Paving the Way for Last-Mile Delivery in Greece: Data-Driven Performance Analysis with a Customized Quadrotor

Abstract

:1. Introduction

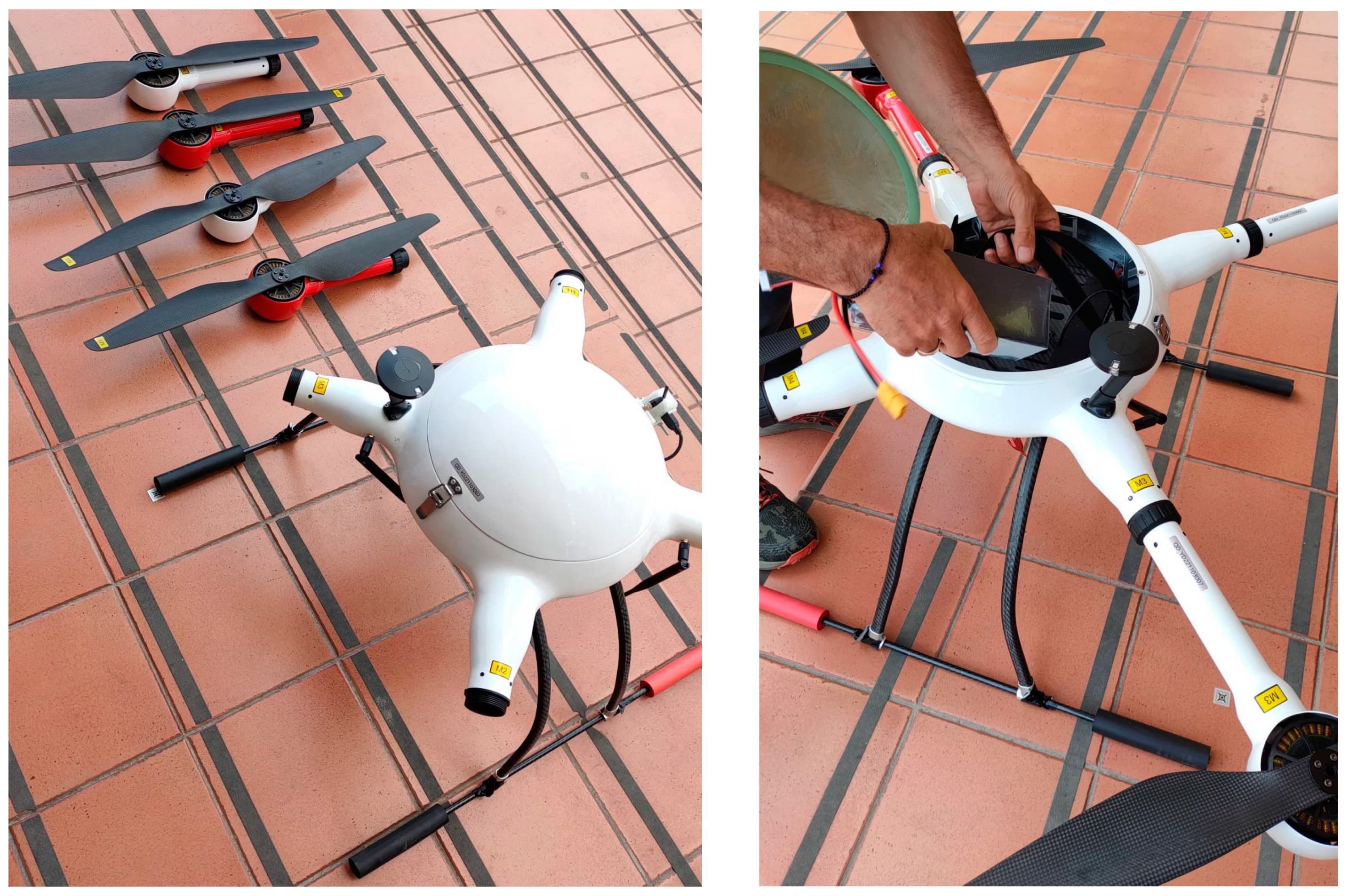

- The design, manufacturing, and semi-autonomous flight testing were conducted using a customized quadrotor of 5 kg payload capacity that supports the following two types of loading–unloading mechanisms: suspended beneath by a cable with auto-retraction or stored in an ultra-light box, attached to the multirotor body.

- Data-driven methodology was used for charging stations for cargo shipping, while also taking in uncertainties encountered during the flight, such as weather conditions and battery discharge.

- The following were conducted performance evaluation of flight range and energy consumption, cost-benefit analysis compared to a conventional delivery van, and the altimetric assessment of SRTM Digital Terrain Elevation Data (DTED) for systematic errors at a local and regional base in Greece.

2. Literature Review

2.1. State of Cargo Drone Operations

2.2. Work Contributions

- Vertical errors of STRM DTM to reduce the likelihood of infeasible routes, ground collisions, and inaccurate deliveries.

- The choice between two package delivery mechanisms: the suspended cable system is preferred for precise locations with altitude accuracies, especially in urban and semi-urban areas, while the ultra-light box attachment is suitable for cases of excessive wind or unavailability of the customer.

3. Design and Computer Systems of Cargo Drone

3.1. Drone Characteristics

3.1.1. Structure and Performance

3.1.2. Assistive Sensors

3.1.3. Flight Control System and Communication

3.1.4. Firmware and Ground Control Station

- Control mechanisms of the motors, actuators, sensors, and other components that ensure its safe operation. They are referred to as the Flight Management Unit (FMU).

- Stabilization of the drone in flight by adjusting the position of the propellers and blades to maintain the desired position and altitude.

- Flight policies, i.e., rules and measures that determine how the drone will react in different situations, such as obstacle avoidance, flight behavior during bad weather conditions, flight area restrictions, etc.

- Safety mechanisms, including actions for automatic landing in case of unexpected situations, avoidance of air accidents, and protection of system data.

- Communication protocols with the operator, including flight commands, status reports, and data from sensors.

- Loading of the firmware that controls the drone on the autopilot board.

- Drawing, storing, and loading autonomous missions to the autopilot by simply entering waypoints on any cartographic background.

- Downloading and analyzing in real-time mission logs generated by the autopilot.

- Monitoring the status of the drone during telemetry operation.

- Monitoring and analyzing telemetry logs after the completion of delivery missions.

3.2. Safety and Regulation Specifications

3.3. Cargo Handling Mechanisms

4. Methodology

4.1. Performance-Based Formulas

- Null hypothesis (H0): there is no linear relationship between payload weight and electrical energy consumption (0).

- Alternative hypothesis (Ha): there is a linear relationship between payload weight and electrical energy consumption (≠ 0).

4.2. Altimetric Assessment

4.3. Charging Stations Distribution

4.3.1. Problem Statement and Assumptions

4.3.2. Model Formulation

5. Implementation

5.1. Flight Missions

5.2. Data Processing

- General system status: power supply, battery consumption, and system temperatures.

- Speed monitoring: rate of climb (vertical movement) and actual speed relative to the ground below, considering the drone’s airspeed and the effects of wind.

- Geospatial position: the geographical position in a geocentric system derived from GPS data and sensor values.

- Attitude: the drone’s orientation in relation to an aeronautical reference system, including its desired position, speed, and/or acceleration.

- Global coordinate system: the drone’s position, speed, and acceleration in a global coordinate system (WGS84) and the SRTM’s DEM, provided by the operator/pilot during mission planning.

- Vibrations and accelerometer clipping: vibration levels and instances of accelerometer clipping, which is a measure of abrupt changes in acceleration.

5.3. Flight Range

6. Data Analysis

6.1. Results of Performance Evaluation

6.1.1. Energy Consumption

6.1.2. Altimetric Accuracy Assessment

6.2. Charging Stations Distribution

6.3. Environmental and Economic Impact

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Advance Notice of Proposed Amendment 2015-10, EASA. Available online: https://www.easa.europa.eu/sites/default/files/dfu/A-NPA%202015-10.pdf (accessed on 30 October 2023).

- OpenTopography Shuttle Radar Topography Mission (SRTM) Global. 2013. Available online: https://portal.opentopography.org/datasetMetadata?otCollectionID=OT.042013.4326.1 (accessed on 30 October 2023).

- ArduPilot Dev Team. Mission Planner. Available online: https://ardupilot.org/planner/ (accessed on 30 October 2023).

- Amazon. Amazon Prime Air. Available online: https://goo.gl/CScVNp (accessed on 30 October 2023).

- Jung, S.; Kim, H. Analysis of Amazon Prime Air UAV Delivery Service. J. Knowl. Inf. Technol. Syst. 2017, 12, 253–266. [Google Scholar]

- Wingcopter. Available online: https://wingcopter.com/ (accessed on 30 October 2023).

- Dronamics. Available online: https://www.dronamics.com/ (accessed on 30 October 2023).

- Healthcare MEA. Zipline Expands Medical Drone Deliveries in Ghana. HealthCare Middle East & Africa Magazine. Available online: https://www.healthcaremea.com/zipline-expands-medical-drone-deliveries-in-ghana/ (accessed on 30 October 2023).

- Porter, J. Alphabet’s Nascent Drone Delivery Service Is Booming. The Verge. Available online: https://www.theverge.com/2020/4/9/21214709/alphabet-wing-drone-delivery-coronavirus-covid-19-demand-increase-toilet-paper-baby-food (accessed on 30 October 2023).

- Skyports Drone Services. Available online: https://skyportsdroneservices.com/skyports-drone-services-partners-with-equinor-for-cargo-drone-deliveries-to-offshore-oil-field/ (accessed on 30 October 2023).

- AIRCARRUS—Autonomous Drone Delivery System. Available online: https://cordis.europa.eu/article/id/415490-building-the-world-s-drone-infrastructure/ (accessed on 30 October 2023).

- CORUS-XUAM. Available online: https://corus-xuam.eu/ (accessed on 30 October 2023).

- Lappas, V.; Zoumponos, G.; Kostopoulos, V.; Lee, H.I.; Shin, H.-S.; Tsourdos, A.; Tantardini, M.; Shomko, D.; Munoz, J.; Amoratis, E.; et al. EuroDRONE, a European Unmanned Traffic Management Testbed for U-Space. Drones 2022, 6, 53. [Google Scholar] [CrossRef]

- SES Area Member States, U-Space Services, Implementation Monitoring Report. Available online: https://www.eurocontrol.int/sites/default/files/2020-09/uspace-services-implementation-monitoring-report-2020-1-1.pdf (accessed on 30 October 2023).

- Silva, A.T.; Duarte, S.P.; Melo, S.; Witkowska-Konieczny, A.; Giannuzzi, M.; Lobo, A. Attitudes towards Urban Air Mobility for E-Commerce Deliveries: An Exploratory Survey Comparing European Regions. Aerospace 2023, 10, 536. [Google Scholar] [CrossRef]

- Thipphavong, D.P.; Apaza, R.; Barmore, B.; Battiste, V.; Burian, B.; Dao, Q.; Feary, M.; Go, S.; Goodrich, K.H.; Homola, J.; et al. Urban Air Mobility Airspace Integration Concepts and Considerations. In Proceedings of the 2018 Aviation Technology, Integration, and Operations Conference, Atlanta, GA, USA, 24–28 June 2018; American Institute of Aeronautics and Astronautics: Atlanta, GA, USA, 2018. [Google Scholar]

- Yuen, K.F.; Cai, L.; Lim, Y.G.; Wang, X. Consumer Acceptance of Autonomous Delivery Robots for Last-Mile Delivery: Technological and Health Perspectives. Front. Psychol. 2022, 13, 953370. [Google Scholar] [CrossRef] [PubMed]

- Arntz, E.M.; Van Duin, J.H.R.; Van Binsbergen, A.J.; Tavasszy, L.A.; Klein, T. Assessment of Readiness of a Traffic Environment for Autonomous Delivery Robots. Front. Future Transp. 2023, 4, 1102302. [Google Scholar] [CrossRef]

- Sawadsitang, S.; Niyato, D.; Tan, P.S.; Wang, P. Supplier Cooperation in Drone Delivery. In Proceedings of the 2018 IEEE 88th Vehicular Technology Conference (VTC-Fall), Chicago, IL, USA, 27–30 August 2018; IEEE: Chicago, IL, USA, 2018; pp. 1–5. [Google Scholar]

- ElSayed, M.; Foda, A.; Mohamed, M. The Impact of Civil Airspace Policies on the Viability of Adopting Autonomous Unmanned Aerial Vehicles in Last-Mile Applications. Transp. Policy 2024, 145, 37–54. [Google Scholar] [CrossRef]

- Dorling, K.; Heinrichs, J.; Messier, G.G.; Magierowski, S. Vehicle Routing Problems for Drone Delivery. IEEE Trans. Syst. Man Cybern. Syst. 2017, 47, 70–85. [Google Scholar] [CrossRef]

- Huang, H.; Savkin, A.V.; Member, S.; Huang, C. Round trip routing for energy-efficient drone delivery based on a public transportation network. IEEE Trans. Transp. Electr. 2020, 6, 1368–1376. [Google Scholar] [CrossRef]

- Moadab, A.; Farajzadeh, F.; Fatahi Valilai, O. Drone Routing Problem Model for Last-Mile Delivery Using the Public Transportation Capacity as Moving Charging Stations. Sci. Rep. 2022, 12, 6361. [Google Scholar] [CrossRef] [PubMed]

- Hong, I.; Kuby, M.; Murray, A.T. A range-restricted recharging station coverage model for drone delivery service planning. Transp. Res. Part C Emerg. Technol. 2018, 90, 198–212. [Google Scholar] [CrossRef]

- Gan, X.; Zhang, H.; Hang, G.; Qin, Z.; Jin, H. Fast-charging station deployment considering elastic demand. IEEE Trans. Transp. Electrif. 2020, 6, 158–169. [Google Scholar] [CrossRef]

- Huang, H.; Savkin, A.V. A method of optimized deployment of charging stations for drone delivery. IEEE Trans. Transp. Electrif. 2020, 6, 510–518. [Google Scholar] [CrossRef]

- Kim, J.; Morrison, J.R. On the Concerted Design and Scheduling of Multiple Resources for Persistent UAV Operations. J. Intell. Robot Syst. 2014, 74, 479–498. [Google Scholar] [CrossRef]

- Sun, D.; Peng, X.; Qiu, R.; Huang, Y. The traveling salesman problem: Route planning of recharging station-assisted drone delivery. In Proceedings of the Fourteenth International Conference on Management Science and Engineering Management, Toledo, Spain, 1–4 August 2021; Springer: Berlin/Heidelberg, Germany, 2021; Volume 2, pp. 13–23. [Google Scholar]

- Murray, C.C.; Chu, A.G. The flying sidekick traveling salesman problem: Optimization of drone-assisted parcel delivery. Transp. Res. Part C Emerg. Technol. 2015, 54, 86–109. [Google Scholar] [CrossRef]

- Rave, A.; Fontaine, P.; Kuhn, H. Drone Location and Vehicle Fleet Planning with Trucks and Aerial Drones. Eur. J. Oper. Res. 2023, 308, 113–130. [Google Scholar] [CrossRef]

- Mohammed, F.; Idries, A.; Mohamed, N.; Al-Jaroodi, J.; Jawhar, I. UAVs for Smart Cities: Opportunities and Challenges. In Proceedings of the 2014 International Conference on Unmanned Aircraft Systems (ICUAS), Orlando, FL, USA, 27–30 May 2014; IEEE: Orlando, FL, USA, 2014; pp. 267–273. [Google Scholar]

- Li, F.; Kunze, O. A Comparative Review of Air Drones (UAVs) and Delivery Bots (SUGVs) for Automated Last Mile Home Delivery. Logistics 2023, 7, 21. [Google Scholar] [CrossRef]

- Rauhala, A.; Tuomela, A.; Leviäkangas, P. An Overview of Unmanned Aircraft Systems (UAS) Governance and Regulatory Frameworks in the European Union (EU). In Unmanned Aerial Systems in Agriculture; Elsevier: Amsterdam, The Netherlands, 2023; pp. 269–285. [Google Scholar]

- Rabus, B.; Eineder, M.; Roth, A.; Bamler, R. The shuttle radar topography mission—A new class of digital elevation models acquired by spaceborne radar. ISPRS J. Photogramm. Remote Sens. 2003, 57, 241–262. [Google Scholar] [CrossRef]

- NASA. The Shuttle Radar Topography Mission (SRTM) Collection User Guide. Available online: https://lpdaac.usgs.gov/documents/179/SRTM_User_Guide_V3.pdf (accessed on 30 October 2023).

- Ioannidis, C.; Xinogalas, E.; Soile, S. Assessment of the Global Digital Elevation Models ASTER and SRTM in Greece. Surv. Rev. 2014, 46, 342–354. [Google Scholar] [CrossRef]

- MATLAB, 9.13.0 (R2022b); The MathWorks, Inc.: Natick, MA, USA, 2022. Available online: https://www.mathworks.com(accessed on 30 October 2023).

- Digital Elevation Model—DEM—LSO Project, Hellenic Cadastre. Available online: https://gis.ktimanet.gr/geoportal/catalog/search/resource/details.page?uuid=%7B456CB655-B899-450A-87BF-8322B8FB8370%7D (accessed on 30 October 2023).

- PuLP, A Python Linear Programming API. Available online: https://github.com/coin-or/PuLP (accessed on 30 October 2023).

- ArcGIS Online, ESRI. Available online: https://www.arcgis.com/index.html (accessed on 30 October 2023).

| Input Parameters | |

|---|---|

| Name | Description |

| i | Set of waypoints. |

| j | Set of charging points. |

| Set of demand points. | |

| Set of flight paths. | |

| Set of HUBs where launching/landing is allowed. | |

| Set of package weights, where . | |

| Distance from HUB to demand point i, . | |

| Maximum distance the cargo drone can travel during a single mission, including the return trip to the charging station or the HUB, . | |

| Electric energy drain per minute of traveling from to while carrying parcels of w weight. | |

| Power consumption per minute during hovering while carrying parcels of w weight. | |

| U | Cargo drone speed. |

| b | Maximum energy capacity of the cargo drone’s batteries. |

| c | Coverage radius of charging stations j. |

| Decision Variables | |

|---|---|

| Name | Description |

| Indicates if point i is assigned to charging station j, . | |

| Indicates if the charging station j is used, ∀ j ∈ K. | |

| Indicates the use of the winch mechanism for charging station j, ∀, j ∈ K. | |

| Represents the time of flight from location. to location while carrying parcels of w weight. | |

| Coefficients | Energy Consumption |

|---|---|

| β0 | 97.17 ± 13.6 |

| β1 | 22.75 ± 1.8 |

| R2 | 0.49 |

| Case Studies | Total Distance (km) | Total Electric Energy Consumption (kWh) | Demands Points n | Area with No Restrictions (km2) |

|---|---|---|---|---|

| Athens | 37.29 | 26,471.09 | 19 | 146.02 |

| Iraklion | 19.42 | 9929.88 | 9 | 29.33 |

| Patra | 27.03 | 9186.31 | 12 | 132.4 |

| Kalamata | 29.54 | 17,956.45 | 14 | 37.35 |

| Corinth | 35.03 | 9234.52 | 12 | 68.03 |

| Cargo Drone | Truck | |||

|---|---|---|---|---|

| CO2 Emissions (kg/km) | Operational Cost (EUR/km) | CO2 Emissions (kg/km) | Operational Cost (EUR/km) | |

| Mean | 0.18627 | 0.028 | 0.6609 | 1.179 |

| Median (50th percentile) | 0.20058 | 0.030 | 0.4556 | 0.343 |

| Standard deviation | 0.64789 | 0.007 | 0.3455 | 2.342 |

| Minimum | 0.10029 | 0.015 | 0.1608 | 0.062 |

| Maximum | 0.26075 | 0.039 | 1.9028 | 11.083 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ioannidis, C.; Boutsi, A.-M.; Tsingenopoulos, G.; Soile, S.; Chliverou, R.; Potsiou, C. Paving the Way for Last-Mile Delivery in Greece: Data-Driven Performance Analysis with a Customized Quadrotor. Drones 2024, 8, 6. https://doi.org/10.3390/drones8010006

Ioannidis C, Boutsi A-M, Tsingenopoulos G, Soile S, Chliverou R, Potsiou C. Paving the Way for Last-Mile Delivery in Greece: Data-Driven Performance Analysis with a Customized Quadrotor. Drones. 2024; 8(1):6. https://doi.org/10.3390/drones8010006

Chicago/Turabian StyleIoannidis, Charalabos, Argyro-Maria Boutsi, Georgios Tsingenopoulos, Sofia Soile, Regina Chliverou, and Chryssy Potsiou. 2024. "Paving the Way for Last-Mile Delivery in Greece: Data-Driven Performance Analysis with a Customized Quadrotor" Drones 8, no. 1: 6. https://doi.org/10.3390/drones8010006

APA StyleIoannidis, C., Boutsi, A.-M., Tsingenopoulos, G., Soile, S., Chliverou, R., & Potsiou, C. (2024). Paving the Way for Last-Mile Delivery in Greece: Data-Driven Performance Analysis with a Customized Quadrotor. Drones, 8(1), 6. https://doi.org/10.3390/drones8010006