1. Introduction

The hub and spoke network (HSN) has applications in many fields, such as postal systems, railway express [

1], ultra-cold COVID-19 vaccine distribution [

2], and intermodal transportation [

3]. For example, in less-than-truckload (LTL) industries, an HSN can combine demands from many origins, consolidate them at hubs, and then transport them to their destinations. In parcel delivery, drones have great potential, particularly in rural areas. In these areas, drones operate faster than trucks. As drones are limited in their payload, a combination of trucks and drones can be beneficial in reducing last-mile delivery costs. In recent years, the study of parcel delivery using the collaboration of trucks and drones has attracted the interest of many researchers. Karak and Abdelghany [

1] studied a truck–drone cooperative pickup and delivery services problem with a simplified drone endurance model and without precedence constraints, demonstrating the effective cost reduction achieved with the cooperative model. This paper investigates an HSN with a drone-based traveling salesman problem (HSNTSP-D), a new variant of the location routing problem with drones (LRP-D). We considered using drones in an HSN for first- and last-mile pickup and delivery tasks.

Most studies on HSN designs use a star structure network, and every direct link requires a dedicated vehicle [

4]. Such HSNs generally minimize the cost of the hub-to-hub, spoke-to-hub, and hub-to-spoke transportation flows. Nonetheless, the routing decision is not considered. Kartal et al. [

5] proposed that when the spokes do not have enough demand to use the trucks fully, HSN will significantly increase the number of vehicles. In addition, Karimi-Mamaghan et al. [

6] consider that this direct link between each spoke node and hub may cause traffic congestion. In this case, we should consider the location and routing decisions jointly. If each vehicle can access multiple spokes, much fewer vehicles are needed, significantly reducing the total investment cost of the vehicle. In addition, the number of vehicles entering and leaving the hub is reduced, avoiding traffic congestion in the hubs.

Therefore, this paper proposes a model for truck–drone cooperation. Trucks are responsible for hub-to-hub transportation, taking advantage of economies of scale. Drones consolidate packages from and distribute packages to spokes, giving full play to high efficiency and low-cost benefits. The literature on coordinating the logistics operations using a truck–drone combination focused predominantly on extending classical routing problems, a variant of traveling salesman problems with drones (TSP-D), and a generalization of vehicle routing problems (VRP) to include drones (VRP-D). Gómez-Lagos et al. [

7] propose the well-known pickup and delivery problem (PDP) related to the problem defined here. In the PDP, two types of customers are defined, one part of them asks for a pickup operation, and the other asks for a delivery operation. Ham [

8] extended the parallel drone scheduling TSP (PDSTSP) with both pickup and delivery operations to be performed by the drone.

Truck–drone pickup and delivery problem is NP-hard in nature. Previous studies have focused on exact and heuristic methods to solve these NP-hard problems. For example, Ziaei and Jabbarzadeh [

9] studied green location-routing planning of multi-modal transportation systems. Sun et al. [

10] studied green road–rail intermodal routing problem with improved pickup and delivery services. These studies demonstrated that exact solution methods and heuristic algorithms are feasible. Mixed-integer programs (MIP) and dynamic programming exhaustively explore the search space to find the optimal solution. However, they can generally solve small-scale instances. Due to the combinatorial nature of the truck–drone pickup and delivery problem, the performance of the conventional approaches can be significantly affected by the size of the problem. Therefore, the current challenge is to develop a scalable and efficient method for truck–drone pickup and delivery. This paper proposed a new variant of the location routing problem with Drones (LRP-D), considering using a truck fleet consisting of trucks and drones for last-mile pickup and delivery tasks. We seek to construct an HSN design with TSPP-D (HSNTSP-D), which consists of determining the number of hubs to constitute a hub-level network and assigning each spoke node to a single hub to form a spoke-level route. For a hub-level network, it is the interconnection structure between p hubs. While for the spoke-level route, the hub and all the spokes assigned to it form a directed circle route, completed by drones using TSP.

The study contributes to the literature in the following three aspects. First, a variant of the HSN design problem is introduced that encompasses hub location and routing decisions. We combine the advantages of both drones and trucks in parcel delivery operations. Second, we propose a three-stage decomposition model to solve this problem. Third, we developed a three-stage decomposition algorithm to solve practical large-scale instances. The rest of this paper consists of the following parts.

Section 2 presents a systematic literature review summarizing the research background and published results.

Section 3 offers a three-stage decomposition model for HSNTSP-D. In

Section 4, we give details of the proposed three-stage decomposition algorithm. First, we proposed a VNS for the p-hub location and spoke node allocation problem. The nearest neighbor algorithm for the VRP is presented in the second stage. In the third stage, the node allocation reassignment strategy is proposed.

Section 5 analyzes computational results. We conclude and describe the direction of future research in

Section 6.

2. Literature Review

The HSN design problem is often referred to as hub location and allocation problems [

11]. Kartal, Krishnamoorthy, and Ernst [

5] divided the HSN design problems into p-hub median, hub covering, and hub center problems. When HSN design problems consider route optimization, it becomes hub location and routing problem (HLRP), which identifies hubs and assigns non-hubs to hubs to form vehicle routes. Nagy and Salhi [

12] first raised the many-to-many HLRP. In their study, the demands are collected, aggregated at the hub center, and delivered to the demand nodes. Wasner and Zäpfel [

13] develop a generalized hub location and vehicle routing model to optimal design of depot and hub transportation networks for parcel service providers. Çetiner et al. [

14] described an iterative two-stage heuristics for a combined multiple allocation HLRP. The first stage is the implementation of hub location and distribution of spokes. Next stage, the transportation between a hub and its spokes are formatted as VRPs. They considered simultaneous pickup and delivery at the spokes. For many-to-many HLRP, Camargo et al. [

15] proposed a new formulation to solve. They also provided pickup and delivery services on the same vehicle route, and each hub assigned only one vehicle. Rodríguez-Martín et al. [

16] presented a hub network with direct connections between hubs, and each hub has a circular spoke-level route. Lopes et al. [

17] addressed a variant of the MMHLRP wherein they proposed an integer programming model and three heuristics algorithms to solve it. Kartal et al. [

18] studied to minimize transferring cost between hubs and routing cost in the local route, developed mixed integer programming models, and proposed a multi-start simulated annealing heuristic and ant colony system algorithm to solve it. Karimi [

19] proposed Tabu search-based heuristics for hub location and VRP with simultaneous pickup and delivery (VRPPD), in which the nodes assigned to a hub form a tour. Fontes and Goncalves [

20] studied deep sea service through the interconnection between hubs and short sea service by a circular local route. XiaoYang et al. [

21] studied the capacitated single allocation HLRP where collection and delivery served on distinct routes. Danach et al. [

22] located a predetermined number of hubs and allocated the spokes to the hubs. Wu et al. [

23] investigated a multi-allocation hub location routing problem (MAHLRP) to design an intra-city express service system in which mail and parcels are exchanged among the branch offices of the service provider via local tours and hubs.

Table 1 summarizes the pioneering studies on HSNs. The distinct features compared with basic HSNs include tasks of spokes to hubs, the routing constraints of consolidation and distribution, and time and capacity constraints. The HSNs are generally formulated as MILPs.

This work studies the HSNTSP-D and focuses on collaborating the trucks and drones. For the truck–drone routing problem, Murray and Chu [

24] proposed the deployment of trucks and drones together for package delivery in logistics distribution, naming the problem the Flying Sidekick TSP (FSTSP). Agatz et al. [

25] proposed a similar problem called the TSP with Drones (TSP-D), which was solved using a truck-first-drone-second heuristic and a dynamic programming algorithm. A MILP formulation for the problem is detailed and the math heuristic proposed is a Random Restart Local Search (RRLS). Ha et al. [

26] minimized the total operational cost of a drone-truck delivery system. They offered a MILP formulation for the problem and presented a GRASP heuristic. Moshref-Javadi et al. [

27] studied the multi-trip TSP-D (MTSP-D), which assumes that a truck can stop at a discrete set of customer locations and launch one or multiple UAVs to serve other customers. They developed a hybrid algorithm based on Simulated Annealing (SA) and Tabu Search (TS). Dell’Amico et al. [

28] approached the Parallel Drone Scheduling TSP (PDSTSP), proposing a MILP and several math heuristics. Wang et al. [

29] studied the VRP with Drones (VRP-D) from a worst-case point of view. Murray and Raj [

30] introduced the multiple-flying sidekicks TSP (mFSTSP), considering a delivery truck operating in coordination with a fleet of drones. The drones are launched from the truck to deliver a single package, then return to the truck where it can be loaded again.

Karak and Abdelghany [

1] present a mathematical formulation and solution methodology for the hybrid vehicle–drone routing problem (HVDRP) for pickup and delivery services. A novel solution methodology is developed, which extends the classic Clarke and Wright algorithm (HCWH) to solve the HVDRP. Luo et al. [

31] proposed the Multi-Visit TSP with Multiple Drones (MTSP-MD), which considers energy consumption during hovering when a drone waits for the truck to arrive. Gu et al. [

32] proposed a general VRP with Drones and Multiple Visits (VRPD-MV) where the drones can serve multiple customers per trip. They offered a VNS algorithm. Montaña et al. [

33] introduce a new variant of the Location Routing Problem with Drones (LRP-D), in which multiple trucks and drones are deployed to make deliveries. The main idea is to combine the advantages of both drones and trucks in parcel delivery operations. Arishi et al. [

34] introduced the Parking Location and TSP with Homogeneous Drones (PLTSPHD). This paper proposes a two-phase machine learning (ML) approach for the PLTSPHD, which minimizes the total operational cost of the last-mile problem. The proposed ML approach for PLTSPHD consists of clustering and routing phases. Luo et al. [

35] investigate a novel and pioneering problem, the one-to-one pickup and delivery problem with multi-trucks and multi-visit drones (OPDP-MTMV). This problem involves multiple trucks equipped with a single drone for pickup and delivery services. The drones are capable of carrying several packages per trip.

Table 2 presents the studies on drone-based location and routing problems. Using drones to extend the TSP and VRP studies is popular. Because the fundamental problems of TSP and VRP are difficult to solve, coordinating with drones makes them more challenging. Although they can be formatted as MILPs, various basic, meta- and math-heuristics are developed for solving medium- and large-scale instances.

Truck–drone collaboration for parcel delivery can open several research paths due to the evolution of e-commerce and vehicle technology in logistics. The research in this paper adopts the HSN structure, and the transportation route between hub nodes is called hub-level transportation, and the transportation route connecting non-hub nodes is called spoke-level transportation. In hub-level transportation, the OD cargo flow of non-hub nodes within the radiation area is gathered, and the use of truck transportation at the hub will form significant economies of scale and reduce transportation costs. Hub-level transportation generally has a long distance, and due to the limited distance of drone transportation, hub-level lines can only be transported by truck. However, spoke-level transportation usually has a short distance, which is suitable for using drones to complete the last mile of transportation and can fully use the advantages of drone transportation. Montaña, Malagon-Alvarado, Miranda, Arboleda, L.Solano-Charris, and A.Vega-Mejía [

33] combine the benefits of drones and trucks in parcel delivery operations. However, they studied only one central depot, not considering the transportation of the hub trunk line or the need for pickup. Wu, Qureshi, and Yamada [

23] studied the issue of express services in the city and considered the need for simultaneous pickup and delivery, but the cost of spoke-level transportation only depends on the distance between nodes and does not consider the actual flow of goods flowing between spoke-level route nodes. Since the spoke-level transportation in this paper is limited by the carrying capacity of the drone, it is necessary to select the appropriate drone type according to the actual cargo flow of each section of the spoke-level route.

3. Problem Description

This research analyzes a new variant of the location routing problem with drones (LRP-D). We considered using drones in an HSN for first- and last-mile pickup and delivery tasks. First, we describe the research status of HSN network; second, we describe the research status of the truck–drone routing problem. Finally, according to the existing research on the collaboration of trucks and drones, we designed an HSN with a drone-based traveling salesman problem. By adopting the HSNTSP-D structure, both in hub-level transportation and spoke-level transportation, resources are integrated to form a scale effect, which can reduce transport devices significantly reduced, as well as the investment and operating costs.

The HSN consists of four parts: hubs, spokes, transportation among hubs, and transportation between spokes and hubs. The origin-to-destination (OD) requirements for cargo transportation are defined between nodes. An HSN aims to determine the hub’s location among all nodes and the allocation of spokes according to OD requirements between nodes.

The decomposition strategy is prevalent in HSNs, which includes the decomposition of the model, dividing a model into multiple models for the solution. Some literature decomposes the problem into the hub and distribution network construction stages. Based on the above analysis, this paper constructs a three-stage decomposition model. The model of the first stage solves the location problem of hub facilities and obtains the hub selection and node allocation scheme. In the second stage, according to the node allocation relationship, starting from the hub, then visiting each node assigned to the same hub in turn, and finally return to the hub to complete truck route planning. The third stage model is to adjust the distribution scheme of spokes, optimize truck routes, and make the total cost of the network minimal.

Recently, the application of drones in delivery logistics has emerged prominently. Companies are competing to achieve cost-efficient and faster last-mile delivery operations. Integrating emerging technology, such as unmanned aerial trucks or drones, in the last-mile network design can overcome these challenges and provide a competitive advantage.

Parcel delivery with drones has the potential to revolutionize classic parcel delivery since drone delivery can reduce costs and increase the speed of last-mile logistics. In a truck-and-drone coordinated HSN, a truck carries a set of drones and customer orders to a hub located. Then the drones can transport multiple low-weight orders simultaneously within the flight range. In recent research and practice, a new drone that can make three delivery drop-offs on a single flight has proposed as an emerging technology.

This study investigates a novel and pioneering last-mile delivery problem named HSNTSP-D. Each customer order requires a package to be transported from the origin node to the destination node. The origin-to-destination pickup and delivery problem with multi-truck and multi-visit drone deploys multiple truck–drone pairs to serve customers. Both the trucks and the drones can perform pickup and delivery operations. A drone picks up packages from a truck and then drops them into the spokes. A drone picks up packages at the spokes and unloads them onto a truck for consolidation.

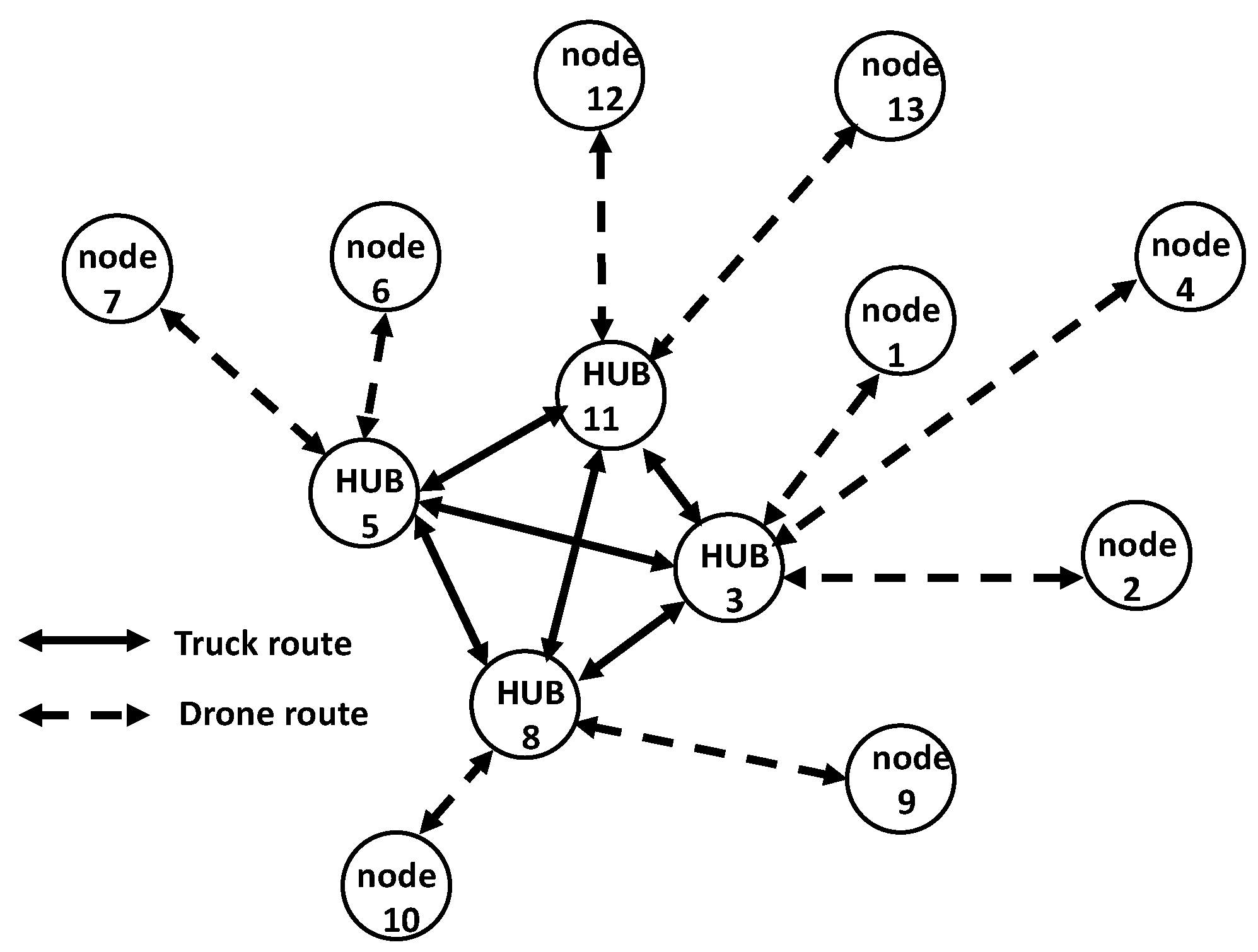

The transportation between hubs can improve the load ratio of trucks through hub-level transportation. When the traffic volume of a spoke is less than a drone load, the direct transportation mode between spokes and hubs will not fully utilize the drones’ loading capacity and depends on too many drones, as shown in

Figure 1. Solid lines represent the trunk transportation between hubs, and dashed lines represent the drone transportation between spoke nodes. We can use drones for all the spokes assigned to the same hub, as shown in

Figure 2. This HSN design with a drone has the dual advantage of HSN planning and traveling salesman problem (TSP). It affects economies of scale in the hub- and spoke-level transportation, improves resource utilization, and reduces resource waste.

5. Proposed Method

In this section, a three-stage decomposition algorithm is described to solve the optimization problem of HSNTSP-D, which consists of a p-hub location and spoke node allocation stage, routing optimization stage, and spoke node reassignment strategy stage. For a p-hub location and spoke node allocation stage (

Section 5.2), we developed a VNS algorithm to select hubs and allocate spokes. The second stage proposed a nearest-neighbor algorithm for drone routing optimization (

Section 5.3). The third stage offers the reassignment strategy to adjust node allocation, and change spoke-hub assignments, then it returns to stage 2 for solving, and after finite iterations of stage 2 and stage 3, the local optimal solution is output. (

Section 5.4).

Figure 3 depicts a system scheme of the solution method.

5.1. Nearest-First Assignment Strategy

A solution of HSN design is to identify a set of hubs, and once the hub is determined, assign spokes to the nearest hub based on distance. A solution can be expressed as

, where

is the set of hubs and

is the assignment relationship between spokes and hubs. For example,

represents hub

service node

,

represents the node

is a hub. In this article, we use O’kelly’s [

36] nearest allocation heuristic to generate a spoke allocation set

. When a hub set

is obtained, the distance from each spoke node to each hub is calculated, and the spokes are assigned to the nearest hub with the shortest distance; hereby the spoke node allocation set

is obtained, which is called the nearest allocation strategy. The detailed procedure of the nearest-first assignment strategy of Algorithm 1 is as follows: given a hub set

in

, the NA strategy allocates each spoke in

to the nearest hub in

(according to the cost matrix

).

| Algorithm 1: Nearest-first assignment strategy [NA] |

| Input | ; ; |

| Output | : a set of assignments of spokes to hubs |

| Step 1 | Initialize |

| Step 2 | For in : |

| Step 3 |

|

| Step 4 | Assign node to the nearest hub in : |

| Step 5 | End For |

| Step 6 | Output |

After obtaining a solution

, we combine a hub and its assigned nodes to form a subset expressed as

, where

indicates that the subset contains all spokes assigned to hub

. To evaluation of a solution

, there are three types of cargo flow according to the method mentioned in Corberán et al. [

37]. Mikić et al. [

38] proposed three types of flows to evaluate feasible solutions

. The first one, the traffic flow between hubs—hub-to-hub flow, called HHF—represents the flow sent between two clusters. For example, the total flow on the inter-hub arc

is obtained as

The second spoke node to the hub traffic flow—node-to-hub flow, called NHF—represents the sent flow from a spoke node to the hub. For instance, the total flow on the node

to hub

is obtained as

The third traffic flow from the hub to the spoke node—hub-to-node flow, called HNF—represents hub-to-node traffic flow. For example, the total flow for hub

to node

is obtained as

5.2. First Stage: The p-Hub Location and Spoke Node Allocation Problem Stage

Inspired by the successful application of the general VNS heuristic to the hub location problem [

39], we proposed a VNS algorithm to seek

number of nodes as hub set, and then assign spoke node to a hub. At this stage, a greedy strategy is used to generate the initial solution and then shake procedure to explore different hub set neighborhood structures. A local search is implemented based on the best improvement search strategy to improve the solution.

5.2.1. An Initialization Algorithm

In this algorithm, select

hubs, and the nearest spokes are assigned to the hub until all spokes are assigned. The initialization algorithm (Algorithm 2) generates the initial solution according to the greedy strategy. Aiming to make the total cost minimal, select a hub, assign nodes according to the nearest-first assignment strategy, and then add a hub, comparing with the previous scheme’s cost. If the cost is reduced, the new hub will continue to be added.

| Algorithm 2: Initialization algorithm |

| Input | |

| Output | |

| Step 1 | |

| Step 2 | While the hub number is not satisfied, do: |

| Step 3 | : |

| Step 4 |

|

| Step 5 |

|

| Step 6 |

|

| Step 7 |

|

| Step 8 | |

| Step 9 |

|

| Step 10 | End If |

| Step 11 | End For |

| Step 12 | End While |

5.2.2. Shake Procedure

The shake procedure consists in selecting one hub

from the neighborhood of the hub set, then take it as an alternative hub. Algorithm 3 shows the critical steps of the shaking process. In the iterative process, each time the first node

is selected from the hub set

, the node

i is moved out of the hub set, adding node

to the spoke node set

, to construct new neighborhoods

and

.

| Algorithm 3: Shaking procedure |

| Input | |

| Output | |

| Step 1 | Get the spokes set by |

| Step 2 | Pick out the first hub in () |

| Step 3 | Add node to the spokes set |

| Step 4 | Return |

5.2.3. Local Search

A local search heuristic starts after the shaking procedure, the search strategy based on the best improvement search strategy. Each iteration chooses a solution that is better than the previous solution and sets it as the new current solution. After iteration, the new current solution is the local optimal solution and the best solution among all improved solutions.

In Algorithm 4, first, traverse the remaining node set

, successively insert the current node

into the hub set

through steps 4.2 to 4.4. The node allocation set

is obtained by using the nearest allocation strategy and calculating the current cost. Then, in steps 4.7 to 4.9, compare the current cost with the previous cost. If

, replace

with

. Finally, the node

is inserted into the original hub set

, the hub set is updated, and the node allocation scheme is output.

| Algorithm 4: Local search based on the best improvement search strategy |

| Input | ; |

| Output | |

| Step 1 | |

| Step 2 | : |

| Step 3 |

|

| Step 4 | |

| Step 5 |

|

| Step 6 |

|

| Step 7 |

|

| Step 8 |

|

| Step 9 | End If |

| Step 10 | End For |

| Step 11 | |

| Step 12 | |

5.2.4. Basic VNS

The basic VNS contains two main procedures: the shaking and local search procedures. The shaking procedure can jump out the optimal local solution, and the local search procedure can obtain an improved solution. In Algorithm 5, we executed alternately shaking and local search procedures until the limit on the number of iterations was reached. The criterion for VNS stopping the iteration is that the solution has not improved after

iterations.

| Algorithm 5: Basic variable neighborhood search |

| Input | |

| Output | |

| Step 1 | |

| Step 2 | |

| Step 3 | : |

| Step 4 |

|

| Step 5 | Local search

|

| Step 6 |

|

| Step 7 |

|

| Step 8 |

|

| Step 9 |

|

| Step 10 | End If |

| Step 11 | End While |

| Step 12 | |

Algorithm 5 is the detailed design process of basic VNS, which outputs the local optimal solution results in limited iterations. Firstly, the initial solution is generated through the Initialization algorithm to promote the execution of the algorithm. In the iterative process, the shaking procedure is used to delete a hub from the hub set as the replacement hub. In Step 5.5, the local search procedure is executed to search the remaining spoke node set , and a spoke node is selected to exchange with the hub. After the exchanges are completed, the node with the lowest current total cost is found to replace the original hub and return to the new hub set . When the objective function is not updated after iterations, the algorithm stops, which means that no better solution can be found by exchanging any hub from with other spokes, and the algorithm converges to the local optimal solution.

5.3. Second Stage: The Nearest Neighbor Algorithm for the Truck Routing Stage

In the second stage, hub set

and node assignment set

are obtained according to the first stage. The nodes assigned to the same hub are summarized into a subset

. If there are

hubs, there are

subsets. The order of nodes in each subset represents the arrival order

of the truck route. The aim of the algorithm is to optimize the sequence order of each subset of nodes—that is, to construct the shortest path optimization problem. Using the nearest neighbor algorithm (NNA), trucks start from the hub, visit the closest node in turn, and return to the hub. Find the node sequence with the shortest path and complete the route optimization. The steps of the nearest neighbor algorithm (Algorithm 6) are as follows:

| Algorithm 6: Nearest neighbor algorithm (NNA) |

| Input | A: a set of nodes;

: a set of hubs;

distance-dependant transportation costs; |

| Output | The best node sequence vector for each hub |

| Step 1 | For each hub sequence vector |

| Step 2 | For in : |

| Step 3 | Set |

| Step 4 | Add to the route : |

| Step 5 | Picking the last node from the sequence vector of nodes at hub Set |

| Step 6 | Visit the nearest unvisited node |

| Step 7 | Update the end node and add to the Set |

| Step 8 | Remove of Set |

| Step 9 | Is there any unvisited node left of Set ? |

| Step 10 | If yes, go to step 6.5 |

| Step 11 | Add the hub sequence vector to Set |

| Step 12 | End For |

| Step 13 | Return |

To find a better sequence of nodes by performing reordering in the same subset , the nearest neighbor algorithm starts from the hub in the local route, then visits the unvisited node closest to the previous node and adds it to the route. After visiting all nodes, the algorithm ends and returns to the hub.

To evaluate the cost of this structure, we consider two types of expenses. First, the transportation between hubs still adopts the direct connection, so the cargo flow calculation method between hub

and hub

is to calculate the cargo flow from subset

to nodes in subset

through the hub-to-hub flow (HHF). The drones arrive at each spoke in turn on the same route according to the sequence of spokes. On the first trip, a truck departing from a hub can pick up any packages and deliver some cargo at those nodes. If the final destination node is on the route, another cargo is brought to the hub for processing. On the second trip, on the same route, the drone only delivers packages on each spoke. According to the above type of service, the packages between spokes on each route can be calculated. The calculation formula of transportation flow from node j to node

in the subset

represents

Therefore, the route cost is computed as the arc length multiplied by the packages

5.4. Third Stage: The Node Allocation Reassignment Strategy (RA) Stage

The reassignment strategy is to find a scheme to reduce the total transportation cost. Select a spoke from the spoke set and replace the hub. Namely, a hub is selected from the hub and is used to replace the initially allocated hub. After the replacement, the number of spokes in the subset served by the two hubs changes. The number of nodes served by the original hub decreases by one, and another hub-served node increases by one. For example, spoke node assigned to hub transitions to hub , changes in cargo flow between hubs can be described as the following three cases:

(1) The change of cargo flow between hub

and other hub

is

(2) The change of cargo flow between hub

and other hub

is

(3) The change of cargo flow between hub

and hub

is

Due to the spokes assigned to hub and hub changes, the two routes of hub and hub be reoptimized, and the transportation costs of the two routes need to be recalculated according to the second stage method.

In brief, the design idea of the three-stage decomposition algorithm is as follows: Firstly, according to the first stage method, the hub set and spoke node allocation set are obtained through VNS. Then, according to the second stage method—for the truck’s shortest path starting from each hub, using the nearest neighbor algorithm to optimize—the node sequence set of each route is obtained. Finally, the spokes are redistributed through the third stage, resulting in the new subset of the hub , the nearest neighbor algorithm is used to optimize the truck route for hub . A solution with a lower total network cost is finally obtained through the multiple iterations of the second and third stages.

The three-stage decomposition algorithm process is described in detail in Algorithm 7. In the first stage, p-hub location and spoke node allocations problem is solved by VNS, and then the hub set and node assignment set

are obtained. Stage 2 optimizes the truck route of each hub by using the nearest neighbor algorithm. The initial solution of truck route

is obtained and calculates the objective function

. Steps 1 to 5 indicate that, from the spoke node set

, a spoke node is selected in turn and assigned to other hubs, change hub allocation scheme

, then call the second stage nearest neighbor algorithm for shortest path optimization, and calculate the total cost. If reducing the total cost, then update the local optimal solution. Finally, a better allocation scheme

is used to replace the original allocation scheme

and outputs the truck route set

.

| Algorithm 7: The three-stage decomposition algorithm (TDA) |

| Input | |

| Output | |

| Stage 1 | |

| | |

| Stage 2 | |

| | |

| Stage 3 | |

| Step 1 | : |

| Step 2 |

|

| Step 3 |

|

| Step 4 | : |

| Step 5 |

|

| Stage 2 |

|

| Step 6 |

|

| Step 7 |

|

| Step 8 |

|

| Step 9 | End If |

| Step 10 | End For |

| Step 11 | End For |

| Step 12 | |

7. Conclusions

This study investigated an extension of the classical hub location problem for HSN to reduce costs. When there is insufficient demand for a spoke node to support a direct connection to the hub, it must consider non-fully connected links between hubs and nodes. Therefore, we form a ring structure route for the hub, and the assigned spokes. Our method has three phases: first select hubs from nodes, then assign the remaining spokes to hubs and then form a cycle structure routing for each cluster of spokes assigned to hubs. This way, the demand from the origin to the destination on the spoke-level route can be delivered directly without being transported to the hub and then dispatched to the destination. Although this may increase travel distance and cost, it can decrease truck investment and operating costs.

To solve the HSNTSP-D, we formulated a three-stage decomposition model, and a three-stage decomposition algorithm was developed to solve large-sized instances. First, a VNS algorithm is proposed to seek hub set and spoke-to-hub assignments. Then, the drone routing problem constituted by hubs and distributed spokes is solved to obtain the optimal TSP routes using an NNP neighborhood search. Last, through the RA strategy to change spoke-hub assignments for improving feasible solutions. We compare the three-stage decomposition algorithm with the CPLEX running results on the CAB date, TR data, and AP data. As the problem size increases, the three-stage decomposition algorithm performs well compared to CPLEX.

Analysis of numerical results presents that our proposed three-stage decomposition method is competitive in obtaining optimal solutions. For large-scale instances, the CPU computing time is within 10 min. To compare the costs of HSN with the drone and star structure HSN, the solutions obtained by our proposed model are compared with the solutions obtained by solving the single allocation p-hub median location problem. The HSN with drone structure replaces the mode of dedicated direct links in spoke-level routes, reducing the fixed and operating costs of using drones. This kind of hub-and-spoke network is most suitable to be applied to the distribution chain of pharmaceutical products, such as the dispatch of small quantities of emergency pharmaceutical supplies in emergency logistics—for instance, traffic congestion or disruptions such as traffic accidents, trucks breaking down, or road closures. In these cases, we need to use drones for transportation.

We provide a theoretical study for HSN design decisions with drones. The mathematical models and heuristics we propose may be critical tools for decision-makers when the fixed and operating costs of drones and hubs are considered when making decisions. However, there are also limitations of the study, such as not considering the parameters/constraints of the drone and the limits on the number of packages it can carry. For future research, the HSNTSP-D structure will add more real-world applications, such as selecting the appropriate drone type (weight, maximum payload, and maximum flight distance).