Numerical Simulation and Development of a Continuous Microwave-Assisted Pilot Plant for Shelled Almond Processing

Abstract

:1. Introduction

2. Materials and Methods

- Study of the dielectric properties of unshelled almonds (Prunus dulcis). Filippo Ceo almonds variety was used. They were harvested in Toritto (BA-Italy) in August 2022, then hulled, dried, and shelled.

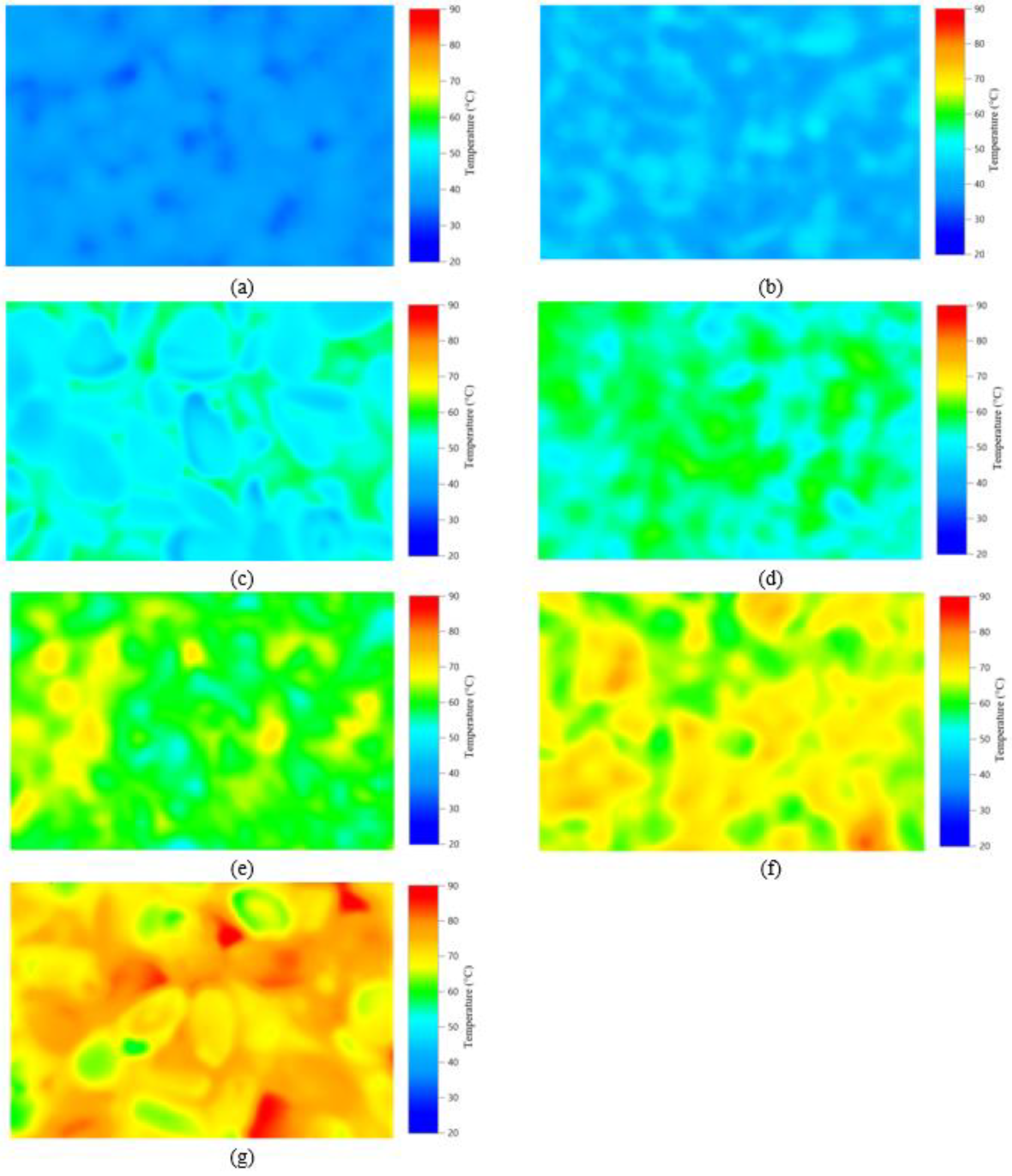

- Development of a numerical model to define the minimum optimal number of magnetrons necessary to achieve the dual objective: (i) obtain uniformity of the magnetic field inside the treatment chamber along its entire length; (ii) ensure that the maximum temperature of at least 60 °C is reached with a residence time of no less than 90 s. Therefore, the numerical simulation was carried out without considering the movement of the almonds along the treatment chamber, as it did not influence the two pre-established objectives.

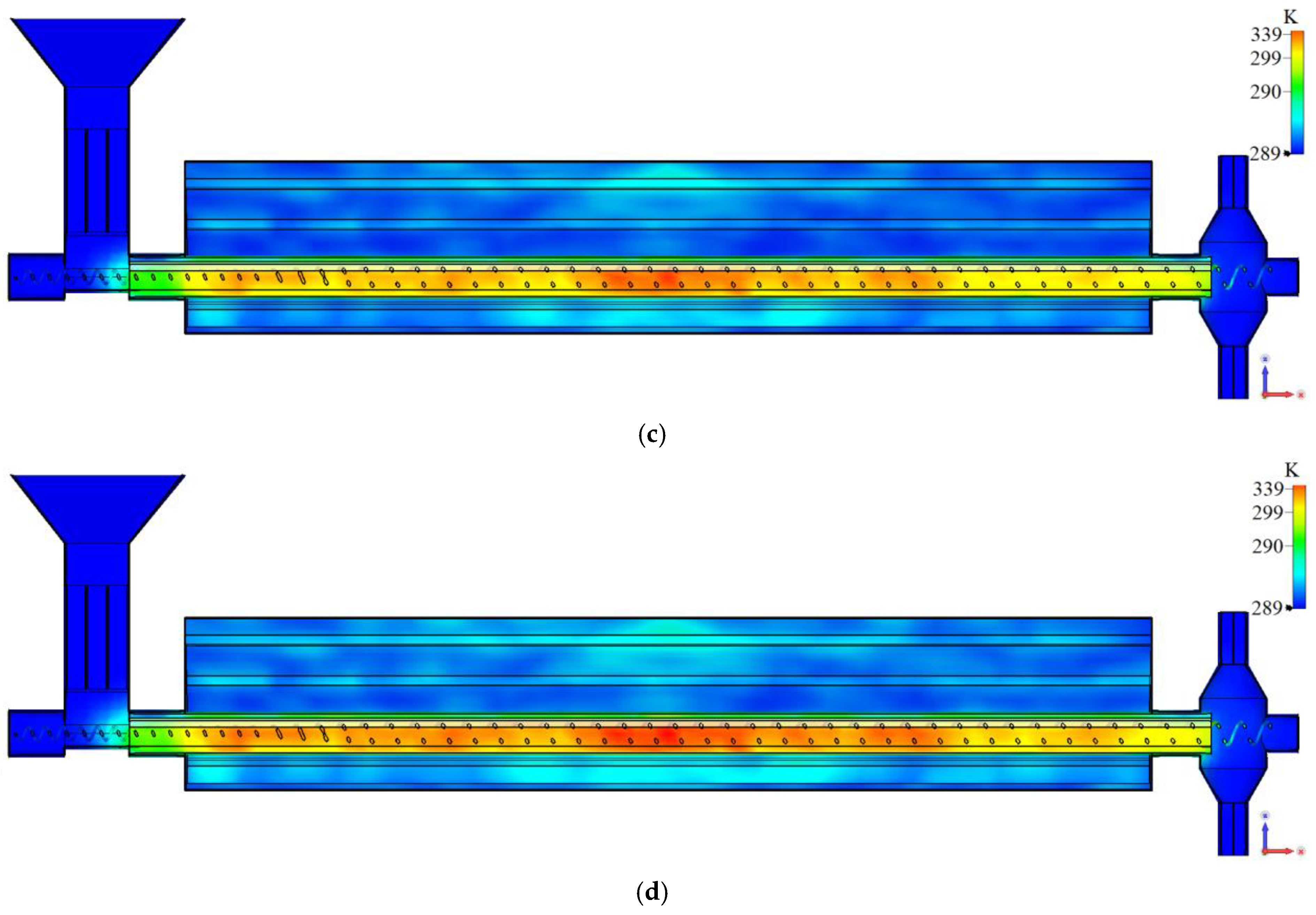

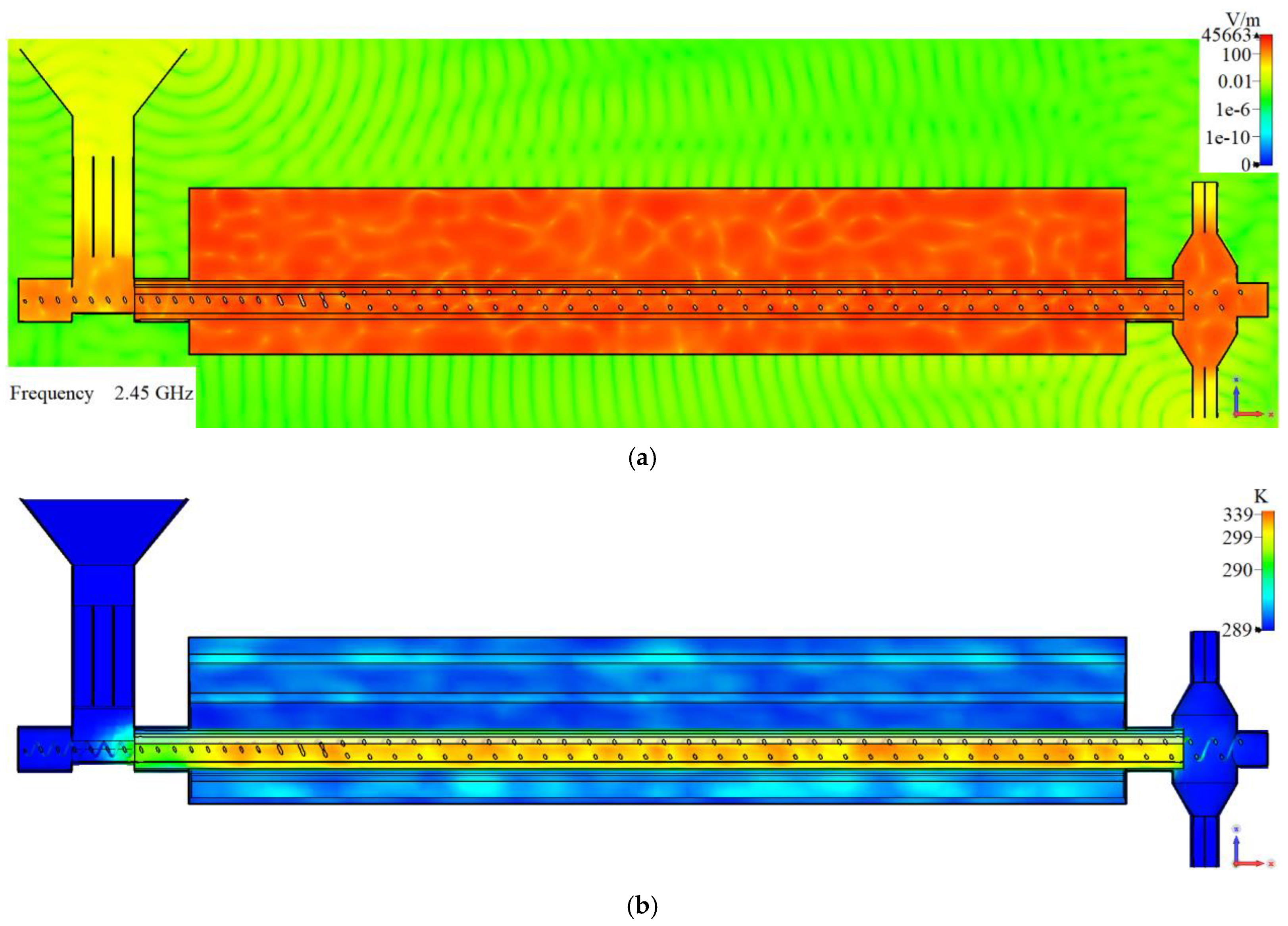

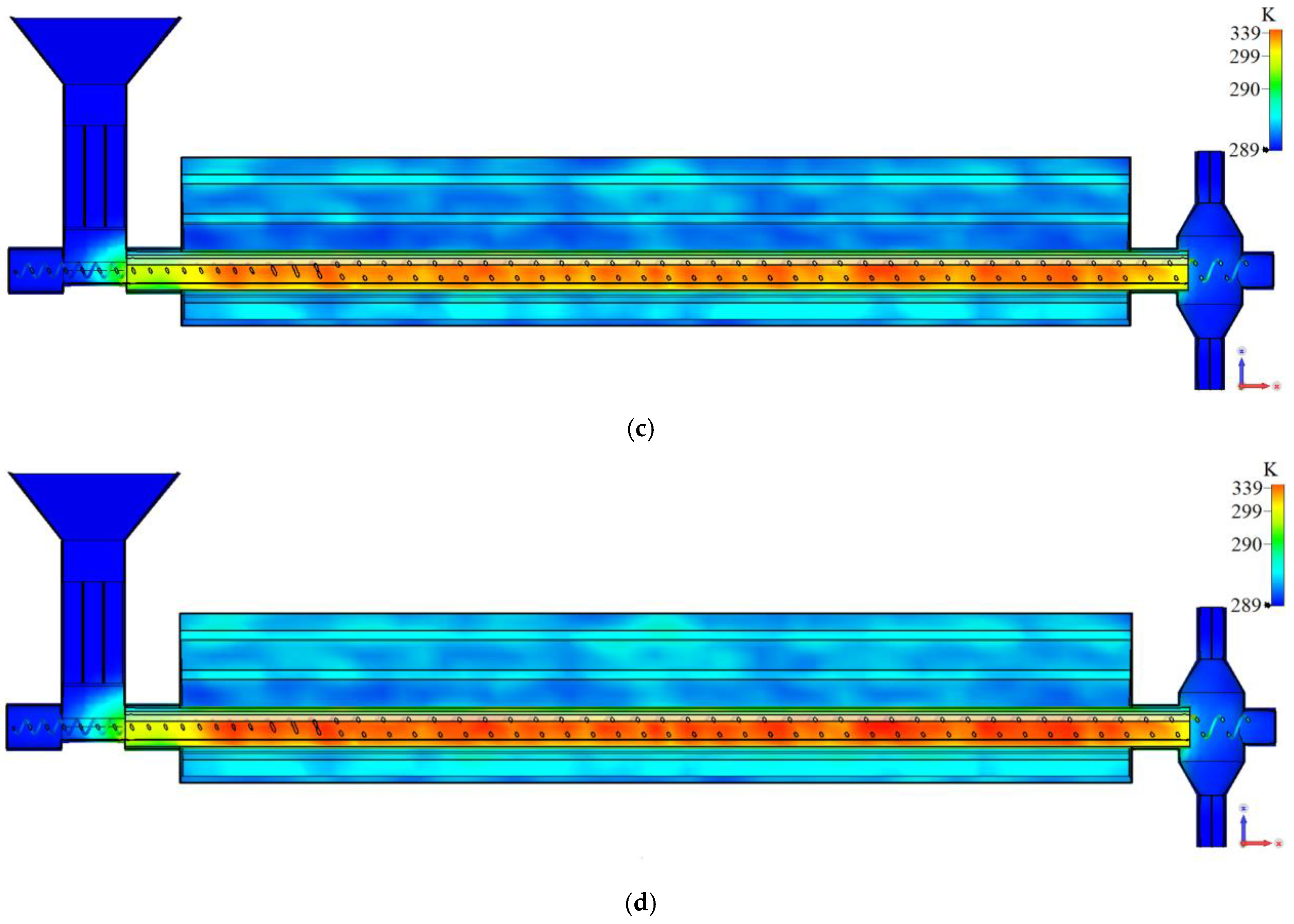

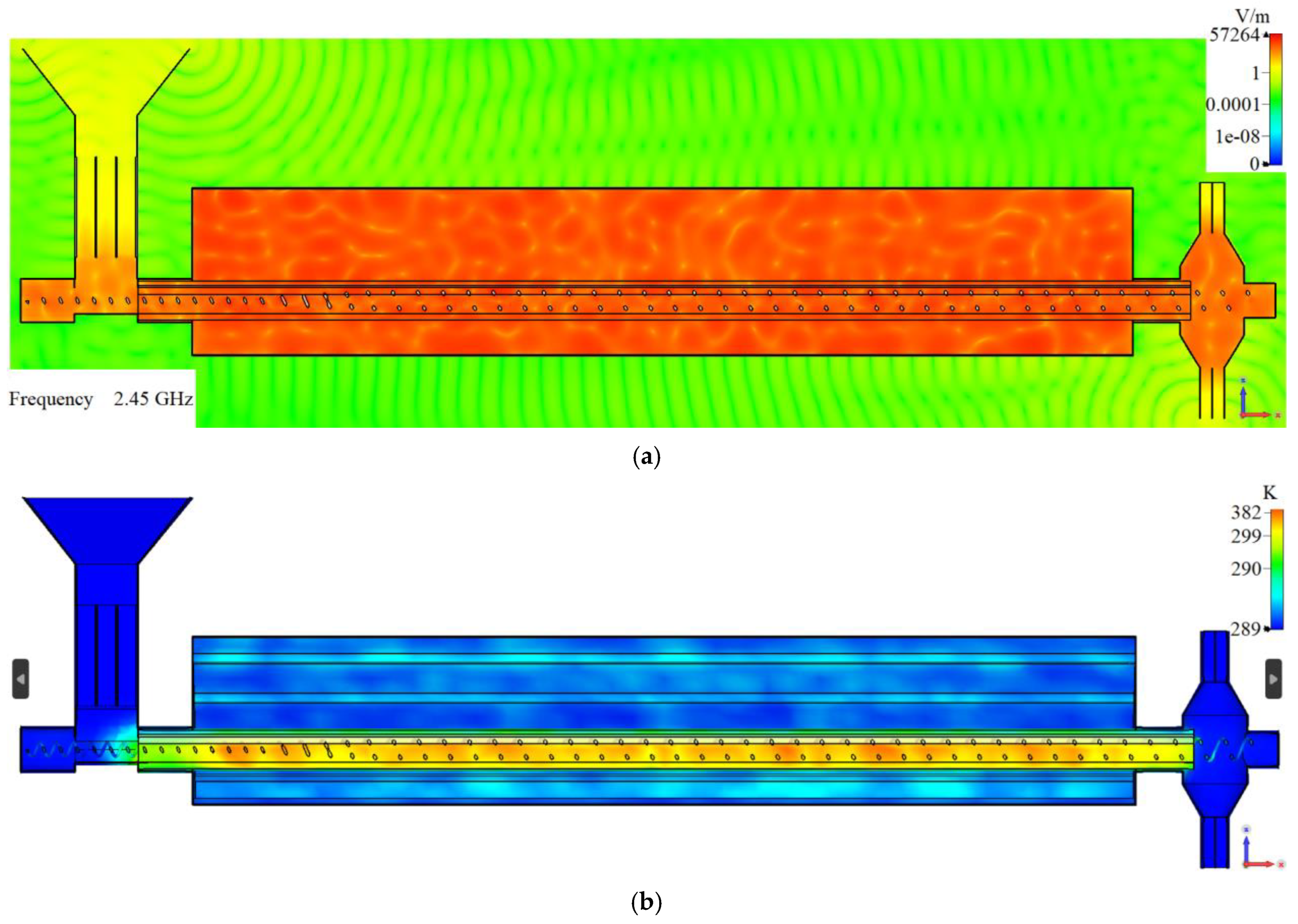

- The placement of the MW sources feeding the treatment chamber of the prototype. In this regard, a 3D model coupling the electromagnetic and heat transfer processes was established using a multiphysics solver [32,33,34]. The temperature and electric field distribution inside the treatment chamber were analyzed under three different placements of the MW sources and at different processing times. The whole design was carried out taking care to prevent and minimize possible microwave energy leakage. To this end, honeycomb filters integrated in both loading and unloading sections of the pilot plant were suitably designed. In this way, the hazards due to the worker’s exposure to microwaves were practically negligible, and the whole plant was compliant with international recommendations [35], European regulations [36] and Italian regulations limiting the exposure of people to electromagnetic fields [37].

- Build of the semi-industrial MW-based pilot plant with continuous flow by means the internal helix.

- Experimental trials with the aim of testing plant performance, and evaluating the temperature reached and the heating uniformity of processed almonds at different processing times. To this regard, the temperature values predicted with the numerical simulations were compared with the experimental results and statistically analyzed.

2.1. Microwave Heating

2.2. Dielectric Properties

2.3. Electromagnetic and Thermal Modeling

2.4. Numerical Modeling

2.5. Experimental Procedure to Evaluate the Thermal Uniformity

2.6. Moisture Content of Almonds

2.7. Statistical Analysis

3. Results and Discussion

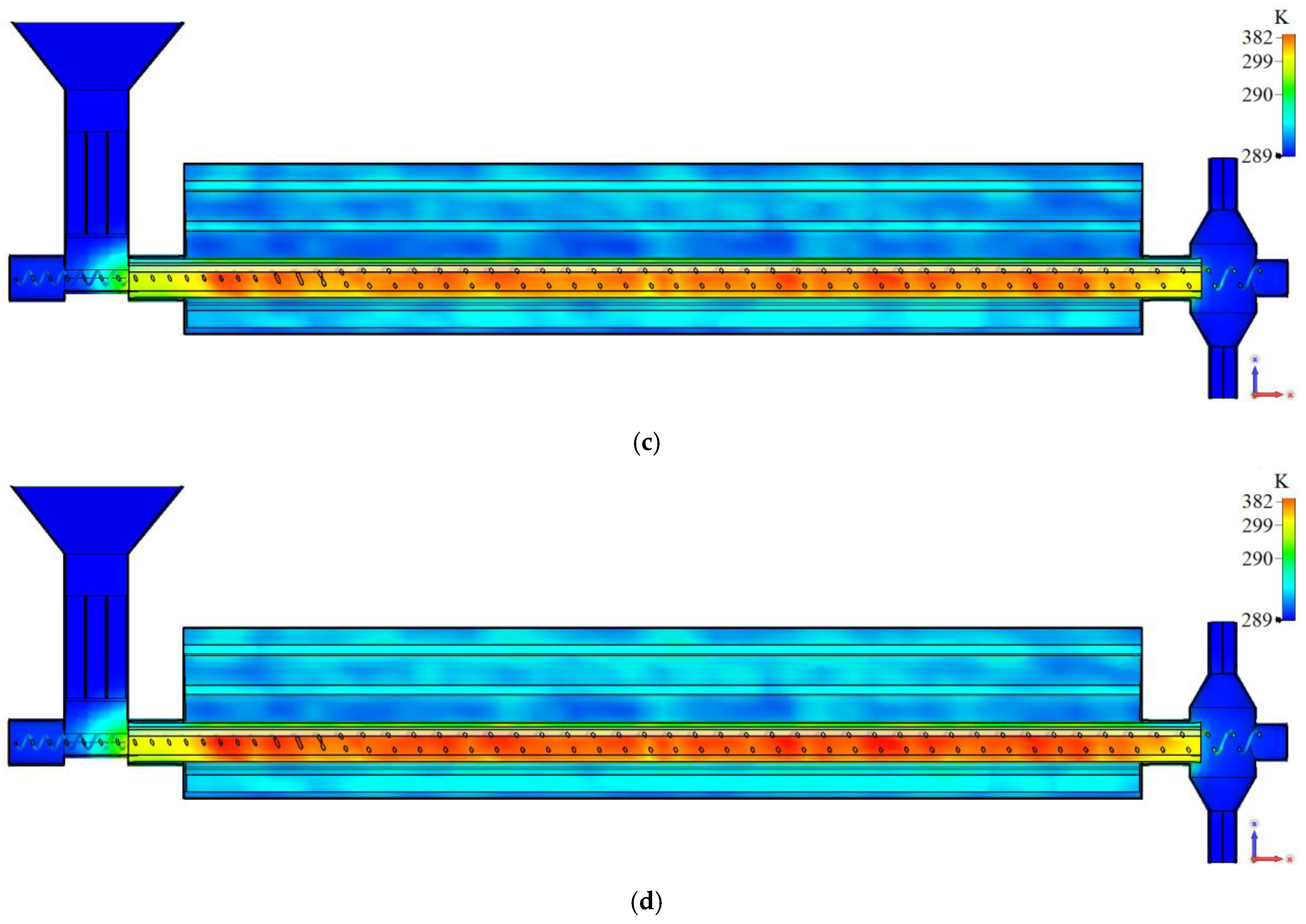

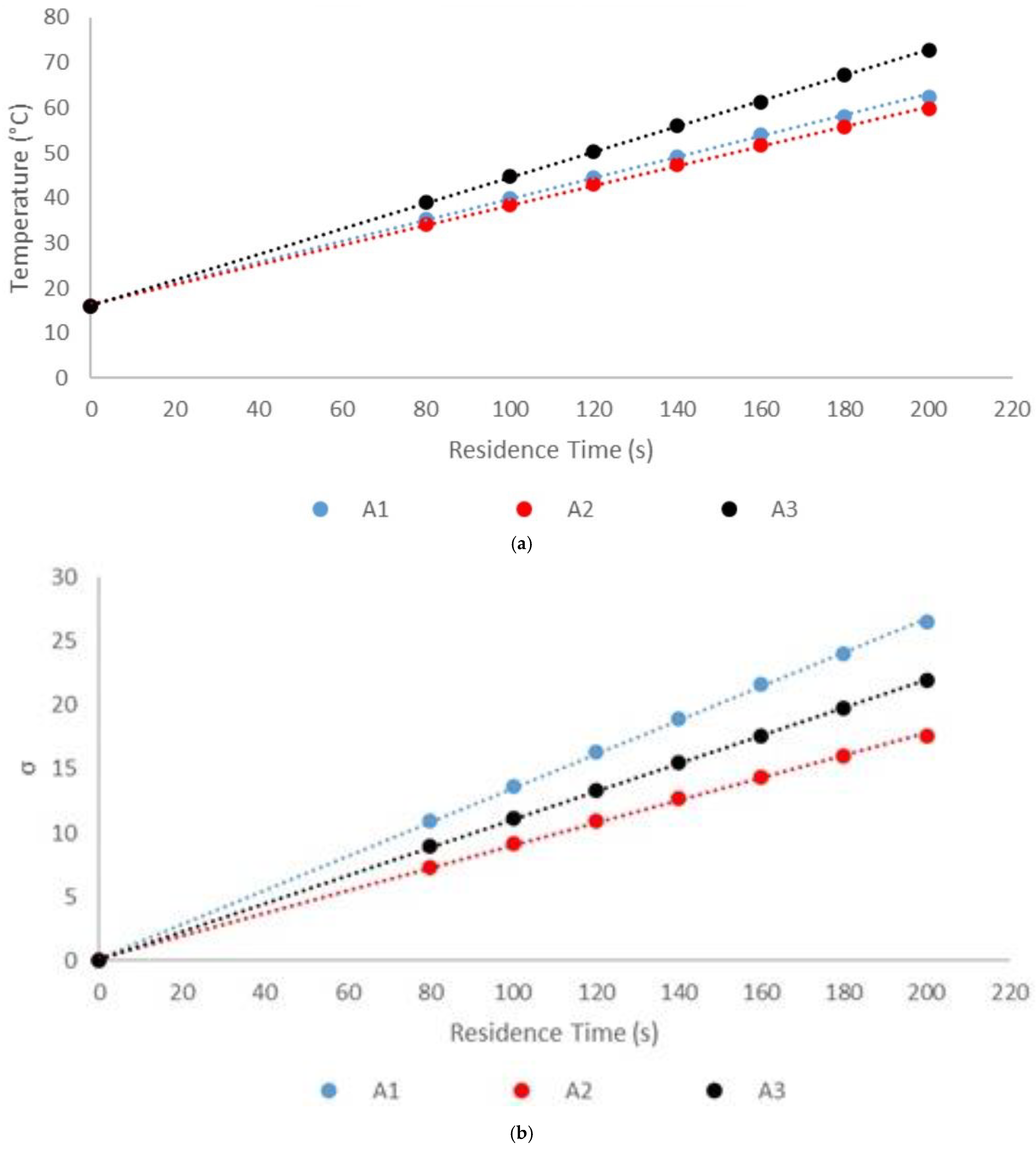

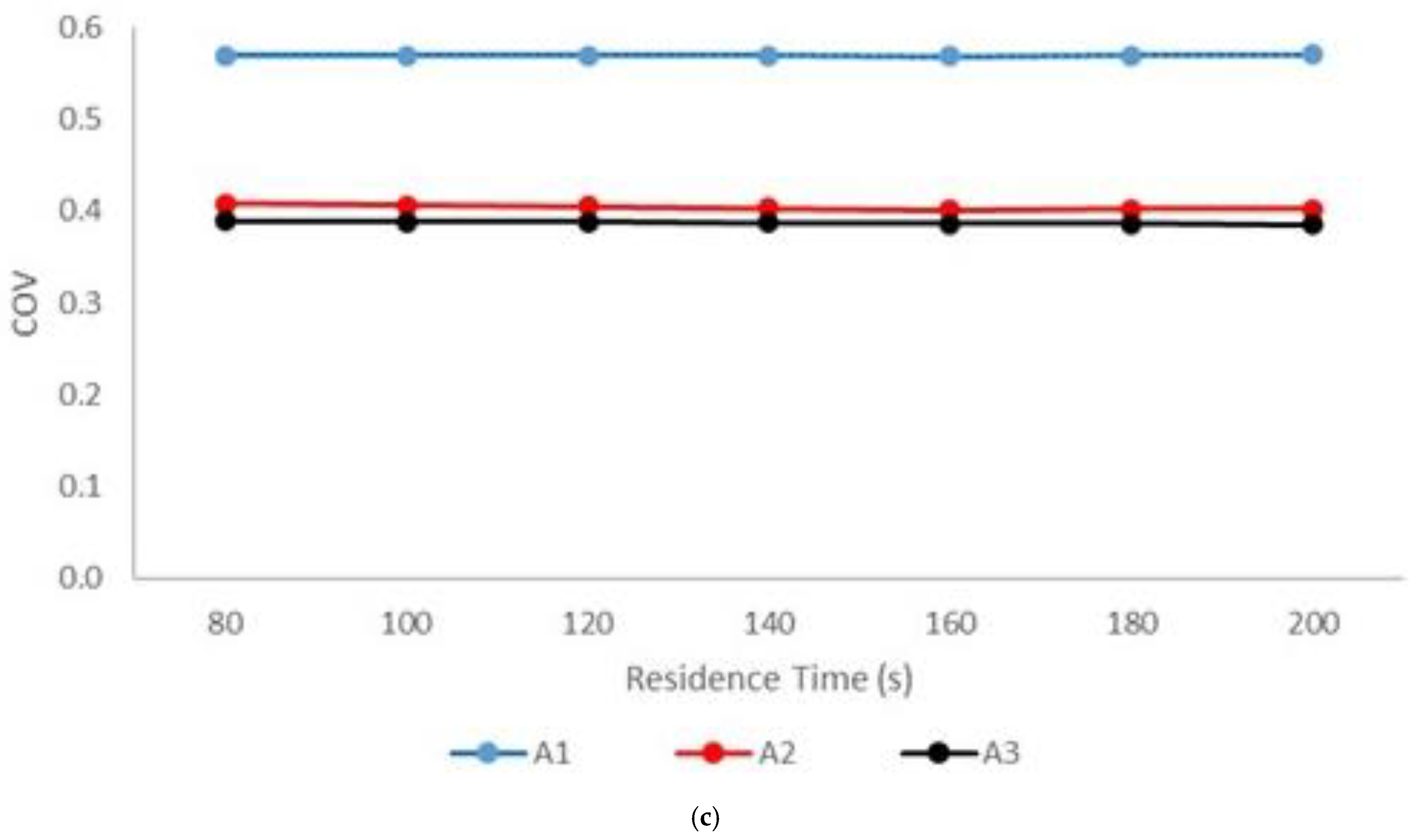

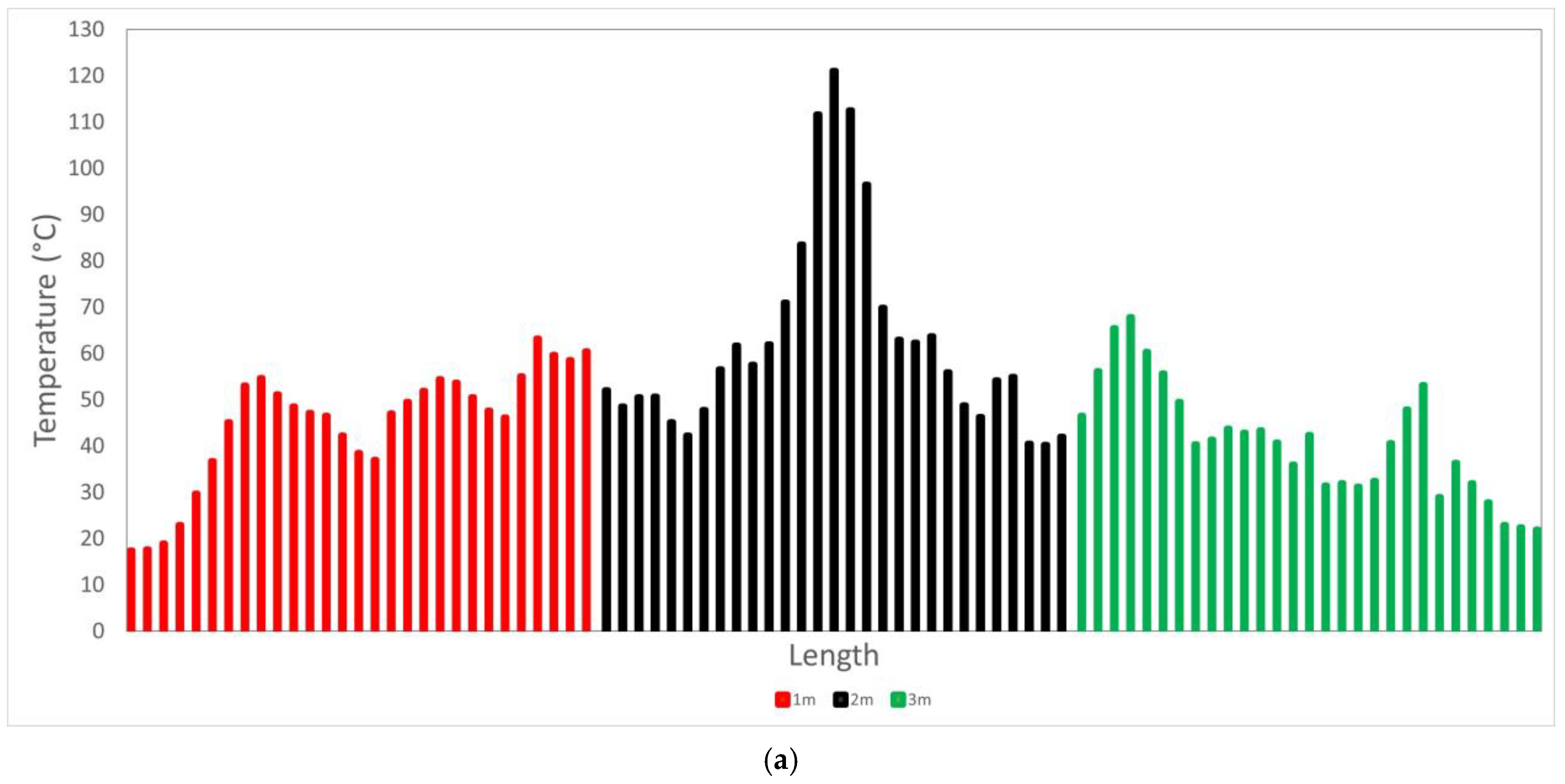

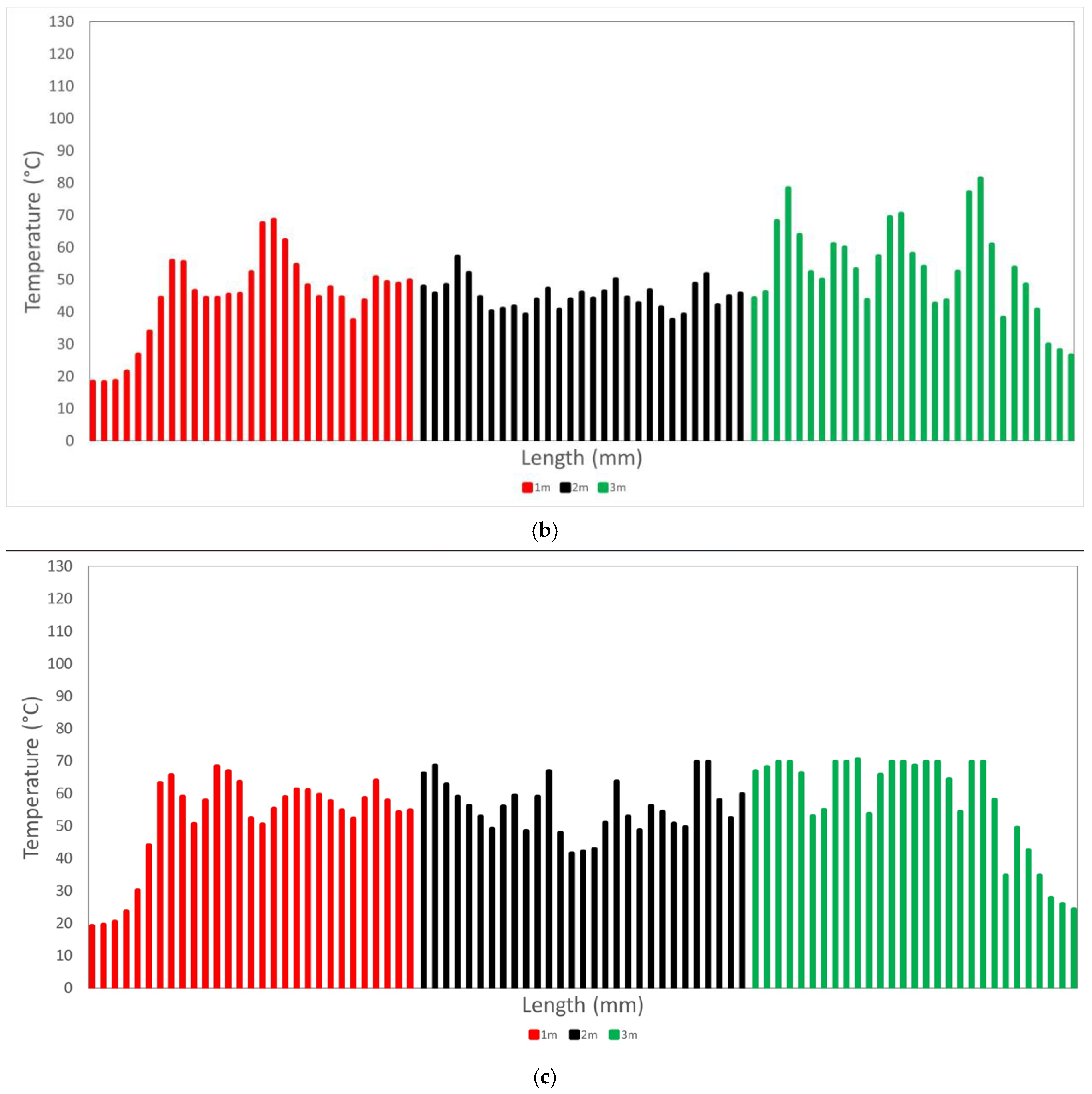

3.1. Simulation Results

3.2. MW-Based Plant Prototype

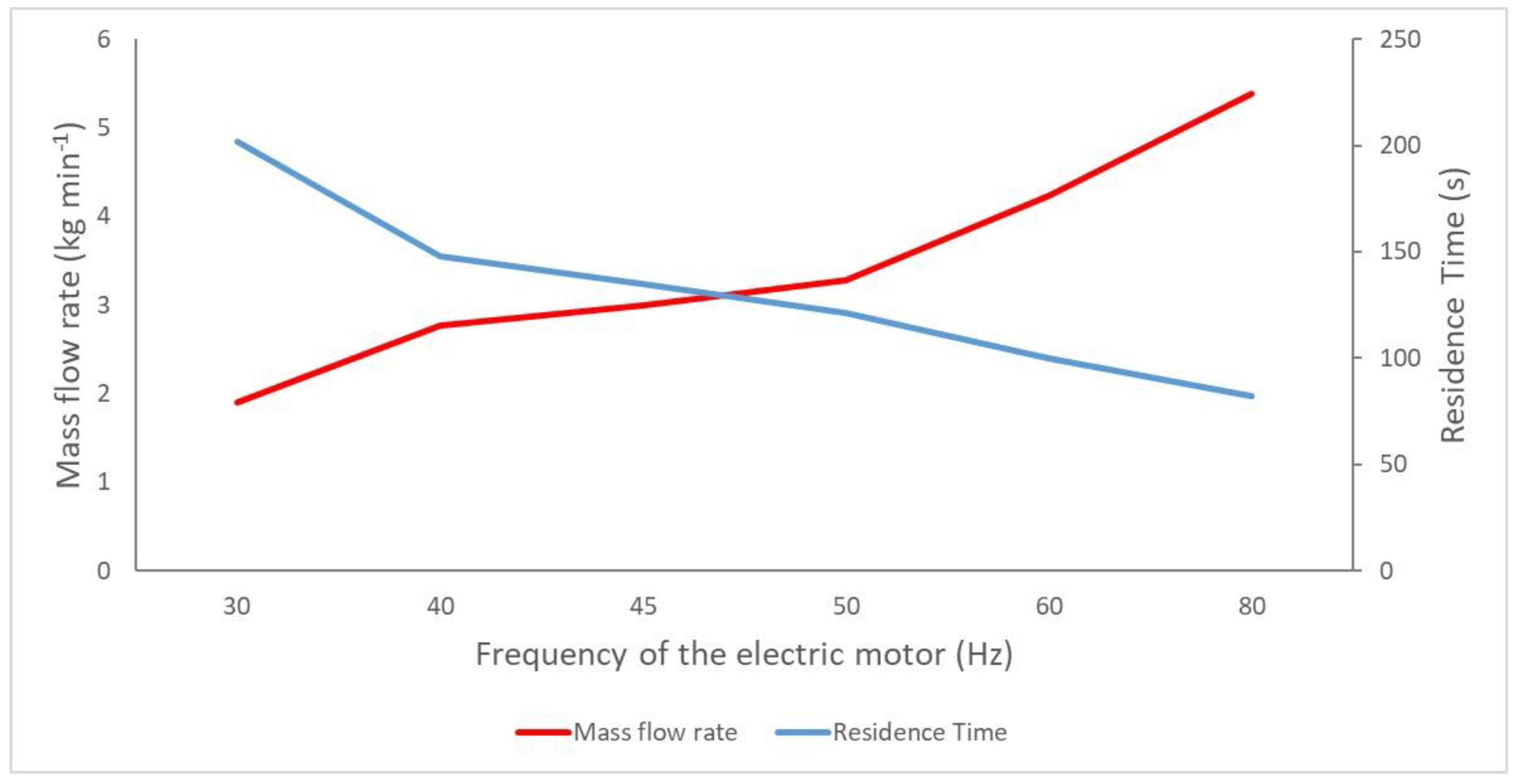

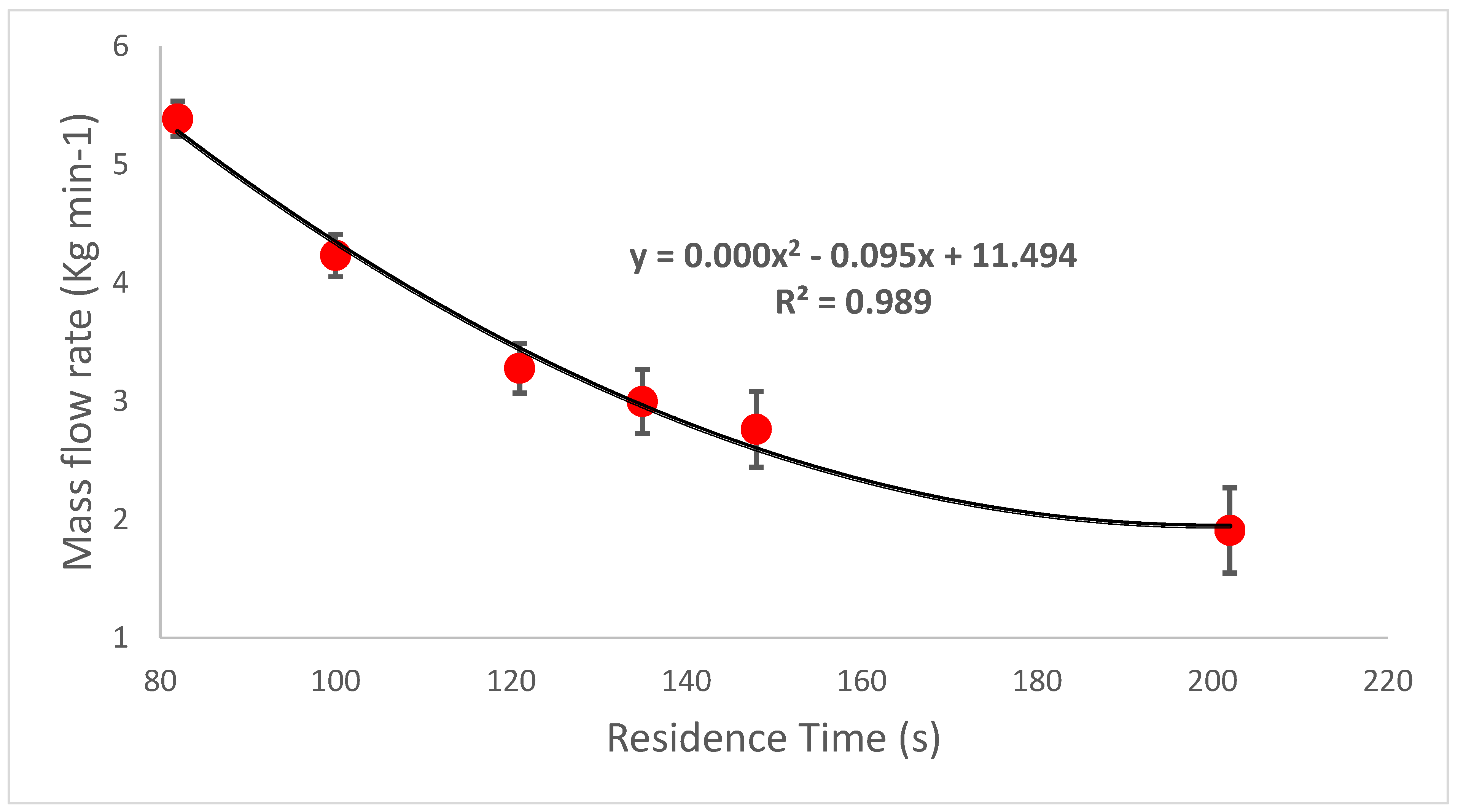

3.3. Operative Parameters of MW-Based Plant Prototype

3.4. Moisture Content

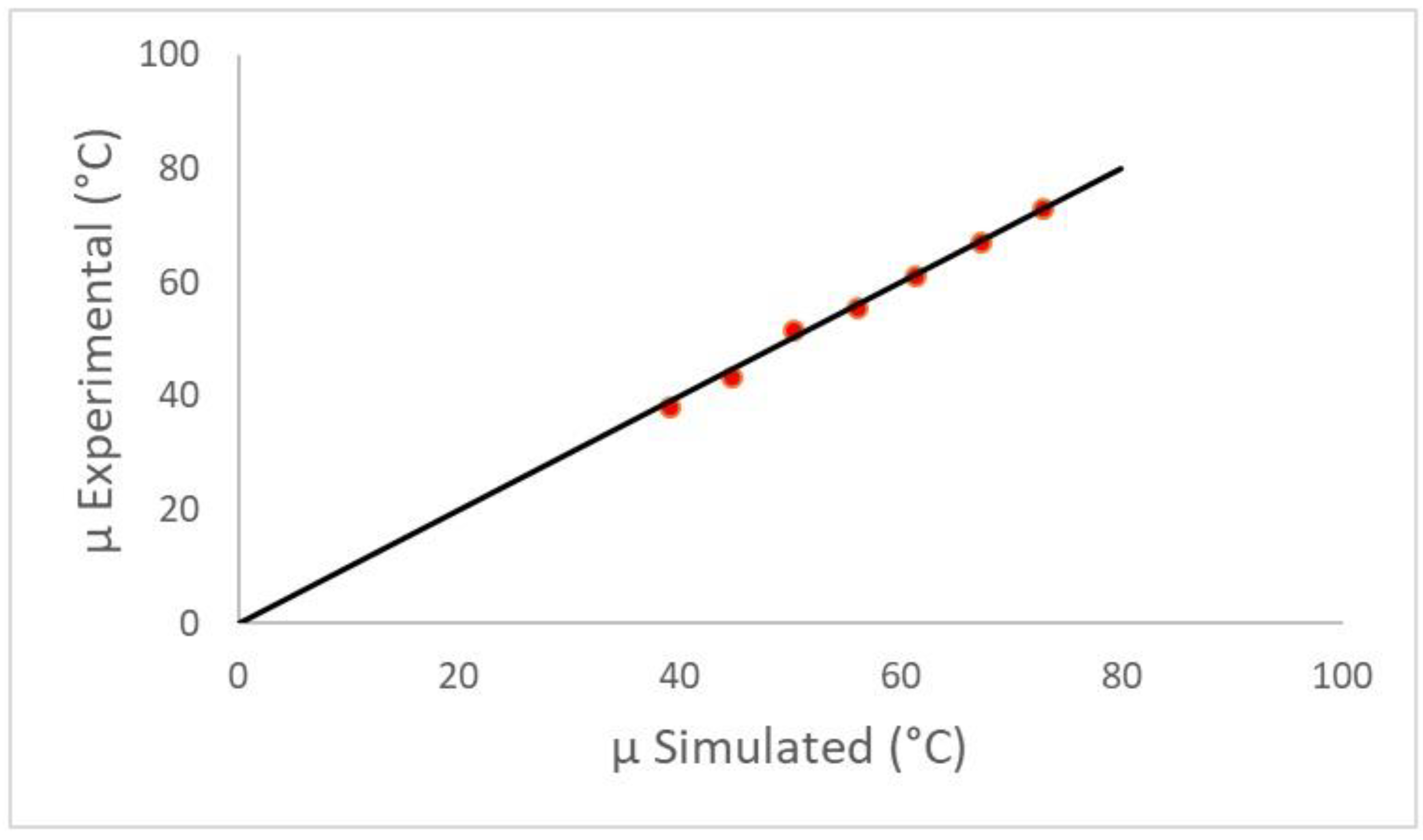

3.5. Model Verification

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yada, S.; Lapsley, K.; Huang, G. A review of composition studies of cultivated almonds: Macronutrients and micronutrients. J. Food Compos. Anal. 2011, 24, 469–480. [Google Scholar] [CrossRef]

- Choo, J.M.; Tran, C.D.; Luscombe-Marsh, N.D.; Stonehouse, W.; Bowen, J.; Johnson, N.; Thompson, C.H.; Watson, E.-J.; Brinkworth, G.D.; Rogers, G.B. Almond consumption affects fecal microbiota composition, stool pH, and stool moisture in overweight and obese adults with elevated fasting blood glucose: A randomized controlled trial. Nutr. Res. 2021, 85, 47–59. [Google Scholar] [CrossRef]

- Barreca, D.; Nabavi, S.M.; Sureda, A.; Rasekhian, M.; Raciti, R.; Silva, A.S.; Annunziata, G.; Arnone, A.; Tenore, G.C.; Süntar, İ.; et al. Almonds (Prunus dulcis Mill. D. A. Webb): A Source of Nutrients and Health-Promoting Compounds. Nutrients 2020, 12, 672. [Google Scholar] [CrossRef]

- Bernat, N.; Cháfer, M.; Chiralt, A.; González-Martínez, C. Development of a non-dairy probiotic fermented product based on almond milk and inulin. Food Sci. Technol. Int. 2015, 21, 440–453. [Google Scholar] [CrossRef] [PubMed]

- Gautam, C.; Islam, S.M.; Sadistap, S.; Sarma, U. Effect of Microwave Heat on the Nutritional Properties of Infected Red Kidney Beans. IEEE Access 2018, 6, 57137–57143. [Google Scholar] [CrossRef]

- Yadav, D.N.; Anand, T.; Sharma, M.; Gupta, R.K. Microwave technology for disinfestation of cereals and pulses: An overview. J. Food Sci. Technol. 2014, 51, 3568–3576. [Google Scholar] [CrossRef]

- Chenlo, F.; Moreira, R.; Chaguri, L.; Torres, M.D. Note. Sugar, moisture contents, and color of chestnuts during different storage regimes. Food Sci. Technol. Int. 2009, 15, 169–178. [Google Scholar] [CrossRef]

- Wang, S.; Tiwari, G.; Jiao, S.; Johnson, J.; Tang, J. Developing postharvest disinfestation treatments for legumes using radio frequency energy. Biosyst. Eng. 2010, 105, 341–349. [Google Scholar] [CrossRef]

- Kovács, E.; Kiss, I.; Boros, A.; Horváth, N.; Tóth, J.; Gyulai, P.; Szalma, Á. Disinfestation of different cereal products by irradiation. Int. J. Radiat. Appl. Instrum. Part C Radiat. Phys. Chem. 1986, 28, 545–548. [Google Scholar] [CrossRef]

- Patil, H.; Shejale, K.P.; Jabaraj, R.; Shah, N.; Kumar, G. Disinfestation of red flour beetle (Tribolium castaneum) present in almonds (Prunus dulcis) using microwave heating and evaluation of quality and shelf life of almonds. J. Stored Prod. Res. 2020, 87, 101616. [Google Scholar] [CrossRef]

- Gao, M.; Tang, J.; Wang, Y.; Powers, J.; Wang, S. Almond quality as influenced by radio frequency heat treatments for disinfestation. Postharvest Biol. Technol. 2010, 58, 225–231. [Google Scholar] [CrossRef]

- Paul, A.; Radhakrishnan, M.; Anandakumar, S.; Shanmugasundaram, S.; Anandharamakrishnan, C. Disinfestation techniques for major cereals: A status report. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1125–1155. [Google Scholar] [CrossRef] [PubMed]

- Hou, L.; Ling, B.; Wang, S. Development of thermal treatment protocol for disinfesting chestnuts using radio frequency energy. Postharvest Biol. Technol. 2014, 98, 65–71. [Google Scholar] [CrossRef]

- Wang, S.; Tang, J. Radio frequency and microwave alternative treatments for nut insect control: A review. Agric. Eng. J. 2001, 10, 105–120. [Google Scholar]

- Manickavasagan, A.; Alahakoon PM, K.; Al-Busaidi, T.K.; Al-Adawi, S.; Al-Wahaibi, A.K.; Al-Raeesi, A.A.; Al-Yahyai, R.; Jayas, D.S. Disinfestation of stored dates using microwave energy. J. Stored Prod. Res. 2013, 55, 1–5. [Google Scholar] [CrossRef]

- Gamage, T.V.; Sanguansri, P.; Swiergon, P.; Eelkema, M.; Wyatt, P.; Leach, P.; Alexander, D.L.J.; Knoerzer, K. Continuous combined microwave and hot air treatment of apples for fruit fly (Bactrocera tryoni and B. jarvisi) disinfestation. Innov. Food Sci. Emerg. Technol. 2015, 29, 261–270. [Google Scholar] [CrossRef]

- Ipsita, D.; Narendra, G.S.; Girish, K. Properties of walnut influenced by short time microwave treatment for disinfestation of insect infestation. J. Stored Prod. Res. 2014, 59, 152–157. [Google Scholar]

- Fuji, J.; Digvir, S.J.; Noel, D.G.W.; Fields, P.G.; Howe, N. An evaluation of insect expulsion from wheat samples by microwave treatment for disinfestation. Biosyst. Eng. 2015, 130, 1–12. [Google Scholar]

- Candido da Silva, A.; Sarturi, H.J.; Dall’Oglio, E.L.; Soares, M.A.; de Sousa, P.T.; Gomes de Vasconcelos, L.; Kuhnen, C.A. Microwave drying and disinfestation of Brazil nut seeds. Food Control 2016, 70, 119–129. [Google Scholar] [CrossRef]

- Wang, S.; Tang, J.; Cavalieri, R.P. Modeling fruit internal heating rates for hot air and hot water treatments. Postharvest Biol. Technol. 2001, 22, 257–270. [Google Scholar] [CrossRef]

- Falciglia, P.P.; Roccaro, P.; Bonanno, L.; De Guidi, G.; Vagliasindi, F.G.A.; Romano, S. A review on the microwave heating as a sustainable technique for environmental remediation/detoxification applications. Renew. Sustain. Energy Rev. 2018, 95, 147–170. [Google Scholar] [CrossRef]

- Liu, T.-C.; Wu, Y.-C.; Chau, C.-F. An Overview of Carbon Emission Mitigation in the Food Industry: Efforts, Challenges, and Opportunities. Processes 2023, 11, 1993. [Google Scholar] [CrossRef]

- Shen, L.; Gao, M.; Feng, S.; Ma, W.; Zhang, Y.; Liu, C.; Liu, C.; Zheng, X. Analysis of heating uniformity considering microwave transmission in stacked bulk of granular materials on a turntable in microwave ovens. J. Food Eng. 2022, 319, 110903. [Google Scholar] [CrossRef]

- Gallo, M.; Bozzetti, M.; Calo, G.; Mescia, L.; Petruzzelli, V. Design of a Dielectric Applicator for Microwave Heating. J. Microw. Power Electromagn. Energy 2009, 43, 4–12. [Google Scholar] [CrossRef] [PubMed]

- Vadivambal, R.; Jayas, D.S. Non-uniform Temperature Distribution During Microwave Heating of Food Materials—A Review. Food Bioprocess Technol. 2010, 3, 161–171. [Google Scholar] [CrossRef]

- Zhu, H.; Ye, J.; Gulati, T.; Yang, Y.; Liao, Y.; Yang, Y.; Huang, K. Dynamic analysis of continuous-flow microwave reactor with a screw propeller. Appl. Therm. Eng. 2017, 123, 1456–1461. [Google Scholar] [CrossRef]

- Sebera, V.; Nasswettrová, A.; Nikl, K. Finite Element Analysis of Mode Stirrer Impact on Electric Field Uniformity in a Microwave Applicator. Dry. Technol. 2012, 30, 1388–1396. [Google Scholar] [CrossRef]

- Birla, S.L.; Pitchai, K. 18—Simulation of microwave processes. In The Microwave Processing of Foods, 2nd ed.; Woodhead Publishing Series in Food Science, Technology and Nutrition; Regier, M., Knoerzer, K., Schubert, H., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 407–431. ISBN 9780081005286. [Google Scholar] [CrossRef]

- Yang, H.; Yan, B.; Meng, L.; Jiao, X.; Huang, J.; Gao, W.; Zhao, J.; Zhang, H.; Chen, W.; Fan, D. Mathematical modeling of continuous microwave heating of surimi paste. J. Food Eng. 2022, 315, 110797. [Google Scholar] [CrossRef]

- Yang, H.; Yan, B.; Chen, W.; Fan, D. Prediction and innovation of sustainable continuous flow microwave processing based on numerical simulations: A systematic review. Renew. Sustain. Energy Rev. 2023, 175, 113183. [Google Scholar] [CrossRef]

- Campañone, L.A.; Bava, J.A.; Mascheroni, R.H. Modeling and process simulation of controlled microwave heating of foods by using of the resonance phenomenon. Appl. Therm. Eng. 2014, 73, 914–923. [Google Scholar] [CrossRef]

- Mescia, L.; Lamacchia, C.M.; Berardi, A.; Leone, A.; Tamborrino, A. Continuous microwave pilot plant for almond disinfestation: Preliminary tests. In Proceedings of the Microwave Mediterranean Symposium (MMS 2022), Pizzo Calabro, Italy, 9–13 May 2022. [Google Scholar] [CrossRef]

- Tamborrino, A.; Berardi, A.; de Lillo, E.; Ragone, G.; De Benedictis, M.; Tufariello, M.; Santino, A.; Leone, A. Using a continuous microwave system for postharvest almond disinfestation. Postharvest Biol. Technol. 2023, 201, 112369. [Google Scholar] [CrossRef]

- Tamborrino, A.; Summo, C.; Berardi, A.; De Angelis, D.; Ragone, G.; Leone, A. Use of a Microwave Pilot Plant for Almond Disinfestation: Study on the Thermal Uniformity of the Treatment and Effect on Volatile Composition. Chem. Eng. Trans. 2023, 102, 79–84. [Google Scholar] [CrossRef]

- ICNIRP. Guidelines for limiting exposure to electromagnetic fields (100 kHz to 300 GHz). Health Phys. 2020, 118, 483–524. [Google Scholar] [CrossRef] [PubMed]

- Directive 2013/35/EU of the European Parliament and of the Council of 26 June 2013 on the Minimum Health and Safety Requirements Regarding the Exposure of Workers to the Risks Arising from Physical Agents (Electromagnetic Fields) (20th Individual Directive within the Meaning of Article 16(1) of Directive 89/391/EEC) and Repealing Directive 2004/40/EC.

- Legislative Decree No. 159 of August 1, 2016, Implementing EU Directive 2013/35/UE on the Minimum Safety and Health Standards Related to the Exposure of Workers to Risks Deriving from Physical Agents (Electromagnetic Fields) and Repealing EU Directive 2004/40/CE (L.D. No. 159), Gazetta Ufficiale, No. 192 (18 August 2016), NORMATTIVA. (In Italian)

- Laneve, D.; Falconi, M.C.; Bozzetti, M.; Rutigliani, G.; Prisco, R.A.; Dimiccoli, V.; Prudenzano, F. Electromagnetic Design of Microwave Cavities for Side-Coupled Linear Accelerators: A Hybrid Numerical/Analytical Approach. IEEE Trans. Nucl. Sci. 2018, 65, 2233–2239. [Google Scholar] [CrossRef]

- Nelson, S.O. Dielectric Properties of Agricultural Materials and their Applications; Academic Press: London, UK, 2015. [Google Scholar]

- Weng, Y.-K.; Chen, J.; Cheng, C.-W.; Chen, C. Use of Modern Regression Analysis in the Dielectric Properties of Foods. Foods 2020, 9, 1472. [Google Scholar] [CrossRef] [PubMed]

- Li, R.; Zhang, S.; Kou, X.; Ling, B.; Wang, S. Dielectric properties of almond kernels associated with radio frequency and microwave pasteurization. Sci. Rep. 2017, 7, srep42452. [Google Scholar] [CrossRef] [PubMed]

- Collin, R.E. Foundation of Microwave Engineering, 2nd ed.; Wiley-IEEE Press: Hoboken, NJ, USA, 2000. [Google Scholar]

- Hahn, D.W.; Ozisik, M.N. Heat Conduction, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2012; pp. 6–16. [Google Scholar]

- Mescia, L.; Bia, P.; Chiapperino, M.A.; Caratelli, D. Fractional Calculus Based FDTD Modeling of Layered Biological Media Exposure to Wideband Electromagnetic Pulses. Electronics 2017, 6, 106. [Google Scholar] [CrossRef]

- UNI EN ISO 18134–1:2015; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 1: Total Moisture—Reference Method. ISO: Geneva, Switzerland, 2022.

- Chen, H.; Tang, J.; Liu, F. Simulation model for moving food packages in microwave heating processes using conformal FDTD method. J. Food Eng. 2008, 88, 294–305. [Google Scholar] [CrossRef]

- Resurreccion, F.; Tang, J.; Pedrow, P.; Cavalieri, R.; Liu, F.; Tang, Z. Development of a computer simulation model for processing food in a microwave assisted thermal sterilization (MATS) system. J. Food Eng. 2013, 118, 406–416. [Google Scholar] [CrossRef]

- Kako, Y.; Llave, Y.; Sakai, N.; Fukuoka, M. Computer simulation of microwave cooking of sweet potato—Kinetics analysis of reactions in the maltose production process and their modeling. J. Food Eng. 2023, 349, 111469. [Google Scholar] [CrossRef]

- Perone, C.; Romaniello, R.; Leone, A.; Berardi, A.; Catalano, P.; Tamborrino, A. CFD Analysis of a Tube-in-tube Heat Exchanger to Pre-heat Olive Pastes. Chem. Eng. Trans. 2021, 87, 253–258. [Google Scholar] [CrossRef]

- Leone, A.; Perone, C.; Berardi, A.; Tamborrino, A. Energy analysis and numerical evaluation of the decanter centrifuge for wastewater management to allow a sustainable energy planning of the process. Energy Convers. Manag. X 2024, 22, 100596. [Google Scholar] [CrossRef]

| Symbol | Value | Description |

|---|---|---|

| f0 | 2.45 GHz | Microwave frequency |

| 1.42 | Dielectric constant of almonds | |

| tan δ | 0.14 | Dielectric loss factor of almonds |

| 2.30 | Dielectric constant of polypropylene | |

| tan δpl | 0.002 | Dielectric loss factor of polypropylene |

| σ | 7 × 106 Sm−1 | Electric conductivity of stainless steel |

| ka | 0.1 Wm−1K−1 | Thermal conductivity of almonds |

| kp | 0.24 Wm−1K−1 | Thermal conductivity of polypropylene tube |

| ks | 65.2 Wm−1K−1 | Thermal conductivity of stainless steel |

| Cpa | 1400 Jkg−1K−1 | Specific heat of almonds |

| Cpp | 1000 Jkg−1K−1 | Specific heat of polypropylene tube |

| Cps | 450 Jkg−1K−1 | Specific heat of stainless steel |

| ρa | 800 kgm−3 | Mass density of almonds |

| ρp | 2200 kgm−3 | Mass density of polypropylene tube |

| ρs | 7870 kgm−3 | Mass density of stainless steel |

| d0 | 125 mm | Outer diameter of the propylene tube |

| di | 90.8 mm | Inner diameter of the propylene tube |

| Lf | 395 mm | Length of the honeycomb filter |

| Wf | 180 mm | Width of the honeycomb filter |

| Hf | 552 mm | Height of the honeycomb filter |

| Wg | 60 mm | Width of the grid honeycomb filter |

| Hg | 60 mm | Height of the grid honeycomb filter |

| L | 3000 mm | Length of the treatment chamber |

| W | 564 mm | Width of the treatment chamber |

| H | 552 mm | Height of the treatment chamber |

| Incoming Power (W) | Outcoming Power (W) | |

|---|---|---|

| Port 1 | 1419.60 | 80.40 |

| Port 2 | 1358.23 | 141.77 |

| Port 3 | 1403.45 | 96.55 |

| Port 4 | 1395.64 | 104.36 |

| Port 5 | 1382.40 | 117.60 |

| TOTAL | 6959.33 | 540.67 |

| Residence | 1 m | 2 m | 3 m |

|---|---|---|---|

| Time [s] | µ ± Σ | µ ± σ | µ ± σ |

| 1 MW source 7.5 kW | |||

| 80 | 32.78 ± 7.46 b | 42.83 ± 12.71 a | 30.50 ± 7.10 b |

| 100 | 36.87 ± 9.28 b | 49.48 ± 15.81 a | 34.08 ± 8.85 b |

| 120 | 40.94 ± 11.09 b | 56.11 ± 18.89 a | 37.65 ± 10.60 b |

| 140 | 45.02 ± 12.89 b | 62.52 ± 22.09 a | 41.18 ± 12.37 b |

| 160 | 49.00 ± 14.65 b | 69.32 ± 24.98 a | 44.77 ± 14.08 b |

| 180 | 52.55 ± 16.23 b | 75.18 ± 27.69 a | 47.92 ± 15.62 b |

| 200 | 56.23 ± 17.85 b | 81.26 ± 30.48 a | 51.19 ± 17.22 b |

| 3 MW sources 2.5 kW | |||

| 80 | 32.27 ± 7.83 b | 32.62 ± 2.55 b | 37.61 ± 8.36 a |

| 100 | 36.32 ± 9.72 b | 36.74 ± 3.17 b | 42.94 ± 10.40 a |

| 120 | 40.37 ± 11.57 b | 40.86 ± 3.78 b | 48.26 ± 12.42 a |

| 140 | 44.41 ± 13.40 b | 44.97 ± 4.38 b | 53.55 ± 14.43 a |

| 160 | 48.44 ± 15.21 b | 49.06 ± 4.98 b | 58.82 ± 16.43 a |

| 180 | 52.00 ± 16.79 b | 52.66 ± 5.52 b | 63.50 ± 18.23 a |

| 200 | 55.71 ± 18.42 b | 56.42 ± 6.08 b | 68.36 ± 20.07 a |

| 5 MW sources 1.5 kW | |||

| 80 | 36.80 ± 8.80 a | 39.05 ± 5.27 a | 41.91 ± 10.47 a |

| 100 | 41.96 ± 10.95 a | 44.75 ± 6.55 a | 48.27 ± 13.04 a |

| 120 | 47.09 ± 13.08 a | 50.43 ± 7.81 a | 54.61 ± 15.59 a |

| 140 | 52.22 ± 15.19 a | 56.09 ± 9.05 a | 60.92 ± 18.12 a |

| 160 | 57.05 ± 17.09 a | 61.48 ± 10.12 a | 66.77 ± 20.32 a |

| 180 | 62.41 ± 19.35 a | 67.36 ± 11.50 a | 73.47 ± 23.15 a |

| 200 | 67.48 ± 21.40 a | 72.96 ± 12.71 a | 79.70 ± 25.64 a |

| Residence Time (s) | RMSE | |||||||

|---|---|---|---|---|---|---|---|---|

| 80 | 100 | 120 | 140 | 160 | 180 | 200 | ||

| µ rilevated | 38.0 | 43.4 | 51.5 | 55.3 | 61.0 | 66.9 | 72.9 | 0.82 |

| µ simulated | 39.0 | 44.7 | 50.4 | 56.0 | 61.3 | 67.3 | 72.8 | |

| σ rilevated | 1.5 | 2.1 | 2.8 | 2.7 | 3.3 | 3.3 | 4.5 | 13.02 |

| σ simulated | 9.0 | 11.2 | 13.3 | 15.5 | 17.5 | 19.8 | 21.9 | |

| COV rilevated | 0.07 | 0.08 | 0.08 | 0.07 | 0.07 | 0.07 | 0.08 | 0.31 |

| COV simulated | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | 0.39 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mescia, L.; Leone, A.; Lamacchia, C.M.; Ferraris, A.; Caggiano, D.; Berardi, A.; Tamborrino, A. Numerical Simulation and Development of a Continuous Microwave-Assisted Pilot Plant for Shelled Almond Processing. Appl. Syst. Innov. 2024, 7, 43. https://doi.org/10.3390/asi7030043

Mescia L, Leone A, Lamacchia CM, Ferraris A, Caggiano D, Berardi A, Tamborrino A. Numerical Simulation and Development of a Continuous Microwave-Assisted Pilot Plant for Shelled Almond Processing. Applied System Innovation. 2024; 7(3):43. https://doi.org/10.3390/asi7030043

Chicago/Turabian StyleMescia, Luciano, Alessandro Leone, Claudio Maria Lamacchia, Angela Ferraris, Domenico Caggiano, Antonio Berardi, and Antonia Tamborrino. 2024. "Numerical Simulation and Development of a Continuous Microwave-Assisted Pilot Plant for Shelled Almond Processing" Applied System Innovation 7, no. 3: 43. https://doi.org/10.3390/asi7030043

APA StyleMescia, L., Leone, A., Lamacchia, C. M., Ferraris, A., Caggiano, D., Berardi, A., & Tamborrino, A. (2024). Numerical Simulation and Development of a Continuous Microwave-Assisted Pilot Plant for Shelled Almond Processing. Applied System Innovation, 7(3), 43. https://doi.org/10.3390/asi7030043