Hybrid Decision-Making-Method-Based Intelligent System for Integrated Bogie Welding Manufacturing

Abstract

:Featured Application

Abstract

1. Introduction

- (i).

- We innovatively joined knowledge graph decision making to case- and rule-based methods and applied this hybrid model to integrated bogie welding manufacturing.

- (ii).

- A production process-based knowledge model is developed to support knowledge system design. An empirical weight-based approach is proposed to calculate the case similarity.

- (iii).

- We developed an intelligent decision system based on a hybrid decision model in conjunction with welding manufacturing, which can complete structured documents and cause-and-effect decisions.

2. Methods and Models

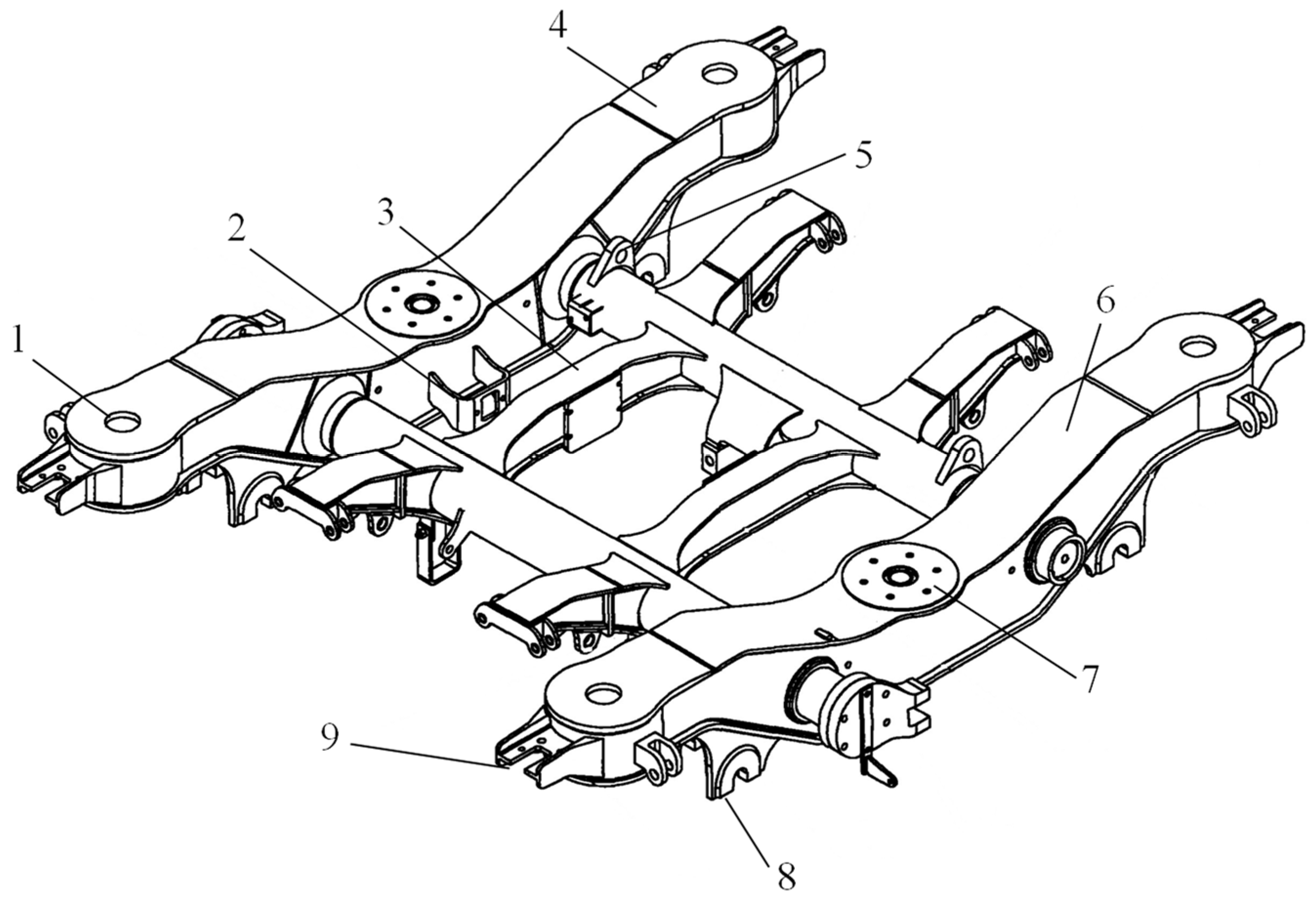

2.1. The Bogie Manufacturing Process

2.2. Domain Knowledge Modeling

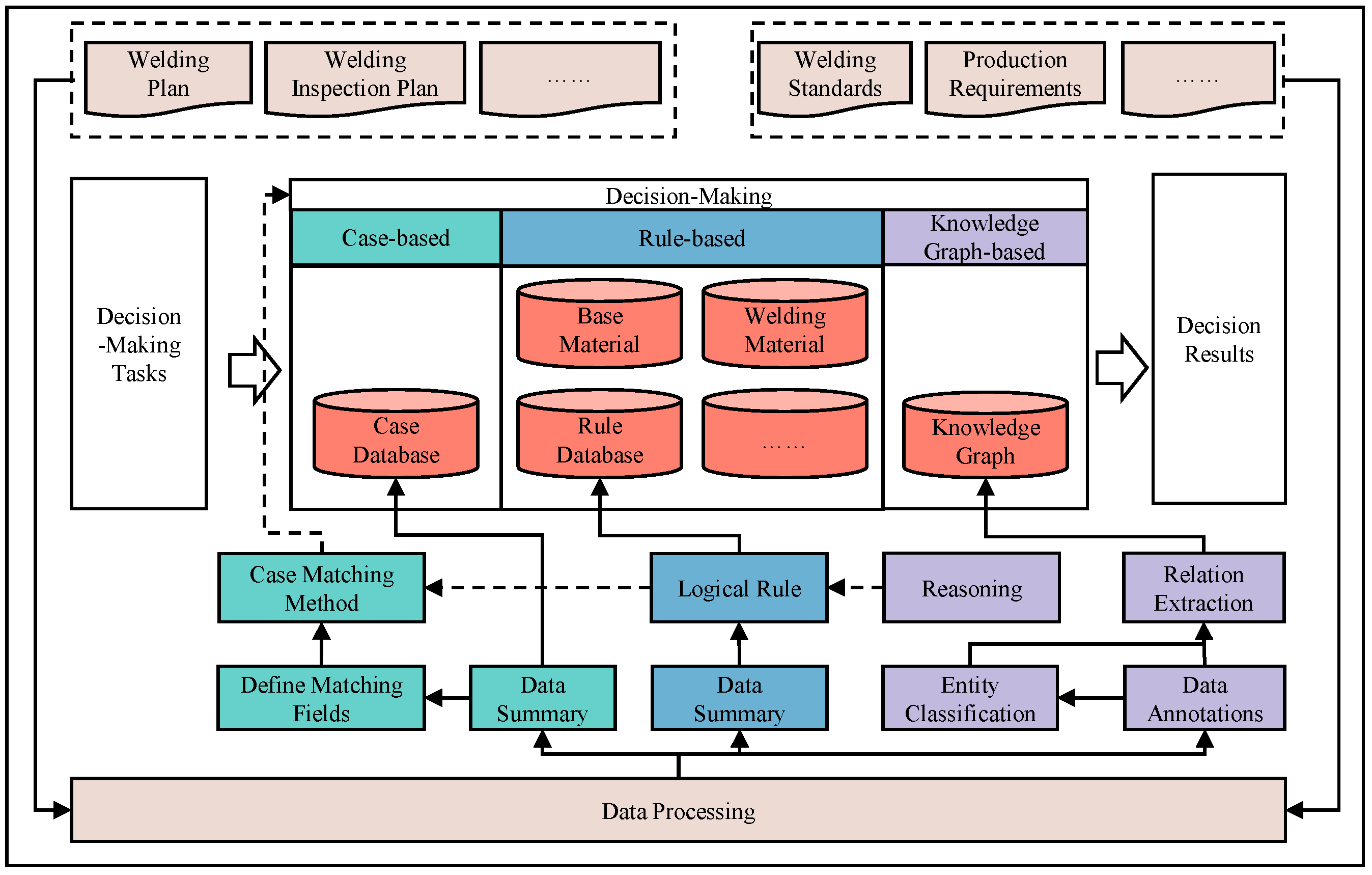

2.3. Collaborative Decision Making

- (1)

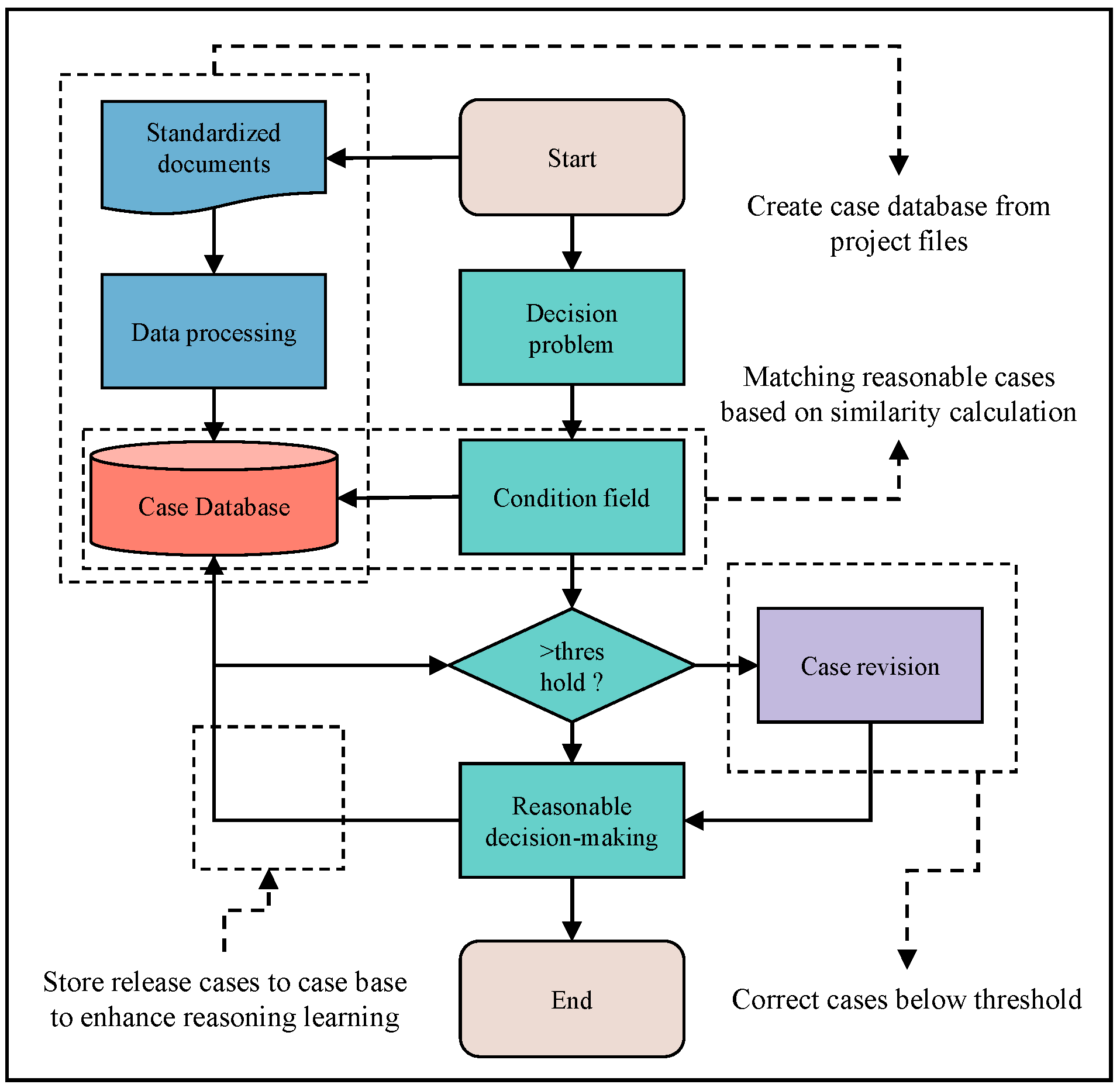

- Case-based decision making. The CBR is a method for completing decisions by analyzing the similarity between a problem and a known case base. Its main elements are case representation, case retrieval, case revision, and case learning. Case representation is the process of designing the rational storage form of data, and the characteristics of actual cases need to be considered. In this study, we divide the data into conditional and result fields and store them in a structured database. Case retrieval is a crucial step of CBR, which realizes case matching by calculating the similarity between cases. When the similarity of the condition fields is greater than a certain threshold for a decision problem, we consider the result field a reasonable decision. Case revision mainly consists of modifying invalid decisions into reasonable decisions. In order to continuously expand the case base and make it have a strong generalization ability, it is necessary to supplement the revised reasonable cases to the case base. This process is called case learning. The decision process is shown in Figure 4.

- (2)

- Rule-based decision making. The RBR is the process of transforming domain expert knowledge into computer logic language to complete decision making. The main steps to complete the decision are the representation, acquisition, and reasoning of knowledge. From the perspective of knowledge, decision making is a process from knowledge representation to knowledge acquisition. Knowledge is generally divided into factual knowledge and process knowledge. Factual knowledge is the basic description of things and represents the characteristics of individual attributes. For example, we can immediately understand the welding angle when referring to the welding position. Process knowledge is a collection of knowledge obtained by some means or logical operation. For example, the preheating temperature needs to compare to the preheating temperature of base-metal-1 and base-metal-2 and select the minimum temperature value. According to different sets of knowledge, choosing different knowledge expression methods is the key to realizing process reasoning. Rules are the logical expression of knowledge relations and expert experience. Rules can be divided into dynamic and logical rules according to different action modes. Dynamic rules refer to the correspondence between fields. They define fields A, B, and C. When A and B occur, C must occur. Therefore, there is a correspondence between A, B, and C. This correspondence is called a dynamic rule. Logical rules refer to the description statements connected with logical expressions, such as defining fields A, B, C, and D, and there is a logical statement “IF A > B THEN C, ELSE D,” which is the logical rule between fields.

- (3)

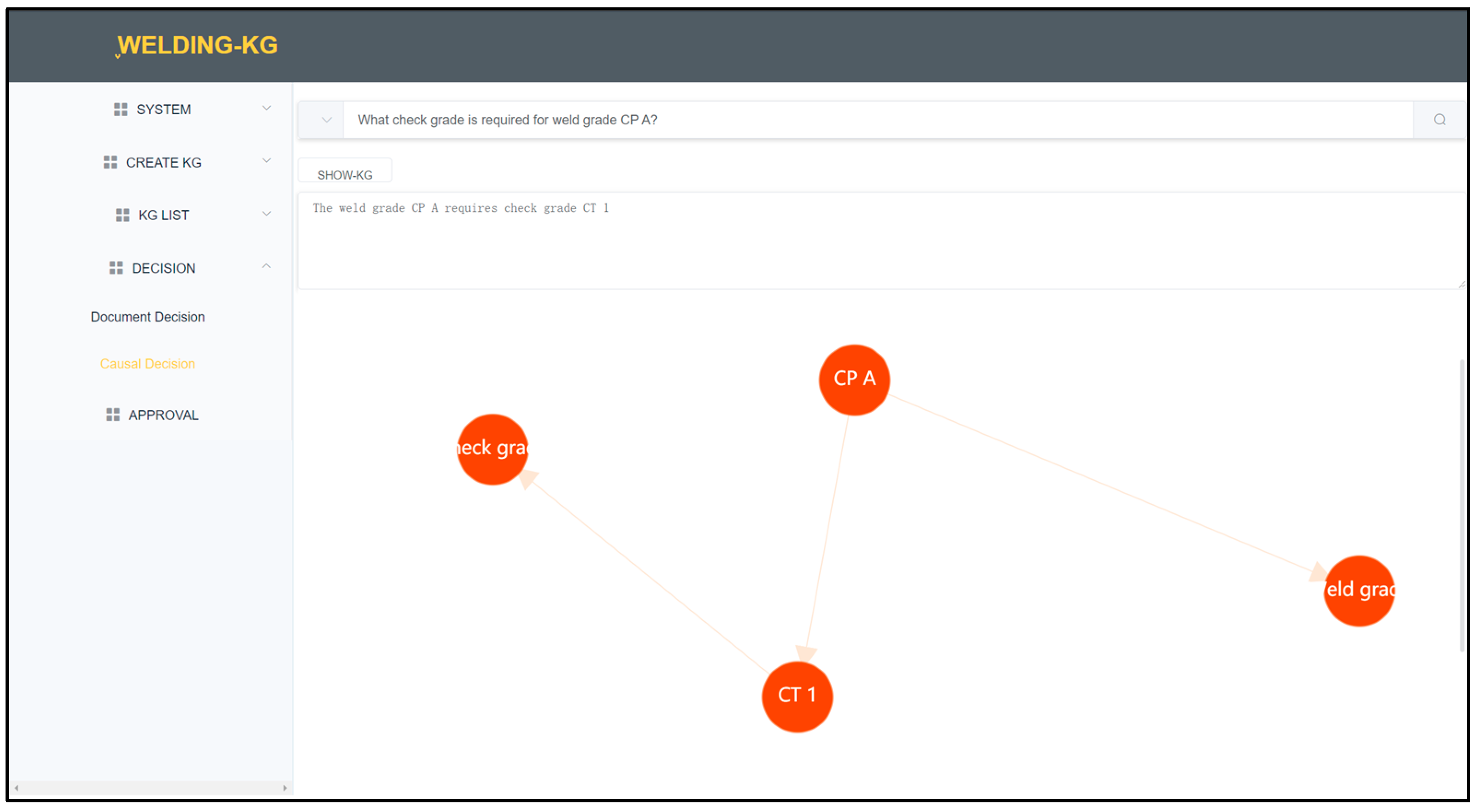

- Knowledge graph-based decision making. Knowledge graph-based decision-making transforms unstructured natural language into structured query statements and retrieves the graph for the best matching answer. Identifying keywords and relationships is a vital part of the search and decision making. The automatic relationship extraction model is trained and used to define interrogative relationship categories in the knowledge graph’s construction. In addition, the trained entity recognition model is also used as a preliminary determination of keywords. Next, the Term Frequency-Inverse Document Frequency (TF-IDF) method is employed to identify the most critical terms. The TF-IDF is calculated according to Equations (1)–(3), and the larger its value, the more critical the corresponding vocabulary. Structured statements are created based on keywords and relationships and are used to retrieve decision results.where nij is the number of occurrences of the target lexical entry in the semantics, and the summation nkj represents the number of all lexical entries. D is the total number of lexical entities in the corpus. {j:ti∈dj} is the number of corpora containing ti.

3. Experiments

3.1. The System Design

3.2. Build Cases and Rules

- (1)

- Case similarity calculation. The new case is defined as P, the old case as C, and the similarity calculation process between cases is shown in Equation (4). We calculate the product of the similarity of each attribute and its weight and sum it to obtain the case similarity. Here, sim (P, C) represents the case similarity, n is the number of case condition attributes, ai represents the i-th attribute, and ωi represents the i-th attribute weight:

- (2)

- Attribute similarity calculation. Attributes generally include numeric, symbolic, and conforming attributes. Equation (5) is the numerical attribute calculation process. For symbolic attributes, the attribute similarity is “1” when the attribute values are equal and “0” when the attribute values are unequal. The calculation process is shown in Equation (6). Composite attributes contain numeric and symbolic characteristics. Among them, the symbolic feature is selected as the first matching element. The similarity is calculated according to Equation (5), when the symbols are equal. If the symbols are not equal, the similarity is “0”:where is the i-th attribute value of the new case, is the i-th attribute value of the old case, and m is constant (m = 1.2 according to field experience).

- (3)

- Attribute weight division. Assigning the same weight to the attributes is unreasonable because the conditional attributes in the case have different degrees of influence on the decision attributes. Therefore, the conditional attribute weights are calculated based on the number of decision attributes associated with the attribute, which is calculated as Equation (7), where ai denotes the i-th conditional attribute and count(ai) denotes the number of decision attributes associated with the conditional attribute:

3.3. Building a Knowledge Graph

- (1)

- Data processing. The purpose of the design knowledge graph is to provide guided decisions for the bogie welding manufacturing process. Domain guidance documents are selected, such as domain standards, regulations, and production requirements. Most of these data are unstructured files and cannot be extracted directly. In order to obtain valid research data, the document information is split into several sentences based on essential separators such as full stops, exclamation marks, question marks, and semicolons. Sentence-level data are saved as a data source and divided into several attribute vocabularies via the CRF model [33]. The vocabulary data and terminology were converted into numerical vectors with the skip-gram model of Word2vec. Sentence-level, word-level, and word vector data are used to support the extraction of entities and relationships. In addition, the Begin-Inside-Outside (BIO) approach is employed to label the entity vocabulary dataset for entity identification. Labels and sentence-level semantics are defined to support relation extraction.

- (2)

- Entity extraction. Based on the established knowledge model, semantic relationships are classified into six categories: “Design,” “Technology,” “Manufacture,” “Quality,” “Department,” and “Standard.” Subordinate production process attributes have a small amount of data with many categories, so high-quality models are challenging to train. The relation “belong_to” is used as a link between the production process category and the subordinate attributes to replace the classification of the subordinate entities. This relation is also trained in the relation extraction task. Several models based on supervised learning Hidden Markov Model (HMM), CRF, and Bi-directional Long Short-Term Memory (BiLSTM) were trained on the same dataset. Higher-quality models are employed to extract domain entities automatically.

- (3)

- Relationship extraction. Relationships are the ties linking entities and are important supporting information for knowledge graph decisions. This study divided the relationships into five main categories: belong_to, reference, requirement, applicable_to, and unknown. The “belong_to” category is used to associate upper-level and lower-level category attributes. We use relation “reference” to express the retroactive relationship in decision making. Equally, relations “requirement” and “applicable_to” are defined to support cause-based decision making. The Bi-directional Long Short-Term Memory and Attention (BiLSTM + Attention) [34] and CR-CNN [35] models for relation extraction are trained under supervision.

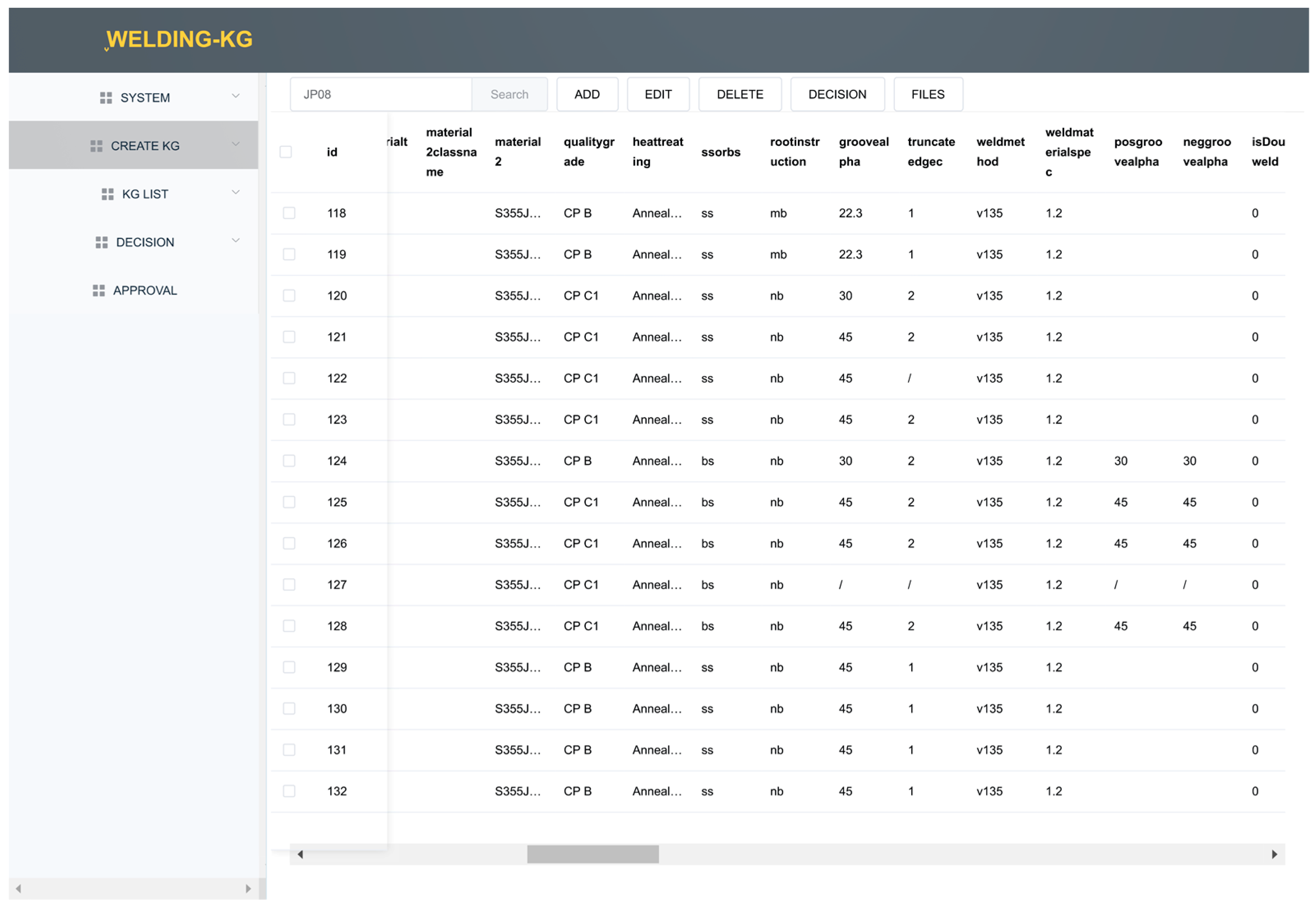

3.4. Database Design

4. Results and Interpretability

4.1. Model Training Results

4.2. Intelligent Decision Results

4.3. System Realization

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Handoyo, I.-T.; Sensuse, D.-I. Knowledge-based systems in decision support context: A literature review. In Proceedings of the 2017 4th International Conference on New Media Studies (CONMEDIA), Yogyakarta, Indonesia, 8–10 November 2017; pp. 81–86. [Google Scholar]

- Kardan, A.A.; Sadeghi, H. A decision support system for course offering in online higher education institutes. Int. J. Comput. Intell. Syst. 2013, 6, 928–942. [Google Scholar] [CrossRef]

- Kim, D.; Han, S.C.; Lin, Y.; Kang, B.H.; Lee, S. Rdr-based knowledge based system to the failure detection in industrial cyber physical systems. Knowl.-Based Syst. 2018, 150, 1–13. [Google Scholar] [CrossRef]

- Ali, R.; Afzal, M.; Sadiq, M.; Hussain, M.; Ali, T.; Lee, S.; Khattak, A.M. Knowledge-based reasoning and recommendation framework for intelligent decision making. Expert Syst. 2018, 35, e12242.1–e12242.23. [Google Scholar] [CrossRef]

- Vitanov, V.-I.; Voutchkov, I.-I. Process parameters selection for friction surfacing applications using intelligent decision support. J. Mater. Process. Technol. 2005, 159, 27–32. [Google Scholar] [CrossRef]

- Kim, I.-S.; Son, J.-S.; Park, C.-E.; Kim, I.-J.; Kim, H.-H. An investigation into an intelligent system for predicting bead geometry in gma welding process. J. Mater. Process. Technol. 2005, 159, 113–118. [Google Scholar] [CrossRef]

- Fukuda, S.; Morita, H.; Yamauchi, Y.; Nagasawa, I.; Tsuji, S. Expert system for determining welding condition for a pressure vessel. ISIJ Int. 1990, 30, 150–154. [Google Scholar] [CrossRef]

- Bai, J.-S.; Fan, B.; Huang, W.-H.; Xue, J. Knowledge Representation and Acquisition Based on Decision Tree for Substation Fault Diagnosis. Proc. Electr. Power Syst. Autom. 2004, 16, 5–8. [Google Scholar]

- Abutair, H.Y.; Belghith, A. Using Case-Based Reasoning for Phishing Detection. Procedia Comput. Sci. 2017, 109, 281–288. [Google Scholar] [CrossRef]

- Prakken, H. A formalization of argumentation schemes for legal case-based reasoning in ASPIC+. J. Log. Comput. 2015, 25, 1141–1166. [Google Scholar] [CrossRef]

- Dymova, L.; Sevastianov, P.; Bartosiewicz, P. A new approach to the rule-base evidential reasoning: Stock trading expert system application. Expert Syst. Appl. 2010, 37, 5564–5576. [Google Scholar] [CrossRef]

- Favi, C.; Garziera, R.; Campi, F. A rule-based system to promote design for manufacturing and assembly in the development of welded structure: Method and tool proposition. Appl. Sci. 2021, 11, 2326. [Google Scholar] [CrossRef]

- Berka, P. Sentiment analysis using rule-based and case-based reasoning. J. Intell. Inf. Syst. 2020, 55, 51–66. [Google Scholar] [CrossRef]

- Singh, D.; Rao, R.-V. A hybrid multiple attribute decision making method for solving problems of industrial environment. Int. J. Ind. Eng. Comput. 2011, 2, 631–644. [Google Scholar] [CrossRef]

- Khosrowshahi, F.; Howes, R. A framework for strategic decision-making based on a hybrid decision support tools. Electron. J. Inf. Technol. Constr. 2005, 10, 111–124. [Google Scholar]

- Iwankowicz, R. A multi-casebased assembly management method for the shipbuilding industry. Pol. Marit. Res. 2021, 28, 27–35. [Google Scholar] [CrossRef]

- Reyes, E.-R.; Negny, S.; Robles, G.-C.; Lann, J.-M.-L. Improvement of online adaptation knowledge acquisition and reuse in case-based reasoning: Application to process engineering design. Eng. Appl. Artif. Intell. 2015, 41, 1–16. [Google Scholar] [CrossRef]

- Liu, Y.; Haichao, L.-I.; Gong, X.; Bingguang, Z.H. Fault Diagnosis of Space TT&C Equipment Based on Case-based Reasoning. Telecommun. Eng. 2017, 57, 236–242. [Google Scholar]

- Chowdhary, K.-R. Rule Based Reasoning. In In Fundamentals of Artificial Intelligence; Springer: New Delhi, India, 2020; pp. 89–109. [Google Scholar]

- Thike, P.-H.; Xu, Z.; Cheng, Y.; Jin, Y.; Shi, P. Materials failure analysis utilizing rule-case based hybrid reasoning method. Eng. Fail. Anal. 2019, 95, 300–311. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, Y.; Pu, J.; Yuan, X. Development and application of knowledge-based software for railcar frame welding process. Int. J. Adv. Manuf. Technol. 2021, 112, 273–284. [Google Scholar] [CrossRef]

- Kose, G.; Sever, H.; Bal, M.; Ustundag, A. Comparison of different inference algorithms for medical decision making. Int. J. Comput. Intell. Syst. 2014, 7, 29–44. [Google Scholar] [CrossRef]

- Wang, C.-N.; Yang, F.-C.; Vo, N.T.M.; Nguyen, V.T.T. Wireless Communications for Data Security: Efficiency Assessment of Cybersecurity Industry—A Promising Application for UAVs. Drones 2022, 6, 363. [Google Scholar] [CrossRef]

- Dang, T.-T.; Nguyen, N.-A.-T.; Nguyen, V.-T.-T.; Dang, L.-T.-H. A Two-Stage Multi-Criteria Supplier Selection Model for Sustainable Automotive Supply Chain under Uncertainty. Axioms 2022, 11, 228. [Google Scholar] [CrossRef]

- Lohakare, P.; Bewoor, A.; Kumar, R.; Said, N.-M.; Sharifpur, M. Benchmark using multi criteria decision making (mcdm) technique to optimally select piston material. Eng. Anal. Bound. Elem. 2022, 142, 52–60. [Google Scholar] [CrossRef]

- Kahraman, C.; Onar, S.-C.; Oztaysi, B. Fuzzy multicriteria decision-making: A literature review. Int. J. Comput. Intell. Syst. 2015, 8, 637–666. [Google Scholar] [CrossRef]

- Livio, J.-A.; Hodhod, R. Ai cupper: A fuzzy expert system for sensorial evaluation of coffee bean attributes to derive quality scoring. IEEE Trans. Fuzzy Syst. 2018, 26, 3418–3427. [Google Scholar] [CrossRef]

- Lamastra, L.; Balderacchi, M.; Guardo, A.-D.; Monchiero, M.; Trevisan, M. A novel fuzzy expert system to assess the sustainability of the viticulture at the wine-estate scale. Sci. Total Environ. 2016, 572, 724–733. [Google Scholar] [CrossRef]

- Aliev, R.; Pedrycz, W.; Fazlollahi, B.; Huseynov, O.-H.; Alizadeh, A.-V.; Guirimov, B.-G. Fuzzy logic-based generalized decision theory with imperfect information. Inf. Sci. 2012, 189, 18–42. [Google Scholar] [CrossRef]

- Guo, C.; Wang, B.; Wu, Z.; Ren, M.; Dong, M. Transformer failure diagnosis using fuzzy association rule mining combined with case-based reasoning. IET Gener. Transm. Distrib. 2020, 14, 2202–2208. [Google Scholar] [CrossRef]

- Ozturk, O.-B.; Basar, E. Multiple linear regression analysis and artificial neural networks based decision support system for energy efficiency in shipping. Ocean. Eng. 2022, 243, 110209. [Google Scholar] [CrossRef]

- Banik, S.; Sharma, N.; Mangla, M.; Mohanty, S.-N.; Shitharth, S. Lstm based decision support system for swing trading in stock market. Knowl.-Based Syst. 2022, 239, 107994. [Google Scholar] [CrossRef]

- Lafferty, J.; McCallum, A.; Pereira, F.-C.-N. Conditional random fields: Probabilistic models for segmenting and labeling sequence data. 2001; ICML-01, 282–289. [Google Scholar]

- Zhou, P.; Shi, W.; Tian, J.; Qi, Z.; Li, B.; Hao, H.; Xu, B. Attention-Based Bidirectional Long Short-Term Memory Networks for Relation Classification. Proc. 54th Annu. Meet. Assoc. Comput. Linguist. 2016, 2, 207–212. [Google Scholar]

- Santos, C.-N.-D.; Xiang, B.; Zhou, B. Classifying Relations by Ranking with Convolutional Neural Networks. Comput. Sci. 2015, 86, 132–137. [Google Scholar]

| No. | Equations | Variable Interpretation |

|---|---|---|

| 1 | TP (True Positive): both true and predicted categories are positive examples. | |

| FP (False Positive): true category is negative and predicted category is positive. | ||

| 2 | TN (True Negative): both true and predicted categories are negative examples. | |

| FN (False Negative): true category is positive and predicted category is negative. | ||

| 3 | Precision and Recall refer to the equations numbered 1 and 2, respectively. | |

| F1-score is calculated by the equation numbered 3. |

| Model | Metrics | Technology | Manufacture | Design | Department | Standard | Quality |

|---|---|---|---|---|---|---|---|

| HMM | Precision | 0.512 | 0.569 | 0.593 | 0.556 | 0.905 | 0.713 |

| Recall | 0.528 | 0.474 | 0.743 | 0.590 | 0.880 | 0.599 | |

| F1-score | 0.519 | 0.517 | 0.646 | 0.569 | 0.892 | 0.650 | |

| CRF | Precision | 0.783 | 0.686 | 0.715 | 0.722 | 0.935 | 0.758 |

| Recall | 0.603 | 0.429 | 0.788 | 0.501 | 0.891 | 0.671 | |

| F1-score | 0.678 | 0.527 | 0.748 | 0.586 | 0.912 | 0.710 | |

| BiLSTM | Precision | 0.613 | 0.476 | 0.592 | 0.662 | 0.937 | 0.569 |

| Recall | 0.386 | 0.463 | 0.542 | 0.497 | 0.818 | 0.497 | |

| F1-score | 0.473 | 0.469 | 0.535 | 0.568 | 0.873 | 0.530 |

| Models | Metrics | Belong_to | Reference | Requirement | Applicable_to | Unknown | Macro-Average |

|---|---|---|---|---|---|---|---|

| BiLSTM + Attention | Precision | 0.838 | 0.568 | 0.806 | 0.857 | 0.872 | 0.788 |

| Recall | 1.000 | 0.875 | 0.625 | 0.878 | 0.850 | 0.846 | |

| F1-score | 0.912 | 0.688 | 0.704 | 0.867 | 0.861 | 0.816 | |

| CR-CNN | Precision | 0.912 | 0.704 | 0.670 | 0.818 | 0.850 | 0.791 |

| Recall | 1.000 | 0.792 | 0.763 | 0.878 | 0.638 | 0.814 | |

| F1-score | 0.954 | 0.745 | 0.713 | 0.847 | 0.729 | 0.802 |

| No. | Part Name | Test Cases | Right Case | Case Accuracy | Corrected Case | Corrected Accuracy |

|---|---|---|---|---|---|---|

| 1 | Side Beam | 107 | 90 | 0.841 | 103 | 0.963 |

| 2 | Vehicle Frame | 110 | 92 | 0.836 | 107 | 0.973 |

| 3 | Crossbeam | 55 | 35 | 0.636 | 49 | 0.891 |

| 4 | Brake hanger/beam | 12 | 8 | 0.667 | 10 | 0.833 |

| Total | - | 284 | 225 | 0.792 | 269 | 0.947 |

| No. | Decision Issues | Decision Results |

|---|---|---|

| 1 | What check grade is required for weld grade CP A? | The weld grade CP A requires check grade CT 1 |

| 2 | How to choose the base material for welding. | The base material reference CEN ISO/TR 15,608, weld grade |

| 3 | What properties determine the preheating temperature? | The preheating temperature reference material, plate thickness |

| 4 | How to determine the welding position. | The welding position reference joint and weld seam form |

| 5 | What does the welding position include? | The welding position includes PA, PB, PC, PD, PE |

| 6 | What welding position is required for a-joint? | The a-joint requires welding position PB |

| 7 | What assembly gap is selected for welding method t135 and plate thickness of 14? | No Result |

| 8 | Which department designs the welded joints? | The design department tasks include welded joint design |

| 9 | What parts are carbon steel applied to? | Carbon steel is applied to side beam, vehicle frame, crossbeam |

| 10 | What does Standard EN ISO 6520 apply to? | The Standard EN ISO 6520 is applied to defect classification |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, K.; Sun, Y.; Yang, G.; Yang, X. Hybrid Decision-Making-Method-Based Intelligent System for Integrated Bogie Welding Manufacturing. Appl. Syst. Innov. 2023, 6, 29. https://doi.org/10.3390/asi6010029

Guan K, Sun Y, Yang G, Yang X. Hybrid Decision-Making-Method-Based Intelligent System for Integrated Bogie Welding Manufacturing. Applied System Innovation. 2023; 6(1):29. https://doi.org/10.3390/asi6010029

Chicago/Turabian StyleGuan, Kainan, Yang Sun, Guang Yang, and Xinhua Yang. 2023. "Hybrid Decision-Making-Method-Based Intelligent System for Integrated Bogie Welding Manufacturing" Applied System Innovation 6, no. 1: 29. https://doi.org/10.3390/asi6010029

APA StyleGuan, K., Sun, Y., Yang, G., & Yang, X. (2023). Hybrid Decision-Making-Method-Based Intelligent System for Integrated Bogie Welding Manufacturing. Applied System Innovation, 6(1), 29. https://doi.org/10.3390/asi6010029