1. Introduction

Industrial design is the most important phase in the lifetime of a product. The design stage controls the style of the components, the costs, the times of production, and the impact on the market. Because of the latter, it is important to gather all of the information possible from customers and start a new project to develop the right car concept from the beginning. Errors in this phase will lead to inefficiencies that will affect the budget. Many approaches to this problem are possible since the design stage is not simple [

1]. The following paper presents a case study based on the different phases of Industrial Design Structure (IDeS) with the integration of AM and AR, dividing the process into several design steps. Using IDeS, it is possible to develop an innovative industrial product [

2] by deconstructing the process into phases concerning style, design, optimization, and production. Because of this methodology, errors are reduced, and the final product result is both innovative and relatively cheap since no changes need be done after the application of the methodology itself. Moreover, the usage of breakthrough technologies such as Augmented Reality (AR) [

3] and Additive Manufacturing (AM) [

4] show that non-expensive solutions for virtual prototyping exist, and they can be implemented in the IDeS process. As previously reported by Donnici et al. [

5], using this methodology, a link is indeed created between the design structure and company organization, dividing the design process into three macro-phases: Setup, Development, and Production (

Figure 1).

The Project SetUp analyzes the background and objectives of the product design.

First of all, Quality Function Deployment (QFD) [

6,

7] is used to define the customer’s requests and the target market segment. Second, a Benchmarking analysis is performed to identify the number of requirements that will allow the product to be innovative. The presented method is an evolution of the past known methodologies, which were analyzed by Sabatier [

8], being enhanced by a Top-Flop analysis to scout the number of the main characteristics of the best products on the market, which will set the level that needs to be overcome in order to achieve innovation in the new project. Ford style was initially studied, in particular of the Ford Falcon (1960–1968) and Ford Mondeo (1996–2019) models, to better understand the characteristics of the brand and the main stylistic properties that have been maintained over the decades. The SDE method proceeds with the sketching of a digital version of the vehicle here presented in order to improve the classic freehand drawing. After finding the satisfactory shape (analyzing and discarding the various proposals of the stylistic trends), the proportions and dimensions of the final sketch are evaluated and corrected through two-dimensional drawings—2D CAD—before moving on to the second part of the IDeS, Product Development.

This step begins with the 3D modelling of the vehicle—3D CAD—to obtain the three-dimensional shape of the product. Once the 3D model and all of its functional and aesthetic details are completed, the realistic renderings of the product are displayed before proceeding with prototyping, which can take place physically with the creation of the model of the vehicle with 3D printing, or virtually using Augmented Reality to show the car in any real setting of everyday life. In the presented paper, the authors chose to test both of these technologies in order to set up a comparison that led to a more complete study. The Product Development phase ends with the optimization and redesign of the vehicle according to an aerodynamic study. Applied to the automotive sector, the SDE method [

9,

10] introduced the ability to digitally sketch the vehicle, which improves the classic freehand drawing of the vehicle. Once the satisfactory shape is found, both a 2D and 3D model are built. After that, a visualization using AR and AM is conducted. The Product Development phase ends with the optimization and redesign of the vehicle according to an aerodynamic study. The choice of segment E was made to take advantage of the lack of models of this specific type by the brand. In car segmentation, which has evolved over time due to market sub-segmentation, as declared by Tartaglia [

11], the E segment identifies executive cars, large sedans such as the Mercedes E-Class or the BMW 5 Series, characterized by elegant, luxurious, and at the same time, sporty shapes. In fact, the US car manufacturer has not owned a flagship sports sedan for years, and the goal of the project is the creation of this type of vehicle which, through an attractive design and a strong degree of innovation, will be able to be successful on the market. The Ford brand vehicle that is considered the starting point of this innovative study is the Ford Falcon. Since the number of models proposed by the Ford company is vast (starting from the small Ka; the timeless Fiesta, Focus, and C-Max; the iconic Mustang; the extreme Ford GT, etc.), the car proposed here will be called the Ford Eagle. The name was chosen because it represents the key symbol of the USA—the eagle—an element of strength, courage, and freedom. Moreover, it wants to proudly show an evolution, and not just inspiration, of the historic Falcon model.

2. Materials and Methods

Electric cars are becoming increasingly popular because of the green transition that will move transportation toward a sustainable form. In recent years, the electric car offerings from manufacturers have increased, and many manufacturers are planning to electrify their portfolio, creating fully battery-powered vehicles across all segments. However, very few users have already tried an electric car, but many of them are interested in buying one of these products soon. According to the Smart Mobility Report 2020 from the Energy & Strategy Group—School of Management of Politecnico di Milano [

12], in 2019 almost 2.3 million electric passenger cars and light duty vehicles were registered globally (+9% compared to 2018), i.e., 2.5% of the total, up 0.3% (less than +1% recorded between 2017 and 2018) and sufficient enough to raise the overall stock of these vehicles up to 7.5 million. The trend shows a decrease in registration of “hybrid” vehicles (PHEV) in favor of “full-electric” (BEV), earning a further 5% compared to 2018, consolidating the rise already recorded in the four-year period between 2015–2018 (+3% year on year). Because of the latter, the trend suggests the need to produce an electric car, as will be descripted in the next sections.

In order to start a new project, a cost analysis is mandatory. It is intended to fore-see the budget of all Research and Development costs, which are essential for the project setting and the product development phases.

The goal of the cost analysis is to minimize risks and maximize earnings for the project itself and for the business organization. It allows the understanding of the advantages and disadvantages of various hypothesis including transactions, activities, business requirements, and investments. The possible analyzed project costs can be related to materials, performances, and prototype equipment.

The ability to create an accurate budget is essential. In the case study, the budget was set on an annual time basis, according to the subdivision of the phases defined with a Gantt chart. To simplify the calculation, some phases have been combined.

Table 1 shows the costs of the entire project defined by the sum of the equipment and worker costs.

2.1. QFD

The Quality Function Deployment (QFD) [

13] is a methodology that focuses on the aspects that pursue customer satisfaction in order to establish quality that must be ensured. The QFD forces the manufacturer to connect the key characteristics of the products to the needs of the customer. Because of this, it is applicable to different sectors [

14,

15] and has a number of applications in transport development [

16] that have also been applied to automotive servicing [

17]. QFD allows movement from the definition of “conformity to use” to “accordance with specifications”, identifying the priorities of the characteristics in order to obtain a product or service that satisfies the customer (

Figure 2).

Therefore, as stated by Donnici et al., the six questions (who, what, where, when, why, and how) have to be applied to any new product need [

18] and are applied to the case study in the first design phase of the innovative sedan together with the customer responses, all of which are reported in

Table 2. The interview allowed the explanation of the customer data, filling a list that contains only qualitative data such as ideas, opinions, perceptions, and desires. Qualitative information is summarized through affinity diagrams and reclassified under general topics or fundamental ideas. In this way, it is possible to determine the logical groupings of a customer’s needs. The data are then collected in homogeneous groups, and appropriate titles are selected for each group. From the interview, a summary list of customer requests was obtained. In this way, the cause and effect relationship for each parameter is determined by asking the question: “how does the element in the row depend on the elements in the columns?”. Numeric values are entered to quantify the dependence relationship between each element in the column and the one in the row, distinguishing between null (empty box), weak (1), medium (3) or strong (9) relationships. As a last step, the interrelation indices are added both for rows and columns to analyze which parameters are more or less influenced (

Table 3).

Afterwards, it was possible to rank the most dependent and the most independent needs. To obtain them, starting from qualitative data, it was necessary to use a second matrix, the Relative Importance Matrix (

Table 4). The analysis indicates that the items “Low price” (31 points) and “Comfort” (31 points) are the most influential ones, and they are therefore the most dependent (higher values on the rows). Rather high values are also recorded for the items “Performance”, “Personalization”, and “Electric”. On the other hand, the item “Electric” reaches a value of 25 points in the columns, meaning that this feature has a higher influence on the other specs.

Once the Dependency Matrix is defined, the data relating to the links between the various customer product requirements are known, while the information regarding the relative importance of the various items is not known yet. To obtain this information, starting from the qualitative data, it is necessary to use a second matrix, the Relative Importance Matrix (

Table 4). The construction is similar to the previous one, but a different question arises: “is the element in the row more important than the element in the column?”. As in the matrix described above, numerical values are introduced, which can be of three types:

1: The row element and the column element have even importance;

0: The row element is less important than the column element;

2: The row element is more important than the column element.

Once the numerical values have been assigned to each box of the matrix, the sums for each row are calculated to classify the absolute importance of the quantities. The last column of the matrix contains the “Normalized Importance” values, i.e., the values relating to the total, which are normalized to the maximum value.

2.2. Benchmarking

To design an innovative electric executive car, the models that already exist on the market must be analyzed to discover strengths and weaknesses. This process of comparison between the various products on the market is called Benchmarking, which has been proved to minimize development costs whilst achieving its quality goals during the preliminary phases [

19], and allows outline of:

How many parameters are considered for the competitor analysis?;

How many parameters are considered for innovation?;

Which metrics are measurable performance?;

Which performances are considered Top—the best ones?;

Which performances are considered Flops—the worst ones?;

Calculating the Top-Flop difference for each type of sedan;

Intercepting the most innovative car model;

Defining the specifications of the innovation targets for the new innovative car to be designed.

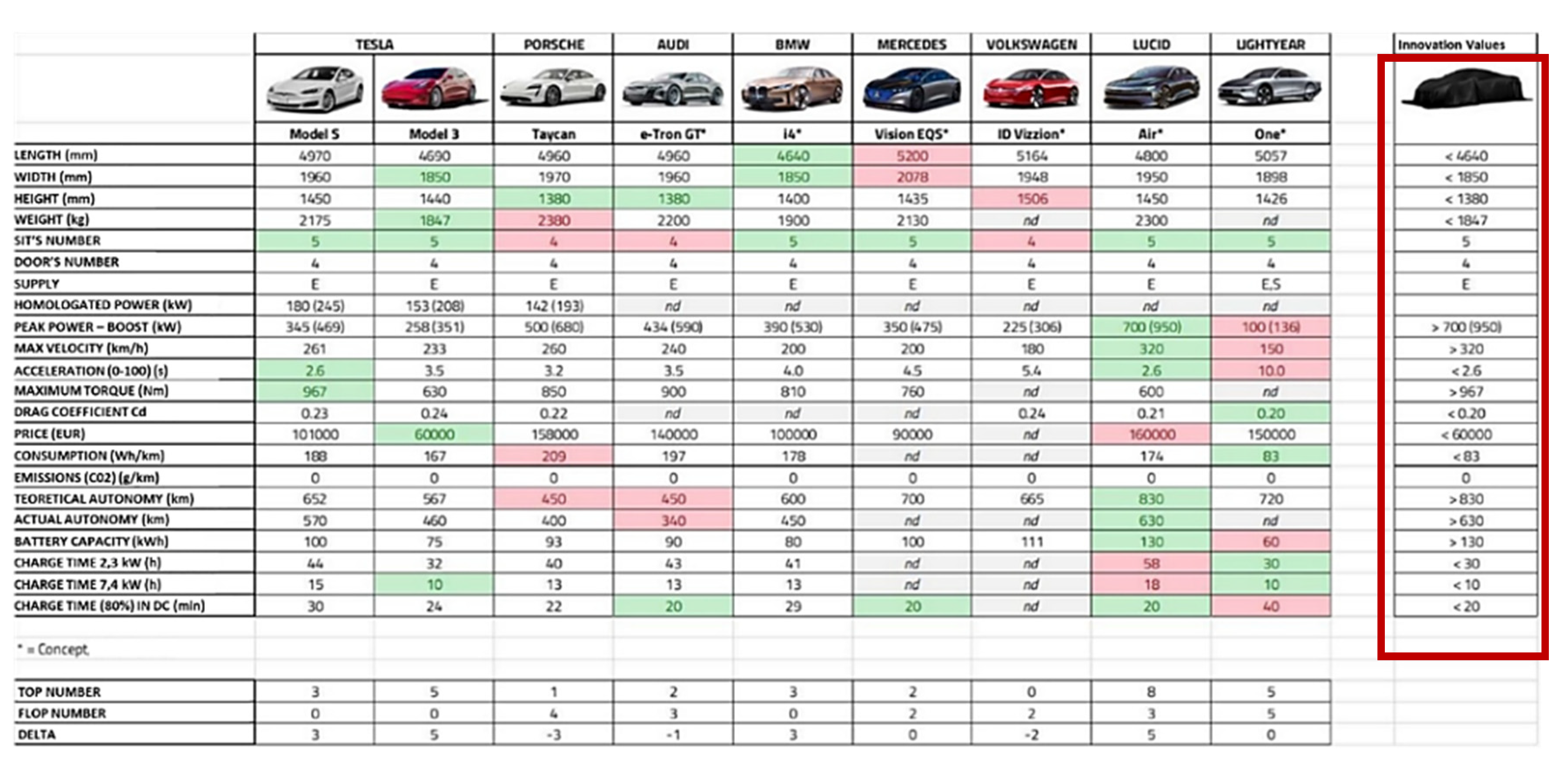

Nevertheless, the compared cars are electric models of the Executive cars segment that are already in production or in prototypes.

Figure 3 shows all the Benchmarking Analysis for the various competitors that were analyzed and the most innovative products.

An analysis of the different segments of the cars on the market was performed. The car segment study allows the establishment of which category each individual car belongs to, based on the size or type of bodywork and the engine.

Not being able to create an innovative model that achieves all 22 objectives of the matrix, a choice was made by using Top-Flop analysis. To understand which parameter is more likely to be improved, reference is made to another tool, the What–How Matrix, which allows the comparison of the customer’s requirements (What) with the designer’s answers (How). The following are the six most important parameters: price, theoretical autonomy WLTP, real autonomy, charging time at 2.3 kW, charging time at 7.4 kW, and charging time for 80% battery power in DC. Improving these six parameters means defining a new and innovative product. The needs of the consumers are analyzed in three main areas: price, performance, and emissions for fee benefits. As expected, the electric engine is both the most innovative of future developments and is the thing that is the most requested by customers.

2.3. SDE

SDE is a design method that consists of the study and analysis of current stylistic trends, their relationship with customer requests, and their visualization within the sketch.

2.3.1. Sketching

For the presented case study, the trends can be classified according to four main stylistic trends from the last few years: Retro, Natural, Stone, and Advanced (

Figure 4). The four stylistic trends are generally separate and distinguishable in different product designs, but they can also be mixed to create a completely new style that combines the past, the present, and the future of car design. The proposed model aims to be innovative both for characteristics and style.

The cars considered for the stylistic analysis of the Ford brand were the Ford Falcon and the Ford Mondeo, as they have experienced evolution over the years. For each proposal, a sketch of the car was made of the front three-quarter, rear three-quarter, and side views of the car (

Figure 5), representing a mix of the four styles and thereafter leading to the final sketch (

Figure 6).

After an analysis of the drawn models, it was decided to combine some those features in order to produce the final proposal for the creation of an innovative electric sedan combining all of the four presented trends. In the final model of the Eagle, the body work remains purely Stone in character, due to its strong design, square lines, and strong verticality, especially in the rear. The front instead follows the Natural trend of the new Ford electric SUV—the Mustang Mach E. The Advanced trend is strongly visible in the Eagle in the external grill and in the rims, due to the presence of LED lights and the introduction of the rear-view camera instead of a classic mirror. Finally, the shape of the sides mimics the 1960s Falcon, introducing a retro trend detail. The final proposal for the Eagle (

Figure 6) therefore contains all four trends described above, some with more weight, such as the Stone and Advanced styles, and others are only represented in some details, such as the Natural and Retro styles.

2.3.2. CAD Design Engineering

After selecting the final sketch, the first step of Product Development consists of transforming the digital sketch into a rigorous 2D drawing. Some changes are then made, and the 2D drawing is meticulously updated to fit the defined area. This procedure continues several times until complete satisfaction is obtained in terms of the lines, proportions, and dimensions (

Figure 7).

Afterwards, the use of the 3D CAD tool allows the creation of an interactive design. Through 3D modelling, it is possible to verify the model in all its parts, both in design and style. Furthermore, 3D CAD models can be used directly in simulation (CAE—Computer Aided Engineering) or in production (CAM—Computer Aided Manufacturing), increasing productivity and eliminating errors associated with file transfer. Because of the latter, introducing 3D CAD modelling into the company is now a necessary operation that involves a specific approach in the technical office and in the entire company and all departments connected to it. A fundamental step in the design process for the construction of Ford Eagle concerns the transition from 2D to 3D.

2.4. Prototyping—Additive Manufacturing & Augmented Reality

The tools used in 3D CAD models are, for example, the Catia software from Dassault, Alias from AutoDesk, or Blender. The latter is the modelling software that has been used in this document for the construction of the Ford Eagle since the final scope was to have a 3D model suitable for Augmented Reality, Additive Manufacturing, and rendering. Blender allows an optimal shaping of surfaces, making it suitable for automotive design as well as for animations and 3D games. A 3D model created with Blender can be exported in different output formats among which the most important are the STL—Standard Triangulation Language—in which the surface of the model is discretized into triangles, used for Additive Manufacturing applications; the OBJ, also used for 3D printing purposes; and the FBX—Filmbox—used for rendering, game editing, and Augmented Reality applications.

Figure 8 shows the model created using Blender software (version 2.91) and the corresponding render. Through the latter step, it was possible to superimpose the car in a real environment.

However, Because of the 3D modelling, it is possible to have a realistic view of the car in a digital realistic environment. However, viewing the 3D model on a monitor has some limitations, such as the correct definition of surface curvatures and the limited perception of the proportions. Therefore, by using Additive Manufacturing and Augmented Reality, it is possible to create a physical and a virtual model of the car in its real shape. The model (maquette) have always been a key point in the design phases [

20] and is used here to test the final result of an SDE by reproducing a “physical object” (1:24 scale) and a “real object (1:1 scale). These two representations are needed to begin the technical phase and the industrialization of the product.

2.4.1. Fast Prototyping by Additive Manufacturing

Furthermore, because of the growing diffusion of rapid prototyping, many technologies are now available for designers, 3D printing in particular. The most widespread 3D printing technology is FDM—Fused Deposition Modelling— where the object is built using the extrusion of a molten thermoplastic polymer. In this case study, the first result of the SDE method was printed through additive manufacturing, using FDM technology in particular. The Ford Eagle 3D printing model is simplified in the number of surfaces that can be made and the complexity of the mesh in order to facilitate the printing process of an scaled model (

Figure 9). The geometry of various elements is modified, including the details of the front bezels, the joints of the doors and windows, and the air intake slots, which are reduced to small extrusions with parallel walls, and flat bottom, making the model suitable for printing with FDM technology. The shell was separated from the wheels. The simplified model of the car, in STL format, was imported into the Ultimaker Cura software, where the slicing process was assessed, and the deposition phase started.

2.4.2. Augmented Reality for Enhanced, Flexible 1:1 Analysis

If 3D printing gives to the designer a first “real” look at the product, it cannot be used for 1:1 representation since it would need too long a time, and it would be expensive from a material point of view. To solve this issue, Augmented Reality was implemented in the design pipeline, reducing costs and enhancing flexibility. Augmented Reality can indeed represent the correct shape and dimensions, which can create many different style possibilities (

Figure 10).

To visualize the Ford Eagle in augmented reality, the 3D model was imported into Unity software.

Figure 11 shows the target image used for the case study. This marker was suitable for this purpose because of its high rating, which defines the quality of the tracker for the generation of the AR object. The image quality is defined based on the tracking point number, which is high in this image.

Figure 12 shows the Unity scene where the Eagle model is superimposed on the target image. It is scaled to be easily framed on the target image and to be equal size to the 3D printed model (1:24).

2.5. Testing & Re-Design

Once the virtual model of Ford Eagle has been designed, it is subjected to tests to confirm the integrity of the product or to show gaps that need to be filled. The vehicle was tested from an aerodynamic point of view and compared with its competitors, which were considered in the previous sections, using the aerodynamic drag coefficient as reference.

A Flow simulation was performed afterwards using

Fd as the aerodynamic drag force calculated using SolidWorks, an air density equal to 1.225 kg/m

3, the applied velocity equal to 36 m/s, and a front section area of the vehicle equal to 2.3 m

2. Flow simulation is set up as an external flow analysis, where the body is immersed in the fluid flow. The car is considered at a highway velocity limit of 130 km/h, equal to 36 m/s, in the Y direction (

Figure 13).

The result of the air flow analysis led to a Cd of 0.25, slightly higher than the Benchmarking values, but compatible with the analyzed model. Following this result, a redesign was conducted, which involved closing the front grille and accentuating the front spoiler.

4. Discussion

By applying a stylistic development of a futuristic and highly innovative electric sedan, a preliminary analysis was possible by means of Stylistic Design Engineering (SDE) and Quality Function Deployment (QFD), in which the customer requirements for vehicles in the E-segment were analyzed and examined by comparing to benchmark models in the industry, achieving a set of innovative parameters known to be useful for mobility in the near future and in urban and extra-urban traffic.

Additionally, by using state of the art software applications, it was possible to characterize different product design values using AR with the Ford Eagle on a real road in its real dimensions. Furthermore, Augmented Reality would create the opportunity to develop several real-scenario analyses for a product during earlier definition stages, saving important time and resources that otherwise would be assigned to manage design changes in a later stage. Additive Manufacturing technology improvements would establish an important milestone in gradually helping technical and styling product developers to save important amounts of time, maintaining timelines; fast prototyping applied in this work was used as a physical fit analysis to compare the dimensions of the scaled car (1:24). These two prototyping solutions are necessary to improve the design phase before final physical prototype testing, potentially avoiding the induction of a later redesign step, which would produce high costs for the total project management.

This study was intended to describe the stylistic development of an electric, futuristic, and highly innovative sedan. Starting from a preliminary analysis (QFD), the characteristics and requests of customers for the vehicles of the E segment were analyzed. These requirements were studied by considering the present and the near future mobility in urban and extra-urban traffic. This work presented a study on current stylistic trends and on stylistic procedures adopted in the US brand Ford, describing the external styling of some models.