Modelling Green VTOL Concept Designs for Reliability and Efficiency

Abstract

:1. Introduction

2. Methodology

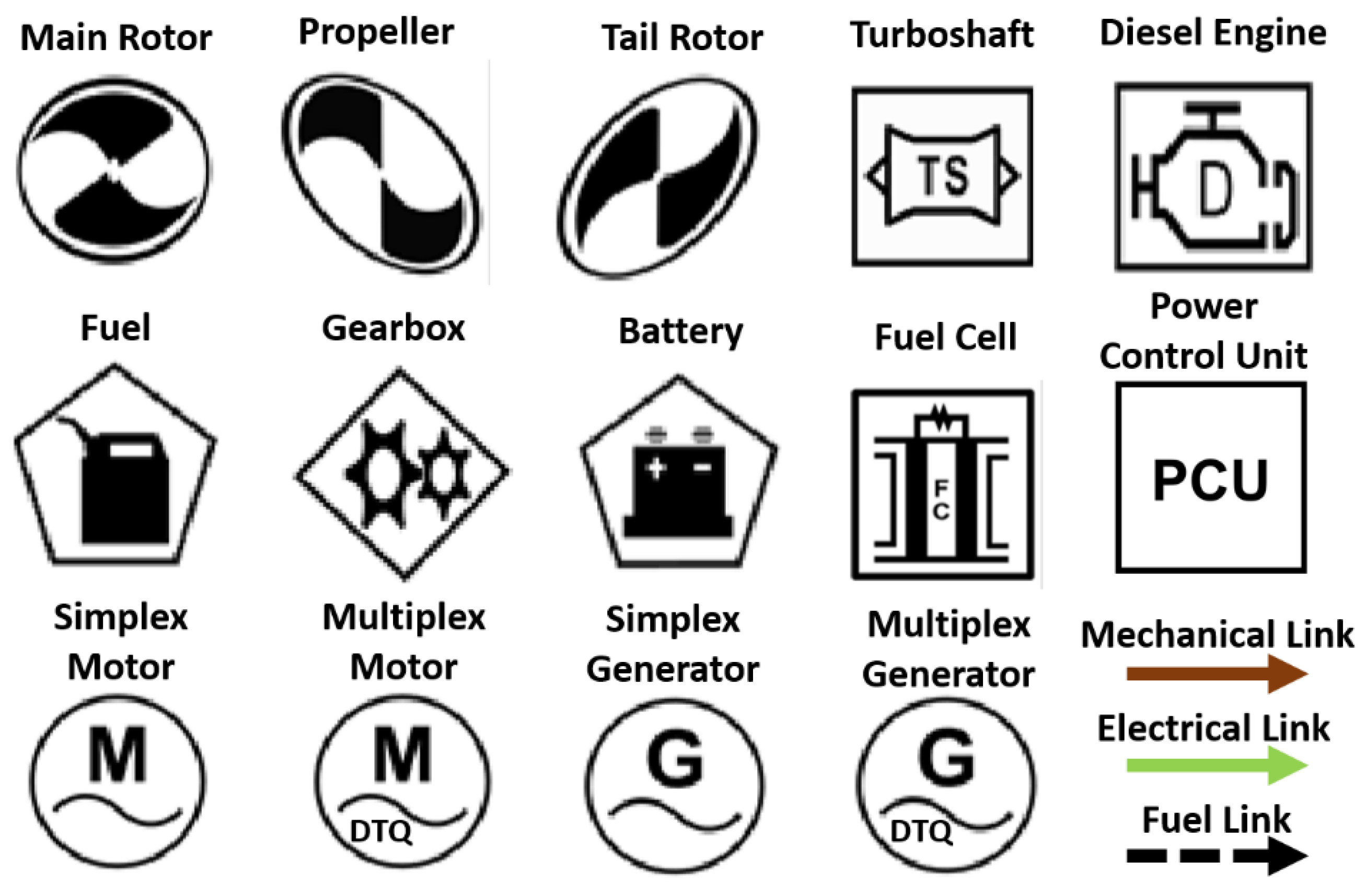

2.1. Symbolic Representation

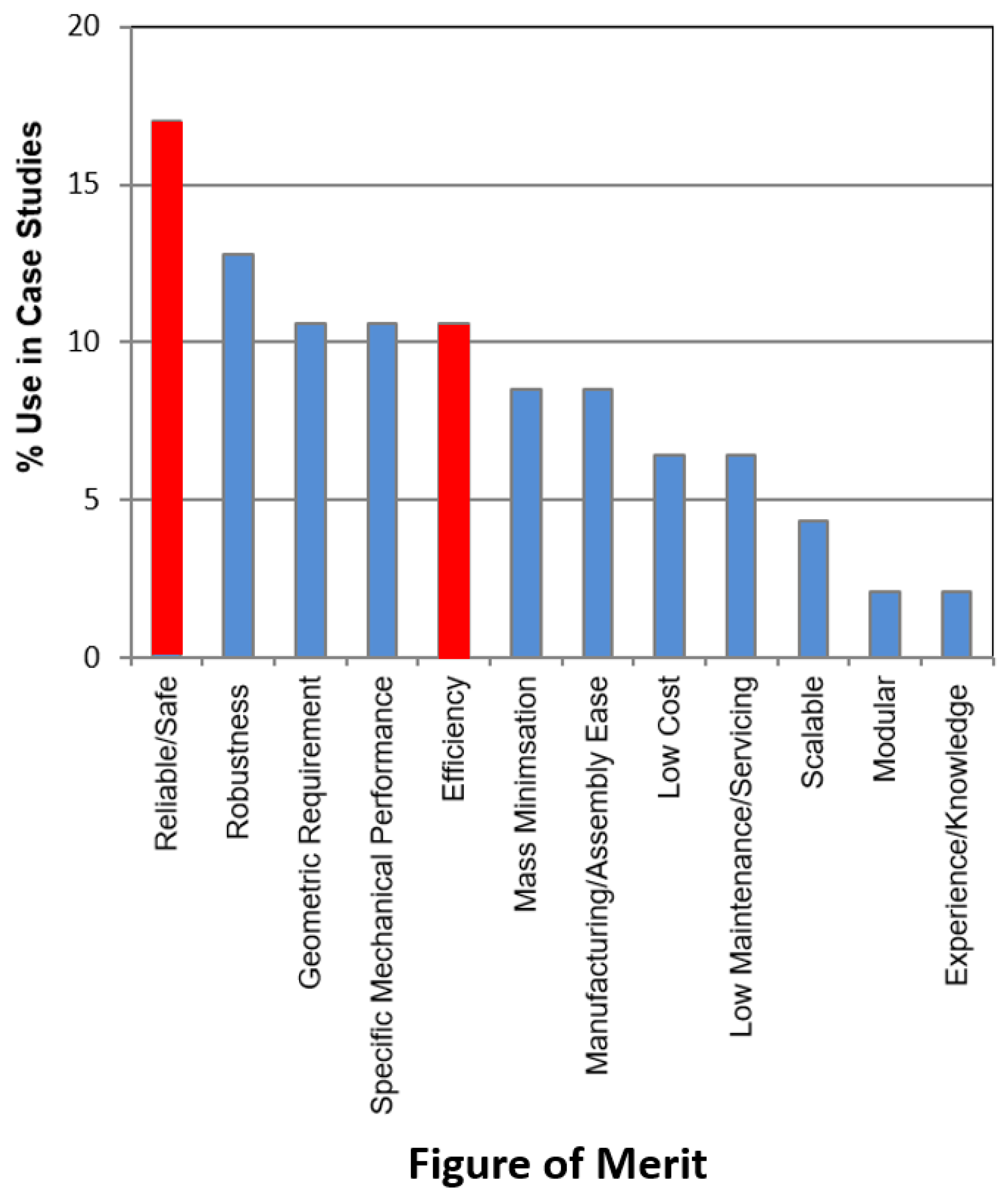

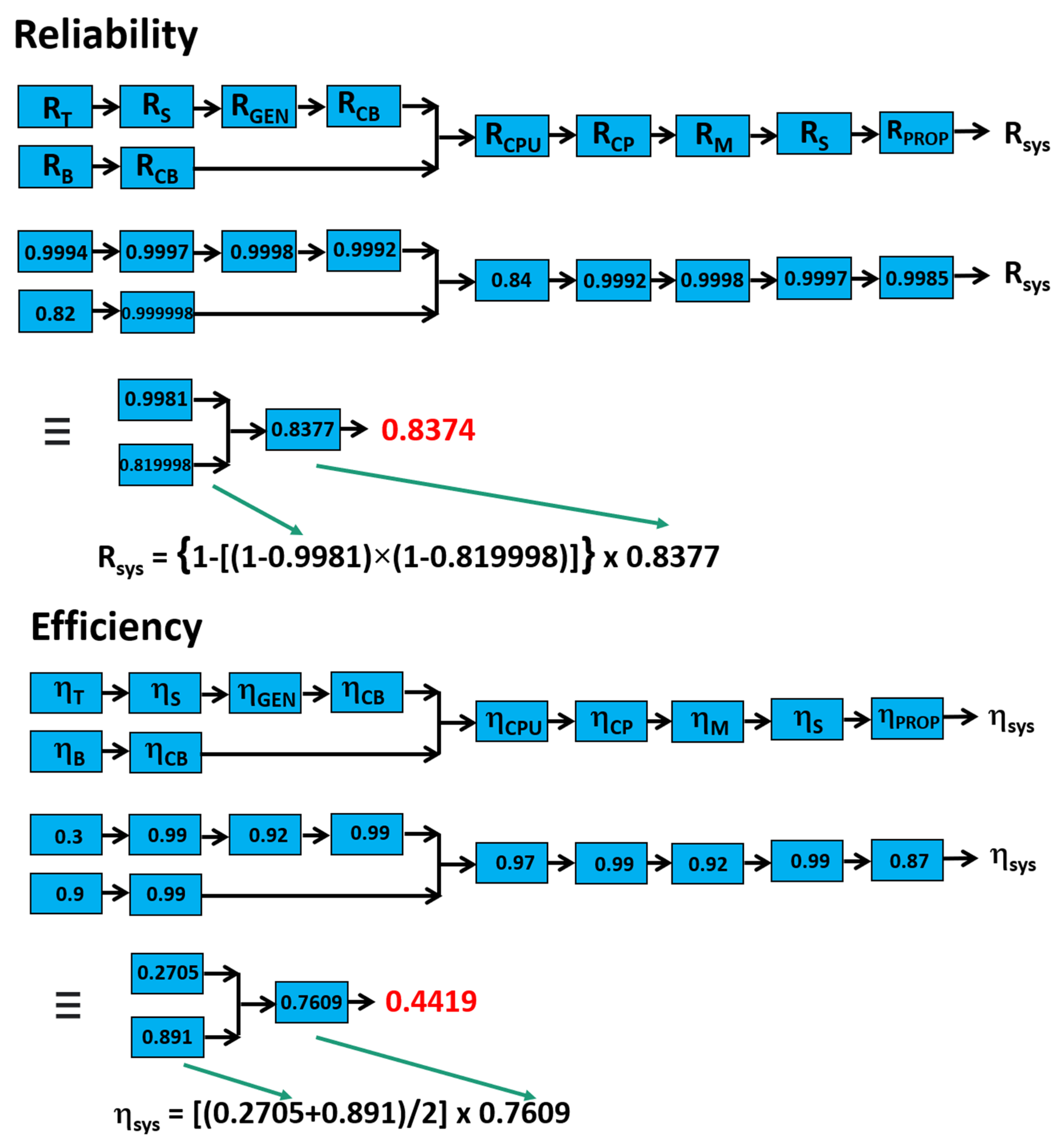

2.2. Figures of Merit

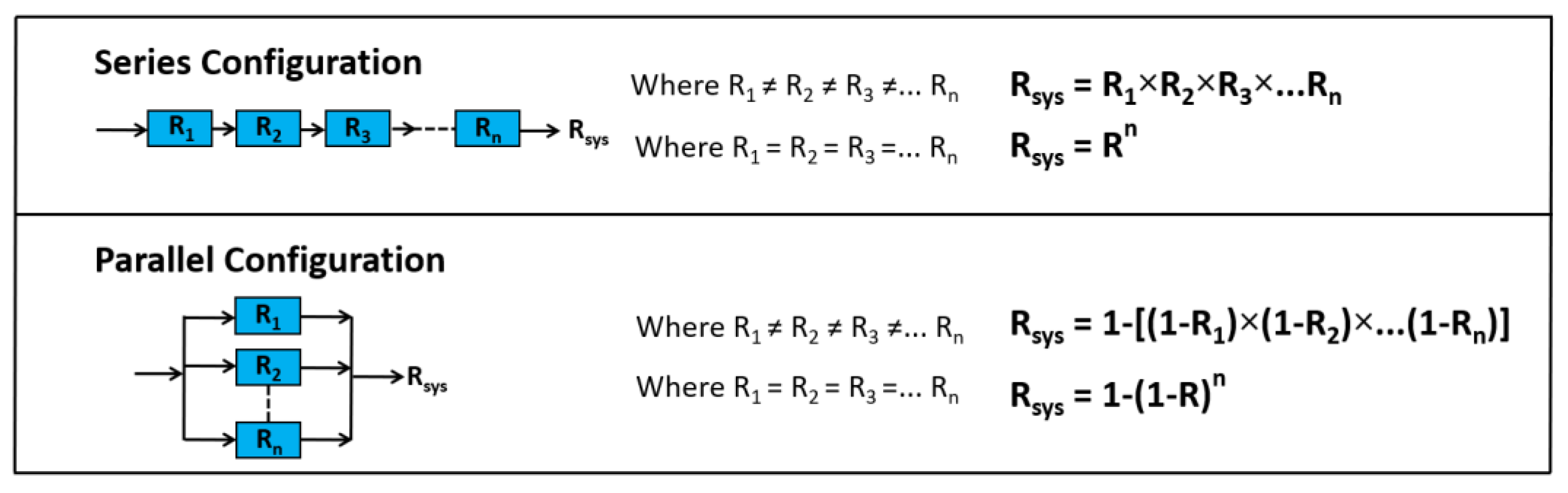

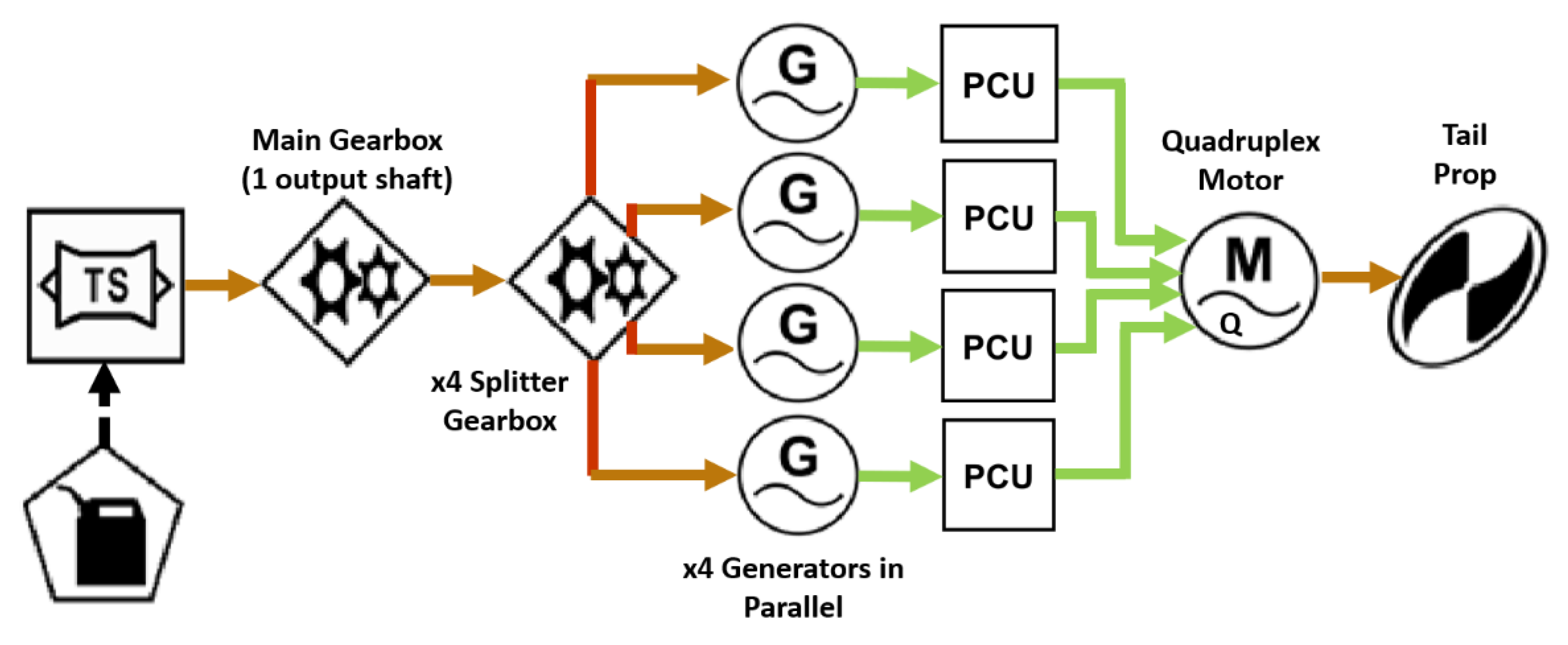

2.3. Block Modelling

2.4. Reliability and Efficiency Data

| Component/Sub-System | Reliability (R) * | Efficiency (η) * |

|---|---|---|

| Main Rotor Gearbox (xGG) | 0.9994 [41] | 0.94 [42] |

| Bevel Gearbox (xGB) | 0.99995 [41] | 0.97 [43] |

| Multiplier/Reducer Gearbox (xGM) | 0.9978 [41] | 0.94 [43] |

| Power Control Unit (xPCU) | 0.84 [26] →0.9 | 0.97 [44] →0.98 |

| Turboshaft (xT) | 0.9994 [41] | 0.3 [45] |

| Battery (xB) | 0.82 [46] →0.9 | 0.9 [47] →0.99 |

| Fuel Cell (xF) | 0.95 [48] →0.98 | 0.65 [47] →0.83 |

| Motor/Generator (xM/xGEN) | 0.9998 [41] →0.99999 | 0.92 [44] →0.99 |

| Diesel Engines (~200 kW) (xD) | 0.78 [41] | 0.40 [49] |

| Shafting (xS) | 0.9997 [41] | ~0.99 |

| Power Cables—Propulsion (xCP) | 0.9992 [41] | 0.99 [50] |

| Power Cables—Batteries (xCB) | 0.999998 [41] | 0.99 [50] |

| Propeller (xPROP) | 0.9985 [41] | 0.87 [51] |

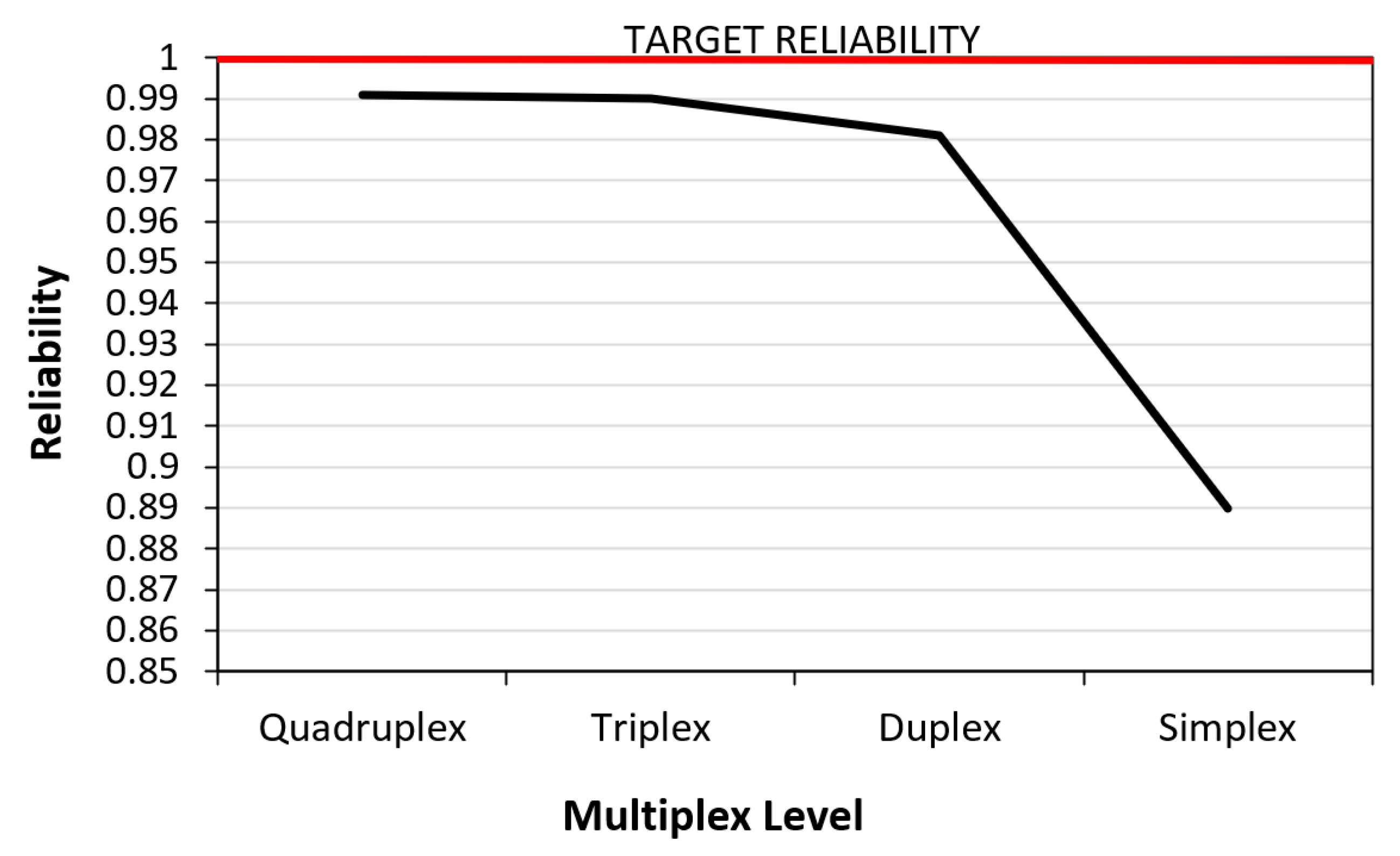

2.5. Reliability Targets

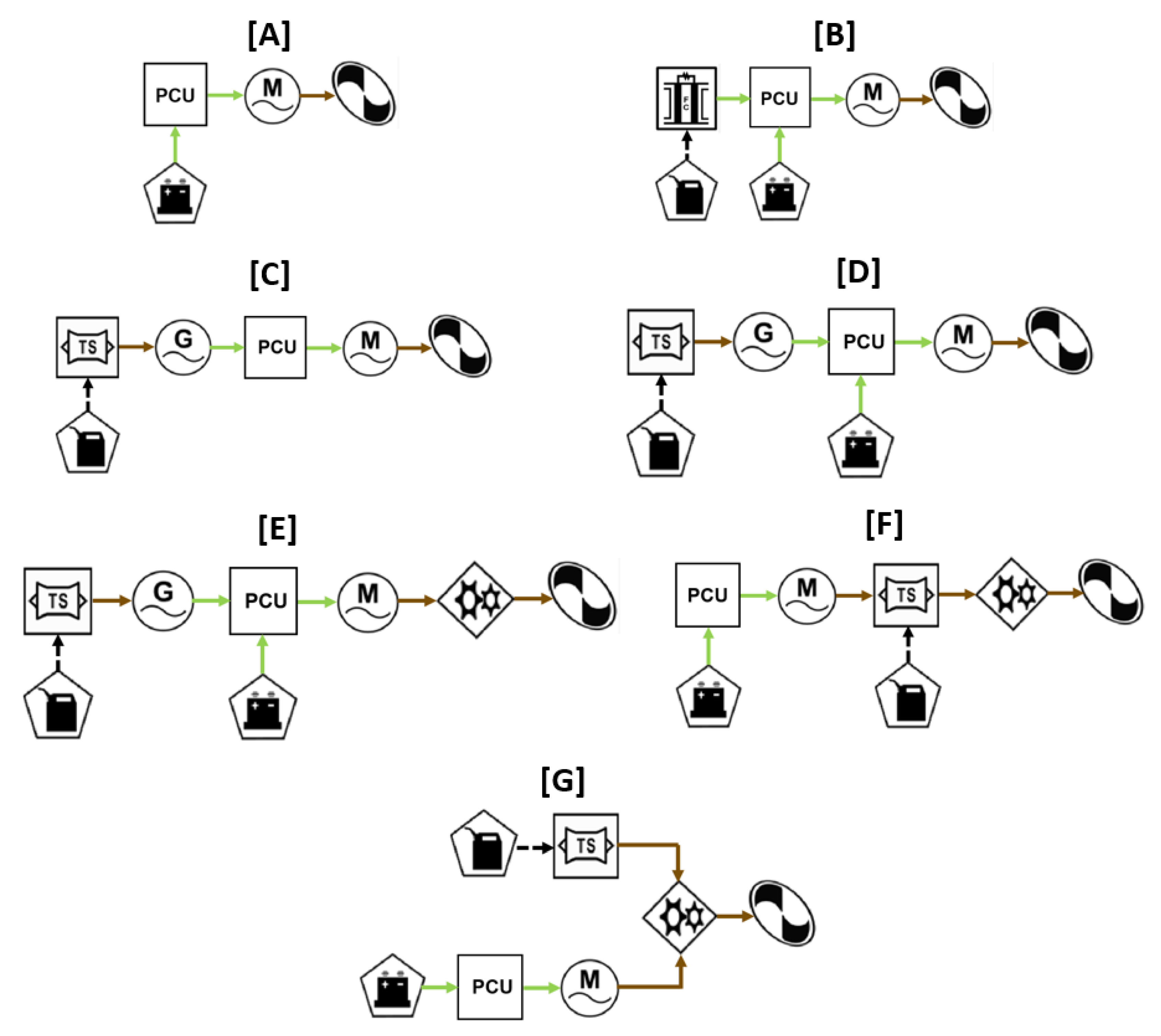

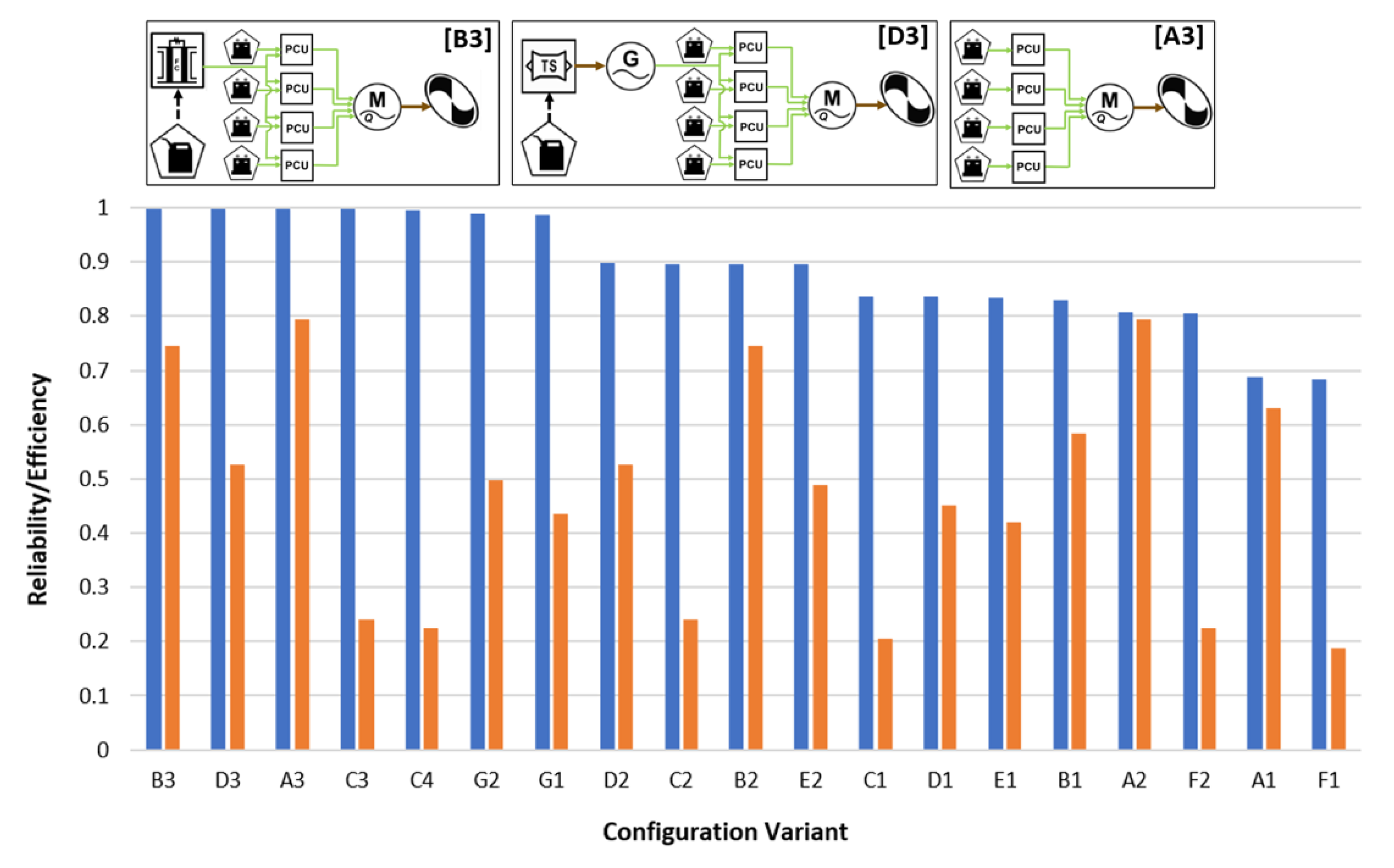

3. Single-Propulsion Channel Study

4. Case Studies

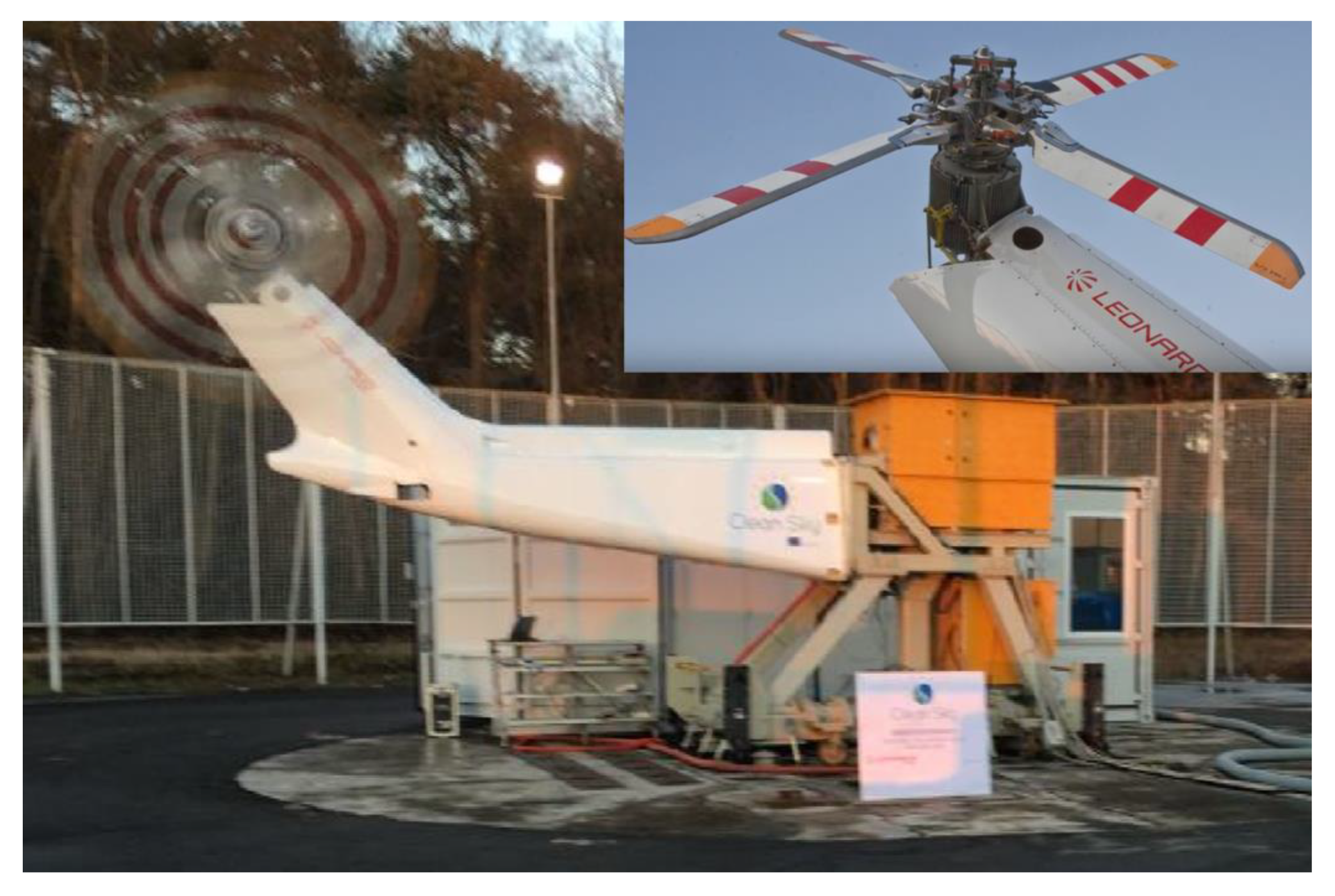

4.1. Electric Tail Rotor (ETR)

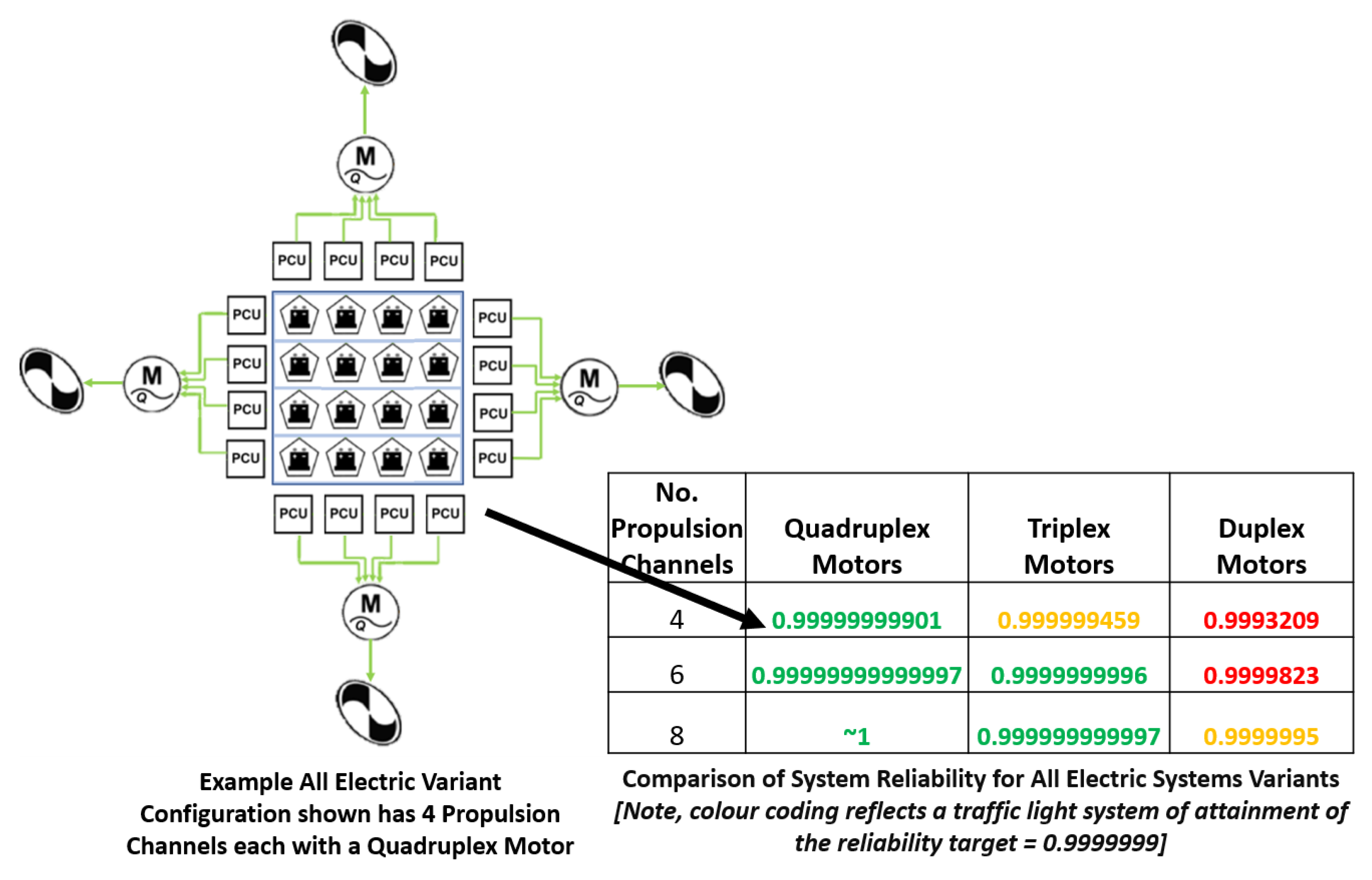

4.2. All Electric VTOL

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zaheer, S. Why Hybrid-Electric Aircraft Will Lead the Way in VTOL. The Startup, 27 November, 2020. Available online: https://medium.com/swlh/why-hybrid-electric-aircraft-will-lead-the-way-in-vtol-c3c1fcec1f6f (accessed on 8 September 2021).

- Voskuijl, M.; van Bogaert, J.; Rao, A.G. Analysis and design of hybrid electric regional turboprop aircraft. CEAS Aeronaut J. 2018, 9, 15–25. [Google Scholar] [CrossRef] [Green Version]

- Fletcher, S.; Flynn, M.; Jones, C.E.; Norman, P.J. Hybrid Electric Aircraft: State of the Art and Key Electrical System Challenges. The Transportation Electrification eNewsletter, September, 2016. Available online: https://tec.ieee.org/newsletter/september-2016/hybrid-electric-aircraft-state-of-the-art-and-key-electrical-system-challenges (accessed on 8 September 2021).

- Gesell, H.; Wolters, F.; Plohr, M. System analysis of turbo-electric and hybrid-electric propulsion systems on a regional aircraft. Aeronaut. J. 2019, 123, 1602–1617. [Google Scholar] [CrossRef]

- Ha, T.H.; Lee, K.; Hwang, J.T. Large-scale multidisciplinary optimization under uncertainty for electric vertical take-off and landing aircraft. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. Paper No. AIAA 2020-0904. [Google Scholar] [CrossRef]

- Kruger, M.; Uranga, A. The Feasibility of Electric Propulsion for Commuter Aircraft. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. Paper No. AIAA 2020-1499. [Google Scholar] [CrossRef]

- Fabri, G.; Parasiliti, M.; Tursini, M.; Villani, M.; Castellini, L. PM brushless motor for helicopters electric tail rotor drive system. In Proceedings of the IEEE International Electric Machines and Drives Conference, Miami, FL, USA, 21–24 May 2017. [Google Scholar] [CrossRef]

- Danis, R.A.; Green, M.W.; Freemna, J.L.; Hall, D.W. Examining the Conceptual Design Process for Future Hybrid-Electric Rotorcraft. NASA/CR—2018–219897, NASA Langley Research Center Hampton, VA, 1 May, 2018. Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20180003214.pdf (accessed on 8 September 2021).

- Avanzini, G.; Carlà, A.; Donateo, T. Parametric analysis of a hybrid power system for rotorcraft emergency landing sequence. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2017, 231, 2282–2294. [Google Scholar] [CrossRef]

- Gurevich, O.; Lukovnikov, A.; Gulienko, A.; Zakharchenko, V.; Kovalenko, I.; Suntsov, P. Analysis of possibilities to apply electric technologies for helicopter propulsion system. In Proceedings of the 29th Congress of the International Council of the Aeronautical Sciences (ICAS 2014), St. Petersburg, Russia, 7–12 September 2014; pp. 2864–2869. Available online: https://www.icas.org/ICAS_ARCHIVE/ICAS2014/data/papers/2014_0404_paper.pdf (accessed on 6 October 2021).

- Roper, J. The Technical challenges Still to Be Solved before eVTOLs Can Become Air Taxis. Aerospace Testing International, 5 May 2021. Available online: https://www.aerospacetestinginternational.com/features/air-taxi-analysis.html (accessed on 8 September 2021).

- Blain, L. Cutting through the eVTOL Hype with the AAM Reality Index. New Atlas, 11 May 2021. Available online: https://newatlas.com/aircraft/evtol-air-taxi-aam-reality-index-sergio-cecutta/ (accessed on 8 September 2021).

- Clarke, D. Public Acceptance of Flying Cars: What’s it Going to Take for UAM to Take off? Aerocar, 11 October 2020. Available online: https://aerocarjournal.com/public-acceptance-of-flying-cars/ (accessed on 8 September 2021).

- Advisory Council for Aviation Research and Innovation in Europe (ACARE). Strategic Research & Innovation Agenda—Volume 1. 2017. Available online: https://www.acare4europe.org/sites/acare4europe.org/files/document/ACARE-Strategic-Research-Innovation-Volume-1.pdf (accessed on 8 September 2021).

- Sahoo, S.; Zhao, X.; Kyprianidis, K. A Review of Concepts, Benefits, and Challenges for Future Electrical Propulsion-Based Aircraft. Aerospace 2020, 7, 44. [Google Scholar] [CrossRef] [Green Version]

- Gazzino, M. State of the Art of More Electric Helicopter. In Proceedings of the More Electric Aircraft Conference (MEA 2012), Bordeaux, France, 20–21 November 2012. [Google Scholar]

- Aigner, B.; Nollmann, M.; Stumpf, E. Design of a Hybrid Electric Propulsion System within a Preliminary Aircraft Design Software Environment, Computer Science, 2018. Available online: https://www.dglr.de/publikationen/2018/480153.pdf (accessed on 8 September 2021).

- Jiang, X.; Huang, W.; Cao, R.; Hao, Z.; Jiang, W. Electric Drive System of Dual-Winding Fault-Tolerant Permanent-Magnet Motor for Aerospace Applications. IEEE Trans. Ind. Electron. 2015, 62, 7322–7330. [Google Scholar] [CrossRef]

- Aigner, B.; Stumpf, E.; Hinz, A.; De Doncker, R.W. An Integrated Design Framework for Aircraft with Hybrid Electric Propulsion. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. Paper No. AIAA 2020-1501. [Google Scholar] [CrossRef]

- Lambert, P.-A.; Alejo, D.; Fefermann, Y.; Maury, C.; Thoraval, B.; Salanne, J.-P.; Isikveren, A.T. Long-term hybrid-electric propulsion architecture options for transport aircraft. In Proceedings of the Greener Aviation 2016, Brussels, Belgium, 11–13 October 2016. Paper No. 87.. [Google Scholar]

- Moir, A.; Seabridge, I. Aircraft Systems: Mechanical, Electrical and Avionics Subsystems Integration, 3rd ed.; Wiley: New York, NY, USA, 2011. [Google Scholar]

- Galea, M. High Performance, Direct Drive Machines for Aerospace Applications. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2013. Available online: http://eprints.nottingham.ac.uk/14431/1/601768.pdf (accessed on 8 September 2021).

- Abdel-Hafez, A. Power Generation and Distribution System for a More Electric Aircraft—A Review. In Recent Advances in Aircraft Technology; Agarwal, R.K., Ed.; IntechOpen Ltd.: London, UK, 2012; Available online: https://www.intechopen.com/books/recent-advances-in-aircraft-technology/more-electric-aircraft (accessed on 8 September 2021).

- Zhao, W.; Xu, L.; Liu, G. Overview of permanent-magnet fault-tolerant machines: Topology and design. China Electrotech. Soc. Trans. Electr. Mach. Syst. 2018, 2, 51–64. [Google Scholar] [CrossRef]

- Tursini, M. Fault-Tolerant Electric Drives for Aeronautical Applications. Electric Motor Engineering. Available online: https://www.electricmotorengineering.com/fault-tolerant-electric-drives-for-aeronautical-applications (accessed on 8 September 2021).

- Cao, W.; Mecrow, B.C.; Atkinson, G.J.; Bennett, J.W.; Atkinson, D.J. Overview of Electric Motor Technologies Used for More Electric Aircraft (MEA). IEEE Trans. Ind. Electron. 2011, 59, 3523–3531. [Google Scholar] [CrossRef]

- Ede, J.D.; Atallah, K.; Wang, J.B.; Howe, D. Modular fault-tolerant permanent magnet brushless machines. In Proceedings of the 2002 International Conference on Power Electronics, Machines and Drives (PEMD), Sante Fe, NM, USA, 4–7 June 2002; pp. 415–420. [Google Scholar] [CrossRef]

- Kotikalpudi, A.; Danowsky, B. Reliability Analysis for Small Unmanned Air Vehicles with Algorithmic Redundancy. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. Paper No. AIAA 2020-0739. [Google Scholar] [CrossRef]

- Sangha, P.S.; Sawata, T. Design and test results for dual-lane fault-tolerant PM motor for safety critical aircraft actuator. In Proceedings of the 2015 IEEE Energy Conversion Congress and Exposition (ECCE), Montreal, QC, USA, 20–24 September 2015; pp. 4055–4060. [Google Scholar] [CrossRef]

- Mashman, J. Tiltrotor Offers a Choice. Flight Safety Foundation—Helicopter Safety, 14(6), Nov/Dec 1988. Available online: https://flightsafety.org/hs/hs_nov-dec88.pdf (accessed on 8 September 2021).

- Brown, G.V. Weights and Efficiencies of Electric Components of a Turboelectric Aircraft Propulsion System. In Proceedings of the 49 AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011. Paper No. AIAA 2011-225. [Google Scholar] [CrossRef]

- Chretien, P. Paving the Way to Hybrid Helicopters, 2019. Available online: http://newsite.solutionf.fr/wp-content/uploads/Paving-the-way-towards-hybrid-helicopter-rev-6A-.pdf (accessed on 8 September 2021).

- Volocopter. Available online: https://www.volocopter.com/solutions (accessed on 8 September 2021).

- eHang. Available online: https://www.ehang.com/ehangaav (accessed on 8 September 2021).

- ByeAerospace. Available online: https://byeaerospace.com/bye-aerospace-unveils-8-seat-all-electric-eflyer-800 (accessed on 8 September 2021).

- Stickels, K. Advances in Helicopter Electric Tail Rotor Drive. In Proceedings of the 43rd European Rotorcraft Forum, Milan, Italy, 12–15 September 2017; Paper No. 662. Available online: https://dspace-erf.nlr.nl/xmlui/bitstream/handle/20.500.11881/3875/662_ERF2017.pdf?sequence=1&isAllowed=y (accessed on 6 October 2021).

- AIAA. Guidelines for Analysis of Hybrid Electric Aircraft System Studies: Nomenclature, Pictographic Representations, Standalone and Combined Properties and Attributes, Metrics, and Figures of Merit”. American Institute of Aeronautics and Astronautics. Available online: https://www.aiaa.org/docs/default-source/uploadedfiles/publications/standards/hybrid-electric_properties_attributes.pdf?sfvrsn=c8eb8f11_0 (accessed on 8 September 2021).

- Booker, J.D.; Lock, R.J.; Williamson, S.; Gómez, J.F. Effective practices for the concept design of electromechanical systems. J. Eng. Des. Technol. 2016, 14, 489–506. [Google Scholar] [CrossRef] [Green Version]

- Billinton, P.; Allan, R. Reliability Evaluation of Engineering System; Springer: New York, NY, USA, 1992. [Google Scholar]

- Vieira, D.R.; Rebaiaia, M.-L.; Chain, M.C. The Application of Reliability Methods for Aircraft Design Project Management. Am. J. Ind. Bus. Manag. 2016, 6, 967–992. [Google Scholar] [CrossRef] [Green Version]

- Denson, W.; Chandler, G.; Crowell, W.; Clark, A.; Jaworski, P. NPRD-95: Nonelectronic Parts Reliability Data; Reliability Analysis Center: New York, NY, USA, 1995. [Google Scholar]

- Astridge, D.G. Helicopter Transmissions—design for Safety and Reliability. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 1989, 203, 123–138. [Google Scholar] [CrossRef]

- Meadinfo, Comparison of Gear Efficiencies—Spur, Helical, Bevel, Worm, Hypoid, Cycloid, 23 October, 2012. Available online: https://www.meadinfo.org/2008/11/gear-efficiency-spur-helical-bevel-worm.html (accessed on 8 September 2021).

- de Vries, R.; Hoogreef, M.; Vos, R. Aero-Propulsive Efficiency Requirements for Turboelectric Transport Aircraft. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. Paper No. 2020-0502. [Google Scholar]

- Misté, G.A.; Benin, E. Performance of a Turboshaft Engine for Helicopter Applications Operating at Variable Shaft Spee. In Proceedings of the Asme 2012 Gas Turbine India Conference (GTINDIA2012), Mumbai, Maharashtra, India, 1 December 2012. Paper No. GTINDIA2012-9505. [Google Scholar] [CrossRef]

- Khalil, Y. Researchgate Post, 4 February 2017. Available online: https://www.researchgate.net/post/Can_anyone_give_me_failure_rates_of_lithium_ion_NMC_pouch_cells#view=5895f53896b7e47ec829eb59 (accessed on 8 September 2021).

- Sabihuddin, S.; Kiprakis, A.E.; Mueller, M. A Numerical and Graphical Review of Energy Storage Technologies. Energies 2014, 8, 172–216. [Google Scholar] [CrossRef]

- Marchesoni, M.; Savio, S. Reliability analysis of a fuel cell electric city car. In Proceedings of the 2005 European Conference on Power Electronics and Applications, Dresden, Germany, 11–14 September 2005; p. 10. [Google Scholar] [CrossRef]

- Suppes, G.J.; Storvick, T.S. The New Electric Vehicle Society. In Sustainable Power Technologies and Infrastructure; Suppes, G.J., Storvick, T.S., Eds.; Academic Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Vankan, J.; Lammen, W. Parallel hybrid electric propulsion architecture for single aisle aircraft—powertrain investigation. MATEC Web Conf. 2019, 304, 03008. [Google Scholar] [CrossRef]

- Sforza, P. Commercial Airplane Design Principles; Butterworth-Heinemann: Oxford, UK, 2014. [Google Scholar]

- Stegeman, R. EVTOL Crashworthiness: Moving Forward. eVTOL Crashworthiness Workshop #2, Federal Aviation Administration (FAA), 9 October 2020. Available online: https://nari.arc.nasa.gov/sites/default/files/attachments/5_FAA_EVTOL%20Crashworthiness%20Moving%20Forward.pdf (accessed on 9 September 2021).

- Head, E. Safety Is about More Than Aircraft design. eVTOL, 3 June 2019. Available online: https://evtol.com/opinions/safety-is-about-more-than-aircraft-design/ (accessed on 9 September 2021).

- EASA. Second Publication of Proposed Means of Compliance with the Special Condition VTOL. European Union Aviation Safety Agency (EASA), Doc. No: MOC-2 SC-VTOL, Issue: 1, 3 June 2021. Available online: https://www.easa.europa.eu/sites/default/files/dfu/moc-2_sc-vtol_-_lssue_1_-_23-06-2021.pdf (accessed on 9 September 2021).

- Johnson, W.; Silva, C. Observations from Exploration of VTOL Urban Air Mobility Designs. In Proceedings of the Asian/Australian Rotorcraft Forum (ARF 2018), Paper No. 20180007847, 2018. Available online: https://ntrs.nasa.gov/citations/20180007847 (accessed on 9 September 2021)Paper No. 20180007847.

- Brelje, B.J.; Martins, J.R. Electric, hybrid, and turboelectric fixed-wing aircraft: A review of concepts, models, and design approaches. Prog. Aerosp. Sci. 2018, 104, 1–19. [Google Scholar] [CrossRef]

- Jun, L.; Huibin, X. Reliability Analysis of Aircraft Equipment Based on FMECA Method. Phys. Procedia 2012, 25, 1816–1822. [Google Scholar] [CrossRef] [Green Version]

- British Standards. BS-5760-5 Part 5: Guide To Failure Modes, Effects & Criticality Analysis (FMEA and FMECA); British Standards Institute: London, UK, 1991. [Google Scholar]

- AAIB. “DJI Matrice 210”, AAIB Bulletin, Doc. Ref. EW/G2019/03/03, Aircraft Accident Investigation Branch (AAIB), January, 2020. Available online: https://assets.publishing.service.gov.uk/media/5f452e37d3bf7f69a89b6c24/DJI_Matrice_210_UAS_registration_na_030319_01-20.pdf (accessed on 9 September 2021).

- Sun, S.; Cioffi, G.; de Visser, C.; Scaramuzza, D. Autonomous Quadrotor Flight Despite Rotor Failure with Onboard Vision Sensors: Frames vs. Events. IEEE Robot. Autom. Lett. 2021, 6, 580–587. [Google Scholar] [CrossRef]

- AAIB. Alauda Airspeeder Mk II. AAIB Bulletin, Doc. Ref. AAIB-25876, Aircraft Accident Investigation Branch (AAIB), March, 2021. Available online: https://assets.publishing.service.gov.uk/media/602bb22f8fa8f50388f9f000/Alauda_Airspeeder_Mk_II_UAS_reg_na_03-21.pdf (accessed on 9 September 2021).

- Barr, L.C.; Newman, R.L.; Ancel, E.; Belcastro, C.M.; Foster, J.V.; Evans, J.K. Preliminary Risk Assessment for Small Unmanned Aircraft Systems. In Proceedings of the 17th AIAA Aviation Technology, Integration, and Operations Conference, Denver, CO, USA, 5–9 June 2017. [Google Scholar] [CrossRef] [Green Version]

- Courtin, C.; Hansman, R.J. Safety Considerations in Emerging Electric Aircraft Architectures. In Proceedings of the Aviation Technology, Integration, and Operations Conference, Atlanta, Georgia, 25–29 June 2018. Paper No. AIAA 2018-4149. [Google Scholar] [CrossRef]

- Ditlevsen, O. Structural reliability codes for probabilistic design—A debate paper based on elementary reliability and decision analysis concepts. Struct. Saf. 1997, 19, 253–270. [Google Scholar] [CrossRef]

- Booker, J.D.; Raines, M.; Swift, K.G. Designing Capable and Reliable Products; Butterworth-Heinemann: Oxford, UK, 2001. [Google Scholar]

- Carter, A.D.S. Mechanical Reliability and Design; Macmillan: London, UK, 1997. [Google Scholar]

- Dieter, G.E. Engineering Design: A Materials and Processing Approach, 3rd ed.; McGraw-Hill: New York, NY, USA, 2000. [Google Scholar]

- Smith, D.J. Reliability, Maintainability and Risk: Practical Methods for Engineers, 4th ed.; Butterworth-Heinemann: Oxford, UK, 1993. [Google Scholar]

- Fajdiga, M.; Jurejevčič, T.; Kernc, J. Reliability Prediction in Early Phases of Product Design. J. Eng. Des. 1996, 7, 107–128. [Google Scholar] [CrossRef]

- Fragola, J.R. Reliability and risk analysis data base development: An historical perspective. Reliab. Eng. Syst. Saf. 1996, 51, 125–136. [Google Scholar] [CrossRef]

- EASA. Proposed Special Condition for Small-Category VTOL Aircraft, European Union Aviation Safety Agency (EASA), Doc. No: SC-VTOL-01, Issue: 1 (Proposed), 15 October, 2018. Available online: https://www.easa.europa.eu/sites/default/files/dfu/SC-VTOL-01.pdf (accessed on 9 September 2021).

- Roland Berger Strategy Consultants. Aircraft Electrical Propulsion—The Next Chapter of Aviation? 10 October, 2017. Available online: https://www.rolandberger.com/en/Publications/New-developments-in-aircraft-electrical-propulsion-(CH).html (accessed on 9 September 2021).

- Boggero, L.; Corpino, S.; De Martin, A.; Evangelista, G.; Fioriti, M.; Sorli, M. A Virtual Test Bench of a Parallel Hybrid Propulsion System for UAVs. Aerospace 2019, 6, 77. [Google Scholar] [CrossRef] [Green Version]

- Bowman, C.L.; Felder, J.L.; Marien, T.V. Turbo- and Hybrid-Electrified Aircraft Propulsion Concepts for Commercial Transport. In Proceedings of the 2018 AIAA/IEEE Electric Aircraft Technologies Symposium, Cincinnati, OH, USA, 9–11 July 2018; Paper No. AIAA 2018-4984. Available online: https://ntrs.nasa.gov/search.jsp?R=20180005437 (accessed on 9 September 2021).

- Dean, T.; Wroblewski, G.E.; Ansell, P.J. Mission Analysis and Component-Level Sensitivity Study of Hybrid-Electric General Aviation Propulsion Systems. J. Aircr. 2018, 55, 2454–2465. [Google Scholar] [CrossRef]

- Domone, J. “The Challenges and Benefits of the Electrification of Aircraft”. Atkins, 2018. Available online: https://www.snclavalin.com/~/media/Files/S/SNC-Lavalin/documents/beyond-engineering/electrification-white-paper.pdf (accessed on 9 September 2021).

- Insight, “Electrical Power Systems –07”, Aerospace Technology Institute (ATI), July, 2018. Available online: https://www.ati.org.uk/media/ntlocbb4/insight_07-electrical-power-systems.pdf (accessed on 9 September 2021).

- Schömann, J. Hybrid-Electric Propulsion Systems for Small Unmanned Aircraft. Ph.D. Thesis, Technical University of Munich, Munich, Germany, 2014. Available online: https://mediatum.ub.tum.de/doc/1183222/document.pdf (accessed on 9 September 2021).

- Booker, J.D.; Yon, J.; Williamson, S.; North, D.; Mellor, P.H. Development of a Power Generation System and Quadruplex Direct Electric Drive for a Helicopter Tail Rotor. In Proceedings of the AIAA SciTech Forum, Orlando, FL, USA, 6–10 January 2020. Paper No. AIAA 2020-0118. [Google Scholar] [CrossRef]

- CAA. Helicopter Tail Rotor Failures. Civil Aviation Authority (CAA), Paper 2003/1, November 2003. Available online: https://publicapps.caa.co.uk/docs/33/CAPAP2003_01.pdf (accessed on 9 September 2021).

- Zakrajsek, J.; Dempsey, P.; Huff, E.; Augustin, M.; Grabill, P.; Decker, H. Rotorcraft health management issues and challenges. In Proceedings of the 1st International Forum on Integrated System Health Engineering and Management in Aerospace, Nampa, CA. Paper No. NASA/TM-2006-214022, 2006. Available online: https://core.ac.uk/reader/10516600 (accessed on 6 October 2021).

- Booker, J.D.; North, D.; Yon, J.M.; Mellor, P.H. Generator configuration for helicopter quadruplex electric tail rotor. J. Eng. 2019, 2019, 4471–4474. [Google Scholar] [CrossRef]

- Usman, N.T. Stator Winding Faults investigation in Permanent Magnet Synchronous Motor using Motor Signatures: Part I. In Proceedings of the 19th International Conference on Electrical Drives & Power Electronics (EDPE), The High Tatras, Slovakia, 24–26 September 2019; pp. 160–168. [Google Scholar] [CrossRef]

| Severity | Description | Rating (S) |

|---|---|---|

| Catastrophic | Sudden loss of primary sub-system function with direct safety implications and effects on green VTOL system | 5 |

| Severe | Sudden loss of primary sub-system function with potential safety implications on green VTOL system and secondary sub-system failures | 4 |

| Major | Gradual failure of sub-systems, which are operable but at reduced level of performance, directly impacting functionality—no immediate effect on green VTOL system | 3 |

| Minor | Failure resulting in minor implications to performance in sub-system functionality, with no direct safety implication on green VTOL system | 2 |

| Insignificant | No failure implications on sub-system performance, functionality or safety on green VTOL system | 1 |

| System Element | Failure Mode | Severity (S) | Effects of Failure |

|---|---|---|---|

| Propellor Failure | Bird Strike | 5 | Loss of lift from propellor resulting in loss of aircraft stability |

| Structural Failure | 5 | Loss of lift from propellor resulting in loss of aircraft stability | |

| Motor Failure | Winding Failure | 4 | Proportional loss of power and subsequent lift from propeller. Remaining components under more stress. |

| Overheating | 3 | Loss of efficiency and performance. Possible further impacts upon components. | |

| Bird Strike | 5 | Complete loss of power, loss of lift. | |

| Overloading | 4 | Higher stresses upon components, causing further failures. | |

| PCU Failure | Short Circuit | 4 | Loss of power from motor, cascade effect. More strain on other components. |

| Overheating | 3 | Increased failure due to degradation. Possible further impacts. | |

| Energy Storage | Puncture | 5 | Battery fire, considerable further failure within power system. Loss of power, loss of lift. |

| Thermal Runaway | 4 | Loss of power, possible further battery failures. | |

| Overloading | 3 | Higher stress on batteries, could cause further degradation | |

| Short Circuit | 4 | Loss of power, provided. Possible thermal runaway. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Booker, J.D.; Patel, C.; Mellor, P. Modelling Green VTOL Concept Designs for Reliability and Efficiency. Designs 2021, 5, 68. https://doi.org/10.3390/designs5040068

Booker JD, Patel C, Mellor P. Modelling Green VTOL Concept Designs for Reliability and Efficiency. Designs. 2021; 5(4):68. https://doi.org/10.3390/designs5040068

Chicago/Turabian StyleBooker, Julian David, Caius Patel, and Phillip Mellor. 2021. "Modelling Green VTOL Concept Designs for Reliability and Efficiency" Designs 5, no. 4: 68. https://doi.org/10.3390/designs5040068

APA StyleBooker, J. D., Patel, C., & Mellor, P. (2021). Modelling Green VTOL Concept Designs for Reliability and Efficiency. Designs, 5(4), 68. https://doi.org/10.3390/designs5040068