Effect of Chill Plate Thickness on Surface Hardening and Dimensional Accuracy of Nodular Cast Iron Gears Manufactured by the Chill Casting Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Manufacturing Processes

2.2. Gear Dimensional Measurement

2.3. Microstructure Testing

2.4. Scanning Electron Microscope-Energy Dispersive X-ray (SEM-EDX)

2.5. Microhardness Testing

2.6. Wear Test

3. Results and Discussions

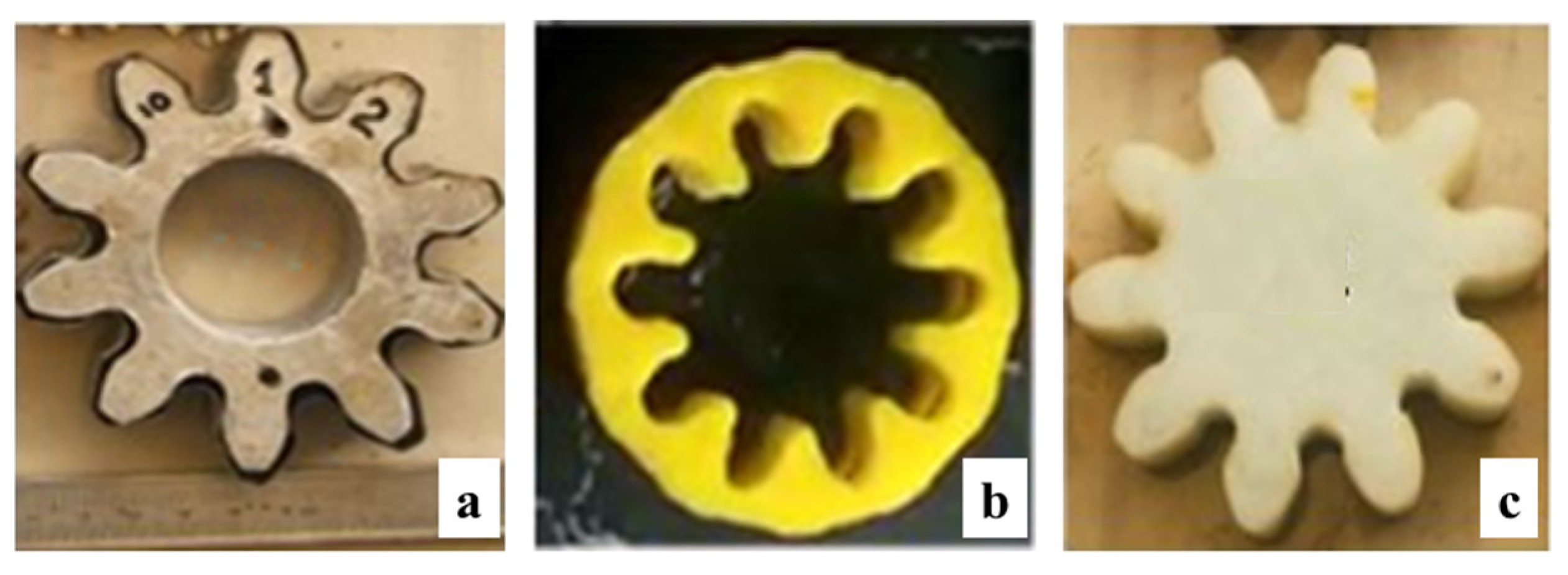

3.1. Photographic Analysis

3.2. Microstructure and Chemical Composition Analysis

3.3. SEM-EDX Analysis

3.4. Microhardness Analysis

3.5. Wear Analysis

3.6. Dimensional Change Analysis

3.6.1. Tooth Thickness Analysis

3.6.2. Pitch Circle Diameter (PCD) Analysis

3.6.3. Addendum Circle Diameter (ACD)

4. Conclusions

- Using chill in the gear casting process has succeeded in changing the value of hardness and hardness thickness layer, type of microstructure, chemical composition content, and wear resistance in the surface area of the chill-coated tooth profile;

- The use of chill in the casting process causes a fast-cooling rate on the surface of the tooth profile, thus changing the graphite nodule structure into a cementite phase, a martensitic phase, and a ledeburite phase in the chilled tooth profile surface area;

- Using chill can increase the hardness value in the chilled area. The hardness value on the surface in the tooth flank area is higher, reaching 700 HV–887 HV, than the hardness value in the middle area of the gear, which is 296 HV–301.04 HV. The thickness of the chill plate affects the cooling rate, which will determine the hardness and microstructure of the hardened layer. A thicker chill plate will provide a slower cooling rate, which can lead to a more homogeneous microstructure and a more uniform hardness distribution in the hardened layer. On the other hand, a thinner chill plate will provide a faster cooling rate, which can lead to higher hardness in the hardened layer;

- With the formation of a matrix structure of ferrous chromium carbide (FeCrC) due to elemental diffusion from the chill material, it can increase the hardness value so that the wear resistance is very good, which has an average specific wear value ranging from 2.691 × 10−6 mm2/kg to 5.502 × 10−6 mm2/kg;

- Using modified gear patterns with various dimensions, such as an enhancer plate thickness of 0.2 mm, can prevent shrinkage in the tooth profile after casting.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- AGMA Standard. Gear Materials And Heat Treatment Manual AGMA 2004-B89. In Metallurgy and Materials Committee; American National Standard: Alexandria, VA, USA, 1989; Volume 89, p. 79. ISBN 1-55589-524-7. [Google Scholar]

- Shama, S. Comparison of Mechanical Properties of Austenitic Ductile Cast Iron with Ferritic/Pearlitic Ductile Cast Iron; Metallurgical and Materials Engineering National Institute of Technology Rourkela Certificate of Examination, National Institute of Technology: Rourkela Odisha, India, 2017. [Google Scholar]

- Davis, J.R. Gear Materials, Properties, and Manufacture; Davis, J.R., Ed.; ASM International: Materials Park, OH, USA, 2005; ISBN 0871708159. [Google Scholar]

- Callister, W.D.; David, G. Rethwisch Materials Science and Engineering an Intruduction, 8th ed.; John Wiley and Sons, Inc.: Hoboken, NJ, USA, 2010; ISBN 978-0-470-41997-7. [Google Scholar]

- Samaddar, S.; Das, T.; Chowdhury, A.K.; Singh, M. Manufacturing of Engineering Components with Austempered Ductile Iron—A Review. Mater. Today Proc. 2018, 5, 25615–25624. [Google Scholar] [CrossRef]

- Hsu, C.H.; Chuang, T.L. Influence of Stepped Austempering Process on the Fracture Toughness of Austempered Ductile Iron. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2001, 32, 2509–2514. [Google Scholar] [CrossRef]

- Concli, F. Austempered Ductile Iron (ADI) for Gears: Contact and Bending Fatigue Behavior. Procedia Struct. Integr. 2018, 8, 14–23. [Google Scholar] [CrossRef]

- Geffroy, P.-M.; Lakehal, M.; Goñi, J.; Beaugnon, E.; Silvain, J.-F. Thermal and Mechanical Behaviour of Grey Cast Iron and Ductile Iron Castings Using Magnetic Molding and Lost Foam Processes. J. Mater. Process. Technol. 2009, 209, 4103–4111. [Google Scholar] [CrossRef]

- Gupta, K.; Jain, N.K.; Laubscher, R.F. Advanced Gear Manufacturing and Finishing (Classical and Modern Processes); Elsevier Ltd.: London, UK, 2017; ISBN 978-0-12-804460-5. [Google Scholar]

- Davis, J.R. Surface Engineering, 1st ed.; Davis, J.R., Ed.; ASM International The Material Information Society: Materials Park, OH, USA, 2001; ISBN 0871707004. [Google Scholar]

- Conrado, E.; Gorla, C.; Davoli, P.; Boniardi, M. A Comparison of Bending Fatigue Strength of Carburized and Nitrided Gears for Industrial Applications. Eng. Fail. Anal. 2017, 78, 41–54. [Google Scholar] [CrossRef]

- Dhanasekaran, S.; Gnanamoorthy, R. Gear Tooth Wear in Sintered Spur Gears under Dry Running Conditions. Wear 2008, 265, 81–87. [Google Scholar] [CrossRef]

- Imrek, H.; Düzcükoǧlu, H. Relation between Wear and Tooth Width Modification in Spur Gears. Wear 2007, 262, 390–394. [Google Scholar] [CrossRef]

- Pisula, J.M.; Budzik, G.; Przeszłowski, Ł. An Analysis of the Surface Geometric Structure and Geometric Accuracy of Cylindrical Gear Teeth Manufactured with the Direct Metal Laser Sintering (DMLS) Method. J. Mech. Eng. 2019, 65, 78–86. [Google Scholar] [CrossRef] [Green Version]

- Kawalec, A.; Wiktor, J.; Ceglarek, D. Comparative Analysis of Tooth-Root Strength Using ISO and AGMA Standards in Spur and Helical Gears with FEM-Based Verification. J. Mech. Des. Trans. ASME 2006, 128, 1141–1158. [Google Scholar] [CrossRef]

- Liu, L.; Pines, D.J. The Influence of Gear Design Parameters on Gear Tooth Damage Detection Sensitivity. J. Mech. Des. Trans. ASME 2002, 124, 794–804. [Google Scholar] [CrossRef]

- Ristivojević, M.; Lazović, T.; Vencl, A. Studying the Load Carrying Capacity of Spur Gear Tooth Flanks. Mech. Mach. Theory 2013, 59, 125–137. [Google Scholar] [CrossRef]

- Venkatesh, B.; Prabhakar Vattikuti, S.V.; Deva Prasad, S. Investigate the Combined Effect of Gear Ratio, Helix Angle, Facewidth and Module on Bending and Compressive Stress of Steel Alloy Helical Gear. Procedia Mater. Sci. 2014, 6, 1865–1870. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; Lai, J.; Lohmann, C.; Tenberge, P.; Weibring, M.; Dong, P. A Model to Predict Initiation and Propagation of Micro-Pitting on Tooth Flanks of Spur Gears. Int. J. Fatigue 2019, 122, 106–115. [Google Scholar] [CrossRef]

- Weibring, M.; Gondecki, L.; Tenberge, P. Simulation of Fatigue Failure on Tooth Flanks in Consideration of Pitting Initiation and Growth. Tribol. Int. 2019, 131, 299–307. [Google Scholar] [CrossRef]

- Budynas, R.G.; Nisbett, J.K. Mechanical Engineering Design, 9th ed.; McGraw-Hill Education: New York, NY, USA, 2015; Volume XXXIII, ISBN 9780073398204. [Google Scholar]

- Das, D.; Bhattacharya, S.; Sarkar, B. Decision-Based Design-Driven Material Selection: A Normative-Prescriptive Approach for Simultaneous Selection of Material and Geometric Variables in Gear Design. Mater. Des. 2016, 92, 787–793. [Google Scholar] [CrossRef]

- Boiadjiev, I.; Witzig, J.; Tobie, T.; Stahl, K. Tooth Flank Fracture—Basic Principles and Calculation Model for a Sub Surface Initiated Fatigue Failure Mode of Case Hardened Gears. In Proceedings of the International Gear Conference 2014, Lyon, France, 26–28 August 2014; pp. 670–680. [Google Scholar] [CrossRef] [Green Version]

- Wan, B.; Barber, G.C.; Tao, C.; Sun, X.; Xu, R. Characteristics of Tempering Response of Austempered Ductile Iron. J. Mater. Res. Technol. 2017, 7, 198–202. [Google Scholar] [CrossRef]

- Myszka, D.; Kłębczyk, M.; Kwiatkowski, L.; Zych, A. The Surface Layer of Austempered Ductile Iron Investment Castings Properties. Arch. Foundry Eng. 2009, 9, 157–162. [Google Scholar]

- Cao, H.T.; Dong, X.P.; Pan, Z.; Wu, X.W.; Huang, Q.W.; Pei, Y.T. Surface Alloying of High-Vanadium High-Speed Steel on Ductile Iron Using Plasma Transferred Arc Technique: Microstructure and Wear Properties. Mater. Des. 2016, 100, 223–234. [Google Scholar] [CrossRef]

- Jeshvaghani, R.A.; Jaberzadeh, M.; Zohdi, H.; Shamanian, M. Microstructural Study and Wear Behavior of Ductile Iron Surface Alloyed by Inconel 617. Mater. Des. 2014, 54, 491–497. [Google Scholar] [CrossRef]

- Ceschini, L.; Campana, G.; Pagano, N.; Angelini, V. Effect of Laser Surface Treatment on the Dry Sliding Behaviour of the EN-GJS400-12 Ductile Cast Iron. Tribiol. Int. 2016, 104, 342–351. [Google Scholar] [CrossRef]

- Hurtado-Delgado, E.; Huerta-Larumbe, L. Microcracks Reduction in Laser Hardened Layers of Ductile Iron. Coatings 2021, 11, 368. [Google Scholar] [CrossRef]

- Zeng, D.; Lu, L.; Zhang, N.; Zhang, Y.; Zhang, J. Investigation on the Scuffing Resistance of Ductile Cast Iron as Affected by Fine Particle Bombardment to Produce Surface Hardened Layer and Micro-Dimpled Surface. Wear 2017, 378–379, 174–182. [Google Scholar] [CrossRef]

- Zammit, A.; Abela, S.; Charles, J.; Michalczewski, R.; Kalbarczyk, M.; Grech, M. Scuffing and Rolling Contact Fatigue Resistance of Discrete Laser Spot Hardened Austempered Ductile Iron. Wear 2019, 422–423, 100–107. [Google Scholar] [CrossRef]

- Hsu, C.H.; Chen, M.L.; Hu, C.J. Microstructure and Mechanical Properties of 4% Cobalt and Nickel Alloyed Ductile Irons. Mater. Sci. Eng. A 2007, 444, 339–346. [Google Scholar] [CrossRef]

- Pongsak, C.; Chaengkham, P. Continuously Cast Ductile Iron : Processing, Structures, and Properties. J. Mater. Process. Tech. 2011, 211, 1372–1378. [Google Scholar] [CrossRef]

- Romano, J.M.; Liang, Y.; Dashtbozorg, B.; Dong, H.; Penchev, P.; Dimov, S.S. Combined Surface Hardening and Laser Patterning Approach for Functionalising Stainless Steel Surfaces. Appl. Surf. Sci. 2018, 439, 516–524. [Google Scholar] [CrossRef]

- Shamanian, M.; Abarghouie, S.M.R.M.; Pour, S.R.M. Effects of Surface Alloying on Microstructure and Wear Behavior of Ductile Iron. Mater. Des. 2010, 31, 2760–2766. [Google Scholar] [CrossRef]

- Nixon, R.G.S.; Mohanty, B.S. Friction Surfacing of Metal Coatings on Stainless Steel AISI 304 over Spheroidal Graphite Iron Substrate. Adv. Mater. Res. 2013, 816–817, 271–275. [Google Scholar] [CrossRef]

- Mahmood, K.; Stevens, N.; Pinkerton, A.J. Laser Surface Modification Using Inconel 617 Machining Swarf as Coating Material. J. Mater. Process. Technol. 2012, 212, 1271–1280. [Google Scholar] [CrossRef]

- Li, Y.; Dong, S.; Yan, S.; Liu, X.; He, P.; Xu, B. Microstructure Evolution during Laser Cladding Fe-Cr Alloy Coatings on Ductile Cast Iron. Opt. Laser Technol. 2018, 108, 255–264. [Google Scholar] [CrossRef]

- Qian, M.; Harada, S.; Kuroshima, Y.; Nagayoshi, H. Surface Hardening of Ductile Cast Iron Using Stainless Steel. Mater. Sci. Eng. A 1996, 208, 88–92. [Google Scholar] [CrossRef]

- Orłowicz, A.W.; Trytek, A. Effect of Rapid Solidification on Sliding Wear of Iron Castings. Wear 2003, 254, 154–163. [Google Scholar] [CrossRef]

- Hurst, S. Metal Casting Appropriate Technology in the Small Foundry; Intermediate Technology Publications Ltd.: London, UK, 1996; ISBN 1 85339 197 2. [Google Scholar]

- Campbell, J. Complete Casting Handbook Metal Casting Process, Techniques and Design, 1st ed.; Elsevier Ltd.: Alpharetta, GA, USA, 2011; ISBN 9781856178099. [Google Scholar]

- da Silva, L.J.; Scheuer, C.J.; D’Oliveira, A.S.C.M. Effect of Microstructure on Wear Performance of NiCrSiBC Coatings. Wear 2019, 428–429, 387–394. [Google Scholar] [CrossRef]

- Lagos, M.A.; Agote, I.; Leizaola, I.; Lopez, D.; Calero, J.A. Fabrication of Chromium Carbide Cermets by Electric Resistance Sintering Process: Processing, Microstructure and Mechanical Properties. Int. J. Refract. Met. Hard Mater. 2021, 95, 105417. [Google Scholar] [CrossRef]

- Laino, S.; Sikora, J.A.; Dommarco, R.C. Development of Wear Resistant Carbidic Austempered Ductile Iron (CADI). Wear 2008, 265, 1–7. [Google Scholar] [CrossRef]

- König, M.; Svensson, I.L.; Wessén, M. The Influence of Alloying Elements on Chill Formation in CGI. Key Eng. Mater. 2011, 457, 126–131. [Google Scholar] [CrossRef]

- Jaromin, M.; Dojka, R.; Jezierski, J.; Dojka, M. Influence of Type and Shape of the Chill on Solidification Process of Steel Casting. Arch. Foundry Eng. 2019, 19, 35–40. [Google Scholar] [CrossRef]

- Wankhede, D.M.; Narkhede, B.E.; Mahajan, S.K.; Choudhari, C.M. Influence of Pouring Temperature and External Chills on Mechanical Properties of Aluminum Silicon Alloy Castings. Mater. Today Proc. 2018, 5, 17627–17635. [Google Scholar] [CrossRef]

- Pavithra, H.S.; Anantha Prasad, M.G. Study on Microstructure and Mechanical Properties of Al/SiO2/C Hybrid Metal Matrix Composite, with the Influence of Chills. Mater. Today Proc. 2018, 5, 6053–6058. [Google Scholar] [CrossRef]

- Gafur, M.A.; Haque, M.N.; Prabhu, K.N. Effect of Chill Thickness and Superheat on Casting/Chill Interfacial Heat Transfer during Solidification of Commercially Pure Aluminium. J. Mater. Process. Technol. 2003, 133, 257–265. [Google Scholar] [CrossRef]

- Mehr, F.F.; Reilly, C.; Cockcroft, S.; Maijer, D.; Mackay, R. Effect of Chill Cooling Conditions on Cooling Rate, Microstructure and Casting/Chill Interfacial Heat Transfer Coefficient for Sand Cast A319 Alloy. Int. J. Cast Met. Res. 2014, 27, 288–300. [Google Scholar] [CrossRef]

- Elsawy, E.E.T.; Mahallawi, I.S.E. El Effect of Manganese Silicon and Chromium Additions on Microstructure and Waer Characteristics of Grey Cast Iron Suger Industries Applications. Wear 2017, 390–391, 113–124. [Google Scholar] [CrossRef]

- Kalpakjian, S.; Schmid, S.R. Manufacturing Engineering and Technology, 6th ed.; Pearson Publishing Company: Upper Saddle River, NJ, USA, 2010; ISBN 978-0-13-608168-5. [Google Scholar]

- Sohi, M.H.; Ebrahimi, M.; Ghasemi, H.; Shahripour, A. Microstructural Study of Surface Melted and Chromium Surface Alloyed Ductile Iron. Appl. Surf. Sci. 2012, 258, 7348–7353. [Google Scholar] [CrossRef]

- Guterres, N.D.F.S.; Rusnaldy; Widodo, A.; Syamsudin, A. Investigate Temperature Preheating on the Chill Plate to Identify Surface Characteristic on the Ductile Iron by Sand Casting. Int. J. Eng. Mater. Manuf. 2021, 6, 141–151. [Google Scholar] [CrossRef]

- Guterres, N.F.D.S.; Rusnaldy; Widodo, A.; Carwita, T. The Effect of Chills Thickness to Microstructure and Surface Hardness Layer on Specimen Ductile Cast Iron. AIP Conf. Proc. 2020, 2384, 040004. [Google Scholar]

- Hughes, I.C.H. ASM Metals Handbook, Volume 15 Casting; ASM International: Materials Park, OH, USA, 1988. [Google Scholar]

- Janerka, K.; Kostrzewski, Ł.; Stawarz, M.; Jezierski, J. The Importance of SiC in the Process of Melting Ductile Iron with a Variable Content of Charge Materials. Materials 2020, 13, 1231. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Olawale, J.O.; Ibitoye, S.A.; Oluwasegun, K.M. Processing Techniques and Productions of Ductile Iron: A Review. Int. J. Sci. Eng. Res. 2016, 7, 397–423. [Google Scholar]

- Alabbasian, F.; Boutorabi, S.M.A.; Kheirandish, S. Effect of Inoculation and Casting Modulus on the Microstructure and Mechanical Properties of Ductile Ni-Resist Cast Iron. Mater. Sci. Eng. A 2016, 651, 467–473. [Google Scholar] [CrossRef]

- Nur, R.; Muas, M.; Apollo; Risal, S. Effect of Current and Wire Speed on Surface Roughness in the Manufacturing of Straight Gear Using Wire-Cut EDM Process. IOP Conf. Ser. Mater. Sci. Eng. 2019, 619, 012002. [Google Scholar] [CrossRef] [Green Version]

- Bouquet, J.; Hensgen, L.; Klink, A.; Jacobs, T.; Klocke, F.; Lauwers, B. Fast Production of Gear Prototypes—A Comparison of Technologies. Procedia CIRP 2014, 14, 77–82. [Google Scholar] [CrossRef]

- Interanational, A. ASTM E3-01 Standard Guide for Preparation of Metallographic Specimens Standard Guide for Preparation of Metallographic Specimens. In ASTM International; Internasional ASTM: West Conshohocken, PA, USA, 2017; Volume 03.01, pp. 1–12. [Google Scholar]

- American Gear Manufacturers Association. ANSI/AGMA 2004---B89 Gear Materials And Heat Treatment Manual. In ANSI/AGMA Standard; AGMA STANDARD: Alexandria, VA, USA, 1995; Volume 89, p. 71. ISBN 1-55589-524-7. [Google Scholar]

- ASTM Standard G99; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: Materials Park, OH, USA, 2006; Volume V.

- Ruff, A.W. ASM Handbook Vol. 18 Friction, Lubrication and Wear Technology; ASM Handbook Committee, Ed.; ASM International Handbook: Materials Park, OH, USA, 1992; Volume 18, ISBN 0-87170-380-7. [Google Scholar]

- Górny, M.; Tyrała, E. Effect of Cooling Rate on Microstructure and Mechanical Properties of Thin-Walled Ductile Iron Castings. J. Mater. Eng. Perform. 2013, 22, 300–305. [Google Scholar] [CrossRef] [Green Version]

- Vicente, A.; De Souza, R.L.; Espinosa, D.C.R.; De Aguiar, R.R.; Paul, P.; Botelho, A.B. Effect of Relative Plate Thickness in the Heat Flow and Cooling Rate during Welding of Super Duplex Stainless Steel. Saudi J. Eng. Technol. 2020, 5, 244–250. [Google Scholar] [CrossRef]

- Megahed, H.; El-Kashif, E.; Shash, A.Y.; Essam, M.A. Effect of Holding Time, Thickness and Heat Treatment on Microstructure and Mechanical Properties of Compacted Graphite Cast Iron. J. Mater. Res. Technol. 2019, 8, 1188–1196. [Google Scholar] [CrossRef]

- Washko, S.D.; Aggen, G. ASM Handbook Volume 1 Properties and Selection: Irons Steels and High Performance Alloys, 10th ed.; ASM International: Materials Park, OH, USA, 1990; ISBN 0-87170-380-7. [Google Scholar]

- SAE J434; Automotive Ductile (Nodular) Iron Castings. SAE Internasional: Warrendale, PA, USA, 1986; pp. 1–10.

- Davidson, J.H. Microstructure of Steels and Cast Irons; Springer: New York, NY, USA, 2004; ISBN 3540209638. [Google Scholar]

- Radzikowska, J.M. ASM Handbook Volume 9, Metallography and Microstructures; ASM Handbook Committee, Ed.; ASM International Handbook: Materials Park, OH, USA, 2004; ISBN 0-87170-706-3. [Google Scholar]

- Qi, D.; Shuming, X.; Bo, Q. Effect of Casting Pressure on Microstructural Evolution and Wear Behavior of Fe-Cr-C White Cast Iron. Mater. Res. Express 2019, 6, 66538. [Google Scholar] [CrossRef]

- Meng, X.M.; Zhang, J.B.; Han, W.; Zhao, J.; Liang, Y.L. Influence of Annealing Treatment on the Microstructure and Mechanical Performance of Cold Sprayed 304 Stainless Steel Coating. Appl. Surf. Sci. 2011, 258, 700–704. [Google Scholar] [CrossRef]

- Günen, A.; Kalkandelen, M.; Karahan, I.H.; Kurt, B.; Kanca, E.; Gök, M.S.; Karakaş, M.S. Properties and Corrosion Behavior of Chromium and Vanadium Carbide Composite Coatings Produced on Ductile Cast Iron by Thermoreactive Diffusion Technique. J. Eng. Mater. Technol. Trans. ASME 2020, 142, 041008. [Google Scholar] [CrossRef]

- Sun, W.; Dierolf, V.; Jain, H. Molecular Dynamics Simulation of the Effect of Cooling Rate on the Structure and Properties of Lithium Disilicate Glass. J. Non. Cryst. Solids 2021, 569, 120991. [Google Scholar] [CrossRef]

- Sungkhaphaitoon, P.; Plookphol, T. Effect of Cooling Rate on the Microstructure and Mechanical Properties of Sn-0.7wt.%Cu Solder Alloy. Key Eng. Mater. 2016, 675–676, 513–516. [Google Scholar] [CrossRef]

- Cardoso, P.H.S.; Israel, C.L.; Strohaecker, T.R. Abrasive Wear in Austempered Ductile Irons: A Comparison with White Cast Irons. Wear 2014, 313, 29–33. [Google Scholar] [CrossRef]

- Berns, H. Comparison of Wear Resistant MMC and White Cast Iron. Wear 2003, 254, 47–54. [Google Scholar] [CrossRef]

- Errichello, R.L. AGMA 11FT17 Technical Paper Morphology of Micropitting. In AGMA Technical Resources; AGMA National Standard: Alexandria, VA, USA, 2011; p. 19. ISBN 978-1-61481-016-2. [Google Scholar]

- Ribeiro, L.; Barbosa, A.; Viana, F.; Baptista, A.M.; Dias, C.; Ribeiro, C.A. Abrasion Wear Behaviour of Alloyed and Chilled Cast Irons. Wear 2011, 270, 535–540. [Google Scholar] [CrossRef]

- Tian, H.; Wang, C.; Guo, M.; Tang, Z.; Wei, S.; Xu, B. Study of the Frictional-Wear Performance and Abrasion Resistance Mechanism of a High-Speed Arc-Sprayed FeNiCrAl Coating. Surf. Coat. Technol. 2019, 370, 320–330. [Google Scholar] [CrossRef]

- Vélez, J.M.; Tanaka, D.K.; Sinatora, A.; Tschiptschin, A.P. Evaluation of Abrasive Wear of Ductile Cast Iron in a Single Pass Pendulum Device. Wear 2001, 250–251, 1315–1319. [Google Scholar] [CrossRef] [Green Version]

- Cruz-Crespo, A.; Fernández-Fuentes, R.; Ferraressi, A.V.; Gonçalves, R.A.; Scotti, A. Microstructure and Abrasion Resistance of Fe-Cr-C and Fe-Cr-C-Nb Hardfacing Alloys Deposited by S-FCAW and Cold Solid Wires. Soldag. Inspeção 2016, 21, 342–353. [Google Scholar] [CrossRef] [Green Version]

- Atraszkiewicz, R.; Januszewicz, B.; Kaczmarek, Ł.; Stachurski, W.; Dybowski, K.; Rzepkowski, A. High Pressure Gas Quenching: Distortion Analysis in Gears after Heat Treatment. Mater. Sci. Eng. A 2012, 558, 550–557. [Google Scholar] [CrossRef]

- ANSI/AGMA 2000-A88 American National Standard. Gera Classification and Inspection Handbook: Tolerance and Measuremnet Methodes for Unassembled Spur and Helical Gears. In Handbook; AGMA Association, Ed.; American National Standard: Washington, DC, USA, 1988; Volume 1988, p. 147. ISBN 155589495X. [Google Scholar]

- Masuyama, T.; Miyazaki, N. Evaluation of Load Capacity of Gears with an Asymmetric Tooth Profile. Int. J. Mech. Mater. Eng. 2016, 11, 11. [Google Scholar] [CrossRef] [Green Version]

| Elements | Fe | C | Si | Mn | Ni | Cr | S | P |

|---|---|---|---|---|---|---|---|---|

| (wt.%) | Balance | 0.059 | 0.27 | 1.32 | 7.91 | 19.34 | 0.011 | 0.009 |

| Nomenclature | Dimensional | Descriptions |

|---|---|---|

| Gear Teeth Number (N) | 10 | 0.27 |

| Module (m) | 8 | N = Number of teeth and D = Outside diameter, m = D/N. |

| Face Width (f), (mm) | 25 | - |

| Diameter Shaft (r), (mm) | 40 | - |

| Whole Depth (ht), (mm) | 18 | (Addendum + Dedendum), (10 mm + 8 mm = 18 mm). |

| Pressure Angle (α)/(deg) | 25 | - |

| Addendum Circle Diameter (Do), (mm) | 96 | - |

| Tooth Thickness (t), (mm) | 15 | - |

| Circular Pitch (ϕ), (mm) | 76 | D = N/P |

| Specimens | Module | Gear Teeth Number | Enhancer Plate Thickness (mm) | Chill Thickness (mm) | Average Dimension Value from All Teeth | ||

|---|---|---|---|---|---|---|---|

| Tooth Thickness (mm) | Addendum Circle Diameter (mm) | Pitch Circle Diameter (mm) | |||||

| G1 | 8 | 10 | - | - | 15.830 | 96.024 | 85.045 |

| G2 | 8 | 10 | 0.2 | 0.2 | 16.230 | 96.417 | 85.245 |

| G3 | 8 | 10 | 0.2 | 0.4 | 16.630 | 96.810 | 85.445 |

| G4 | 8 | 10 | 0.2 | 0.6 | 17.030 | 97.204 | 85.645 |

| Elements | C | Mn | Si | Cr | Ni | Mo | Cu | Mg | Ce | P | S |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (wt.%) | 3.67 | 0.24 | 2.55 | 0.023 | 0.07 | 0.04 | 0.12 | 0.052 | 0.005 | 0.037 | 0.014 |

| Samples | Elements (wt.%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Ni | Na | Mg | Mn | Si | Ca | Al | Zr | S | Cr | |

| G2 | 26.75 | 1.97 | 0.29 | 1.21 | 0.74 | 1.54 | 0.29 | 0.03 | 0.75 | 0.41 | 13.91 |

| G3 | 13.90 | 1.41 | 0.18 | 1.24 | 0.56 | 1.32 | 0.21 | 0.07 | 0.69 | 0.39 | 14.40 |

| G4 | 22.01 | 1.38 | 0.11 | 1.18 | 0.40 | 1.77 | 0.19 | 0.09 | 0.58 | 0.40 | 11.18 |

| Gear Sample | Average Matrix Structure on the Surface (%) | Average Hardness on the Surface Flank (HV) | Wear Specifics (Ws) × 10−6 (mm2/kg) | ||

|---|---|---|---|---|---|

| before Profile Cutting | after Profile Cutting | before Profile Cutting | after Profile Cutting | ||

| G2 | (FeCrC)7C3 and M7C3 | 861 HV | 461 HV | 5.197 | 2.301 |

| G3 | (FeCrC)7C3 and M7C3 | 831 HV | 583 HV | 6.408 | 2.279 |

| G4 | CrC, M3C, and M7C3 | 700 HV | 730 HV | 4.901 | 4.803 |

| Gear Nomenclature | Gear Sample | Tooth Number | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T4 | T5 | T6 | T7 | T8 | T9 | T10 | ||

| Tooth Thickness (mm) | G1 (benchmark) | 16.010 | 15.417 | 15.793 | 16.170 | 15.947 | 15.993 | 16.053 | 15.533 | 15.347 | 16.040 |

| G2 | 16.410 | 15.817 | 16.193 | 16.570 | 16.347 | 16.393 | 16.453 | 15.933 | 15.747 | 16.440 | |

| G3 | 16.810 | 16.217 | 16.593 | 16.970 | 16.747 | 16.793 | 16.853 | 16.333 | 16.147 | 16.840 | |

| G4 | 17.210 | 16.617 | 16.993 | 17.370 | 17.147 | 17.193 | 17.253 | 16.733 | 16.547 | 17.240 | |

| Pitch Circle Diameter (mm) | G1 (benchmark) | 85.020 | 85.100 | 84.990 | 85.000 | 84.970 | 84.880 | 85.110 | 85.050 | 85.220 | 85.110 |

| G2 | 85.220 | 85.300 | 85.190 | 85.200 | 85.170 | 85.080 | 85.310 | 85.250 | 85.420 | 85.310 | |

| G3 | 85.420 | 85.500 | 85.390 | 85.400 | 85.370 | 85.280 | 85.510 | 85.450 | 85.620 | 85.510 | |

| G4 | 85.620 | 85.700 | 85.590 | 85.600 | 85.570 | 85.480 | 85.710 | 85.650 | 85.820 | 85.710 | |

| Addendum Circle Diameter (mm) | G1 (benchmark) | 95.977 | 96.017 | 96.010 | 96.027 | 96.047 | 96.007 | 96.003 | 96.137 | 96.027 | 95.987 |

| G2 | 96.377 | 96.417 | 96.410 | 96.427 | 96.447 | 96.407 | 96.403 | 96.537 | 96.427 | 96.320 | |

| G3 | 96.777 | 96.817 | 96.810 | 96.827 | 96.847 | 96.807 | 96.803 | 96.937 | 96.827 | 96.653 | |

| G4 | 97.177 | 97.217 | 97.210 | 97.227 | 97.247 | 97.207 | 97.203 | 97.337 | 97.227 | 96.987 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guterres, N.F.D.S.; Rusnaldy, R.; Widodo, A. Effect of Chill Plate Thickness on Surface Hardening and Dimensional Accuracy of Nodular Cast Iron Gears Manufactured by the Chill Casting Method. Designs 2023, 7, 56. https://doi.org/10.3390/designs7020056

Guterres NFDS, Rusnaldy R, Widodo A. Effect of Chill Plate Thickness on Surface Hardening and Dimensional Accuracy of Nodular Cast Iron Gears Manufactured by the Chill Casting Method. Designs. 2023; 7(2):56. https://doi.org/10.3390/designs7020056

Chicago/Turabian StyleGuterres, Natalino Fonseca Da Silva, Rusnaldy Rusnaldy, and Achmad Widodo. 2023. "Effect of Chill Plate Thickness on Surface Hardening and Dimensional Accuracy of Nodular Cast Iron Gears Manufactured by the Chill Casting Method" Designs 7, no. 2: 56. https://doi.org/10.3390/designs7020056

APA StyleGuterres, N. F. D. S., Rusnaldy, R., & Widodo, A. (2023). Effect of Chill Plate Thickness on Surface Hardening and Dimensional Accuracy of Nodular Cast Iron Gears Manufactured by the Chill Casting Method. Designs, 7(2), 56. https://doi.org/10.3390/designs7020056