Turbulence Measurements Downstream of a Combustor Simulator Designed for Studies on the Combustor–Turbine Interaction †

Abstract

:1. Introduction

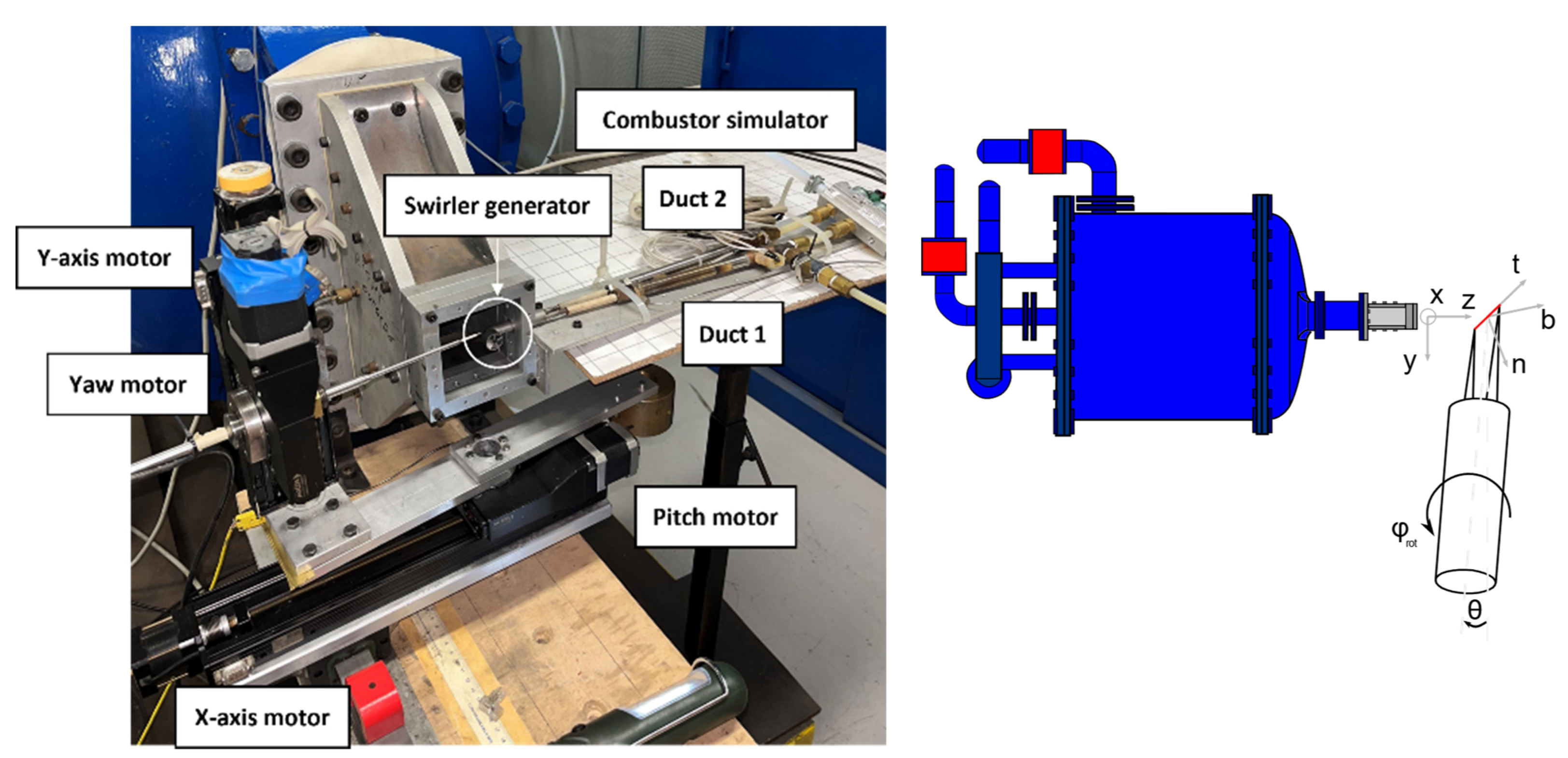

2. Materials and Methods

2.1. Generated Combustor Disturbances

2.2. CFD Setup

2.3. Measuring Technique

2.3.1. Five-Hole Probe

2.3.2. Hot-Wire

- 1.

- The acquired voltages are used to compute and by applying King’s law.

- 2.

- Assuming low-turbulence content and Q = [0, , 0], the mean flow field is solved by iterating Equation (9) over 13 sets of rotations.

- 3.

- The first prediction of the velocity vector is used to update the rotational range and solve the Reynolds tensor (Equation (14)). The updated rotational range is centered on the nearest multiple of 20° relative to the measured yaw angle, encompassing 13 rotations spaced every 20° within the range of ±120° with respect to that closest multiple of 20°.

- 4.

- Considering that the mean velocity depends on the Reynolds stress tensor components (Equation (10)), the assumption made in step 2 is now relaxed. The mean velocity components are recalculated using a least-square regression on Equation (10), utilizing the Reynolds stresses computed in step 3.

- 5.

- With the new mean velocities, the cycle is repeated, starting from step 3 until convergence.

3. Results

3.1. Steady Cold Streak

3.2. Unsteady Cold Streaks at 110 Hz

3.3. Temperature Effect

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| A, B, n | King’s coefficients |

| Coefficients of Equation (9) | |

| c | Chord |

| CS | Cold streak |

| d | Diameter |

| E | Voltage supply |

| e | Fluctuating voltage supply |

| EW | Entropy wave |

| HS | Hot streak |

| HW | Hot wire |

| , | Jorgensen’s calibration coeff. |

| LE | Leading edge |

| Unit vector normal to S | |

| M | Mach number |

| MS | Mainstream |

| p | Pressure |

| Q | Cooling velocity |

| q | Fluctuating cooling velocity |

| r, Θ, z | Coordinates of polar reference system |

| R | Coefficients of Equation (11) |

| Re | Reynolds number |

| S | Surface |

| SN | Swirl number |

| T | Temperature |

| Ti | Turbulence intensity |

| U | Velocity |

| u | Fluctuating velocity |

| x, y, z | ref. system coordinates |

| Z | Coefficients of Equation (13) |

| α | Hot-wire slanted angle |

| θ | Pitch angle |

| λ | Integral length scale |

| φ | Yaw angle |

| Subscripts | |

| 0 | Rest condition |

| 1, 2, 3 | Components on y, z, x |

| corr | After temperature correction |

| n, t, b | Hot-wire reference system |

| rot | Motor rotation |

| t | Total |

| w | Wire |

| Θ | Tangential component |

References

- Gundy-Burlet, K.L.; Dorney, D.J. Influence of 3D hot streaks on turbine heat transfer. In Proceedings of the ASME Turbo Expo 1997, Orlando, FL, USA, 2–5 June 1997. [Google Scholar]

- Morgans, A.S.; Duran, I. Entropy noise: A review of theory, progress and challenges. Int. J. Spray Combust. Dyn. 2016, 8, 285–298. [Google Scholar] [CrossRef]

- Khanal, B.; He, L.; Northall, J.; Adami, P. Analysis of radial migration of hot-streak in swirling flow through high-pressure turbine stage. ASME J. Turbomach. 2013, 135, 041005. [Google Scholar] [CrossRef]

- Rahim, A.; He, L. Rotor blade heat transfer of high pressure turbine stage under inlet hot-streak and swirl. ASME J. Eng. Gas. Turbines Power 2015, 137, 062601. [Google Scholar] [CrossRef]

- Andreini, A.; Bacci, T.; Insinna, M.; Mazzei, L.; Salvadori, S. Hybrid RANS-LES modeling of the aerothermal field in an annular hot streak generator for the study of combustor–turbine interaction. ASME J. Eng. Gas. Turbines Power 2016, 139, 021508. [Google Scholar] [CrossRef]

- Werschnik, H.; Schneider, M.; Herrmann, J.; Ivanov, D.; Schiffer, H.P.; Lyko, C. The Influence of Combustor Swirl on Pressure Losses and the Propagation of Coolant Flows at the Large Scale Turbine Rig (LSTR): Experimental and Numerical Investigation. Int. J. Turbomach. Propuls. Power. 2017, 2, 12. [Google Scholar] [CrossRef]

- Adams, M.G.; Beard, P.F.; Stokes, M.R.; Wallin, F.; Chana, K.S.; Povey, T. Effects of a combined hot-streak and swirl profile on cooled 1.5-stage turbine aerodynamics: An experimental and computational study. ASME J. Turbomach. 2021, 143, 021011. [Google Scholar] [CrossRef]

- Mansouri, Z.; Jefferson-Loveday, R. Heat transfer characteristics of a high-pressure turbine under combined distorted hot-streak and residual swirl: An unsteady computational study. Int. J. Heat Mass Transf. 2022, 195, 123143. [Google Scholar] [CrossRef]

- Notaristefano, A.; Gaetani, P. The Role of Turbine Operating Conditions on Combustor–Turbine Interaction—Part I: Change in Expansion Ratio. ASME J. Turbomach. 2023, 145, 051001. [Google Scholar] [CrossRef]

- Gaetani, P.; Persico, G. Transport of Entropy Waves Within a High Pressure Turbine Stage. ASME J. Turbomach. 2019, 141, 031006. [Google Scholar] [CrossRef]

- Pinelli, L.; Marconcini, M.; Pacciani, R.; Notaristefano, A.; Gaetani, P. The Effects of Swirling Flows in Entropy Wave Convection Through High-Pressure Turbine Stage. ASME J. Turbomach. 2023, 145, 031004. [Google Scholar] [CrossRef]

- Folk, M.; Miller, R.J.; Coull, J.D. The Impact of Combustor Turbulence on Turbine Loss Mechanisms. ASME J. Turbomach. 2020, 142, 091009. [Google Scholar] [CrossRef]

- Bons, J.P. St and cf augmentation for real turbine roughness with elevated freestream turbulence. ASME J. Turbomach. 2002, 124, 623–644. [Google Scholar] [CrossRef]

- Thole, K.A.; Bogard, D.G. Enhanced heat transfer and shear stress due to high free-stream turbulence. ASME J. Turbomach. 1995, 117, 418–424. [Google Scholar] [CrossRef]

- Zimmerman, D.R. Laser Anemometer Measurements at the Exit of a T63-C20 Combustor; NASA CR-159623; NASA: Washington, DC, USA, 1979.

- Seasholtz, R.G.; Oberle, L.G.; Weikle, D.H. Laser Anemometry for Hot Section Applications; NASA CP-2289; NASA: Washington, DC, USA, 1983.

- Cha, C.M.; Hong, S.; Ireland, P.T.; Denman, P.; Savarianandam, V. Turbulence levels are high at the combustor-turbine interface. In Proceedings of the ASME Turbo Expo 2012, Copenhagen, Denmark, 11–15 June 2012. [Google Scholar]

- Folk, M.; Miller, R.J. Design and Test of a Combustor Simulator. In Proceedings of the AIAA Propulsion and Energy 2019 Forum, Indianapolis, IN, USA, 19–22 August 2019. AIAA 2019-4256. [Google Scholar]

- Cresci, I.; Ireland, P.T.; Bacic, M.; Tibbott, I.; Rawlinson, A. Realistic velocity and turbulence intensity profiles at the combustor-turbine interaction (CTI) plane in a nozzle guide vane test facility. In Proceedings of the 11th European Conference on Turbomachinery Fluid dynamics & Thermodynamics ETC11, Madrid, Spain, 23–27 March 2015. [Google Scholar]

- Bacci, T.; Facchini, B.; Picchi, A.; Tarchi, L.; Koupper, C.; Champion, J. Turbulence Field Measurements at the Exit of a Combustor Simulator Dedicated to Hot Streaks Generation. In Proceedings of the ASME Turbo Expo 2015, Montreal, QC, Canada, 15–19 June 2015. [Google Scholar]

- Notaristefano, A.; Gaetani, P.; Dossena, V.; Fusetti, A. Uncertainty Evaluation on Multi-Hole Aerodynamic Pressure Probes. ASME J. Turbomach. 2021, 143, 091001. [Google Scholar] [CrossRef]

- Bruun, H.H. Hot-Wire Anemometry; Oxford University Press: New York, NY, USA, 1995. [Google Scholar]

- Perdichizzi, A.; Ubaldi, M.; Zunino, P. A hot wire measuring technique for mean velocity and Reynolds stress components in compressible flow. In Proceedings of the X Biannual Symposium on Measuring Techniques in Turbomachinery, Sint-Genesius-Rode, Belgium, 7–8 April 1990. [Google Scholar]

- Fitouri, A.; Khan, M.K.; Bruun, H.H. A multiposition hot-wire technique for the study of swirling flows in vortex chambers. Exp. Therm. Fluid Sci. 1995, 10, 142–151. [Google Scholar] [CrossRef]

- Buresti, G.; Di Cocco, N.R. Hot-wire measurement procedures and their appraisal through a simulation technique. J. Phys. E Sci. Instrum. 1987, 20, 87–99. [Google Scholar] [CrossRef]

- Roach, P.E. The generation of nearly isotropic turbulence by means of grids. Int. J. Heat. Fluid. Flow 1987, 8, 82–92. [Google Scholar] [CrossRef]

- Kundu, P.K.; Cohen, I.M.; Dowling, D.R. Fluid Mechanics; Elsevier Science: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Notaristefano, A.; Persico, G.; Gaetani, P. Turbulence Measurements Downstream of a Combustor Simulator Designed for Studies on the Combustor–Turbine Interaction. In Proceeding of the 15th European Turbomachinery Conference, Budapest, Hungary, 24–28 April 2023; Paper n. ETC2023-323. Available online: https://www.euroturbo.eu/publications/conference-proceedings-repository/ (accessed on 25 September 2023).

| Duct 1 | Duct 2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Injection Case Name | Frequency (Hz) | Feed? | CFD Inlet-Plane Treatment | Tt (K) | Feed? | CFD Inlet-Plane Treatment | Tt (K) | Exp. | CFD |

| HS | 0 | No | Wall | Yes | Inlet | 670 | ✓ | ||

| CS | 0 | No | Wall | Yes | Inlet | 303 | ✓ | ✓ | |

| EW | 110 | Yes | Inlet | 303 | Yes | Inlet | 670 | ✓ | |

| Unsteady CS | 110 | Yes | Inlet | 303 | Yes | Inlet | 303 | ✓ | ✓ |

| Reduct | Rec,swirler | Red,injector | M | Tt [K] | |||||

| Mainstream | 2.35 × 105 | 3.5 × 104 | 3.8 × 104 | 0.13 | 303 | ||||

| Quantity | Coarse | Fine | Δ |

|---|---|---|---|

| Number of cells | 6 mln | 12 mln | |

| ( | 0.038 | 0.034 | 0.49% |

| [K] | 0.79 | 0.76 | 0.03 |

| Variable | Mainstream | Perturbed Region |

|---|---|---|

| Ti | 0.07% | 5% |

| U (m/s) | 0.5 | 4.8 |

| U3 (m/s) | 1 | 8 |

| (m) | 2.6 × 10−4 | 8 × 10−5 |

| Duct | Phase | CFD | HW |

|---|---|---|---|

| Streak 1 | Phase 1 | 0.087 | 0.088 |

| Phase 2 | 0.084 | 0.088 | |

| Phase 3 | 0.096 | 0.092 | |

| Streak 2 | Phase 4 | 0.101 | 0.094 |

| Phase 5 | 0.108 | 0.093 | |

| Phase 6 | 0.114 | 0.092 |

| Plane | Technique | SN | Ti | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Unsteady CS | EW | CS | HS | Unsteady CS | EW | CS | HS | ||

| Plane 1 | Exp | 0.12 | 0.09 | 6.5% | 6.1% | ||||

| CFD | 0.12 | 0.11 | 0.10 | 0.10 | 7.2% | 7.3% | 7.2% | 7.4% | |

| Plane 2 | Exp | 0.09 | 0.09 | 5.9% | 5.9% | ||||

| CFD | 0.09 | 0.08 | 0.08 | 0.08 | 6.4% | 6.4% | 6.4% | 6.9% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY-NC-ND) license (https://creativecommons.org/licenses/by-nc-nd/4.0/).

Share and Cite

Notaristefano, A.; Persico, G.; Gaetani, P. Turbulence Measurements Downstream of a Combustor Simulator Designed for Studies on the Combustor–Turbine Interaction. Int. J. Turbomach. Propuls. Power 2024, 9, 4. https://doi.org/10.3390/ijtpp9010004

Notaristefano A, Persico G, Gaetani P. Turbulence Measurements Downstream of a Combustor Simulator Designed for Studies on the Combustor–Turbine Interaction. International Journal of Turbomachinery, Propulsion and Power. 2024; 9(1):4. https://doi.org/10.3390/ijtpp9010004

Chicago/Turabian StyleNotaristefano, Andrea, Giacomo Persico, and Paolo Gaetani. 2024. "Turbulence Measurements Downstream of a Combustor Simulator Designed for Studies on the Combustor–Turbine Interaction" International Journal of Turbomachinery, Propulsion and Power 9, no. 1: 4. https://doi.org/10.3390/ijtpp9010004

APA StyleNotaristefano, A., Persico, G., & Gaetani, P. (2024). Turbulence Measurements Downstream of a Combustor Simulator Designed for Studies on the Combustor–Turbine Interaction. International Journal of Turbomachinery, Propulsion and Power, 9(1), 4. https://doi.org/10.3390/ijtpp9010004