Analysis of Aerodynamic Characteristics of Propeller Systems Based on Martian Atmospheric Environment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Dynamic Conditions in the Atmospheric Environment of Mars

2.1.1. Martian Atmosphere

2.1.2. Air Dynamics under Low Reynolds Numbers

2.1.3. Effect of Reynolds Number on the Aerodynamic Performance of Mars Propellers

2.2. Mars UAV Rotor System Design

2.3. Numerical Simulation

2.3.1. Unsteady Compressible Streams

2.3.2. Numerical Simulation Calculations

2.4. Lightweight Design and Strength Calibration of Mars Propellers

2.5. First-Generation Mars UAV Flight

2.5.1. Dynamical Equations and Equations of Motion of an Unmanned Helicopter on Mars

2.5.2. System Nonlinear Model

3. Results

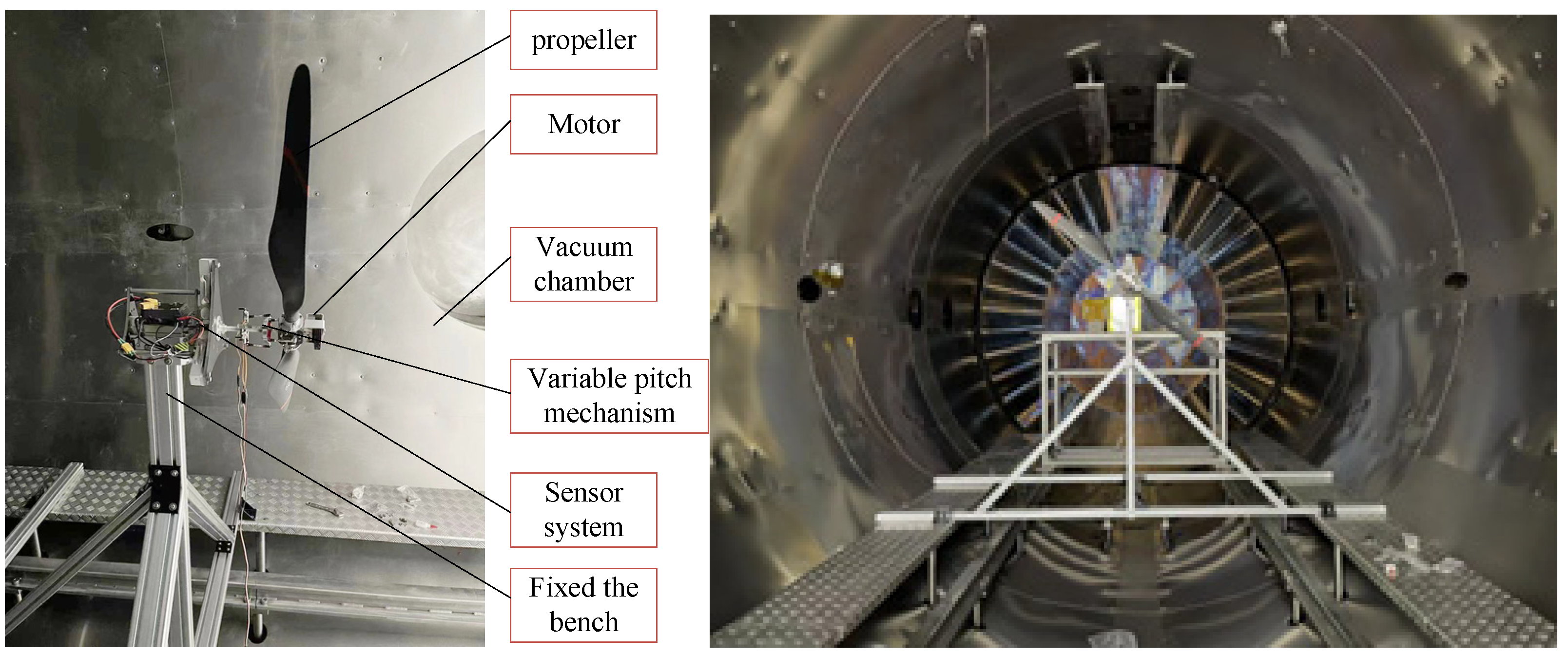

3.1. Experimental Protocol

3.2. Experimental Results and Analysis

- (1)

- In the process of pumping the density of air in the vacuum chamber to the same as that of the Martian atmosphere, there were errors, and there were difficulties in achieving exactly the same between the two;

- (2)

- The accuracy of force and torque sensors was not enough, leading to the deviation of the tested data;

- (3)

- Due to the mechanism of the experimental bench, a great centrifugal force will be generated when the propeller rotates at a high rotational speed, which will lead to the vibration of the test bench in the process of testing, and then produce a certain deviation;

- (4)

- Due to the existence of an idle stroke (due to mechanical structural gaps), the angle of attack will produce a certain deviation in each variation of pitch, which will affect the experimental results to a great extent;

- (5)

- The vacuum chamber is a closed container. In the process of the experiment, certain wall effects and air reflux will be formed.

3.3. Mars Unmanned Helicopter Hover Experiment

4. Conclusions

- (1)

- In order to reduce the weight of the Martian propeller, the adopted foam sandwich structure had a good weight reduction effect, and through finite element calculation and Earth environment bench experiments, the three-layer carbon fiber ply was verified to not only meet the lightweight and strength requirements, but also meet the requirements of the manufacturing process, which is the most suitable manufacturing method of the Mars propeller at present.

- (2)

- Under the CFD numerical simulation, when the angle of attack was fixed, the thrust coefficient of the Martian propeller increased with the increase in speed, and the power coefficient decreased accordingly. The merit factor also increased with the increase in the propeller speed. When the propeller speed was constant, the thrust coefficient and power coefficient of the propeller increased accordingly with the increase in angle of attack, and the merit factor also increased accordingly. However, at 8° and 10° angles of attack, it had almost the same quality factor.

- (3)

- A vacuum chamber experiment simulating the Martian atmospheric environment was conducted on the Martian propeller, and the aerodynamic characteristics of the Martian propeller in the Martian atmospheric environment were further explored. There was an error between the experimental results and the numerical simulation results, mainly because the numerical simulation was a simulation calculation in an ideal environment, while the experimental test had many external interferences, but the two exhibited roughly the same trend.

- (4)

- The numerical simulation method considered the unsteady compressible flow and the vacuum chamber experiment of the simulated Martian atmospheric environment verified that the designed propeller system had good aerodynamic performance in the Martian atmospheric environment. On this basis, the initial design of the Mars unmanned helicopter was formulated, and the relevant hover experiments were conducted, providing reference and theoretical support for the design of subsequent Mars UAV sequences.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Petritoli, E.; Leccese, F. Unmanned Autogyro for Mars Exploration: A Preliminary Study. Drones 2021, 5, 53. [Google Scholar] [CrossRef]

- Wu, W.R.; Yu, D.Y. Development of deep space exploration and its future key technologies. J. Deep Space Explor. 2014, 1, 5–17. [Google Scholar]

- Datta, A.; Roget, B.; Griffiths, D.; Pugliese, G.; Sitaraman, J.; Bao, J.; Liu, L.; Gamard, O. Design of a Martian autonomous rotary-wing vehicle. J. Aircr. 2015, 40, 461–472. [Google Scholar] [CrossRef]

- Chi, C.; Lumba, R.; Su Jung, Y.; Datta, A. Aeromechanical Analysis of a Next-Generation Mars Helicopter Rotor. J. Aircr. 2022, 59, 1463–1477. [Google Scholar] [CrossRef]

- Ruiz, M.C.; D’Ambrosio, D. Aerodynamic optimization and analysis of quadrotor blades operating in the Martian atmosphere. Aerosp. Sci. Technol. 2023, 132. [Google Scholar]

- Balaram, J.; Aung, M.; Golombek, M.P. The Ingenuity Helicopter on the Perseverance Rover. Space Sci. Rev. 2021, 217, 2–11. [Google Scholar] [CrossRef]

- Balaram, J.; Daubar, I.J.; Bapst, J.; Tzanetos, T. Helicopters on Mars: Compelling Science of Extreme Terrains Enabled by an Aerial Platform. In Proceedings of the 9th International Conference on Mars, Pasadena, CA, USA, 22–25 July 2019; Volume 2089. [Google Scholar]

- Pipenberg, B.T.; Keennon, M.T.; Langberg, S.A.; Tyler, J.D.; Balaram, J. Development of the Mars Helicopter Rotor System. In Vertical Flight Society Annual Forum and Technology Display, Proceedings of the 75th American Helicopter Society Annual Forum, Philadelphia, PA, USA, 13–16 May 2019; Vertical Flight Society: Fairfax, VA, USA, 2019; Volume 382. [Google Scholar]

- Takaki, R. Aerodynamic characteristics of NACA4402 in low Reynolds number flows. Jpn. Soc. Aeronaut. Space Sci. 2006, 54, 367–373. [Google Scholar]

- Shrestha, R.; Benedict, M.; Chopra, I. Hover Performance of a Small-Scale Helicopter Rotor for Flying on Mars. J. Aircr. 2016, 53, 1160–1167. [Google Scholar] [CrossRef]

- Kurane, K.; Uechi, K.; Takahashi, K.; Fujita, K.; Nagai, H. Aerodynamic Characteristics of Mars Airplane Airfoils with Control Surface in Propeller Slipstream. In Proceedings of the 2018 AIAA Aerospace Sciences Meeting, AIAA-2018-2058, Kissimmee, FL, USA, 8–12 January 2018. [Google Scholar]

- Pipenberg, B.T.; Keennon, M.; Tyler, J.; Hibbs, B.; Langberg, S.; Balaram, J.; Grip, H.F.; Pempejian, J. Design and Fabrication of the Mars Helicopter Rotor, Airframe, and Landing Gear Systems. In Proceedings of the AIAA Scitech 2019 Forum, AIAA-2019-0620, San Diego, CA, USA, 7–11 January 2019. [Google Scholar]

- Koning, W.J.; Johnson, W.; Grip, H.F. Improved Mars Helicopter Aerodynamic Rotor Model for Comprehensive Analyses. AIAA J. 2019, 57, 3969–3979. [Google Scholar] [CrossRef] [Green Version]

- Kunz, P.J. Aerodynamics and Design for Ultra-Low Reynolds Number Flight; Stanford University: Stanford, CA, USA, 2003. [Google Scholar]

- Liu, Z.; Albertani, R.; Moschetta, J.M.; Thipyopas, C.; Xu, M. Experimental and Computational Evaluation of Small Microcoaxial Rotor in Hover. J. Aircr. 2011, 48, 220–229. [Google Scholar] [CrossRef]

- Bohorquez, F. Rotor Hover Performance and System Design of an Efficient Coaxial Rotary Wing Micro Air Vehicle; University of Maryland: College Park, MD, USA, 2007. [Google Scholar]

- Oyama, A.; Fujii, K. Airfoil design optimization for airplane for Mars exploration. In Proceedings of the J-55, the Third China-Japan-Korea Joint Symposium on Optimization of Structual and Mechanical Systems, CJK-OSM3, Kanazawa, Japan, 30 October–2 November 2004; pp. 1–3. [Google Scholar]

- Koning, W.J.; Romander, E.A.; Johnson, W. Low Reynolds number airfoil evaluation for the Mars helicopter rotor. In Proceedings of the American Helicopter Society 74th Annual Forum, Phoenix, AZ, USA, 14–17 May 2018; pp. 1–17. [Google Scholar]

- Désert, T.; Jardin, T.; Bézard, H.; Moschetta, J. Numerical predictions of low Reynolds number compressible aerodynamics. Aerosp. Sci. Technol. 2019, 92, 211–223. [Google Scholar] [CrossRef] [Green Version]

- Braun, R.D.; Wright, H.S.; Croom, M.A.; Levine, J.S.; Spencer, D.A. Design of the ARES Mars Airplane and Mission Architecture. J. Spacecr. Rockets 2006, 43, 1026–1034. [Google Scholar] [CrossRef]

- Marko, Ž.; Ekmedzic; Aleksandar, B.; Boško, R. Conceptual Design and Flight Envelopes of a Light Aircraft for Mars Atmosphere. Teh. Vjesn. 2018, 25, 375–381. [Google Scholar]

- Chen, S.T. Lift Drag Characteristics and Experimental Study of Mars Probe Rotor Uav; Harbin Institute of Technology: Harbin, China, 2019; pp. 13–17. [Google Scholar]

- Desert, T.; Moschetta, J.M.; Bezard, H. Numerical and experimental investigation of an airfoil design for a Martian micro rotorcraft. Int. J. Micro Air Veh. 2018, 10, 262–272. [Google Scholar] [CrossRef]

- Jung, J.; Yee, K.; Misaka, T.; Jeong, S. Low Reynolds Number Airfoil Design for a Mars Exploration Airplane Using a Transition Mode. Jpn. Soc. Aeronaut. Space Sci. 2017, 60, 333–340. [Google Scholar]

- Mcmasters, J.H.; Henderson, M.L. Low-Speed Single-Element Airfoil Synthesis. Tech. Soar. 1979, 6, 19–23. [Google Scholar]

- Drela, M. Transonic low-Reynolds number airfoils. J. Aircr. 1992, 29, 1106–1113. [Google Scholar] [CrossRef]

- Anyoji, M.; Numata, D.; Nagai, H.; Asai, K. Effects of Mach Number and Specific Heat Ratio on Low-Reynolds-Number Airfoil Flows. AIAA J. 2014, 53, 1640–1654. [Google Scholar] [CrossRef]

- Ananda, G.K.; Sukumar, P.P.; Selig, M.S. Measured aerodynamic characteristics of wings at low Reynolds numbers. Aerosp. Sci. Technol. 2015, 42, 392–406. [Google Scholar] [CrossRef]

- Okamoto, M. An Experimental Study in Aerodynamic Characteristics of Steady and Unsteady Airfoils at Low Reynolds Number; Nihon University: Tokyo, Japan, 2005. [Google Scholar]

- Bézard, H.; Désert, T.; Jardin, T.; Moschetta, J.M. Numerical and Experimental Aerodynamic Investigation of a Micro-UAV for Flying on Mars. In Proceedings of the 76th Annual Forum & Technology Display, Online, 5–8 October 2020; Volume 17. [Google Scholar]

- Liu, P.Q. Theory and Application of Air Propeller; Beijing University of Aeronautics and Astronautics Press: Beijing, China, 2006; pp. 148–234. [Google Scholar]

- Zahra, S.; Hwang, Y.; Sotoudeh, Z. A Variational Principle for Unsteady Compressible Flow. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016; pp. 4–8. [Google Scholar]

| Features | Mars | Earth |

|---|---|---|

| Acceleration of gravity (m/s2) | 3.72 | 9.78 |

| Atmospheric pressure (Pa) | 756 | 101,300 |

| Air density (kg/m3) | 0.0167 | 1.22 |

| Mean temperature (°C) | −63 | 15 |

| Sound velocity (m/s) | 227 | 340 |

| Atmospheric dynamic viscosity (kg/(m·s)) | 1.289 × 10−5 | 1.789 × 10−5 |

| Gas constants (J/kg/K) | 188 | 287 |

| Specific heat capacity ratioγ | 1.29 | 1.40 |

| Molar mass (g/mol) | 44.01 | 28.96 |

| Mesh Density (104) | Simulation Time (h) | Thrust Error | Torque Error | |

|---|---|---|---|---|

| Coarse | 1237 | 15 | 5.77% | 6.228% |

| Medium | 2506 | 26 | 0.985% | 2.076% |

| Fine | 5032 | 38 | 0% | 0% |

| Range | Accuracy | |

|---|---|---|

| Force sensor/kg | 0~3 | 0.2% ± 20 g |

| Temperature sensor/°C | −40~350 | ±1% ± 1.5 |

| Voltage sensor/V | 11~55 | ±0.03% ± 0.03 |

| Current sensor/A | 0.2~80 | ±0.4% ± 0.1 |

| Speed sensor/rpm | 1500~3000 | ±0.5% ± 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Xu, B.; Zhang, H.; Xiang, C.; Fan, W.; Zhao, Z. Analysis of Aerodynamic Characteristics of Propeller Systems Based on Martian Atmospheric Environment. Drones 2023, 7, 397. https://doi.org/10.3390/drones7060397

Zhang W, Xu B, Zhang H, Xiang C, Fan W, Zhao Z. Analysis of Aerodynamic Characteristics of Propeller Systems Based on Martian Atmospheric Environment. Drones. 2023; 7(6):397. https://doi.org/10.3390/drones7060397

Chicago/Turabian StyleZhang, Wangwang, Bin Xu, Haitao Zhang, Changle Xiang, Wei Fan, and Zhiran Zhao. 2023. "Analysis of Aerodynamic Characteristics of Propeller Systems Based on Martian Atmospheric Environment" Drones 7, no. 6: 397. https://doi.org/10.3390/drones7060397