Experimental Investigation of Icing Effects on a Hovering Drone Rotor Performance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Cold Chamber

2.2. Drone Rotor Assembly

2.3. Test Parameters

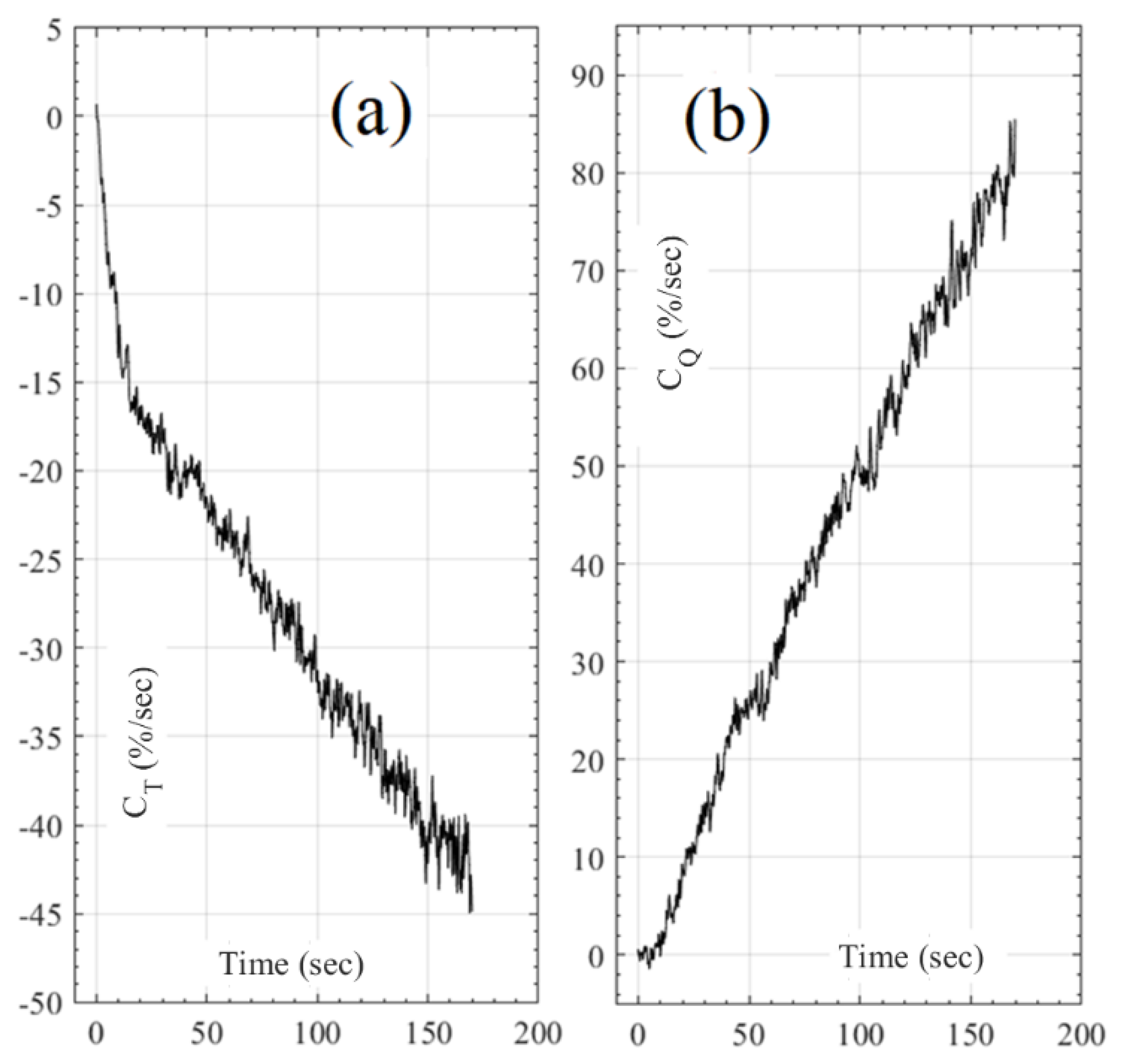

2.4. Post-Processing and Non-Dimensional Coefficients

3. Results

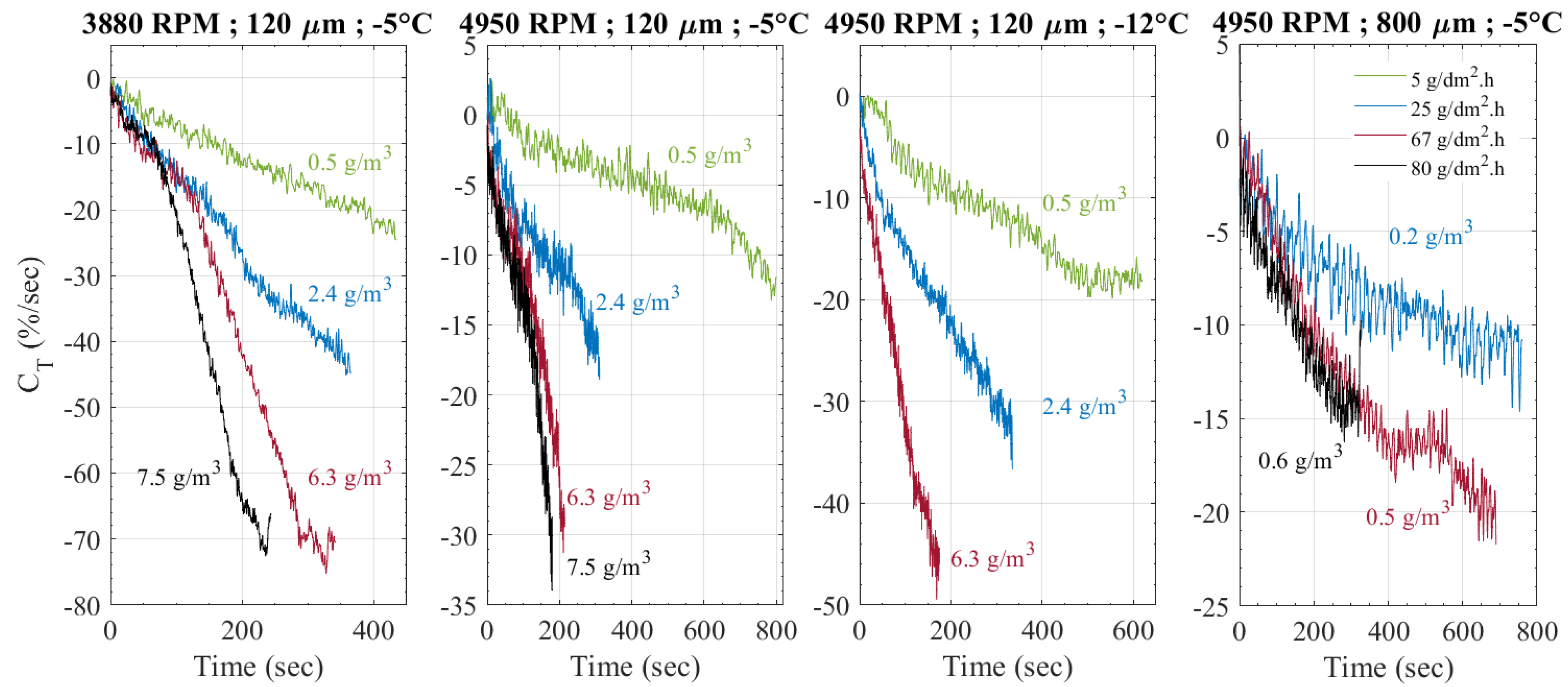

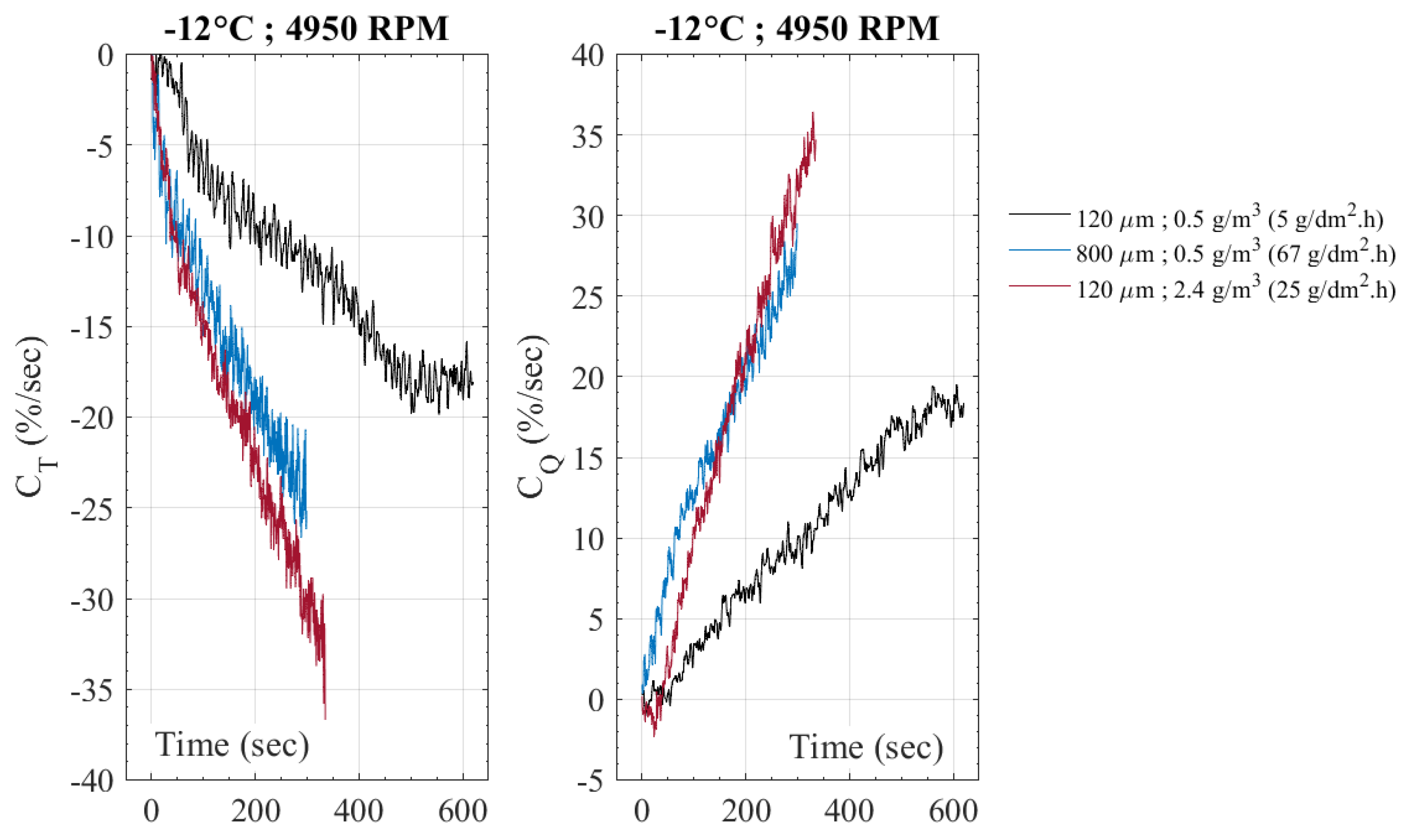

3.1. Icing Intensity (Precipitation Rate and Liquid Water Content)

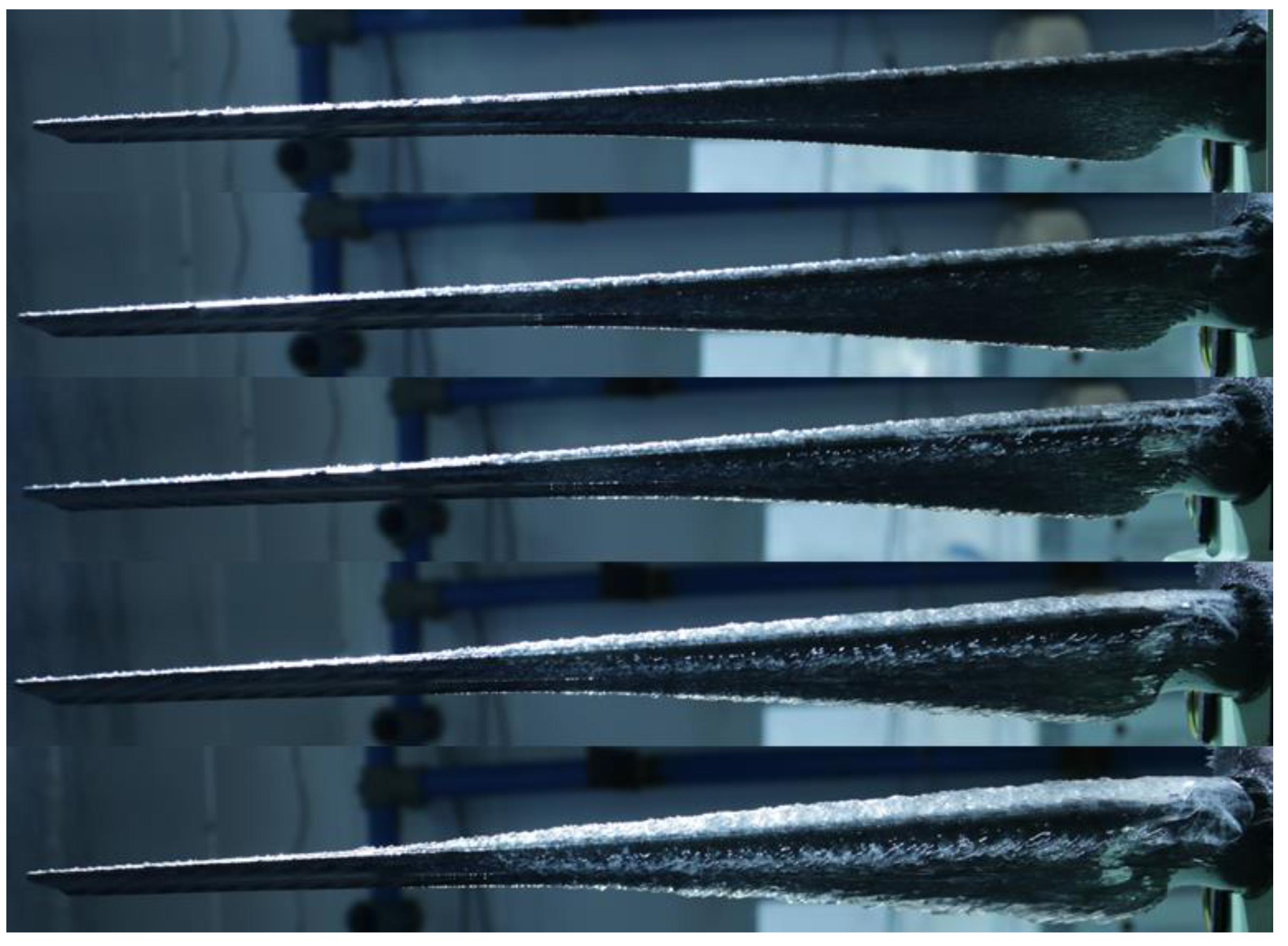

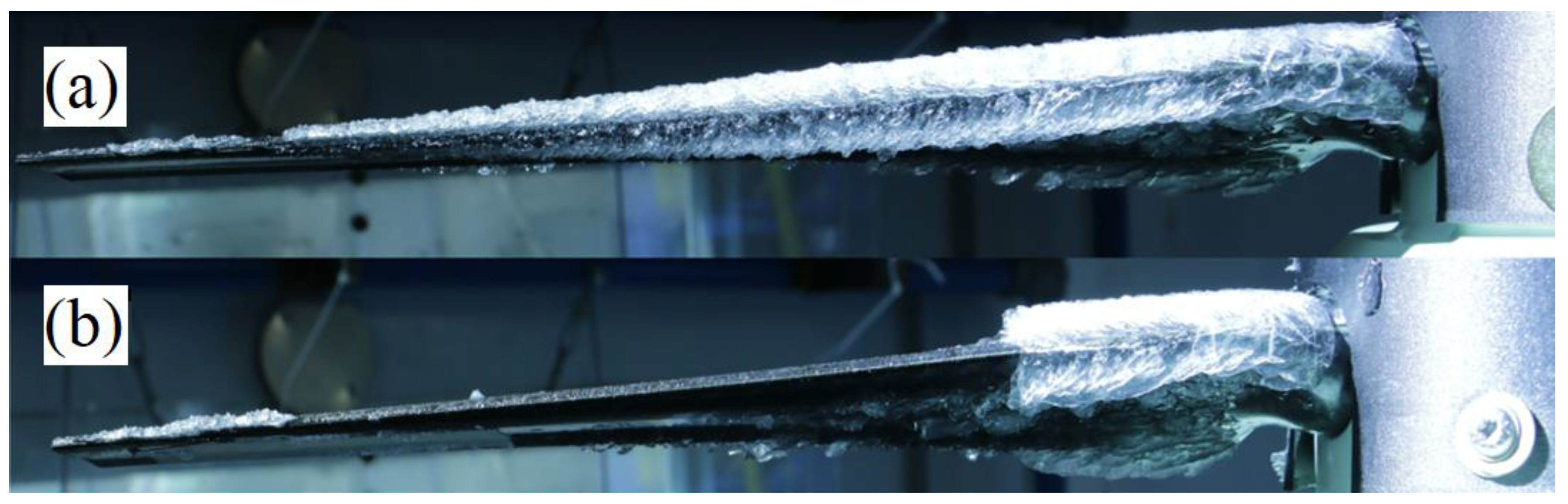

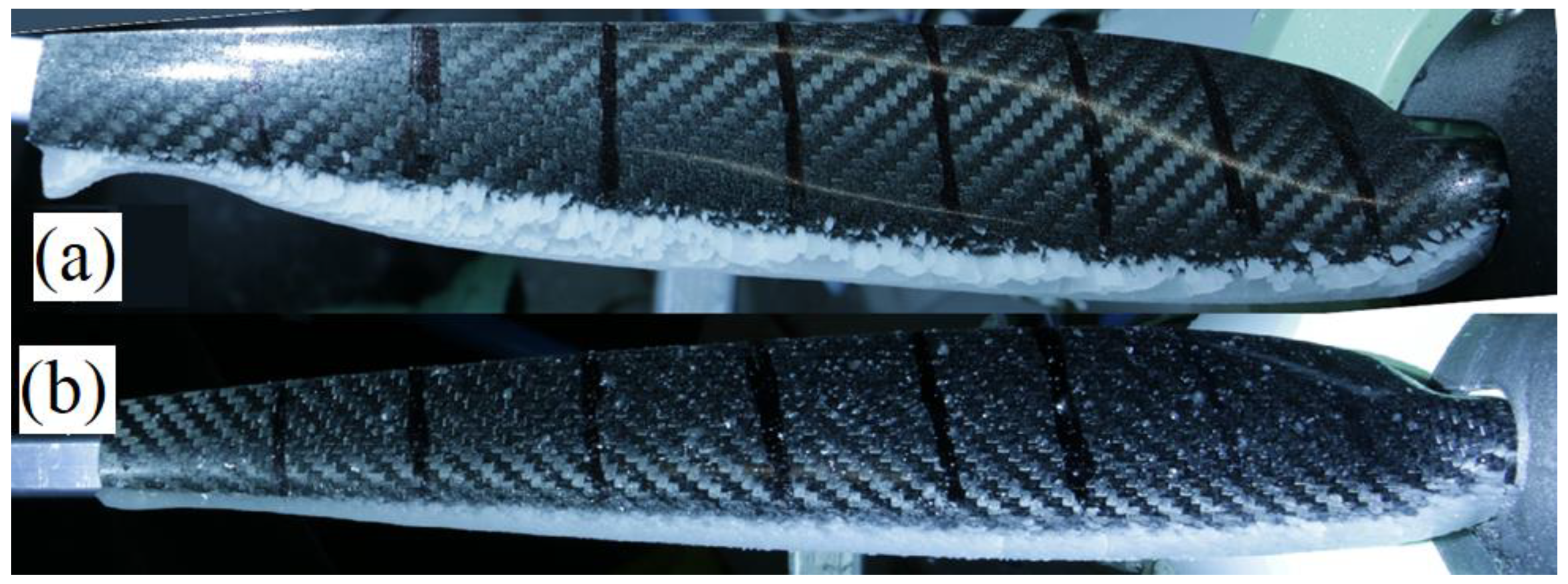

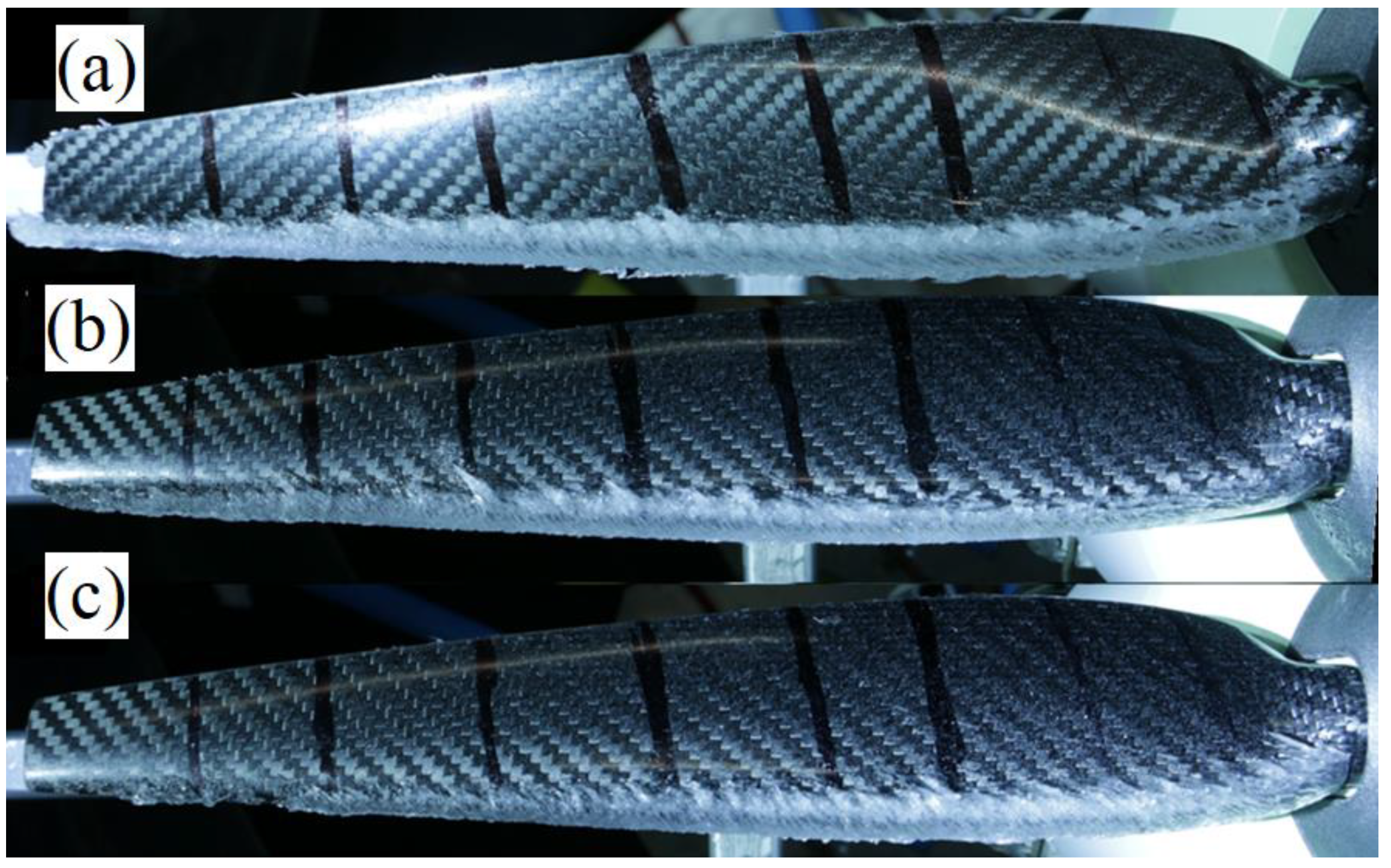

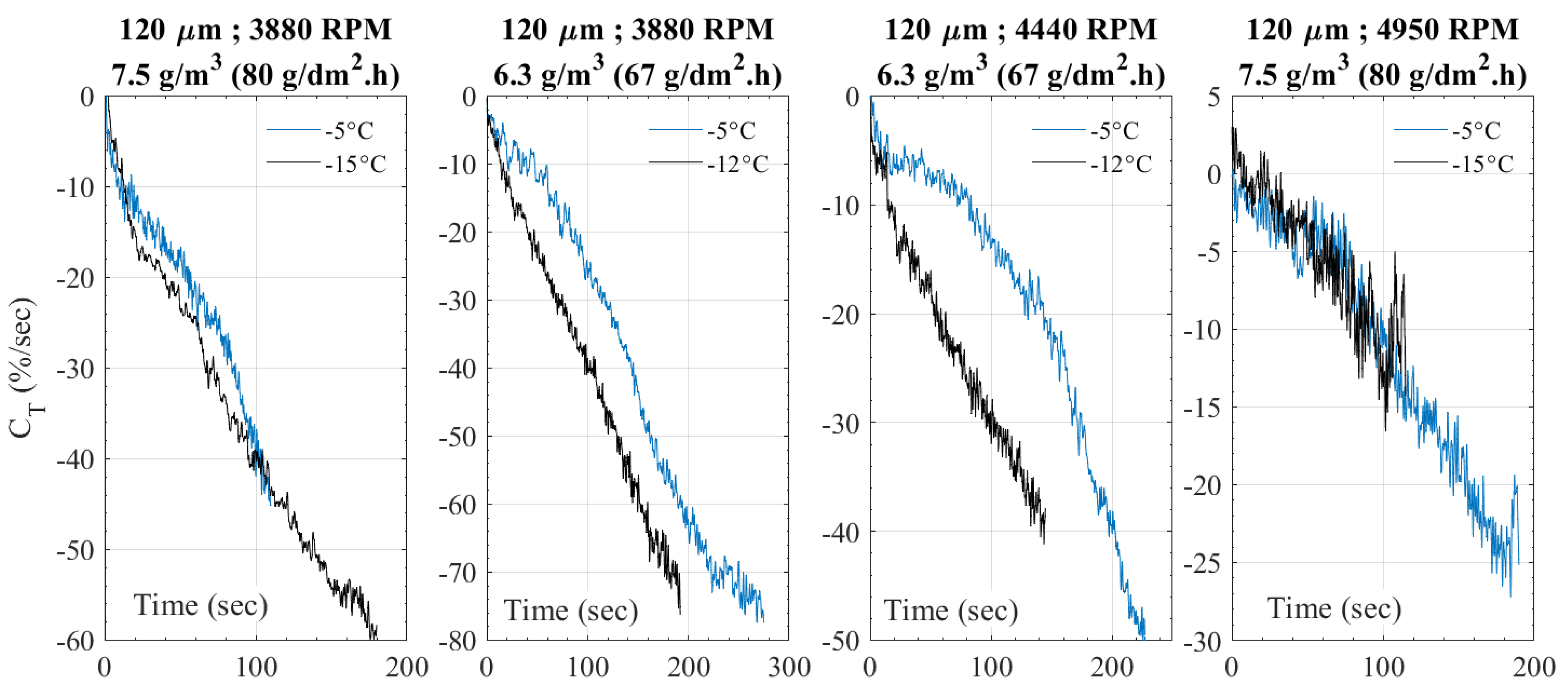

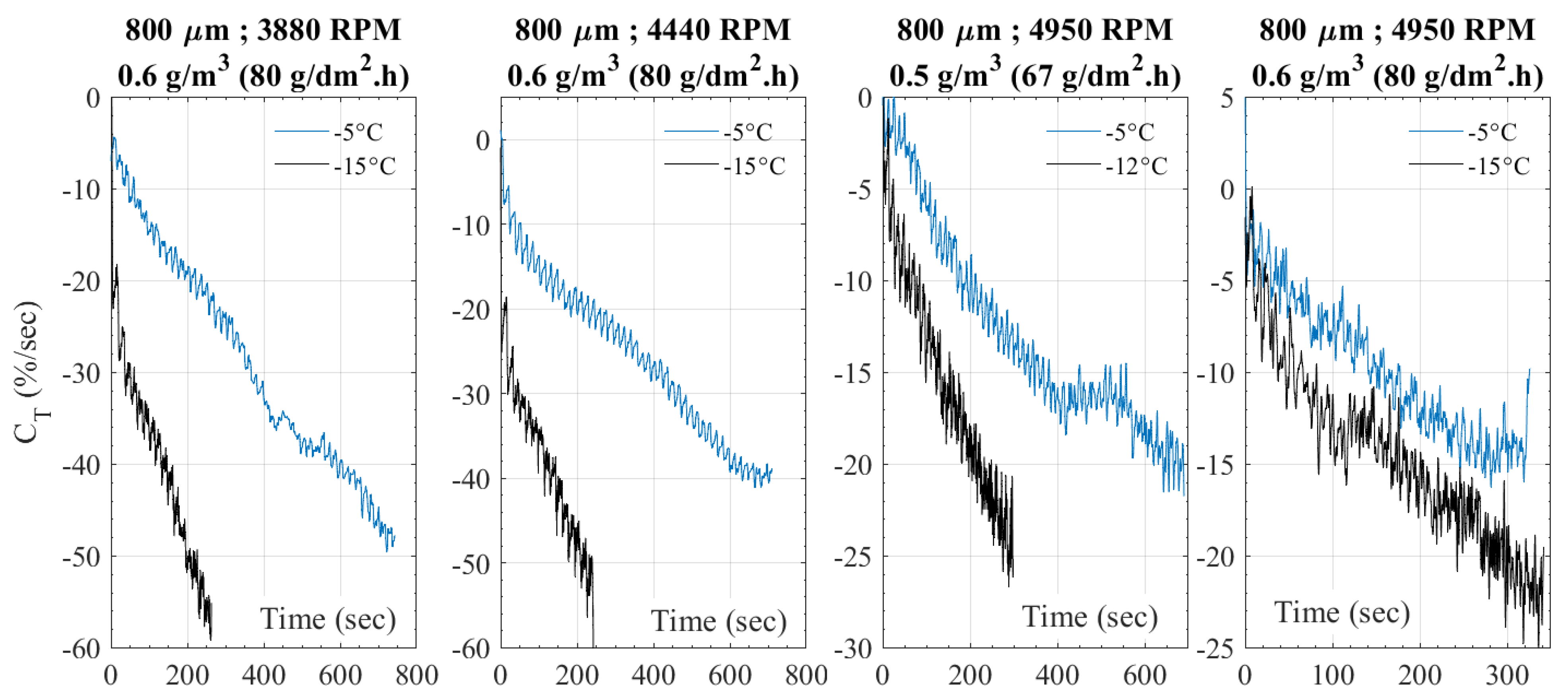

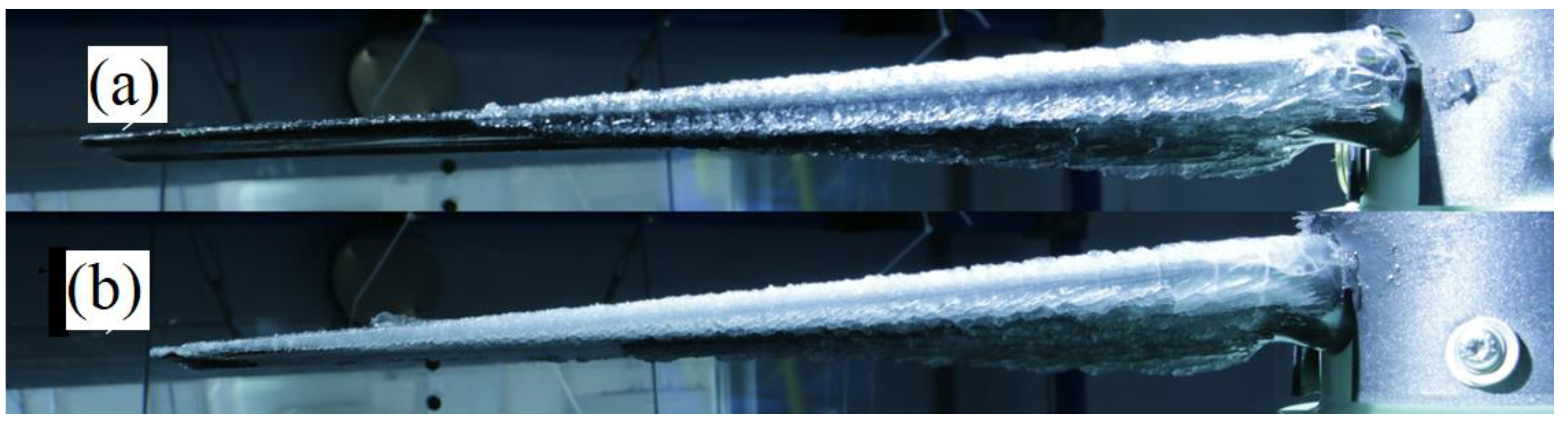

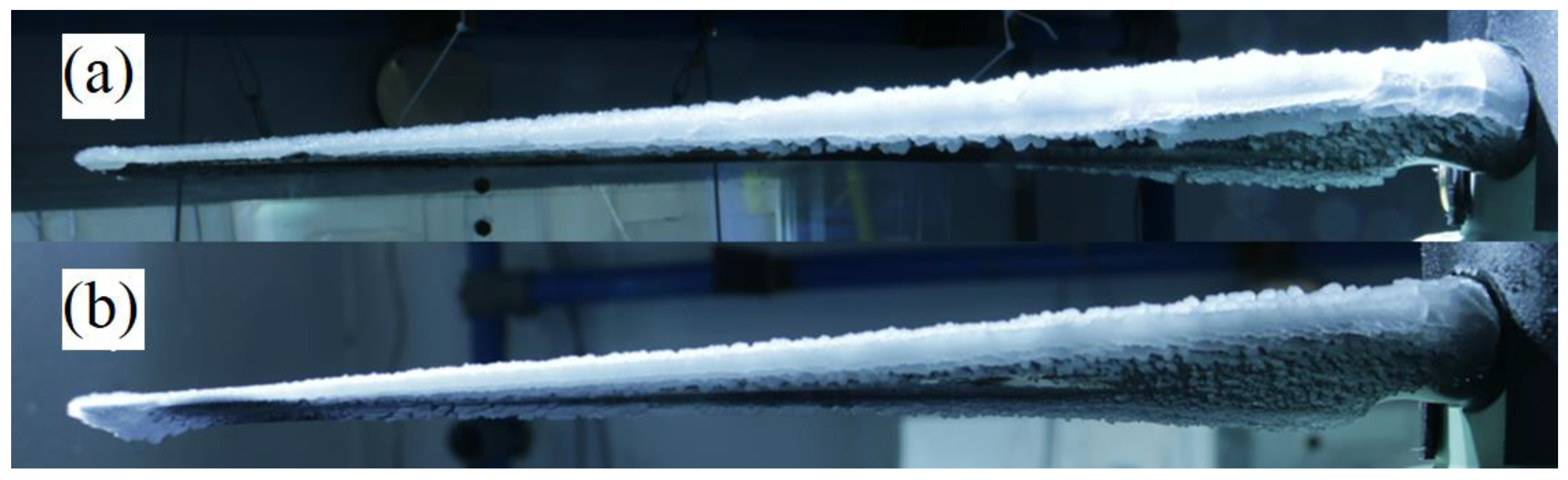

3.2. Droplet Size (MVD)

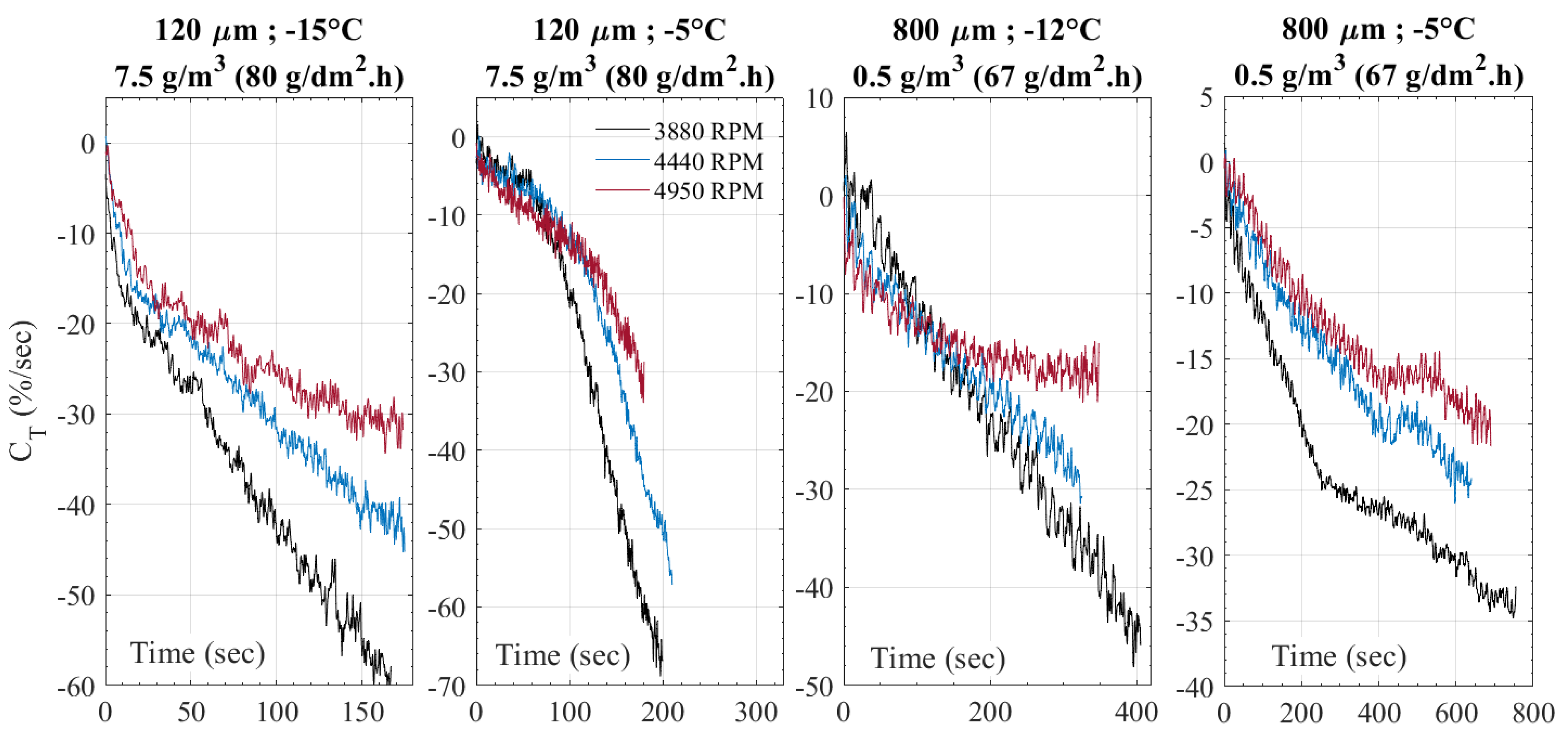

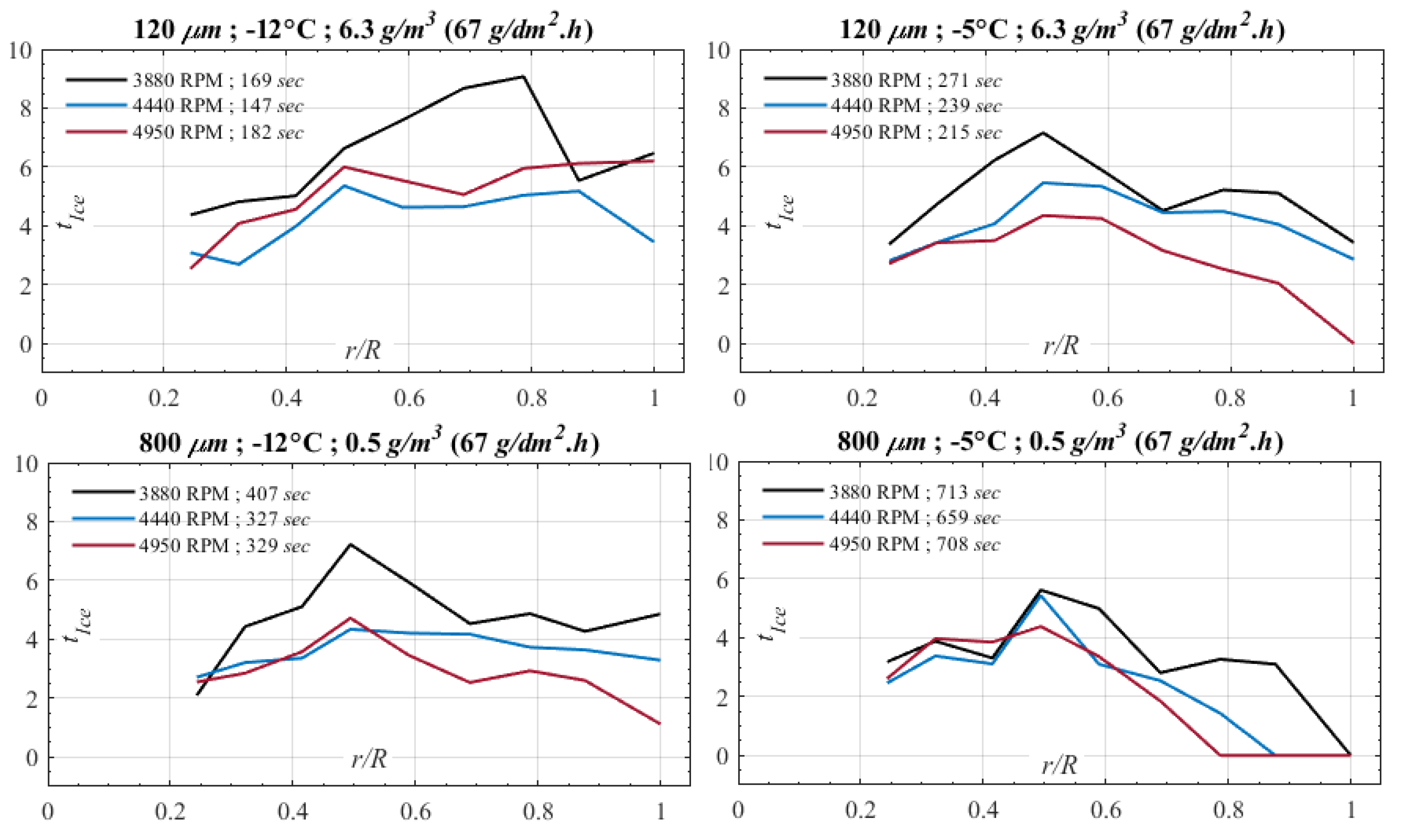

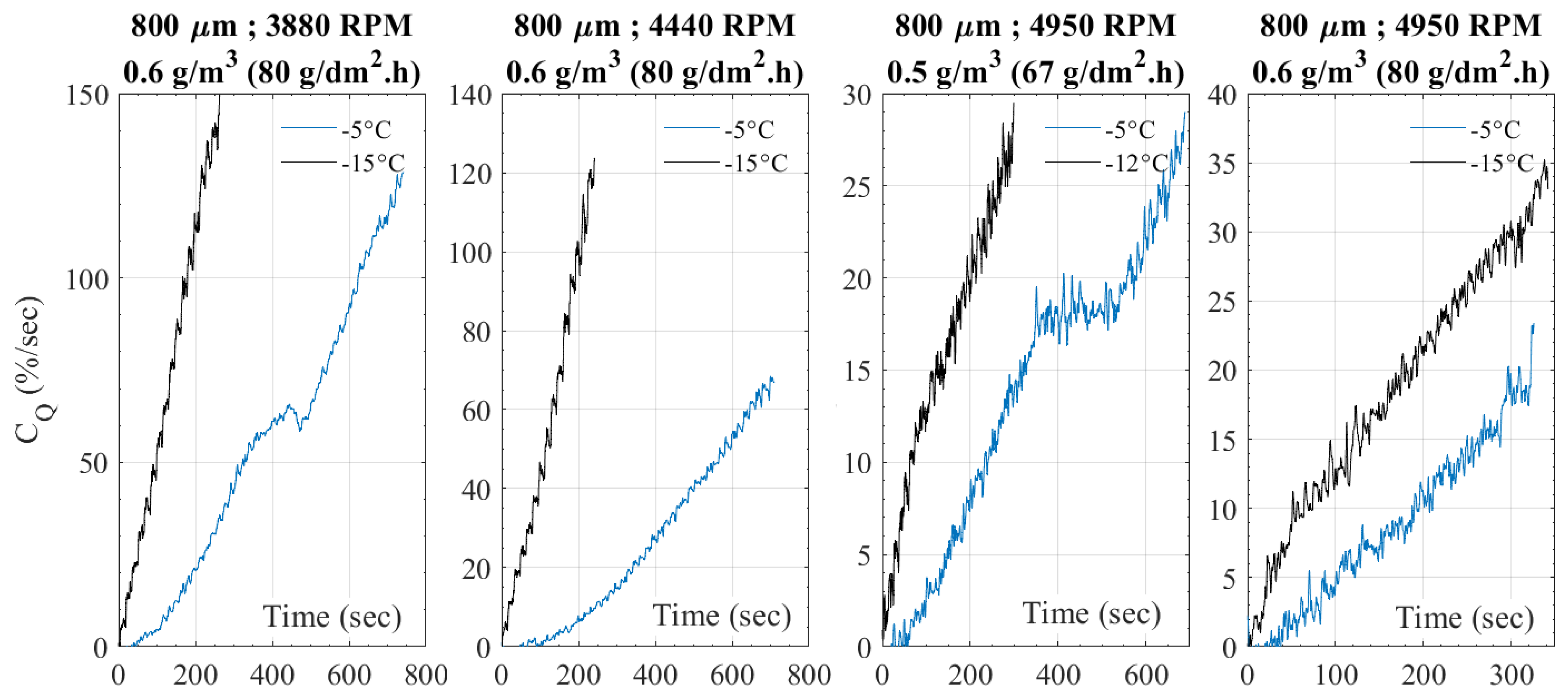

3.3. Rotor Speed

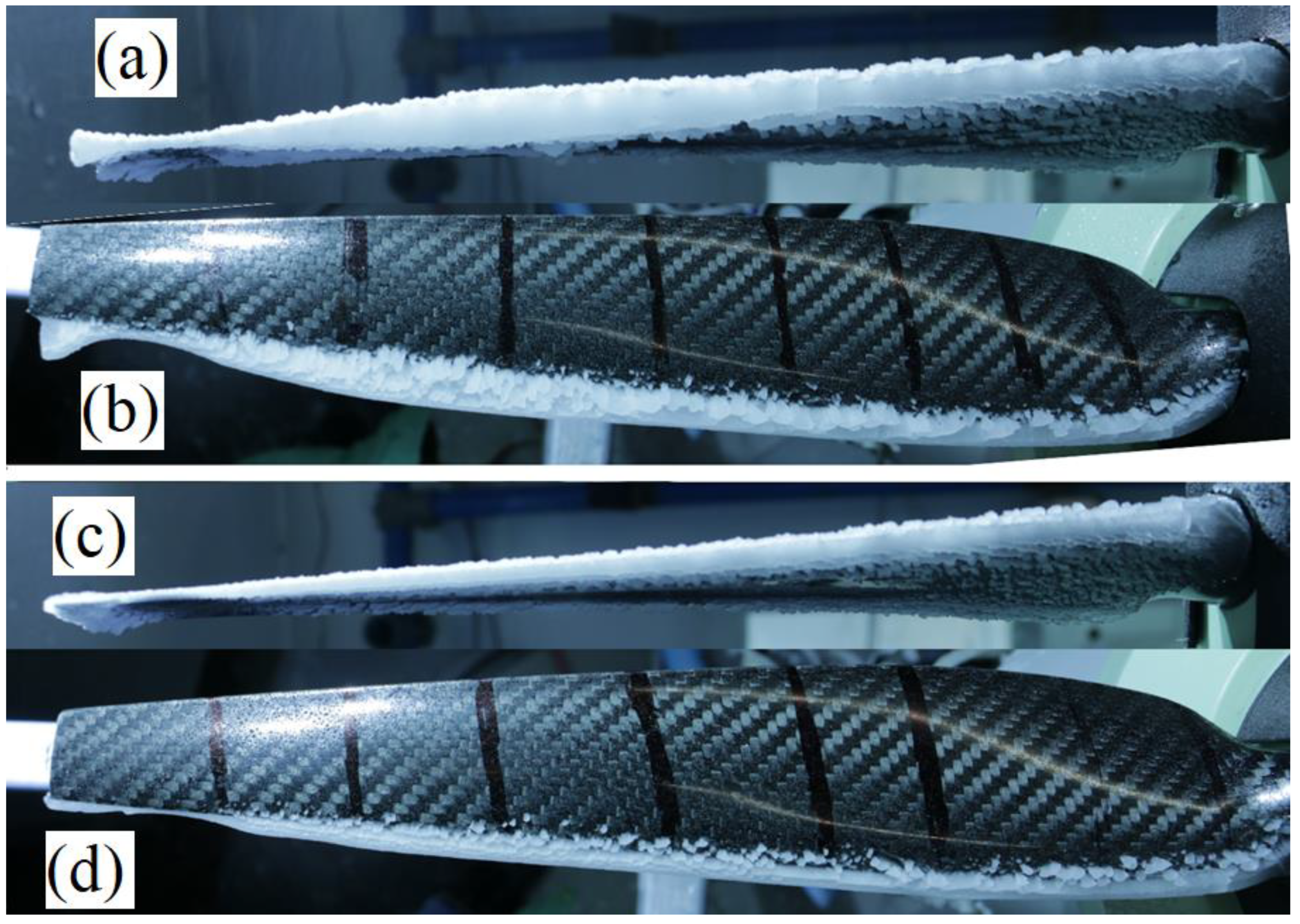

3.4. Air Temperature

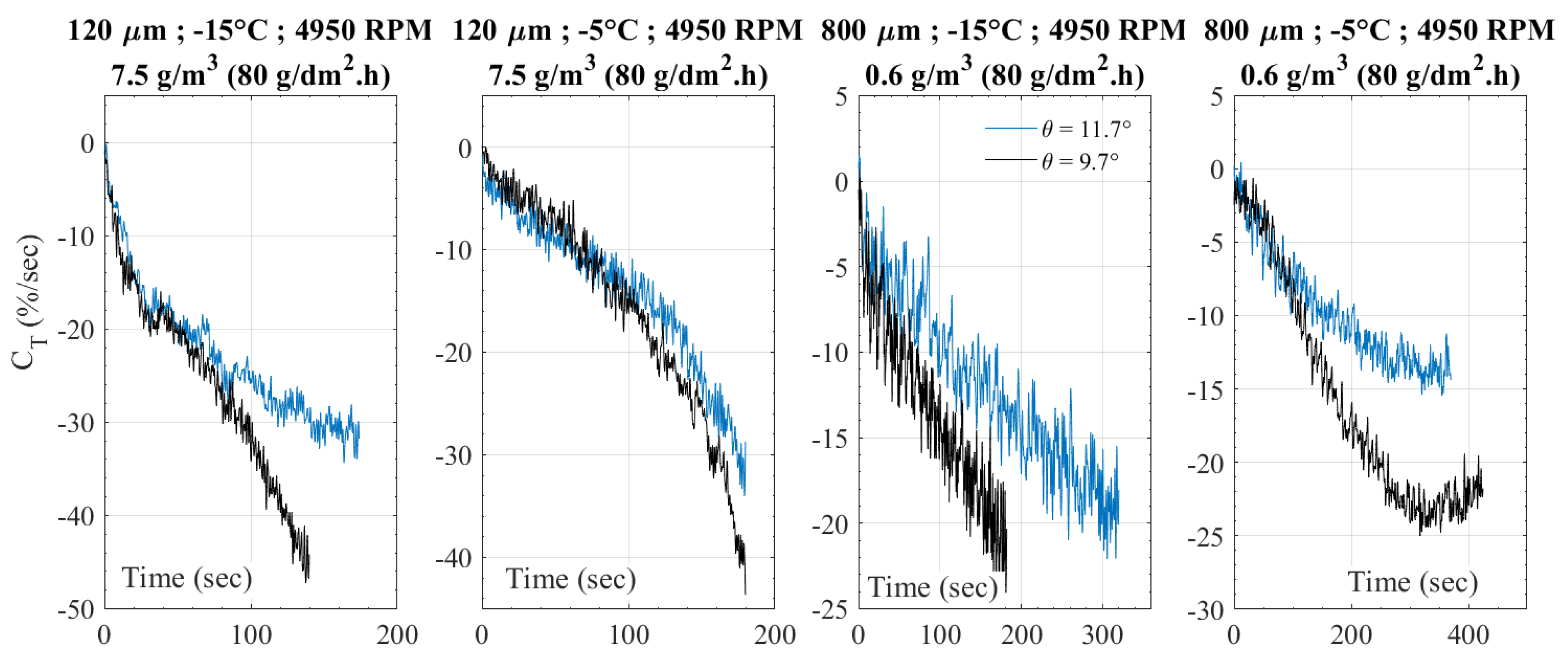

3.5. Pitch Angle

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Canada, T. Transport Canada’s Drone Strategy to 2025; Government of Canada: Ottawa, ON, Canada, 2021. [Google Scholar]

- Villeneuve, E.; Karmouch, E.; Boulerice, X. Development of a small and transportable de-icing/anti-icing drone-mounted system. Part 1: System design. Drone Syst. Appl. 2022, 2, 28. [Google Scholar] [CrossRef]

- Villeneuve, E.; Karmouch, E.; Boulerice, X. Development of a small and transportable de-icing/anti-icing drone-mounted system. Part 2: Prototype testing and proof of concept. Drone Syst. Appl. 2022, 10, 382–398. [Google Scholar] [CrossRef]

- Hann, R.; Johansen, T.A. Unsettled Topics in Unmanned Aerial Vehicle Icing; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2020. [Google Scholar]

- Yamazaki, M.; Jemcov, A.; Sakaue, H. A Review on the Current Status of Icing Physics and Mitigation in Aviation. J. Aerosp. 2021, 8, 188. [Google Scholar] [CrossRef]

- Siquig, R. Impact of Icing on Unmanned Aerial Vehicle (UAV) Operations; Naval Environmental Prediction Research Facility: Monterey, CA, USA, 1990. [Google Scholar]

- Henry, R.C.; Guffond, D.; Atilde, F.; Garnier, O.; Andre, B. Heat transfer coefficient measurement on iced airfoil in small icing wind tunnel. J. Thermophys. Heat Transf. 2000, 14, 348–354. [Google Scholar] [CrossRef]

- Dukhan, N.; Dukhan, N.; de Witt, K.J.; Masiulaniec, K.C.; van Fossen, G.J., Jr. Experimental Frossling numbers for ice-roughened NACA 0012 airfoils. J. Aircr. 2003, 40, 1161–1167. [Google Scholar] [CrossRef]

- Tsao, J.-C.; Lee, S. Evaluation of Icing Scaling on Swept NACA 0012 Airfoil Models; NASA Glenn Research Center: Cleveland, OH, USA, 2012. [Google Scholar]

- Tsao, J.-C. Further Evaluation of Swept Wing Icing Scaling with Maximum Combined Cross Section Ice Shape Profiles. In Proceedings of the 2018 Atmospheric and Space Environments Conference, 25–29 June 2018; American Institute of Aeronautics and Astronautics: Atlanta, GA, USA, 2018; p. 3183. [Google Scholar]

- Korkan, K. Experimental Study of Performance Degradation of a Rotating System in the NASA Lewis RC Icing Tunnel; Texas A&M University; Department of Aerospace Engineering: College Station, TX, USA, 1992. [Google Scholar]

- Brouwers, E.W.; Palacios, J.L.; Smith, E.C. The experimental investigation of a rotor hover icing model with shedding. In Proceedings of the American Helicopter Society 66th Annual Forum, Phoenix, AZ, USA, 11–13 May 2010; pp. 1863–1875. [Google Scholar]

- Palacios, J.L.; Han, Y.; Brouwers, E.W.; Smith, E.C. Icing environment rotor test stand liquid water content measurement procedures and ice shape correlation. J. Am. Helicopter Soc. 2012, 57, 29–40. [Google Scholar] [CrossRef]

- Liu, Y.; Li, L.; Hu, H. An Experimental Study on the Effects of Surface Wettability on the Ice Accretion over a Rotating UAS Propeller. In Proceedings of the 9th AIAA Atmospheric and Space Environments Conference, AIAA, Denver, CO, USA, 5–9 June 2017. [Google Scholar]

- Villeneuve, E.; Volat, C.; Ghinet, S. Numerical and Experimental Investigation of the Design of a Piezoelectric De-Icing System for Small Rotorcraft Part 3/3: Numerical Model and Experimental Validation of Vibration-Based De-Icing of a Flat Plate Structure. J. Aerosp. 2020, 7, 54. [Google Scholar] [CrossRef]

- Villeneuve, E.; Blackburn, C.; Volat, C. Design and Development of an Experimental Setup of Electrically Powered Spinning Rotor Blades in Icing Wind Tunnel and Preliminary Testing with Surface Coatings as Hybrid Protection Solution. J. Aerosp. 2021, 8, 98. [Google Scholar] [CrossRef]

- Villeneuve, E.; Ghinet, S.; Volat, C. Experimental Study of a Piezoelectric De-Icing System Implemented to Rotorcraft Blades. J. Appl. Sci. 2021, 11, 9869. [Google Scholar] [CrossRef]

- Samad, A.; Villeneuve, E.; Blackburn, C.; Morency, F.; Volat, C. An experimental investigation of the convective heat transfer on a small helicopter rotor with anti-icing and de-icing test setups. J. Aerosp. 2021, 8, 96. [Google Scholar] [CrossRef]

- Narducci, R.; Kreeger, R.E. Analysis of a Hovering Rotor in Icing Conditions; NASA: Phoenix, AZ, USA, 2012. [Google Scholar]

- Narducci, R.; Kreeger, R.E. Application of a High-Fidelity Icing Analysis Method to a Model-Scale Rotor in Forward Flight; NASA: Virginia Beach, VA, USA, 2012. [Google Scholar]

- Aubert, R. Additional Considerations for Analytical Modeling of Rotor Blade Ice. In Proceedings of the SAE 2015 International Conference on Icing of Aircraft, Engines, and Structures, 22–25 June 2015; SAE International: Prague, Czech Republic, 2015. [Google Scholar]

- Beaugendre, H.; Morency, F.; Habashi, W.G. FENSAP-ICE’s three-dimensional in-flight ice accretion module: ICE3D. J. Aircr. 2003, 40, 239–247. [Google Scholar] [CrossRef]

- Hannat, R.; Morency, F. Numerical validation of conjugate heat transfer method for anti-/de-icing piccolo system. J. Aircr. 2014, 51, 104–116. [Google Scholar] [CrossRef]

- Pendenza, A.; Habashi, W.G.; Fossati, M. A 3D mesh deformation technique for irregular in-flight ice accretion. Int. J. Numer. Methods Fluids 2015, 79, 215–242. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Y.; Wu, Q.; Chen, Z.; Peng, Y. Numerical Simulation and Optimization Analysis of Anti-/De-Icing Component of Helicopter Rotor Based on Big Data Analytics. In Proceedings of the Theory, Methodology, Tools and Applications for Modeling and Simulation of Complex Systems, AsiaSim 2016, SCS AutumnSim 2016, Beijing, China, 8–11 October 2016; Springer: Singapore, 2016; pp. 585–601. [Google Scholar]

- Lavoie, P.; Pena, D.; Hoarau, Y.; Laurendeau, E. Comparison of thermodynamic models for ice accretion on airfoils. Int. J. Numer. Methods Heat Fluid Flow 2018, 28, 1004–1030. [Google Scholar] [CrossRef]

- Özgen, S.; Canıbek, M. Ice accretion simulation on multi-element airfoils using extended Messinger model. J. Heat Mass Transf. 2009, 45, 305–322. [Google Scholar] [CrossRef]

- Bottyán, Z. Landscape and Environment. In-flight icing characteristics of unmanned aerial vehicles during special atmospheric condition over the carpathian-basin. ACTA Geogr. Debrecina Landsc. Environ. 2014, 7, 74–80. [Google Scholar]

- Szilder, K.; McIlwain, S. In-flight icing of UAVs–the influence of flight speed coupled with chord size. Can. Aeronaut. Space J. 2012, 58, 83–94. [Google Scholar] [CrossRef]

- Armanini, S.F.; Polak, M.; Gautrey, J.E.; Lucas, A.; Whidborne, J.F. Decision-making for unmanned aerial vehicle operation in icing conditions. CEAS Aeronaut. J. 2016, 7, 663–675. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Li, L.; Ning, Z.; Tian, W.; Hu, H. Experimental investigation on the dynamic icing process over a rotating propeller model. J. Propuls. Power 2018, 34, 933–946. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Li, L.; Li, H.; Hu, H. An experimental study of surface wettability effects on dynamic ice accretion process over an UAS propeller model. Aerosp. Sci. Technol. 2018, 73, 164–172. [Google Scholar] [CrossRef]

- Hann, R.; Enache, A.; Nielsen, M.; Stovner, B.; van Beeck, J.; Johansen, T.; Borup, K. Experimental Heat Loads for Electrothermal Anti-Icing and De-Icing on UAVs. J. Aerosp. 2021, 8, 83. [Google Scholar] [CrossRef]

- Villeneuve, E.; Samad, A.; Volat, C.; Béland, M.; Lapalme, M. An Experimental Apparatus for Icing Tests of Low Altitude Hovering Drones. Drones 2022, 6, 68. [Google Scholar] [CrossRef]

- Jeck, R.K. FAA/AR-09/45: Models and Characteristics of Freezing Rain and Freezing Drizzle for Aircraft Icing Applications; Federal Aviation Administration, Department of Transportation: Springfield, VA, USA, 2010. [Google Scholar]

- SAE. Endurance Time Tests for Aircraft Deicing/Anti-Icing Fluids SAE Type II, III, and IV—Aerospace Standard ARP5485; G-12HOT Holdover Time Committee; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

- SAE. Water Spray and High Humidity Endurance Test Methods for AMS1424 and AMS1428 Aircraft Deicing/Anti-Icing Fluids–Aerospace Standard ARP5901; G-12ADF Aircraft Deicing Fluids; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Anttho, A.M.; Slupski, B.J.; Mohiudeen, A.; Kara, K. Determination of Water Droplet Collection Efficiency: An Empirical Model. In Proceedings of the AIAA Atmospheric Flight Mechanics Conference, Grapevine, TX, USA, 9–13 January 2017. [Google Scholar]

- Orchard, D. Investigation of tolerance for icing of UAV rotors/propellers: Phase 3 test results. In Laboratory Memorandum (National Research Council of Canada. Aerospace. Aerodynamics Laboratory); no. LM-AL-2021-0051; National Research Council of Canada; Aerospace: Ottawa, ON, Canada, 2021. [Google Scholar]

- Xi, C.; Qi-Jun, Z. Numerical simulations for ice accretion on rotors using new three-dimensional icing model. J. Aircr. 2017, 54, 1428–1442. [Google Scholar] [CrossRef]

- Lee, J.D.; Harding, R.; Palko, R.L. Documentation of Ice Shapes on the Main Rotor of a UH-1H Helicopter in Hover; NASA: Columbus, OH, USA, 1984. [Google Scholar]

- Wang, Z.; Zhu, C.; Zhao, N. Experimental Study on the Effect of Different Parameters on Rotor Blade Icing in a Cold Chamber. Appl. Sci. 2020, 10, 5884. [Google Scholar] [CrossRef]

- Hansman, R.J., Jr.; Yamaguchi, K.; Berkowitz, B.; Potapczuk, M. Modeling of surface roughness effects on glaze ice accretion. J. Thermophys. Heat Transf. 1991, 5, 54–60. [Google Scholar] [CrossRef]

| Temp. (°C) | λ (g/dm2.hr) | MVD (μm) | LWC (g/m3) | Rational |

|---|---|---|---|---|

| −15, −12 and −5 | 5 | 120 | 0.5 | 0.5 g/m3 (FAA/AR-09/45) |

| 25 | 120 | 2.4 | Typical Ground Icing + Light Rain (2 L/h/m2) | |

| 25 | 800 | 0.2 | Typical Ground Icing + Light Rain (2 L/h/m2) | |

| 67 | 120 | 6.3 | 0.25 in. Water/h for APT70 Requirement + Moderate Rain (6.75 L/h/m2) | |

| 67 | 800 | 0.5 | 0.25 in. Water/h for APT70 Requirement + 0.5 g/m3 (FAA/AR-09/45) + Moderate Rain (6.75 L/h/m2) | |

| 80 | 120 | 7.5 | Typical Ground Icing + Moderate Rain (8 L/h/m2) | |

| 80 | 800 | 0.6 | Typical Ground Icing + Moderate Rain (8 L/h/m2) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Villeneuve, E.; Samad, A.; Volat, C.; Béland, M.; Lapalme, M. Experimental Investigation of Icing Effects on a Hovering Drone Rotor Performance. Drones 2022, 6, 345. https://doi.org/10.3390/drones6110345

Villeneuve E, Samad A, Volat C, Béland M, Lapalme M. Experimental Investigation of Icing Effects on a Hovering Drone Rotor Performance. Drones. 2022; 6(11):345. https://doi.org/10.3390/drones6110345

Chicago/Turabian StyleVilleneuve, Eric, Abdallah Samad, Christophe Volat, Mathieu Béland, and Maxime Lapalme. 2022. "Experimental Investigation of Icing Effects on a Hovering Drone Rotor Performance" Drones 6, no. 11: 345. https://doi.org/10.3390/drones6110345

APA StyleVilleneuve, E., Samad, A., Volat, C., Béland, M., & Lapalme, M. (2022). Experimental Investigation of Icing Effects on a Hovering Drone Rotor Performance. Drones, 6(11), 345. https://doi.org/10.3390/drones6110345