A Comprehensive Review of Applications of Drone Technology in the Mining Industry

Abstract

:1. Introduction

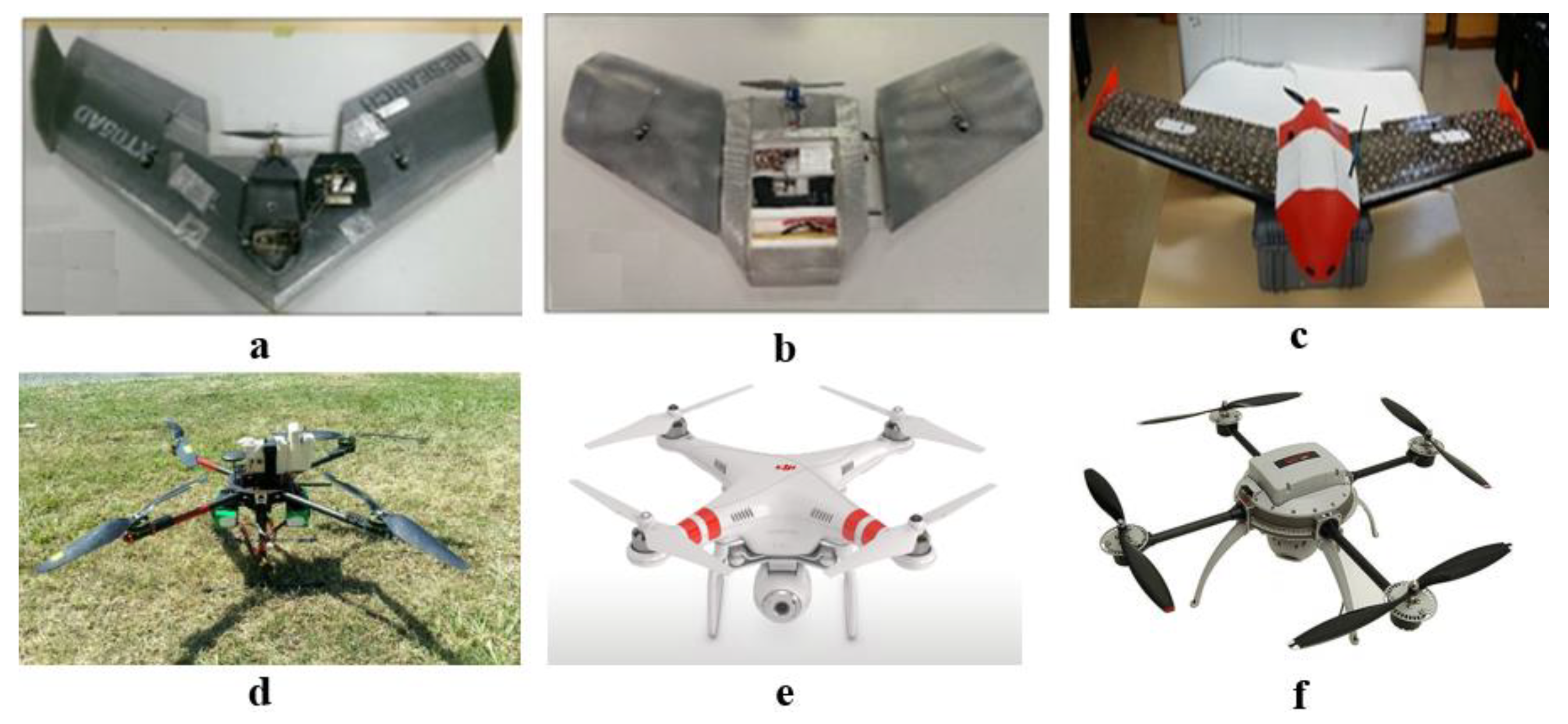

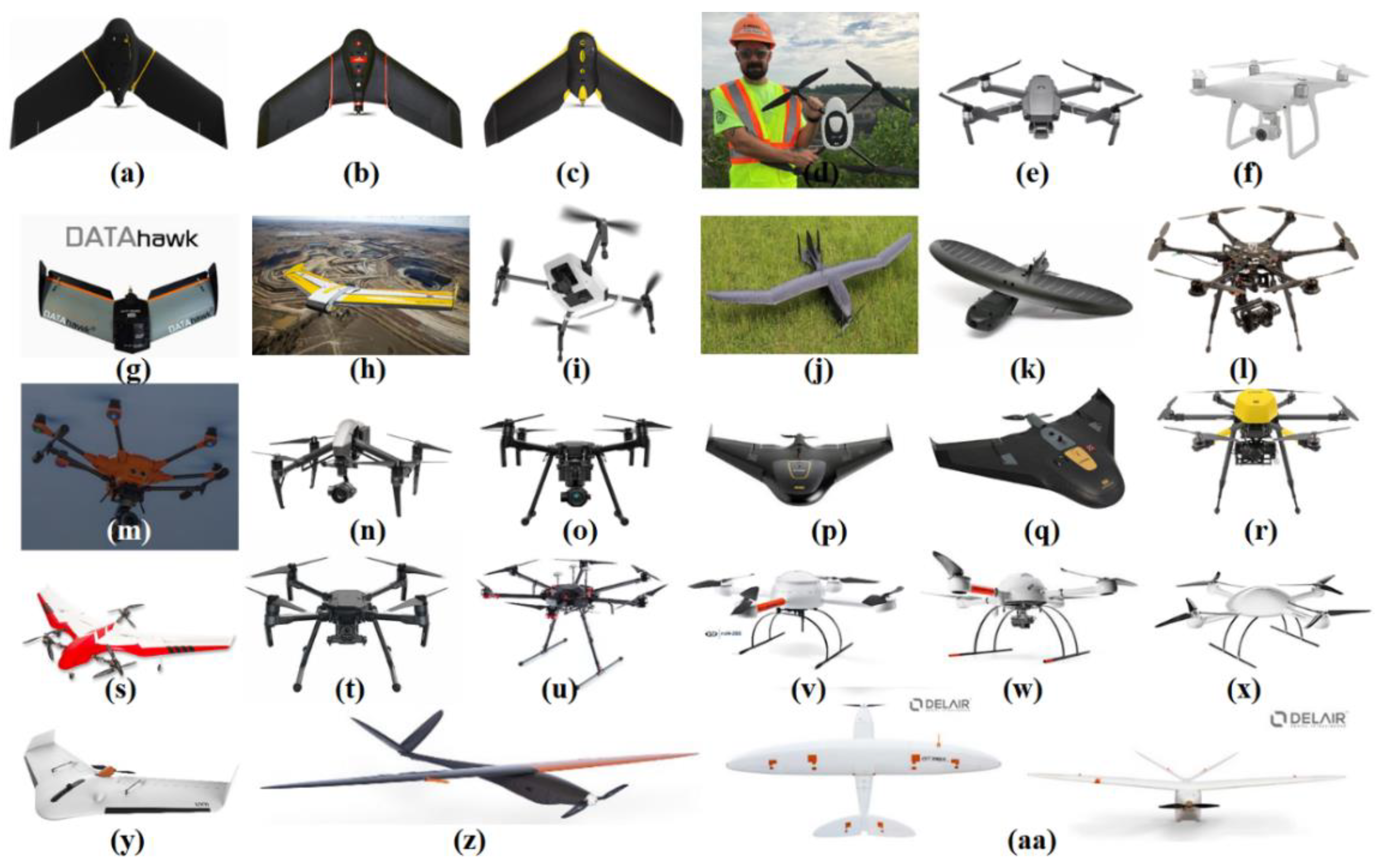

2. Drone Technology Applications in the Mining Industry

3. Applications of Drones in Surface Mining

CommerCialized Drones for Surface Mining Applications

| Type of Drone | Model | Company | Wingspan (mm) | Weight (g) | Endurance (min) | Payload (g) | Speed (m/s) |

|---|---|---|---|---|---|---|---|

| Fixed-wing | eBee X | Sensefly | 1160 | 1400 | 90 | - | 11–30 |

| Fixed-wing | eBee SQ | Sensefly | 960 | 1100 | 55 | - | 11–30 |

| Fixed-wing | eBee Classic | Sensefly | 1100 | 690 | 50 | - | 11–25 |

| Quadcopter | Kespry 2s | Kespry | - | 2000 | 30 | - | - |

| Quadcopter | DJI Mavic 2 Pro | Kespry, 3D Robotics | 350 | 907 | 30 | - | 20 |

| Quadcopter | DJI Phantom 4 Pro | Propeller Aero, 3D Robotics | 350 | 1388 | 30 | - | 20 |

| Fixed-wing | Q-200 Surveyor | QuestUAV | 1950 | 4600 | 60 | 590 | - |

| Fixed-wing | datahawk | QuestUAV | 1164 | 2150 | 45 | - | 19 |

| Quadcopter | Explore-1 | Skycatch | 650 | 3600 | 17 | - | 17 |

| Fixed-wing | Leviathan | Prioria | 2590 | 5897 | 90 | 907 | - |

| Fixed-wing | Maveric | Prioria | 749 | 1179 | 45–90 | - | 13.5 |

| Hexacopter | Hex | Prioria | 800 | 6350 | 15 | - | 6.2 |

| Hexacopter | Yuneec 3DR | 3D Robotics | - | 1645 | 28 | - | 13.5 |

| Quadcopter | DJI M200 | Precision-hawk | 643 | 6140 | 13–24 | 1610 | 23 |

| Quadcopter | DJI Inspire 2 | 3D Robotics | 427 | 4250 | 32–27 | - | 26 |

| Hexacopter | Trimble ZX5 | Trimble | 850 | 5000 | 20 | 2300 | 9 |

| Fixed-wing | Trimble UX5 | Trimble | 1000 | 2500 | 50 | - | 22 |

| Fixed-wing | Trimble UX5 | Trimble (HP) | 1000 | 2900 | 35 | - | 24 |

| Fixed-wing | FIREFLY6 PRO | Precision-hawk | 1524 | 4500 | 50–59 | 700 | 15–18 |

| Quadcopter | DJI M210 | Precision-hawk | 643 | 4570 | 13–24 | 1570 | 24 |

| Hexacopter | MATRICE 600 | Precision-hawk | 1133 | 10000 | 18 | 5500 | 18 |

| Quadcopter | md4-200 | Microdrones | 540 | 800 | 25 | 250 | 8 |

| Quadcopter | md4-1000 | Microdrones | 1030 | 2650 | 45 | 1200 | 12 |

| Quadcopter | md4-3000 | Microdrones | 2052 | 6000 | 45 | 5000 | 20 |

| Fixed-wing | UX11 | Delair | 1100 | 1400 | 59 | - | 15 |

| Fixed-wing | DT18 HD | Delair | 1800 | 2000 | 120 | - | 17 |

| Fixed-wing | DT26X LiDAR | Delair | 3300 | 17000 | 110 | - | 17 |

| Quadcopter | ELIOS | Flyability | 400 | 700 | 10 | - | 6.5 |

| Quadcopter | ELIOS2 | Flyability | 400 | 550 | 10 | - | 4.68 |

4. Application of Arones in Underground Mines

4.1. Geotechnical Characterization of Underground Mines

4.2. Rock Size Distribution Analysis in Underground Mines

4.3. Gas Detection in Underground Coal Mines

4.4. Mine Rescue Mission in Underground Mines

4.5. Common Sensing Methods for Drones in Underground Mining

4.6. Challenges in Using Drones in Underground Mines

5. Application of Drone Technology in Abandoned Mines

6. Application of Drones in Search and Rescue Operations

7. Commonly Used Sensors on Mining Drones

7.1. Infrared Sensors (IR)

7.2. Ultrasonic Sensors (US)

7.3. Red-Green-Blue (RGB) Sensors

7.4. Stereo Cameras

7.5. Laser Range Finders (LRFs)

7.6. Ultra-Wideband Radar (UWB)

7.7. Hyperspectral Sensors

7.8. Magnetic Sensors

7.9. Visible and Near-Infrared Spectral Range (VNIR

7.10. Air Quality Sensors

8. Discussion

8.1. Challenges in Using Drones in the Mining Industry

8.2. Suitable Drone Configuration for Underground Mining Applications

| Type | Model | Goal | Company | Diameter (mm) | Weight (g) | Speed (m/s) |

|---|---|---|---|---|---|---|

| Single rotor | Fleye Racer | Learn how to fly a drone | Fleye | 110 | 235 | 27 |

| Four propeller | Fleye Helmet | Learn how to fly a drone | Fleye | 210 | 210 | 11 |

| Single rotor | Fleye Duct | Learn how to fly a drone | Fleye | 110 | 400 | 4 |

| Dual rotor | FLYBOTIX | Industrial Inspection | Flybotix | 300 | - | - |

| Quadcopter | Elios 2 | Industrial inspection | Flyability | 400 | 1450 | 1.5 |

| Single Rotor | UFRO | Search and rescue | Oklahoma State University | 560 | 950 | - |

| Encased single-rotor | Glimball | Flying multiple collisions environment | Laboratory of Intelligent Systems-Switzerland | - | 385 | 1.5 |

| Encased Multirotor | PRSS UAV | Indoor inspection after the disaster | Tohoku University Japan | 894 | 1956 | 2.5 |

| Encased single-rotor | Spherical drone | Indoor operations | Cranfield University | 226 (inner) | 590 | - |

| Encased Multirotor | Sphere | flying spherical display surface | Research Labs, NTT DOCOMO | 880 | 4500 | - |

9. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Moore, G.K. What is a picture worth? A history of remote sensing/Quelle est la valeur d’une image? Un tour d’horizon de télédétection. Hydrol. Sci. Bull. 2010, 24, 477–485. [Google Scholar] [CrossRef] [Green Version]

- Rambat, S. A Los-cost Remote Sensing System for Agricultural Applications. Ph.D. Dissertation, Aston University, Birmingham , UK, 2011. [Google Scholar]

- Keane, J.F.; Carr, S.S. A brief history of early unmanned aircraft. Johns Hopkins APL Tech. Dig. 2013, 32, 558–571. [Google Scholar]

- Kindervater, K.H. The emergence of lethal surveillance: Watching and killing in the history of drone technology. Secur. Dialogue 2016, 47, 223–238. [Google Scholar] [CrossRef]

- Cai, G.; Lum, K.-Y.; Chen, B.M.; Lee, T.H. A brief overview on miniature fixed-wing unmanned aerial vehicles. In Proceedings of the IEEE ICCA 2010, Xiamen, China, 9–11 June 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 285–290. [Google Scholar]

- Hassanalian, M.; Abdelkefi, A. Classifications, applications, and design challenges of drones: A review. Prog. Aerosp. Sci. 2017, 91. [Google Scholar] [CrossRef]

- Hassanalian, M.; Khaki, H.; Khosravi, M. A new method for design of fixed wing micro air vehicle. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2015, 229, 837–850. [Google Scholar] [CrossRef]

- Hassanalian, M.; Abdelkefi, A. Design, manufacturing, and flight testing of a fixed wing micro air vehicle with Zimmerman planform. Meccanica 2017, 52. [Google Scholar] [CrossRef]

- Hassanalian, M.; Rice, D.; Abdelkefi, A. Evolution of space drones for planetary exploration: A review. Prog. Aerosp. Sci. 2018, 97. [Google Scholar] [CrossRef]

- Hassanalian, M.; Rice, D.; Abdelkefi, A. Aerodynamic performance analysis of fixed wing space drones in different solar system bodies. In Proceedings of the 2018 AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 8–12 January 2018; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2018. [Google Scholar]

- Finn, R.L.; Wright, D. Privacy, data protection and ethics for civil drone practice: A survey of industry, regulators and civil society organisations. Comput. Law Secur. Rev. 2016, 32, 577–586. [Google Scholar] [CrossRef]

- Hassanalian, M.; Rice, D.; Johnstone, S.; Abdelkefi, A. Performance analysis of fixed wing space drones in different solar system bodies. Acta Astronaut. 2018, 152. [Google Scholar] [CrossRef]

- Rouse, M.; Earls, A.; Sharon Shea, I.W. What is Drone (Unmanned Aerial Vehicle, UAV)?-Definition from WhatIs.com. Available online: https://internetofthingsagenda.techtarget.com/definition/drone (accessed on 2 March 2019).

- Karjalainen, M.; Ahokas, E.; Hyyppä, J.; Heinonen, T.; Jaakkola, A.; Matikainen, L.; Lehtomäki, M.; Kukko, A. Remote sensing methods for power line corridor surveys. ISPRS J. Photogramm. Remote Sens. 2016, 119, 10–31. [Google Scholar] [CrossRef] [Green Version]

- Zlatanova, S.; Çöltekin, A.; Ledoux, H.; Stoter, J.; Biljecki, F. Applications of 3D City Models: State of the Art Review. ISPRS Int. J. Geo-Inf. 2015, 4, 2842–2889. [Google Scholar] [CrossRef] [Green Version]

- Leitloff, J.; Rosenbaum, D.; Kurz, F.; Meynberg, O.; Reinartz, P. An operational system for estimating road traffic information from aerial images. Remote Sens. 2014, 6, 11315–11341. [Google Scholar] [CrossRef] [Green Version]

- Barmpounakis, E.N.; Golias, J.C. Unmanned Aerial Aircraft Systems for transportation engineering: Current practice and future challenges. Int. J. Transp. Sci. Technol. 2016, 5, 111–122. [Google Scholar] [CrossRef]

- Lee, S.; Choi, Y. Reviews of unmanned aerial vehicle (drone) technology trends and its applications in the mining industry. Geosyst. Eng. 2016, 19, 197–204. [Google Scholar] [CrossRef]

- Hodgson, J.C.; Baylis, S.M.; Mott, R.; Herrod, A.; Clarke, R.H. Precision wildlife monitoring using unmanned aerial vehicles. Sci. Rep. 2016, 6, 22574. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hardin, P.J.; Jensen, R.R. Small-Scale Unmanned Aerial Vehicles in Environmental Remote Sensing: Challenges and Opportunities. GISci. Remote Sens. 2011, 48, 99–111. [Google Scholar] [CrossRef]

- Fernández-Hernandez, J.; González-Aguilera, D.; Rodríguez-Gonzálvez, P.; Mancera-Taboada, J. Image-Based Modelling from Unmanned Aerial Vehicle (UAV) Photogrammetry: An Effective, Low-Cost Tool for Archaeological Applications. Archaeometry 2015, 57, 128–145. [Google Scholar] [CrossRef]

- Rohrbach, A.; Rohrbach, M.; Hu, R.; Darrell, T.; Schiele, B. Learning Social Etiquette: Human Trajectory Understanding in Crowded Scenes. In Computer Vision—ECCV 2016; Springer: Cham, Switzerland, 2016; Volume 9905. [Google Scholar] [CrossRef] [Green Version]

- Xiang, T.-Z.; Xia, G.-S.; Zhang, L. Mini-UAV-based Remote Sensing: Techniques, Applications and Prospectives. arXiv 2018, arXiv:1812.07770v1. [Google Scholar]

- Elijah, O.; Rahman, T.A.; Orikumhi, I.; Leow, C.Y.; Hindia, M.N. An Overview of Internet of Things (IoT) and Data Analytics in Agriculture: Benefits and Challenges. IEEE Internet Things J. 2018, 5, 3758–3773. [Google Scholar] [CrossRef]

- Whipple, J.; Jeirath, N.; Archer, C.; Sisk, D.A.; Gray, S.; Lee, C.J.; Gonzalez, J.; Wilmes, T. Aerial Drone for Well-Site and Signal Survey. U.S. Patent Application No. 10,192,182, 29 January 2019. Available online: https://patentimages.storage.googleapis.com/2b/3f/ec/0dddba63cb6be5/US10192182.pdf (accessed on 8 July 2020).

- Li, Y.; Liu, C. Applications of multirotor drone technologies in construction management. Int. J. Constr. Manag. 2019, 19, 401–412. [Google Scholar] [CrossRef]

- Vergouw, B.; Nagel, H.; Bondt, G.; Custers, B. The Future of Drone Use; Asser Press: The Hague, The Netherlands, 2016; Volume 27, pp. 21–46. [Google Scholar] [CrossRef]

- Green, J. Mine rescue robots requirements: Outcomes from an industry workshop. In Proceedings of the 2013 6th Robotics and Mechatronics Conference (RobMech), Durban, South Africa, 30–31 October 2013; IEEE Computer Society: Washington, DC, USA, 2013; pp. 111–116. [Google Scholar]

- McLeod, T.; Samson, C.; Labrie, M.; Shehata, K.; Mah, J.; Lai, P.; Wang, L.; Elder, J.H. Using video acquired from an unmanned aerial vehicle (UAV) to measure fracture orientation in an open-PIT mine. Geomatica 2013, 67, 173–180. [Google Scholar] [CrossRef]

- Ranjan, A.; Panigrahi, B.; Sahu, H.B.; Misra, P. SkyHelp: UAV Assisted Emergency Communication in Deep Open Pit Mines. In Proceedings of the 1st International Workshop on Internet of People, Assistive Robots and ThingS-IoPARTS’18, Munich, Germany, 10 June 2018; pp. 31–36. [Google Scholar]

- Rupprecht, S.M.; Pieters, J.E. Re-opening of old gold mines for small scale mining in South Africa-The Process of Creating a Small Scale Mine in a Historically Mined out South African Gold Field. University of Johannesburg: Johannesburg, South Africa, 2018. Available online: https://core.ac.uk/download/pdf/161412655.pdf (accessed on 8 July 2020).

- Dunnington, L.; Nakagawa, M. Fast and safe gas detection from underground coal fire by drone fly over. Environ. Pollut. 2017, 229, 139–145. [Google Scholar] [CrossRef] [PubMed]

- Hoffmann, R.; McAllister, I. Use of Unmanned Aerial Systems Reduces HES Risks; Society of Petroleum Engineers: Calgary, AB, Canada, 2018. [Google Scholar] [CrossRef]

- Schroedter, R. Using Photogrammetry To Transform Mining. Available online: https://www.digitalistmag.com/iot/2018/05/01/using-photogrammetry-to-transform-mining-06148346 (accessed on 1 April 2019).

- Alvarado Molina, M. Design and development of a methodology to monitor PM10 dust particles produced by industrial activities using UAV’s. Master Thesis, The University of Queensland, Brisbane, Australia, 2018. [Google Scholar]

- DJI-The World Leader in Camera Drones/Quadcopters for Aerial Photography. Available online: https://www.dji.com/ (accessed on 31 August 2019).

- senseFly|LinkedIn. Available online: https://www.linkedin.com/company/sensefly (accessed on 29 August 2019).

- senseFly-The Professional’s Mapping Drone of Choice. Available online: https://www.sensefly.com/ (accessed on 23 March 2019).

- DroneDeploy|LinkedIn. Available online: https://www.linkedin.com/company/dronedeploy (accessed on 16 March 2019).

- Drone Software for Mining Operations|DroneDeploy. Available online: https://www.dronedeploy.com/solutions/mining/ (accessed on 16 March 2019).

- Kespry|LinkedIn. Available online: https://www.linkedin.com/company/kespry-inc (accessed on 29 August 2019).

- Industrial Drones|Drone Software & Analytics|Kespry. Available online: https://www.kespry.com/ (accessed on 1 April 2019).

- Propeller Aero: Overview|LinkedIn. Available online: https://www.linkedin.com/company/propeller-aero/ (accessed on 29 August 2019).

- The Drone Data & Analytics Platform for Worksites|Propeller. Available online: https://www.propelleraero.com/?CA (accessed on 29 August 2019).

- QuestUAV Ltd: About|LinkedIn. Available online: https://www.linkedin.com/company/questuav-ltd/about/ (accessed on 29 August 2019).

- Skycatch|LinkedIn. Available online: https://www.linkedin.com/company/skycatch (accessed on 29 August 2019).

- Explore1 Drone|Skycatch. Available online: https://www.skycatch.com/solution/high-precision-package/explore1/ (accessed on 29 August 2019).

- Prioria Robotics|LinkedIn. Available online: https://www.linkedin.com/company/prioria-robotics (accessed on 22 March 2019).

- Volume Calculation-Prioria Robotics. Available online: http://www.prioria.com/volume/ (accessed on 22 March 2019).

- 3D Robotics|LinkedIn. Available online: https://www.linkedin.com/company/3d-robotics (accessed on 22 March 2019).

- 3DR Site Scan-The Drone Data Platform for AEC|3DR. Available online: https://3dr.com/ (accessed on 22 March 2019).

- Trimble Inc.|LinkedIn. Available online: https://www.linkedin.com/company/trimble (accessed on 22 March 2019).

- Mining Solutions. Available online: https://www.trimble.com/industries/mining/index.aspx (accessed on 24 March 2019).

- PrecisionHawk|LinkedIn. Available online: https://www.linkedin.com/company/precisionhawk (accessed on 24 March 2019).

- PrecisionHawk|UAV & Drone Enterprise Platform Solution. Available online: https://www.precisionhawk.com/ (accessed on 24 March 2019).

- Microdrones®|LinkedIn. Available online: https://www.linkedin.com/company/microdrones-gmbh (accessed on 25 March 2019).

- Drones for Mining: Quick Deployment. Extreme Efficiency. Cost Savings. Ease. Available online: https://www.microdrones.com/en/industry-experts/mining/ (accessed on 25 March 2019).

- Delair: Overview|LinkedIn. Available online: https://www.linkedin.com/company/delair-tech/ (accessed on 29 August 2019).

- DELAIR-Professional Drones for Industry and Aerial Data solutions. Available online: https://delair.aero/ (accessed on 29 August 2019).

- Survey Drone and Fixed Wing UAV Developer|QuestUAV. Available online: https://www.questuav.com/ (accessed on 29 August 2019).

- Mining: De-Risk the Mine Site with Drone Mapping|Pix4D. Available online: https://www.pix4d.com/industry/mining (accessed on 25 March 2019).

- UAV/Drone Solutions for Mapping, Aerial Inspection, Unmanned Cargo. Available online: https://www.microdrones.com/en/ (accessed on 25 March 2019).

- Mirzaeinia, A.; Shahmoradi, J.; Roghanchi, P.; Hassanalian, M. Autonomous routing and power management of drones in gps-denied environments through dijkstra algorithm. In Proceedings of the AIAA Propulsion and Energy Forum and Exposition, Indianapolis, IN, USA, 19–22 August 2019; American Institute of Aeronautics and Astronautics Inc. (AIAA): Reston, VA, USA, 2019. [Google Scholar]

- Freire, G.; Cota, R. Capture of images in inaccessible areas in an underground mine using an unmanned aerial vehicle. In Proceedings of the 1st International Conference on Underground Mining Technology, Sudbury, ON, Canada, 11–13 October 2017. [Google Scholar] [CrossRef] [Green Version]

- Hennage, D.H.; Nopola, J.R.; Haugen, B.D. Fully Autonomous Drone for Underground Use; American Rock Mechanics Association: Alexandria, VA, USA, 2019. [Google Scholar]

- Russell, E. Uav-Based Geotechnical Modeling And Mapping Of An Inaccessible Underground Site. Master Thesis, Montana Tech, Butte, MT, Canada, 2018. [Google Scholar]

- Azhari, F.; Kiely, S.; Sennersten, C.; Lindley, C.; Matuszak, M.; Hogwood, S. A comparison of sensors for underground void mapping by unmanned aerial vehicles. In Proceedings of the 1st International Conference on Underground Mining Technology, Sudbury, ON, Canada, 11–13 October 2017; pp. 419–430. [Google Scholar] [CrossRef] [Green Version]

- Mining. Available online: https://www.flyability.com/mining (accessed on 26 March 2019).

- Turner, R.M.; Bhagwat, N.P.; Galayda, L.J.; Knoll, C.S.; Russell, E.A.; MacLaughlin, M.M. Geotechnical Characterization of Underground Mine Excavations from UAV-Captured Photogrammetric & Thermal Imagery. In Proceedings of the 52nd US Rock Mechanics/Geomechanics Symposium, Washington, DC, USA, 17–20 June 2018. [Google Scholar]

- Mosher, J. Crushing, Milling, and Grinding. In SME Mining Engineering Handbook, 3rd ed.; Darling, P., Ed.; Society for Mining, Metallurgy and Exploration: Englewood, CO, USA, 2011; pp. 1461–1465. [Google Scholar]

- Bamford, T.; Esmaeili, K.; Schoellig, A.P. Aerial Rock Fragmentation Analysis in Low-Light Condition Using UAV Technology. arXiv 2017, arXiv:1708.06343. [Google Scholar]

- Villaescusa, E. Rock Mass Characterization. Geotech. Des. Sublevel Open Stoping 2014, 113–190. [Google Scholar] [CrossRef]

- Hoffman, S. Latching Mechanism between UAV and UGV Team for Mine Rescue. Ph.D. Dissertation, University of Alaska Fairbanks, Fairbanks, AK, USA, 2017. [Google Scholar]

- Gupta, S.G.; Ghonge, M.M.; Jawandhiya, P.M. Review of Unmanned Aircraft System (UAS). Int. J. Adv. Res. Comput. Eng. Technol. 2013, 2, 1646–1658. [Google Scholar] [CrossRef]

- Gageik, N.; Benz, P.; Montenegro, S. Obstacle detection and collision avoidance for a UAV with complementary low-cost sensors. IEEE Access 2015, 3, 599–609. [Google Scholar] [CrossRef]

- Roberts, J.F.; Stirling, T.; Zufferey, J.C.; Floreano, D. Quadrotor Using Minimal Sensing For Autonomous Indoor Flight. In In Proceedings of the European Micro Air Vehicle Conference and Flight Competition (EMAV2007), Toulouse, France, 17–21 September 2007; Volume 7, pp. 1–8. [Google Scholar]

- Santos, J.M.; Couceiro, M.S.; Portugal, D.; Rocha, R.P. A Sensor Fusion Layer to Cope with Reduced Visibility in SLAM. J. Intell. Robot. Syst. Theory Appl. 2015, 80, 401–422. [Google Scholar] [CrossRef]

- Brunner, C.; Peynot, T.; Vidal-Calleja, T.; Underwood, J. Selective combination of visual and thermal imaging for resilient localization in adverse conditions: Day and night, smoke and fire. J. Field Robot. 2013, 30, 641–666. [Google Scholar] [CrossRef] [Green Version]

- Bachrach, A.; De Winter, A.; He, R.; Hemann, G.; Prentice, S.; Roy, N. RANGE-Robust Autonomous Navigation in GPS-denied Environments. J. Field Robot. 2010, 28, 1096–1097. [Google Scholar] [CrossRef]

- Cunha, F.; Youcef-Toumi, K. Ultra-Wideband Radar for Robust Inspection Drone in Underground Coal Mines. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, Australia, 21–25 May 2018; pp. 86–92. [Google Scholar] [CrossRef] [Green Version]

- Forooshani, A.E.; Bashir, S.; Michelson, D.G.; Noghanian, S. A survey of wireless communications and propagation modeling in underground mines. IEEE Commun. Surv. Tutorials 2013, 15, 1524–1545. [Google Scholar] [CrossRef]

- Ranjan, A.; Sahu, H.; Sahu, H.B. Communication Challenges in Underground Mines. Search Res. 2014, V, 23–29. [Google Scholar]

- Pamela Drones Go Underground as Mining Applications Expand-Unmanned Systems Source. Available online: https://www.unmannedsystemssource.com/drones-go-underground-as-mining-applications-expand/ (accessed on 8 May 2020).

- 10 Limitations of Drones-Grind Drone. Available online: http://grinddrone.com/features/10-limitations-of-drones (accessed on 9 May 2020).

- Khonji, M.; Alshehhi, M.; Tseng, C.M.; Chau, C.K. Autonomous inductive charging system for battery-operated electric drones. In Proceedings of the e-Energy 2017 8th International Conference on Future Energy Systems, Hong Kong, China, 16–19 May 2017; Association for Computing Machinery, Inc.: New York, NY, USA, 2017; pp. 322–327. [Google Scholar]

- 5 Challenges Confronting Enterprise Drones|Computerworld. Available online: https://www.computerworld.com/article/3195749/5-challenges-confronting-enterprise-drones.html (accessed on 9 May 2020).

- Gong, A.; Verstraete, D. Design and Bench Test of a Fuel-Cell/Battery Hybrid UAV Propulsion System using Metal Hydride Hydrogen Storage. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanta, GA, USA, 10–12 July 2017; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2017. [Google Scholar]

- Afolabi, D.; Man, K.L.; Liang, H.N.; Lim, E.G.; Shen, Z.; Lei, C.U.; Krilavicius, T.; Yang, Y.; Cheng, L.; Hahanov, V.; et al. A WSN approach to unmanned aerial surveillance of traffic anomalies: Some challenges and potential solutions. In Proceedings of the IEEE East-West Design and Test Symposium (EWDTS 2013), Rostov-on-Don, Russia, 27–30 September 2013. [Google Scholar]

- Mine Safety and Productivity|Location Running. Available online: https://nanotron.com/EN/pr_mining_and_tunneling-php/ (accessed on 9 May 2020).

- Home|AbandonedMines. Available online: https://www.abandonedmines.gov/ (accessed on 4 April 2020).

- Pauley, E.; Schumaker, T.; Cole, B. Preliminary Report of Investigation: Underground Bituminous Coal Mine. In Noninjury Mine Inundation Accident (Entrapment); Black Wolf Coal Company, Inc.: Quecreek, PA, USA, 24 July 2002. [Google Scholar]

- Thrun, S.; Thayer, S.; Whittaker, W.; Baker, C.; Burgard, W.; Ferguson, D.; Hahnel, D.; Montemerlo, M.; Morris, A.; Omohundro, Z.; et al. Autonomous exploration and mapping of abandoned mines: Software architecture of an autonomous robotic system. IEEE Robot. Autom. Mag. 2004, 11, 79–91. [Google Scholar] [CrossRef] [Green Version]

- Bell, F.G.; Stacey, T.R.; Genske, D.D. Mining subsidence and its effect on the environment: Some differing examples. Environ. Geol. 2000, 40, 135–152. [Google Scholar] [CrossRef]

- O’Connor, K.M.; Murphy, E.W. TDR monitoring as a component of subsidence risk assessment. Int. J. rock Mech. Min. Sci. Geomech. Abstr. 1997, 34, 619. [Google Scholar] [CrossRef]

- Fu, A. Strategies for the Reduction of Methane Emissions and Harnessing for Use as an Alternative Energy Resource: A Review. McGill Green Chem. J. 2015, 1, 26–30. [Google Scholar]

- Neumann, P.P.; Hernandez Bennetts, V.; Lilienthal, A.J.; Bartholmai, M.; Schiller, J.H. Gas source localization with a micro-drone using bio-inspired and particle filter-based algorithms. Adv. Robot. 2013, 27, 725–738. [Google Scholar] [CrossRef]

- Lee, S.; Choi, Y. Topographic Survey at Small-scale Open-pit Mines using a Popular Rotary-wing Unmanned Aerial Vehicle (Drone). J. Korean Soc. Rock Mech. 2015, 25, 462–469. [Google Scholar] [CrossRef]

- Lee, S.; Choi, Y. On-site Demonstration of Topographic Surveying Techniques at Open-pit Mines using a Fixed-wing Unmanned Aerial Vehicle (Drone). J. Korean Soc. Rock Mech. 2016, 25, 527–533. [Google Scholar] [CrossRef] [Green Version]

- Suh, J.; Choi, Y. Mapping hazardous mining-induced sinkhole subsidence using unmanned aerial vehicle (drone) photogrammetry. Environ. Earth Sci. 2017, 76, 1–12. [Google Scholar] [CrossRef]

- Molnar, A. Volume analysis of surface formations on the basis of aerial photographs taken by drones Faculty of Economy 2 3D model creation based on the. Int. J. Signal Process. 2016, 1, 152–159. [Google Scholar]

- Shen, B.; Poulsen, B.; Luo, X.; Qin, J.; Thiruvenkatachari, R.; Duan, Y. Remediation and monitoring of abandoned mines. Int. J. Min. Sci. Technol. 2017, 27, 803–811. [Google Scholar] [CrossRef]

- Motyka, Z. Systems for Spatial and Physico-Chemical Parameters Mapping of Anthropogenic Landscape Forms and Plants Formations in Mining Areas With the Use of Photogrammetry and Remote Laser Sensing From Low Height. J. Civ. Eng. Environ. Archit. 2017, 64, 171–182. [Google Scholar] [CrossRef] [Green Version]

- Knight, R. Monitoring, Mapping, Measuring: How Drones Are Changing The Mining Industry. Available online: http://insideunmannedsystems.com/monitoring-mapping-measuring-drones-changing-mining-industry/ (accessed on 9 May 2020).

- Ali, M.; Recep, Y.; Turan, Y. Areal Change Detection and 3D Modeling of Mine Lakes Using High-Resolution Unmanned Aerial Vehicle Images. Arab. J. Sci. Eng. 2016, 4867–4878. [Google Scholar] [CrossRef]

- Cawood, F. Surveying technical Digital Mine laboratory prepared for digital mining. Position IT Magazine. March 2015, 26–30. Available online: https://www.ee.co.za/wp-content/uploads/2015/03/positionit-march15-p26-30.pdf (accessed on 8 July 2020).

- Underground Mine Drone. Available online: https://www.youtube.com/watch?v=E9e0FYLcE8g (accessed on 9 May 2020).

- Grehl, S.; Donner, M.; Ferber, M.; Dietze, A.; Mischo, H.; Jung, B. Mining-RoX–Mobile Robots in Underground Mining. In Proceedings of the Third International Future Mining Conference, Sydney, Australia, 4–6 November 2015; pp. 57–64. [Google Scholar]

- Matthews, S. The age of the drone–Keeping an eye on the nation’s water. Water Wheel 2018, 17, 12–16. [Google Scholar]

- Available online: http://www.coastwaysurveys.co.uk (accessed on 8 July 2020).

- Zhou, J.; Zhu, H.; Kim, M.; Cummings, M.L. The Impact of Different Levels of Autonomy and Training on Operators’ Drone Control Strategies. ACM Trans. Hum.-Robot Interact. 2019, 8, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Uncovering the Coal Industry’s Hidden Legacy DroneApps DroneApps. Available online: https://droneapps.co/drone-inspection-coal-industry/ (accessed on 9 May 2020).

- Hayat, S.; Yanmaz, E.; Muzaffar, R. Survey on Unmanned Aerial Vehicle Networks for Civil Applications: A Communications Viewpoint. IEEE Commun. Surv. Tutorials 2016, 18, 2624–2661. [Google Scholar] [CrossRef]

- Shakhatreh, H.; Sawalmeh, A.H.; Al-Fuqaha, A.; Dou, Z.; Almaita, E.; Khalil, I.; Othman, N.S.; Khreishah, A.; Guizani, M. Unmanned Aerial Vehicles (UAVs): A Survey on Civil Applications and Key Research Challenges. IEEE Access 2019, 7, 48572–48634. [Google Scholar] [CrossRef]

- Silvagni, M.; Tonoli, A.; Zenerino, E.; Chiaberge, M. Multipurpose UAV for search and rescue operations in mountain avalanche events. Geomat. Nat. Hazards Risk 2017, 8, 18–33. [Google Scholar] [CrossRef] [Green Version]

- Digital Mining Solutions|Hexagon Mining. Available online: https://hexagonmining.com/ (accessed on 1 September 2019).

- Tír 3D-Chartered Land Surveyors and Geospatial Engineers. Available online: https://www.tir3d.ie/ (accessed on 1 September 2019).

- Sankey, T.T.; McVay, J.; Swetnam, T.L.; McClaran, M.P.; Heilman, P.; Nichols, M. UAV hyperspectral and lidar data and their fusion for arid and semi-arid land vegetation monitoring. Remote Sens. Ecol. Conserv. 2018, 4, 20–33. [Google Scholar] [CrossRef]

- Valavanis, K.P.; Vachtsevanos, G.J. (Eds.) Handbook of Unmanned Aerial Vehicles; Springer: Dordrecht, The Netherlands, 2015; ISBN 978-90-481-9706-4. [Google Scholar]

- Rango, A.; Laliberte, A.; Herrick, J.E.; Winters, C.; Havstad, K.; Steele, C.; Browning, D. Unmanned aerial vehicle-based remote sensing for rangeland assessment, monitoring, and management. J. Appl. Remote Sens. 2009, 3, 033542. [Google Scholar] [CrossRef]

- Harwin, S.; Lucieer, A. Assessing the accuracy of georeferenced point clouds produced via multi-view stereopsis from Unmanned Aerial Vehicle (UAV) imagery. Remote Sens. 2012, 4, 1573–1599. [Google Scholar] [CrossRef] [Green Version]

- Anderson, K.; Gaston, K.J. Lightweight unmanned aerial vehicles will revolutionize spatial ecology. Front. Ecol. Environ. 2013, 11, 138–146. [Google Scholar] [CrossRef] [Green Version]

- Javernick, L.; Brasington, J.; Caruso, B. Modeling the topography of shallow braided rivers using Structure-from-Motion photogrammetry. Geomorphology 2014, 213, 166–182. [Google Scholar] [CrossRef]

- Thermal Imaging, Night Vision and Infrared Camera Systems|FLIR Systems. Available online: https://www.flir.com/ (accessed on 1 September 2019).

- Ultrasonic Transducer, Parking Sensor, Ultrasonic Flow Sensor, Ultrasonic Flow Sensor Module Manufacturers and Supplier-Factory Quotation-Audiowell. Available online: https://www.audiowellsensor.com/ (accessed on 1 September 2019).

- Digital Photography Review. Available online: http://www.dpreview.com/ (accessed on 1 September 2019).

- DIY Drones. Available online: https://diydrones.com/ (accessed on 1 September 2019).

- Gobizkorea.com-You Can Meet Reliable Korean Suppliers and Manufacturers. Available online: https://www.gobizkorea.com/user/main.do (accessed on 1 September 2019).

- Drone Rental, Sales, Repairs & Aerial Services Made Easy! Professional UAVs & Sensors. Available online: https://www.blueskiesdronerental.com/ (accessed on 1 September 2019).

- Homepage-Geometrics: Geometrics. Available online: https://www.geometrics.com/ (accessed on 1 September 2019).

- Research International, Inc.|CBRNe Instruments & Systems. Available online: https://www.resrchintl.com/ (accessed on 1 September 2019).

- OptoKnowledge Systems, Inc.|Hyperspectral Sensors and EO/IR Systems. Available online: https://optoknowledge.com/ (accessed on 1 September 2019).

- Bingham, B.; Foley, B.; Singh, H.; Camilli, R.; Delaporta, K.; Eustice, R.; Mallios, A.; Mindell, D.; Roman, C.; Sakellariou, D. Robotic tools for deep water archaeology: Surveying an ancient shipwreck with an autonomous underwater vehicle. J. Field Robot. 2010, 27, 702–717. [Google Scholar] [CrossRef] [Green Version]

- Henry, P.; Krainin, M.; Herbst, E.; Ren, X.; Fox, D. RGB-D mapping: Using Kinect-style depth cameras for dense 3D modeling of indoor environments. Int. J. Rob. Res. 2012, 31, 647–663. [Google Scholar] [CrossRef] [Green Version]

- Konolige, K. Projected texture stereo. Proc.-IEEE Int. Conf. Robot. Autom. 2010, 148–155. [Google Scholar] [CrossRef] [Green Version]

- Toomay, J.C.; Hannen, P.J. Radar Principles for the Non-Specialist; SciTech Publishing: Raleigh, NC, USA, 2004. [Google Scholar]

- Fontana, R.J.; Richley, E.A.; Marzullo, A.J.; Beard, L.C.; Mulloy, R.W.T.; Knight, E.J. An ultra wideband radar for micro air vehicle applications. In Proceedings of the 2002 IEEE Conference on Ultra Wideband Systems and Technologies, Baltimore, MD, USA, 21–23 May 2002; pp. 187–192. [Google Scholar] [CrossRef]

- Seitz, J.; Schaub, M.; Hirsch, O.; Zetik, R.; Deißler, T.; Thomä, R.; Thielecke, J. UWB feature localization for imaging. In Proceedings of the 2008 IEEE International Conference on Ultra-Wideband, Hannover, Germany, 10–12 September 2008; Volume 2, pp. 199–202. [Google Scholar] [CrossRef]

- Hyperspectral Firefleye S185 SE-Cubert-GmbH. Available online: http://cubert-gmbh.com/product/uhd-185-firefly/ (accessed on 4 March 2019).

- Senop-Optronics Hyperspectral. Available online: https://senop.fi/en/optronics-hyperspectral (accessed on 4 March 2019).

- Jakob, S.; Zimmermann, R.; Gloaguen, R. The Need for Accurate Geometric and Radiometric Corrections of Drone-Borne Hyperspectral Data for Mineral Exploration: MEPHySTo-A Toolbox for Pre-Processing Drone-Borne Hyperspectral Data. Remote Sens. 2017, 9, 88. [Google Scholar] [CrossRef] [Green Version]

- Shippert, P. Why Use Hyperspectral Imagery? Photogramm. Eng. Remote Sens. 2004, 70, 377–379. [Google Scholar]

- van der Meer, F.D.; van der Werff, H.M.A.; van Ruitenbeek, F.J.A.; Hecker, C.A.; Bakker, W.H.; Noomen, M.F.; van der Meijde, M.; Carranza, E.J.M.; de Smeth, J.B.; Woldai, T. Multi- and hyperspectral geologic remote sensing: A review. Int. J. Appl. Earth Obs. Geoinf. 2012, 14, 112–128. [Google Scholar] [CrossRef]

- Rivard, B.; Harris, J.; Maloley, M.; White, H.P.; Peter, J.M.; Laakso, K.; Rogge, D. Application of Airborne, Laboratory, and Field Hyperspectral Methods to Mineral Exploration in the Canadian Arctic: Recognition and Characterization of Volcanogenic Massive Sulfide-Associated Hydrothermal Alteration in the Izok Lake Deposit Area, Nunavut. Econ. Geol. 2015, 110, 925–941. [Google Scholar] [CrossRef]

- Jakob, S.; Gloaguen, R.; Laukamp, C. Remote sensing-based exploration of structurally-related mineralizations around Mount Isa, Queensland, Australia. Remote Sens. 2016, 8, 358. [Google Scholar] [CrossRef] [Green Version]

- Zimmermann, R.; Brandmeier, M.; Andreani, L.; Mhopjeni, K.; Gloaguen, R. Remote sensing exploration of Nb-Ta-LREE-enriched carbonatite (Epembe/Namibia). Remote Sens. 2016, 8, 620. [Google Scholar] [CrossRef] [Green Version]

- Guo, H.; Bai, D.; Chen, B.; Cao, Y.; Ju, F.; Qi, F.; Wang, Y. Continuum robot shape estimation using permanent magnets and magnetic sensors. Sensors Actuators A Phys. 2018, 285, 519–530. [Google Scholar] [CrossRef]

- Eck, C.; Imbach, B. Aerial Magnetic Sensing With an Uav Helicopter. ISPRS-Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2012, XXXVIII-1/C22, 81–85. [Google Scholar] [CrossRef] [Green Version]

- Waiser, T.H.; Morgan, C.L.S.; Brown, D.J.; Hallmark, C.T. In Situ Characterization of Soil Clay Content with Visible Near-Infrared Diffuse Reflectance Spectroscopy. Soil Sci. Soc. Am. J. 2007, 71, 389. [Google Scholar] [CrossRef]

- Moseley, T.; Zabierek, G. Guidance on the Safe Use of Lasers in Education and Research, Aurpo Guidance, Note No. 7; Association of University Radiation Protection Officers. August 2012. Available online: https://www.gla.ac.uk/media/Media_418032_smxx.pdf (accessed on 8 July 2020).

- Honkavaara, E.; Mannila, R.; Rosnell, T.; Pulkkanen, M.; Hakala, T.; Eskelinen, M.A.; Viljanen, N.; Litkey, P.; Polonen, I.; Holmlund, C.; et al. Remote Sensing of 3-D Geometry and Surface Moisture of a Peat Production Area Using Hyperspectral Frame Cameras in Visible to Short-Wave Infrared Spectral Ranges Onboard a Small Unmanned Airborne Vehicle (UAV). IEEE Trans. Geosci. Remote Sens. 2016, 54, 5440–5454. [Google Scholar] [CrossRef] [Green Version]

- Hunt, G. Spectral Signatures of Particulate Minerals in the Visible and Near Infrared. GEOPHYSICS 1977, 42, 501–511. [Google Scholar] [CrossRef] [Green Version]

- Khan, A.; Schaefer, D.; Roscoe, B.; Sun, K.; Tao, L.; Miller, D.; Lary, D.J.; Zondlo, M.A. Open-Path Greenhouse Gas Sensor for UAV applications. In Proceedings of the 2012 Conference Lasers Electro-Optics, San Jose, CA, USA, 6–11 May 2013; Volume 1, p. JTh1L.6. [Google Scholar] [CrossRef]

- Hernandez Bennetts, V.; Lilienthal, A.J.; Neumann, P.P.; Trincavelli, M. Mobile Robots for Localizing Gas Emission Sources on Landfill Sites: Is Bio-Inspiration the Way to Go? Front. Neuroeng. 2012, 4, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Alvarado, M.; Gonzalez, F.; Fletcher, A.; Doshi, A. Towards the development of a low cost airborne sensing system to monitor dust particles after blasting at open-pit mine sites. Sensors 2015, 15, 19703–19723. [Google Scholar] [CrossRef] [Green Version]

- Malaver, A.; Gonzalez, F.; Motta, N. Towards the development of a gas sensor system to monitoring pollutant gases in the low troposphere using small unmanned aerial vehicles. In Proceedings of the 2012 Workshop on Robotics for Environmental Monitoring, Vilamoura, Portugal, 7 October 2012. [Google Scholar]

- Watai, T.; Machida, T.; Ishizaki, N.; Inoue, G. A lightweight observation system for atmospheric carbon dioxide concentration using a small unmanned aerial vehicle. J. Atmos. Ocean. Technol. 2006, 23, 700–710. [Google Scholar] [CrossRef]

- Brown, J. Remote Gas Sensing of SO 2 on a 2D CCD (Gas Camera). 6 October 2008. Available online: http://resonance.on.ca/index_htm_files/Gas%20Camera,%20Remote%20Gas%20Sensing%20of%20SO2%20on%20a%202D%20CCD,%20Concept%20Paper.pdf (accessed on 8 July 2020).

- Lega, M.; Napoli, R.M.A.; Persechino, G.; Kosmatka, J. New techniques in real-time 3D air quality monitoring: CO, NOx, O3, CO2, and PM. In Proceedings of the NAQC 2011, San Diego, CA, USA, 7–11 March 2011. [Google Scholar]

- Lega, M.; Kosmatka, J.; Ferrara, C.; Russo, F.; Napoli, R.M.A.; Persechino, G. Using Advanced Aerial Platforms and Infrared Thermography to Track Environmental Contamination. Environ. Forensics 2012, 13, 332–338. [Google Scholar] [CrossRef]

- Jordan, B.R. A birds-eye view of geology: The use of micro drones/UAVs in geologic fieldwork and education. GSA Today 2015, 25, 50–52. [Google Scholar] [CrossRef]

- Vergouw, B.; Nagel, H.; Bondt, G.; Custers, B. Drone Technology: Types, Payloads, Applications, Frequency Spectrum Issues and Future Developments; TMC Asser Press: The Hague, The Netherlands, 2016; pp. 21–45. [Google Scholar]

- Gupta, L.; Jain, R.; Vaszkun, G. Survey of Important Issues in UAV Communication Networks. IEEE Commun. Surv. Tutorials 2016, 18, 1123–1152. [Google Scholar] [CrossRef] [Green Version]

- The Fleye Drone Could Be the Safest Flying Robot at CES|Engadget. Available online: https://www.engadget.com/2016-01-08-the-fleye-drone-could-well-be-the-safest-flying-robot-at-ces.html (accessed on 9 May 2020).

- Flybotix–Professional Portable Drone. Available online: https://flybotix.com/ (accessed on 27 September 2019).

- Fleye|Home. Available online: https://www.gofleye.com/ (accessed on 27 September 2019).

- Japanese Defense Ministry Shows World’s First Spherical Flying Machine. Available online: https://newatlas.com/japanese-spherical-flying-machine/20286/ (accessed on 9 May 2020).

- Loh, B.; Jacob, J.D. Modeling and attitude control analysis of a spherical VTOL aerial vehicle. In Proceedings of the 51st AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Grapevine, TX, USA, 7–10 January 2013; pp. 1–15. [Google Scholar]

- Briod, A.; Kornatowski, P.; Zufferey, J.C.; Floreano, D. A collision-resilient flying Robot. J. Field Robot. 2014, 31, 496–509. [Google Scholar] [CrossRef] [Green Version]

- Mizutani, S.; Okada, Y.; Salaan, C.J.; Ishii, T.; Ohno, K.; Tadokoro, S. Proposal and experimental validation of a design strategy for a UAV with a passive rotating spherical shell. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Hamburg, Germany, 28 September–2 October 2015; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2015; pp. 1271–1278. [Google Scholar]

- Simha, A.; Tallam, M.; Shankar, H.N.; Muralishankar, R.; Hnln, S. Adaptive attitude control of the spherical drone on SO(3). In Proceedings of the International Conference on Distributed Computing, VLSI, Electrical Circuits and Robotics (DISCOVER), Mangalore, India, 13–14 August 2016; pp. 90–94. [Google Scholar] [CrossRef]

- Malandrakis, K.; Dixon, R.; Savvaris, A.; Tsourdos, A. Design and Development of a Novel Spherical UAV. IFAC-PapersOnLine 2016, 49, 320–325. [Google Scholar] [CrossRef]

- Yamada, W.; Yamada, K.; Manabe, H.; Ikeda, D. ISphere: Self-luminous spherical drone display. In Proceedings of the 30th Annual ACM Symposium on User Interface Software and Technology (UIST 2017), Quebec City, QC, Canada, 22–25 October 2017; pp. 635–643. [Google Scholar]

| Surface Mine | Underground Mines | Abandoned Mines |

|---|---|---|

|

|

|

| Type of Drone | Model | Goal | Wingspan (mm) | Length (mm) | Weight (g) | Endurance (min) | Payload (g) |

|---|---|---|---|---|---|---|---|

| Fixed-wing | Teklite | Characterization of blasting plumes | 900 | 575 | 900–950 | 45 | 200 |

| Fixed-wing | GoSurv | Characterization of blasting plumes | 850 | 350 | 900–1200 | 50 | >300 |

| Fixed-wing | Swamp Fox | Characterization of blasting plumes | 1800 | 1000 | 4500 | 40 | 1000 |

| Multirotor | Quadcopter | Characterization of blasting plumes | - | - | 2500 | 20 | 150 |

| Multirotor | Phantom 2 Vision+ | Topographic Survey | 35 cm | - | 1240 | 25 | - |

| Multirotor | Aeryon Scout | Measuring fracture orientations | 80×80×20 | - | 1300 | 25 | 400 |

| Applications | Objectives |

|---|---|

| Safety and risk management |

|

| Daily routines and control |

|

| Daily routines and control |

|

| Monthly routines |

|

| Strategic planning |

|

| Financial |

|

| Legal |

|

| Environmental |

|

| Infrastructure |

|

| Type of Drone | Model | Goal | Wingspan (mm) | Weight (g) | Endurance (min) | Payload (g) | Speed (m/s) |

|---|---|---|---|---|---|---|---|

| Helium gas balloon | Zeppelin | Monitoring inaccessible areas in an underground mine [64] | 1200 | - | - | - | - |

| Octocopter | DJI S1000 | Gas detection of underground coal fire [32] | 1045 | 4.2 | 15 | 1800~6800 | - |

| Quadcopter | DJI M210 | Reduce personnel exposure to unsafe conditions of underground mines [65] | 643 | 4570 | 13–24 | 1570 | 12 |

| Quadcopter | MATRICE 100 | Geotechnical data collection [66] | 650 | 2431 | 23 | 1169 | 5 |

| Quadcopter | D JI’s F450 | Underground void mapping [67] | 450 | - | - | - | |

| Quadcopter | D JI’s F450 | Underground mine rescue | 450 | 800–1600 | 33 | - | |

| Quadcopter | ELIOS | Supporting backfilling operations by monitoring shadow areas, identifying ground conditions in open stopes, and inspecting conveyor belts without interrupting operation [68] | 400 | 700 | 10 | - | 6.5 |

| Quadcopter | ELIOS2 | Same as ELIOS | 400 | 550 | 10 | - | 4.68 |

| Mine Type | Application | Description |

|---|---|---|

| Surface Mines | Surveying photogrammetry and hazardous subsidence mapping | - Creating a subsidence inventory map demonstrating the locations and details of past subsidence occurrence [18,97,98,99]. |

| Photogrammetry and filling material calculation | - Creating a high-quality 3D digital elevation model (DEM) to calculate the amount of required soil for the recultivation of a closed mine [100,101]. | |

| Anthropogenic formations of invasive plants on Abandoned Mine Lands | - Creating a map and determining accurate dimensions and volumes of anthropogenic landscape forms, such as landfills [102]. - Mapping of places where some invasive plants exist [102]. | |

| Rehabilitation | - Creating a 3D train model of mine lake in order to rehabilitate the abandoned mine [103,104]. | |

| Underground Mines | Pillar mapping | - Collecting data, communicating, and mapping pillars in abandoned underground mines when there is a risk of deploying a crew [105,106,107]. |

| Detection of gas storage | - Creating a 3D virtual mine map from 3D point cloud information of optical sensors to calculate the volume capacity for gas storage in abandoned mines [95,96]. | |

| Monitoring acid mine drainage | - Investigation and monitoring of acid mine drainage from abandoned mines and tailings to the water stream [108]. | |

| Mine shaft investigation | - Combination of the GPS data with the digital photographs taken by the drone to create orthorectified photography maps [18,109,110,111]. |

| Type of Drone. | Model | Goal | Where | Wingspan (mm) | Weight (g) | Endurance (min) |

|---|---|---|---|---|---|---|

| Multirotor | Phantom 2 Vision+ | Surveying photogrammetry | Open-pit limestone mine in Korea | 3500 | 1240 | 25 |

| Fixed-wing | - | Photogrammetry | Open-pit mine | 1000–3000 | 2000–5000 | - |

| Fixed-wing | AeroVironment RQ-11 Raven | Rehabilitation | Coal mine | 1372 | 1906 | 60–90 |

| Fixed-wing | SenseFly swingletCAM | Mine shaft investigation | Coal mine in UK | 116 | 1100–1400 | - |

| Multirotor | Honeywell RQ-16 T-Hawk | Rehabilitation | Coal mine | - | 8390 | 40 |

| Company | Mine site | Application |

|---|---|---|

| Hexagon | Coal mine | - The thermal image camera of the drone detects heat arising from the facilities in the dressing plant, such as the conveyor belt system, to prepare for the problems due to the overheating of the facilities. It can also quickly detect the self-ignition point of the coal in the coal mine to monitor accidents [115]. |

| Tir3D | Abandoned mineshaft in an exhausted mine | - The drone technology helps to prevent the environmental disruption caused due to mining by effectively investigating the location of the mineshaft of an exhausted mine [116]. |

| Instrument | Description | Gases/Particles | Characteristics |

|---|---|---|---|

| Handheld | |||

| Dräger X-am 5600 | Close-packed instrument for the measurement of up to 6 gases; follow standard IP67; IR sensor for CO2 and electrochemical for other gases. | O2, Cl2, CO, CO2, H2, H2S, HCN, NH3, NO, NO2, PH3, SO2, O3, Amine, Odorant, COCl2 and organic vapors. | Dimensions: 4.7 × 13.0 × 4.4 cm Weight: 250 g |

| Installed in ground vehicles | |||

| Picarro Surveyor | Cavity ring-down spectroscopy (CRDS) technology, sensitivity down to parts-per-billion (ppb); survey gas at traffic speeds and map results in real-time; real-time analysis to distinguish natural gas and other biogenic sources. | CO2, CO, CH4, and water vapor | Dimensions: Analyzer 43.2 × 17.8 × 44.6 cm; external pump 19 × 10.2 × 28.0 cm Weight: 24 kg + vehicle Power: 100–240 VAC |

| Tapered Element Oscillating Microbalance (TEOM) | Continuous particle monitoring. The tapered element consists of a filter cartridge installed on the tip of a hollow glass tube. Additional weight from particles that collect on the filter changes the frequency at which the tube oscillates. | Total suspended particles (TSP), PM10, PM2.5 | Dimensions: 43.2 × 48.3 × 127.0 cm) Weight: 34 kg Power: 100–240 VAC |

| Networks | |||

| AQMesh | Wireless monitor; high sensitivity (levels to ppb); designed to work through a network of arrayed monitors. | NO, NO2, O3, CO, SO2, humidity and atmospheric pressure. | Dimensions: 17.0 × 18.0 × 14.0 cm Weight: <2 kg Power: LiPo batteries |

| Airborne | |||

| Yellow scan | LIDAR technology with a total weight of 2.2 kg; 80,000 shots/s; resolution of 4 cm; class 1 laser at 905 nm. | Dust and aerosols | Dimensions: 17.2 × 20.6 × 4.7 cm Weight: 2.2 kg Power: 20 W |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahmoradi, J.; Talebi, E.; Roghanchi, P.; Hassanalian, M. A Comprehensive Review of Applications of Drone Technology in the Mining Industry. Drones 2020, 4, 34. https://doi.org/10.3390/drones4030034

Shahmoradi J, Talebi E, Roghanchi P, Hassanalian M. A Comprehensive Review of Applications of Drone Technology in the Mining Industry. Drones. 2020; 4(3):34. https://doi.org/10.3390/drones4030034

Chicago/Turabian StyleShahmoradi, Javad, Elaheh Talebi, Pedram Roghanchi, and Mostafa Hassanalian. 2020. "A Comprehensive Review of Applications of Drone Technology in the Mining Industry" Drones 4, no. 3: 34. https://doi.org/10.3390/drones4030034

APA StyleShahmoradi, J., Talebi, E., Roghanchi, P., & Hassanalian, M. (2020). A Comprehensive Review of Applications of Drone Technology in the Mining Industry. Drones, 4(3), 34. https://doi.org/10.3390/drones4030034