Thermochemical Conversion of Sugarcane Bagasse: A Comprehensive Analysis of Ignition and Burnout Temperatures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

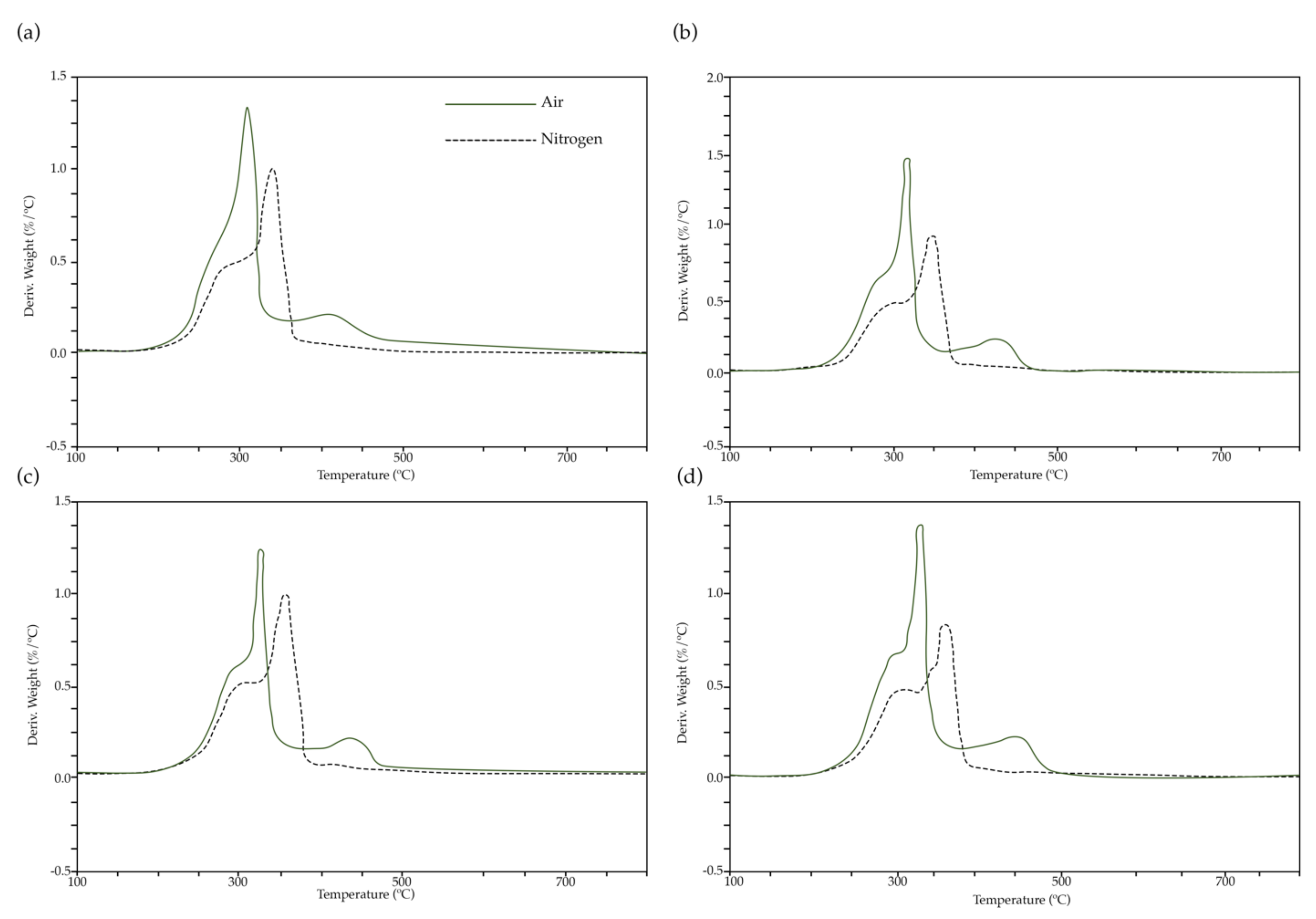

2.2. Thermogravimetric Analysis

2.3. Ignition and Burnout Temperatures

2.3.1. Intersection Method

2.3.2. Deviation Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yadav, S.; Jackson, P.; Wei, X.; Ross, E.M.; Aitken, K.; Deomano, E.; Atkin, F.; Hayes, B.J.; Voss-Fels, K.P. Accelerating genetic gain in sugarcane breeding using genomic selection. Agronomy 2020, 10, 585. [Google Scholar] [CrossRef] [Green Version]

- Lim, H.Y.; Yusup, S.; Loy, A.C.M.; Samsuri, S.; Ho, S.S.K.; Manaf, A.S.A.; Lam, S.S.; Chin, B.L.F.; Acda, M.N.; Unrean, P. Review on conversion of lignin waste into value-added resources in tropical countries. Waste Biomass Valorization 2021, 12, 5285–5302. [Google Scholar] [CrossRef]

- Holkar, S.K.; Balasubramaniam, P.; Kumar, A.; Kadirvel, N.; Shingote, P.R.; Chhabra, M.L.; Kumar, S.; Kumar, P.; Viswanathan, R.; Jain, R.K. Present status and future management strategies for Sugarcane yellow leaf virus: A major constraint to the global sugarcane production. Plant Pathol. J. 2020, 36, 536. [Google Scholar] [CrossRef] [PubMed]

- Eggleston, G. Positive aspects of cane sugar and sugar cane derived products in food and nutrition. J. Agric. Food Chem. 2018, 66, 4007–4012. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, S. Diversification of Sugar and Sugarcane Industry: Agro-industrial Alternatives. In Sugar and Sugar Derivatives: Changing Consumer Preferences; Springer: Berlin/Heidelberg, Germany, 2020; pp. 151–169. [Google Scholar]

- Neto, J.V.S.; Gallo, W.L. Potential impacts of vinasse biogas replacing fossil oil for power generation, natural gas, and increasing sugarcane energy in Brazil. Renew. Sustain. Energy Rev. 2021, 135, 110281. [Google Scholar]

- Prasad, S.; Yadav, A.N.; Singh, A. Impact of climate change on sustainable biofuel production. In Biofuels Production–Sustainability and Advances in Microbial Bioresources; Springer: Berlin/Heidelberg, Germany, 2020; pp. 79–97. [Google Scholar]

- Khan, M.A.H.; Bonifacio, S.; Clowes, J.; Foulds, A.; Holland, R.; Matthews, J.C.; Percival, C.J.; Shallcross, D.E. Investigation of Biofuel as a Potential Renewable Energy Source. Atmosphere 2021, 12, 1289. [Google Scholar] [CrossRef]

- Mizik, T. Economic Aspects and Sustainability of Ethanol Production—A Systematic Literature Review. Energies 2021, 14, 6137. [Google Scholar] [CrossRef]

- García-Lara, S.; Serna-Saldivar, S.O. Corn history and culture. In Corn; Elsevier: Amesterdam, The Netherlands, 2019; pp. 1–18. [Google Scholar]

- Nunes, L.J.; Loureiro, L.M.; Sá, L.C.; Silva, H.F. Sugarcane industry waste recovery: A case study using thermochemical conversion technologies to increase sustainability. Appl. Sci. 2020, 10, 6481. [Google Scholar] [CrossRef]

- Gavahian, M.; Munekata, P.E.; Eş, I.; Lorenzo, J.M.; Khaneghah, A.M.; Barba, F.J. Emerging techniques in bioethanol production: From distillation to waste valorization. Green Chem. 2019, 21, 1171–1185. [Google Scholar] [CrossRef]

- Ayodele, B.V.; Alsaffar, M.A.; Mustapa, S.I. An overview of integration opportunities for sustainable bioethanol production from first-and second-generation sugar-based feedstocks. J. Clean. Prod. 2020, 245, 118857. [Google Scholar] [CrossRef]

- Zetty-Arenas, A.M.; Alves, R.F.; Portela, C.A.F.; Mariano, A.P.; Basso, T.O.; Tovar, L.P.; Maciel Filho, R.; Freitas, S. Towards enhanced n-butanol production from sugarcane bagasse hemicellulosic hydrolysate: Strain screening, and the effects of sugar concentration and butanol tolerance. Biomass Bioenergy 2019, 126, 190–198. [Google Scholar] [CrossRef]

- Vieira, S.; Barros, M.V.; Sydney, A.C.N.; Piekarski, C.M.; de Francisco, A.C.; de Souza Vandenberghe, L.P.; Sydney, E.B. Sustainability of sugarcane lignocellulosic biomass pretreatment for the production of bioethanol. Bioresour. Technol. 2020, 299, 122635. [Google Scholar] [CrossRef]

- Bizzo, W.A.; Lenço, P.C.; Carvalho, D.J.; Veiga, J.P.S. The generation of residual biomass during the production of bio-ethanol from sugarcane, its characterization and its use in energy production. Renew. Sustain. Energy Rev. 2014, 29, 589–603. [Google Scholar] [CrossRef]

- Hofsetz, K.; Silva, M.A. Brazilian sugarcane bagasse: Energy and non-energy consumption. Biomass Bioenergy 2012, 46, 564–573. [Google Scholar] [CrossRef]

- De Matos, M.; Santos, F.; Eichler, P. Sugarcane world scenario. In Sugarcane Biorefinery, Technology and Perspectives; Elsevier: Berlin/Heidelberg, Germany, 2020; pp. 1–19. [Google Scholar]

- Souza, M.A.T.d.; Rubin, J.C.R.d. Entangled Relations: The Expansion of a Colonial Frontier in Central Brazil During the Eighteenth Century. In Historical Archaeology and Environment; Springer: Berlin/Heidelberg, Germany, 2018; pp. 155–179. [Google Scholar]

- Lu, J.-J.; Chen, W.-H. Investigation on the ignition and burnout temperatures of bamboo and sugarcane bagasse by thermogravimetric analysis. Appl. Energy 2015, 160, 49–57. [Google Scholar] [CrossRef]

- Santos, V.; Ely, R.; Szklo, A.; Magrini, A. Chemicals, electricity and fuels from biorefineries processing Brazil׳ s sugarcane bagasse: Production recipes and minimum selling prices. Renew. Sustain. Energy Rev. 2016, 53, 1443–1458. [Google Scholar] [CrossRef]

- Duque, A.; Álvarez, C.; Doménech, P.; Manzanares, P.; Moreno, A.D. Advanced bioethanol production: From novel raw materials to integrated biorefineries. Processes 2021, 9, 206. [Google Scholar] [CrossRef]

- Ajewole, O.; Larwanou, M. Bioenergy production and land use changes in the context of the food-fuel-fibre nexus and climate change in West Africa. Int. For. Rev. 2019, 21, 75–86. [Google Scholar] [CrossRef]

- Lourenço, R.V.; Kobelnik, M.; Ribeiro, C.A.; Fernonani, F.L. Thermal behavior of residues (sludge) originating from the sugarcane industry. J. Therm. Anal. Calorim. 2011, 106, 735–740. [Google Scholar] [CrossRef]

- Lee, H.; Hamid, S.B.A.; Zain, S. Conversion of lignocellulosic biomass to nanocellulose: Structure and chemical process. Sci. World J. 2014, 2014, 631013. [Google Scholar] [CrossRef] [Green Version]

- Maia, A.A.D.; de Morais, L.C. Kinetic parameters of red pepper waste as biomass to solid biofuel. Bioresour. Technol. 2016, 204, 157–163. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Lv, Y.; Ma, B.; Jian, S.; Tan, H. Thermogravimetric investigation on co-combustion characteristics of tobacco residue and high-ash anthracite coal. Bioresour. Technol. 2011, 102, 9783–9787. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Quek, A.; Hoekman, S.K.; Srinivasan, M.; Balasubramanian, R. Thermogravimetric investigation of hydrochar-lignite co-combustion (vol 123, pg 646, 2012). Bioresour. Technol. 2013, 133, 639–640. [Google Scholar] [CrossRef]

- Essenhigh, R.H.; Misra, M.K.; Shaw, D.W. Ignition of coal particles: A review. Combust. Flame 1989, 77, 3–30. [Google Scholar] [CrossRef]

- Chen, Y.; Mori, S.; Pan, W.-P. Studying the mechanisms of ignition of coal particles by TG-DTA. Thermochim. Acta 1996, 275, 149–158. [Google Scholar] [CrossRef]

- Luo, S.; Xiao, B.; Hu, Z.; Liu, S.; Guan, Y. Experimental study on oxygen-enriched combustion of biomass micro fuel. Energy 2009, 34, 1880–1884. [Google Scholar] [CrossRef]

- Jiang, T.L.; Chen, W.S.; Tsai, M.J.; Chiu, H.H. A numerical investigation of multiple flame configurations in convective droplet gasification. Combust. Flame 1995, 103, 221–238. [Google Scholar] [CrossRef]

- Jones, J.; Saddawi, A.; Dooley, B.; Mitchell, E.; Werner, J.; Waldron, D.; Weatherstone, S.; Williams, A. Low temperature ignition of biomass. Fuel Process. Technol. 2015, 134, 372–377. [Google Scholar] [CrossRef] [Green Version]

- Schwarzer, L.; Sárossy, Z.; Jensen, P.A.; Glarborg, P.; Karlström, O.; Holm, J.K.; Dam-Johansen, K. Kinetic parameters for biomass under self-ignition conditions: Low-temperature oxidation and pyrolysis. Energy Fuels 2019, 33, 8606–8619. [Google Scholar] [CrossRef]

- Castells, B.; Amez, I.; Medic, L.; Fernandez-Anez, N.; Garcia-Torrent, J. Study of lignocellulosic biomass ignition properties estimation from thermogravimetric analysis. J. Loss Prev. Process Ind. 2021, 71, 104425. [Google Scholar] [CrossRef]

- Restuccia, F.; Fernandez-Anez, N.; Rein, G. Experimental measurement of particle size effects on the self-heating ignition of biomass piles: Homogeneous samples of dust and pellets. Fuel 2019, 256, 115838. [Google Scholar] [CrossRef]

- Liu, M.; Zhu, X.; Chen, R.; Liao, Q.; Xia, A.; Huang, Y. Influence of torrefaction, hydrothermal carbonization and degradative solvent extraction pretreatments on moisture absorption and self-ignition characteristics of biomass. Fuel 2020, 282, 118843. [Google Scholar] [CrossRef]

- Zhou, S.; Su, H.; Wu, Z.; Zhu, X.; Yan, B.; Chen, G. Numerical study on self-ignition temperature of biomass gasified gas for the application of MILD combustion. Fuel Process. Technol. 2022, 236, 107417. [Google Scholar] [CrossRef]

- Restuccia, F.; Mašek, O.; Hadden, R.M.; Rein, G. Quantifying self-heating ignition of biochar as a function of feedstock and the pyrolysis reactor temperature. Fuel 2019, 236, 201–213. [Google Scholar] [CrossRef]

- Liu, L.; Pang, Y.; Lv, D.; Wang, K.; Wang, Y. Thermal and kinetic analyzing of pyrolysis and combustion of self-heating biomass particles. Process Saf. Environ. Prot. 2021, 151, 39–50. [Google Scholar] [CrossRef]

- Nunes, L.J. A case study about biomass torrefaction on an industrial scale: Solutions to problems related to self-heating, difficulties in pelletizing, and excessive wear of production equipment. Appl. Sci. 2020, 10, 2546. [Google Scholar] [CrossRef] [Green Version]

- Lester, E.; Avila, C.; Pang, C.H.; Williams, O.; Perkins, J.; Gaddipatti, S.; Tucker, G.; Barraza, J.M.; Trujillo-Uribe, M.P.; Wu, T. A proposed biomass char classification system. Fuel 2018, 232, 845–854. [Google Scholar] [CrossRef]

- Yao, Y.; Panahi, A.; Schiemann, M.; Levendis, Y.A. Determination of size and porosity of chars during combustion of biomass particles. Combust. Flame 2022, 242, 112182. [Google Scholar] [CrossRef]

- Budzeń, M.; Zając, G.; Sujak, A.; Szyszlak-Bargłowicz, J. Energetic and thermal characteristics of Lavatera thuringiaca L. biomass of different age produced from He–Ne laser light stimulated seeds. Renew. Energy 2021, 178, 520–531. [Google Scholar] [CrossRef]

- Liu, Y.; Shen, Y. Modelling and optimisation of biomass injection in ironmaking blast furnaces. Prog. Energy Combust. Sci. 2021, 87, 100952. [Google Scholar] [CrossRef]

- Reinmöller, M.; Sieradzka, M.; Laabs, M.; Schreiner, M.; Mlonka-Mędrala, A.; Kopia, A.; Meyer, B.; Magdziarz, A. Investigation of the thermal behaviour of different biomasses and properties of their low-and high-temperature ashes. Fuel 2021, 301, 121026. [Google Scholar] [CrossRef]

- Kumar, P.; Subbarao, P.; Kala, L.; Vijay, V. Thermogravimetric Devolatilization Behavior of Agricultural Residue for Generation of Syngas. J. Energy Resour. Technol. 2021, 143, 112106. [Google Scholar] [CrossRef]

- Varol, M.; Atimtay, A.; Bay, B.; Olgun, H. Investigation of co-combustion characteristics of low quality lignite coals and biomass with thermogravimetric analysis. Thermochim. Acta 2010, 510, 195–201. [Google Scholar] [CrossRef]

- Yorulmaz, S.Y.; Atimtay, A.T. Investigation of combustion kinetics of treated and untreated waste wood samples with thermogravimetric analysis. Fuel Process. Technol. 2009, 90, 939–946. [Google Scholar] [CrossRef]

| Material | Heating Rate (°C·min−1) | |||

|---|---|---|---|---|

| 5 | 7.5 | 10 | 15 | |

| Bagasse | Temperature (°C) | |||

| DTG peak | 346.82 | 347.40 | 353.49 | 358.79 |

| Intensity (%·min−1—%·°C−1) | ||||

| DTG peak | 5.13–0.99 | 7.15–0.94 | 9.95–0.98 | 12.41–0.82 |

| Material | Heating Rate (°C·min−1) | |||

|---|---|---|---|---|

| 5 | 7.5 | 10 | 15 | |

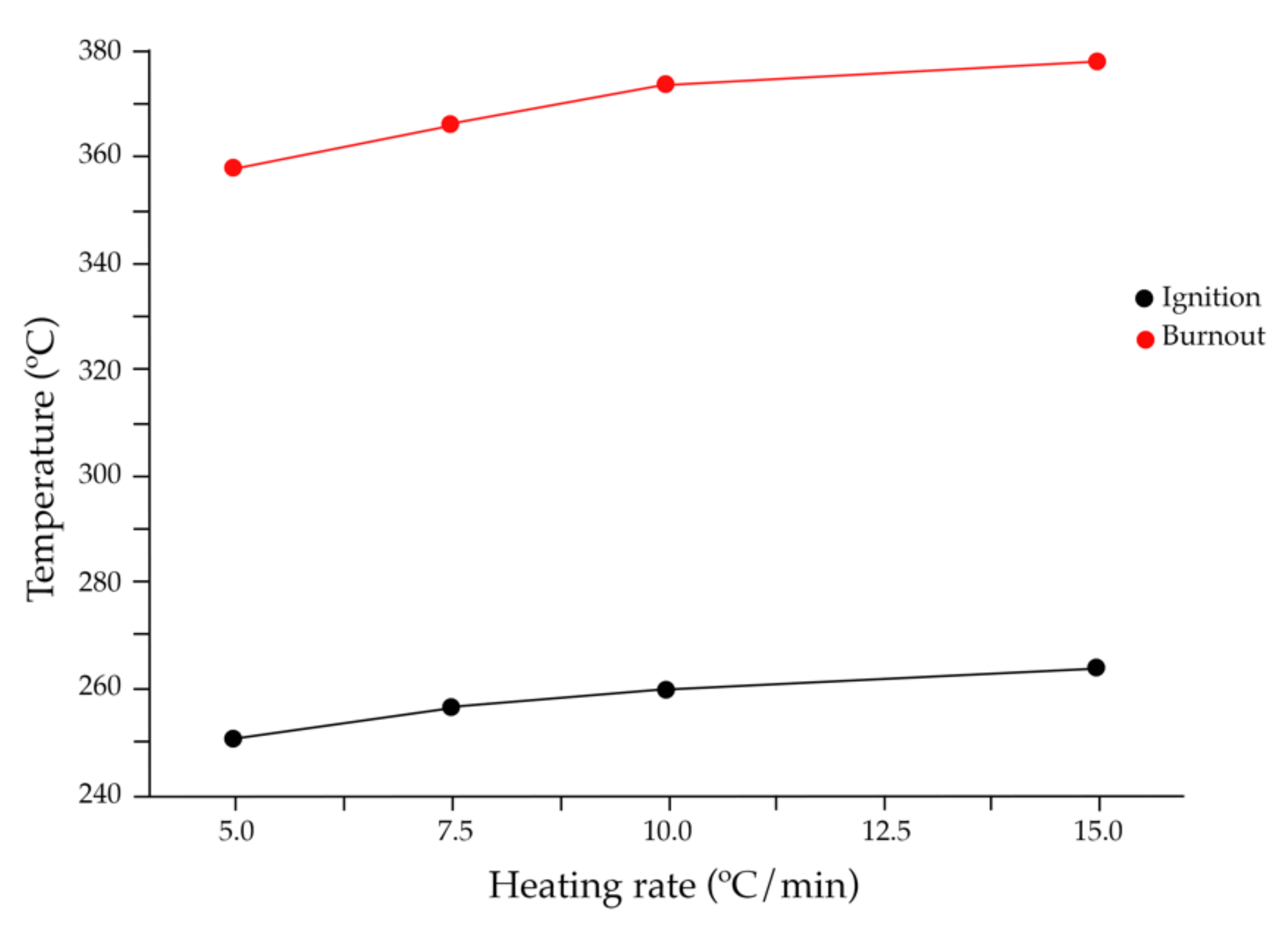

| Bagasse | Ignition temperature—Ti (°C) | |||

| IMa | 250.50 | 256.45 | 259.54 | 263.73 |

| DMb | 205.52 | 227.64 | 234.03 | 236.16 |

| Burnout temperature—Tf (°C) | ||||

| IM | 357.69 | 366.29 | 373.57 | 377.89 |

| Sugarcane Bagasse | Combustion Parameters | Ignition Characteristics | Burnout Characteristics | |||||

|---|---|---|---|---|---|---|---|---|

| Heating Rate (°C·min−1) | DTGmax (%·min−1) | tp (min) | ti (min) | tf (min) | Ti (°C) | Di | Tf (°C) | Df |

| 5 | 5.10 | 65 | 45 | 68 | 250.50 | 1.74 × 10−3 | 357.69 | 1.56 × 10−5 |

| 7.5 | 7.05 | 44 | 32 | 47 | 256.45 | 5.01 × 10−3 | 366.29 | 7.03 × 10−5 |

| 10 | 9.93 | 33 | 23 | 35 | 259.54 | 1.31 × 10−2 | 373.57 | 2.15 × 10−4 |

| 15 | 12.41 | 23 | 17 | 25 | 263.73 | 3.17 × 10−2 | 377.89 | 1.19 × 10−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morais, L.C.d.; Maia, A.A.; Resende, P.R.; Rosa, A.H.; Nunes, L.J.R. Thermochemical Conversion of Sugarcane Bagasse: A Comprehensive Analysis of Ignition and Burnout Temperatures. Clean Technol. 2022, 4, 1127-1137. https://doi.org/10.3390/cleantechnol4040068

Morais LCd, Maia AA, Resende PR, Rosa AH, Nunes LJR. Thermochemical Conversion of Sugarcane Bagasse: A Comprehensive Analysis of Ignition and Burnout Temperatures. Clean Technologies. 2022; 4(4):1127-1137. https://doi.org/10.3390/cleantechnol4040068

Chicago/Turabian StyleMorais, Leandro C. de, Amanda A. Maia, Pedro R. Resende, André H. Rosa, and Leonel J. R. Nunes. 2022. "Thermochemical Conversion of Sugarcane Bagasse: A Comprehensive Analysis of Ignition and Burnout Temperatures" Clean Technologies 4, no. 4: 1127-1137. https://doi.org/10.3390/cleantechnol4040068

APA StyleMorais, L. C. d., Maia, A. A., Resende, P. R., Rosa, A. H., & Nunes, L. J. R. (2022). Thermochemical Conversion of Sugarcane Bagasse: A Comprehensive Analysis of Ignition and Burnout Temperatures. Clean Technologies, 4(4), 1127-1137. https://doi.org/10.3390/cleantechnol4040068