Visual-Inertial Cross Fusion: A Fast and Accurate State Estimation Framework for Micro Flapping Wing Rotors

Abstract

:1. Introduction

- 1

- We proposed a generic method integrating inertial and external visual sensors by using EKFs’ convex combination that simultaneously guarantees the accuracy and updating frequency of FWRs’ state estimation. Such a method effectively addressed the above-mentioned sensing challenges of typical flapping-wing microvehicles;

- 2

- A cross fusion framework to fusion pose information from the external visual sensors with the consideration of the transmission delay. This framework fundamentally benefits the control of small-sized agile aerial vehicles, which have high system sensitivity and were severely affected by the delay of pose feedback;

- 3

- We implement the proposed method into two different prototypes of FWRs and conduct extensive real-world evaluation of our proposed method. Based on the test results, in addition to the aforementioned advantages, such a framework is capable of attenuating the influence of anomalous data.

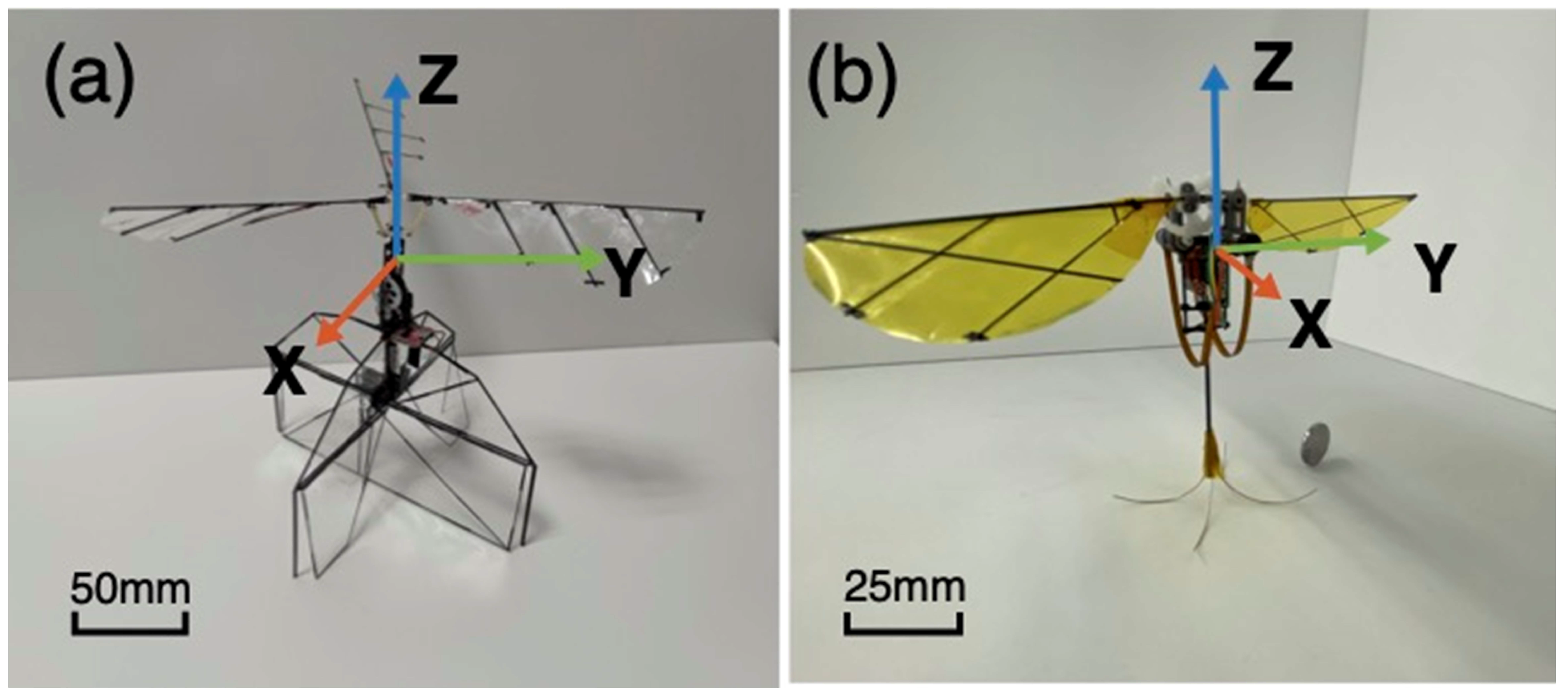

2. Test Platforms and Their Sensory System

2.1. Platform (a): A Linkage-Drive MicroFWR

2.2. Platform (b): A Motor Direct-Drive MicroFWR

2.3. Sensory System

3. State Estimation Challenges of FWRs

3.1. Limitation of Inertial Sensors

3.2. Limitation of External Visual Sensors

4. State Estimation Framework

4.1. Spatial Frames

- 1

- Vehicle body frame: Vehicle body frame is attached to the Center of the Gravity (CoG) of the vehicle and denoted by ;

- 2

- Onboard sensor frame: Onboard IMU sensor frame is a local frame in which it generates 10-DoF inertial feedback of the vehicle, including three-axis acceleration , three-axis angular rate , three-axis magnetic field , and air-pressure. In this study, we attach the IMU frame to the CoG of the test vehicle and mark it as our estimated body frame ;

- 3

- Inertial frame: As shown in Figure 9, the conventional frame is introduced in which the external visual-feedback system operates as the inertial frame. The origin of the Inertial frame is arbitrarily set, which is defined by the vision system’s calibration. The z-axis is often chosen to be orthogonal to the local ground plane.

4.2. Vehicle States

4.3. State Prediction

4.4. Convex Combination Based Sensor Fusion

4.5. Cross Fusion Framework

| Algorithm 1 Cross Fusion. |

Notation: State x, History State , Imu I,History imu Output:

|

5. Experimental Results

5.1. Sensor Fusion on FWR (a)

5.2. Sensor Fusion on FWR (b)

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, S.; Li, D.; Wu, J. Theoretical and experimental study of a piezoelectric flapping wing rotor for micro aerial vehicle. Aerosp. Sci. Technol. 2012, 23, 429–438. [Google Scholar] [CrossRef]

- Keennon, M.; Klingebiel, K.; Won, H. Development of the Nano Hummingbird: A Tailless Flapping Wing Micro Air Vehicle. In Proceedings of the 50th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, Nashville, TN, USA, 9–12 January 2012. [Google Scholar]

- Ma, K.Y.; Chirarattananon, P.; Fuller, S.B.; Wood, R.J. Controlled flight of a biologically inspired, insect-scale robot. Science 2013, 340, 603–607. [Google Scholar] [CrossRef] [Green Version]

- Roll, J.A.; Bardroff, D.T.; Deng, X. Mechanics of a scalable high frequency flapping wing robotic platform capable of lift-off. In Proceedings of the 2016 IEEE International Conference on Robotics and Automation (ICRA), Stockholm, Sweden, 16–21 May 2016; pp. 4664–4671. [Google Scholar] [CrossRef]

- Phan, H.V.; Kang, T.; Park, H.C. Design and stable flight of a 21 g insect-like tailless flapping wing micro air vehicle with angular rates feedback control. Bioinspir. Biomim. 2017, 12, 036006. [Google Scholar] [CrossRef]

- Fuller, S. Four Wings: An Insect-Sized Aerial Robot with Steering Ability and Payload Capacity for Autonomy. IEEE Robot. Autom. Lett. 2019, 4, 570–577. [Google Scholar] [CrossRef]

- Karásek, M.; Muijres, F.T.; Wagter, C.D.; Remes, B.D.W.; de Croon, G.C.H.E. A tailless aerial robotic flapper reveals that flies use torque coupling in rapid banked turns. Science 2018, 361, 1089–1094. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Zhao, H.; Mao, J.; Chirarattananon, P.; Wood, R.J. Controlled flight of a microrobot powered by soft artificial muscles. Nature 2019, 575, 324–329. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, W.; Zou, Y.; Meng, R.; Zhao, J.; Wei, M. A Sub-100 mg Electromagnetically Driven Insect-inspired Flapping-wing Micro Robot Capable of Liftoff and Control Torques Modulation. J. Bionic Eng. 2020, 17, 1085–1095. [Google Scholar] [CrossRef]

- Xin, D.; Daochun, L.; Xiang, J.; Ziyu, W. Design and experimental study of a new flapping wing rotor micro aerial vehicle. Chin. J. Aeronaut. 2020, 33, 3092–3099. [Google Scholar]

- Tu, Z.; Fei, F.; Deng, X. Untethered flight of an at-scale dual-motor hummingbird robot with bio-inspired decoupled wings. IEEE Robot. Autom. Lett. 2020, 5, 4194–4201. [Google Scholar] [CrossRef]

- Wu, J.H.; Zhou, C.; Zhang, Y.L. A novel design in micro-air-vehicle: Flapping rotary wings. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2012; Volume 232, pp. 189–193. [Google Scholar]

- Wu, J.; Wang, D.; Zhang, Y. Aerodynamic analysis of a flapping rotary wing at a low Reynolds number. AIAA J. 2015, 53, 2951–2966. [Google Scholar] [CrossRef]

- Li, H.; Guo, S.; Zhang, Y.; Zhou, C.; Wu, J. Unsteady aerodynamic and optimal kinematic analysis of a micro flapping wing rotor. Aerosp. Sci. Technol. 2017, 63, 167–178. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Guo, S. Aerodynamic efficiency of a bioinspired flapping wing rotor at low Reynolds number. R. Soc. Open Sci. 2018, 5, 171307. [Google Scholar] [CrossRef] [Green Version]

- Guo, S.; Li, H.; Zhou, C.; Zhang, Y.; He, Y.; Wu, J. Analysis and experiment of a bio-inspired flyable micro flapping wing rotor. Aerosp. Sci. Technol. 2018, 79, 506–517. [Google Scholar] [CrossRef] [Green Version]

- Shao, H.; Li, D.; Kan, Z.; Li, H.; Yuan, D.; Xiang, J. Influence of wing camber on aerodynamic performance of flapping wing rotor. Aerosp. Sci. Technol. 2021, 113, 106732. [Google Scholar] [CrossRef]

- Chen, S.; Wang, L.; He, Y.; Tong, M.; Pan, Y.; Ji, B.; Guo, S. Aerodynamic performance of a flyable flapping wing rotor with passive pitching angle variation. IEEE Trans. Ind. Electron. 2021, in press. [Google Scholar] [CrossRef]

- Chen, S.; Wang, L.; Guo, S.; Zhao, C.; Tong, M. A Bio-Inspired Flapping Wing Rotor of Variant Frequency Driven by Ultrasonic Motor. Appl. Sci. 2020, 10, 412. [Google Scholar] [CrossRef] [Green Version]

- Beloev, I.H. A review on current and emerging application possibilities for unmanned aerial vehicles. Acta Technol. Agric. 2016, 19, 70–76. [Google Scholar] [CrossRef] [Green Version]

- Madgwick, S.O.; Harrison, A.J.; Vaidyanathan, R. Estimation of IMU and MARG orientation using a gradient descent algorithm. In Proceedings of the 2011 IEEE International Conference on Rehabilitation Robotics, Zurich, Switzerland, 29 June–1 July 2011; pp. 1–7. [Google Scholar]

- Loianno, G.; Brunner, C.; McGrath, G.; Kumar, V. Estimation, control, and planning for aggressive flight with a small quadrotor with a single camera and IMU. IEEE Robot. Autom. Lett. 2016, 2, 404–411. [Google Scholar] [CrossRef]

- Verboom, J.; Tijmons, S.; De Wagter, C.; Remes, B.; Babuska, R.; de Croon, G.C. Attitude and altitude estimation and control on board a flapping wing micro air vehicle. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 5846–5851. [Google Scholar]

- Tu, Z.; Fei, F.; Yang, Y.; Zhang, J.; Deng, X. Realtime on-board attitude estimation of high-frequency flapping wing mavs under large instantaneous oscillation. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, Australia, 21–25 May 2018; pp. 6806–6811. [Google Scholar]

- Fuller, S.B.; Helbling, E.F.; Chirarattananon, P.; Wood, R.J. Using a MEMS Gyroscope to Stabilize the Attitude of a Fly-Sized Hovering Robot. 2014. Available online: https://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.951.1367&rep=rep1&type=pdf (accessed on 7 March 2022).

- Rongfa, M.N.; Pantuphag, T.; Srigrarom, S. Analysis of kinematics of flapping wing uav using optitrack systems. Aerospace 2016, 3, 23. [Google Scholar] [CrossRef] [Green Version]

- Merriaux, P.; Dupuis, Y.; Boutteau, R.; Vasseur, P.; Savatier, X. A study of vicon system positioning performance. Sensors 2017, 17, 1591. [Google Scholar] [CrossRef]

- Zhong, S.; Chirarattananon, P. An efficient iterated EKF-based direct visual-inertial odometry for MAVs using a single plane primitive. IEEE Robot. Autom. Lett. 2020, 6, 486–493. [Google Scholar] [CrossRef]

- Taylor, G.K.; Krapp, H.G. Sensory systems and flight stability: What do insects measure and why? Adv. Insect Physiol. 2007, 34, 231–316. [Google Scholar]

- Elzinga, M.J.; Dickson, W.B.; Dickinson, M.H. The influence of sensory delay on the yaw dynamics of a flapping insect. J. R. Soc. Interface 2012, 9, 1685–1696. [Google Scholar] [CrossRef] [Green Version]

- Tu, Z.; Fei, F.; Zhang, J.; Deng, X. An at-scale tailless flapping-wing hummingbird robot. I. Design, optimization, and experimental validation. IEEE Trans. Robot. 2020, 36, 1511–1525. [Google Scholar] [CrossRef]

- D’Alfonso, L.; Grano, A.; Muraca, P.; Pugliese, P. Sensor fusing using a convex combination of two Kalman filters—Experimental results. In Proceedings of the 2013 16th International Conference on Advanced Robotics (ICAR), Montevideo, Uruguay, 25–29 November 2013. [Google Scholar] [CrossRef]

- Mourikis, A.; Roumeliotis, S. A Multi-State Constraint Kalman Filter for Vision-Aided Inertial Navigation. In Proceedings of the 2007 IEEE International Conference on Robotics and Automation, Rome, Italy, 10–14 April 2007; Volume 22, pp. 3565–3572. [Google Scholar] [CrossRef]

- Bell, B.M.; Cathey, F.W. The iterated Kalman filter update as a Gauss-Newton method. IEEE Trans. Autom. Control 1993, 38, 294–297. [Google Scholar] [CrossRef]

- Forster, C.; Carlone, L.; Dellaert, F.; Scaramuzza, D. On-manifold preintegration for real-time visual–inertial odometry. IEEE Trans. Robot. 2016, 33, 1–21. [Google Scholar] [CrossRef] [Green Version]

| Test Platform | MicroFWR (a) | MicroFWR (b) |

|---|---|---|

| Vehicle Parameters | ||

| Wing length () | 120 mm | 85 mm |

| Wingbeat frequency (f) | 16 Hz | 31 Hz |

| Total weight (m) | 27 g | 12.5 g |

| x-axis moments of inertia () | 70,399 | 4238.13 |

| y-axis moments of inertia () | 68,782 | 3970.16 |

| z-axis moments of inertia () | 29,056 | 2440.95 |

| Sensor Specifications | ||

| IMU sampling rate | 512 | 1024 Hz |

| Gyroscope measurement range | ±2000 deg/s | ±2000 deg/s |

| Accelerometer measurement range | ±16 g | ±16 g |

| Vision feedback frequency | 100 Hz | 120 Hz |

| Method | Roll | Pitch |

|---|---|---|

| Proposed Method | 1.8160 | 1.7444 |

| OptiTrack with delay | 3.4175 | 3.9250 |

| Extended Kalman Filter | 6.0504 | 5.8439 |

| Method | Roll | Pitch |

|---|---|---|

| Proposed Method | 5.3086 | 4.3171 |

| OptiTrack with delay | 6.1177 | 5.3715 |

| Extended Kalman filter | 11.1964 | 9.5309 |

| Complementary Filter | 10.8845 | 7.8824 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, X.; Wang, Z.; Liu, F.; Li, S.; Fei, F.; Li, D.; Tu, Z. Visual-Inertial Cross Fusion: A Fast and Accurate State Estimation Framework for Micro Flapping Wing Rotors. Drones 2022, 6, 90. https://doi.org/10.3390/drones6040090

Dong X, Wang Z, Liu F, Li S, Fei F, Li D, Tu Z. Visual-Inertial Cross Fusion: A Fast and Accurate State Estimation Framework for Micro Flapping Wing Rotors. Drones. 2022; 6(4):90. https://doi.org/10.3390/drones6040090

Chicago/Turabian StyleDong, Xin, Ziyu Wang, Fangyuan Liu, Song Li, Fan Fei, Daochun Li, and Zhan Tu. 2022. "Visual-Inertial Cross Fusion: A Fast and Accurate State Estimation Framework for Micro Flapping Wing Rotors" Drones 6, no. 4: 90. https://doi.org/10.3390/drones6040090

APA StyleDong, X., Wang, Z., Liu, F., Li, S., Fei, F., Li, D., & Tu, Z. (2022). Visual-Inertial Cross Fusion: A Fast and Accurate State Estimation Framework for Micro Flapping Wing Rotors. Drones, 6(4), 90. https://doi.org/10.3390/drones6040090