Abstract

No-tillage farming can improve crop productivity and the reliability of cropping compared with conventional tillage. The effects of three different seeding system configurations on surface residue handling, sunflower emergence and stand establishment, yield, and gross income were investigated over three cropping seasons. The seeding system configurations comprised of (1) turbo coulter blade, (2) notched disc row cleaner before turbo coulter blade, and (3) no residue handling unit installed in front of a double-disc opener. For all three seeding system configurations, crop residue cover on sown rows (after seeding) was greater than the minimum recommended value of 30% for no-tillage. Residue cover was best with the notched disc row cleaner in front of the turbo coulter blade compared to the other two seeding systems. Furthermore, the notched disc row cleaner in front of the turbo coulter blade produced the highest plant emergence counts and the most uniform stand establishment. Sunflower yield and gross income were highest with the notched disc row cleaner in front of the turbo coulter blade (3.16 Mg·ha−1 and 902 USD·ha−1) compared to when only the turbo coulter blade (2.38 Mg·ha−1 and 680 USD·ha−1) or no residue handling unit (1.69 Mg·ha−1 and 482 USD·ha−1) was used.

1. Introduction

Planting is one of the most critical operations in crop production. Uniform emergence and rapid establishment are key factors underlying high crop productivity. Achieving uniform seeding depth and seed distribution over the desired planting depth is required for successful crop establishment [1]. Failure to optimize plant stand can result in economic penalties [2]. The type of seeding system and the settings will have a significant influence on the final result of the planting operation [3]. Seeding systems of no-tillage equipment are made up of components such as residue handling or management unit, furrow opener, seed and fertilizer delivery units, and seed covering and firming units [4,5,6].

Conservation tillage includes any tillage or seeding system that maintains at least 30% soil cover with crop residue after planting [7]. This includes noninversion tillage systems, such as chisel plowing and seeding without previously plowing, also called direct seeding or no-tillage [1]. No-tillage has been in used in Argentina since the late 1980s, facilitated by the introduction of genetically modified (GM) crops, the rapid development and adoption of no-tillage technology, and a combination of high price of diesel (which prompted farmers to reduce costs associated with energy use on farm, including tillage) and reduced cost of herbicides (which enabled effective weed control in GM crops) [8]. In central and western Argentina, sunflower (Helianthus annuus L.) is grown on medium- and light-textured soils (e.g., Entic Hapludolls). These soils extend over an area of approximately 1.27 M ha, and no-tillage cropping is the dominant mechanization system.

Traffic intensities in no-tillage systems are lower compared with conventional tillage systems [9,10]. Yield penalties in permanent no-tillage systems have been attributed to the effects of soil compaction caused by farm machinery traffic [10,11] and choice of suboptimal seeding system design or settings for given operating conditions [4,5,6]. For example, Klocke [12] reported unsatisfactory performance of planters as a result of residue accumulation between adjacent furrow openers. Some of the challenges faced by operators of no-tillage equipment include (after [1,13]) (1) poor seed–soil contact where crops are planted through surface residues, (2) planting on wet residue or on low-strength soil (which may result in residues being pushed into the soil instead of cut), (3) poor soil penetration in firm soil or too thick surface residue (without sufficient loose soil to cover the seed, or when firm soil does not allow press wheels to close off the slot around the seed), and (4) planting in wet, poorly drained clay soils where high water content causes soil to adhere to the soil-engaging components of the planter and wheeled implements may cause compaction (which may affect seedling emergence if the soil dries out before seed germination is completed). In order to improve the performance of no-tillage equipment, these challenges must be overcome. The inability of furrow openers to cut through the soil and maintain the correct seed placement (that is, at the desired planting depth and with uniform spacing between seeds) is also a significant contributing factor to reduced stand establishment and yield [14].

Surface residues will tend to slow down the rate of soil drying while lowering soil temperatures (compared with conventionally prepared seedbeds), which may compensate for poor seed–soil contact [1,15]. Slower evaporation will also delay the development of strengthened soil surface seals (particularly, in hard-setting, poorly structured, and low-organic-matter soils) that may affect seedling emergence [16]. Lower soil temperatures with a high level of crop residues on the soil surface can affect germination and lead to uneven emergence; this can make crop management difficult, particularly at later stages of development (e.g., for timing field operations for crop protection and fertilizer application). When soil temperatures remain suboptimal around planting time, farmers may resort to increasing seeding density to achieve the desire plant population [2,5]. Additionally, when there is nonuniform spatial distribution of residues over the soil surface, temperature variations across the field may be significant [13,17]. A study by Bragachini et al. [18] assessed the performance of toothed coulters in cutting a high-residue crop on sandy loam and clay loam soils, and compared it with notched and smooth coulters. Their study showed that depth uniformity was significantly improved with toothed compared with smooth and notched coulters. Toothed coulters were more efficient at cutting through thick crop residue, with less torque and lower vertical and draught forces required.

The need for seeding sunflower directly into the soil at an early planting date (when the amount of residue from the previous crop may still be large while ensuring plant population is adequate for a high-yielding crop) has prompted the use of row cleaners in no-tillage seeding systems. The use of row cleaners also responds to the need to reduce the amount of crop residue along the seeding line, which then enhances seedling emergence, stand establishment, and consequently yield [19,20]. Undocumented evidence from field observations (both by the authors of this article and by local agronomists, farm advisers, and machinery contractors) suggested that underperformance of crops in no-tillage systems may be explained by problems relating to the design or settings of planting equipment, with these being inadequate for the specific operating conditions (e.g., amount of surface residue, soil moisture content, soil strength, forward speed, and downward pressure) under which the equipment is used. However, underperformance of crops and occasionally crop failure are rarely attributed to lack of optimization of the planter’s settings (or its components) for given operating conditions; yet this is a critical practical consideration for maximizing crop yield potential [21,22,23]. Instead, reasons explaining crop underperformance or even failure (e.g., poor crop establishment leading to farmers’ decisions to prematurely terminate a crop and replant) are often sought in agronomic-related constraints (e.g., seed germinating power, inadequate soil moisture, low soil temperature). Therefore, the objective of the work reported in this article was to assess the effects of different configurations of seeding units (namely, turbo coulter blade and notched disc row cleaner attachments to a no-tillage planter with double-disc seeding system, all of which are commonly used in no-tillage planting equipment in Argentina) on sunflower seedling emergence and yield, and to determine the associated impact on the crop profit margin.

2. Materials and Methods

2.1. Experimental Site

The study was conducted on a commercial farm (35°58′53.63′′ S and 62°35′12.64′′ W, elevation: 27 m above sea level) located near Trenque Lauquen (Provincia de Buenos Aires, Argentina) on a soil classified as Entic Hapludoll [24]. The site is well drained with moderate permeability. Surface runoff was regarded as negligible given that average slopes were less than 1.2%. The soil did not have stones (Class 0), and the soil organic matter content [25] ranged from 12.3 g·kg−1 in the top 150 mm of the profile to 5.2 g·kg−1 at a depth of 650 mm. The crop rotation over the 10-year period prior to the experiment was wheat (Triticum aestivum L.) followed by soybean (Glycine max L., Merrill), short winter fallow, and then sunflower.

Ten-day aggregation of rainfall data and mean maximum air temperatures within the periods between 1 October 2012, 2013, and 2014 and 31 March 2013, 2014, and 2015, respectively, are shown in Table 1. The average maximum air temperature was moderate during the months of October, November, December, February, and March, but exceeded 32 °C in January, which could have induced temporary thermal or water stresses at this time of the cropping cycle [26]. Rainfall in October was suitable for sunflower emergence and establishment, but appreciable rain often occurred before harvest (typically during the last 2 weeks of March, all years), which resulted in soil water content being near or slightly above the drained upper limit at this time of the year. The effect of temperature on sunflower growth and development is well documented (e.g., [27,28,29]). It is also known that, during the vegetative phase, the rates of leaf formation and expansion, as well as the number of days between emergence and the reproductive phase, are controlled by temperature, whereas the photoperiod influences the time between sprouting and flowering [30]. Given that key environmental conditions (rainfall, temperature) influencing growth and development of sunflower during the main part of the season were similar across all years, and that management × genotype (DK4065 by Syngenta, Basel, Switzerland, https://www.syngenta.com.ar/dk4065) (accessed on 1 December 2021) was also identical, it is fair to consider that any difference in agronomic performance between treatments could be explained by the configurations of the seeding system used to establish the crop.

Table 1.

Ten-day aggregation of rainfall and temperature data recorded for Trenque Lauquen (Provincia de Buenos Aires, Argentina) for the sunflower growing seasons of 2012–2013, 2013–2014, and 2014–2015 (after INTA [31]).

2.2. Soil Description and Soil Measurements

A description of the soil profile examined at the experimental site is shown in Table 2. Soil water content (%, w/w) [32], dry soil bulk density [33], and soil cone index (CI) [34] were measured each year at the time of seeding at random locations within the experimental plots. Soil bulk density was measured at 50 mm depth increments to a depth of 450 mm using 50 mm diameter by 50 mm long cores (n = 10). After being collected, soil cores were weighed, placed in an oven at 105 °C for 72 h, and reweighed for determination of gravimetric soil water content. Soil CI was determined with a SC-900 FieldScout™ digital cone penetrometer (Spectrum Technologies Inc., Aurora, IL, USA, https://www.specmeters.com/) (accessed on 30 November 2021). Measurements (n = 20) were taken to a depth of 450 mm at increments of 25 mm from sampling locations near those used for determination of soil bulk density and soil water content. Soil water content was then used as a covariate of soil penetration resistance to account for its effect on soil strength [34,35]. For all measurements, the number of replications ensured that the spatial variability within the experimental plots could be captured [36]. Immediately before seeding, plant residue cover on the soil surface was quantified as per Gargicevich [37], and reported an average of 97.3% (SD: 5.2%). The maximum dry density and the corresponding soil water content were obtained from the Standard Proctor test [38]. The Proctor test was conducted for the bulked 0–450 mm depth interval, and the value reported is the mean of three observations (n = 3). The Proctor density was then used as a reference for comparison with field measurements of soil bulk density, as a means to determine the degree of soil compaction encountered at the site at the time the experiments were conducted.

Table 2.

Soil profile characterization for the Entic Hapludoll at the study site (N/A: data not available). Values are means ± SD.

2.3. Description of Farm Equipment

A 120 CV/88 kW engine tractor with front-wheel assist (FWA) weighing 98 kN (40 kN and 58 kN on the front and rear axles, respectively) was operated at a travel speed of 5.5 km·h−1. New 16.9R28 and 20.1R30 single tires were inflated to 100 kPa (front) and 80 kPa (rear), both within the range advised by the Firestone Agricultural Tire Handbook [40] for load and speed. Tire ground pressures were 52 kPa and 35.5 kPa for the front and rear tires, respectively, which were measured using a Tekscan® 5330 pressure mapping sensor (https://www.tekscan.com/products-solutions/pressure-mapping-sensors/5330) (accessed on 15 November 2021). The planter was a Super-Walter (SW650, https://superwalter.com.ar/) (accessed on 28 November 2021) with specifications as shown in Table 3. Both tractor and planter models are commonly used on commercial farms in the study area.

Table 3.

Specification of the equipment used in the study.

2.4. Experimental Treatments and Crop Measurements

Twelve 100 m by 7 m plots (which accommodated 10 rows at 700 mm row spacing) were randomly assigned to three treatments with four replications each (n = 4). The treatments were three combinations of a turbo coulter blade (Tc), notched disc row cleaner (Rc), and double-disc opener (DDO); i.e., Treatment 1 (T1): Tc + DDO, Treatment 2 (T2): Rc + Tc + DDO, and Treatment 3 (T3): no Tc + DDO. These combinations are commonly used by local growers, but their relative performance does not appear to have been quantified or documented in the scientific literature. Details of the coulter blade, row cleaner, and double-disc opener are shown in Table 4.

Table 4.

Characteristics of the turbo coulter blade, row cleaner, and double-disc opener used in the study.

Sunflower was planted on 14 October 2012 in the first study year, on 15 October 2013 in the second year, and on 14 October 2014 in the third year. The planting density used at the site was five plants per square meter, and the seeding depth was 30 mm, consistent with standard agronomic practice in the region [41]. The sowing rate was checked as per Nardón [42]. The planter had an inter-row spacing of 700 mm (Table 3), with individual pressure and depth control wheels for each one of the furrow openers. The sunflower crops were harvested on 28 March 2013, 10 March 2014, and 9 March 2015 for all treatments, and yield was determined as per Tolón-Becerra et al. [43]. Edge effects were avoided by discarding agronomic data 10 m either end of the plots, and the side rows in each plot were discarded. The number of emerged plants per linear meter were counted and recorded for all rows in each plot at 11, 14, and 18 days after seeding.

2.5. Statistical Analyses

The statistical package GenStat Release® 19th Edition [44] was used to analyze cone index, soil bulk density, soil water content, residue cover, plant count, and yield data, and involved analysis of variance (ANOVA) using a 5% probability level (α = 0.05). Means were separated by Duncan’s multiple range test [45] using the same package, and they are reported as ± standard deviation.

3. Results and Discussion

3.1. Soil Characterization

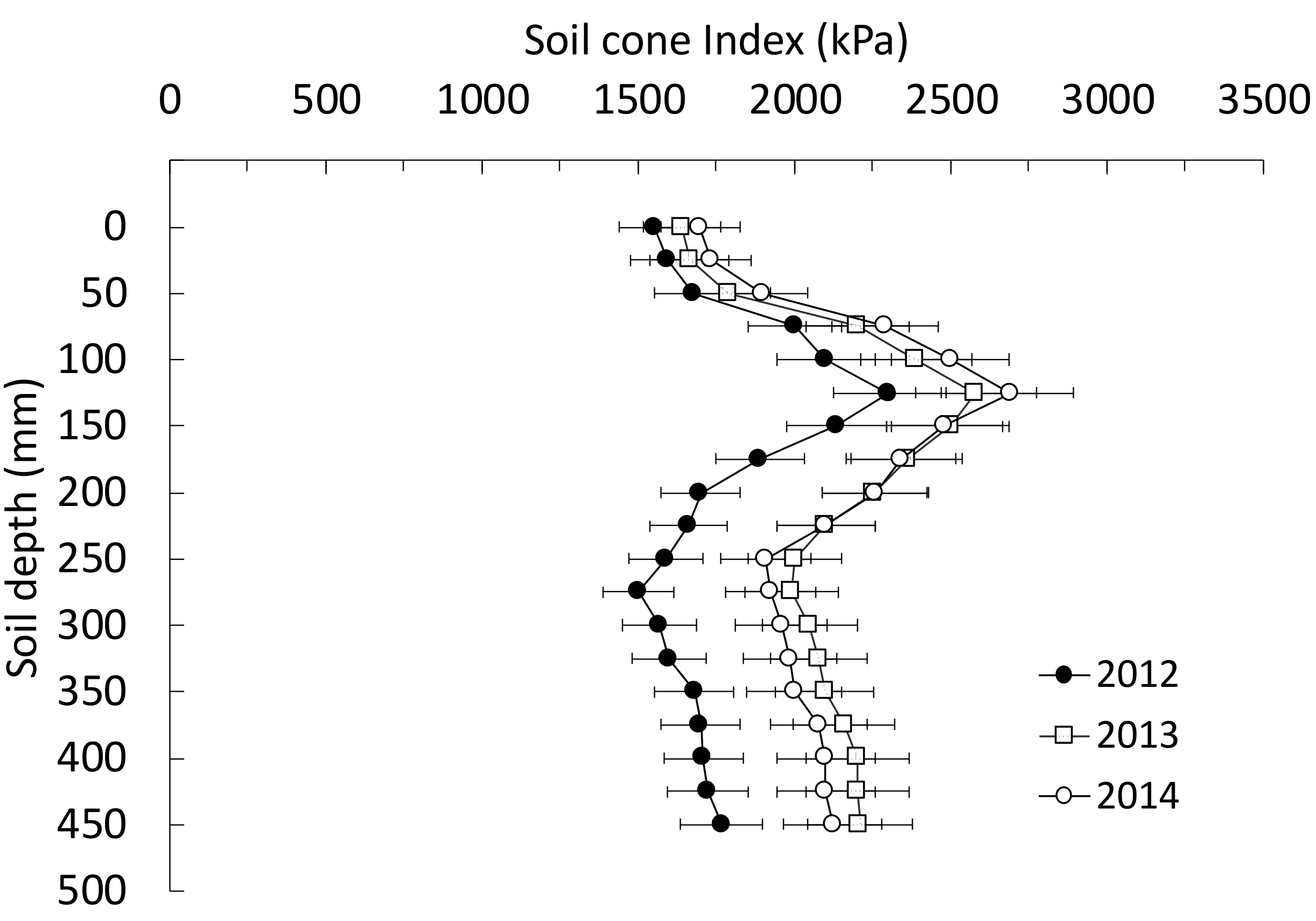

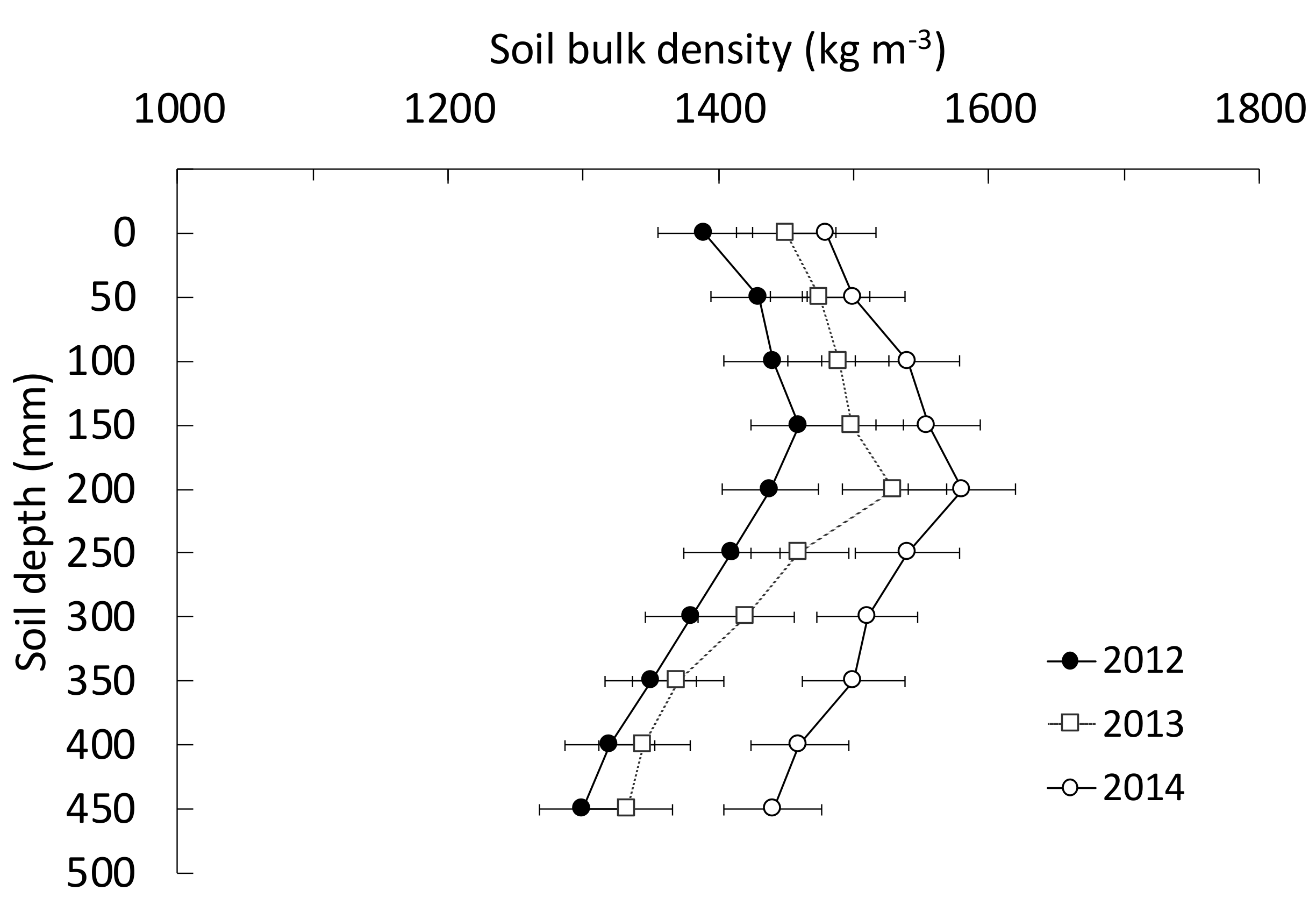

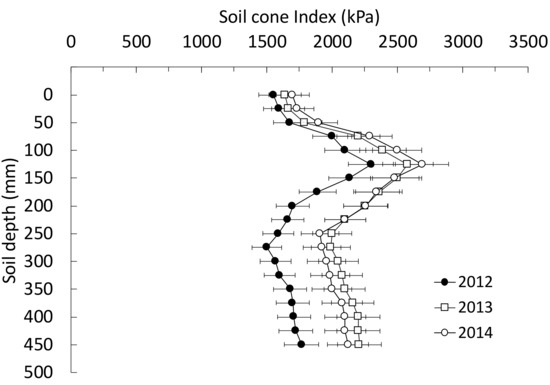

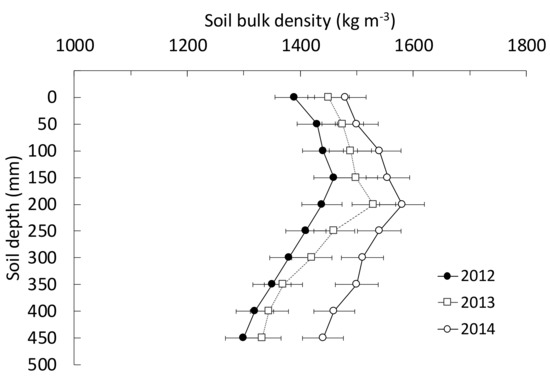

Soil water contents, as recorded on the seeding day and averaged across all three cropping seasons, were 17.80% ± 1.56% (w/w) at 0–150 mm, 18.5% ± 2.13% (w/w) at 150–300 mm, and 19.0% ± 2.54% (w/w) at 300–450 mm. There were no significant differences (p > 0.05) in soil water content between treatments at plant emergence; therefore, differences in plant emergence were explained by treatment effects. Figure 1 and Figure 2 show soil cone index (adjusted for covariate) and soil bulk density data, respectively. The soil exhibited a densified, strengthened layer between about 75 and 150 mm depth, but no significant differences were observed in bulk density or cone index between years (p > 0.05). Therefore, these observations revealed that treatment differences in crop agronomic performance were not due to differences in soil mechanical properties. However, it was noted that soil bulk density values recorded at the site were between 88% and 96% of the Proctor density, which yielded a value of 1567 ± 101 kg·m−3 at a soil water content of 21.97% ± 1.23% (w/w). According to textural composition (loam), growth-limiting bulk densities for this soil are between 1600 and 1650 kg·m−3 [46], suggesting that bulk densities found at the site were below critical values for this soil type. However, some restriction to root elongation may be encountered by sunflower plants as the soil dries out (that is, soil water contents below 50% of plant available water capacity) due to increased soil strength [47,48], particularly at the 75–150 mm depth interval. This response will be more significant in drier compared with wetter years [49,50], because of the effect of soil water on soil strength [51,52].

Figure 1.

Soil cone index (adjusted for covariate) recorded at the site on seeding days in 2012, 2013, and 2014, respectively. Error bars on mean datapoints (n = 20) denote standard deviation; p < 0.05 (depth) and p > 0.05 (years).

Figure 2.

Soil bulk density recoded at the site on seeding days in 2012, 2013, and 2014. Error bars on mean datapoints (n = 10) denote standard deviation; p < 0.05 (depth) and p > 0.05 (years).

3.2. Residue Cover

Table 5 shows the amount of residue cover before and after planting for each treatment (T1, T2, and T3). Compared to the condition before planting, residue cover after planting was reduced significantly for all treatments (p < 0.05). However, the amount of residue on the surface after planting was higher than 30% cover for all treatments, with this value being the minimum amount of residue cover recommended for no-tillage systems [5,53,54]. A survey of planting practices in the study area revealed that excessive crop residue cover (e.g., >50%) is a significant management challenge in no-tillage systems, especially when heavy planters with runner-type furrow openers are used [55]. In sunflower cultivation, clearing surface residues helps reduce allelopathy [56] caused by seeding over rows from the previous year’s crop while also improving soil warming [57]. Thus, for a compromise between the benefits and disadvantages of crop residue retention on the soil surface, treatment T2 performed significantly better than T1 and T3. Consequently, inclusion of row cleaners in the turbo disc coulter will improve the residue handling ability of the planter.

Table 5.

Surface residue cover recorded before and after planting left by the assembly used for seeding (3-year averages ± SD). Different letters indicate that mean values are significantly different at a 95% confidence interval. Treatments were Tc + DDO (T1), Rc + Tc + DDO (T2), and no Tc + DDO (T3), where Tc is turbo coulter blade, Rc is row cleaner, and DDO is double-disc opener.

3.3. Seedling Emergence

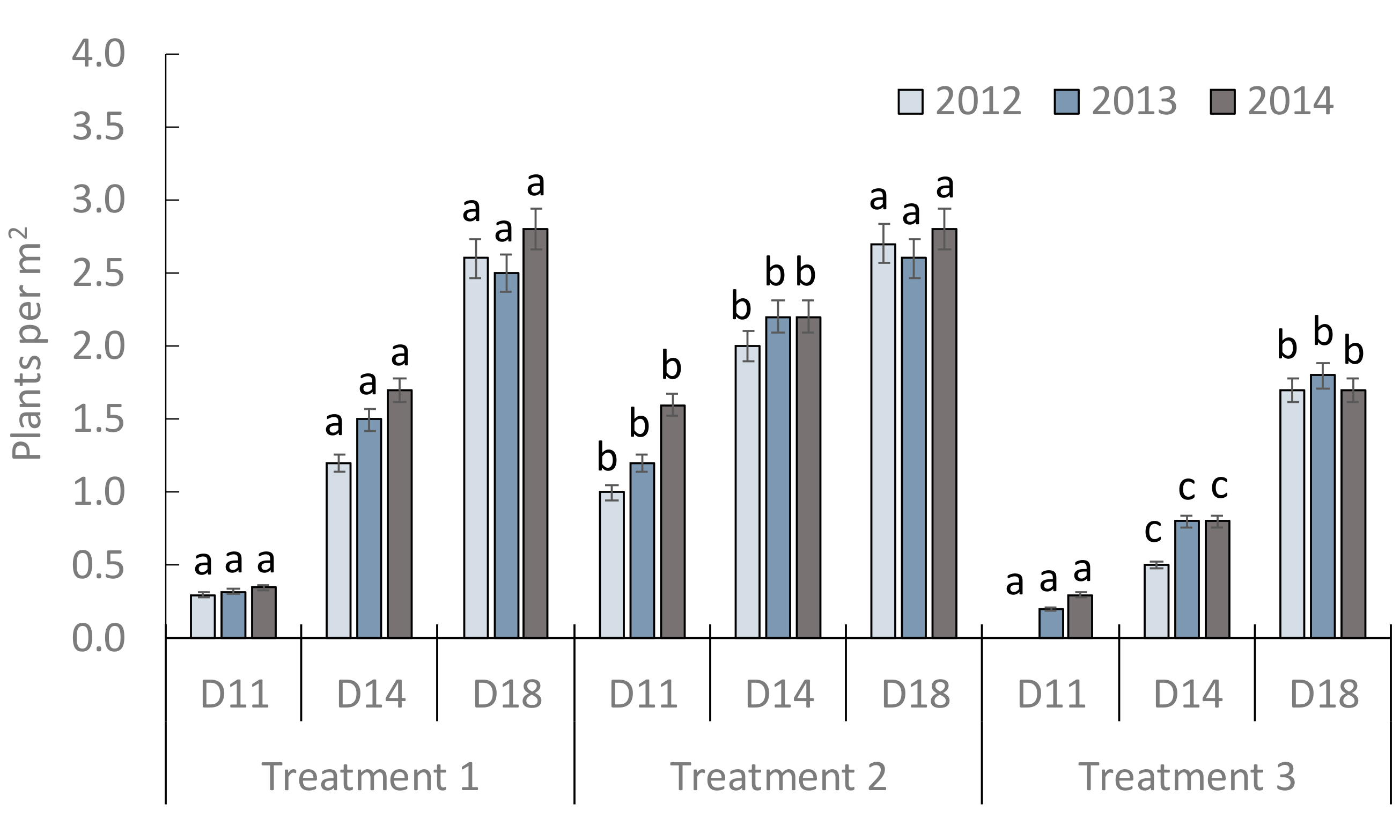

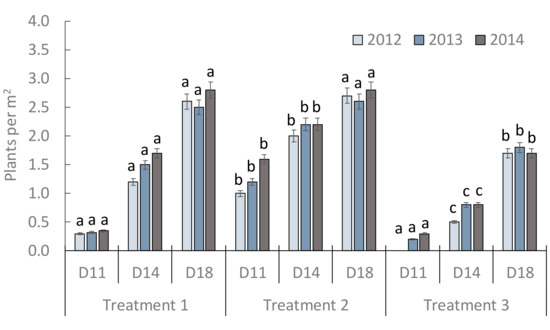

Results of seedling emergence as affected by treatments are shown in Figure 3. In agreement with findings by Tourn et al. [13], residue clearance by the row cleaner prior to the action of the turbo blade with T2 significantly improved plant counts in all three growing seasons. Although similar (absolute) plant counts for T1 and T2 were observed over the three seasons, stand establishment was relatively more uniform for T2. This effect was of particular relevance in assessing the different treatments because lack of uniformity in crop stand can result in subordinate plants with reduced number of grains per plant [58]. Whilst dominant sunflower plants may have some capacity to compensate for the small reduction in the grain number exhibited by subordinate plants, the net effect will be loss of crop yield [59]. Results presented in Figure 3 suggest that the turbo blade was efficient in cutting and was also good at penetrating and loosening the soil while being able to bury a small amount of plant residue assisted by the row cleaner. The turbo blade cut the soil and disturbed about 80–100 mm deep and 35 mm wide. The furrow was then shaped by the double-disc opener guided by the side wheel for seed placement. Moreover, a slight displacement of soil contributed to the action of the covering or packing wheels, which improved the coverage of seeds placed in the soil and seed–soil contact.

Figure 3.

Plant count per square meter on days (D) 11, 14, and 18 after seeding for three treatments (T1, T2, and T3) in three growing seasons (2012, 2013, and 2014). Error bars on mean values denote the standard deviation. Different letters (between treatments and within the same year) indicate that mean values are significantly different at a 95% confidence interval. Treatments were Tc + DDO (T1), Rc + Tc + DDO (T2), and no Tc + DDO (T3), where Tc is turbo coulter blade, Rc is row cleaner, and DDO is double-disc opener.

3.4. Yield

Sunflower yield and gross income recorded for the three treatments over the three growing seasons are shown in Table 6. Treatment T2, following its superior performance in residue handling and seedling emergence, produced significantly higher yield relative to T1 and T3 across all three growing seasons. Average sunflower yield for T2 was about 33% and 87% greater than T1 and T3, respectively. In T3, it was observed that furrow openers could not efficiently cut into soil, possibly due to soil being firm after several years of no-tillage (Figure 1 and Figure 2), as shown by Botta et al. [2,60] for similar soils in the region. Poor soil penetration of the units used in T3 adversely affected the accuracy and uniformity of seed placement, both at depth and along the planting line [5,61], which impacted sunflower yield. It appeared that the units used in T1 and T2 performed better than T3 in firm soil. Estimates of crop gross incomes (using a 3-year average sunflower price of 285.5 USD·Mg−1 as perceived by the grower) were consistent with yield data. Treatment T2 returned the highest gross income across all seasons followed by T1 and T3, respectively (Table 6).

Table 6.

Sunflower yield and gross income (price of crop × crop yield) for the three treatments in the three growing seasons. The price of the crop was taken to be 285.5 USD·Mg−1, which equated to the 3-year average (2012–2014) perceived by the grower. Different letters (between treatments and within the same year) indicate that mean values are significantly different at a 95% confidence interval. Treatments were Tc + DDO (T1), Rc + Tc + DDO (T2), and no Tc + DDO (T3), where Tc is turbo coulter blade, Rc is row cleaner, and DDO is double-disc opener.

4. Conclusions

Three different configurations of seeding systems were evaluated for their effect on soil surface residue cover, plant count at emergence, and sunflower yield and gross income over three growing seasons. The seeding systems consisted of (1) turbo coulter blade, (2) notched disc row cleaner before turbo coulter blade, and (3) no residue handling unit installed in front of a double-disc opener. For all three seeding systems, on-row crop residue cover after seeding was greater than the 30% minimum recommended residue cover for no-tillage. The use of the notched disc row cleaner in front of the turbo coulter blade resulted in the best residue cover (47.2%). This, in turn, consistently led to the highest plant emergence counts and the most uniform stand establishment in all crop seasons. Consequently, average yield (3.16 Mg·ha−1) and gross income (903 USD·ha−1) were highest when the notched disc row cleaner in front of the turbo coulter blade was used compared to when only the turbo coulter blade (2.38 Mg·ha−1 and 680 USD·ha−1) and no residue handling unit in front of the double-disc opener (1.69 Mg·ha−1 and 483 USD·ha−1) were used. Sunflower growers operating in long-term no-tillage systems (with high surface residue and relatively firm soil conditions) may wish to consider the use of notched disc row cleaners combined with turbo coulter blades, as this option improved crop establishment and agronomic performance.

Author Contributions

Conceptualization, G.F.B., G.F.N. and D.R.; methodology, G.F.N., G.F.B. and D.R.; formal analysis, G.F.N., D.L.A. and F.B.; investigation, G.F.B., F.B. and D.R.; resources, D.R.; data curation, D.L.A., K.A.A. and F.B.; writing—original draft preparation, G.F.B., K.A.A. and D.L.A.; writing—review and editing, D.L.A., K.A.A. and G.F.B.; project administration and funding acquisition, G.F.B. All authors have read and agreed to the published version of the manuscript.

Funding

The work reported in this article was supported by grants provided by Departamento de Tecnología at Universidad Nacional del Luján (Luján, Argentina, http://www.unlu.edu.ar/) through Project ID: T088-UNLu, and Facultad de Agronomía at Universidad Nacional de La Pampa (Santa Rosa, Argentina, https://www.unlpam.edu.ar/) through Project ID: I-153/19-FA.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data reported in this article are available from Guido F. Botta (gfbotta@agro.uba.ar) and Diogenes L. Antille (Dio.Antille@csiro.au).

Acknowledgments

Operational support provided by the owners of the farm where this study was conducted is gratefully acknowledged. We also thank the contractors for facilitating the use of farm equipment and enabling our experiments to be conducted, and Jeff Tullberg (Center for Agricultural Engineering at the University of Southern Queensland, Australia) for revising the drafts. Comments and suggestions by the Editor and Reviewers of this journal are appreciated.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Godwin, R.J. Agricultural Engineering in Development: Tillage for Crop Production in Areas of Low Rainfall. In FAO Agricultural Services Bulletin No.: 83; Food and Agricultural Organization of the United Nations: Rome, Italy, 1990; p. 124. ISBN 92-5-102542-8. [Google Scholar]

- Botta, G.F.; Becerra, A.T.; Melcon, F.B. Seedbed compaction produced by traffic on four tillage regimes in the rolling Pampas of Argentina. Soil Tillage Res. 2009, 105, 128–134. [Google Scholar] [CrossRef]

- Lekavičienė, K.; Šarauskis, E.; Naujokienė, V.; Kriaučiūnienė, Z. Effect of Row Cleaner Operational Settings on Crop Residue Translocation in Strip-Tillage. Agronomy 2019, 9, 247. [Google Scholar] [CrossRef] [Green Version]

- Aikins, K.A.; Barr, J.B.; Ucgul, M.; Jensen, T.A.; Antille, D.L.; Desbiolles, J.M.A. No-tillage furrow opener performance: A review of tool geometry, settings and interactions with soil and crop residue. Soil Res. 2020, 58, 603. [Google Scholar] [CrossRef]

- Aikins, K.A.; Antille, D.L.; Jensen, T.A.; Blackwell, J. Performance comparison of residue management units of no-tillage sowing systems: A review. Eng. Agric. Environ. Food 2019, 12, 181–190. [Google Scholar] [CrossRef]

- Ashworth, M.; Desbiolles, J.M.A.; Tola, E. Disc Seeding in Zero-Till Farming Systems: A Review of Technology and Paddock Issues; Western Australian No-Tillage Farmers Association: Northam, WA, Australia, 2010; p. 224. ISBN 9780646528762. [Google Scholar]

- ASAE. ASAE Standard EP291.2: Terminology and Definitions for Soils Tillage and Soil Tool Relationships Engineering Practice; American Society of Agricultural Engineering: St. Joseph, MI, USA, 1992; pp. 106–108. [Google Scholar]

- Botta, G.F.; Jorajuria, D.; Rosatto, H.; Ferrero, C. Light tractor traffic frequency on soil compaction in the Rolling Pampa region of Argentina. Soil Tillage Res. 2006, 86, 9–14. [Google Scholar] [CrossRef]

- Bluett, C.; Tullberg, J.N.; McPhee, J.E.; Antille, D.L. Soil and Tillage Research: Why still focus on soil compaction? Soil Tillage Res. 2019, 194, 104282. [Google Scholar] [CrossRef]

- Botta, G.F.; Antille, D.L.; Nardon, G.F.; Rivero, D.; Bienvenido, F.; Contessotto, E.E.; Ezquerra-Canalejo, A.; Ressia, J.M. Zero and controlled traffic improved soil physical conditions and soybean yield under no-tillage. Soil Tillage Res. 2021, 215, 105235. [Google Scholar] [CrossRef]

- Botta, G.F.; Rivero, D.; Tourn, M.; Melcon, F.; Pozzolo, O.; Nardon, G.; Balbuena, R.; Becerra, A.; Rosatto, H.; Stadler, S. Soil compaction produced by tractor with radial and cross-ply tyres in two tillage regimes. Soil Tillage Res. 2008, 101, 44–51. [Google Scholar] [CrossRef]

- Klocke, N.L. No-Till Drill for Fall Seeding Small Grains; ASAE Paper No.: 79-1023; American Society of Agricultural Engineers: St. Joseph, MI, USA, 1979. [Google Scholar]

- Tourn, M.; Soza, E.; Botta, G.; Mete, A. Direct corn seedling. Effects of residue clearance on implant efficiency. Span. J. Agric. Res. 2003, 1, 99. [Google Scholar] [CrossRef] [Green Version]

- Raoufat, M.; Mahmoodieh, R. Stand establishment response of maize to seedbed residue, seed drill counters and primary tillage systems. Biosyst. Eng. 2005, 90, 261–269. [Google Scholar] [CrossRef]

- Papendick, R.I.; Lindstrom, M.J.; Cochran, V.L. Soil Mulch Effects on Seedbed Temperature and Water During Fallow in Eastern Washington. Soil Sci. Soc. Am. Proc. 1973, 37, 307–314. [Google Scholar] [CrossRef]

- Abrecht, D.G.; Bristow, K.L. Maize seedling response to the soil environment at varying distances from a mulched soil-bare soil boundary. Soil Tillage Res. 1990, 15, 205–216. [Google Scholar] [CrossRef]

- Erbach, D.C.; Kaspar, T.C. Reducing Stand Establishment Risk in Conservation Tillage; ASAE Paper No.: 931559; American Society of Agricultural Engineers: St. Joseph, MI, USA, 1993. [Google Scholar]

- Bragachini, M.; Bianchini, M.; Magalhães, P.S.G.; von Martin, A.; Ruiz, S. Ensayo comparativo de diferentes trenes de siembra. In Proyecto Agricultura de Precisión; Manfredi INTA: Córdoba, Argentina, 2000; p. 8. [Google Scholar]

- Morrison, J.E.; Allen, J.R.R.; Wilkins, D.E.; Powell, G.M.; Grisso, R.D.; Erbach, D.C.; Herndon, L.P.; Murray, D.L.; Formanek, G.E.; Pfost, D.L.; et al. Conservation Planter, Drill and Air-Type Seeder Selection Guideline. Appl. Eng. Agric. 1988, 4, 300–309. [Google Scholar] [CrossRef]

- Kaspar, T.C.; Erbach, D.C.; Cruse, R.M. Corn Response to Seed-Row Residue Removal. Soil Sci. Soc. Am. J. 1990, 54, 1112–1117. [Google Scholar] [CrossRef]

- Poncet, A.M.; Fulton, J.P.; McDonald, T.P.; Knappenberger, T.; Shaw, J.N.; Bridges, R.W. Effect of Heterogeneous Field Conditions on Corn Seeding Depth Accuracy and Uniformity. Appl. Eng. Agric. 2018, 34, 819–830. [Google Scholar] [CrossRef]

- Murray, J.R.; Tullberg, J.N.; Antille, D.L. Selecting and Managing No-Till Planters and Controlled Traffic Farming in Extensive Grain Production Systems. In No-till Farming Systems for Sustainable Agriculture; Springer: Cham, Switzerland, 2020; pp. 83–105. [Google Scholar] [CrossRef]

- Aikins, K.A.; Antille, D.L.; Ucgul, M.; Barr, J.B.; Jensen, T.A.; Desbiolles, J.M. Analysis of effects of operating speed and depth on bentleg opener performance in cohesive soil using the discrete element method. Comput. Electron. Agric. 2021, 187, 106236. [Google Scholar] [CrossRef]

- Heredia, O.S.; Mengoni, H.; Márquez, J.J.; Sainato, C. Caracterización de Suelos Bajo Feedlot y su Evaluación Para la Protección de Agua Subterránea. In Avances en Ingeniería Rural 2007–2009, 1st ed.; Di Leo, N., Montico, S., Nardón, G., Eds.; Universidad Nacional de Rosario: Rosario, Argentina, 2009; pp. 552–557. ISBN 978-950-673-752-8. [Google Scholar]

- Walkley, A.; Black, I.A. An examination of the Degtjareff method for determining soil organic matter, and a proposed modification of the chromic acid titration method. Soil Sci. 1934, 37, 29–38. [Google Scholar] [CrossRef]

- Villalobos, F.; Ritchie, J. The effect of temperature on leaf emergence rates of sunflower genotypes. Field Crop. Res. 1992, 29, 37–46. [Google Scholar] [CrossRef]

- Marc, J.; Palmer, J.H. Determination of the Length of the Vegetative and Pre-floral Stages in the Day-Neutral PlantHelianthus annuusby Chilling Pulses. J. Exp. Bot. 1978, 29, 367–373. [Google Scholar] [CrossRef]

- Marc, J.; Palmer, J. Photoperiodic sensitivity of inflorescence initiation and development in sunflower. Field Crop. Res. 1981, 4, 155–164. [Google Scholar] [CrossRef]

- Sadras, V.O.; Ferreiro, M.; Gutheim, F.; Kantolic, A.G. Desarrollo fenológico y su respuesta a temperatura y fotoperíodo. In Bases para el Manejo del Maíz, el Girasol y la Soja. Ediciones Instituto Nacional de Tecnología Agropecuaria; Andrade, F.H., Sadras, V.O., Eds.; INTA: Balcarce, Argentina, 2009; ISBN 987-521-047-1. [Google Scholar]

- Villalobos, F.J.; Hall, A.J.; Ritchie, J.T.; Orgaz, F. OILCROP-SUN: A Development, Growth, and Yield Model of the Sunflower Crop. Agron. J. 1996, 88, 403–415. [Google Scholar] [CrossRef]

- INTA. Carta de suelos de la Provincia de Buenos Aires. Buenos Aires, Instituto Nacional de Tecnología Agropecuaria, Argentina. 2015. Available online: https://inta.gob.ar/documentos/carta-desuelos-de-la-provincia-de-buenos-aires (accessed on 25 November 2021).

- MAFF. The Analysis of Agricultural Materials, 3rd ed.; Reference Book 427; Ministry of Agriculture, Fisheries, and Food: London, UK, 1986. [Google Scholar]

- Erbach, D.C. Measurement of Soil Bulk Density and Moisture. Trans. ASAE 1987, 30, 0922–0931. [Google Scholar] [CrossRef]

- ASABE. ASAE Standard EP542.1-NOV2019: Procedures for Using and Reporting Data Obtained with the Soil Cone Penetrometer; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2019; p. 6. [Google Scholar]

- Ayers, P.D.; Perumpral, J.V. Moisture and Density Effect on Cone Index. Trans. ASAE 1982, 25, 1169–1172. [Google Scholar] [CrossRef]

- Cassel, D.K. Tillage effects on soil bulk density and mechanical impedance. In Predicting Tillage Effects on Soil Physical Properties and Processes; Unger, P.W., Van Doren, D.M., Jr., Whisler, F.D., Skidmore, E.L., Eds.; ASA-SSSA Inc.: Madison, WI, USA, 1982; Chapter 4; Volume 44, pp. 45–67. [Google Scholar] [CrossRef]

- Gargicevich, A. Sembradoras de siembra directa y su efecto sobre la cobertura. In Proyecto Agricultura Conservacionista II. Serie Experiencias; Instituto Nacional de Tecnología Agropecuaria: Oliveros, Argentina, 1995; p. 4. [Google Scholar]

- Ray, P.N.; Chapman, T.G. The British Standard Compaction Test for Soils: A Study of Some Factors Affecting the Test Results. Geotechnique 1954, 4, 169–177. [Google Scholar] [CrossRef]

- Bouyoucos, G.J. Hydrometer Method Improved for Making Particle Size Analyses of Soils 1. Agron. J. 1962, 54, 464–465. [Google Scholar] [CrossRef]

- Firestone. Data Book Version 2; Firestone, A.G: Akron, OH, USA, 2018; p. 275. Available online: https://commercial.firestone.com/content/dam/bcs-sites/firestone/AG/Databook/2018%20FIRESTONE%20AG%20DATA%20BOOK%20-%20FIRESTONE%20AGRICULTURE.pdf (accessed on 28 October 2021).

- Villalobos, F.; Sadras, V.; Soriano, A.; Fereres, E. Planting density effects on dry matter partitioning and productivity of sunflower hybrids. Field Crop. Res. 1994, 36, 1–11. [Google Scholar] [CrossRef]

- Nardón, G.F. Siembra de Precisión: Modelización de la Distancia Entre Semillas. Master’s Thesis, Universidad Nacional de La Plata, Facultad de Ciencias Agrarias y Forestales, La Plata, Argentina, 2003; p. 158. [Google Scholar]

- Tolon-Becerra, A.; Tourn, M.; Botta, G.; Lastra-Bravo, X. Effects of different tillage regimes on soil compaction, maize (Zea mays L.) seedling emergence and yields in the eastern Argentinean Pampas region. Soil Tillage Res. 2011, 117, 184–190. [Google Scholar] [CrossRef]

- VSN International. GenStat Release®. Reference Manual, 19th ed.; VSN International: Hemel Hempstead, UK, 2020. [Google Scholar]

- Duncan, D.B. Multiple range and multiple F tests. Biometrics 1955, 11, 1–42. [Google Scholar] [CrossRef]

- Daddow, R.L.; Warrington, G.E. Growth-limiting bulk densities as influenced by soil texture. In WSDG Report No.: WSDG-TN-00005 (January 1983); Watershed Systems Development Group: Fort Collins, CO, USA, 1983; p. 17. [Google Scholar]

- Pilatti, M.A.; de Orellana, J.A.; Imhoff, S.C.; Da Silva, A.P. Actualización de los límites críticos del intervalo hídrico óptimo. Ciencia del Suelo 2012, 30, 9–21. [Google Scholar]

- Ngo-Cong, D.; Antille, D.L.; van Genuchten, M.T.; Nguyen, H.Q.; Tekeste, M.Z.; Baillie, C.P.; Godwin, R.J. A modeling framework to quantify the effects of compaction on soil water retention and infiltration. Soil Sci. Soc. Am. J. 2021, 85, 1931–1945. [Google Scholar] [CrossRef]

- McKyes, E.; Negi, S.; Douglas, E.; Taylor, F.; Raghavan, V. The effect of machinery traffic and tillage operations on the physical properties of a clay and on yield of silage corn. J. Agric. Eng. Res. 1979, 24, 143–148. [Google Scholar] [CrossRef]

- Hussein, M.A.; Antille, D.L.; Kodur, S.; Chen, G.; Tullberg, J.N. Controlled traffic farming effects on productivity of grain sorghum, rainfall and fertiliser nitrogen use efficiency. J. Agric. Food Res. 2021, 3, 100111. [Google Scholar] [CrossRef]

- Taylor, H.M.; Ratliff, L.F. Root elongation rates of cotton and peanuts as a function of soil strength and soil water content. Soil Sci. 1969, 108, 113–119. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, X.; Xia, J.; Miller, G.A.; Cai, C.; Guo, Z.; Hassanikhah, A. The effect of water content on the shear strength characteristics of granitic soils in South China. Soil Tillage Res. 2018, 187, 50–59. [Google Scholar] [CrossRef]

- Kassam, A.; Friedrich, T.; Derpsch, R.; Lahmar, R.; Mrabet, R.; Basch, G.; González-Sánchez, E.J.; Serraj, R. Conservation agriculture in the dry Mediterranean climate. Field Crop. Res. 2012, 132, 7–17. [Google Scholar] [CrossRef] [Green Version]

- Godwin, D. Principles of reduced tillage. J. R. Agric. Soc. Engl. 2011, 172, 1–9. Available online: https://www.scopus.com/record/display.uri?eid=2-s2.0-84868024314&origin=resultslist&sort=plf-f (accessed on 28 October 2021).

- INTA. Guía Práctica Para el Cultivo de Girasol: Información Actualizada y Compaginada de la Biblioteca del Productor de Cambio Rural; Instituto Nacional de Tecnología Agropecuaria: Buenos Aires, Argentina, 1997; p. 187. Available online: https://inta.gob.ar/sites/default/files/script-tmp-guia_prctica_para_el_cultivo_de_girasol.pdf (accessed on 28 October 2021).

- McCalla, T.; Norstard, F.A. Toxicity problems in mulch tillage. Agric. Environ. 1974, 1, 153–174. [Google Scholar] [CrossRef]

- Chung, S.-O.; Horton, R. Soil heat and water flow with a partial surface mulch. Water Resour. Res. 1987, 23, 2175–2186. [Google Scholar] [CrossRef] [Green Version]

- Vega, C.R.C.; Andrade, F.H. Densidad de plantas y espaciamiento entre hileras. In Bases para el Manejo del Maíz, el Girasol y la Soja. Ediciones Instituto Nacional de Tecnología Agropecuaria; Andrade, F.H., Sadras, V.O., Eds.; INTA: Balcarce, Argentina, 2009; Chapter 4; pp. 69–97. ISBN 987-521-047-1. [Google Scholar]

- Miller, J.F.; Roath, W.W. Compensatory response of sunflower to stand reduction applied at different plant growth stages. Agron. J. 1982, 74, 119–121. [Google Scholar] [CrossRef]

- Botta, G.F.; Antille, D.L.; Bienvenido, F.; Rivero, D.; Contessotto, E.E. Energy requirements for alleviation of subsoil compaction and the effect of deep tillage on sunflower (Helianthus annus L.) yield in the western region of Argentina’s Rolling Pampa. Eng. Rural. Dev. 2019, 18, 174–178. [Google Scholar] [CrossRef]

- Aikins, K.A.; Antille, D.L.; Jensen, T.A.; Blackwell, J. Advances in residue management mechanisms of zero-tillage planters. In ASABE Paper No.: 1700449; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2017. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).