Design and Implementation of Sensor Platform for UAV-Based Target Tracking and Obstacle Avoidance

Abstract

:1. Introduction

2. Problem Statement and Methodology

3. Custom Platform Design

3.1. Airframe Selection

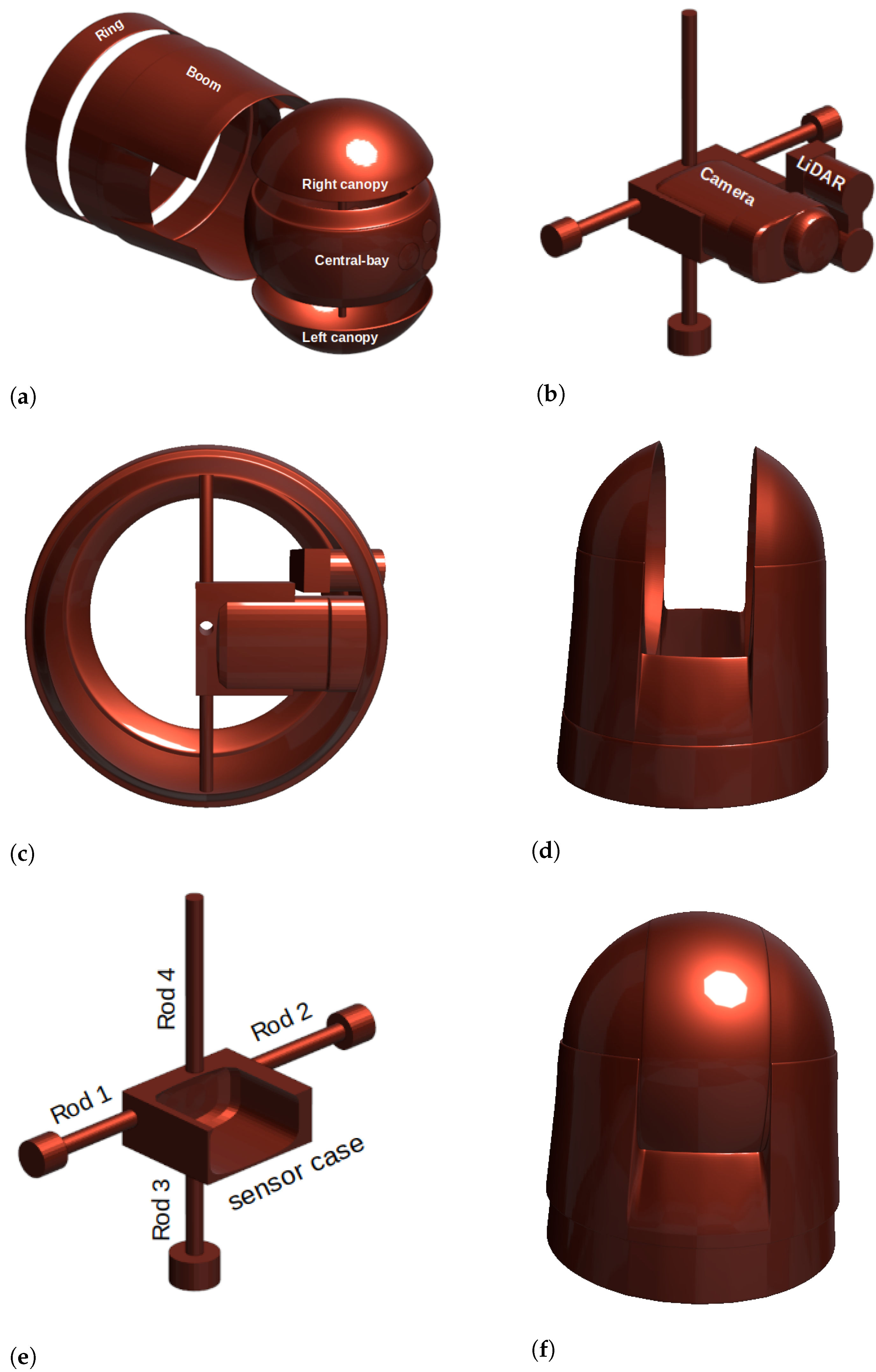

3.2. Platform Design

3.3. Platform Implementation Techniques

4. Platform Motion Control

4.1. Kinematics of the Platform

4.1.1. Coordinated Frame Transformation

4.1.2. Jacobian Transformation

4.2. Dynamics of the Platform

5. Platform Performance Validation Test

SITL-Based Performance Tests

Gazebo Simulation Environment

- ⊙

- The platform engages the sensors for obstacle avoidance if the parameter is tuned to be in a certain range of values and UAV flight status is in either of the following flight modes:

- ⊳

- automatic take-off;

- ⊳

- automatic landing;

- ⊳

- fly to a known location of interest (e.g., crime scene);

- ⊳

- return-to-launch.

- ⊙

- Under the condition that the UAV is in hover or altitude control mode, manual override of the mode is disabled and the platform is set to ready to be manually steered by RC transmitter to search for an intended target. Although manual override is disabled during a UAV’s hover and altitude control mode, flight mode switching is active and can be carried out through either aground control unit or an RC transmitter.

- ⊙

- If a target is identified and the parameter is tuned to certain range of values, then the platform locks on the target and pursues it. The flight mode is then switched to mission so that the UAV tracks the target.

6. Results and Discussion

6.1. Obstacle Avoidance

6.2. Target Tracking

7. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Burgués, J.; Marco, S. Environmental chemical sensing using small drones: A review. Sci. Total Environ. 2020, 748, 141172. [Google Scholar] [CrossRef] [PubMed]

- Smith, M.L.; Smith, L.N.; Hansen, M.F. The quiet revolution in machine vision—A state-of-the-art survey paper, including historical review, perspectives, and future directions. Comput. Ind. 2021, 130, 103472. [Google Scholar] [CrossRef]

- Agarwal, A.; Kumar, S.; Singh, D. Development of Neural Network Based Adaptive Change Detection Technique for Land Terrain Monitoring with Satellite and Drone Images. Def. Sci. 2019, 69, 474. [Google Scholar] [CrossRef]

- Salhaoui, M.; Guerrero-González, A.; Arioua, M.; Ortiz, F.J.; El Oualkadi, A.; Torregrosa, C.L. Smart Industrial IoT Monitoring and Control System Based on UAV and Cloud Computing Applied to a Concrete Plant. Sensors 2019, 19, 3316. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Glaser, A. Police Departments Are Using Drones to Find and Chase down Suspects. Vox. 2017. Available online: https://www.vox.com/2017/4/6/15209290/police-fire-department-acquired-drone-us-flying-robot-law-enforcement (accessed on 28 December 2021).

- Murphy, D.W.; Cycon, J. Application for mini VTOL UAV for law enforcement. In Proceedings of the Volume 3577, Sensors, C3I, Information, and Training Technologies for Law Enforcement, Boston, MA, USA, 7 January 1999. [Google Scholar] [CrossRef] [Green Version]

- Durscher, R. How Law Enforcement Has Been Using Drones. Government Fleet. 2020. Available online: https://www.government-fleet.com/359403/how-law-enforcement-has-been-utilizing-drones (accessed on 28 December 2021).

- Hardin, P.J.; Jensen, R.R. Small-Scale Unmanned Aerial Vehicles in Environmental Remote Sensing: Challenges and Opportunities. J. GISci. Remote Sens. 2011, 48, 99–111. [Google Scholar] [CrossRef]

- Geuther, S.; Capristan, F.; Kirk, J.; Erhard, R. A VTOL small unmanned aircraft system to expand payload capabilities. In Proceedings of the 31st Congress of the International Council of the Aeronautical Sciences, Belo Horizonte, Brazil, 9–14 September 2018. [Google Scholar]

- Chand, B.N.; Mahalakshmi, P.; Naidu, V.P.S. Sense and Avoid Technology in Unmanned Aerial Vehicles: A Review. In Proceedings of the International Conference on Electrical, Electronics, Communication, Computer and Optimization Techniques, Mysuru, India, 15–16 December 2017. [Google Scholar]

- Mukhamediev, R.I.; Symagulov, A.; Kuchin, Y.; Zaitseva, E.; Bekbotayeva, A.; Yakunin, K.; Assanov, I.; Levashenko, V.; Popova, Y.; Akzhalova, A.; et al. Review of Some Applications of Unmanned Aerial Vehicles Technology in the Resource-Rich Country. Appl. Sci. 2021, 11, 10171. [Google Scholar] [CrossRef]

- Hardin, P.J.; Lulla, V.; Jensen, R.R.; Jensen, J.R. Small Unmanned Aerial Systems (sUAS) for environmental remote sensing: Challenges and opportunities revisited. GISci. Remote Sens. 2019, 56, 309–322. [Google Scholar] [CrossRef]

- Zhang, J. Multi-source remote sensing data fusion: Status and trends. Int. J. Image Data Fusion 2010, 1, 5–24. [Google Scholar] [CrossRef] [Green Version]

- Khaleghi, B.; Khamis, A.; Karray, F.O.; Razavi, S.N. Multisensor data fusion: A review of the state-of-the-art. Inf. Fusion 2013, 14, 28–44. [Google Scholar] [CrossRef]

- Quigley, M.; Goodrich, M.A.; Griffiths, S.; Eldredge, A.; Beard, R.W. Target Acquisition, Localization, and Surveillance Using a Fixed-Wing Mini-UAV and Gimbaled Camera. In Proceedings of the 2005 IEEE International Conference on Robotics and Automation, Barcelona, Spain, 18–22 April 2005. [Google Scholar]

- Kuzey, B.; Yemenicioğlu, E.; Kuzucu, A. 2 Axis Gimbal Camera Design. ResearchGate 2007, 1, 32–39. [Google Scholar] [CrossRef]

- Gremsy. Stabilizing Gimbals & Stabilized Camera Mounts for Drones & UAVs. Unmanned System Technology. Available online: https://www.unmannedsystemstechnology.com/company/gremsy/ (accessed on 12 October 2021).

- Sánchez, P.; Casado, R.; Bermúdez, A. Real-Time Collision-Free Navigation of Multiple UAVs Based on Bounding Boxes. Electronics 2020, 9, 1632. [Google Scholar] [CrossRef]

- Shakhatreh, H.; Sawalmeh, A.; Al-Fuqaha, A.I.; Dou, Z.; Almaita, E.; Khalil, I.M.; Othman, N.S.; Khreishah, A.; Guizani, M. Unmanned Aerial Vehicles: A Survey on Civil Applications and Key Research Challenges. arXiv 2018, arXiv:1805.00881. [Google Scholar] [CrossRef]

- Lancovs, D. Broadcast transponders for low flying unmanned aerial vehicles. Transp. Res. Procedia 2017, 24, 370–376. [Google Scholar] [CrossRef]

- Ahmad, M.H.; Osman, K.; Zakeri, M.F.M.; Samsudin, S.I. Mathematical Modelling and PID Controller Design for Two DOF Gimbal System. In Proceedings of the 2021 IEEE 17th International Colloquium on Signal Processing & Its Applications (CSPA), Langkawi, Malaysia, 5–6 March 2021. [Google Scholar] [CrossRef]

- Isaev, A.M.; Adamchuk, A.S.; Amirokov, S.R.; Isaev, M.A.; Grazhdankin, M.A. Mathematical Modelling of the Stabilization System for a Mobile Base Video Camera Using Quaternions. Available online: http://ceur-ws.org/Vol-2254/10000051.pdf (accessed on 17 February 2022).

- Aytaç, A.; Rıfat, H. Model predictive control of three-axis gimbal system mounted on UAV for real-time target tracking under external disturbances. Mech. Syst. Signal Process. 2020, 138, 106548. [Google Scholar] [CrossRef]

- Nguyen, K.D.; Nguyen, T.T. Vision-based software-in-the-loop-simulation for Unmanned Aerial Vehicle Using Gazebo and PX4 Open Source. In Proceedings of the 2019 International Conference on System Science and Engineering (ICSSE), Dong Hoi, Vietnam, 20–21 July 2019. [Google Scholar]

- Nguyen, K.D.; Ha, C. Development of Hardware-in-the-Loop Simulation Based on Gazebo and Pixhawk for Unmanned Aerial Vehicles. Int. J. Aeronaut. Space Sci. 2018, 19, 238–249. [Google Scholar] [CrossRef]

- Omar, H.M. Hardware-In-the-Loop Simulation of Time-Delayed Anti-SwingController for Quadrotor with Suspended Load. Appl. Sci. 2022, 12, 1706. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| platform thickness | mm | 3 |

| canopy diameter | mm | 128.3 |

| boom—front diameter | mm | 140.1 |

| boom—rear diameter | mm | 153.9 |

| boom—length | mm | 99.4 |

| ring—front diameter | mm | 156.0 |

| ring—rear diameter | mm | 156.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tullu, A.; Hassanalian, M.; Hwang, H.-Y. Design and Implementation of Sensor Platform for UAV-Based Target Tracking and Obstacle Avoidance. Drones 2022, 6, 89. https://doi.org/10.3390/drones6040089

Tullu A, Hassanalian M, Hwang H-Y. Design and Implementation of Sensor Platform for UAV-Based Target Tracking and Obstacle Avoidance. Drones. 2022; 6(4):89. https://doi.org/10.3390/drones6040089

Chicago/Turabian StyleTullu, Abera, Mostafa Hassanalian, and Ho-Yon Hwang. 2022. "Design and Implementation of Sensor Platform for UAV-Based Target Tracking and Obstacle Avoidance" Drones 6, no. 4: 89. https://doi.org/10.3390/drones6040089