Digital Twin: Origin to Future

Abstract

:1. Introduction

2. Digital Twin in Literature

2.1. History of Digital Twin

2.2. Digital Twin Description in Literature

- In-depth analysis of physical twin;

- Design and validation of new or existing product/process;

- Simulate the health conditions of physical twin;

- Increase safety and reliability of physical twin;

- Optimization of part, product, process, or production line;

- Track the status of physical twin throughout its lifetime;

- Predict the performance of physical twin;

- Real-time control over physical twin.

“A Digital Twin is a dynamic and self-evolving digital/virtual model or simulation of a real-life subject or object (part, machine, process, human, etc.) representing the exact state of its physical twin at any given point of time via exchanging the real-time data as well as keeping the historical data. It is not just the Digital Twin which mimics its physical twin but any changes in the Digital Twin are mimicked by the physical twin too.”

3. Advantages, Characteristics and Types of Digital Twin

3.1. Advantages of Digital Twin

- Speed prototyping as well as product re-designing: Since simulations allow the investigation of a number of scenarios, the design and analysis cycles shorten, making the whole process of prototyping or re-designing easier and faster. Once implemented, DT can be used in different stages of the product design process, from conceptualizing the idea of the product to its testing [68]. Besides that, it also creates an opportunity where the customization of each product based on users’ needs and usage data is possible [69]. Since the DT is connected to its physical twin throughout its lifetime, the comparison between the actual and predicted performance can be made, allowing engineer/product designers to reconsider their assumptions on which the product was designed [70].

- Cost-effective: Due to DT involving mostly virtual resources for its creation, the overall cost of prototyping decreases with time. In traditional prototyping, redesigning a product is time-consuming as well as expensive because of the use of physical materials and labour, and on top of that, a destructive test means the end of that costly prototype, whereas using DT, products can be recreated and put through destructive tests without any additional material cost. Thus, assuming even if the cost is equal at the start, the physical costs keep increasing as inflation rises but the virtual cost decreases significantly as time progresses (Figure 4) [47]. DT allows the testing of products under different operating scenarios, including destructive scenarios, without any additional costs. Moreover, DT can reduce operating costs and extend the life of equipment and assets once implemented.

- Predicting Problems/System Planning: Using DT, we can predict the problems and errors for future states of its physical twin, providing us an opportunity to plan the systems accordingly. Due to the real-time data flowing between the physical asset and its DT, it can predict problems at different stages of the product lifecycle. This is beneficial especially for products that have multiple parts, complex structures, and are made up of multiple materials such as aircraft, vehicles, factory equipment, etc., because as the complexity of any product increases, it gets harder to predict component failures using conventional methods [68].

- Optimizing Solutions and Improved Maintenance: The traditional methods of maintenance are based on heuristic experience and worst-case scenarios rather than on the specific material, structural configuration, and usage of an individual product, making them reactive rather than proactive [26]. However, DT can foresee defects and damage in the manufacturing machine or system and thus can schedule the maintenance of the product in advance. By simulating different scenarios, DT provides the best possible solution or maintenance strategy that makes the maintenance of the product/system much easier. In addition, the constant feedback loop between DT and its physical counterpart can be used to validate and optimize the system’s process all the time.

- Accessibility: The physical device can be controlled and monitored remotely using its DT. Unlike physical systems, which are restricted by their geographical location, virtual systems such as DT can be widely shared and can be remotely accessed [47]. Remote monitoring and controlling of equipment and systems becomes a necessity in a situation where local access is limited, like during the COVID-19 pandemic when lockdowns have been enforced by governments and working remotely or non-contact is the only viable option [71].

- Safer than the Physical Counterpart: In industries such as oil and gas or mining where the working conditions are extreme and hazardous, the capability of DT to remotely access its physical twin, as well as its predictive nature, can reduce the risk of accidents and hazardous failures. However, DT’s advantage of accessing remotely is not limited to preventing accidents. During the global COVID-19 pandemic, not having human contact and in-person monitoring is also a way to guarantee safety. According to a recent Gartner survey, almost one-third of companies are using DT amidst the global COVID-19 pandemic to increase the safety of employees and customers through remote monitoring [72].

- Waste Reduction: Using DT to simulate and test product or system prototypes in a virtual environment significantly reduces wastage. Prototype designs can be probed and scrutinized virtually, under a variety of different test scenarios, to finalize the final product design prior to manufacture. This not only saves on material wastage but also reduces development costs and time to market.

- Documentation and Communication: To create a DT, it is important to synchronize data scattered across different software applications, databases, hard copies, etc., which simplifies the process of accessing and maintaining the data in one place [33]. DT enable a better understanding of system reactions and thus it can be used to document and communicate the behaviour and mechanisms of the physical twin [32].

- Training: DT can be used to develop more efficient and illustrative safety training programmes than the traditional one [73]. Before working on a high-risk site or hazardous machinery, operators can be trained using a DT to reduce the dangers, as exposing and educating them about different processes or scenarios will make them confident in dealing with the same situations in person. For example, mining is a high-risk environment where new employees can be trained using DT on machinery operations, as well as how to deal with emergency scenarios [74]. DT can also be a great tool in closing the knowledge gap from experienced workers to newcomers.

3.2. Characteristics of Digital Twin

- High-fidelity: A DT needs to be a near-identical copy of its physical counterpart in terms of appearance, contents, functionality, etc., with a very high degree of accuracy. A super-realistic digital model helps DT in mimicking every aspect of its physical twin. Ultra-high fidelity computer models are considered the backbone of the DT [48]. This level of detail allows DT simulation and prediction tools to be more reliable when presented with a set of alternative actions or scenarios [21].

- Dynamic: The physical is dynamic, meaning it changes with respect to time. Thus, a DT also needs to change as the physical system changes. This is achieved through the seamless connection and continuous exchange between the physical and virtual worlds. The data exchanging can be dynamic data, historical static data, as well as descriptive static data [9]. DT has been described as a ‘living model in 3D’ [38]. The objective of DT being dynamic is to mirror the physical twin and its behaviour realistically in the digital world [33].

- Self-evolving: A DT evolves along with its physical counterpart throughout its life cycle. Any changes in either the physical or Digital Twin are reflected in its counterpart, creating a closed feedback loop [33]. A DT is self-adapting and self-optimizing with the help of the data collected by physical twin in real time, thus maturing along with its physical counterpart throughout its lifetime [9].

- Identifiable: Every physical asset needs to have its own DT. During different stages of the product lifecycle, the data and information related to it evolve and so does the model, including 3D geometric models, manufacturing models, usage models, functional models, etc. Due to the existence of such models created for DT, a DT can be uniquely identified from its physical twin or vice versa anywhere in the globe and for the entirety of its life cycle [75].

- Multiscale and Multiphysical: DT, being the virtual copy of its physical twin, needs to incorporate the properties of the physical twin at multiple scales or levels. Thus, the virtual model in DT is based on macroscopic geometric properties of the physical twin such as shape, size, tolerance, etc., as well as on microscopic properties such as surface roughness, etc. In other words, DT contains the set of information about the physical twin from micro atomic level to macro geometric level [47]. DT is also multiphysical because, besides the aforementioned geometric properties, the model is also based on physical properties of the physical twin such as structural dynamics models, thermodynamic models, stress analysis models, fatigue damage models, and material properties of physical twin such as stiffness, strength, hardness, fatigue strength, etc. [76].

- Multidisciplinary: Industry 4.0 revolves around many disciplines, and DT being the backbone of Industry 4.0 sees the fusion of disciplines such as computer science, information technology, and communications; mechanical, electrical, electronic, and mechatronic engineering; automation and industrial engineering; and system integration physics, just to name a few [34].

- Hierarchical: The hierarchical nature of DT comes from the fact that the different components and parts that make up the final product all have their corresponding DT model, e.g., DT of an aircraft is comprised of rack DT, DT of the flight control system, DT of the propulsion system, etc. [23]. Therefore, a DT can be seen as a series of integrated submodels [29].

3.3. Classification of Digital Twin

3.3.1. DT Creation Time

- Digital Twin Prototype (DTP): DTP can be described as a DT that contains the set of data/information that is essential to create or manufacture a physical copy from the virtual version. This includes BOM (bill of materials), design files, CAD models, etc. The product cycle will start from the creation of DTP, which can be put through several tests, even the destructive ones, before creating its physical twin. In addition, DTP helps us in identifying and avoiding unpredictable and undesirable scenarios that are difficult to identify with traditional prototyping. Once DTP is complete and validated, its physical twin can be manufactured in the real world. The accuracy of the simulation/model will determine the quality of the physical twin.

- Digital Twin Instance (DTI): This type of DT is connected to its physical counterpart throughout its life cycle. DTI came into being during the production phase. Once a physical system has been built, the data from the real space are sent to the virtual space and vice versa to monitor and predict the system behaviour. With these data, it can be found out if the system is depicting the predicted desirable behaviour or not, as well as if the predicted undesirable scenarios has been successfully eliminated. Since the linkage between both the systems is bidirectional, any changes in one will be duplicated on the other. A collection of DTIs is called Digital Twin Aggregate (DTA) by the authors.

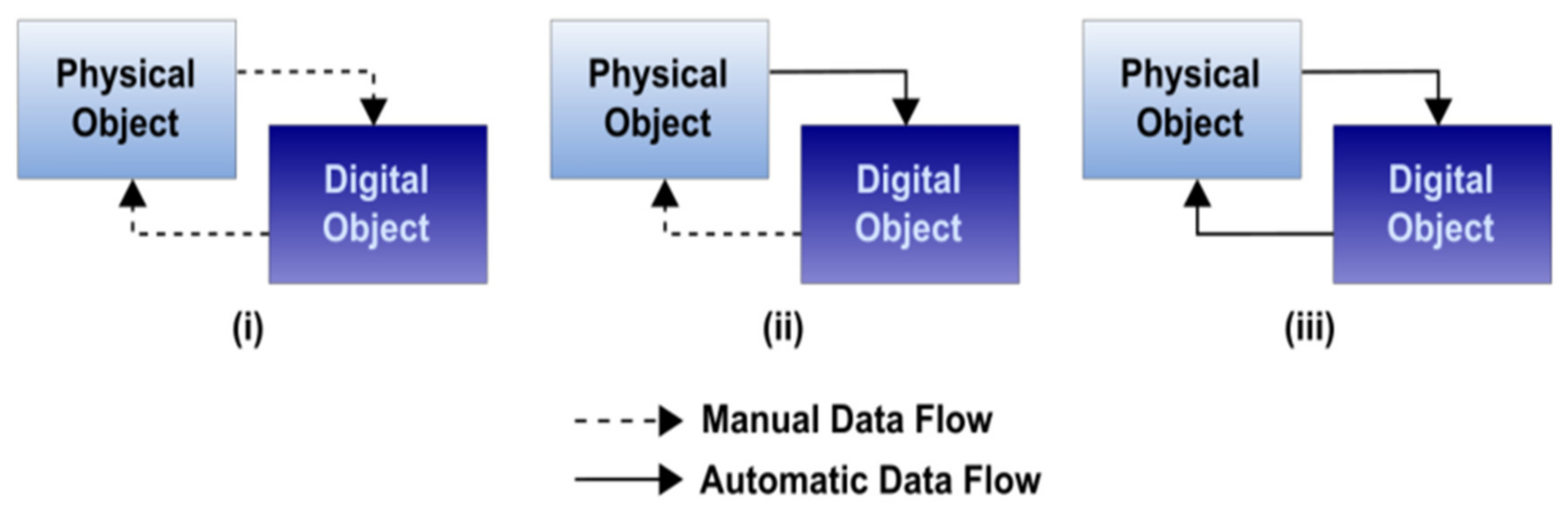

3.3.2. Level of Integration

- Digital Model: In this type of DT, the data between the physical and digital object are exchanged manually, due to which any changes in the state of the physical object are not reflected in the digital one directly, and vice versa.

- Digital Shadow: The data from the physical object flow to the digital automatically, but this is still manual the other way around. As a result, any change in the physical object can be seen in its digital copy, but not vice versa.

- Digital Twin: In this type of DT, there is an automatic bidirectional flow of data between the physical and digital object. Therefore, the changes in either object, physical or digital, directly lead to changes in the other.

3.3.3. Application

- Product DT: It is used for prototyping as it analyses the product under different conditions and makes sure that the next physical product is behaving as planned. By virtually validating the product, the prototyping can be rapid as the total development time is reduced and there is no longer a need to develop multiple of them.

- Production DT: It is used for validating the processes by simulating and then analyzing them even before the actual production. This helps in developing an efficient production methodology under different conditions. The data from Product and Production DT can be used together for monitoring and maintenance of the machinery.

- Performance DT: It is used for decision-making processes by capturing, Aggregating, and analyzing data from smart products and plants. Since Performance DT includes performances of both product and production, it optimizes the operations depending on the availability of plant resources, which creates an opportunity to improve on the Production and Product DTs via a feedback loop.

3.3.4. Hierarchy

- Unit level: It is the smallest participating unit in manufacturing and can be a piece of equipment, material, or environmental factors. Unit-level DT is based on the geometric, functional, behavioural, and operational model of unit-level physical twin.

- System level: It is an amalgamation of several unit-level DTs in a production system such as production line, shop floor, factory, etc. Interconnectivity and collaboration among multiple unit-level DT lead to a wider flow of data and better resource allocation. A complex product, e.g., aircraft, can also be considered as system-level DT.

- System of Systems (SoS) level: A number of system-level DT are connected together to form SoS-level DT, which helps in collaborating different enterprises or different departments with an enterprise such as supply chain, design, service, maintenance, etc. In other words, SoS-level DT integrates different phases of the product throughout its life cycle.

3.3.5. Level of Maturity/Sophistication

- Partial DT: It contains a small number of data points, e.g., pressure, temperature, humidity, etc., which is useful in determining the connectivity and functionality of DT.

- Clone DT: It contains all significant and relevant data from the product/system that can be used for making prototypes and categorizing development phases.

- Augmented DT: It utilizes data from the asset along with its historical data and at the same time derives and correlates the useful data using algorithms and analytics.

- Pre-Digital Twin: This is level 1, where DT is created prior to the physical asset for the purpose of making decisions on prototype designs to reduce any technical risk and resolve issues upfront by using a generic system model.

- Digital Twin: Level 2 incorporates the data from the physical asset related to its performance, health, and maintenance. The virtual system model uses these data to assist high-level decision-making in the design and development of the asset, along with scheduling maintenance. The data transfer at this level is bidirectional.

- Adaptive Digital Twin: This level 3 provides an adaptive user interface between physical and Digital Twin, and has the capability to learn from the preferences and priorities of human operators using supervised machine learning. Using this DT, real-time planning and decision-making during operations is possible.

- Intelligent Digital Twin: In addition to the features from level 3, level 4 has unsupervised machine-learning capability, making it more autonomous than level 3. It can recognize patterns in the operational environment and using that along with reinforced learning allows for a more precise and efficient analysis of the system.

4. Future and Challenges of Digital Twin

4.1. Future Applications of Digital Twin

4.2. Challenges to Implement Digital Twin

4.2.1. Novelty of Technology

4.2.2. Time and Cost

4.2.3. Lack of Standards and Regulations

4.2.4. Data Related Issues

4.2.5. Life-Cycle Mismatching

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Tao, F.; Zhang, M.; Nee, A.Y.C. Chapter 2—Applications of Digital Twin. In Digital Twin Driven Smart Manufacturing; Tao, F., Zhang, M., Nee, A.Y.C., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 29–62. [Google Scholar]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Parrott, A.; Warshaw, L. Industry 4.0 and the Digital Twin: Manufacturing Meets its Match; Deloitte University Press: New York, NY, USA, 2017; pp. 1–17. [Google Scholar]

- Tao, F.; Zhang, M.; Nee, A.Y.C. Chapter 1—Background and Concept of Digital Twin. In Digital Twin Driven Smart Manufacturing; Tao, F., Zhang, M., Nee, A.Y.C., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 3–28. [Google Scholar]

- MarketsandMarkets. Digital Twin Market by Technology, Type (Product, Process, and System), Application (Predictive Maintenance, and Others), Industry (Aerospace & Defense, Automotive & Transportation, Healthcare, and others), and Geography—Global Forecast to 2026; MarketsandMarkets: Pune, India, 2020; p. 177. [Google Scholar]

- Erol, T.; Mendi, A.F.; Doğan, D. Digital Transformation Revolution with Digital Twin Technology. In Proceedings of the 2020 4th International Symposium on Multidisciplinary Studies and Innovative Technologies (ISMSIT), Istanbul, Turkey, 22–24 October 2020; pp. 1–7. [Google Scholar]

- Negri, E.; Fumagalli, L.; Macchi, M. A review of the roles of digital twin in cps-based production systems. Procedia Manuf. 2017, 11, 939–948. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y. Digital twin in industry: State-of-the-art. IEEE Trans. Ind. Inform. 2018, 15, 2405–2415. [Google Scholar] [CrossRef]

- Barricelli, B.R.; Casiraghi, E.; Fogli, D. A Survey on Digital Twin: Definitions, Characteristics, Applications, and Design Implications. IEEE Access 2019, 7, 167653–167671. [Google Scholar] [CrossRef]

- Cimino, C.; Negri, E.; Fumagalli, L. Review of digital twin applications in manufacturing. Comput. Ind. 2019, 113, 103130. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2020, 58, 346–361. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Kevin, I.; Wang, K.; Huang, H.; Xu, X. Digital Twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput. Integr. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- He, B.; Bai, K.-J. Digital twin-based sustainable intelligent manufacturing: A review. Adv. Manuf. 2020, 9, 1–21. [Google Scholar] [CrossRef]

- Magomadov, V. The digital twin technology and its role in manufacturing. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Krasnoyarsk, Russia, 16–18 April 2020; p. 032080. [Google Scholar]

- Grieves, M. Origins of the Digital Twin Concept. 2016. Available online: https://www.researchgate.net/publication/307509727_Origins_of_the_Digital_Twin_Concept. (accessed on 25 September 2020).

- Grieves, M.W. Product lifecycle management: The new paradigm for enterprises. Int. J. Prod. Dev. 2005, 2, 71–84. [Google Scholar] [CrossRef]

- Gelernter, D. Mirror Worlds: Or: The Day Software Puts the Universe in a Shoebox. How it Will Happen and What it Will Mean; Oxford University Press: Oxford, UK, 1993. [Google Scholar]

- Främling, K.; Holmström, J.; Ala-Risku, T.; Kärkkäinen, M. Product agents for handling information about physical objects. Rep. Lab. Inf. Process. Sci. Ser. B TKO-B 2003, 153. [Google Scholar]

- Grieves, M. Back to the future: Product lifecycle management and the virtualization of product information. In Product Realization; Springer: Boston, MA, USA, 2009; pp. 1–13. [Google Scholar]

- Shafto, M.; Conroy, M.; Doyle, R.; Glaessgen, E.; Kemp, C.; LeMoigne, J.; Wang, L. Draft modeling, simulation, information technology & processing roadmap. Technol. Area 2010, 11. [Google Scholar]

- Rosen, R.; Von Wichert, G.; Lo, G.; Bettenhausen, K.D. About the importance of autonomy and digital twins for the future of manufacturing. IFAC-PapersOnLine 2015, 48, 567–572. [Google Scholar] [CrossRef]

- Boschert, S.; Rosen, R. Digital twin—The simulation aspect. In Mechatronic Futures; Springer: Cham, Switzerland, 2016; pp. 59–74. [Google Scholar]

- Tuegel, E. The airframe digital twin: Some challenges to realization. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, HI, USA, 23–26 July 2012; p. 1812. [Google Scholar]

- Tuegel, E.J.; Ingraffea, A.R.; Eason, T.G.; Spottswood, S.M. Reengineering aircraft structural life prediction using a digital twin. Int. J. Aerosp. Eng. 2011, 2011. [Google Scholar] [CrossRef] [Green Version]

- Gockel, B.T.; Tudor, A.H.; Brandyberry, M.D.; Penmetsa, R.C.; Tuegel, E.J. Challenges with Structural Life Forecasting Using Realistic Mission Profiles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, HI, USA, 23–26 July 2012; p. 1813. [Google Scholar]

- Glaessgen, E.; Stargel, D. The digital twin paradigm for future NASA and US Air Force vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Honolulu, HI, USA, 23–26 July 2012; p. 1818. [Google Scholar]

- Majumdar, P.K.; FaisalHaider, M.; Reifsnider, K. Multi-physics response of structural composites and framework for modeling using material geometry. In Proceedings of the 54th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Boston, MA, USA, 8–11 April 2013; p. 1577. [Google Scholar]

- Lee, J.; Lapira, E.; Bagheri, B.; Kao, H.-A. Recent advances and trends in predictive manufacturing systems in big data environment. Manuf. Lett. 2013, 1, 38–41. [Google Scholar] [CrossRef]

- Hollkamp, J.J. Modeling vibratory damage with reduced-order models and the generalized finite element method. J. Sound Vib. 2014, 333, 6637–6650. [Google Scholar]

- Bielefeldt, B.; Hochhalter, J.; Hartl, D. Computationally efficient analysis of SMA sensory particles embedded in complex aerostructures using a substructure approach. In Proceedings of the ASME 2015 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Colorado Springs, CO, USA, 21–23 September 2015. [Google Scholar]

- Leiva, C. Demystifying the digital thread and digital twin concepts. Ind. Week. August 2016, 1, 2016. [Google Scholar]

- Redelinghuys, A.; Basson, A.; Kruger, K. A six-layer digital twin architecture for a manufacturing cell. In Proceedings of the International Workshop on Service Orientation in Holonic and Multi-Agent Manufacturing, Bergamo, Italy, 11–12 June 2018; pp. 412–423. [Google Scholar]

- LaGrange, E. Developing a Digital Twin: The Roadmap for Oil and Gas Optimization. In Proceedings of the SPE Offshore Europe Conference and Exhibition, Aberdeen, UK, 3–6 September 2019. [Google Scholar]

- Bajaj, M.; Cole, B.; Zwemer, D. Architecture to geometry-integrating system models with mechanical design. In Proceedings of the AIAA SPACE, Long Beach, CA, USA, 13–16 September 2016; p. 5470. [Google Scholar]

- Bazilevs, Y.; Deng, X.; Korobenko, A.; Lanza di Scalea, F.; Todd, M.; Taylor, S. Isogeometric fatigue damage prediction in large-scale composite structures driven by dynamic sensor data. J. Appl. Mech. 2015, 82. [Google Scholar] [CrossRef]

- Demkovich, N.; Yablochnikov, E.; Abaev, G. Multiscale modeling and simulation for industrial cyber-physical systems. In Proceedings of the 2018 IEEE Industrial Cyber-Physical Systems (ICPS), St. Petersburg, Russia, 15–18 May 2018; pp. 291–296. [Google Scholar]

- Ríos, J.; Hernández, J.C.; Oliva, M.; Mas, F. Product Avatar as Digital Counterpart of a Physical Individual Product: Literature Review and Implications in an Aircraft. In Proceedings of the ISPE CE, Delft, The Netherlands, 20–23 July 2015; pp. 657–666. [Google Scholar]

- Wired Brand Lab; Digital Twin: Bridging the Physical-Digital Divide. 2017. Available online: https://www.ibm.com/blogs/internet-of-things/iot-digital-twin-enablers/ (accessed on 11 October 2020).

- Banerjee, A.; Dalal, R.; Mittal, S.; Joshi, K.P. Generating digital twin models using knowledge graphs for industrial production lines. UMBC Inf. Syst. Dep. 2017. [Google Scholar] [CrossRef]

- Mayani, M.G.; Svendsen, M.; Oedegaard, S. Drilling Digital Twin Success Stories the Last 10 Years. In Proceedings of the SPE Norway One Day Seminar, Bergen, Norway, 18 April 2018. [Google Scholar]

- Volodin, V.; Tolokonskii, A. Concept of instrumentation of digital twins of nuclear power plants units as observers for digital NPP I&C system. J. Phys. Conf. Ser. 2019, 1391, 012083. [Google Scholar]

- Canedo, A. Industrial IoT lifecycle via digital twins. In Proceedings of the Eleventh IEEE/ACM/IFIP International Conference on Hardware/Software Codesign and System Synthesis, Pittsburgh, PA, USA, 2–7 October 2016; p. 1. [Google Scholar]

- Schluse, M.; Rossmann, J. From simulation to experimentable digital twins: Simulation-based development and operation of complex technical systems. In Proceedings of the 2016 IEEE International Symposium on Systems Engineering (ISSE), Edinburgh, UK, 3–5 October 2016; pp. 1–6. [Google Scholar]

- Schroeder, G.N.; Steinmetz, C.; Pereira, C.E.; Espindola, D.B. Digital twin data modeling with automationml and a communication methodology for data exchange. IFAC-PapersOnLine 2016, 49, 12–17. [Google Scholar] [CrossRef]

- Rauch, L.; Pietrzyk, M. Digital twins as a modern approach to design of industrial processes. J. Mach. Eng. 2019, 19. [Google Scholar] [CrossRef]

- Fergani, O. The digital twin of production, the ultimate tool to achieve first-time-right in metal additive manufacturing. In Progress in Digital and Physical Manufacturing: Proceedings of ProDPM’19; Almeida, H.A., Vasco, J.C., Eds.; Springer: Cham, Switzerland, 2020; pp. xxvii–xxx. [Google Scholar]

- Grieves, M.; Vickers, J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In Transdisciplinary Perspectives on Complex Systems; Springer: Cham Switzerland, 2017; pp. 85–113. [Google Scholar]

- Reifsnider, K.; Majumdar, P. Multiphysics stimulated simulation digital twin methods for fleet management. In Proceedings of the 54th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Boston, MA, USA, 8–11 April 2013; p. 1578. [Google Scholar]

- Gabor, T.; Belzner, L.; Kiermeier, M.; Beck, M.T.; Neitz, A. A simulation-based architecture for smart cyber-physical systems. In Proceedings of the 2016 IEEE International Conference on Autonomic Computing (ICAC), Wuerzburg, Germany, 17–22 July 2016; pp. 374–379. [Google Scholar]

- Kraft, E.M. The air force digital thread/digital twin-life cycle integration and use of computational and experimental knowledge. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–8 January 2016; p. 0897. [Google Scholar]

- Zhang, H.; Liu, Q.; Chen, X.; Zhang, D.; Leng, J. A digital twin-based approach for designing and multi-objective optimization of hollow glass production line. IEEE Access 2017, 5, 26901–26911. [Google Scholar] [CrossRef]

- Zheng, Y.; Yang, S.; Cheng, H. An application framework of digital twin and its case study. J. Ambient Intell. Humaniz. Comput. 2019, 10, 1141–1153. [Google Scholar] [CrossRef]

- Lee, J.; Lapira, E.; Yang, S.; Kao, A. Predictive manufacturing system-Trends of next-generation production systems. IFAC Proc. Vol. 2013, 46, 150–156. [Google Scholar] [CrossRef]

- Vachálek, J.; Bartalský, L.; Rovný, O.; Šišmišová, D.; Morháč, M.; Lokšík, M. The digital twin of an industrial production line within the industry 4.0 concept. In Proceedings of the 21st international conference on process control (PC), Strbske Pleso, Slovakia, 6–9 June 2017; pp. 258–262. [Google Scholar]

- El Saddik, A. Digital twins: The convergence of multimedia technologies. IEEE Multimed. 2018, 25, 87–92. [Google Scholar] [CrossRef]

- Enders, M.R.; Hoßbach, N. Dimensions of Digital Twin Applications-A Literature Review. In Proceedings of the 2019 Americas Conference on Information Systems (AMCIS), Cancún, México, 15–17 August 2019. [Google Scholar]

- Application of Digital Twin in Industrial Manufacturing. Available online: https://www.futurebridge.com/industry/perspectives-mobility/application-of-digital-twin-in-industrial-manufacturing/ (accessed on 13 October 2020).

- Madni, A.M.; Madni, C.C.; Lucero, S.D. Leveraging digital twin technology in model-based systems engineering. Systems 2019, 7, 7. [Google Scholar] [CrossRef] [Green Version]

- Maloney, A. The Difference between a Simulation and a Digital Twin. 2019. Available online: https://blogs.sw.siemens.com/mindsphere/the-difference-between-a-simulation-and-a-digital-twin/#:~:text=While%20a%20digital%20twin%20begins,from%20its%20real%2Dworld%20counterpart.&text=Because%20it%20dynamically%20changes%20based,matures%20through%20the%20product%20lifecycle. (accessed on 13 October 2020).

- Miskinis, C. What Does a Digital Thread Mean and How it Differs from Digital Twin. 2018. Available online: https://www.challenge.org/insights/digital-twin-and-digital-thread/#:~:text=Simply%20stated%20the%20digital%20twin,its%20creation%20to%20its%20removal. (accessed on 13 October 2020).

- Gartner Identifies the Top 10 Strategic Technology Trends for 2017. Available online: https://www.gartner.com/en/newsroom/press-releases/2016-10-18-gartner-identifies-the-top-10-strategic-technology-trends-for-2017 (accessed on 12 October 2020).

- Gartner Identifies the Top 10 Strategic Technology Trends for 2018. Available online: https://www.gartner.com/en/newsroom/press-releases/2017-10-04-gartner-identifies-the-top-10-strategic-technology-trends-for-2018 (accessed on 12 October 2020).

- Gartner Identifies the Top 10 Strategic Technology Trends for 2019. Available online: https://www.gartner.com/en/newsroom/press-releases/2018-10-15-gartner-identifies-the-top-10-strategic-technology-trends-for-2019 (accessed on 12 October 2020).

- Qi, Q.; Tao, F.; Zuo, Y.; Zhao, D. Digital twin service towards smart manufacturing. Procedia Cirp. 2018, 72, 237–242. [Google Scholar] [CrossRef]

- Marr, B. These 25 Technology Trends Will Define the Next Decade. Available online: https://www.forbes.com/sites/bernardmarr/2020/04/20/these-25-technology-trends-will-define-the-next-decade/#3153a5329e3b (accessed on 12 October 2020).

- D’mello, A. Spend on Digital Twins to Reach $12.7bn by 2021, as Solutions Offer IoT Investment RoI. 2020. Available online: https://www.iot-now.com/2020/06/02/103204-spend-on-digital-twins-to-reach-12-7bn-by-2021-as-solutions-offer-iot-investment-roi/ (accessed on 12 October 2020).

- Digital Twin: Market Estimates & Trend Analysis To 2025; Grand View Research: San Francisco, CA, USA, 2018; p. 80.

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, H.; Leng, J.; Chen, X. Digital twin-driven rapid individualised designing of automated flow-shop manufacturing system. Int. J. Prod. Res. 2019, 57, 3903–3919. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F. Digital twin and big data towards smart manufacturing and industry 4.0:360 degree comparison. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Shen, W.; Yang, C.; Gao, L. Address business crisis caused by COVID-19 with collaborative intelligent manufacturing technologies. IET Collab. Intell. Manuf. 2020, 2, 96–99. [Google Scholar] [CrossRef]

- Gartner Survey Reveals 47% of Organizations Will Increase Investments in IoT Despite the Impact of COVID-19. 2020. Available online: https://www.gartner.com/en/newsroom/press-releases/2020-10-29-gartner-survey-reveals-47-percent-of-organizations-will-increase-investments-in-iot-despite-the-impact-of-covid-19- (accessed on 13 October 2020).

- Kaarlela, T.; Pieskä, S.; Pitkäaho, T. Digital Twin and Virtual Reality for Safety Training. In Proceedings of the 2020 11th IEEE International Conference on Cognitive Infocommunications (CogInfoCom), Mariehamn, Finland, 23–25 September 2020; pp. 115–120. [Google Scholar]

- Miskinis, C. How are Mining Will be Improved Using Digital Twin Simulations. 2018. Available online: https://www.challenge.org/insights/digital-twin-in-mining/ (accessed on 13 October 2020).

- Tao, F.; Qi, Q.; Wang, L.; Nee, A. Digital twins and cyber–physical systems toward smart manufacturing and industry 4.0: Correlation and comparison. Engineering 2019, 5, 653–661. [Google Scholar] [CrossRef]

- Wang, Z. Digital Twin Technology. In Industry 4.0-Impact on Intelligent Logistics and Manufacturing; IntechOpen: London, UK, 2020. [Google Scholar]

- Lamb, K. Principle-Based Digital Twins: A Scoping Review; Centre for Digital Built Britain: Cambridge, UK, 2019. [Google Scholar]

- Digital Twin. Available online: https://www.plm.automation.siemens.com/global/en/our-story/glossary/digital-twin/24465 (accessed on 12 October 2020).

- Parks, M. Digita Twinning: Types of Digital Twins. Method: Mouser’s Technology & Solutions Journal. 2018. Available online: https://eu.mouser.com/applications/digital-twinning-types/ (accessed on 12 October 2020).

- Woods, D. Why Digital Twins Should Be the CEO’s Best Friend. 2018. Available online: https://www.forbes.com/sites/danwoods/2018/07/18/why-digital-twins-should-be-the-ceos-best-friend/?sh=11dfe0a63c75 (accessed on 12 October 2020).

- Exosite. The 3 Types of Digital Twin Maturity Models. 2017. Available online: https://blog.exosite.com/3-digital-twin-maturity-models. (accessed on 12 October 2020).

- Saracco, R. Digital Twins: Advantages & Issues of a Powerful Emerging Technology. 2018. Available online: https://cmte.ieee.org/futuredirections/2018/06/14/digital-twins-advantages-issues-of-a-powerful-emerging-technology/ (accessed on 12 October 2020).

- Umeda, Y.; Ota, J.; Kojima, F.; Saito, M.; Matsuzawa, H.; Sukekawa, T.; Takeuchi, A.; Makida, K.; Shirafuji, S. Development of an education program for digital manufacturing system engineers based on ‘Digital Triplet’concept. Procedia Manuf. 2019, 31, 363–369. [Google Scholar] [CrossRef]

- Umeda, Y.; Ota, J.; Shirafuji, S.; Kojima, F.; Saito, M.; Matsuzawa, H.; Sukekawa, T. Exercise of digital kaizen activities based on ‘digital triplet’concept. Procedia Manuf. 2020, 45, 325–330. [Google Scholar] [CrossRef]

- Gichane, M.M.; Byiringiro, J.B.; Chesang, A.K.; Nyaga, P.M.; Langat, R.K.; Smajic, H.; Kiiru, C.W. Digital Triplet Approach for Real-Time Monitoring and Control of an Elevator Security System. Designs 2020, 4, 9. [Google Scholar] [CrossRef]

- Liu, Z.; Meyendorf, N.; Mrad, N. The role of data fusion in predictive maintenance using digital twin. In Proceedings of the AIP Conference Proceedings, Provo, UT, USA, 16–21 July 2017; p. 020023. [Google Scholar]

- Sherry, D. The Car Battery Just Calle. 2017. Available online: https://www.linkedin.com/pulse/car-battery-just-called-deborah-sherry (accessed on 14 October 2020).

- Coors-Blankenship, J. Taking Digital Twins for a Test Drive with Tesla, Apple. 2020. Available online: https://www.industryweek.com/technology-and-iiot/article/21130033/how-digital-twins-are-raising-the-stakes-on-product-development (accessed on 14 October 2020).

- Martinez-Velazquez, R.; Gamez, R.; El Saddik, A. Cardio Twin: A Digital Twin of the human heart running on the edge. In Proceedings of the 2019 IEEE International Symposium on Medical Measurements and Applications (MeMeA), Istanbul, Turkey, 26–28 June 2019; pp. 1–6. [Google Scholar]

- The Future of Digital Twins. 2020. Available online: https://www.nec.com/en/global/insights/article/2020022510/index.html#:~:text=Digital%20twins%20are%20now%20seeing,robust%20and%20more%20cost%20effective (accessed on 14 October 2020).

- MentorMate. The Future of Farming: 7 Ways A Digital Twin Can Be Applied to Agriculture. 2020. Available online: https://medium.com/@MentorMate/the-future-of-farming-7-ways-a-digital-twin-can-be-applied-to-agriculture-595a1750c453 (accessed on 12 October 2020).

- Nicholls, J. Unleashing the Potential of Digital Twins. 2020. Available online: https://www.csiro.au/en/work-with-us/industries/mining-resources/resourceful-magazine/issue-20/digital-twins (accessed on 13 October 2020).

- Pang, J.; Li, J.; Xie, Z.; Huang, Y.; Cai, Z. Collaborative City Digital Twin for Covid-19 Pandemic: A Federated Learning Solution. arXiv 2020, arXiv:2011.02883. [Google Scholar]

- Sepasgozar, S.M. Digital Twin and Web-Based Virtual Gaming Technologies for Online Education: A Case of Construction Management and Engineering. Appl. Sci. 2020, 10, 4678. [Google Scholar] [CrossRef]

- Singh, S.; Shehab, E.; Higgins, N.; Fowler, K.; Tomiyama, T.; Fowler, C. Challenges of Digital Twin in High. Value Manufacturing; 0148-7191; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2018. [Google Scholar]

- Simchenko, N.; Tsohla, S.; Chyvatkin, P. IoT & Digital Twins Concept Integration Effects on Supply Chain Strategy: Challenges and Effects. Int. J. Sup. Chain. Mgt. Vol. 2019, 8, 803. [Google Scholar]

- Bulygina, I. Product Owner Talks: 20 Digital Twins Solution Providers. 2017. Available online: https://www.dashdevs.com/blog/product-owner-talks-20-digital-twins-service-companies/ (accessed on 15 October 2020).

- Ogewell, V. Digital Twins: Beware of Naive Faith in Simplicity. 2018. Available online: https://www.engineering.com/PLMERP/ArticleID/16272/Digital-Twins-Beware-of-Naive-Faith-in-Simplicity.aspx (accessed on 15 October 2020).

- West, T.D.; Blackburn, M. Is Digital Thread/Digital Twin Affordable? A Systemic Assessment of the Cost of DoD’s Latest Manhattan Project. Procedia Comput. Sci. 2017, 114, 47–56. [Google Scholar] [CrossRef]

- Wagner, R.; Schleich, B.; Haefner, B.; Kuhnle, A.; Wartzack, S.; Lanza, G. Challenges and potentials of digital twins and Industry 4.0 in product design and production for high performance products. Procedia CIRP 2019, 84, 88–93. [Google Scholar] [CrossRef]

- Wyckoff, A.; Pilat, D. Key Issues for Digital Transformation in the G20; OECD: Berlin, Germany, 2017.

- Common Pitfalls to Digital Twin Implementation. Available online: https://www.compunneldigital.com/infographic/common-pitfalls-to-digital-twin-implementation/#gref (accessed on 12 October 2020).

- Shao, G.; Helu, M. Framework for a digital twin in manufacturing: Scope and requirements. Manuf. Lett. 2020, 24, 105–107. [Google Scholar] [CrossRef] [PubMed]

- Tyagi, P.; Demirkan, H. Data Lakes: The Biggest Big Data Challenges. Anal. Mag. 2016. [Google Scholar] [CrossRef]

- Gagné, M.R. Digital Twins, Another Reason to Worry about the iot and Data Security. 2020. Available online: https://irishtechnews.ie/digital-twins-iot-and-data-security/ (accessed on 12 October 2020).

- Digital Twin: 5 Challenges for 7 Benefits. 2019. Available online: https://www.ingenium-magazine.it/en/digital-twin-6-sfide-per-7-benefici/ (accessed on 12 October 2020).

- Goasduff, L. Confront Key Challenges to Boost Digital Twin Success. 2018. Available online: https://www.gartner.com/smarterwithgartner/confront-key-challenges-to-boost-digital-twin-success/ (accessed on 12 October 2020).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, M.; Fuenmayor, E.; Hinchy, E.P.; Qiao, Y.; Murray, N.; Devine, D. Digital Twin: Origin to Future. Appl. Syst. Innov. 2021, 4, 36. https://doi.org/10.3390/asi4020036

Singh M, Fuenmayor E, Hinchy EP, Qiao Y, Murray N, Devine D. Digital Twin: Origin to Future. Applied System Innovation. 2021; 4(2):36. https://doi.org/10.3390/asi4020036

Chicago/Turabian StyleSingh, Maulshree, Evert Fuenmayor, Eoin P. Hinchy, Yuansong Qiao, Niall Murray, and Declan Devine. 2021. "Digital Twin: Origin to Future" Applied System Innovation 4, no. 2: 36. https://doi.org/10.3390/asi4020036

APA StyleSingh, M., Fuenmayor, E., Hinchy, E. P., Qiao, Y., Murray, N., & Devine, D. (2021). Digital Twin: Origin to Future. Applied System Innovation, 4(2), 36. https://doi.org/10.3390/asi4020036