In this section, first, the results of the wind tunnel experimental campaign are shown. Before performing experiments, the wind tunnel flow uniformity and repeatability were checked. For each test shown in this paper, the repeatability was assessed by repeating each test at least twice. The last subsection shows the definitive EWG injector layout and its results in the turbine test rig.

3.1. Aerodynamic Field

The outcomes of the three swirler devices are discussed here. The main difference between the devices is the amount of swirled flow (

Figure 4): type A has a tangential geometry which turns only the EW; type B injects the EW axially and the swirler blades act on the mainstream air; in type C, both the mainstream and partially the EW are swirled. In all the figures shown in this subsection, the point (0,0) represents the core of the vortex. The injector is placed horizontally so its stem is located at about Y = 0 and on the positive X.

The results shown in

Figure 7 and

Figure 8 lead us to discard the type A solution: despite the easy manufacturing, the aerodynamic flow field is not symmetrical, i.e., the vortex is strongly stretched in the X direction. Furthermore, the total pressure field has a complex pattern (

Figure 8a), so the resulting flow cannot be considered representative of a combustor outlet flow. Type B is more symmetrical than type A, however, the strong axial jet leads to a distortion of the total pressure field (

Figure 8b): for this reason, it is not considered as representative of the flow released by a combustor [

19,

20]. Type C has the highest angles (

Figure 7c) and all the requirements to be considered combustor representative. The low-pressure core (

Figure 8c) is unavoidable if a high degree of swirl is expected [

21], as happens in aero-engine combustors [

19].

Besides the geometry, a second important parameter is the feeding pressure. Its level is set as a tradeoff between the EW penetration in the mainstream and the viscous dissipation between the axial jet and the surrounding swirled flow. The feeding pressure also has an impact on the temperature field and specifically on the temperature fluctuation, as will be described in the next subsection.

For the type C swirler, the aerodynamic flow field is weakly influenced by the feeding pressure, as shown in

Figure 9. A higher feeding pressure (

Figure 9a,c) increases the jet axial velocity and the viscous dissipation between the axial jet and the surrounding swirling flow; this implies slightly lower pitch and yaw angles than the case with a smaller feeding pressure (

Figure 9b,d). However, besides these small differences, in both cases, pitch and yaw angles are in the range of ±25°; so far, the best feeding pressure will be chosen on the basis of temperature outcomes.

3.2. Temperature Field

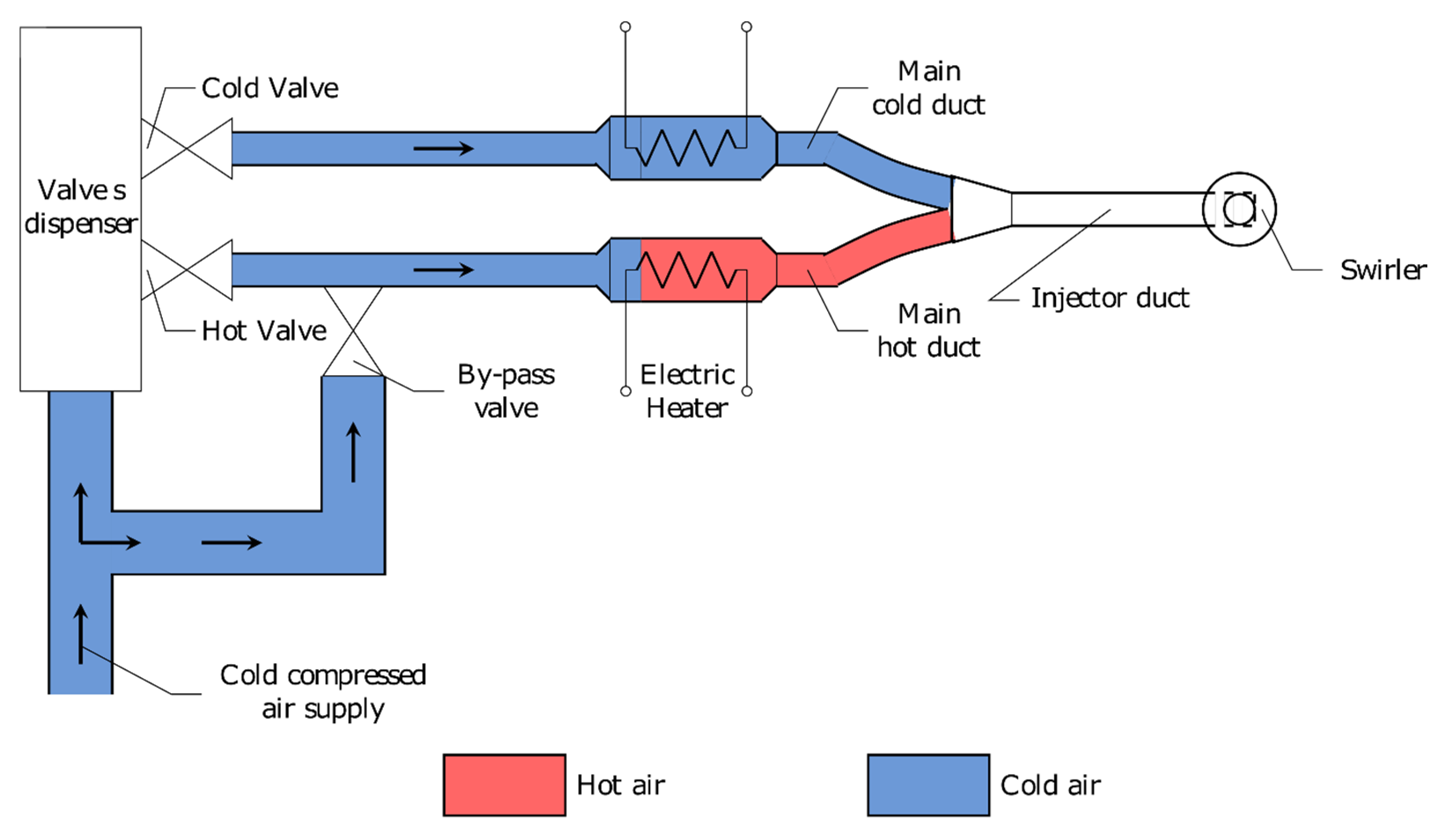

This experimental campaign is carried out by means of the fast response 25 µm thermocouple, already described in the measuring instruments section. Entropy waves are inherently unsteady as they are generated through the alternative opening and closing of the two valves which feed the hot and the cold ducts. The unsteadiness makes very critical the interaction between the hot and the cold flows in the injector section where they join. In fact, given the same expansion ratio, the hot stream is faster than the cold one, leading to a mixing between the two streams, that unfortunately is unavoidable. Hence, to optimize the peak temperature, different layouts are tested to minimize the mixing and the heat dissipation: basically, the idea is to delay the hot and cold stream joining and to increase the thermal insulation.

A simplified model has been developed to investigate the mixing process between hot and cold flows and to find the parameters which minimize it. Using a quasi-steady assumption, the injector is modeled as a fixed volume which is fed by a square wave

, which is the entropy wave produced by the alternating opening and closing of the hot and cold valves. The two temperature levels of

represent the hot and cold streams; the peak is the temperature measured at the electric heater outlet; the trough is the cold stream temperature equal to the ambient one. At each time step

, the square wave fills the volume entirely in its height and depth and of an amount

along its length, where

where

is the flow velocity and

is the volume length. Therefore, every

, a new mass

at temperature

enters in the volume, while the same

leaves it at a temperature equal to the equilibrium temperature at the previous time step

(

Figure 10). Therefore, the equilibrium temperature is calculated by solving the power balance applied on the volume surfaces:

The volume equilibrium temperature evolution in time is shown for 10 and 110 Hz in

Figure 11. The model outcomes state that at the lower frequency, the mixing is negligible since the maximum and minimum volume temperature at equilibrium correspond to the squared wave ones. The mixing has the only effect of producing a time shift in achieving the settled temperatures. However, moving at the higher frequency, mixing becomes more severe and the volume temperature fluctuates between two values that are not the wave maximum and minimum. Since the hotter the flow, the lower the density, the equilibrium temperature at 110 Hz is always far from the EW hot temperature (Equation (1)).

It has to be noted that in the experimental measurements, these temperature values will not be achieved because the EW is not exactly a square wave since valves do not open and close instantaneously; the measurements are carried out 50 mm downstream of the injector outlet section, hence, thermal dissipation reduces the peak temperature.

The yellow line in

Figure 11 show the effect of a volume reduction: decreasing the volume by reducing the injector length, the system promptness increases.

Considering the previous conclusion, different layouts are designed and tested in order to obtain the best thermal performance (

Figure 12). These tests are carried out without the swirler generator since the analysis focuses on finding the best thermal insulation and layout which maximize the peak-to-valley temperature fluctuation. However, on the basis of the aerodynamic campaign previously discussed, it has to be noted that the different layouts in

Figure 12 have different injector dimensions that make the devices suitable for different swirler generators: layouts A and B have a longer injector length and a smaller stem diameter (5 mm, 4 mm outer and inner diameters, respectively) which can be equipped with SG type B; layouts C and D have a shorter injector length and a larger stem diameter (external diameter of 10 mm and internal of 8 mm) and so they are designed for SG type C (hot and cold tubes have 4 mm outer and 3 mm inner diameter).

Layouts A and B have a longer injector length, therefore, the flow is mixed far from the injector outlet. The difference between them regards the thermal insulation: layout A has no insulation, layout B has a coaxial stainless steel cylinder filled with stone wool. Layouts C and D delay the mixing process as much as possible and shorten the length where the mixing can occur, as suggested by the previous quasi-steady state analysis. While in layout C, both the hot and the cold ducts enter parallelly in the injector and only the hot duct is insulated, in layout D, both the hot and the cold ducts are insulated and they have an angle of ±10° with respect to the injector axis. The insulation for these two cases is made wrapping the tubes in a stone wool shell. In layout D, the stone wool is also at the injector inlet to separate the two ducts.

In

Figure 13, the different layout outcomes are compared. Layouts A and B are fed with a pressure of 0.3 bar

g, layouts C and D with 0.5 bar

g. This difference in the pressure values is justified by the lower pressure required by SG type B to obtain an engine representative aerodynamic flow field; on the contrary, a higher pressure is needed by SG type C. Therefore, the comparison is made given the same outlet aerodynamic conditions and with the heater outlet temperature set at 670 K.

Since in layouts A and B, the injector length is longer than in layouts C and D, the mixing process is huge, as confirmed by the high valley temperature (see gray and red lines). Furthermore, the addition of the thermal insulation in layout B increases both the peak and valley temperature, but the peak-to-valley value is reduced because the trough temperature increases more than the peak one. The shorter the duct where the hot and cold flows are forced together, the lower the mixing intensity and the interaction between the EW and the walls. Therefore, in layout D, the best peak-to-valley value is achieved: both hot and cold flows are close to their injected condition at 10 Hz (

Figure 13a). Nevertheless, layout C, which also features a lower injector length looks worse because bad insulation between hot–cold ducts is designed. At 100 Hz in this layout, the results show that hot–cold phasing at the injector head failed so that peaks and valleys collapse to the mean value and there is no repeatability. At 100 Hz, the general trend in all configurations shows a strong reduction of the peak-to-valley values due to a more severe mixing.

To conclude, the best layout which guarantees the highest peak-to-valley temperature value is layout D. Moreover, considering that SG type C is chosen as the best device to produce a good aerodynamic flow field, layout D equipped with swirler generator type C is the final EWG layout. Furthermore, the larger injector diameter allows us to generate a larger EW perturbation in space.

As for the pressure effect,

Figure 14 shows the average peak-to-valley temperature in X direction, which is consistent with the radial coordinates in the turbine test rig for layout D with SG type C with a feeding pressure of 0.5 and 0.75 bar

g at 10 Hz and with a heater temperature of 670 K. The results clearly show the strong improvement obtained by increasing the pressure: the EW penetration increases, and its thermal power as well, due to the flow rate increase (

). Therefore, having already proved that a pressure increase has negligible effects on the aerodynamic flow field, the best pressure is chosen as the one able to provide the highest temperature perturbation; finally, p = 0.75 bar

g is chosen as the one able to provide the operating conditions closest to the engine ones for both aerodynamic and thermal flow fields.

3.3. Definitive EWG and Turbine Inlet Measurements

The previous analysis brings us to the selection of the best geometry of the EWG in terms of SG and layout to minimize mixing and thermal dissipation.

Figure 15 shows the final EWG geometry. The device is 3D printed in a cobalt-chrome alloy. This material has similar thermal properties to the stainless steel used in the previous devices. The hot–cold tubes are connected with the EWG by means of straight manifolds. Due to space constraints, the hot and cold tubes have an angle of 2° with respect to the injector axis instead of 10° as in layout D.

The EWG is placed upstream of the turbine test rig to simulate the combustor unsteadiness that occurs in the first stage aero-engine turbine. The investigation of these effects on the turbine aerodynamics will be the subject of future works. On the contrary, the main features of the unsteadiness produced by the novel EWG are described in this section.

Figure 16 shows the measuring plane location with respect to the injector axis, the injector outlet section and the stator leading edge. Probes are mounted on a linear stepping motor that moves them in the radial direction. The ring hosting the EWG is moved circumferentially; the coupled movement of probes and EWG allows for the coverage of the whole measuring plane.

There are spots for 11 injectors on the turbine test rig, making it possible to have one injector per two stator blades (i.e., there are 22 stator blades). To carry out the aerodynamic and thermal assessment of the EWG, only three injectors are mounted for the sake of simplicity. Measurements are done on the central of the three injectors, thus guaranteeing the periodicity. However, if in future experimental campaigns, stage efficiency or acoustic measurements are investigated, all 11 injectors will be mounted to guarantee the whole annular periodicity.

Figure 17 shows the peak-to-valley variation of the temperature profile in a valve period. It refers to a condition of 110 Hz, which is a period of about 9 ms. In the data reduction, the period is divided into 100 frames;

Figure 17 shows frames at 1%, 20%, 40%, 60%, 80% and 100% of the period.

The best peak to valley is 25 K, the highest difference in temperature between the injected EW and the undisturbed flow is 70 K. These results show a good performance of the novel entropy wave generator compared with already documented ones [

12,

13]. When reducing the frequency to 10 Hz, the peak-to-valley value increases up to 75 K at the measuring plane location.

Figure 18 shows the total pressure measurements and velocity field performed with a steady 5-hole probe, thus neglecting at this measuring step the EWG-induced pressure fluctuations. The total pressure pattern highlights the main features of a high swirled flow: a core of low total pressure which is recovered moving outward radially. The central upper part of the contour shows a low total pressure region caused by the injector stem wake and boundary layer at the turbine casing. The two high total pressure regions (red circles in the figure) are the injected hot and cold streams in the EWG. The reasons for this discrepancy between total pressure fields shown in

Figure 8 and

Figure 18, that refer respectively to nozzle and turbine experiments, are twofold. In the wind tunnel experimental campaign, measurements are carried out at a distance representative of the stator position, i.e., 50 mm downstream of the swirler exit (

Figure 16). When the EWG is applied on the turbine test facility, measurements are performed at 33.2 mm, hence the two cold–hot flows are not yet fully mixed with the main flow. Secondly, the feeding pressure is tuned to high values because the turbine mainstream has a higher pressure (1.4 bar) than the wind tunnel flow, which has an ambient pressure.

Figure 19 shows the mass weighted average of the velocity profile along the radial coordinate in a cylindrical system of reference centered in the vortex core (white point in

Figure 18). The axial velocity is the lowest at the vortex center (radius = 0 mm) and increases linearly up to a radius of 6 mm. At 6 mm the axial velocity has a plateau; the injector wake is significant and modifies the axial velocity trend. At higher radii, the wake weight is smaller and so the axial velocity increases again up to 45 m/s, which is approximately the undisturbed axial velocity.

The tangential velocity flow field follows a common vortex pattern: the core has zero tangential velocity, then it increases rapidly to a 3 mm radius according to a forced vortex trend. For higher radii, it decreases slowly following something like a free vortex structure until it reaches the zero-value component that means undisturbed flow. The field vorticity is positive for radii lower than 5 mm, negative from 5 to 8 mm and null elsewhere, evidencing an irrotational vortex structure. Vorticity becomes negative due to an interaction in the region close to the hub between the swirled flow and the mainstream that makes the flow turn counterclockwise (

Figure 18).

Finally, a fast Pitot pressure probe [

13] is used to measure the unsteady total pressure field. The results are comparable to the steady total pressure field measured by the 5-hole probe. This was expected when the EWG was designed; lot of efforts were made to reduce differences in the pressure drop across the hot and cold ducts. The only unavoidable unsteadiness in the total pressure regards the two red circled zones shown in

Figure 18, that follow the valve frequency (not shown in the paper for the sake of brevity). Therefore, the fast Pitot tube results confirm that the two regions correspond to the hot or cold flows that are not yet fully mixed with the main flow. The STD value, as a percentage of the mean total pressure, is shown in

Figure 20. The results show that there is an increase from 0.6% in the freestream to 3.3% in the region perturbed by the EW. According to [

22,

23], this quantity can be considered as an estimate of the turbulence level, whose specific characterization will be the subject of a future study.