Experimental and Numerical Considerations for the Motor-Propeller Assembly’s Air Flow Field over a Quadcopter’s Arm

Abstract

:1. Introduction

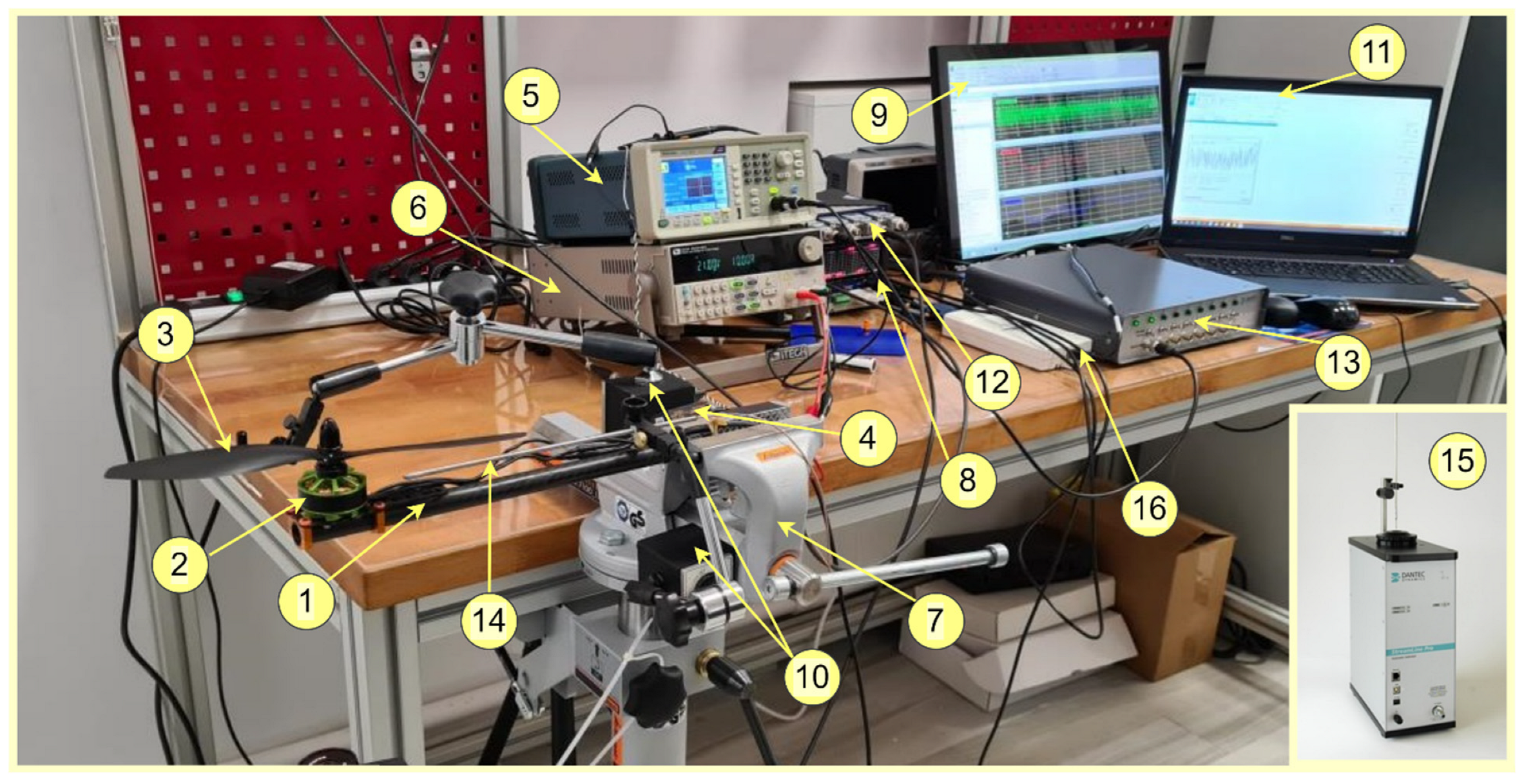

2. Materials and Methods

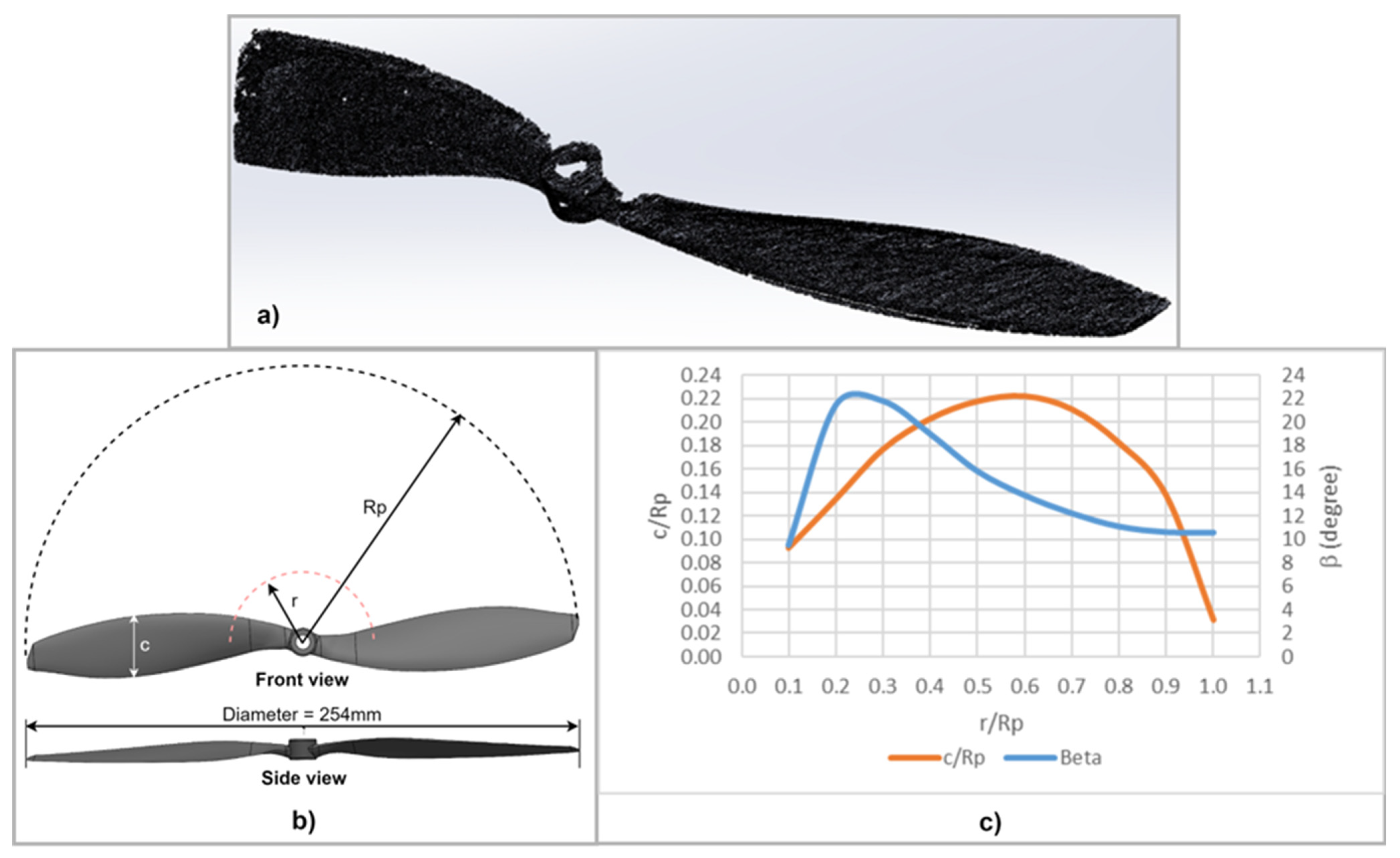

- motor–propeller assembly: (composed of TURNIGY Multistar 3508 640 v2 brushless electric motor and Multistar propeller with DJI adapter 254 × 114 mm);

- esc: HOBBYWING XRotorPro50A ESC (ESC = electronic speed controller, which was used to control and regulate the speed of the electric motor);

- the signal generator: TEKTRONIX-AFG1062 (through which, the step-type signal was introduced to drive the motor with the following characteristics: frequency of 500 Hz, power/duty cycle 50%, start phase 0°, amplitude 5 Vpp, compensation 2.5 V);

- voltage source: ITECH IT6722A 400 W DC with 80 V 20 A power supply (through which, 21 V voltage and 10 A electric current were introduced to drive the electric motor).

- the signal amplifier: QuantumX MX840B from HBM (used to amplify the measurement data acquired by the anemometer);

- hot wire anemometer: MultiChannel CTA 54N80 from Dantec Dynamics (CTA = constant temperature anemometer—multi-channel constant temperature anemometer was used to measure the speeds at different points of the air jet produced by the engine–propeller assembly in the vicinity of the quadcopter arm);

- miniature wire probes: 55P11 (used together with the anemometer of acquisition board: National Instruments NI USB-6212 (used for real-time viewing in StreamWare Basic software V6.50 of the results recorded by the anemometer);

- supports for probes with a single sensor: 55H21 (used together with the anemometer for recording the velocity field of the air jet);

- the anemometer calibration system: StreamLine (used to calibrate the miniature wire probes before and after each experimental test);

- acquisition board: National Instruments NI USB-6212 (used for real-time viewing in StreamWare Basic software of the results recorded by the anemometer);

- the computer: for running the StreamWave Basic software (software used together with the anemometer to measure air speeds in real time);

- the computer: for running the CATMAN-HBM software 5.5.3 (software used to display and interpret the results of measuring the speeds acquired from the anemometer).

3. Results

3.1. Determination of Air Jet Velocity Variations in the Vicinity of the Quadcopter Arm Generated by Propellers in Rotational Motion in Engine Operating Regimes Resulting from Experimental Testing

3.1.1. Calibration of Sensors

3.1.2. Recording Measurement Data from CTA

3.1.3. Analysis of Data Acquired with the CTA Anemometer

Analysis of Data in the Amplitude Domain

- The average value of the velocity (the first-order moment of the statistical series):

- The standard deviation of the velocity (defined as the second-order moment of the statistical series), also called the root mean square deviation of the velocity, which is determined as a simple mean square of the deviations of the values of the series from their mean, with the result representing the square root of the variance:

- The variance, also called the dispersion (defined as the second-order moment of the statistical series), which represents the turbulent kinetic energy per unit mass at a given point and is calculated as a simple arithmetic mean of the squares of the deviations of the terms of the series from their trend plant:

3.2. Numerical Analysis

3.2.1. Input Parameters

- For the 60% duty cycle (1350 RPM)—a physical time of 0.834 s was achieved until a periodic transient cycle was identified, and the time step for saving the results was 0.00055 s;

- For the 70% duty cycle (3900 RPM)—a physical time of 0.306 s was achieved until a periodic transient cycle was identified, and the time step for saving the results was 0.0002 s;

- For the 80% duty cycle (6100 RPM)—a physical time of 0.236 s was reached until a periodic transient cycle was identified, and the time step for saving the results was 0.000125 s;

- For the 90% duty cycle (7600 RPM)—a physical time of 0.151 s was achieved until a periodic transient cycle was identified, and the time step for saving the results was 0.0001 s.

3.2.2. Determination of the Air Jet Velocity Variations Resulting from the Numerical Analysis

3.2.3. Representation of the Variations in the Air Speed Component in the Z-Axis Direction

3.3. Comparative Analysis between Experimental and Numerical Results

4. Conclusions

5. Further Directions of Development

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Krijnen, D.; Dekker, C. AR Drone 2.0 with Subsumption Architecture. In Artificial Intelligence Research Seminar; Leiden University: Leiden, The Netherland, 2014; Available online: https://coendekker.nl/media/pdf/rsai_subsumption_drone.pdf (accessed on 23 November 2022).

- Cavoukian, A. Privacy and Drones: Unmanned Aerial Vehicles; Information and Privacy Commissioner of Ontario: Toronto, ON, Canada, 2012; Available online: https://www.ipc.on.ca/wp-content/uploads/resources/pbd-drones.pdf (accessed on 23 November 2022).

- Bachmann, R.J.; Boria, F.J.; Vaidyanathan, R.; Ifju, P.G.; Quinn, R.D. A Biologically Inspired Micro-Vehicle Capable of Aerial and Terrestrial Locomotion. Mech. Mach. Theory 2009, 44, 513–526. [Google Scholar] [CrossRef] [Green Version]

- Hassanalian, M.; Khaki, H.; Khosravi, M. A new method for design of fixed wing micro air vehicle. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2014, 229, 837–850. [Google Scholar] [CrossRef]

- Hassanalian, M.; Abdelkefi, A.; Wei, M.; Ziaei-Rad, S. A novel methodology for wing sizing of bio-inspired flapping wing micro air vehicles: Theory and prototype. Acta Mech. 2017, 228, 1097–1113. [Google Scholar] [CrossRef]

- IMAV 2021 Competition Rules for Indoor and Outdoor Competitions, and Special Challenges. International Micro Vehicle Conference and Competition, [Interactiv]. Available online: https://imav2021.inaoep.mx (accessed on 15 July 2022).

- Mohamed, A.; Abdulrahim, M.; Watkins, S.; Clothier, R. Development and flight testing of a turbulence mitigation system for micro air vehicles. J. Field Robot. 2015, 33, 639–660. [Google Scholar] [CrossRef]

- Deng, X.; Schenato, L.; Sastry, S.S. Attitude control for a micromechanical flying insect including thorax and sensor models. In Proceedings of the International Conference on Robotics & Automation, Taipei, Taiwan, 14–19 September 2003. [Google Scholar]

- Nvss, S.; Esakki, B.; Yang, L.-J.; Udayagiri, C.; Vepa, K.S. Design and Development of Unibody Quadcopter Structure Using Optimization and Additive Manufacturing Techniques. Designs 2022, 6, 8. [Google Scholar] [CrossRef]

- Geronel, R.S.; Botez, R.M.; Bueno, D.D. Design and Experimental Study on Vibration Reduction of an UAV Lidar Using Rubber Material. Actuators 2022, 11, 345. [Google Scholar] [CrossRef]

- Ge, C.; Dunno, K.; Singh, M.A.; Yuan, L.; Lu, L.-X. Development of a Drone’s Vibration, Shock, and Atmospheric Profiles. Appl. Sci. 2021, 11, 5176. [Google Scholar] [CrossRef]

- Zhou, H.; Ma, A.; Niu, Y.; Ma, Z. Small-Object Detection for UAV-Based Images Using a Distance Metric Method. Drones 2021, 6, 308. [Google Scholar] [CrossRef]

- Beltran-Carbajal, F.; Yañez-Badillo, H.; Tapia-Olvera, R.; Favela-Contreras, A.; Valderrabano-Gonzalez, A.; Lopez-Garcia, I. On Active Vibration Absorption in Motion Control of a Quadrotor UAV. Mathematics 2022, 10, 235. [Google Scholar] [CrossRef]

- Kang, N.; Sun, M. Simulated flowfields in near-ground operation of single- and twin-rotor configurations. J. Aircr. 2000, 37, 214–220. [Google Scholar] [CrossRef]

- Raza, S.A.; Sutherland, M.; Etele, J.; Fusina, G. Experimental validation of quadrotor simulation tool for flight within building wakes. Aero. Sci. Technol. 2017, 67, 169–180. [Google Scholar] [CrossRef]

- Kaya, K.; Ozcan, O. A numerical investigation on aerodynamic characteristics of an air-cushion vehicle. J. Wind Eng. Ind. Aerod. 2013, 120, 70–80. [Google Scholar] [CrossRef]

- Kutty, H.A.; Rajendran, P. 3D CFD simulation and experimental validation of small APC slow flyer propeller blade. Aerospace 2017, 4, 10. [Google Scholar] [CrossRef] [Green Version]

- Stajuda, M.; Karczewski, M.; Obidowski, D.; J’ozwik, K. Development of a CFD model for propeller simulation. Mech. Mech. Eng. 2016, 20, 579–593. [Google Scholar]

- Zhang, T.; Wang, Z.; Huang, W.; Ingham, D.; Ma, L.; Pourkashanian, M. A numerical study on choosing the best configuration of the blade for vertical axis wind turbines. J. Wind Eng. Ind. Aerod. 2020, 201, 104162. [Google Scholar] [CrossRef]

- Joo, S.; Choi, H.; Lee, J. Aerodynamic characteristics of two-bladed H-Darrieus at various solidities and rotating speeds. Energy 2015, 90, 439–451. [Google Scholar] [CrossRef]

- ANSYS. ANSYS Fluent Theory Guide; ANSYS: Canonsburg, PA, USA, 2016. [Google Scholar]

- Fernandes, N.D.S. Design and Construction of a Multi-Rotor with Various Degrees of Freedom. Master’s Thesis, Technical University of Lisbon, Lisbon, Portugal, 2011. [Google Scholar]

- Theys, B.; Dimitriadis, G.; Hendrick, P.; De Schutter, J. Influence of propeller configuration on propulsion system efficiency of multi-rotor Unmanned Aerial Vehicles. In Proceedings of the 2016 International Conference on Unmanned Aircraft Systems (ICUAS), Arlington, VA, USA, 7–10 June 2016. [Google Scholar]

- Penkov, I.; Aleksandrov, D. Analysis and study of the influence of the geometrical parameters of mini unmanned quad-rotor helicopters to optimise energy saving. Int. J. Automot. Mech. Eng. 2017, 14, 4730–4746. [Google Scholar] [CrossRef]

- Negru, A.; Ștefan, A.; Barbu, C. Aspects Regarding the Transverse Vibrations Eigenmodes of a Cantilever Beam Used for Clamping the Electric Motor on Unmanned Aerial Vehicle. In Proceedings of the 2019 E-Health and Bioengineering Conference (EHB), Iasi, Romania, 21–23 November 2019. [Google Scholar]

- Ștefan, A.; Negru, A.; Bucur, F. On the analytical, numerical and experimental models for determining the mode shapes of transversal vibrations of a cantilever beam. U.P.B. Sci. Bull. 2020, 82, 169–178. [Google Scholar]

- Jørgensen, F.E. The computer-controlled constant-temperature anemometer. Aspects of set-up, probe calibration, data acquisition and data conversion. Meas. Sci. Technol. 1996, 7, 1378–1387. [Google Scholar] [CrossRef]

- Teo, C.J.; Khoo, B.C.; Chew, Y.T. The dynamic response of a hot-wire anemometer: IV. Sine-wave voltage perturbation testing for near-wall hot-wire/film probes and the presence of low-high frequency response characteristics. Meas. Sci. Technol. 2000, 12, 37–51. [Google Scholar] [CrossRef]

- Bearman, P.W. Corrections for the Effect of Ambient Temperature Drift on Hot-Wire Measurements in Incompressible Flows; DISA Information No. 11; National Technical Reports Library: Springfield, VA, USA, 1971. [Google Scholar]

- Ali, S.F. Hot-wire anemometry in moderately heated flow. Rev. Sci. Instrum. 1975, 46, 185–191. [Google Scholar] [CrossRef]

- Bradshaw, P.; Woods, W.A. An Introduction to Turbulence and Its Measurement; Pergamon Press: Oxford, UK, 1971. [Google Scholar]

- Bruun, H.H. Hot-Wire Anemometry, Principles and Signal Analysis; Oxford Science Publications: Oxford, UK, 1995. [Google Scholar]

- Freymuth, P. Frequency response and electronic testing for constant-temperature hot-wire anemometers. J. Phys. E Sci. Instrum. 1977, 10, 705–710. [Google Scholar] [CrossRef]

- Smol’yakov, A.V.; Tkachenko, V.M. The Measurement of Turbulent Fluctuations: An Introduction to Hot-Wire Anemometry and Related Transducers; Springer: Berlin/Heidelberg, Germany; New York, NY, USA, 1983. [Google Scholar]

- Negru, A.; Pahonie, R.-C.; Mihai, R.-V.; Mihăilă-Andres, M. Tailoring capabilities of carbon fiber angle ply composites. MTA Rev. 2016, XXVI, 337–350. [Google Scholar]

- Wieczorowski, M. Industrial application of optical scanner. Zesz. Nauk. Akad. Tech.-Humanist. Bielsk. Białej 2006, 22, 381–390. [Google Scholar]

- Galanulis, K.; Reich, C.; Thesing, J.; Winter, D. Optical Digitizing by ATOS for Press Parts and Tools; Publikacja wewnętrzna GOM: Braunschweig, Germany, 2005; pp. 65–89. [Google Scholar]

| No. Calibration Point | U Generated | U | E1 | T [°C] | P [kPa] | U1calc |

|---|---|---|---|---|---|---|

| 1 | 0.500 | 0.501 | 1.424 | 22.512 | 101.325 | 0.504 |

| 2 | 0.619 | 0.618 | 1.445 | 22.516 | 101.325 | 0.616 |

| 3 | 0.767 | 0.781 | 1.471 | 22.518 | 101.325 | 0.777 |

| 4 | 0.950 | 0.947 | 1.494 | 22.518 | 101.325 | 0.945 |

| 5 | 1.177 | 1.173 | 1.522 | 22.514 | 101.325 | 1.175 |

| 6 | 1.458 | 1.460 | 1.551 | 22.511 | 101.325 | 1.462 |

| 7 | 1.805 | 1.841 | 1.586 | 22.507 | 101.325 | 1.846 |

| 8 | 2.236 | 2.232 | 1.616 | 22.509 | 101.325 | 2.237 |

| 9 | 2.770 | 2.818 | 1.655 | 22.509 | 101.325 | 2.815 |

| 10 | 3.430 | 3.429 | 1.690 | 22.515 | 101.325 | 3.425 |

| 11 | 4.249 | 4.314 | 1.735 | 22.514 | 101.325 | 4.310 |

| 12 | 5.263 | 5.261 | 1.776 | 22.520 | 101.325 | 5.243 |

| 13 | 6.518 | 6.610 | 1.829 | 22.522 | 101.325 | 6.627 |

| 14 | 8.074 | 8.073 | 1.877 | 22.529 | 101.325 | 8.082 |

| 15 | 10.000 | 10.022 | 1.933 | 22.521 | 101.325 | 10.015 |

| Measurements I—Sensor in the Direction Perpendicular to the Arm and the Propeller Axis at a Distance of 75 mm and r = 0 | |

|---|---|

| Regime 60% | Regime 70% |

|  |

| Regime 80% | Regime 90% |

|  |

| Measurements II—Sensor parallel to the arm at a distance of 25 mm from the plane of the propeller and r = 25 mm | |

| Regime 60% | Regime 70% |

|  |

| Regime 80% | Regime 90% |

|  |

| Experimental Measurements for Positions I and II | The Distance r Relative to the Helix Origin for the Measurement Point | The Relative Distance r/Rp (Rp—Propeller Radius) | Equivalent Point from Numerical Analysis | |

|---|---|---|---|---|

| Measurements I—sensor in the direction perpendicular to the arm in the position 0 degrees at the height z = 75 mm | r = 0 | 0 | PG Velocity (Z) | 4 |

| r = 20 | 0.1574 | PG Velocity (Z) | 8 | |

| r = 40 | 0.3149 | PG Velocity (Z) | 12 | |

| r = 60 | 0.4724 | PG Velocity (Z) | 16 | |

| r = 80 | 0.6299 | PG Velocity (Z) | 20 | |

| r = 100 | 0.7874 | PG Velocity (Z) | 24 | |

| r = 120 | 0.9448 | PG Velocity (Z) | 28 | |

| r = 140 | 1.1024 | PG Velocity (Z) | 32 | |

| Measurements II—sensor on the direction along the arm in the position 0 degrees at the height z = 25 mm | r = 25 | 0.1968 | PG Velocity (Z) | 36 |

| r = 35 | 0.2756 | PG Velocity (Z) | 40 | |

| r = 45 | 0.3543 | PG Velocity (Z) | 44 | |

| r = 55 | 0.4331 | PG Velocity (Z) | 48 | |

| r = 65 | 0.5118 | PG Velocity (Z) | 52 | |

| r = 75 | 0.5905 | PG Velocity (Z) | 56 | |

| r = 85 | 0.6693 | PG Velocity (Z) | 60 | |

| r = 95 | 0.7480 | PG Velocity (Z) | 64 | |

| r = 105 | 0.8268 | PG Velocity (Z) | 68 | |

| r = 115 | 0.9055 | PG Velocity (Z) | 72 | |

| r = 125 | 0.9843 | PG Velocity (Z) | 76 | |

| r = 135 | 1.0630 | PG Velocity (Z) | 80 | |

| Experimental Measurements for Positions I and II | The Relative Distance r/Rp (Rp—Propeller Radius) | Equivalent Point from Numerical Analysis | Engine Power Cycles [%] | Average Velocity Component Measured with Dantec Dynamics CTA [m/s] | Average Velocity from Numerical Analysis [m/s] | Absolute Percentage Error [%] |

|---|---|---|---|---|---|---|

| Measurements I—sensor on the direction along the arm in the position 0 degrees at the height z = 75 mm | 0 | 4 | 60% 70% 80% 90% | 1.674 4.073 6.736 7.628 | 1.190 3.594 5.726 7.087 | 28.91 11.76 14.99 7.09 |

| 0.1574 | 8 | 60% 70% 80% 90% | 2.094 6.498 10.565 12.191 | 2.159 6.409 10.098 12.596 | 3.10 1.36 4.42 3.32 | |

| 0.3149 | 12 | 60% 70% 80% 90% | 3.700 10.524 16.932 18.706 | 3.217 9.491 14.984 18.652 | 13.05 9.81 11.50 0.28 | |

| 0.4724 | 16 | 60% 70% 80% 90% | 4.092 11.916 18.932 22.387 | 3.834 11.316 17.780 22.267 | 6.30 5.04 6.08 0.54 | |

| 0.6299 | 20 | 60% 70% 80% 90% | 4.064 11.692 19.109 22.808 | 3.817 11.285 17.772 22.233 | 6.08 3.48 7.00 2.52 | |

| 0.7874 | 24 | 60% 70% 80% 90% | 1.645 7.541 11.787 13.896 | 1.556 4.618 7.509 9.451 | 5.41 38.76 36.29 31.99 | |

| 0.9448 | 28 | 60% 70% 80% 90% | 0.576 1.571 2.926 3.831 | 0.196 0.598 0.710 0.904 | 65.97 61.94 75.73 76.40 | |

| 1.1024 | 32 | 60% 70% 80% 90% | 0.279 0.556 0.822 1.001 | 0.353 1.079 1.485 1.890 | 26.52 94.06 80.66 88.81 | |

| Measurements II—sensor on the direction along the arm in the position 0 degrees at the height z = 25 mm | 0.1968 | 36 | 60% 70% 80% 90% | 1.098 2.974 5.915 6.670 | 0.850 2.530 3.959 4.990 | 22.68 14.92 33.07 25.19 |

| 0.2756 | 40 | 60% 70% 80% 90% | 2.131 6.275 10.059 11.947 | 1.939 5.711 8.993 11.192 | 9.01 8.99 10.60 6.32 | |

| 0.3543 | 44 | 60% 70% 80% 90% | 2.088 5.807 9.379 11.034 | 2.128 6.282 9.894 12.326 | 1.92 8.18 5.49 11.71 | |

| 0.4331 | 48 | 60% 70% 80% 90% | 1.985 5.766 9.162 10.536 | 2.121 6.362 10.030 12.521 | 6.85 10.34 9.47 18.84 | |

| 0.5118 | 52 | 60% 70% 80% 90% | 2.277 6.647 10.851 12.823 | 2.363 6.962 10.960 13.685 | 3.78 4.74 1.00 6.72 | |

| 0.5905 | 56 | 60% 70% 80% 90% | 2.519 7.475 12.190 14.606 | 2.550 7.501 11.792 14.721 | 1.15 0.33 3.26 0.78 | |

| 0.6693 | 60 | 60% 70% 80% 90% | 2.941 8.984 14.482 17.215 | 2.980 8.823 13.915 17.343 | 1.33 1.79 3.92 0.74 | |

| 0.7480 | 64 | 60% 70% 80% 90% | 3.190 9.506 15.188 18.223 | 2.945 8.628 13.519 16.959 | 7.68 9.24 10.99 6.94 | |

| 0.8268 | 68 | 60% 70% 80% 90% | 1.507 5.113 9.254 11.758 | 1.962 5.648 8.708 11.182 | 30.19 10.46 5.90 4.90 | |

| 0.9055 | 72 | 60% 70% 80% 90% | 0.543 1.330 2.624 3.039 | 0.760 2.271 3.590 4.704 | 39.96 70.75 36.81 54.79 | |

| 0.9843 | 76 | 60% 70% 80% 90% | 0.356 0.929 1.256 1.523 | 0.773 2.275 3.628 4.248 | 117.13 144.89 188.85 178.92 | |

| 1.0630 | 80 | 60% 70% 80% 90% | 0.438 0.788 1.439 1.394 | 0.671 2.076 3.209 4.065 | 53.20 163.45 123.00 191.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tofan-Negru, A.; Ștefan, A.; Grigore, L.Ș.; Oncioiu, I. Experimental and Numerical Considerations for the Motor-Propeller Assembly’s Air Flow Field over a Quadcopter’s Arm. Drones 2023, 7, 199. https://doi.org/10.3390/drones7030199

Tofan-Negru A, Ștefan A, Grigore LȘ, Oncioiu I. Experimental and Numerical Considerations for the Motor-Propeller Assembly’s Air Flow Field over a Quadcopter’s Arm. Drones. 2023; 7(3):199. https://doi.org/10.3390/drones7030199

Chicago/Turabian StyleTofan-Negru, Andra, Amado Ștefan, Lucian Ștefăniță Grigore, and Ionica Oncioiu. 2023. "Experimental and Numerical Considerations for the Motor-Propeller Assembly’s Air Flow Field over a Quadcopter’s Arm" Drones 7, no. 3: 199. https://doi.org/10.3390/drones7030199

APA StyleTofan-Negru, A., Ștefan, A., Grigore, L. Ș., & Oncioiu, I. (2023). Experimental and Numerical Considerations for the Motor-Propeller Assembly’s Air Flow Field over a Quadcopter’s Arm. Drones, 7(3), 199. https://doi.org/10.3390/drones7030199