Nonlinear Dynamics of a Resonant-Impact Dielectric Elastomer Actuator

Abstract

1. Introduction

2. Methods

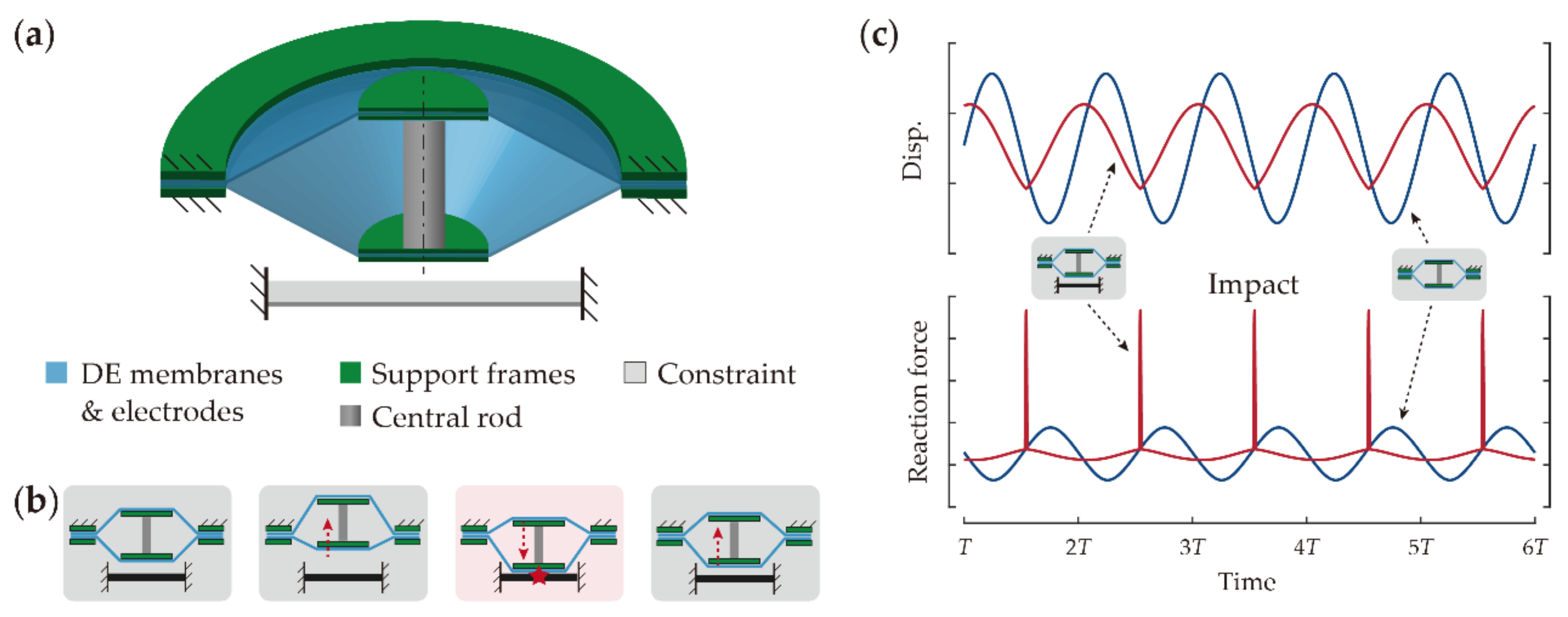

2.1. Design Overview and Working Principle

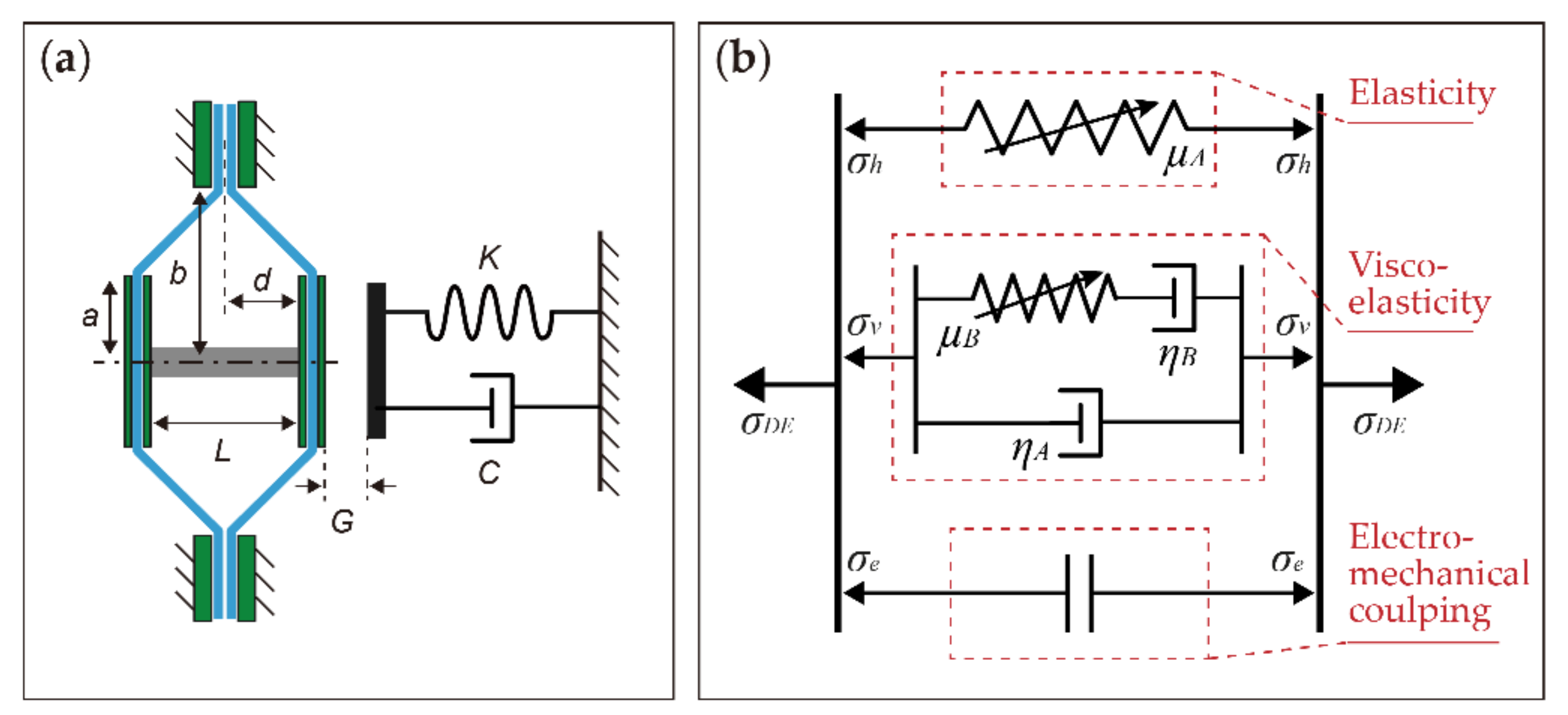

2.2. Numerical Model

2.2.1. Equation of Motion Development

2.2.2. Nondimensional Equations

2.3. Experimental Methods

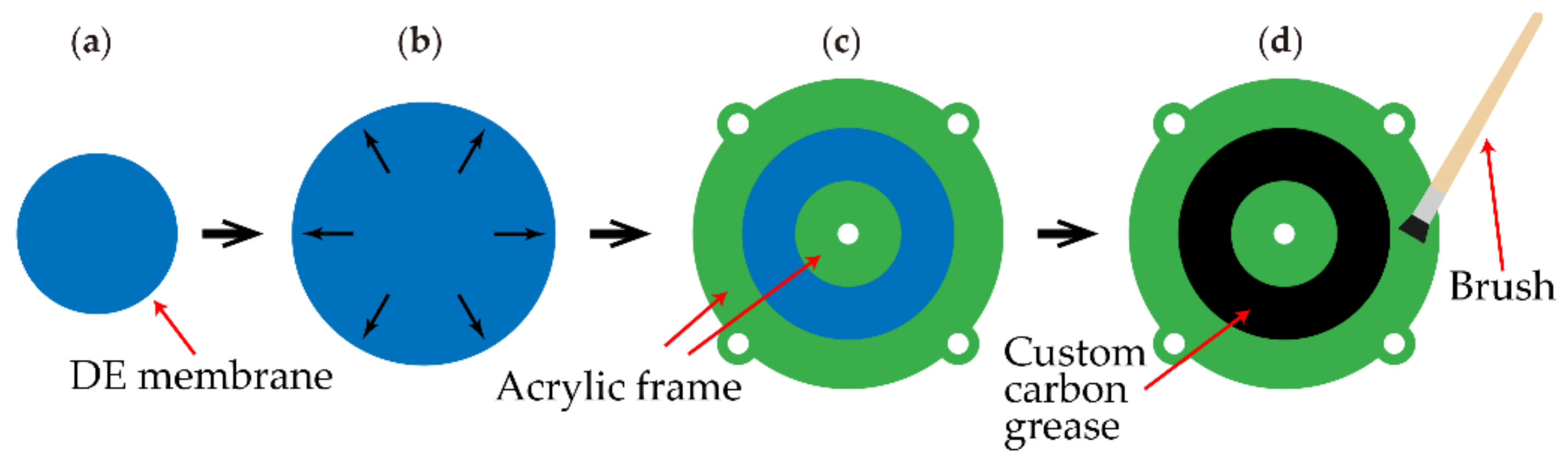

2.3.1. Fabrication Process

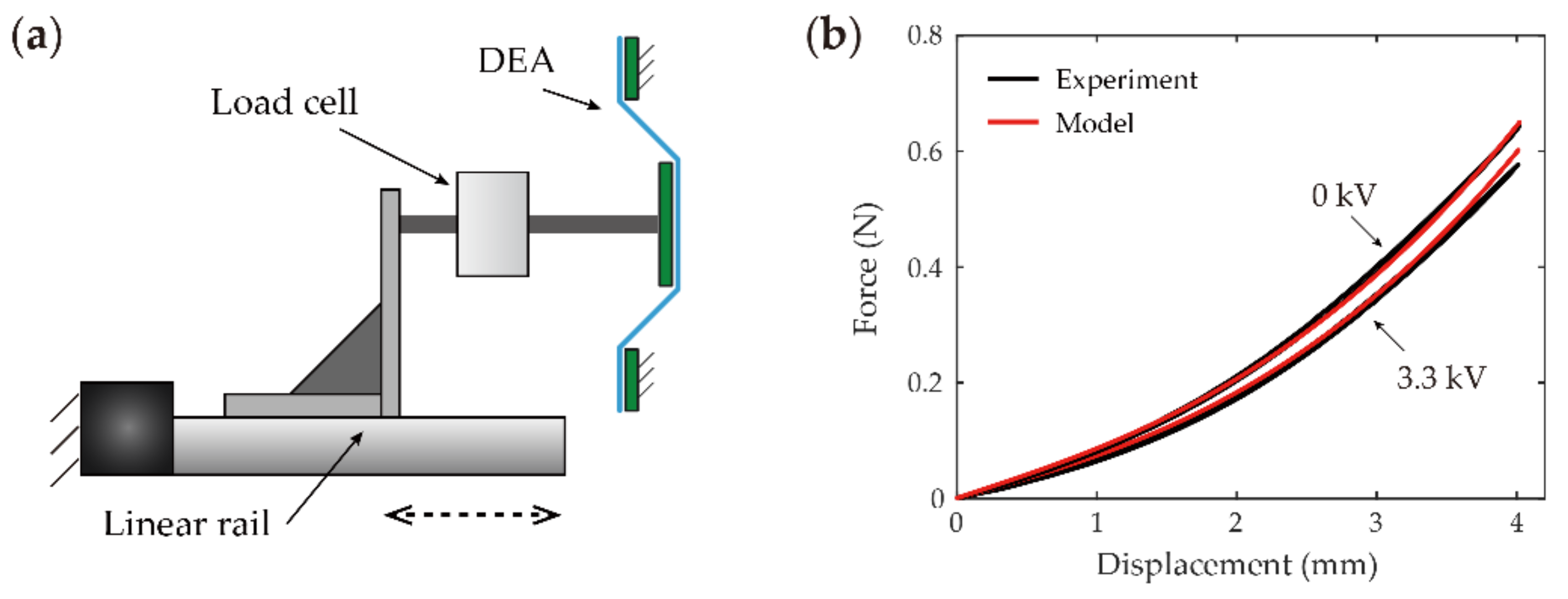

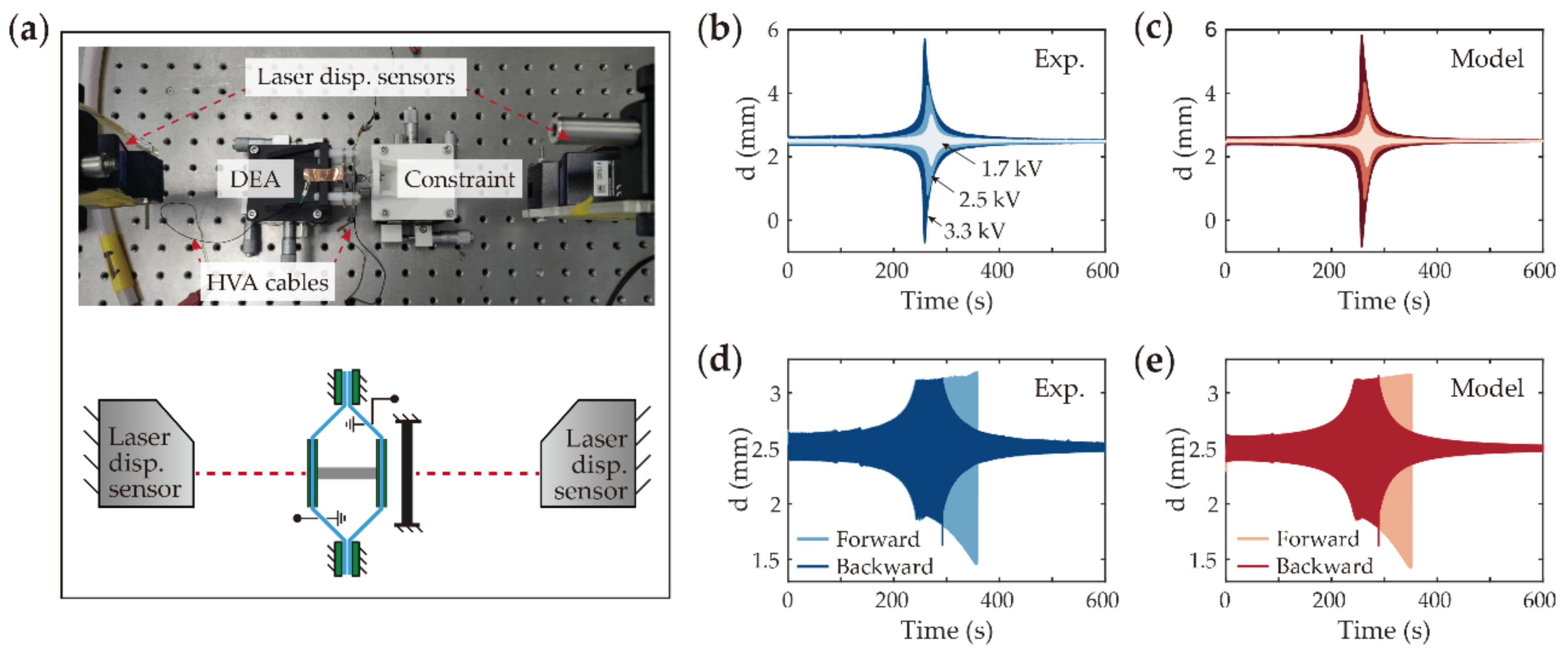

2.3.2. Experimental Setups and Model Validations

3. Numerical and Experimental Study Results

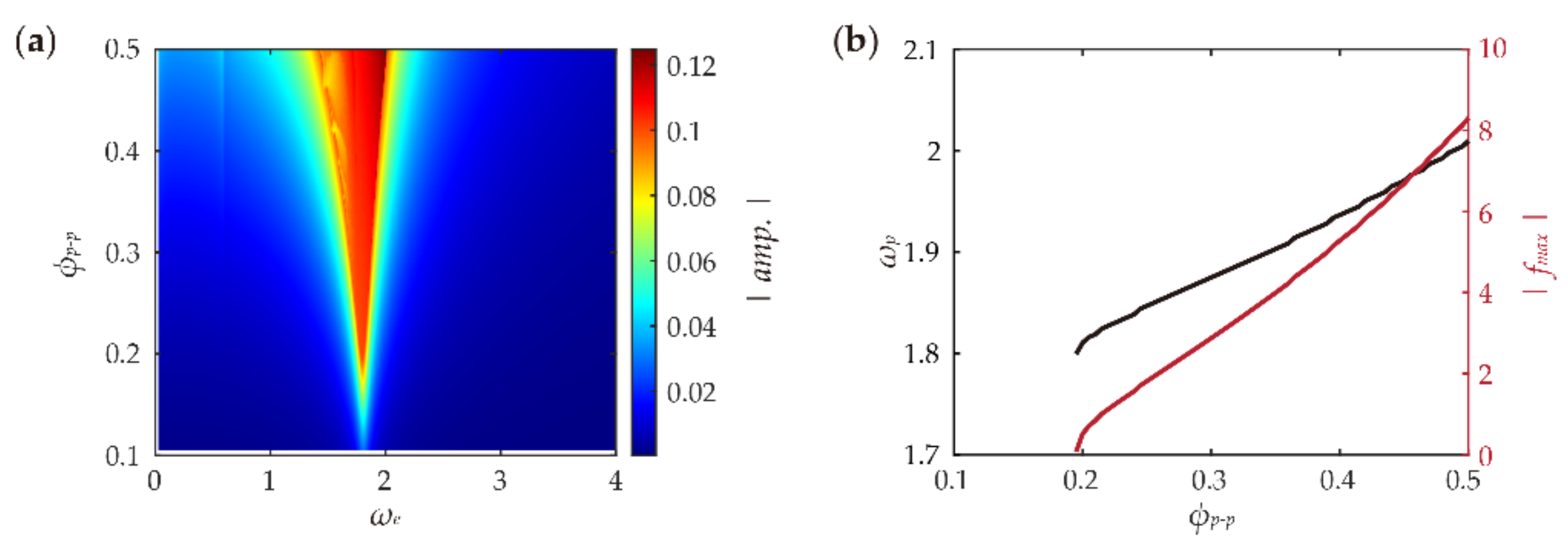

3.1. Frequency Response Overview

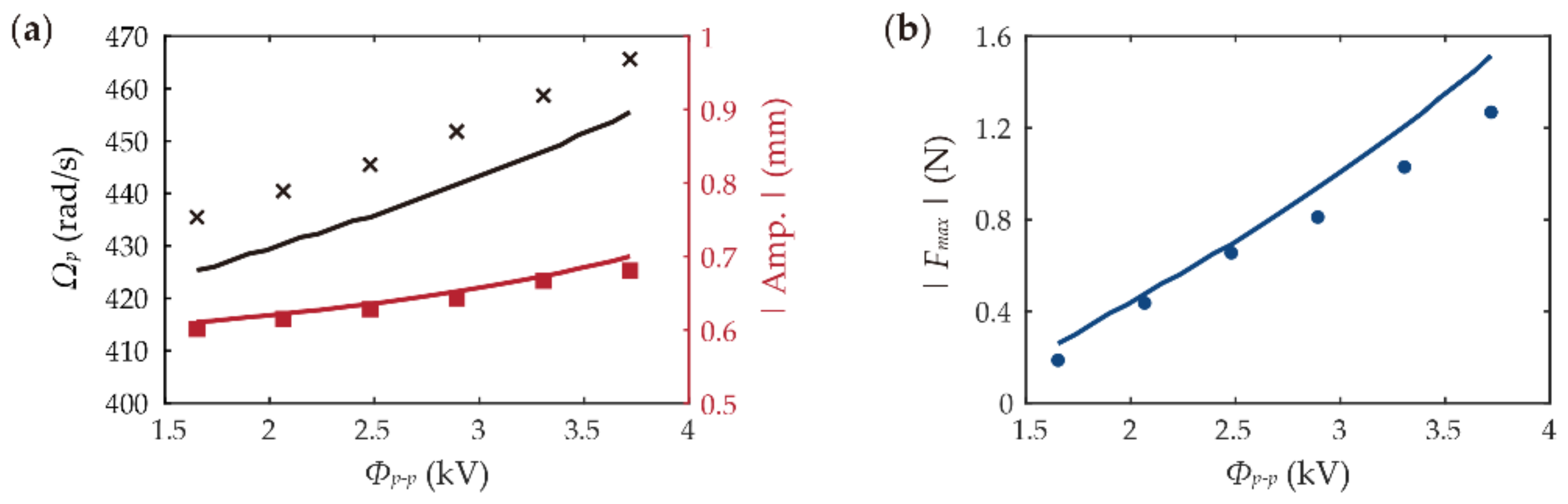

3.2. Effects of Excitation Voltage Amplitude

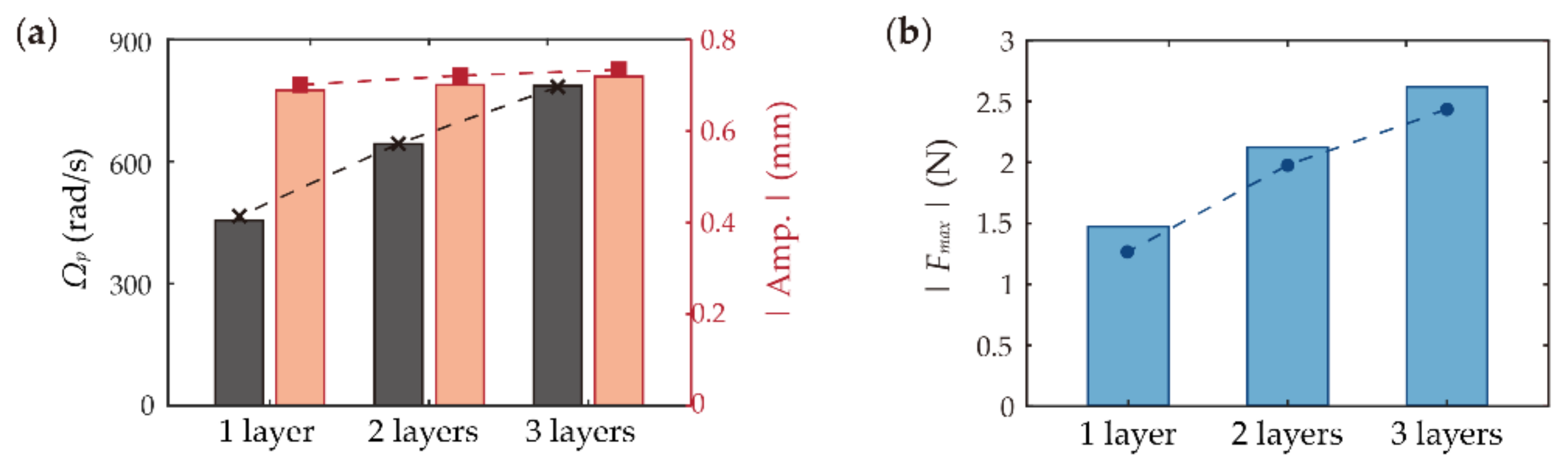

3.3. Effects of Number of DEA Layers

3.4. Effects of Constraint Gap

3.5. Effects of Constraint Stiffness

4. Conclusions

- The constraint introduced in the impact system results in strong nonlinearity in the equation of motion, which causes severe distortion of the frequency response curves and shifts in the resonant frequencies towards larger values.

- Increasing the excitation voltage amplitude simultaneously increases the peak oscillation amplitude, frequency, and impact force.

- Although adding a greater number of DEA layers to the system can effectively increase the peak frequency and impact force, it shows negligible effects on the peak oscillation amplitude.

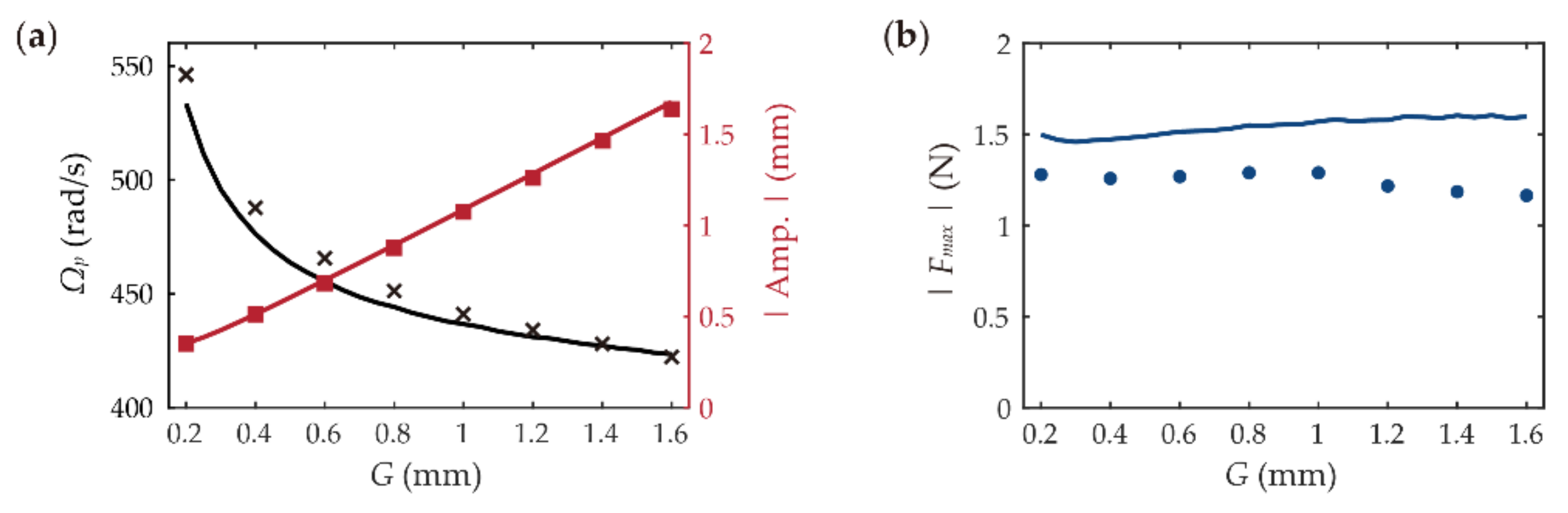

- A wider constraint gap increases the peak oscillation amplitude of the system while at the same time reducing its peak frequency, and shows negligible effects on the peak impact force in a wide range.

- A stiffer constraint mainly contributes to increasing the peak impact force, while its effects on peak oscillation amplitude and frequency are minor.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Villani, V.; Pini, F.; Leali, F.; Secchi, C. Survey on human–robot collaboration in industrial settings: Safety, intuitive interfaces and applications. Mechatronics 2018, 55, 248–266. [Google Scholar] [CrossRef]

- Cherubini, A.; Passama, R.; Crosnier, A.; Lasnier, A.; Fraisse, P. Collaborative manufacturing with physical human–robot interaction. Robot. Comput. Integr. Manuf. 2016, 40, 1–13. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, N.; Ye, N.; Fang, J.; Han, X. Hybrid Learning Algorithm of Radial Basis Function Networks for Reliability Analysis. IEEE Trans. Reliab. 2020, 70, 887–900. [Google Scholar] [CrossRef]

- Wang, H.; Totaro, M.; Beccai, L. Toward Perceptive Soft Robots: Progress and Challenges. Adv. Sci. 2018, 5, 1800541. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Sim, K.; Chen, J.; Kim, H.; Rao, Z.; Li, Y.; Chen, W.; Song, J.; Verduzco, R.; Yu, C. Soft Ultrathin Electronics Innervated Adaptive Fully Soft Robots. Adv. Mater. 2018, 30, e1706695. [Google Scholar] [CrossRef]

- Thuruthel, T.G.; Ansari, Y.; Falotico, E.; Laschi, C. Control Strategies for Soft Robotic Manipulators: A Survey. Soft Robot. 2018, 5, 149–163. [Google Scholar] [CrossRef]

- Pelrine, R.; Kornbluh, R.; Pei, Q.; Joseph, J. High-Speed Electrically Actuated Elastomers with Strain Greater Than 100%. Science 2000, 287, 836–839. [Google Scholar] [CrossRef]

- Cao, C.; Gao, X.; Conn, A.T. Towards efficient elastic actuation in bio-inspired robotics using dielectric elastomer artificial muscles. Smart Mater. Struct. 2019, 28, 095015. [Google Scholar] [CrossRef]

- Cao, C.; Gao, X.; Burgess, S.; Conn, A.T. Power optimization of a conical dielectric elastomer actuator for resonant robotic systems. Extrem. Mech. Lett. 2019, 35, 100619. [Google Scholar] [CrossRef]

- Christianson, C.; Goldberg, N.N.; Deheyn, D.D.; Cai, S.; Tolley, M.T. Translucent soft robots driven by frameless fluid electrode dielectric elastomer actuators. Sci. Robot. 2018, 3, eaat1893. [Google Scholar] [CrossRef]

- Duduta, M.; Berlinger, F.; Nagpal, R.; Clarke, D.R.; Wood, R.J.; Temel, F.Z. Tunable Multi-Modal Locomotion in Soft Dielectric Elastomer Robots. IEEE Robot. Autom. Lett. 2020, 5, 3868–3875. [Google Scholar] [CrossRef]

- Shintake, J.; Cacucciolo, V.; Shea, H.; Floreano, D. Soft Biomimetic Fish Robot Made of Dielectric Elastomer Actuators. Soft Robot. 2018, 5, 466–474. [Google Scholar] [CrossRef]

- Li, G.; Chen, X.; Zhou, F.; Liang, Y.; Xiao, Y.; Cao, X.; Zhang, Z.; Zhang, M.; Wu, B.; Yin, S.; et al. Self-powered soft robot in the Mariana Trench. Nature 2021, 591, 66–71. [Google Scholar] [CrossRef]

- Li, J.; Liu, L.; Liu, Y.; Leng, J. Dielectric Elastomer Spring-Roll Bending Actuators: Applications in Soft Robotics and Design. Soft Robot. 2019, 6, 69–81. [Google Scholar] [CrossRef]

- Xing, Z.; Zhang, J.; McCoul, D.; Cui, Y.; Sun, L.; Zhao, J. A Super-Lightweight and Soft Manipulator Driven by Dielectric Elastomers. Soft Robot. 2020, 7, 512–520. [Google Scholar] [CrossRef]

- Zhao, H.; Hussain, A.M.; Israr, A.; Vogt, D.M.; Duduta, M.; Clarke, D.R.; Wood, R.J. A Wearable Soft Haptic Communicator Based on Dielectric Elastomer Actuators. Soft Robot. 2020, 7, 451–461. [Google Scholar] [CrossRef]

- Lee, D.-Y.; Jeong, S.H.; Cohen, A.J.; Vogt, D.M.; Kollosche, M.; Lansberry, G.; Mengüç, Y.; Israr, A.; Clarke, D.R.; Wood, R.J. A Wearable Textile-Embedded Dielectric Elastomer Actuator Haptic Display. Soft Robot. 2022. ahead of print. [Google Scholar] [CrossRef]

- Tang, C.; Du, B.; Jiang, S.; Shao, Q.; Dong, X.; Liu, X.-J.; Zhao, H. A pipeline inspection robot for navigating tubular environments in the sub-centimeter scale. Sci. Robot. 2022, 7, eabm8597. [Google Scholar] [CrossRef]

- Cao, C.; Gao, X.; Conn, A.T. A Magnetically Coupled Dielectric Elastomer Pump for Soft Robotics. Adv. Mater. Technol. 2019, 4, 1900128. [Google Scholar] [CrossRef]

- Gu, G.; Zou, J.; Zhao, R.; Zhao, X.; Zhu, X. Soft wall-climbing robots. Sci. Robot. 2018, 3, eaat2874. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, H.; Mao, J.; Chirarattananon, P.; Helbling, E.F.; Hyun, N.-S.P.; Clarke, D.R.; Wood, R.J. Controlled flight of a microrobot powered by soft artificial muscles. Nature 2019, 575, 324–329. [Google Scholar] [CrossRef] [PubMed]

- Cao, C.; Chen, L.; Duan, W.; Hill, T.L.; Li, B.; Chen, G.; Li, H.; Li, Y.; Wang, L.; Gao, X. On the Mechanical Power Output Comparisons of Cone Dielectric Elastomer Actuators. IEEE/ASME Trans. Mechatron. 2021, 26, 3151–3162. [Google Scholar] [CrossRef]

- Duong, H.T.; Nguyen, V.-D.; Nguyen, H.-C.; Vu, N.-P.; Ngo, N.-K. A new design for bidirectional autogenous mobile systems with two-side drifting impact oscillator. Int. J. Mech. Sci. 2018, 140, 325–338. [Google Scholar] [CrossRef]

- Cao, Q.; Shi, H.; Xu, W.; Xiong, C.; Yang, Z.; Ji, R. Theoretical and Experimental Studies of Impact Energy and Rock-Drilling Efficiency in Vibro-Impact Drilling. J. Energy Resour. Technol. 2021, 144, 023201. [Google Scholar] [CrossRef]

- Afebu, K.O.; Liu, Y.; Papatheou, E. Application and comparison of feature-based classification models for multistable impact motions of percussive drilling. J. Sound Vib. 2021, 508, 116205. [Google Scholar] [CrossRef]

- Ghoneim, M.E.; Khan, Z.; Zuhra, S.; Ali, A.; Tag-Eldin, E. Numerical solution of Rosseland’s radiative and magnetic field effects for Cu-Kerosene and Cu-water nanofluids of Darcy-Forchheimer flow through squeezing motion. Alex. Eng. J. 2022, in press. [CrossRef]

- Moss, S.D.; McLeod, J.E.; Galea, S.C. Wideband vibro-impacting vibration energy harvesting using magnetoelectric transduction. J. Intell. Mater. Syst. Struct. 2012, 24, 1313–1323. [Google Scholar] [CrossRef]

- Serdukova, L.; Kuske, R.; Yurchenko, D. Stability and bifurcation analysis of the period-T motion of a vibroimpact energy harvester. Nonlinear Dyn. 2019, 98, 1807–1819. [Google Scholar] [CrossRef]

- Alhazmi, S.E.; Abdelmohsen, S.A.M.; Alyami, M.A.; Ali, A.; Asamoah, J.K.K. A Novel Analysis of Generalized Perturbed Zakharov–Kuznetsov Equation of Fractional-Order Arising in Dusty Plasma by Natural Transform Decomposition Method. J. Nanomater. 2022, 2022, 7036825. [Google Scholar] [CrossRef]

- Nguyen, K.-T.; La, N.-T.; Ho, K.-T.; Ngo, Q.-H.; Chu, N.-H.; Nguyen, V.-D. The effect of friction on the vibro-impact locomotion system: Modeling and dynamic response. Meccanica 2021, 56, 2121–2137. [Google Scholar] [CrossRef]

- Guo, B.; Ley, E.; Tian, J.; Zhang, J.; Liu, Y.; Prasad, S. Experimental and numerical studies of intestinal frictions for propulsive force optimisation of a vibro-impact capsule system. Nonlinear Dyn. 2020, 101, 65–83. [Google Scholar] [CrossRef]

- Li, S.; Yan, L.; Li, W.; Zhao, H.; Ling, X. Research on Energy Response Characteristics of Rock under Harmonic Vibro-Impacting Drilling. J. Vib. Eng. Technol. 2019, 7, 487–496. [Google Scholar] [CrossRef]

- Liu, Y.; Chávez, J.P.; Pavlovskaia, E.; Wiercigroch, M. Analysis and control of the dynamical response of a higher order drifting oscillator. Proc. R. Soc. A Math. Phys. Eng. Sci. 2018, 474, 20170500. [Google Scholar] [CrossRef]

- Moss, S.D.; Barry, A.; Powlesland, I.; Galea, S.; Carman, G.P. A low profile vibro-impacting energy harvester with symmetrical stops. Appl. Phys. Lett. 2010, 97, 234101. [Google Scholar] [CrossRef]

- Guo, B.; Ringwood, J.V. Non-Linear Modeling of a Vibro-Impact Wave Energy Converter. IEEE Trans. Sustain. Energy 2020, 12, 492–500. [Google Scholar] [CrossRef]

- Guo, B.; Liu, Y.; Birler, R.; Prasad, S. Self-propelled capsule endoscopy for small-bowel examination: Proof-of-concept and model verification. Int. J. Mech. Sci. 2020, 174, 105506. [Google Scholar] [CrossRef]

- Wu, C.; Yan, H.; Cai, A.; Cao, C. A Dielectric Elastomer Actuator-Driven Vibro-Impact Crawling Robot. Micromachines 2022, 13, 1660. [Google Scholar] [CrossRef]

- Hau, S.; Rizzello, G.; Seelecke, S. A novel dielectric elastomer membrane actuator concept for high-force applications. Extreme Mech. Lett. 2018, 23, 24–28. [Google Scholar] [CrossRef]

- Cao, C.; Chen, L.; Hill, T.L.; Wang, L.; Gao, X. Exploiting Bistability for High-Performance Dielectric Elastomer Resonators. IEEE/ASME Trans. Mechatron. 1–12. [CrossRef]

- Cao, C.; Chen, L.; Li, B.; Chen, G.; Nie, Z.; Wang, L.; Gao, X. Toward broad optimal output bandwidth dielectric elastomer actuators. Sci. China Technol. Sci. 2022, 65, 1137–1148. [Google Scholar] [CrossRef]

- Ogden, R.W. Large deformation isotropic elasticity—On the correlation of theory and experiment for incompressible rubberlike solids. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1972, 326, 565–584. [Google Scholar] [CrossRef]

- Zhang, J.; Ru, J.; Chen, H.; Li, D.; Lu, J. Viscoelastic creep and relaxation of dielectric elastomers characterized by a Kelvin-Voigt-Maxwell model. Appl. Phys. Lett. 2017, 110, 044104. [Google Scholar] [CrossRef]

- Foo, C.C.; Cai, S.; Koh, S.J.A.; Bauer, S.; Suo, Z. Model of dissipative dielectric elastomers. J. Appl. Phys. 2012, 111, 034102. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, C.; Cai, A.; Gao, X.; Cao, C. Nonlinear Dynamics of a Resonant-Impact Dielectric Elastomer Actuator. Appl. Syst. Innov. 2022, 5, 122. https://doi.org/10.3390/asi5060122

Wu C, Cai A, Gao X, Cao C. Nonlinear Dynamics of a Resonant-Impact Dielectric Elastomer Actuator. Applied System Innovation. 2022; 5(6):122. https://doi.org/10.3390/asi5060122

Chicago/Turabian StyleWu, Chuang, Anjiang Cai, Xing Gao, and Chongjing Cao. 2022. "Nonlinear Dynamics of a Resonant-Impact Dielectric Elastomer Actuator" Applied System Innovation 5, no. 6: 122. https://doi.org/10.3390/asi5060122

APA StyleWu, C., Cai, A., Gao, X., & Cao, C. (2022). Nonlinear Dynamics of a Resonant-Impact Dielectric Elastomer Actuator. Applied System Innovation, 5(6), 122. https://doi.org/10.3390/asi5060122