Abstract

The use of biochar in water resource and recovery facilities (WRRF) shows promise for recovery of phosphorus (P) to use as a biochar-based fertilizer (BBF) that can replace conventional fertilizers, promote carbon sequestration, and improve soil quality. In this study, biochar was recovered after being dosed into secondary-treated discharge from a municipal WRRF. The value of the recovered biochar as a BBF was tested in a lettuce (Lactuca sativa) growth trial. The BBF was compared to an inorganic fertilizer, raw biochar, and controls that had either only nitrogen (N) fertilizer or no amendment. The ability of the treatments to support plant growth was determined by measuring plant height, biomass, leaf tissue total N and P concentration, and plant quality. Plant quality for the Fe-modified biochar used in the WRRF was 9.05 (±0.44) on a 10-point scale compared to 9.61 (±0.46) for the inorganic fertilizer treatment and 2.22 (±0.82) for the untreated control. Plant tissue P concentrations were 6.28 (±0.83), 9.88 (±0.90), 15.46 (±2.54), and 6.36 (±1.91) g plant−1 for the raw biochar, Fe-modified biochar used in the WRRF, inorganic fertilizer, and no amendment treatments, respectively. Soil P availability and P uptake amount in the leaves indicated that the BBF released P more slowly than the inorganic P fertilizer; however, it was sufficiently available for uptake to support plant growth to maturity. Results from these experiments show that Fe-modified biochar used in WRRF can supply adequate P to plants. The slow release will reduce P leaching into surface waters.

1. Introduction

Phosphorus (P) is a macronutrient fertilizer required for crop production and is mainly derived from mining of non-renewable resources, of which there are limited reserves [1,2,3]. Additionally, P mining is energy intensive, making it a greenhouse gas-contributing process [4,5]. Thus, innovative methods to recover and recycle P from wastewater are needed [6,7,8]. In the research presented in this paper, P recovered on biochar that was used as a filter aid in tertiary treatment at a water resource recovery facility (WRRF) [9] was evaluated for its potential as a biochar-based fertilizer (BBF) to support plant growth.

Global population growth is increasing the volume of wastewater that contains elevated amounts of P and nitrogen (N), which causes eutrophication and water quality degradation [10,11,12]. To address this, tertiary treatment technologies to remove nutrients from wastewater to low levels can be used; however, this adds to treatment costs and does not have a beneficial use of the removed P and N [13]. Tertiary treatment typically uses reactive filtration or membranes to separate P from the secondary treated water [14,15]. Thus, the development of alternative technologies to recover nutrients from wastewater in a form that will allow nutrient recycling opportunities and decrease costs is needed [8,16,17,18]. One promising approach that is a developing technology of interest is adding biochar to the water treatment processes [9,19,20,21,22,23].

Biochar is a carbon-rich substance that is produced through pyrolysis [24]. It is generally derived from waste biomass, such as agricultural and forestry residues or municipal biosolids. Biochar’s physical and chemical properties make it suitable for use as a filter aid to remove excess N and P from the wastewater [19,25,26,27,28,29]. Other benefits of using biochar in WRRFs include economic and environmental advantages, such as the utilization of a byproduct from renewable energy production [30], and, if used as a soil amendment after use in the WRRF, it will sequester carbon (C), thereby reducing the C footprint of treating wastewater [31]. However, due to the high C/N and C/P ratios, it is speculated that it will decrease N and P availability to plants; however, this does not likely occur because the biochar-C is added in a largely unavailable form [32].

Several studies have observed that amending soils with biochar improves soil properties for plant growth [33,34,35,36] and offsets greenhouse gas emissions [37]. Because of the potential agronomic benefits, there is a growing interest in using biochar as a soil amendment. However, since the properties of biochars depend on feedstock, production conditions, and modification methods [38], the realized benefits can vary. Furthermore, the costs associated with applying biochar may outweigh the benefits [39]. However, biochar enriched with recycled nutrients from wastewater treatment plants yields a BBF that will contribute to the circular bioeconomy needed to develop sustainable WRRF treatment plants and recycle nutrients [40].

By using biochar in a WRRF, P and N can be removed from the effluent [41,42], and nutrient-rich biochar can be produced that can be used as a BBF [43,44] to improve soil quality, provide plant nutrients, and promote C sequestration [45,46]. Dai et al. [47] conducted a meta-analysis of research on biochar effects on plant growth across 1254 pairs of treated and untreated soils and observed that adding biochar to the soil made plants on average 16% (±1.3%) more productive. Niraula et al. [48] observed that incorporating two to eight percent of biochar soaked in dairy lagoon wastewater into soil increased total N in the soils by 38 to 75% and increased total P in the soils by 28 to 75%. Schmidt et al. [46] mixed biochar with cow urine and compost and observed an approximately 10 to 30% yield increase as compared to conventional fertilizer controls.

Biochar can be modified to improve nutrient recovery and yield better BBFs. Compared to physical and biological methods, chemical modification is the most efficient [25]. By adding metals that create biochar-metal surface complexation sites, biochar’s P sorption capacity can be increased [22,49]. Iron modification facilitates the formation of biochar–metal bridges with phosphate anions. Compared to unmodified biochar, Fe-modified biochar has been observed to have up to a 2.4-times more P adsorption capacity [50], which depends on the amount of Fe added [21]. Liu et al. [51] observed increased P absorption in Fe3O4-modified biochar, which was attributed to the formation of new Fe-O-P bonds. While the Fe modification enhances P uptake on biochar, the strong Fe-phosphate bonds may decrease P availability to plants.

Many studies have highlighted the positive impact of biochar application on crop productivity when used as an amendment [36,52,53] and a nutrient source [54,55]. Biochars mixed with fertilizers to produce BBF have been shown to increase yield above unenriched biochars in several field trials [56]. For example, Ng et al. [57] modified a peanut shell biochar with K3PO4 and observed that 3% and 5% by mass amendment to soil resulted in a 69% and 136% yield increase in P. heterophylla. Gao et al. [22] used Fe-modified biochar that was used in a WRRF to show that the recycled nutrients on the biochar improved germination of green beans (Phaseolus vulgaris). However, they did not grow the plants to maturity in the amended soils, which does not assess the slow-release P and overall ability of the BBF to support plant growth. Thus, uncertainties persist regarding the effectiveness of using Fe-modified biochar as a BBF amendment to soils because few studies have tested this recycled nutrient material in plant growth trials.

The aim of this study was to assess if biochar used as a filter aid in a WRRF can be used as a BBF to replace conventional inorganic P fertilizers and if it provides more benefit than raw biochar that was not used in the WRRF. To achieve this, Fe-modified and non-Fe-modified softwood biochar used in a WRRF process [9] were added at equivalent amounts to a soil growth medium. Lettuce (Lactuca sativa) plants were grown in the amended soils in a greenhouse growth trial. The value of the WRRF-treated biochar as a BBF was determined by comparing plant growth, P and N uptake in above-ground plant tissue, and extractable soil P across the treatments. The treatments were prepared to test the following hypotheses:

Hypothesis 1.

WRRF-treated biochar will provide adequate P needed to grow plants to maturity.

Hypothesis 2.

Fe-modified biochar used in a WRRF will provide more P to plants than unmodified biochar used in a WRRF.

Hypothesis 3.

WRRF-treated biochar will provide more P to plants than raw, untreated biochar.

Hypothesis 4.

WRRF-treated Fe-modified biochar will support plant growth and health to the same level as conventional inorganic fertilizers.

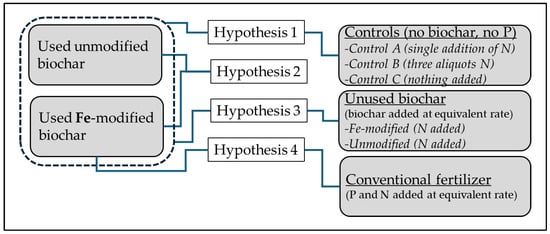

To test the first and second hypotheses, Fe-modified and unmodified biochars used in the WRRF were amended to soils used in the greenhouse growth trials and compared to an unamended soil treatment growth trial. To eliminate N as a variable, all soils were amended with urea to have the same total N, except for one of the unamended soil treatments (control) that did not receive any amendments. To test the third hypothesis, treatments with the two biochars used in the WRRF were compared to treatments with an equivalent amount of biochar that were not used in the WRRF. To test the fourth hypothesis, the treatment with Fe-amended biochar used in the WRRF was compared to a treatment with conventional inorganic fertilizers added at a rate equivalent to the total P added in the Fe-amended biochar used in the WRRF treatment. The experimental design is depicted in Figure 1. The objective of the main treatments was to assess how the different biochars affect P supply for plant growth; thus, biochars were added to the treatments at the same rate, and all treatments had the same total N addition.

Figure 1.

Experimental design of biochar soil amendment greenhouse growth trials. Hypotheses are described in the text. The connector lines show which treatments are being compared for each hypothesis.

2. Materials and Methods

2.1. Biochar

In this study, Blacklite Pure pine biochar (Pacific Biochar, Santa Rosa, CA, USA) was used. The biochar was manufactured from softwood forestry residues at a forest waste bioenergy plant using pyrolysis. The biochar was sieved to less than 2 mm maximum diameter. Biochar properties are listed in Table S1. The research study involves four treatments of the biochar (Figure 1, Table S2): (1) unmodified biochar, (2) Fe-modified biochar, (3) unmodified biochar exposed to municipal WRRF effluent, and (4) Fe-modified biochar exposed to municipal WRRF effluent.

2.2. Production of 4% Fe-Modified Biochar

The Fe-modified biochar is created by adding a concentrated FeCl3 solution (PIX-311, Kemira Water Solutions, Inc., Helsinki, Finland) to a biochar slurry using a process similar to the process described in [21]. Moreover, 4% Fe-modified biochar was produced by adding biochar to water at a ratio of 100 g per L and dosing the FeCl3. The pH of the slurry is adjusted to approximately three using dilute HCl. The percentage Fe in the stock solution was 12.94%. Next, 1 M NaOH was slowly added until the pH reached 6–6.5. The stepwise procedure of adjusting the pH creates an Fe oxide coating on the biochar particles [21]. The biochar suspension is filtered using 80 µm nylon–cloth mesh bags. Subsequently, the modified biochar material is evenly spread out on plastic tarps and allowed to dry for 48 to 72 h at ambient air temperature (approximately 15–37 °C).

2.3. Wastewater-Treated Biochar

The biochar was used in a field pilot-scale reactor to recover P from a municipal WRRF [9,31,58]. The experiments were conducted over a period of eight consecutive days at the municipal WRRF in Sandpoint, Idaho, USA, using a pilot-scale reactive filtration water treatment process [9]. The pilot water treatment process uses hydrous ferric oxide in a flow-through sand bed reactor with ozone injected to sterilize the water and destructively remove organic micropollutants. The secondary effluent water from the post-chlorination and de-chlorination stages of the treatment process prior to outfall discharge was used as influent flow to the pilot filter. The inflow rate was 0.57 ± 0.02 L s−1. The influent and effluent water quality parameters are provided in Yu et al. [9]. Because the influent water is secondary treated water, metal concentrations are relatively low as compared to the raw sewage water, where metals are associated with the solids that are removed in the settling and clarification steps [59]. Thus, there are minimal risks of metal contaminants such as lead and zinc being present in the biochars used from the pilot reactor study. Furthermore, the reactive filtration uses catalytic oxidation to sterilize and destructively remove organic compounds of emerging concern common in WRRF that are not removed from secondary water treatment effluents [9,60], thus these compounds are not sequestered on the WRRF-treated biochar.

The biochar was added to the pilot treatment process at a rate of 0.47 ± 0.05 g L−1 into a 1514 L HDPE tank (stirred contactor) filled with 1363 L of WRRF plant effluent water and mixed using a propellor (described in Yu et al. [9]). The ozone is injected into the influent water prior to going into the stirred contactor. After the stirred contactor, the water is pumped into the reactive filters. The biochar in the stirred contactor is split into two fractions; some of it goes into the reactive filters, and some remains in the stirred contactor and settles to the bottom. The nutrient-loaded biochar sediment at the bottom of the stirred contactor was collected at the end of each experiment (typically 4–6 h of treatment time per batch) and air-dried for approximately two days. The reported average daily values for total suspended solids, total N, and total P in the WRRF effluent (the influent to the pilot reactor) were 1130 kg day−1, 144 kg day−1, and 36.3 kg day−1, respectively [9].

2.4. Characterization of Biochar

The biochar was analyzed for total P and K using a modified dry ash method followed by acid digestion [61]. The digestates were analyzed for elemental composition using an ICP-AES (Agilent, Santa Clara, CA, USA). Quantities of carbon, nitrogen, and sulfur (CNS) present in the biochar samples were measured using a combustion analyzer (Elementar Vario Max Cube; Ronkonkoma, NY, USA). Available NO3, NO2, and NH4 in the biochars were measured on 2 M KCl-extracts of the biochar and analyzed on a QuickChem 8500 (Lachat Instruments, Milwaukee, WI, USA) [62]. Plant-available P in the biochar was estimated using the 2% formic acid extraction method [63], followed by P analysis on ICP-AES. Table 1 lists the total N, P, and K in the different biochars. In the biochar analyses, at least one sample was analyzed in triplicate. Relative standard deviation was less than 6% for all analyses.

Table 1.

Total N, P, K, and extractable (available) N, P content of the biochar samples used in the greenhouse experiment.

2.5. Potting Mixture Composition and Fertilizer Application

The growing medium consisted of a mixture of commercial potting mixture (Pro-Mix BX, Premier Horticulture Ltd., Quebec City, QC, Canada), sand (Sandlastic, Waupaca Northwoods Llc., Waupaca, WI, USA), and perlite (Uni-Grow Premium Perlite, L&L Nursery Supply Inc., San Bernadino, CA, USA). Each pot contained 40 g of commercial potting mixture, 960 g of sand, and 20 g of perlite. Preliminary growth trials using the potting mixture showed that without added nutrients, lettuce growth was severely stunted due to nutrient deficiencies.

This study is designed to test if the nutrient recovered biochar provides enough P to support plant growth. The amount of N, P, and K fertilizer recommended for the lettuce is 315 kg N ha−1, 210 kg P2O5 ha−1, and 285 kg K2O ha−1 (315 kg N ha−1, 93.75 kg P ha−1, and 235.53 kg K ha−1) [64]. The total P in the Fe-modified biochar sample (Table 1) was used to calculate that 27.25 g of biochar per pot was needed to supply 100% of the P required to grow lettuce. For the other treatments, the same mass of the different biochars was added to the soils (biochar additions and fertilizers are described in Table S2). The biochar was thoroughly mixed with the potting mixture before adding it to the pots. Each greenhouse treatment was replicated nine times (three replications within three blocks).

The P and N amendment in the Fe-modified used biochar and the conventional fertilizer treatment was 100% of the required amount for lettuce growth. The P fertilizer used was super phosphate mineral (Hi Yield Triple Super Phosphate (0-45-0), Volunteer Purchasing Groups, Inc., Bonham, TX, USA).

Total N additions to all biochar treatments and control A and control B treatments were added to meet the N requirement for lettuce. Control C treatment had no P and no N additions (growth medium alone). Different rates of N fertilizer were required to be added to meet the total N requirement of lettuce because the biochars had different total N amounts (Table 1). The N fertilizer (Fortify Phosphorus Free Lawn Food (21-0-7) urea and polymer-coated slow-release urea; Andersons Lawn Fertilizer Division, Inc., Maumee, OH, USA) was added as a dissolved solution in all treatments except for control B treatment, where it was added as a powder that was mixed with the greenhouse soil mix. In the biochar, fertilizer, and control A treatments, N was dosed in three aliquots approximately one week apart, starting on day 20. Potassium from the biochar and fertilizer was several times the amount required for lettuce growth in all treatments, except control C treatment, thus it was not a limiting factor in lettuce growth in the growth trial.

2.6. Greenhouse Setup

Romaine lettuce (Lactuca sativa) was used for the greenhouse growth trial experiment. Lettuce was chosen because growth performance can be assessed without any interferences in assessing plant productivity and health caused by seeding or fruiting. A complete block design experiment consisted of 24 pots per block, with eight treatments and three replications per block. There were three replicated blocks. The treatment details are described in Table S2. The plants were regularly irrigated using greenhouse tap water. Water was checked daily to ensure the plants had enough moisture for plant growth (65–70% water holding capacity). Each plant was given the same volume of water. The temperature in the greenhouse was kept between 23 °C and 25 °C, and lettuce plants were given 16 h of additional light each day using 400 W high-pressure sodium fixture-type lamps (P.L. Light System, Hamilton, ON, Canada). The blocks and treatments within the blocks were rotated every four days.

2.7. Lettuce Germination and Transplantation

Moistened potting mix was used for lettuce seed germination. After nine days of germination, healthy lettuce seedlings were transferred into the pots. Initially, three lettuce seedlings were placed in each pot, followed by a thinning on day 7 to one lettuce plant per pot. The lettuce was grown for 57 days (48 days in the pots).

2.8. Measurement of Plant Growth Amount and Quality

Soil Plant Analysis Development (SPAD) chlorophyll readings were measured using a SPAD 502 Chlorophyll meter (Spectrum Technologies, Inc., Aurora, IL, USA). The SPAD chlorophyll reading was recorded from fully opened lettuce leaves that were among the tallest leaves near the center of the plant. SPAD readings from three leaves were taken from each plant, and the mean value of three replicate measurements was used.

Before the lettuce harvest on day 57, the plants underwent scoring based on parameters such as leaf length and overall plant quality. Plant quality was assessed on a 10-point rating scale (see Figure S5 for examples). A score of 1 was assigned to plants exhibiting the fewest leaves, shortest leaf length, and most chlorotic color. A score of 10 was assigned to plants that had the most abundant and tallest leaves, the longest leaf length, and were good overall green color. Intermediate scores indicate that the plant quality of at least one of the plant metrics is less than the best-performing plant. Although careful plant quality rating was performed, including anonymous treatment scoring, some bias on the absolute differences is inherent in this semi-quantitative plant quality rating method; therefore, statistical difference tests between the plant ratings were not performed. However, the evaluation of the ratings based on morphology and phenology provides a good relative assessment of the overall plant quality.

The above-ground fresh and dry weights (70 °C) of the plants were measured after the crop was harvested. The height of the tallest leaf from each pot was measured each week, starting on day 23. Height was measured from the base of the stem to the top edge of the tallest leaf.

2.9. Analysis of Soil Physicochemical Properties

Soil electrical conductivity (EC) was measured in a soil–water suspension 1:2 (mass basis). pH was measured on 1:1 soil–water suspensions. Plant-available P was estimated using the Olsen P extraction test [65,66]. The concentrations of orthophosphate in the Olsen extraction solutions were measured using molybdate blue chemistry and absorbance on a spectrophotometer at 882 nm [67].

2.10. Plant Tissue Elemental Analysis

The plant leaves were powdered using a ball mill and subsequently sent to Brookside Laboratory (New Bremen, OH, USA) for total nutrient composition analysis. Plant N content was determined using a C/N combustion analyzer. Elemental composition was measured on plants digested in a closed microwave digestion vessel with a mixture of nitric acid and hydrogen peroxide. The digested samples were analyzed using an ICP-OES.

2.11. Statistical Analysis

The statistical analysis was performed using the program R (Version 4.1.2). The differences among the treatments are examined by ANOVA, and separation of means was evaluated using the least squares difference (LSD) separation method, with significance set at p < 0.05.

3. Results

3.1. Plant Growth Performance

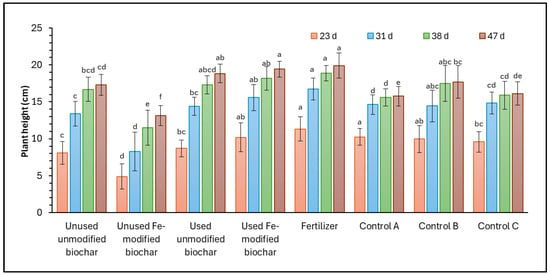

The effects of the different biochar treatments on plant height are presented in Figure 2. The final plant height was measured on day 47, and there were no noticeable increases in height after that. Plant heights were significantly different between the treatments. Throughout the growing period, the plant height of unused Fe-modified biochar was lower compared to the controls. The plant height in both of the biochars treated with wastewater were significantly taller than unused biochars and the control treatments (no biochar). The wastewater-treated biochar treatment heights were not significantly shorter than the conventional inorganic fertilizer treatment.

Figure 2.

The effects of biochar and fertilizer treatment on plant height. Columns marked by different letters are significantly different at each time measurement (p = 0.05). Error bars are standard deviations.

Chlorophyll contents were slightly different for some of the treatments on day 27 and day 36 measurements (Figure S1). Control A and control B, which had inorganic N fertilizer added and no P amendment, had the greatest chlorophyll content. The control C treatment had the lowest chlorophyll content, indicating it was the most chlorotic of all treatments.

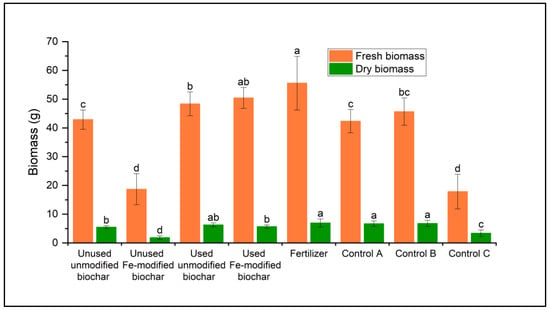

The effects of treatments on the fresh and dry above-ground biomass are shown in Figure 3. The conventional inorganic fertilizer treatment had the highest fresh biomass, followed by the used Fe-modified biochar, which was not statistically different. The unused Fe-modified biochar and control C treatments had the lowest fresh and dry biomasses.

Figure 3.

The effects of biochar applications and fertilizer treatments on the fresh biomass (yield) and dry biomass. Columns marked by different letters are significantly different within fresh or dry biomass measurement (p = 0.05). Error bars are standard deviations.

The conventional inorganic fertilizer treatment had the highest dry biomass (Figure 3). The used Fe biochar had 17.9% less dry biomass than the conventional inorganic fertilizer treatment. Fresh and dry biomasses from the control A and control B treatments that had only N fertilizer added were similar to the used biochar treatments biomasses.

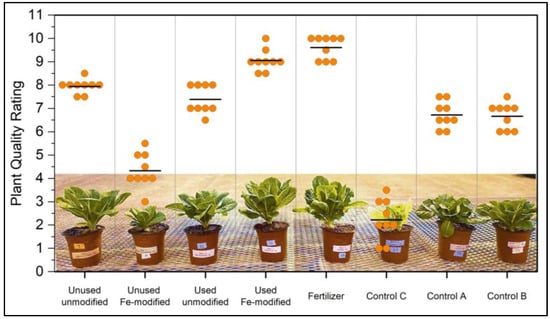

The plant quality rating data are shown in Figure 4. A score of 10 was assigned to plants that had lush green foliage with the best plant quality. A score of 1 was assigned to plants with the poorest plant quality (minimal foliage growth and chlorotic appearance; see images in Figure S5). Using the plant quality rating assessment, the effects of treatments on plant quality were very apparent. The conventional inorganic fertilizer-treated lettuce had the highest average score (9.61 ± 0.46). The used Fe-modified biochar treatment had a slightly lower plant quality rating of 9.05 (±0.44). Both the unmodified biochars had lower plant quality ratings than the used Fe-modified biochar and the conventional inorganic fertilizer treatments. The unused Fe-modified biochar had a much lower plant quality rating than the other biochar treatments; it was the second poorest plant quality (4.33 (±0.71)), just ahead of control C (no fertilizer amendment) (2.22 (±0.82)).

Figure 4.

Plant quality scores and their respective treatment mean (bar). Background image shows representative plants for each treatment (image tone, contrast, and brightness were adjusted and the image was cropped). See Figure S5 for additional images of plant quality ratings.

The controls all had lower plant quality ratings than all the biochar treatments except for the unused Fe-modified biochar treatment, even though control A and control B treatments were provided equivalent N fertilizer. Control C treatment plants were small, had few leaves, and were chlorotic, reflecting the lack of nutrients. In contrast, control A and control B treatments were larger and were darker green in color (as indicated in the SPAD readings in Figure S1), thus they had higher plant quality ratings (6.7 (±0.5) for both). However, control A and control B treatments had decreased leaf height as compared to the used biochar and conventional inorganic fertilizer treatments (Figure 2), which was why they had a lower plant quality score.

3.2. Soil Characteristics

The highest soil pH occurred in the soil amended with the unused unmodified biochar (7.28 (±0.02)) (Table S3). Other amendments had only small effects on pH, which ranged from 6.04 to 6.82. In the unused biochar treatments, the EC was higher than in the biochars used in the WRRF (Table S3).

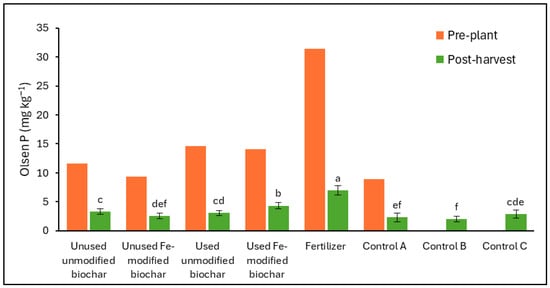

Figure 5 shows the soil P availability measured by the Olsen bicarbonate extraction test. Prior to planting, the available P in the biochar-treated soils ranged from 9.37 mg kg−1 to 14.57 mg kg−1. The unused Fe-modified biochar and controls had the lowest concentration of Olsen-extractable P, and the conventional inorganic fertilizer treatment had the highest. The used biochar treatments had the second-highest available P concentration amongst the pre-plant soils.

Figure 5.

Olsen-extractable P in pre-planting and post-harvest soils. Different letters in the post-harvest soil indicate significant differences within either pre-plant or post-harvest measurements (p = 0.05). Error bars are standard deviations. Control B and control C samples were the same pre-plant soil as control A. In the pre-plant samples there were no treatment replicates since they all came from the same soil batch.

Post-harvest, the highest Olsen-extractable P value was in the soil treated with conventional inorganic fertilizer, followed by soil treated with the used Fe-modified biochar (Figure 5). The controls (no P amendment) had the lowest available P content post-harvest.

3.3. Nutrient Uptake in Plants

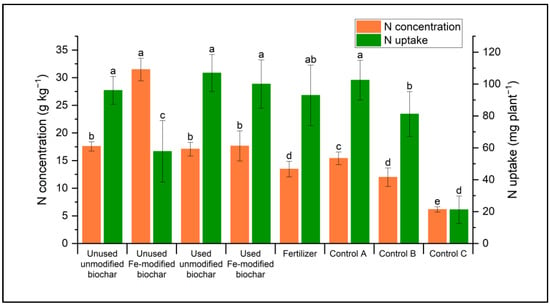

The effects of biochar treatments on N and P uptake in lettuce leaves are shown in Figure 6 and Figure 7, respectively. The highest leaf tissue N concentrations occurred in the unused Fe-modified biochar treatment. The lowest N concentration occurred in the control C treatments (no amendments). Normalizing the N concentration by the dry plant mass provides a direct assessment of plant N uptake based on the amount of plant growth (Figure 6). Plant N uptake amount was similar in all the biochar treatments and controls except for the unused Fe-modified biochar samples and control C treatments, which were significantly lower.

Figure 6.

The effects of biochar treatments on the N content and N uptake in the lettuce leaves. Columns marked by different letters are significantly different (p = 0.05). Error bars are standard deviations.

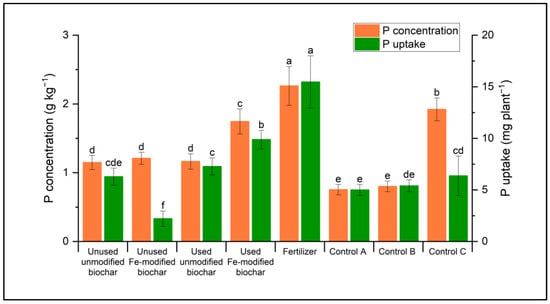

Figure 7.

The effects of biochar treatments on the P content and P uptake in the lettuce leaves. Columns marked by different letters are significantly different (p = 0.05). Error bars are standard deviations.

The uptake of P (mg plant−1) was greatest in the conventional inorganic fertilizer treatment, followed by the used Fe-modified biochar treatment (Figure 7). The least amount of P uptake occurred in the unused Fe-modified biochar sample. Control A and control B treatments had the second lowest plant uptake of P. The unused unmodified biochar and used unmodified biochar had less plant uptake of P than the used Fe-modified biochar.

The plant tissue amounts of potassium, calcium, magnesium, sulfur, iron, manganese, copper, zinc, and boron are shown in Figures S2–S4. Although there were some significant differences between the treatments, it is difficult to draw any conclusions because the experiments were not designed to test effects from these elements. However, notably, control C had the lowest concentrations of all the measured elements (except copper), which reflects the nutrient poor conditions of the growth medium soil. Potassium uptake in the used biochar, fertilizer, control A treatment, and control B treatment was similar (Figure S2), confirming that K was not a limiting nutrient.

4. Discussion

4.1. Influence of Biochar on Plant Phenology

The ability of the recycled nutrients in biochar to support lettuce growth was assessed using plant height, biomass productivity, and overall plant quality. Comparison of the biochars used in the WRRF treatments to the control C and the conventional inorganic fertilizer treatments provides direct evaluation of recycled nutrient performance (Hypotheses 1 and 4, respectively). Average plant height, biomass productivity, and overall plant quality of the used biochar treatments were slightly less than the fertilizer treatment. In contrast, all plant measurements in the used biochar-treated samples were much greater than control C plants. These results indicate that amending the soils with biochar used in the WRRF improved the soil’s ability to support plant growth. The plant quality rating of the used Fe-modified biochar treatment was slightly greater than the plant quality rating of the used unmodified biochar, which shows that modifying the biochar with iron prior to its use in the WRRF provided some benefit (Hypothesis 2), likely from the increased P sequestered in the used Fe-modified biochar.

To assess specific effects of recycled P for supporting plant growth, plant growth parameters from the used biochar treatments can be compared to the control treatments that had nitrate fertilizer addition only (control A and control B treatments) (Hypothesis 1). The total amount of N added to all treatments was the same. The aboveground plant biomasses of control A and control B treatments were not significantly different than the used biochars, and the controls did not show any signs of chlorosis. However, plant height and plant quality rating for the used biochar treatments were better than the control A and control B treatments. The lack of P in control A and control B may have caused the stem and leaf thicknesses to increase [68], thus causing their biomasses to be equivalent to the used biochars even though their plant height and plant quality ratings were lower.

The biochars not used in the WRRF did not support plant growth as well as the used biochars (Hypothesis 3), ruling out that the improved plant growth was solely due to the biochar amendment improving the physical or biological properties of the soil growth medium. The unused Fe-modified biochar treatment had very low plant growth and plant quality measurements, likely due to the reduced amount of P added and the sequestration of P that was present in the biochar onto the Fe oxide minerals precipitated on the biochar surfaces.

These results support the conclusion that the recycled P added to the biochars from the wastewater was beneficial to plant growth. Melo et al. [56] did a meta-analysis of field studies that compared the potential of BBF as replacements for conventional fertilizers. They found that the average crop productivity increased by 10% in fields that were amended with BBF. However, the Melo et al. [56] meta-analysis did not show any overall effect of increased P availability on crop productivity from using BBF. In contrast, the Fe-amended biochar used in the WRRF showed increased P availability that resulted in greater above-ground plant tissue concentrations.

Some reports of biochar amendment to soils have shown that biochar causes slightly lower yields in the first crop as compared to conventional inorganic fertilizers [69,70]. Compared to control A and control B treatments, the unused unmodified biochar treatment had similar plant performance for height and biomass, but plant quality was higher, and the leaf P content was greater. All plant growth parameters for the unused biochar treatment were higher than the control C treatment (no amendment). Compared to the biochars used in the WRRF, the unused biochar was not as good at supporting plant growth; the main difference was that the used biochar treatments had much more total P added (Table S2). Overall, the plant growth parameters of the unused unmodified biochar compared to the three controls show that the biochar had a positive impact on plant growth, even without P enhancement from the WRRF. This finding agrees with a meta-analysis of biochar amendment studies that concluded that the average plant productivity from 148 comparisons was improved by a mean of 10% in biochar-amended soils as compared to the fertilized controls [47]. Thus, the softwood biochar in this study did not inhibit plant growth, as has been reported in some studies using biochar amendments to soils [69,70].

4.2. Influence of Biochar on Olsen-Extractable P Content in the Soil

Phosphorus extracted from soils using the Olsen-P test is a good estimate of the P that is available for plant uptake and the general availability of P for leaching [71,72]. However, extraction of soils or biochars to estimate plant-available P does not assess some pools of P that may be plant-available [73,74]. Accurate amounts of plant-available P must be assessed using plant tissue analysis, which we discuss in the next section.

Prior to being planted in the greenhouse, both treatments that were amended with biochars used in the WRRF had ~40 to 50% more Olsen-extractable P than the treatments amended with biochars that were not used in the WRRF. In the post-harvest soils, the Olsen-extractable P amount was significantly higher (~40% more) in the soil amended with the used Fe-modified biochar than the used unmodified biochar. Based on plant productivity and quality, the used Fe-modified biochar treatment was better able to support plant growth than the used unmodified biochar, supporting Hypothesis 2. This may be because the Fe-modified biochar released P more slowly, better meeting the plant uptake requirements through the growth period. Biochars modified with Ca, Mg, and Fe have been shown to be better slow-release fertilizers than unmodified biochars [75,76,77]. Phosphorus adsorption on iron oxide surfaces present in Fe-modified biochar attracts and holds phosphate from wastewater and can slowly release it to the plant rhizosphere [21,78,79]. Strawn et al. [21] observed that Fe-modified biochars had 86% less P release potential than unmodified biochar. Since slow release P is more compatible with plant uptake rates, it will reduce risks for P leaching and loading to surface water [80]. The success of the plant growth and the P leaf content show that the Fe amendment does not immobilize P to such an extent that it is unavailable for plant uptake, and the increased Olsen-extractable P suggests it may be a slow-release P source to the plant.

4.3. Influence of Biochar on Tissue Nutrient Content

Uptake of P and N in plant tissues provides direct measurement of nutrient availability. Tissue P concentrations and P uptake amount per plant were highest in the fertilizer treatment, followed by the used Fe-modified biochar treatment, which was greater than any of the other biochar treatments. The total P added to the soil amended with the used Fe-modified biochar and conventional inorganic fertilizer were both equal to the amount of P required for lettuce growth. However, some of the P in the biochar may not be immediately available, which was supported by the amount of formic acid extractable P from the biochars prior to their use in the greenhouse experiments (2 to 47% of total P (Table 1)).

In contrast to the leaf P uptake amounts, the amounts of N uptake per plant across the treatments were similar (except for control C, which was much lower because it did not receive any N addition). In all treatments, N was added in equal amounts; however, in the biochar treatments, some of the N was added with the biochar and the rest as urea. The availability of biochar-based N for plant uptake is likely less than the urea fertilizer [81]. In the used Fe-amended biochar, the N added as urea was 46% of the total added N, while in the other biochar treatments, most of the N was from urea fertilizer addition (>85%). Available N from the biochars as measured by KCl extraction ranged from 1.7 to 16% of the total N (Table 1), suggesting a significant fraction of the N in the biochar may be only slowly available for plant uptake. Despite having less N availability, the used Fe-modified biochar treatment supported plant growth better than the control A and control B treatments, suggesting that the addition of P from using the biochars in the WRRF sufficiently met the plant requirements, and the biochar-based N and urea together were sufficient to support plant growth.

The P uptake amounts by the plants suggest that the used Fe-modified biochar was an effective source of P for plant growth; however, since the lettuce plants had slightly less biomass than the conventional inorganic fertilizer, there may have been some P or N limitation on productivity. Thus, replacing conventional inorganic fertilizer with BBF may require slightly more biochar amendment than the amount calculated based on total biochar P and N content. This would compensate for some of the unavailable P and N. Alternatively, biochar and a small amount of conventional fertilizer could be combined to support plant growth. Ye et al. [82] did a meta-analysis on crop performance when biochar was added together with fertilizers, and they reported that biochar plus fertilizer had an average yield increase of 15% as compared to inorganic fertilizer alone. An et al. [83] observed that 1.5 t ha−1 of biochar added with typical rates of inorganic NPK fertilizer yielded an average of 6.6% greater rice yield over six years as compared to the inorganic fertilizer alone. The meta-analysis performed by Melo et al. [56] concluded that BBFs increased crop productivity by at least 10% as compared to conventional fertilizer-amended soils. However, they did not observe an increase in soil P availability from the BBF. The plant tissue concentrations in the current study indicate that the used WRRF-treated biochar increased plant-available P.

5. Conclusions

The Fe-modified biochar used in the WRRF supplied sufficient nutrients for plant growth at nearly the same level as conventional inorganic fertilizer and much better than raw untreated biochar and non-biochar amended controls, supporting our Hypotheses 1–4. Thus, the modified biochar used in a WRRF can recover nutrients and be used as a BBF to support plant growth to maturity, and it is an adequate source of recycled P. This provides a direct pathway for upcycling biochar so that it can be used to support the sustainable bioeconomy directive to recycle nutrients, thereby avoiding mining P ores while simultaneously reducing P loading to surface waters. The use of BBF also provides a pathway to sequester C, helping offset greenhouse gas emissions [40].

To continue to advance recycled nutrients on biochar to produce BBFs, research needs to be conducted to investigate how to increase the P and N recovery on the biochar by altering the biochar and WRRF filtration process while ensuring that the recovered wastewater-treated biochar is not harmful for plant growth or food safety. In addition, molecular-level studies on the species of the P in the recycled BBF and varied rate studies should also be conducted. Finally, successive growth trials need to be conducted to determine the effects of BBF over many seasons of crop growth. This additional research will allow for the optimization of the BBFs from recycled nutrients so that they can potentially completely replace conventional fertilizers.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/soilsystems8030093/s1. Figure S1: Chlorophyll content. Figure S2: Plant tissue K concentration and uptake. Figure S3: Plant tissue Ca, Mg, and S concentrations. Figure S4: Plant tissue Fe, Mn, Cu, Zn, and B concentrations. Figure S5: Plant quality rating images. Table S1: Biochar properties. Table S2: Treatment details. Table S3: Soil pH and EC. Table S4: Plant quality score means and standard deviations.

Author Contributions

Conceptualization, D.G.S. and G.M.; methodology, K.L.S., D.G.S. and A.R.C.; formal analysis, K.L.S., D.G.S. and A.R.C.; investigation, K.L.S., D.G.S., A.R.C., M.B. and G.M.; resources, D.G.S. and G.M.; data curation, K.L.S. and A.R.C.; writing—review and editing, K.L.S., D.G.S., A.R.C., M.B. and G.M.; supervision, D.G.S.; project administration, D.G.S., A.R.C. and G.M.; funding acquisition, D.G.S., M.B. and G.M. All authors have read and agreed to the published version of the manuscript.

Funding

This publication was developed under Assistance Agreement No. 84008701, awarded by the U.S. Environmental Protection Agency (to D.G.S., G.M., and M.B.), and under Agreement No. 2020-69012-31871, funded by the U.S. Department of Agriculture (USDA), National Institute of Food and Agriculture (to D.G.S. and G.M.). This work is also supported by the Idaho Agricultural Experiment Station, USDA, NIFA Project Number IDA01711 (to D.G.S. and G.M.). The funders had no role in study design, data collection and analysis, decision to publish, or preparation of the manuscript. The research has not been formally reviewed by the funding agencies. The contents of this document do not necessarily reflect the views and policies of the USEPA, nor does USEPA endorse trade names or recommend the use of commercial products mentioned in this document.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article/Supplementary Material; further inquiries can be directed to the corresponding author(s).

Acknowledgments

We appreciate assistance in preparing nutrient-loaded biochar in a pilot-scale study by Paulo Yu.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of this study, in the collection, analysis, or interpretation of data, in the writing of the manuscript, or in the decision to publish the results.

References

- Zamparas, M. The role of resource recovery technologies in reducing the demand of fossil fuels and conventional fossil-based mineral fertilizers. In Low Carbon Energy Technologies in Sustainable Energy Systems; Kyriakopoulos, G.L., Ed.; Academic Press: New York, NY, USA, 2021; pp. 3–24. [Google Scholar]

- Cordell, D.; Rosemarin, A.; Schröder, J.J.; Smit, A.L. Towards global phosphorus security: A systems framework for phosphorus recovery and reuse options. Chemosphere 2011, 84, 747–758. [Google Scholar] [CrossRef]

- U.S. Geological Survey. Mineral Commodity Summaries 2021; US Geological Survey: Reston, VA, USA, 2021; p. 200.

- Chowdhury, R.B.; Moore, G.A.; Weatherley, A.J.; Arora, M. Key sustainability challenges for the global phosphorus resource, their implications for global food security, and options for mitigation. J. Clean. Prod. 2017, 140, 945–963. [Google Scholar] [CrossRef]

- Scholz, R.W.; Roy, A.H.; Hellums, D.T.; Roy, A.H.; Hellums, D.T.; Scholz, R.W.; Beaver, C.; Scholz, R.W.; Le, Q.B.; Le, Q.B. Sustainable phosphorus management: A transdisciplinary challenge. In Sustainable Phosphorus Management: A Global Transdisciplinary Roadmap; Springer: Dordrecht, The Netherlands, 2014; pp. 1–128. [Google Scholar]

- Hollas, C.E.; Bolsan, A.C.; Venturin, B.; Bonassa, G.; Tápparo, D.C.; Cândido, D.; Antes, F.G.; Vanotti, M.B.; Szögi, A.A.; Kunz, A. Second-generation phosphorus: Recovery from wastes towards the sustainability of production chains. Sustainability 2021, 13, 5919. [Google Scholar] [CrossRef]

- Roy, E.D. Phosphorus recovery and recycling with ecological engineering: A review. Ecol. Eng. 2017, 98, 213–227. [Google Scholar] [CrossRef]

- Robles, Á.; Aguado, D.; Barat, R.; Borrás, L.; Bouzas, A.; Giménez, J.B.; Martí, N.; Ribes, J.; Ruano, M.V.; Serralta, J.; et al. New frontiers from removal to recycling of nitrogen and phosphorus from wastewater in the Circular Economy. Bioresour. Technol. 2020, 300, 122673. [Google Scholar] [CrossRef] [PubMed]

- Yu, P.; Baker, M.C.; Crump, A.R.; Vogler, M.; Strawn, D.G.; Möller, G. Biochar integrated reactive filtration of wastewater for P removal and recovery, micropollutant catalytic oxidation, and negative CO2e: Process operation and mechanism. Water Environ. Res. 2023, 95, e10926. [Google Scholar] [CrossRef] [PubMed]

- Schindler, D.W.; Carpenter, S.R.; Chapra, S.C.; Hecky, R.E.; Orihel, D.M. Reducing Phosphorus to Curb Lake Eutrophication is a Success. Environ. Sci. Technol. 2016, 50, 8923–8929. [Google Scholar] [CrossRef]

- Beaulieu, J.J.; DelSontro, T.; Downing, J.A. Eutrophication will increase methane emissions from lakes and impoundments during the 21st century. Nat. Commun. 2019, 10, 1375. [Google Scholar] [CrossRef]

- Preisner, M.; Neverova-Dziopak, E.; Kowalewski, Z. Mitigation of eutrophication caused by wastewater discharge: A simulation-based approach. Ambio 2021, 50, 413–424. [Google Scholar] [CrossRef]

- Zahmatkesh, S.; Bokhari, A.; Karimian, M.; Zahra, M.M.A.; Sillanpää, M.; Panchal, H.; Alrubaie, A.J.; Rezakhani, Y. A comprehensive review of various approaches for treatment of tertiary wastewater with emerging contaminants: What do we know? Environ. Monit. Assess. 2022, 194, 884. [Google Scholar] [CrossRef]

- Plakas, K.V.; Georgiadis, A.A.; Karabelas, A.J. Sustainability assessment of tertiary wastewater treatment technologies: A multi-criteria analysis. Water Sci. Technol. 2015, 73, 1532–1540. [Google Scholar] [CrossRef]

- Zagklis, D.P.; Bampos, G. Tertiary Wastewater Treatment Technologies: A Review of Technical, Economic, and Life Cycle Aspects. Processes 2022, 10, 2304. [Google Scholar] [CrossRef]

- Rout, P.R.; Shahid, M.K.; Dash, R.R.; Bhunia, P.; Liu, D.; Varjani, S.; Zhang, T.C.; Surampalli, R.Y. Nutrient removal from domestic wastewater: A comprehensive review on conventional and advanced technologies. J. Environ. Manag. 2021, 296, 113246. [Google Scholar] [CrossRef] [PubMed]

- Di Capua, F.; de Sario, S.; Ferraro, A.; Petrella, A.; Race, M.; Pirozzi, F.; Fratino, U.; Spasiano, D. Phosphorous removal and recovery from urban wastewater: Current practices and new directions. Sci. Total Environ. 2022, 823, 153750. [Google Scholar] [CrossRef]

- Sniatala, B.; Kurniawan, T.A.; Sobotka, D.; Makinia, J.; Othman, M.H.D. Macro-nutrients recovery from liquid waste as a sustainable resource for production of recovered mineral fertilizer: Uncovering alternative options to sustain global food security cost-effectively. Sci. Total Environ. 2023, 856, 159283. [Google Scholar] [CrossRef]

- Mohan, D.; Pittman, C.U.; Misna, T.E. (Eds.) Sustainable Biochar for Water and Wastewater Treatment; Elsevier: Amsterdam, The Netherlands, 2022; p. 825. [Google Scholar]

- Nobaharan, K.; Bagheri Novair, S.; Asgari Lajayer, B.; van Hullebusch, E.D. Phosphorus removal from wastewater: The potential use of biochar and the key controlling factors. Water 2021, 13, 517. [Google Scholar] [CrossRef]

- Strawn, D.G.; Crump, A.R.; Peak, D.; Garcia-Perez, M.; Möller, G. Reactivity of Fe-amended biochar for phosphorus removal and recycling from wastewater. PLoS Water 2023, 2, e0000092. [Google Scholar] [CrossRef]

- Gao, A.L.; Wan, Y. Iron modified biochar enables recovery and recycling of phosphorus from wastewater through column filters and flow reactors. Chemosphere 2023, 313, 137434. [Google Scholar] [CrossRef] [PubMed]

- Enaime, G.; Baçaoui, A.; Yaacoubi, A.; Lübken, M. Biochar for Wastewater Treatment—Conversion Technologies and Applications. Appl. Sci. 2020, 10, 3492. [Google Scholar] [CrossRef]

- Kumar, A.; Bhattacharya, T. Biochar: A sustainable solution. Environ. Dev. Sustain. 2021, 23, 6642–6680. [Google Scholar] [CrossRef]

- Min, L.; Zhongsheng, Z.; Zhe, L.; Haitao, W. Removal of nitrogen and phosphorus pollutants from water by FeCl3-impregnated biochar. Ecol. Eng. 2020, 149, 105792. [Google Scholar] [CrossRef]

- Li, X.; Shi, J. Simultaneous adsorption of tetracycline, ammonium and phosphate from wastewater by iron and nitrogen modified biochar: Kinetics, isotherm, thermodynamic and mechanism. Chemosphere 2022, 293, 133574. [Google Scholar] [CrossRef] [PubMed]

- Xiang, W.; Zhang, X.; Chen, J.; Zou, W.; He, F.; Hu, X.; Tsang, D.C.W.; Ok, Y.S.; Gao, B. Biochar technology in wastewater treatment: A critical review. Chemosphere 2020, 252, 126539. [Google Scholar] [CrossRef] [PubMed]

- Xue, L.; Gao, B.; Wan, Y.; Fang, J.; Wang, S.; Li, Y.; Muñoz-Carpena, R.; Yang, L. High efficiency and selectivity of MgFe-LDH modified wheat-straw biochar in the removal of nitrate from aqueous solutions. J. Taiwan Inst. Chem. Eng. 2016, 63, 312–317. [Google Scholar] [CrossRef]

- Luo, D.; Wang, L.; Nan, H.; Cao, Y.; Wang, H.; Kumar, T.V.; Wang, C. Phosphorus adsorption by functionalized biochar: A review. Environ. Chem. Lett. 2023, 21, 497–524. [Google Scholar] [CrossRef]

- Hoang, A.T.; Goldfarb, J.L.; Foley, A.M.; Lichtfouse, E.; Kumar, M.; Xiao, L.; Ahmed, S.F.; Said, Z.; Luque, R.; Bui, V.G. Production of biochar from crop residues and its application for anaerobic digestion. Bioresour. Technol. 2022, 363, 127970. [Google Scholar] [CrossRef]

- Taslakyan, L.; Baker, M.C.; Strawn, D.G.; Möller, G. Biochar-integrated reactive filtration of wastewater for P removal and recovery, micropollutant catalytic oxidation, and negative CO2e: Life cycle assessment and techno-economic analysis. Water Environ. Res. 2023, 95, e10962. [Google Scholar] [CrossRef]

- Phillips, C.L.; Meyer, K.M.; Garcia-Jaramillo, M.; Weidman, C.S.; Stewart, C.E.; Wanzek, T.; Grusak, M.A.; Watts, D.W.; Novak, J.; Trippe, K.M. Towards predicting biochar impacts on plant-available soil nitrogen content. Biochar 2022, 4, 9. [Google Scholar] [CrossRef]

- Guo, X.-X.; Liu, H.-T.; Zhang, J. The role of biochar in organic waste composting and soil improvement: A review. Waste Manag. 2020, 102, 884–899. [Google Scholar] [CrossRef]

- Mašek, O.; Buss, W.; Brownsort, P.; Rovere, M.; Tagliaferro, A.; Zhao, L.; Cao, X.; Xu, G. Potassium doping increases biochar carbon sequestration potential by 45%, facilitating decoupling of carbon sequestration from soil improvement. Sci. Rep. 2019, 9, 5514. [Google Scholar] [CrossRef]

- Alkharabsheh, H.M.; Seleiman, M.F.; Battaglia, M.L.; Shami, A.; Jalal, R.S.; Alhammad, B.A.; Almutairi, K.F.; Al-Saif, A.M. Biochar and its broad impacts in soil quality and fertility, nutrient leaching and crop productivity: A review. Agronomy 2021, 11, 993. [Google Scholar] [CrossRef]

- Singh, H.; Northup, B.K.; Rice, C.W.; Prasad, P.V. Biochar applications influence soil physical and chemical properties, microbial diversity, and crop productivity: A meta-analysis. Biochar 2022, 4, 8. [Google Scholar] [CrossRef]

- Windeatt, J.H.; Ross, A.B.; Williams, P.T.; Forster, P.M.; Nahil, M.A.; Singh, S. Characteristics of biochars from crop residues: Potential for carbon sequestration and soil amendment. J. Environ. Manag. 2014, 146, 189–197. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Guo, Z.; Hu, Z.; Zhang, J. Recent advances in biochar application for water and wastewater treatment: A review. PeerJ 2020, 8, e9164. [Google Scholar] [CrossRef]

- Nematian, M.; Keske, C.; Ng’ombe, J.N. A techno-economic analysis of biochar production and the bioeconomy for orchard biomass. Waste Manag. 2021, 135, 467–477. [Google Scholar] [CrossRef] [PubMed]

- Cheng, D.; Ngo, H.H.; Guo, W.; Pandey, A.; Varjani, S. Chapter 13—Sustainable production and applications of biochar in circular bioeconomy. In Biomass, Biofuels, Biochemicals; Varjani, S., Pandey, A., Bhaskar, T., Mohan, S.V., Tsang, D.C.W., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 337–361. [Google Scholar]

- Li, X.; Wang, C.; Zhang, J.; Liu, J.; Liu, B.; Chen, G. Preparation and application of magnetic biochar in water treatment: A critical review. Sci. Total Environ. 2020, 711, 134847. [Google Scholar] [CrossRef]

- Kamali, M.; Appels, L.; Kwon, E.E.; Aminabhavi, T.M.; Dewil, R. Biochar in water and wastewater treatment-a sustainability assessment. Chem. Eng. J. 2021, 420, 129946. [Google Scholar] [CrossRef]

- Fang, Z.; Liu, F.; Li, Y.; Li, B.; Yang, T.; Li, R. Influence of microwave-assisted pyrolysis parameters and additives on phosphorus speciation and transformation in phosphorus-enriched biochar derived from municipal sewage sludge. J. Clean. Prod. 2021, 287, 125550. [Google Scholar] [CrossRef]

- Ghodszad, L.; Reyhanitabar, A.; Maghsoodi, M.R.; Lajayer, B.A.; Chang, S.X. Biochar affects the fate of phosphorus in soil and water: A critical review. Chemosphere 2021, 283, 131176. [Google Scholar] [CrossRef] [PubMed]

- Ghezzehei, T.A.; Sarkhot, D.V.; Berhe, A.A. Biochar can be used to capture essential nutrients from dairy wastewater and improve soil physico-chemical properties. Solid Earth 2014, 5, 953–962. [Google Scholar] [CrossRef]

- Schmidt, H.-P.; Pandit, B.H.; Cornelissen, G.; Kammann, C.I. Biochar-Based Fertilization with Liquid Nutrient Enrichment: 21 Field Trials Covering 13 Crop Species in Nepal. Land Degrad. Dev. 2017, 28, 2324–2342. [Google Scholar] [CrossRef]

- Dai, Y.H.; Zheng, H.; Jiang, Z.X.; Xing, B.S. Combined effects of biochar properties and soil conditions on plant growth: A meta-analysis. Sci. Total Environ. 2020, 713, 136635. [Google Scholar] [CrossRef] [PubMed]

- Niraula, S.; Choi, Y.-K.; Payne, K.; Muir, J.P.; Kan, E.; Chang, W.-S. Dairy Effluent-Saturated Biochar Alters Microbial Communities and Enhances Bermudagrass Growth and Soil Fertility. Agronomy 2021, 11, 1794. [Google Scholar] [CrossRef]

- Bakshi, S.; Fidel, R.; Banik, C.; Aller, D.; Brown, R.C. 7—Retention of oxyanions on biochar surface. In Sustainable Biochar for Water and Wastewater Treatment; Mohan, D., Pittman, C.U., Mlsna, T.E., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 233–276. [Google Scholar]

- Wu, L.; Zhang, S.; Wang, J.; Ding, X. Phosphorus retention using iron (II/III) modified biochar in saline-alkaline soils: Adsorption, column and field tests. Environ. Pollut. 2020, 261, 114223. [Google Scholar] [CrossRef]

- Liu, F.; Zuo, J.; Chi, T.; Wang, P.; Yang, B. Removing phosphorus from aqueous solutions by using iron-modified corn straw biochar. Front. Environ. Sci. Eng. 2015, 9, 1066–1075. [Google Scholar] [CrossRef]

- Diatta, A.A.; Fike, J.H.; Battaglia, M.L.; Galbraith, J.M.; Baig, M.B. Effects of biochar on soil fertility and crop productivity in arid regions: A review. Arab. J. Geosci. 2020, 13, 595. [Google Scholar] [CrossRef]

- Pathy, A.; Ray, J.; Paramasivan, B. Biochar amendments and its impact on soil biota for sustainable agriculture. Biochar 2020, 2, 287–305. [Google Scholar] [CrossRef]

- Puga, A.P.; Grutzmacher, P.; Cerri, C.E.P.; Ribeirinho, V.S.; de Andrade, C.A. Biochar-based nitrogen fertilizers: Greenhouse gas emissions, use efficiency, and maize yield in tropical soils. Sci. Total Environ. 2020, 704, 135375. [Google Scholar] [CrossRef]

- Li, H.; Li, Y.; Xu, Y.; Lu, X. Biochar phosphorus fertilizer effects on soil phosphorus availability. Chemosphere 2020, 244, 125471. [Google Scholar] [CrossRef]

- Melo, L.C.A.; Lehmann, J.; Carneiro, J.S.D.; Camps-Arbestain, M. Biochar-based fertilizer effects on crop productivity: A meta-analysis. Plant Soil 2022, 472, 45–58. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Wang, Y.C.; Ni, J.J.; So, P.S. Effects of phosphorus-modified biochar as a soil amendment on the growth and quality of Pseudostellaria heterophylla. Sci. Rep. 2022, 12, 7268. [Google Scholar] [CrossRef] [PubMed]

- Baker, M.C.; McCarthy, D.; Taslakyan, L.; Henchion, G.; Mannion, R.; Strawn, D.G.; Möller, G. Iron–ozone catalytic oxidation reactive filtration of municipal wastewater at field pilot and full-scale with high-efficiency pollutant removal and potential negative CO2e with biochar. Water Environ. Res. 2023, 95, e10876. [Google Scholar] [CrossRef]

- Cantinho, P.; Matos, M.; Trancoso, M.A.; dos Santos, M.M.C. Behaviour and fate of metals in urban wastewater treatment plants: A review. Int. J. Environ. Sci. Technol. 2016, 13, 359–386. [Google Scholar] [CrossRef]

- Golovko, O.; Örn, S.; Sörengård, M.; Frieberg, K.; Nassazzi, W.; Lai, F.Y.; Ahrens, L. Occurrence and removal of chemicals of emerging concern in wastewater treatment plants and their impact on receiving water systems. Sci. Total Environ. 2021, 754, 142122. [Google Scholar] [CrossRef]

- Singh, B.; Camps-Arbestain, M.; Lehmann, J.; CSIRO (Australia). Biochar: A Guide to Analytical Methods; CSIRO Publishing: Clayton, Victoria, Australia, 2017; p. ix. 310p. [Google Scholar]

- Krounbi, L.; Enders, A.; Gaunt, J.; Ball, M.; Lehmann, J. Plant uptake of nitrogen adsorbed to biochars made from dairy manure. Sci. Rep. 2021, 11, 15001. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Camps-Arbestain, M.; Hedley, M.; Bishop, P. Predicting phosphorus bioavailability from high-ash biochars. Plant Soil 2012, 357, 173–187. [Google Scholar] [CrossRef]

- Hong, J.; Xu, F.; Chen, G.; Huang, X.; Wang, S.; Du, L.; Ding, G. Evaluation of the Effects of Nitrogen, Phosphorus, and Potassium Applications on the Growth, Yield, and Quality of Lettuce (Lactuca sativa L.). Agronomy 2022, 12, 2477. [Google Scholar] [CrossRef]

- Schoenau, J.; Karamanos, R. Sodium bicarbonate extractable P, K, and N. Soil Sampling Methods of Analysis; Carter, M.R., Ed.; Canadian Society of Soil Science: Ottawa, ON, Canada, 1993; pp. 51–58. [Google Scholar]

- Reeuwijk, L.P.V.; International Soil, R.; Information, C. Procedures for Soil Analysis, 5th ed.; International Soil Reference and Information Centre: Wageningen, The Netherlands, 1995. [Google Scholar]

- Olsen, S.R.; Sommers, L.E. Phosphorus. Methods of Soil Analysis. Part 2: Chemical and Microbiological Properties; Page, A.L., Miller, R.H., Keeney, D.R., Eds.; American Society of Agronomy: Madison, WI, USA, 1982; pp. 403–427. [Google Scholar]

- Woodman, R.M. Studies in the nutrition of vegetables—Phosphate deficiency and yield tests on sand cultures of may king lettuce. J. Agric. Sci. 1939, 29, 229–248. [Google Scholar] [CrossRef]

- Mahmoud, E.; El-Beshbeshy, T.; El-Kader, N.A.; El Shal, R.; Khalafallah, N. Impacts of biochar application on soil fertility, plant nutrients uptake and maize (Zea mays L.) yield in saline sodic soil. Arab. J. Geosci. 2019, 12, 719. [Google Scholar] [CrossRef]

- Bai, S.H.; Omidvar, N.; Gallart, M.; Kämper, W.; Tahmasbian, I.; Farrar, M.B.; Singh, K.; Zhou, G.; Muqadass, B.; Xu, C.-Y. Combined effects of biochar and fertilizer applications on yield: A review and meta-analysis. Sci. Total Environ. 2022, 808, 152073. [Google Scholar] [CrossRef]

- Fortune, S.; Lu, J.; Addiscott, T.M.; Brookes, P.C. Assessment of phosphorus leaching losses from arable land. Plant Soil 2005, 269, 99–108. [Google Scholar] [CrossRef]

- Andersen, H.E.; Windolf, J.; Kronvang, B. Leaching of dissolved phosphorus from tile-drained agricultural areas. Water Sci. Technol. 2016, 73, 2953–2958. [Google Scholar] [CrossRef]

- Wuenscher, R.; Unterfrauner, H.; Peticzka, R.; Zehetner, F. A comparison of 14 soil phosphorus extraction methods applied to 50 agricultural soils from Central Europe. Plant Soil Environ. 2015, 61, 86–96. [Google Scholar] [CrossRef]

- Hartmann, T.E.; Wollmann, I.; You, Y.; Müller, T. Sensitivity of Three Phosphate Extraction Methods to the Application of Phosphate Species Differing in Immediate Plant Availability. Agronomy 2019, 9, 29. [Google Scholar] [CrossRef]

- Wang, C.; Luo, D.; Zhang, X.; Huang, R.; Cao, Y.; Liu, G.; Zhang, Y.; Wang, H. Biochar-based slow-release of fertilizers for sustainable agriculture: A mini review. Environ. Sci. Ecotechnol. 2022, 10, 100167. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.s.; Liu, T.; Dong, J.f.; Chen, G.; Li, Z.; Zhou, J.l.; Chen, Z. Sustainable Application for Agriculture Using Biochar-Based Slow-Release Fertilizers: A Review. ACS Sustain. Chem. Eng. 2023, 11, 1–12. [Google Scholar] [CrossRef]

- Marcińczyk, M.; Oleszczuk, P. Biochar and engineered biochar as slow- and controlled-release fertilizers. J. Clean. Prod. 2022, 339, 130685. [Google Scholar] [CrossRef]

- Bakshi, S.; Laird, D.A.; Smith, R.G.; Brown, R.C. Capture and Release of Orthophosphate by Fe-Modified Biochars: Mechanisms and Environmental Applications. ACS Sustain. Chem. Eng. 2021, 9, 658–668. [Google Scholar] [CrossRef]

- Micháleková-Richveisová, B.; Frišták, V.; Pipíška, M.; Ďuriška, L.; Moreno-Jimenez, E.; Soja, G. Iron-impregnated biochars as effective phosphate sorption materials. Environ. Sci. Pollut. Res. 2017, 24, 463–475. [Google Scholar] [CrossRef]

- Shaviv, A. Advances in controlled-release fertilizers. In Advances in Agronomy; Academic Press: New York, NY, USA, 2001; Volume 71, pp. 1–49. [Google Scholar]

- Sim, D.H.H.; Tan, I.A.W.; Lim, L.L.P.; Hameed, B.H. Encapsulated biochar-based sustained release fertilizer for precision agriculture: A review. J. Clean. Prod. 2021, 303, 127018. [Google Scholar] [CrossRef]

- Ye, L.; Camps-Arbestain, M.; Shen, Q.; Lehmann, J.; Singh, B.; Sabir, M. Biochar effects on crop yields with and without fertilizer: A meta-analysis of field studies using separate controls. Soil Use Manag. 2020, 36, 2–18. [Google Scholar] [CrossRef]

- An, N.; Zhang, L.; Liu, Y.; Shen, S.; Li, N.; Wu, Z.; Yang, J.; Han, W.; Han, X. Biochar application with reduced chemical fertilizers improves soil pore structure and rice productivity. Chemosphere 2022, 298, 134304. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).