An Investigation of the Effects of Drill Operator Posture on Vibration Exposure and Temporary Threshold Shift of Vibrotactile Perception Threshold

Abstract

:1. Introduction

- Direction of the vibration.

- Working method and operator’s skill.

- Age, constitution and health of operator.

- Coupling forces (grip and feed force).

- Hand, arm and body posture.

- Condition of the machinery used, accessories or work pieces used.

- Area of the hand in contact with the tool.

2. Experimental Method

2.1. Test Participants

2.2. Experimental Method

- Vertical downwards (single handed) similar to ISO 28927-5 test protocol.

- Horizontal (tool located in front of subject, held with both hands).

- Vertically upwards (tool located overhead, single handed use).

3. Results

4. Statistical Analysis of Results

5. Discussion of Results

6. Conclusions

- (a)

- The existing international standards for assessing human exposure to hand–arm vibration based upon the ISO 5349-1 utilising tool vibration measurement values may not effectively capture posture factors and individual human response to vibration.

- (b)

- A new evaluation method to assess HTV inclusive of the limitations outlined within Annex D would be desirable.

- (c)

- The results demonstrate that there is a potential requirement for apparatus suitable for hand-transmitted measurement on the human operative as a means of assessing real time work environment exposure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HAV | Hand–arm vibration |

| HTV | Hand-transmitted vibration |

| MEMS | Micro-electromechanical systems |

| TTS | Tactile threshold shift |

| VPA | Vibration power adsorption |

| VPT | Vibrotactile perception threshold |

| VR | Vibration reducing |

References

- Bovenzi, M. Hand-arm vibration syndrome and dose-response relation for vibration induced white finger among quarry drillers and stonecarvers. Occup. Environ. Med. 1994, 51, 603–611. [Google Scholar] [CrossRef] [Green Version]

- Palmer, K.; Griffin, M.; Syddall, H.; Pannett, B.; Cooper, C.; Coggon, D. Risk of hand-arm vibration syndrome according to occupation and sources of exposure to hand-transmitted vibration: A national survey. Am. J. Ind. Med. 2001, 39, 389–396. [Google Scholar] [CrossRef] [PubMed]

- Griffin, M.J.; Bovenzi, M.; Nelson, C.M. Dose-response patterns for vibration-induced white finger. Occup. Environ. Med. 2003, 60, 16–26. [Google Scholar] [CrossRef] [PubMed]

- Su, A.T.; Maeda, S.; Fukumoto, J.; Miyai, N.; Takemura, S.; Bulgiba, A.; Yoshimasu, K.; Miyashita, K. A Proposal on Neurological Dose–Response Relationship for Inclusion in ISO 5349-1 Documentation to be Used in Tropical Environment. Acoust. Aust. 2016, 44, 379–382. [Google Scholar] [CrossRef]

- International Organization for Standardization. Mechanical Vibration-Measurement and Evaluation of Human Exposure to Hand-Transmitted Vibration—Part 1: General Requirements; ISO 5349-1:2001; International Organization for Standardization: Geneva, Switzerland, 2001. [Google Scholar]

- International Organization for Standardization. Mechanical Vibration-Measurement and Evaluation of Human Exposure to Hand-Transmitted Vibration—Part 2: Practical Guidance for Measurement at the Workplace; ISO 5349-2:2001; International Organization for Standardization: Geneva, Switzerland, 2001. [Google Scholar]

- International Organization for Standardization. Human Response to Vibration-Measuring Instrumentation—Part 1: General Purpose Vibration Meters; ISO 8041-1:2017; International Organization for Standardization: Geneva, Switzerland, 2017. [Google Scholar]

- International Organization for Standardization. Mechanical Vibration–Vibrotactile Perception Thresholds for the Assessment of Nerve Dysfunction—Part 1: Methods of Measurement at the Fingertips; ISO 13091-1:2001; International Organization for Standardization: Geneva, Switzerland, 2001. [Google Scholar]

- International Organization for Standardization. Hand-Held Portable Power Tools-Test Methods for Evaluation of Vibration Emission—Part 5: Drills and Impact Drills; ISO 28927-5:2009; International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

- Maeda, S.; Griffin, M.J. Temporary threshold shifts in fingertip vibratory sensation from hand-transmitted vibration and repetitive shock. Occup. Environ. Med. 1993, 50, 360–367. [Google Scholar] [CrossRef]

- Aldien, Y.; Marcotte, P.; Rakheja, S.; Boileau, P.-E. Influence of hand-arm posture on biodynamic response of the human hand-arm exposed to zh-axis vibration. Int. J. Ind. Ergon. 2006, 36, 45–59. [Google Scholar] [CrossRef]

- Besa, A.J.; Valero, F.J.; Suner, J.L.; Carballeira, J. Characterisation of the mechanical impedance of the human hand-arm system: The influence of vibration direction, hand-arm posture and muscle tension. Int. J. Ind. Ergon. 2007, 37, 225–231. [Google Scholar] [CrossRef]

- Dong, R.G.; Dong, J.H.; Wu, J.Z.; Rakheja, S. Modelling of biodynamic responses distributed at the fingers and the palm of the human hand-arm system. J. Biomech. 2007, 40, 2335–2340. [Google Scholar] [CrossRef]

- Adewusi, S.; Rakheja, S.; Marcotte, P. Biomechanical models of the human hand-arm to stimulate distributed biodynamic responses for different postures. Int. J. Ind. Ergon. 2012, 42, 249–260. [Google Scholar] [CrossRef]

- Tarabini, M.; Saggin, B.; Scaccabarozzi, D.; Moschioni, G. Hand-arm mechanical impedance in presence of unknown vibration direction. Int. J. Ind. Ergon. 2013, 43, 52–61. [Google Scholar] [CrossRef]

- Radziukevich, T.M. Interrelationship between temporary and permeanent shifts in the threshold of vibration and pain sensitivity under the effect of local vibration. Ind. Health 1969, 13, 20–23. [Google Scholar]

- Malinskaya, N.N.; Filin, A.P.; Shkarinov, L.N. Problem of occupational hygiene in operating mechanised tools. Vestimik Akad. Meditsinkikh USSR 1969, 19, 31–36. [Google Scholar]

- Clemm, T.; Fæarden, K.; Ulvestad, B.; Lunde, L.-K.; Nordby, K.-C. Dose-response relationship between hand-arm vibration exposure and vibrotactile thresholds among roadworkers. Occup. Environ. Med. 2020, 77, 188–193. [Google Scholar] [CrossRef] [PubMed]

- Hartung, E.; Dupuis, H.; Scheffer, M. Effects of grip and push forces on the acute response of the hand-arm system under vibrating conditions. Int. Arch. Occup. Environ. Health 1993, 64, 463–467. [Google Scholar] [CrossRef] [PubMed]

- Löfgren, A.; Vihlborg, P.; Fornander, L.; Bryngelsson, I.-L.; Graff, P. Nerve function impairement after acute vibration exposure. J. Occup. Environ. Med. 2020, 62, 124–129. [Google Scholar] [CrossRef] [PubMed]

- Dong, R.G.; Xu, X.S.; Welcome, D.E.; McDowell, T.W. A Method for Analyzing the Effectiveness of Vibration-Reducing. Vibration 2021, 4, 16–29. [Google Scholar] [CrossRef]

| Participant | Posture 1 | Posture 2 | Posture 3 | |||

|---|---|---|---|---|---|---|

| Tool Vibration (ms) | TTS (dB) | Tool Vibration (ms) | TTS (dB) | Tool Vibration (ms) | TTS (dB) | |

| A | 5.3 | 20.00 | 3.7 | 15.00 | 3.7 | 22.50 |

| B | 5.5 | 22.50 | 3.1 | 15.00 | 3.1 | 25.00 |

| C | 5.3 | 25.00 | 2.0 | 17.50 | 2.0 | 20.00 |

| D | 5.2 | 22.50 | 4.5 | 20.00 | 4.5 | 17.50 |

| E | 5.7 | 20.00 | 4.4 | 20.00 | 4.4 | 25.00 |

| F | 4.9 | 20.00 | 3.6 | 20.00 | 3.6 | 27.50 |

| G | 5.5 | 17.50 | 3.0 | 12.50 | 3.0 | 20.00 |

| H | 5.1 | 17.50 | 3.6 | 15.00 | 3.6 | 20.00 |

| I | 5.3 | 20.80 | 4.0 | 20.00 | 4.0 | 20.00 |

| J | 5.5 | 22.50 | 2.8 | 22.50 | 2.8 | 25.00 |

| K | 5.4 | 21.70 | 3.7 | 15.00 | 3.7 | 22.50 |

| L | 5.3 | 15.00 | 2.8 | 17.50 | 2.8 | 17.50 |

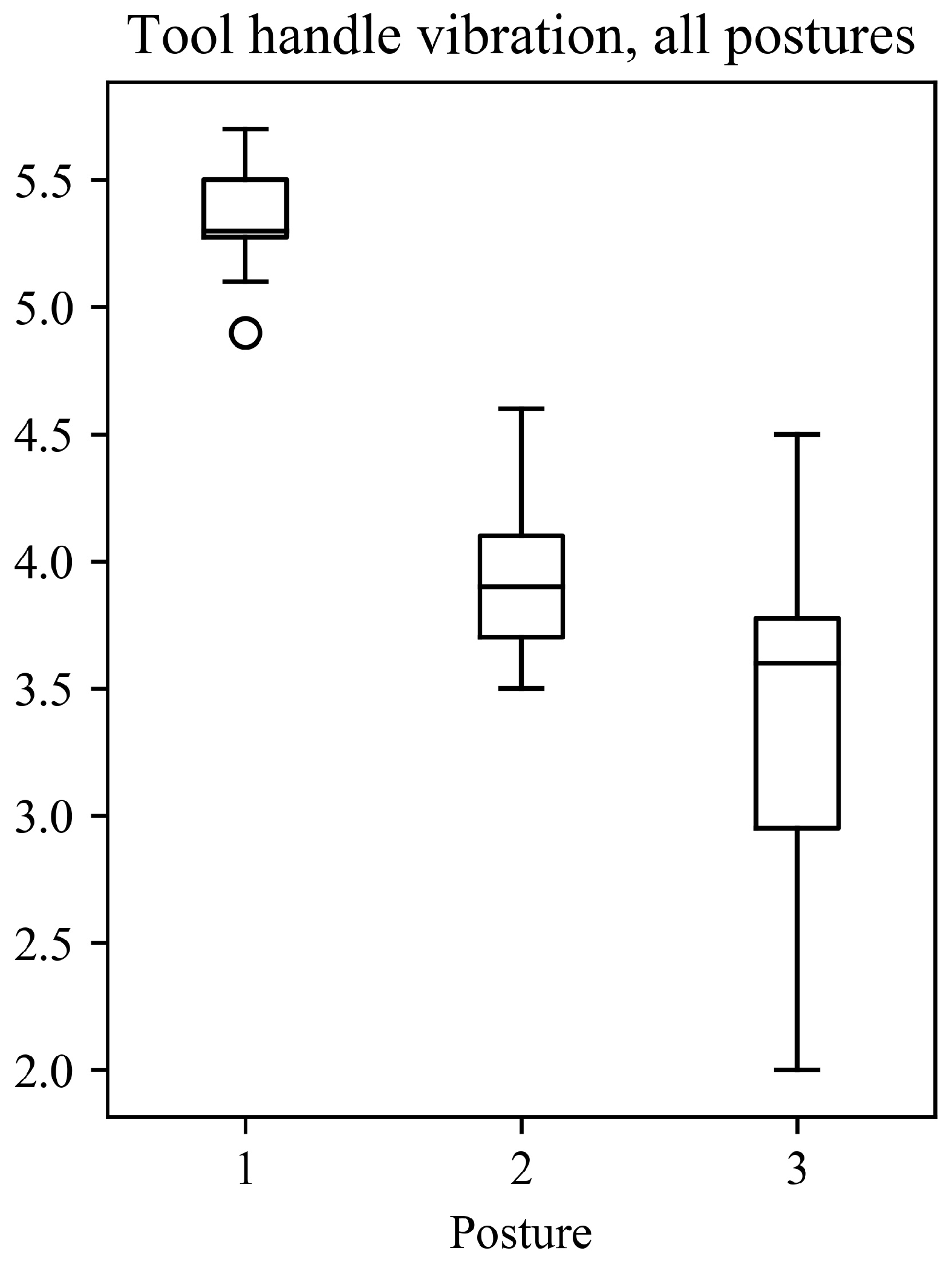

| Posture | n | Mean (ms) | S.D | C.V | S.E | 95% Conf. | Interval |

|---|---|---|---|---|---|---|---|

| Posture 1 | 12 | 5.33 | 0.21 | 3.94 | 0.06 | 5.19 | 5.46 |

| Posture 2 | 12 | 3.94 | 0.31 | 8.05 | 0.09 | 3.73 | 4.14 |

| Posture 3 | 12 | 3.43 | 0.72 | 21.05 | 0.20 | 2.97 | 3.89 |

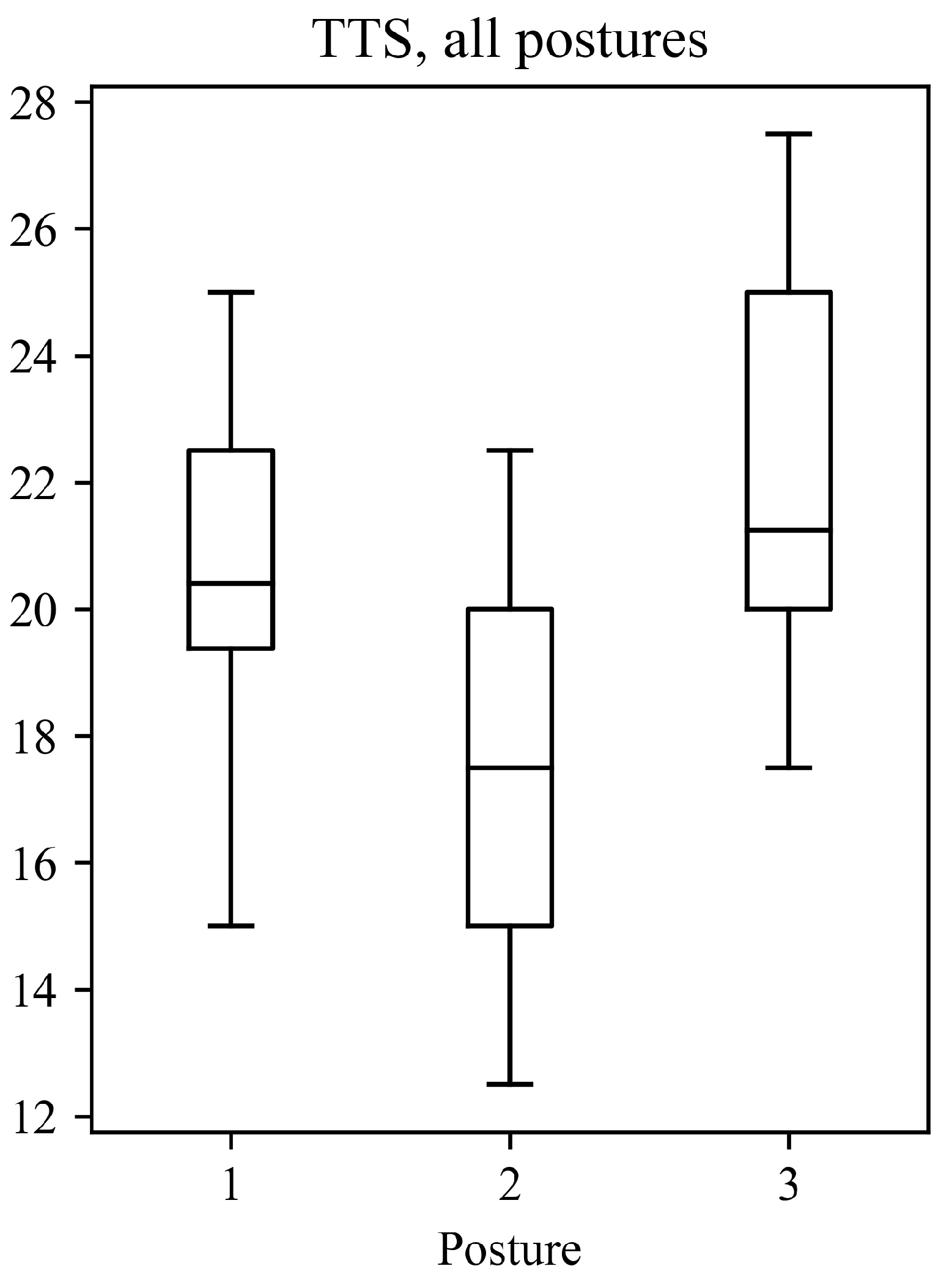

| Posture | n | Mean (dB) | S.D | C.V | S.E | 95% Conf. | Interval |

|---|---|---|---|---|---|---|---|

| Posture 1 | 12 | 20.41 | 2.74 | 13.42 | 0.79 | 18.67 | 22.15 |

| Posture 2 | 12 | 17.50 | 3.01 | 17.22 | 0.87 | 15.58 | 19.41 |

| Posture 3 | 12 | 21.87 | 3.22 | 14.72 | 0.92 | 19.82 | 23.92 |

| Group 1 | Group 2 | Mean Diff. (ms) | p-Value | Lower | Upper | Reject |

|---|---|---|---|---|---|---|

| Posture 1 | Posture 2 | −1.391 | 0.001 | −1.864 | −0.919 | True |

| Posture 1 | Posture 3 | −1.900 | 0.001 | −2.372 | −1.427 | True |

| Posture 2 | Posture 3 | −0.508 | 0.032 | −0.980 | −0.035 | True |

| Group 1 | Group 2 | Mean Diff. (dB) | p-Value | Lower | Upper | Reject |

|---|---|---|---|---|---|---|

| Posture 1 | Posture 2 | −2.916 | 0.058 | −5.920 | 0.086 | False |

| Posture 1 | Posture 3 | 1.458 | 0.468 | −1.545 | 4.461 | False |

| Posture 2 | Posture 3 | 4.375 | 0.003 | 1.371 | 7.378 | True |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taylor, M.; Maeda, S.; Miyashita, K. An Investigation of the Effects of Drill Operator Posture on Vibration Exposure and Temporary Threshold Shift of Vibrotactile Perception Threshold. Vibration 2021, 4, 395-405. https://doi.org/10.3390/vibration4020025

Taylor M, Maeda S, Miyashita K. An Investigation of the Effects of Drill Operator Posture on Vibration Exposure and Temporary Threshold Shift of Vibrotactile Perception Threshold. Vibration. 2021; 4(2):395-405. https://doi.org/10.3390/vibration4020025

Chicago/Turabian StyleTaylor, Mark, Setsuo Maeda, and Kazuhisa Miyashita. 2021. "An Investigation of the Effects of Drill Operator Posture on Vibration Exposure and Temporary Threshold Shift of Vibrotactile Perception Threshold" Vibration 4, no. 2: 395-405. https://doi.org/10.3390/vibration4020025

APA StyleTaylor, M., Maeda, S., & Miyashita, K. (2021). An Investigation of the Effects of Drill Operator Posture on Vibration Exposure and Temporary Threshold Shift of Vibrotactile Perception Threshold. Vibration, 4(2), 395-405. https://doi.org/10.3390/vibration4020025