metals Conference; Southern African Institute of Mining and Metallurgy: Muldersdrift, South Africa, 2010; pp. 337–344. [Google Scholar]

- Lütjering, G.; Williams, J.C.; Gysler, A. Microstructure and mechanical properties of Titanium alloys. In Microstructure and Properties of Materials; World Scientific: Singapore, 2000; Volume 2, pp. 1–74. [Google Scholar]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; van Humbeeck, J. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Cottam, R.; Palanisamy, S.; Avdeev, M.; Jarvis, T.; Henry, C.; Cuiuri, D.; Balogh, L.; Rashid, R.A.R. Diffraction Line Profile Analysis of 3D Wedge Samples of Ti-6Al-4V Fabricated Using Four Different Additive Manufacturing Processes. Metals 2019, 9, 60. [Google Scholar] [CrossRef]

- Xu, W.; Brandt, M.; Sun, S.; Elambasseril, J.; Liu, Q.; Latham, K.; Xia, K.; Qian, M. Additive manufacturing of strong and ductile Ti-6Al-4V by selective laser melting via in situ martensite decomposition. Acta Mater. 2015, 85, 74–84. [Google Scholar] [CrossRef]

- Edwards, P.; Ramulu, M. Fatigue performance evaluation of selective laser melted Ti-6Al-4V. Mater. Sci. Eng. A 2014, 598, 327–337. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.D. As-fabricated and heat-treated microstructures of the Ti-6Al-4V alloy processed by selective laser melting. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2011, 42, 3190–3199. [Google Scholar] [CrossRef]

- Mertens, A.; Reginster, S.; Paydas, H.; Contrepois, Q.; Dormal, T.; Lemaire, O.; Lecomte-Beckers, J. Mechanical properties of alloy Ti-6Al-4V and of stainless steel 316L processed by selective laser melting: influence of out-of-equilibrium microstructures. Powder Metall. 2014, 57, 184–189. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti-6Al-4V. Mater. Sci. Eng. A 2014, 616, 1–11. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Wang, Z.; Zeng, X. Effect of crystallographic orientation on mechanical anisotropy of selective laser melted Ti-6Al-4V alloy. Mater. Charact. 2017, 127, 137–145. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Formation and control of martensite in Ti-6Al-4V alloy produced by selective laser melting. Mater. Des. 2016, 108, 308–318. [Google Scholar] [CrossRef]

- Facchini, L.; Magalini, E.; Robotti, P.; Molinari, A.; Höges, S.; Wissenbach, K. Ductility of a Ti-6Al-4V alloy produced by selective laser melting of prealloyed powders. Rapid Prototyp. J. 2010, 16, 450–459. [Google Scholar] [CrossRef]

- Kasperovich, G.; Hausmann, J. Improvement of fatigue resistance and ductility of TiAl6V4 processed by selective laser melting. J. Mater. Process. Technol. 2015, 220, 202–214. [Google Scholar] [CrossRef]

- Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.A.; Maier, H.J. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- Murr, L.E.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Rodela, A.; Martinez, E.Y.; Hernandez, D.H.; Martinez, E.; Medina, F.; Wicker, R.B. Microstructure and mechanical behavior of Ti-6Al-4V produced by rapid-layer manufacturing, for biomedical applications. J. Mech. Behav. Biomed. Mater. 2009, 2, 20–32. [Google Scholar] [CrossRef]

- Koike, M.; Greer, P.; Owen, K.; Lilly, G.; Murr, L.E.; Gaytan, S.M.; Martinez, E.; Okabe, T. Evaluation of titanium alloys fabricated using rapid prototyping technologies-electron beam melting and laser beam melting. Materials 2011, 4, 1776–1792. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Lui, E.W.; Pateras, A.; Qian, M.; Brandt, M. In situ tailoring microstructure in additively manufactured Ti-6Al-4V for superior mechanical performance. Acta Mater. 2017, 125, 390–400. [Google Scholar] [CrossRef]

- Carroll, B.E.; Palmer, A.; Beese, A.M. Anisotropic tensile behavior of Ti-6Al-4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- Beese, A.M.; Carroll, B.E. Review of mechanical properties of Ti-6Al-4V made by laser-based additive manufacturing using powder feedstock. Jom 2016, 68, 724–734. [Google Scholar] [CrossRef]

- Akram, J.; Chalavadi, P.; Pal, D.; Stucker, B. Understanding grain evolution in additive manufacturing through modeling. Addit. Manuf. 2018, 21, 255–268. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. On the texture formation of selective laser melted Ti-6Al-4V. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2014, 45, 2863–2872. [Google Scholar] [CrossRef]

- Antonysamy, A.A.; Meyer, J.; Prangnell, P.B. Effect of build geometry on the β-grain structure and texture in additive manufacture of Ti-6Al-4V by selective electron beam melting. Mater. Charact. 2013, 84, 153–168. [Google Scholar] [CrossRef]

| Reference | Process Parameter *P(W), V(mm/s), HS (µm), LT (µm), LHI (J/mm3), SS, SP, PH (℃) | Sample Orientation | Microstructure W is Width in (μm) | YS (MPa) | UTS (MPa) | EL (%) | E (GPa) |

|---|---|---|---|---|---|---|---|

| [10] | P: 200, V: 200, HS: 180, LT: 50 µm, LHI: 111, SP: bidirectional scan vector with 67° rotated, MTT SLM 250 | L | Acicular α’, β columnar grains (W: 109.48) | 910 ± 9.9 | 1035 ± 29 | 3.3 ± 0.76 | - |

| [11] | P: 160, V: 600, HS: 200, LT: 40, LHI: 33, BD: 220, SP: bidirectional scan vector with 90° rotated, PH: 500, Trumpf LF 250 | L | Acicular α’ (W: 0.36) | 1137 ± 20 | 1206 ± 8 | 7.6 ± 2 | 105 ± 5 |

| T | 962 ± 47 | 1166 ± 25 | 1.7±0.3 | 102 ± 7 | |||

| Heat treated at 950 ℃ for 1h followed by water quenching | L | Acicular α’ + α + β (W: 1.7) | 944 ± 8 | 1036 ± 30 | 8.5 ± 1 | 103 ± 11 | |

| T | 925 ± 14 | 1040 ± 4 | 7.5 ± 2 | 98 ± 3 | |||

| [12] | P: 175, V: 710, HS: 120, LT: 30 µm, LHI: 68.5, SP: bidirectional scan vector with 79° rotation, MTT SLM250 | L | Acicular α’, β columnar grains (W: 117.2) | 1166 ± 6 | 1321 ± 6 | 2.0 ± 0.7 | - |

| [7] | P: 250, V: 1600, HS: 60, LT: 30, LHI: 86.8, SS: 50, SP: bidirectional scan vector with 90° rotation | L | Acicular α’, β columnar grains (W: 55.5) | 1110 ± 9 | 1267 ± 5 | 7.28 ± 1.12 | 109.2 ± 3.1 |

| Heat treated at 850 °C for 2 h, followed by furnace cooling | L | Mixture of α + β (W:1.27 ± 0.13, V: 73%), β columnar grains (W: 82.17) | 955 ± 6 | 1004 ± 6 | 12.84 ± 1.36 | 114.7 ± 3.6 | |

| Heat treated at 940 °C for 1 h, followed by 650 °C for 2 h, then air cooled | L | Lamellar mixture of α + β (W: ~2), β columnar grains (W: 82.17) | 899 ± 27 | 948 ± 27 | 13.59 ± 0.32 | 115.5 ± 2.4 | |

| [13] | P: 157, V: 225, HS: 100, LT: 50, LHI: 139.5, SS: 70, SP: bidirectional scan vector with 67° rotated, flat sample, Renishaw AM250 | L, XY plane | Acicular α’ (W: 0.57 ± 0.13, L: 8 ± 3), β columnar grains (W: XY: 91.29, XZ: 89.61, and YZ: 76.68) | 1075 ± 25 | 1199 ± 49 | 7.6 ± 0.5 | 113 ± 5 |

| Flat sample | L, XZ plane | 978 ± 5 | 1143 ± 6 | 11.8 ± 0.5 | 115 ± 6 | ||

| T, ZX plane | 967 ± 10 | 1117 ± 3 | 8.9 ± 0.4 | 119 ± 7 | |||

| Stress relieved at 730 °C for 2 h, FC at 283.15 K/min | L, XY plane | Mixture of α + β (W: 1.2 ± 0.3, L: 8.7 ± 2.4), β columnar grains (W: XY: 91.29, XZ: 89.61, and YZ: 76.68) | 974 ± 7 | 1065 ± 21 | 7.0 ± 0.5 | 112 ± 6 | |

| L, XZ plane | 958 ± 6 | 1057 ± 8 | 12.4 ± 0.7 | 113 ± 9 | |||

| T, ZX plane | 937 ± 9 | 1052 ± 11 | 9.6 ± 0.9 | 117 ± 6 | |||

| [14,15] | P: 194, V: 1000, HS: 80, LT: 20, LHI: 121.25, SP: bidirectional scan vector with 90° rotation | L | Acicular α’ (W: ~1.5), β columnar grains (W: 53.7) | 937.95 | 1140.8 | 4.2 | - |

| T | 853.5 | 1077.5 | 4.5 | - | |||

| [16] | P: 120–200, BD: 200–600 | L | Acicular α’ | 990 ± 5 | 1065 ± 10 | 8.1 ± 0.3 | - |

| Heat treatment variant 1: NI | L | Lamellar α + β | 835 ± 5 | 915 ± 10 | 10.6 ± 0.6 | ||

| Heat treatment variant 2: NI | L | Lamellar α + β and Globular α | 870 ± 15 | 990 ± 15 | 11.0 ± 0.5 | ||

| [17] | P: 200, V: 1250, HS: ~100, LT: 40, LHI: 40, SS: 250, SP: bidirectional scan vector with 90° rotation, Concept Laser M2 | T | Acicular α’ (W: <0.5) | 986 | 1155 | 10.9 | 112.4 |

| Heat treated at 700 °C for 1 h, 10 K/min cool | T | Acicular α’ (W: <1) | 1051 | 1115 | 11.3 | 117.4 | |

| Heat treated at 900 °C for 2 hours + 700 °C for 1 h, 10 K/min | T | Lamellar α + β (W: 2–3, L: 50–60) | 908 | 988 | 9.5 | 118.8 | |

| HIP at 900 °C and 100 MPa for 2 h in Ar2 gas atmosphere + 700 °C for 1 h, 10 K/min cool. | T | Lamellar α + β (W: 2–3, L: 50–60) | 885 | 973 | 19.0 | 115.4 | |

| [18] | P: 175, V: 710, HS: 120, LT: 30, PH: 100, LHI: 68.46, SLM 250HL | T | Acicular α’ (W: 0.37 ± 0.07) | 1008 ± 30 | 1080 ± 30 | 1.6 ± 2 | - |

| Heat treated at 800 °C for 2 h in Ar2 gas, FC | T | Mixture of α + β (W: 0.57 ± 0.06) | 962 ± 30 | 1040 ± 30 | 5 ± 2 | - | |

| HIPed at 920 °C and 1000 bar for 2 h in Ar2 gas, FC | T | Lamellar α + β (W: 2.38 ± 0.3) and Globular α (S: 5.0 ± 1.6) | 912 ± 30 | 1005 ± 30 | 8.3 ± 2 | - | |

| Heat treated at 1050 °C for 2 h in vacuum, FC | T | Lamellar α+β (W: 9.75 ± 3.7) and If globular (S: 13.73 ± 5.3) | 798 ± 30 | 945 ± 30 | 11.6 ± 2 | - | |

| [19] | No information | L | Acicular α’ (W: 0.1 to 0.3) | 1330 | 1400 | 4.4 | - |

| [20] | P: 5500, V: 104, LT: 40, LHI: 0.55, PH: 700, EOSINT M270 | T | Acicular α’ (W: 0.23 to 0.3) | ~850 | ~940 | 6.5 | - |

| [21] | P: 375, V: 1029, HS: 120, LT: 60, FOD: 2, Ti: 1, LHI: 50.62, SP: bidirectional scan vector with 90° rotation, SLM 250HL | T | Lamellar α + β (W: 0.52 ± 0.22) | 1022 ± 10 | 1090 ± 10 | 12.7 ± 2.1 | |

| Ti: 5 and all the parameters remain same | T | Lamellar α + β (W: 0.29 ± 0.13) | 1093 ± 15 | 1149 ± 11 | 11.3 ± 0.5 | ||

| Ti: 8 and all the parameters remain same | T | Lamellar α + β (W: 0.25 ± 0.10) | 1112 ± 3 | 1165 ± 2 | 11.6 ± 1.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akram, J.; Pal, D.; Stucker, B. Establishing Flow Stress and Elongation Relationships as a Function of Microstructural Features of Ti6Al4V Alloy Processed using SLM. Designs 2019, 3, 21. https://doi.org/10.3390/designs3020021

Akram J, Pal D, Stucker B. Establishing Flow Stress and Elongation Relationships as a Function of Microstructural Features of Ti6Al4V Alloy Processed using SLM. Designs. 2019; 3(2):21. https://doi.org/10.3390/designs3020021

Chicago/Turabian StyleAkram, Javed, Deepankar Pal, and Brent Stucker. 2019. "Establishing Flow Stress and Elongation Relationships as a Function of Microstructural Features of Ti6Al4V Alloy Processed using SLM" Designs 3, no. 2: 21. https://doi.org/10.3390/designs3020021

APA StyleAkram, J., Pal, D., & Stucker, B. (2019). Establishing Flow Stress and Elongation Relationships as a Function of Microstructural Features of Ti6Al4V Alloy Processed using SLM. Designs, 3(2), 21. https://doi.org/10.3390/designs3020021