Unsteady Cavitation Analysis of the Centrifugal Pump Based on Entropy Production and Pressure Fluctuation †

Abstract

:1. Introduction

2. Model and Methods

2.1. Pump Model and Test Rig

2.2. Numerical Method

2.3. Data Reduction Method

3. Results Analysis

3.1. Experimental Verification of Pump Performance

3.2. Entropy Generation Analysis

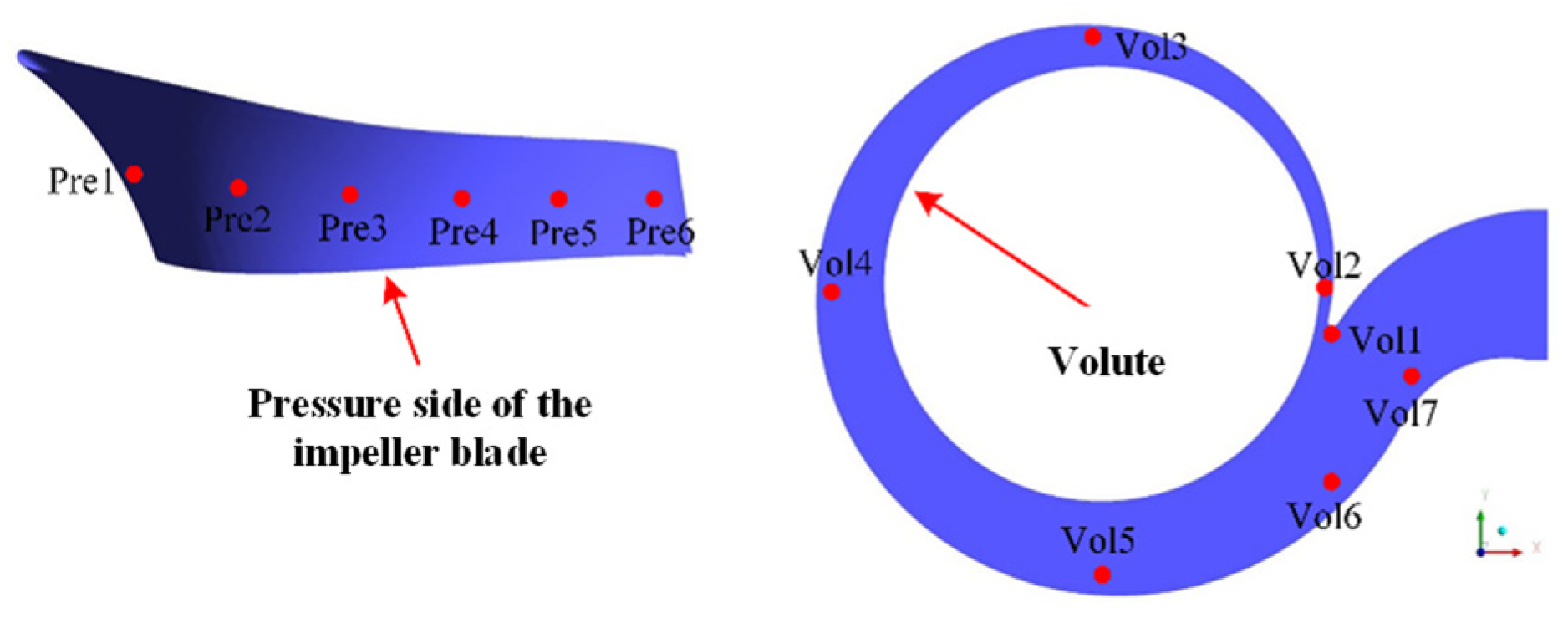

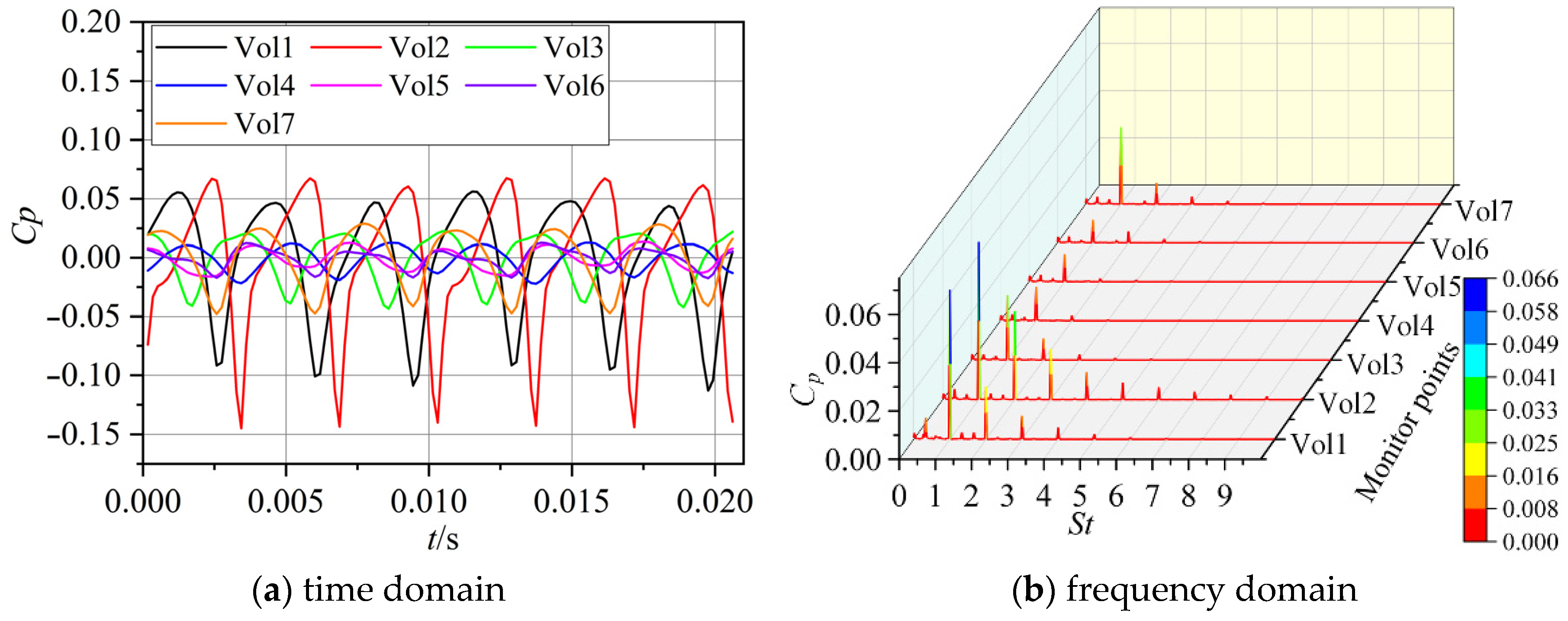

3.3. Analysis of Pressure Fluctuation Characteristics

4. Conclusions

- (1)

- Unsteady cavitation flow of the centrifugal pump was calculated by combined DES and RZGB cavitation models; then, the entropy generation analysis of the flow field and the pressure fluctuation characteristics were carried out. The main conclusions are as follows:

- (2)

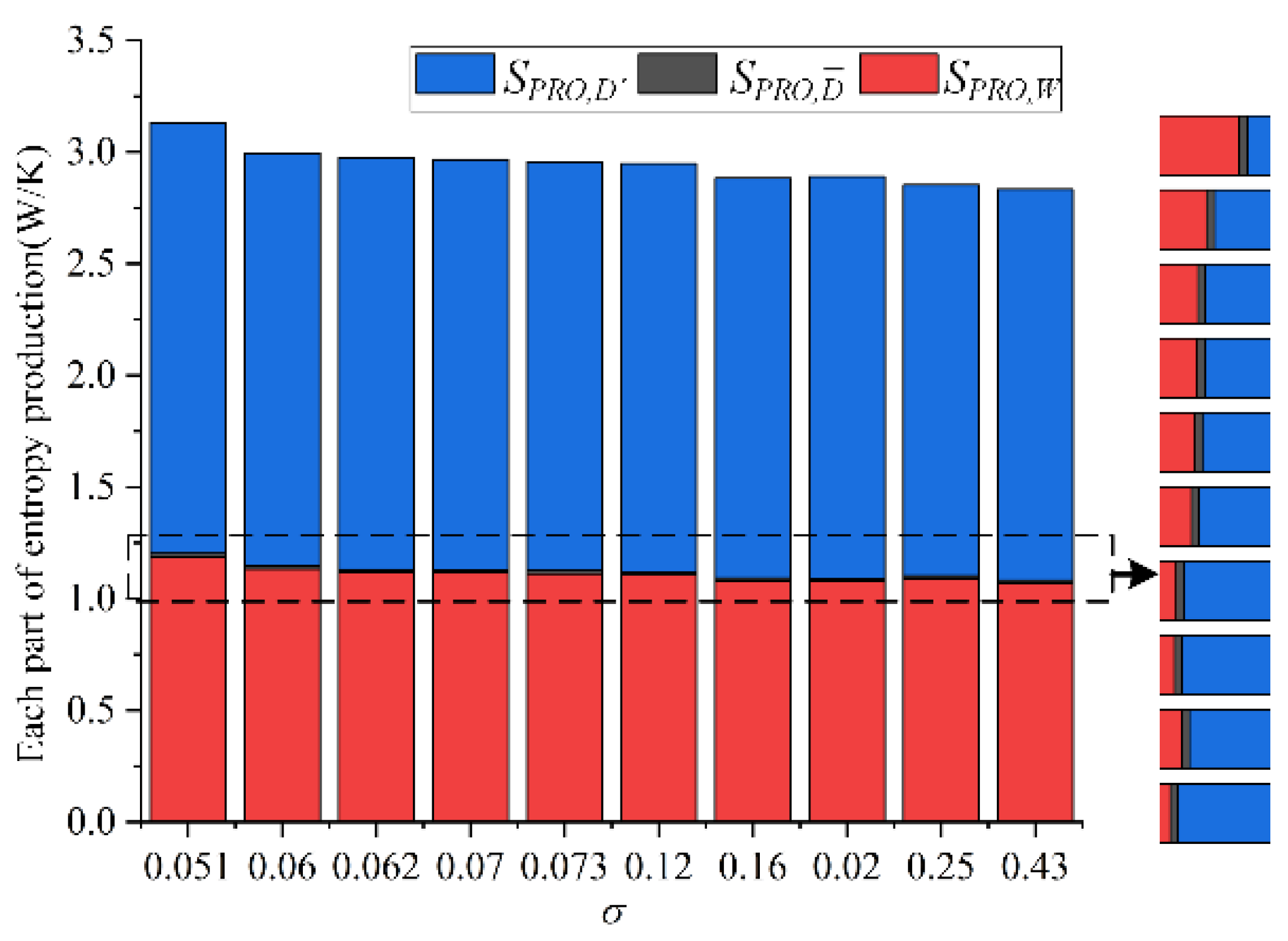

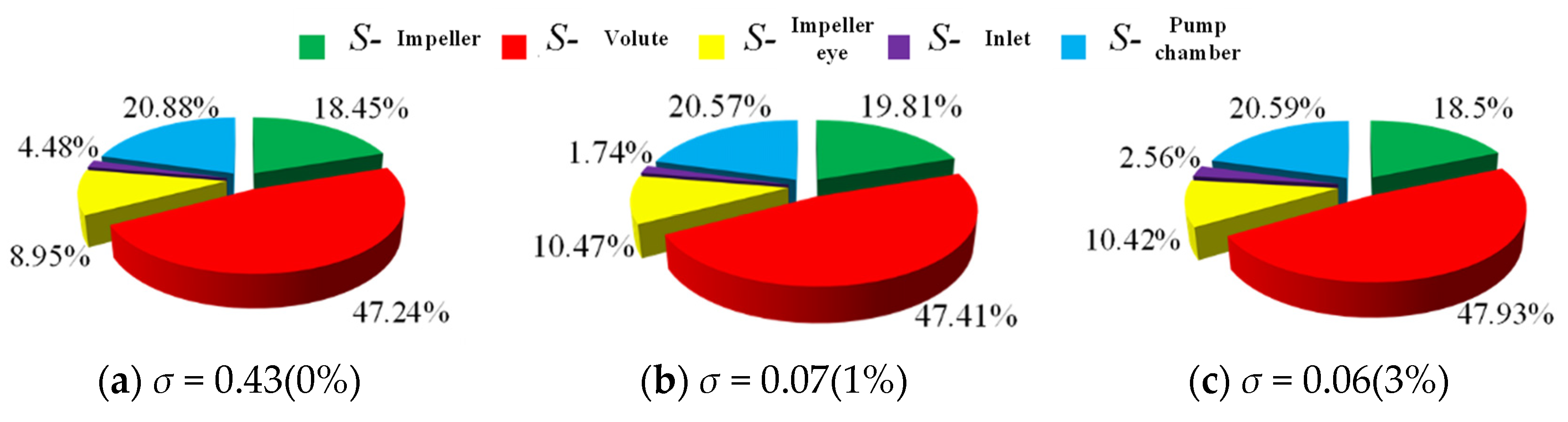

- Under different cavitation numbers, the turbulent dissipative entropy generation and wall entropy generation play an important role in the flow loss of the pump, while the viscous dissipative entropy generation is very small and can even be ignored. The sum of the three types of entropy output values increases with the decrease in cavitation numbers. The internal energy loss is mainly concentrated in the impeller, volute, and pump cavity areas, which account for more than 85% of the total entropy generation. The impact between the leading edge of the blade and the incoming flow, as well as the dynamic and static interference between the blade outlet and the volute tongue, are the main reasons for the flow loss in the impeller area.

- (3)

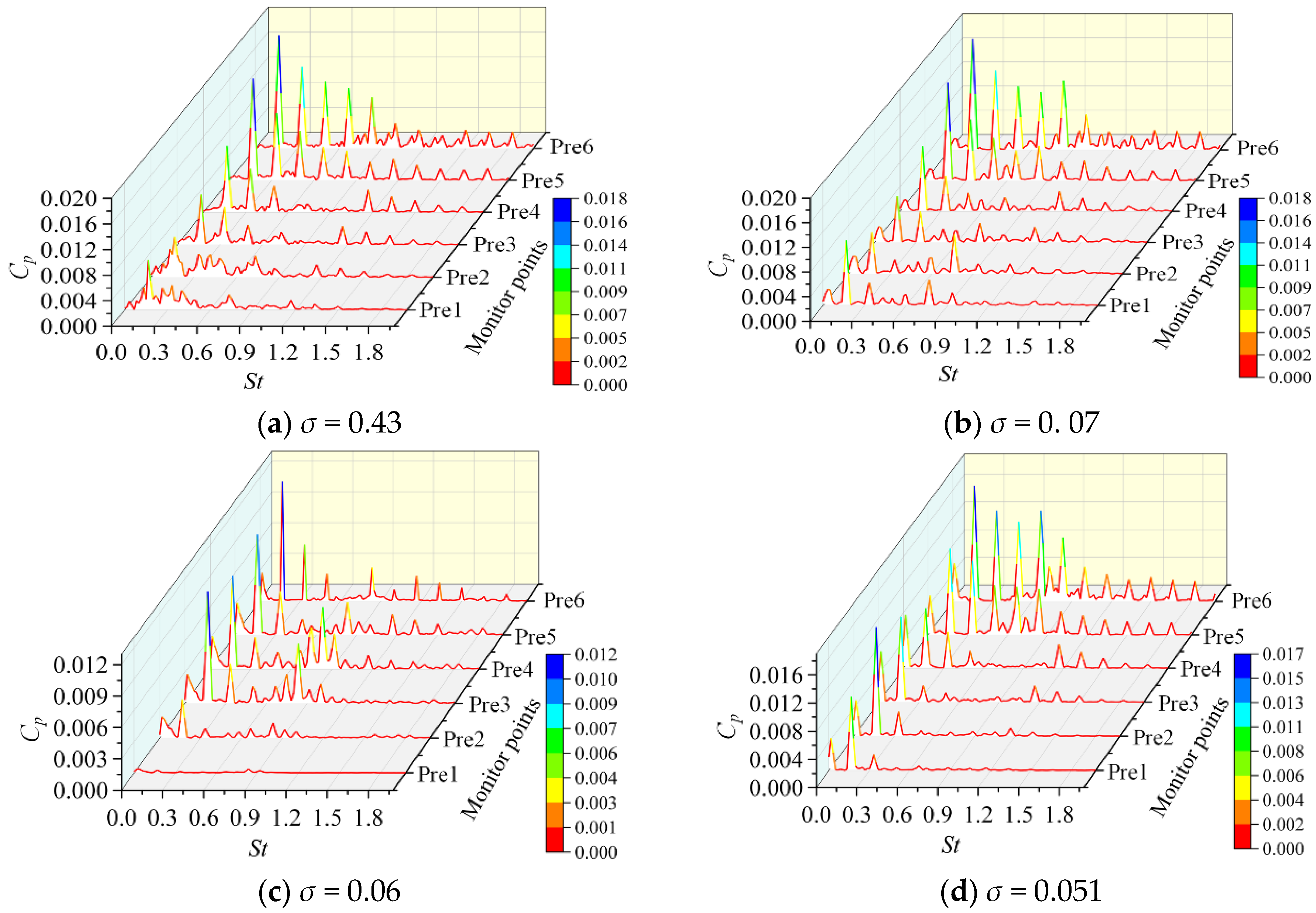

- In the non-cavitation stage and cavitation development stage, there are many low-frequency pulsations at each monitoring point. When the cavitation number decreases to 0.06, the expansion of the cavitation volume will absorb part of the pressure pulsation, resulting in a decrease in the amplitude of the pressure pulsation coefficient at the Pre6 monitoring point compared with the previous cavitation stage. The Pre3 and Pre4 has a brand frequency characteristic between St = 0.075 and 0.9. The characteristic frequency of about 0.333 StBPF appears at Vol1, which is mainly caused by the strong three-dimensional unsteady cavitation flow. In the initial cavitation stage and the severe cavitation stage, the low-frequency pulsations are reduced. The position of the monitoring point with large pressure fluctuation amplitude is consistent with large wall entropy generation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| b2 | impeller outlet width | n | rotate speed |

| Cp | Pressure fluctuation coefficient, | ns | specific rotate speed |

| Ds | pump inlet diameter | average pressure | |

| Dd | pump outlet diameter | pv | Saturated pressure |

| D1 | impeller inlet diameter | ρl | density |

| D2 | impeller outlet diameter | pin | pressure at the pump inlet |

| σ | cavitation number, | Q | flow rate |

| η | efficiency | u1 | tangential velocity at the impeller inlet |

| f | frequency | u2 | tangential velocity at the impeller outlet |

| H | head | Ψ | head coefficient |

| Hd | Design head | z | blade number of impeller |

| n | rotational speed |

References

- Bachert, R.; Stoffel, B.; Dular, M. Unsteady Cavitation at the Tongue of the Volute of a Centrifugal Pump. J. Fluids Eng. Trans. ASME 2010, 132, 061301. [Google Scholar] [CrossRef]

- Reuter, F.; Gonzalez-Avila, S.R.; Mettin, R.; Ohl, C.D. Flow fields and vortex dynamics of bubbles collapsing near a solid boundary. Phys. Rev. Fluids 2017, 2, 064202. [Google Scholar] [CrossRef]

- Fu, Y.; Yuan, J.; Yuan, S.; Pace, G.; d’Agostino, L.; Huang, P.; Li, X. Numerical and Experimental Analysis of Flow Phenomena in a Centrifugal Pump Operating Under Low Flow Rates. J. Fluids Eng. Trans. ASME 2015, 137, 011102. [Google Scholar] [CrossRef]

- Schnerr, G.H.; Sezal, I.H.; Schmidt, S.J. Numerical investigation of three-dimensional cloud cavitation with special emphasis on collapse induced shock dynamics. Phys. Fluids 2008, 20, 040703. [Google Scholar] [CrossRef]

- Srinivasan, V.; Salazar, A.J.; Saito, K. Numerical simulation of cavitation dynamics using a cavitation-induced-momentum-defect (CIMD) correction approach. Appl. Math. Model. 2009, 33, 1529–1559. [Google Scholar] [CrossRef]

- Ji, B.; Luo, X.; Arndt, R.E.; Wu, Y. Numerical simulation of three dimensional cavitation shedding dynamics with special emphasis on cavitation-vortex interaction. Ocean Eng. 2014, 87, 64–77. [Google Scholar] [CrossRef]

- Huang, B.A.; Zhao, Y.; Wang, G.Y. Large Eddy Simulation of turbulent vortex-cavitation interactions in transient sheet/cloud cavitating flows. Comput. Fluids 2014, 92, 113–124. [Google Scholar] [CrossRef]

- Cheng, H.; Long, X.; Ji, B.; Peng, X.; Farhat, M. A new Euler-Lagrangian cavitation model for tip-vortex cavitation with the effect of non-condensable gas. Int. J. Multiph. Flow 2021, 134, 103441. [Google Scholar] [CrossRef]

- Jian, W.; Yong, W.; Houlin, L.; Qiaorui, S.; Dular, M. Rotating Corrected-Based Cavitation Model for a Centrifugal Pump. J. Fluids Eng. Trans. ASME 2018, 140, 111301. [Google Scholar] [CrossRef]

- Si, Q.; Deng, F.J.; Lu, Y.; Liao, M.Q.; Yuan, S.Q. Unsteady Cavitation Analysis of the Centrifugal Pump Based on Entropy Production and Pressure Fluctuation. In Proceedings of the 15th European Turbomachinery Conference, paper n. ETC2023-254, Budapest, Hungary, 24–28 April 2023; Available online: https://www.euroturbo.eu/publications/conference-proceedings-repository/ (accessed on 6 June 2023).

- Kock, F.; Herwig, H. Local entropy production in turbulent shear flows: A high-Reynolds number model with wall functions. Int. J. Heat Mass Transf. 2004, 47, 2205–2215. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Y.; Hou, H.; Zhang, J.; Xu, C. Entropy production diagnostic analysis of energy consumption for cavitation flow in a two-stage LNG cryogenic submerged pump. Int. J. Heat Mass Transf. 2019, 129, 342–356. [Google Scholar] [CrossRef]

- Zhang, N.; Zheng, F.; Liu, X.; Gao, B.; Li, G. Unsteady flow fluctuations in a centrifugal pump measured by laser Doppler anemometry and pressure pulsation. Phys. Fluids 2020, 32, 125108. [Google Scholar] [CrossRef]

| Parameter | z | Ds/mm | Dd/mm | D1/mm | D2/mm | b2/mm | n/r min−1 |

|---|---|---|---|---|---|---|---|

| Value | 6 | 65 | 50 | 140 | 79 | 15.5 | 2910 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY-NC-ND) license (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Share and Cite

Si, Q.; Deng, F.; Lu, Y.; Liao, M.; Yuan, S. Unsteady Cavitation Analysis of the Centrifugal Pump Based on Entropy Production and Pressure Fluctuation. Int. J. Turbomach. Propuls. Power 2023, 8, 46. https://doi.org/10.3390/ijtpp8040046

Si Q, Deng F, Lu Y, Liao M, Yuan S. Unsteady Cavitation Analysis of the Centrifugal Pump Based on Entropy Production and Pressure Fluctuation. International Journal of Turbomachinery, Propulsion and Power. 2023; 8(4):46. https://doi.org/10.3390/ijtpp8040046

Chicago/Turabian StyleSi, Qiaorui, Fanjie Deng, Yu Lu, Minquan Liao, and Shouqi Yuan. 2023. "Unsteady Cavitation Analysis of the Centrifugal Pump Based on Entropy Production and Pressure Fluctuation" International Journal of Turbomachinery, Propulsion and Power 8, no. 4: 46. https://doi.org/10.3390/ijtpp8040046

APA StyleSi, Q., Deng, F., Lu, Y., Liao, M., & Yuan, S. (2023). Unsteady Cavitation Analysis of the Centrifugal Pump Based on Entropy Production and Pressure Fluctuation. International Journal of Turbomachinery, Propulsion and Power, 8(4), 46. https://doi.org/10.3390/ijtpp8040046