Identification of Emission Source Using a Micro Sampler Carried by a Drone

Abstract

:1. Introduction

2. Method

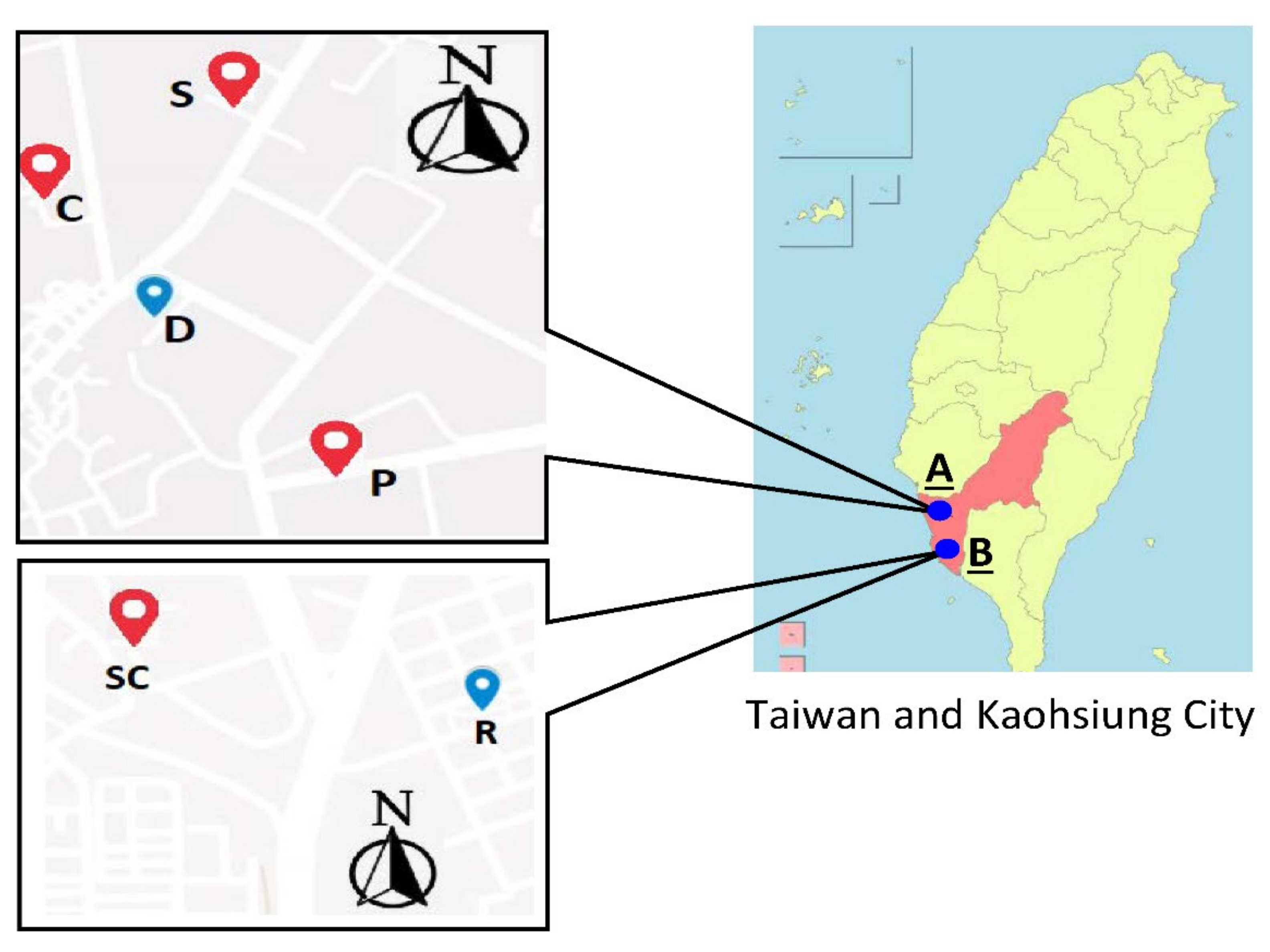

2.1. Sites for Sampling

2.2. Drone and Sampling Device

2.3. Preparation of Micro Samplers

2.4. Materials and Chemicals

2.5. Instrumentation and Calibration Procedures

3. Result

3.1. Identifying VOC Emission Sources around a Dormitory Community by Drone Sampling

3.2. Monitoring the Vertical Profile of VOC Concentrations along an Emission Source

4. Discussions

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Greenberg, J.P.; Guenther, A.B.; Zimmerman, P.; Baugh, W.M.; Geron, C.; Davis, K.; Helmig, D.; Klinger, L.F. Tethered balloon measurements of biogenic VOCs in the atmospheric boundary layer. Atmos. Environ. 1999, 33, 855–867. [Google Scholar] [CrossRef] [Green Version]

- Corrigan, C.E.; Roberts, G.C.; Ramana, M.V.; Kim, D.; Ramanathan, V. Capturing vertical profiles of aerosols and black carbon over the Indian Ocean using autonomous unmanned aerial vehicles. Atmos. Chem. Phys. 2008, 8, 737–747. [Google Scholar] [CrossRef] [Green Version]

- Aurell, J.; Mitchell, W.; Chirayath, V.; Jonsson, J.; Tabor, D.; Gullett, B. Field determination of multipollutant, open area combustion source emission factors with a hexacopter unmanned aerial vehicle. Atmos. Environ. 2017, 166, 433–440. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.C.; Wang, J.L.; Chang, C.Y.; Liang, M.C.; Lin, M.R. Development of a multicopter-carried whole air sampling apparatus and its applications in environmental studies. Chemosphere 2016, 144, 484–492. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vo, T.D.H.; Lin, C.; Weng, C.E.; Yuan, C.S.; Lee, C.W.; Hung, C.H.; Bui, X.T.; Lo, K.C.; Lin, J.X. Vertical stratification of volatile organic compounds and their photochemical product formation potential in an industrial urban area. J. Environ. Manag. 2018, 217, 327–336. [Google Scholar] [CrossRef]

- Chang, C.C.; Chang, C.Y.; Wang, J.L.; Lin, M.R.; Ou-Yang, C.F.; Pan, H.H.; Chen, Y.C. A study of atmospheric mixing of trace gases by aerial sampling with a multi-rotor drone. Atmos. Environ. 2018, 184, 254–261. [Google Scholar] [CrossRef]

- Yuan, C.-S.; Cheng, W.-H.; Su, S.-Y.; Chen, W.-H. Field measurement of spatiotemporal distributions of ambient concentrations of volatile organic compounds around a high-tech industrial park using a drone. Atm. Pollut. Res. 2021, 12, 101187. [Google Scholar] [CrossRef]

- Yuan, C.-S.; Cheng, W.-H.; Huang, H.-Y. Spatiotemporal distribution characteristics and potential sources of VOCs at an industrial harbor city in southern Taiwan: Three-year VOCs monitoring data analysis. J. Environ. Manag. 2022, 303, 114259. [Google Scholar] [CrossRef]

- Lippmann, M. Environmental Toxicants; Van Nostrand Reinhold: New York, NY, USA, 1992; pp. 633–646. [Google Scholar]

- Kent, C. Basics of Toxicology; John Wiley & Sons: New York, NY, USA, 1998; pp. 149–163. [Google Scholar]

- Pinthong, N.; Thepanondh, S.; Kondo, A. Source identification of VOCs and their environmental health risk in a petrochemical industrial area. Aerosol Air Qual. Res. 2022, 22, 210064. [Google Scholar] [CrossRef]

- Baberi, Z.; Azhdarpoor, A.; Hoseini, M.; Baghapour, M.; Derakhshan, Z.; Giannaki, Z. Monitoring benzene, toluene, ethylbenzene, and xylene (BTEX) levels in mixed-use residential-commercial buildings in Shiraz, Iran: Assessing the carcinogenicity and non-carcinogenicity risk of their inhabitants. Int. J. Environ. Res. Public Health 2022, 19, 723. [Google Scholar] [CrossRef]

- Kaohsiung City Environmental Education Network. 2019. Available online: https://khenvedu.kcg.gov.tw/News/Detail?progId=NEWS001&pageNbr=2&dsn=2368 (accessed on 12 March 2022).

- Kaohsiung City Micro Sensor Information Network. 2019. Available online: https://www.ksmicrosensor.com.tw (accessed on 12 March 2022).

- Chung Yuan Christian University, Chung Yuan Christian University News Network Taoyuan, Taiwan. 2020. Available online: https://enews.cycu.edu.tw/Paper2/Paper.srv?cmd=detailPaper&sn=6793 (accessed on 12 March 2022).

- Cheng, W.-H.; Hsieh, T.-S.; Chu, C.-M.; Chiang, C.-C.; Yuan, C.-S. Application of a telescoping microextraction needle trap sampling device on a drone to extract airborne organic vapors. Aerosol Air Qual. Res. 2019, 19, 1593–1601. [Google Scholar] [CrossRef] [Green Version]

- Cheng, W.H.; Yuan, C.S. Using a micro sampler on a drone to extract organic vapors—A case study of monitoring industrial pollution. Aerosol Air Qual. Res. 2021, 21, 200359. [Google Scholar] [CrossRef]

- Environmental Protection Administration Taiwan. Method for the Detection of Gaseous Organic Compounds in a Discharge Pipeline-Sampling Bag Sampling/Gas Chromatography Flame Ionization Detection. NIEA A722.76B; Environmental Protection Administration Taiwan: Taipei, Taiwan, 2019. [Google Scholar]

- DJI. Users’ Operation Manual for Mavic Pro; DJI: Shenzhen, China, 2016; Available online: https://www.dji.com/tw/mavic (accessed on 11 February 2020).

- SolidWorks. SolidWorks: Flow Simulation; Technical Reference; Solidworks Corporation: Waltham, MA, USA, 2018. [Google Scholar]

- Lord, H.; Zhan, W.; Pawliszyn, J. Fundamentals and applications of needle trap devices. Anal. Chim. Acta 2010, 677, 3–18. [Google Scholar] [CrossRef] [PubMed]

- Cheng, W.-H.; Zhan, W.; Pawliszyn, J. Extraction of gaseous VOCs using passive needle trap samplers. Aerosol Air Qual. Res. 2011, 11, 387–392. [Google Scholar] [CrossRef]

- Cheng, W.-H.; Zhan, W.; Pawliszyn, J. Gaseous and particle-bound VOC products of combustion extracted by needle trap samplers. J. Chin. Chem. Soc. 2013, 60, 1027–1032. [Google Scholar] [CrossRef]

- Cheng, W.H.; Lai, C.H. Sampling gaseous compounds from essential oils evaporation by solid phase microextraction devices. Atmos. Environ. 2014, 99, 124–129. [Google Scholar]

- Cheng, W.H.; Chang, C.Y.; Chen, Y.Y.; Su, H.W. Chemical composition of aerosols of an electronic cigarette. Aerosol Air Qual. Res. 2021, 21, 200672. [Google Scholar] [CrossRef]

- Cheng, W.H.; Huang, H.L.; Chen, K.S.; Chang, Y.C. Quantification of VOC emissions from paint spraying on a construction site using solid phase microextraction devices. J. Environ. Sci. Health 2017, A52, 1158–1163. [Google Scholar] [CrossRef]

- Cheng, W.H.; Huang, H.L.; Chuang, M.H. Use of passive SPME sampling devices to determine exposure of oil painters to organic compounds. J. Air Waste Manag. Assoc. 2020, 73, 253–259. [Google Scholar] [CrossRef]

- Yung Chi Paint & Varnish MFG. Co. Ltd. Steel Treatment Standards and Coating. Available online: https://www.rainbowpaint.com.tw/wiki/technologies (accessed on 28 February 2022).

- Andreae, M.O. Emission of trace gases and aerosols from biomass burning—An updated assessment. Atmos. Chem. Phys. 2019, 19, 8523–8546. [Google Scholar] [CrossRef] [Green Version]

- Clean Air Farming Project, Ammonia and Methane Emissions from Agriculture. 2019. Available online: https://eeb.org/wp-content/uploads/2019/07/Clean-Air-farming_Flyer_mitCopyright25_6_19_online-1.pdf (accessed on 12 March 2022).

- Lee, S.C.; Chiu, M.Y.; Ho, K.F.; Zou, S.C.; Wang, X. Volatile organic compounds (VOCs) in urban atmosphere of Hong Kong. Chemosphere 2002, 48, 375–382. [Google Scholar] [CrossRef]

- Fumian, F.; Giovanni, D.D.; Martellucci, L.; Rossi, R.; Gaudio, P. Application of miniaturized sensors to unmanned aerial systems, a new pathway for the survey of polluted areas: Preliminary results. Atmosphere 2020, 11, 471. [Google Scholar] [CrossRef]

| Sampling Upwind or Downwind | Concentrations (ppb) of VOCs at Different Sampling Points a | Dormitory | ||||||

|---|---|---|---|---|---|---|---|---|

| Plant C | Plant S | Plant P | Urea d | 1.0 | ||||

| (a) Upwind | Acetaldehyde | 1.0 | Methane | 1.4 | See note b | Toluene d | 14.0 | |

| Ethylbenzene d | 5.5 | |||||||

| (b) Downwind | p-Xylene d | 12.5 | ||||||

| Methane | See note c | |||||||

| Acetaldehyde | 2.0 | Toluene | 15.0 | PGMEA | 2.0 | |||

| Ethylene oxide | 2.2 | Ethylbenzene | 9.0 | |||||

| p-Xylene | 12.0 | |||||||

| VOCs | Concentrations (ppm) at Different Sampling Points a | ||||

|---|---|---|---|---|---|

| RTO Exhaust Chimney Point a (@ 65 m) b | Community (Near Boundary Wall) | Community (in a Park) Point c (Ground) d | |||

| Point b1 (@ 65 m) c | Point b2 (@ 20 m) c | Point b3 (Ground) d | |||

| Methanol | 1.96–2.00 | <0.18 | <0.18 | <0.15 | <0.15 |

| Acetone | 0.05–0.10 | <0.01 | <0.01 | <0.022 | <0.022 |

| Benzene | <0.005 | <0.005 | <0.005 | 0.13–0.24 | <0.008 |

| Toluene | 1.04–2.00 | <0.005 | <0.005 | 0.20–0.35 | <0.008 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, W.-H.; Yuan, C.-S. Identification of Emission Source Using a Micro Sampler Carried by a Drone. Drones 2022, 6, 116. https://doi.org/10.3390/drones6050116

Cheng W-H, Yuan C-S. Identification of Emission Source Using a Micro Sampler Carried by a Drone. Drones. 2022; 6(5):116. https://doi.org/10.3390/drones6050116

Chicago/Turabian StyleCheng, Wen-Hsi, and Chung-Shin Yuan. 2022. "Identification of Emission Source Using a Micro Sampler Carried by a Drone" Drones 6, no. 5: 116. https://doi.org/10.3390/drones6050116

APA StyleCheng, W.-H., & Yuan, C.-S. (2022). Identification of Emission Source Using a Micro Sampler Carried by a Drone. Drones, 6(5), 116. https://doi.org/10.3390/drones6050116