Wind–PV–Battery Hybrid Off-Grid System: Control Design and Real-Time Testing

Abstract

:1. Introduction

- (1)

- (2)

- Achieving the desired efficiency at high irradiances and wind speed levels without using any weather data or MPPT techniques;

- (3)

- Achieving high performance from the battery and extending their lifespan;

- (4)

- A hybrid off-grid power distribution system with a multitasking control strategy for a two-switch buck–boost converter to perform well and balance the power by only controlling the DC link voltage and ESS current;

- (5)

- An optimized cascade control strategy based on LADRC controllers to achieve high performance under noise and disturbance conditions;

- (6)

- Design of the LADRC controller and optimizing its parameters.

2. System Description and Operation

3. Control and Parameters Design for the Hybrid Off-Grid Configuration

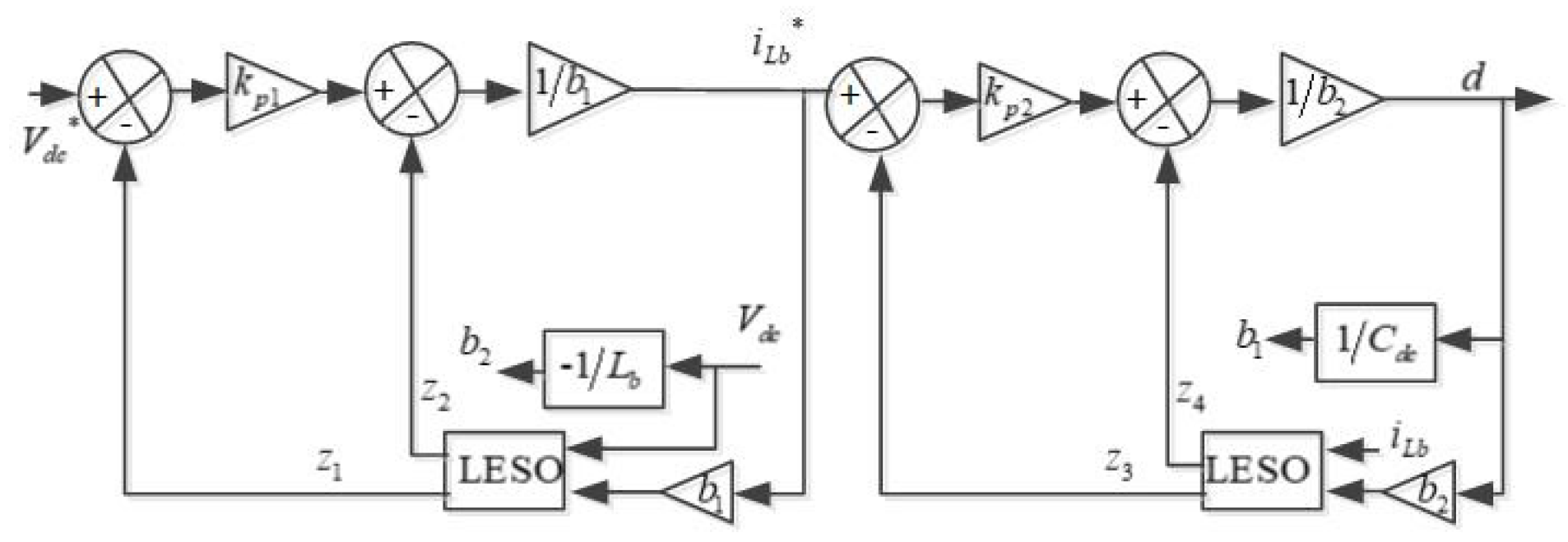

3.1. Control of Buck–Boost Converter

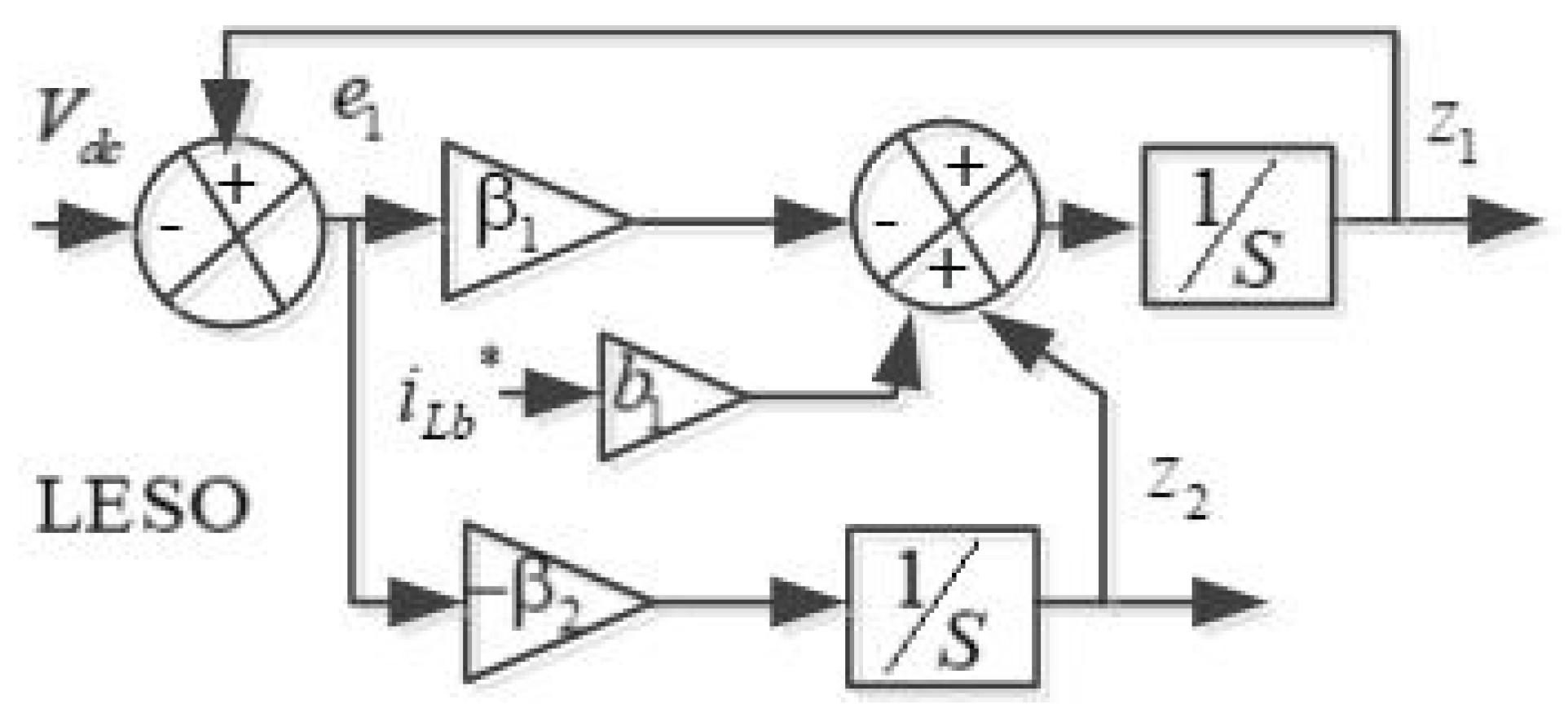

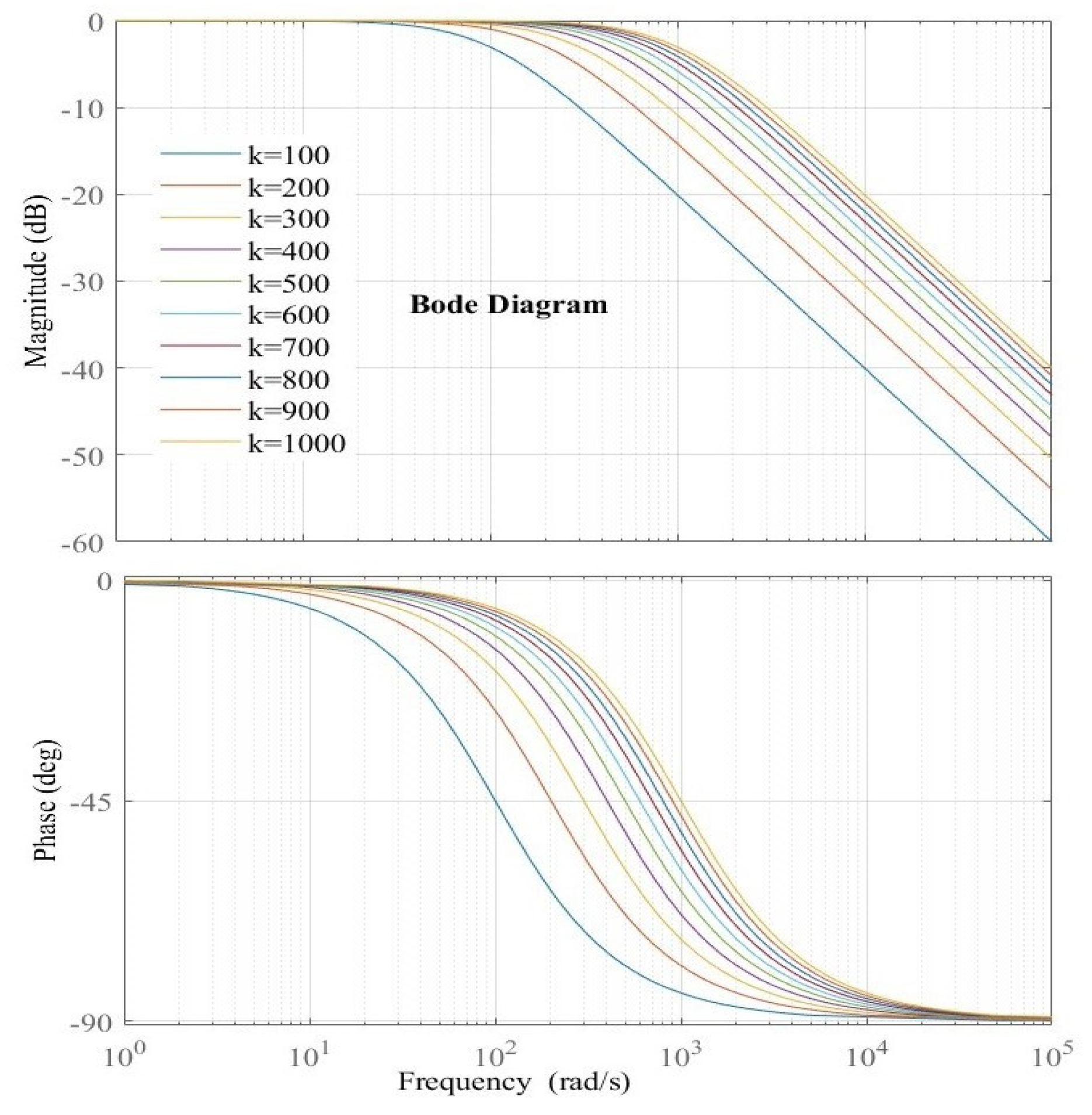

3.2. Design Parameters for LADRC and LESO

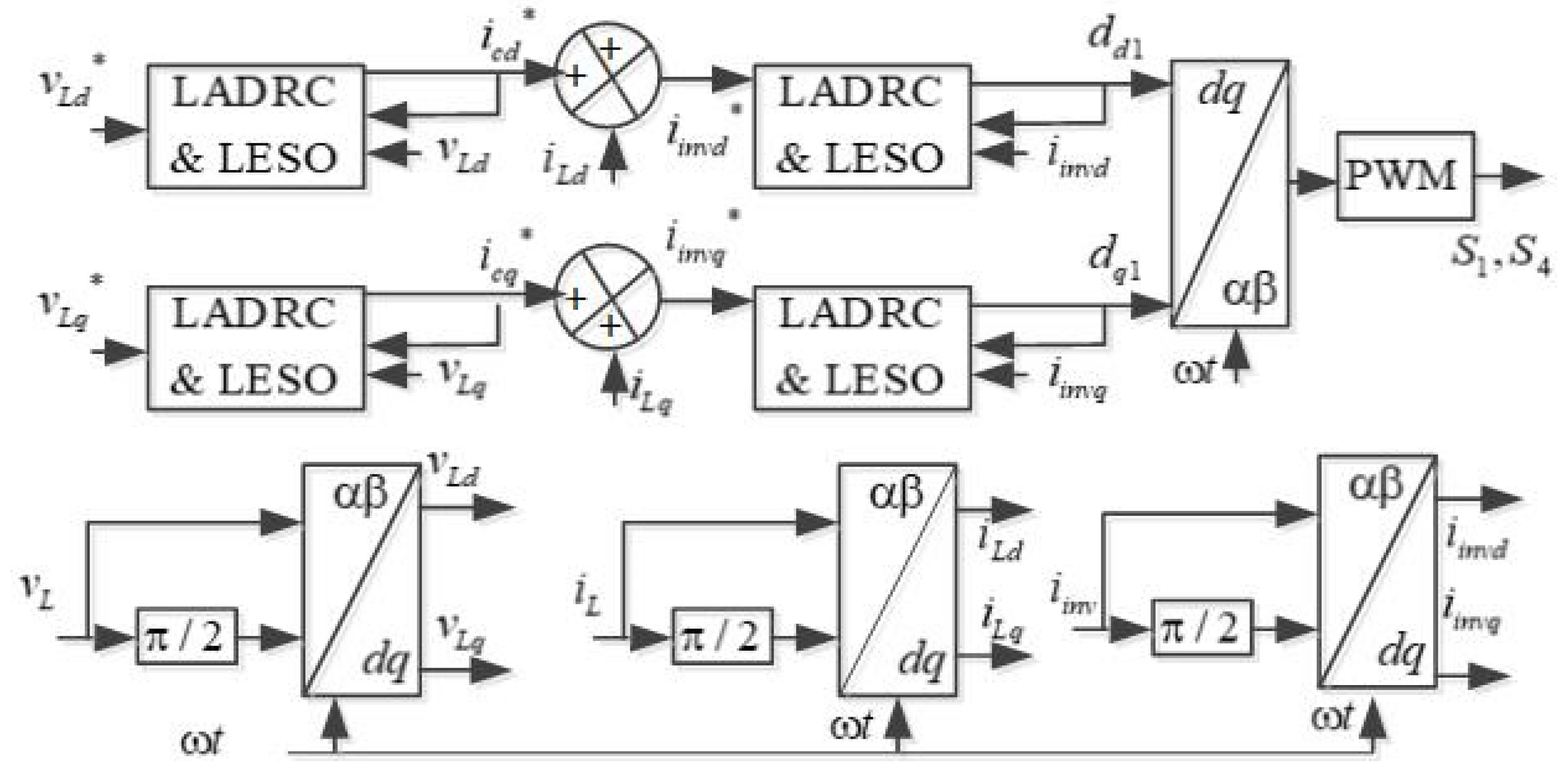

3.3. Control of the FBSPI

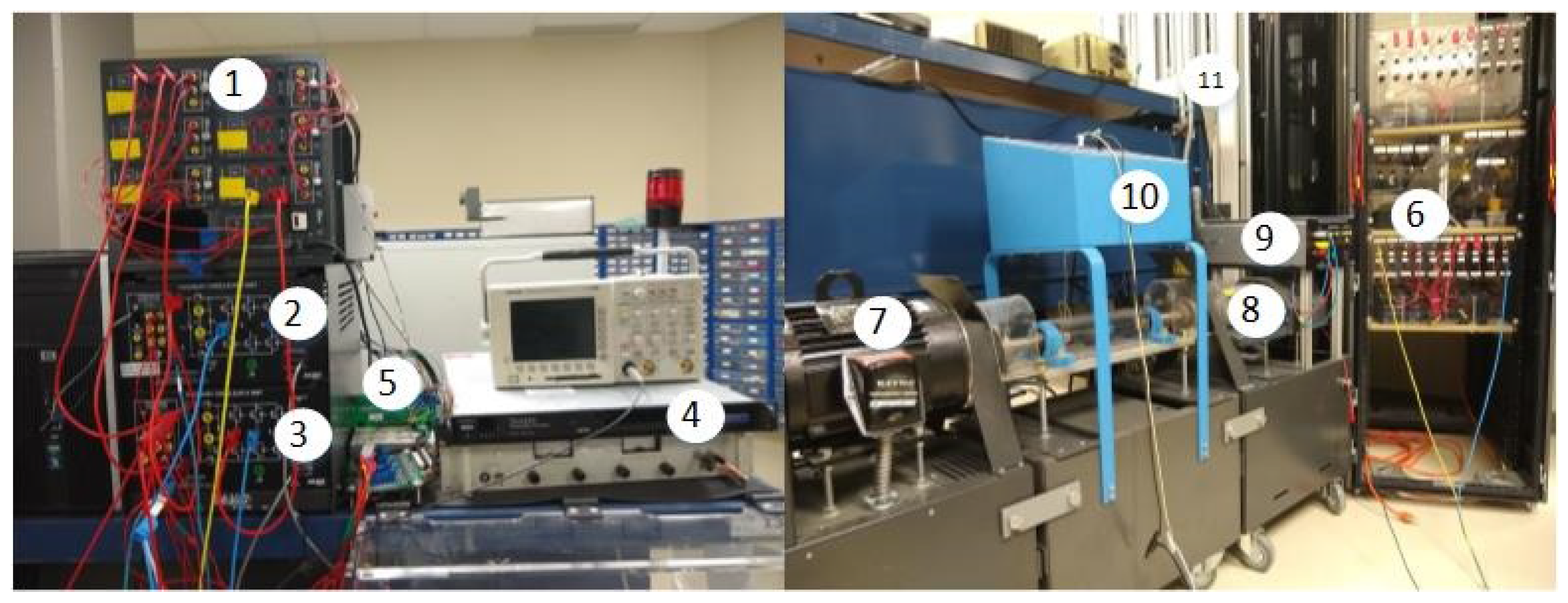

4. Results and Discussion

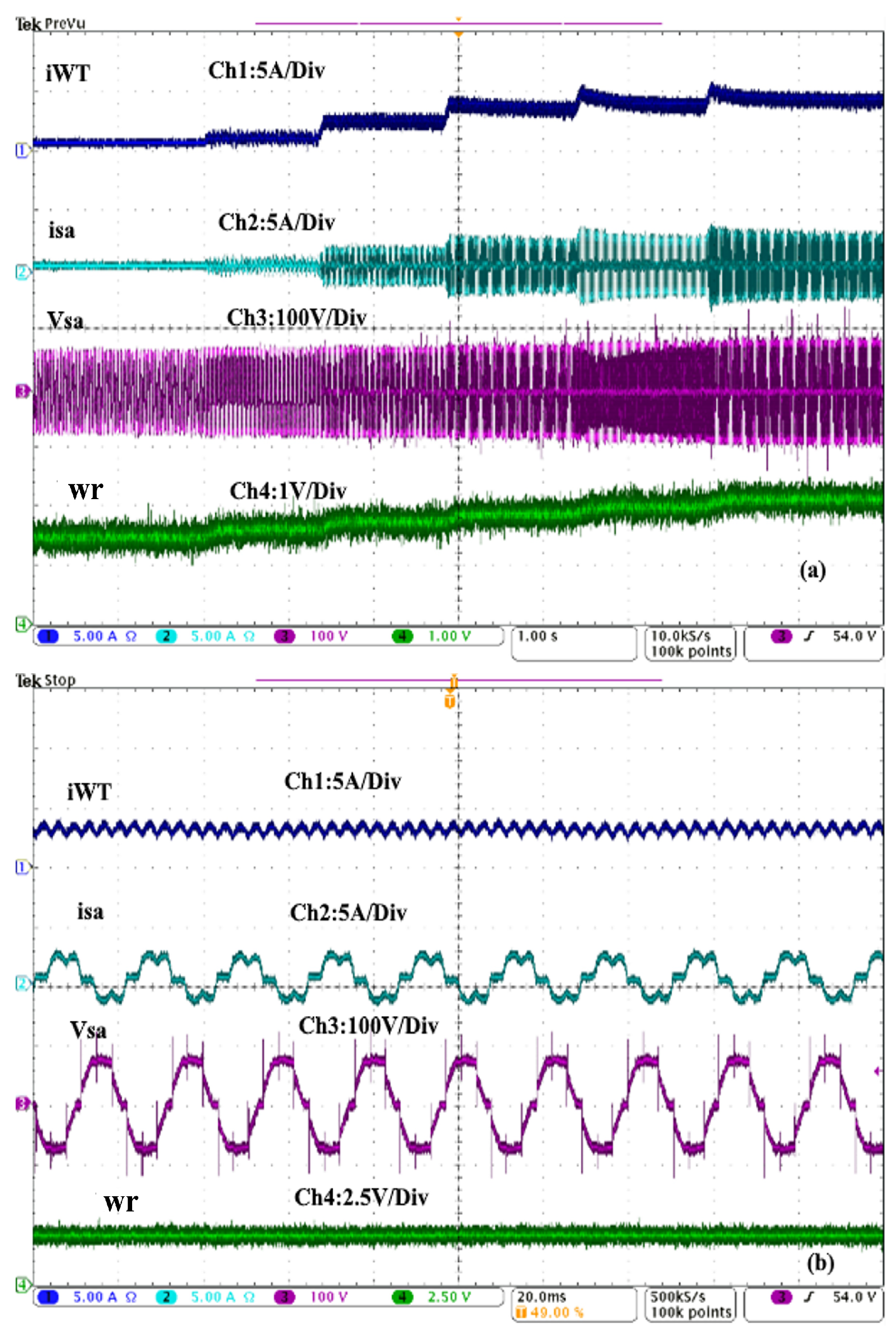

4.1. Load-Side Performance Analysis

4.2. DC Side Performance Analysis

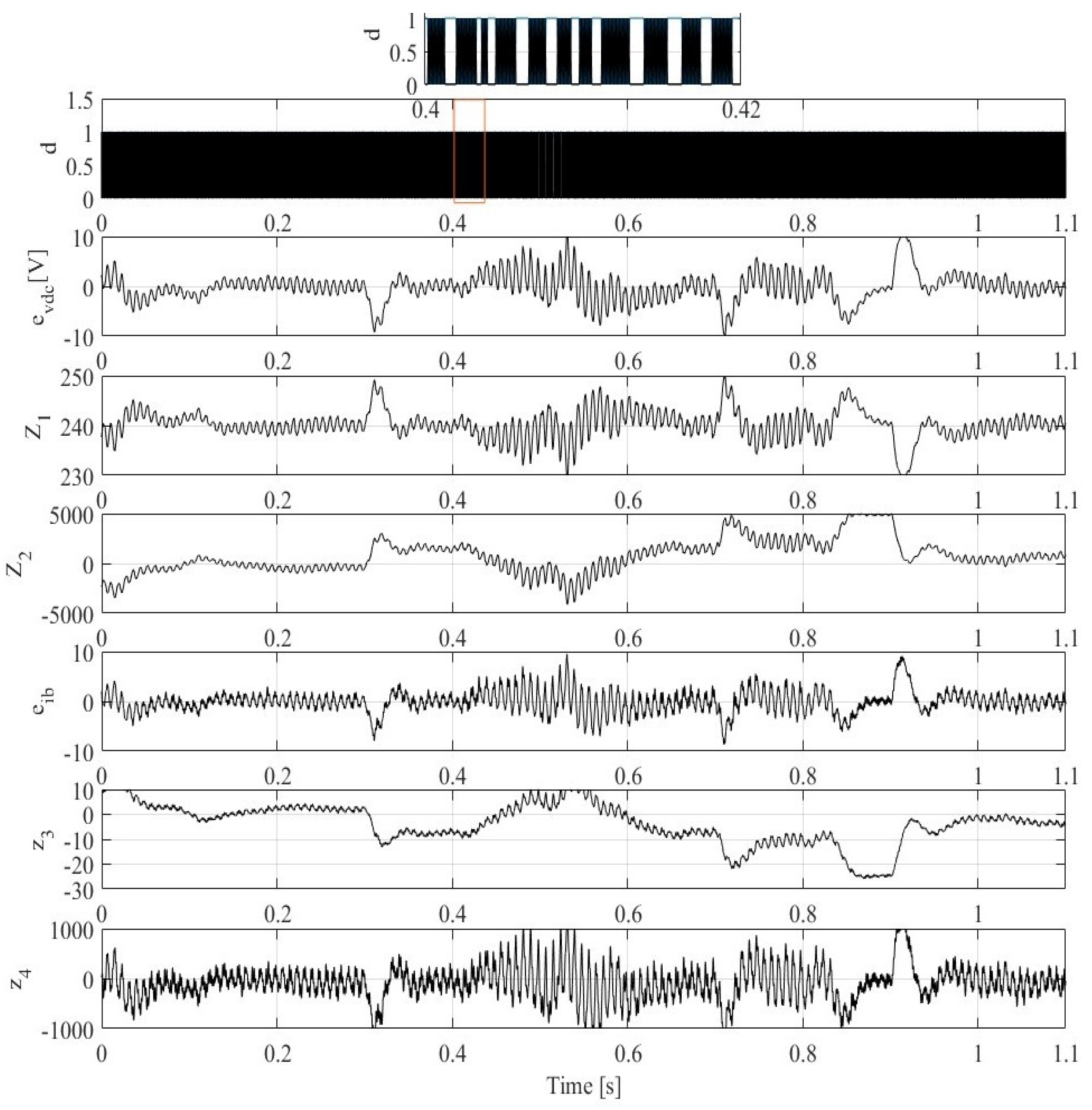

4.3. Performance of LADRC with LESO under the Presence of All Operation Conditions

4.4. Performance Analysis under Steady-State and Load Variation in the Non-Existence of the Solar Irradiation and Wind Speed

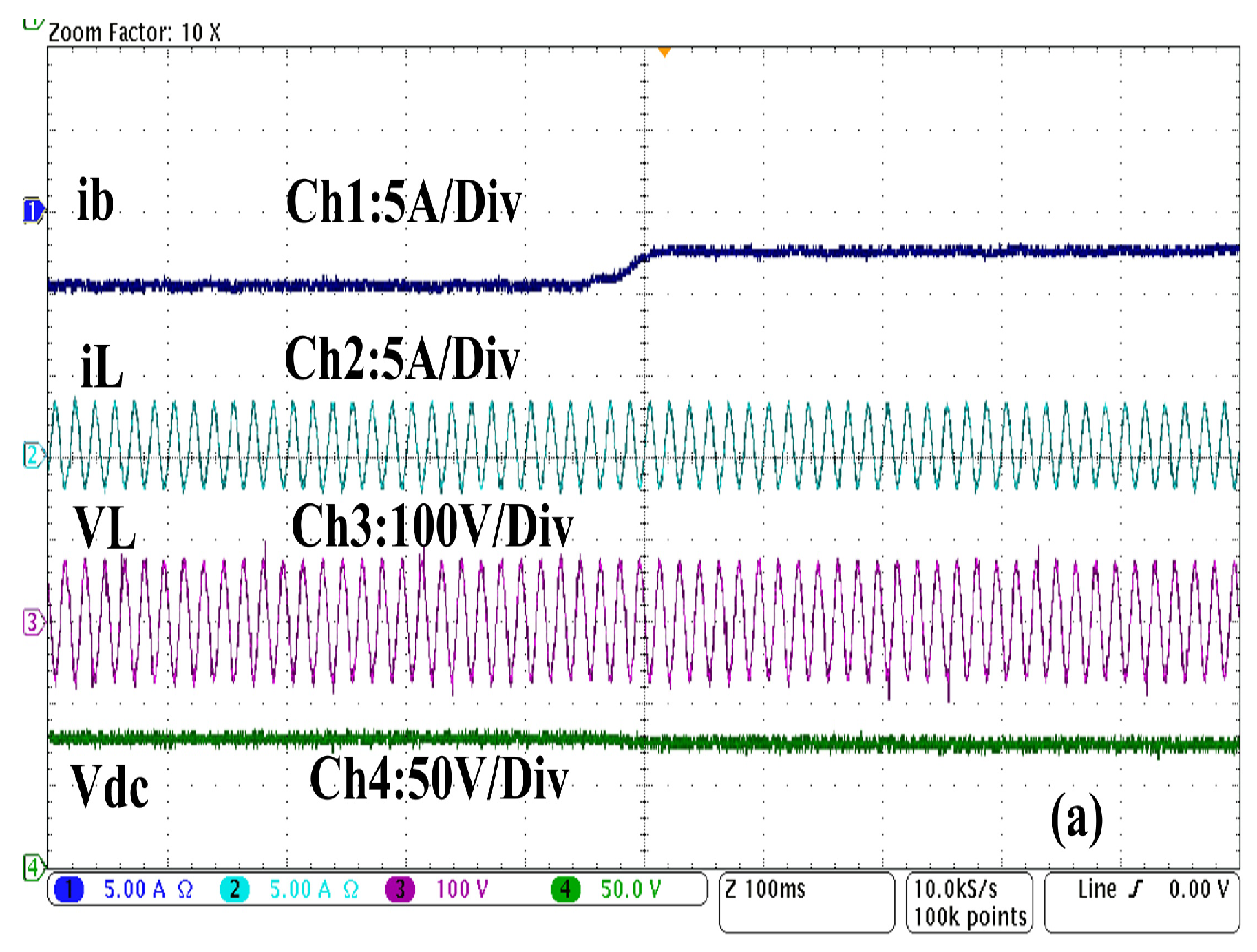

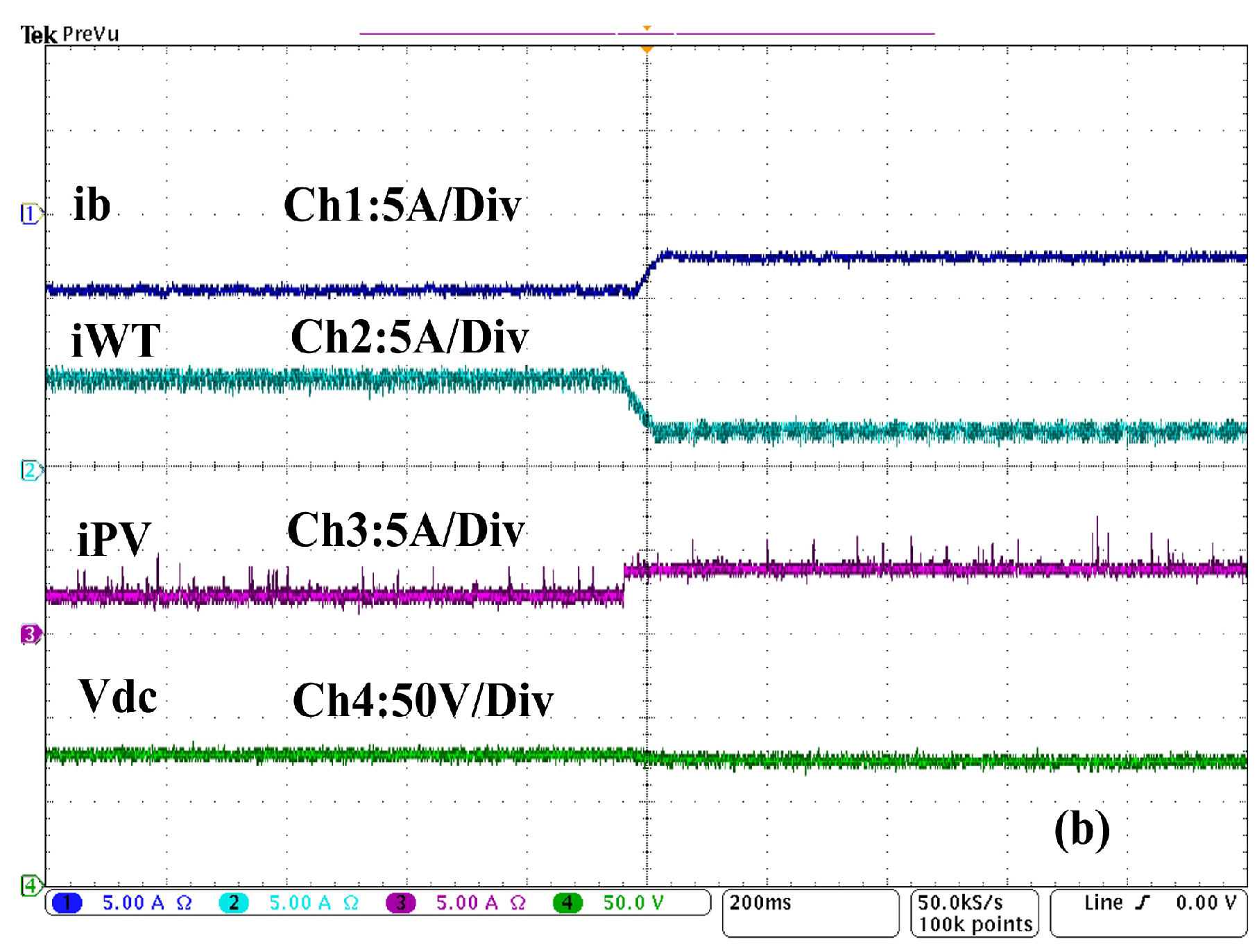

4.5. Performance Analysis under Fixed Load and during Wind Speed Variation and Non-Existence of the Solar Irradiation

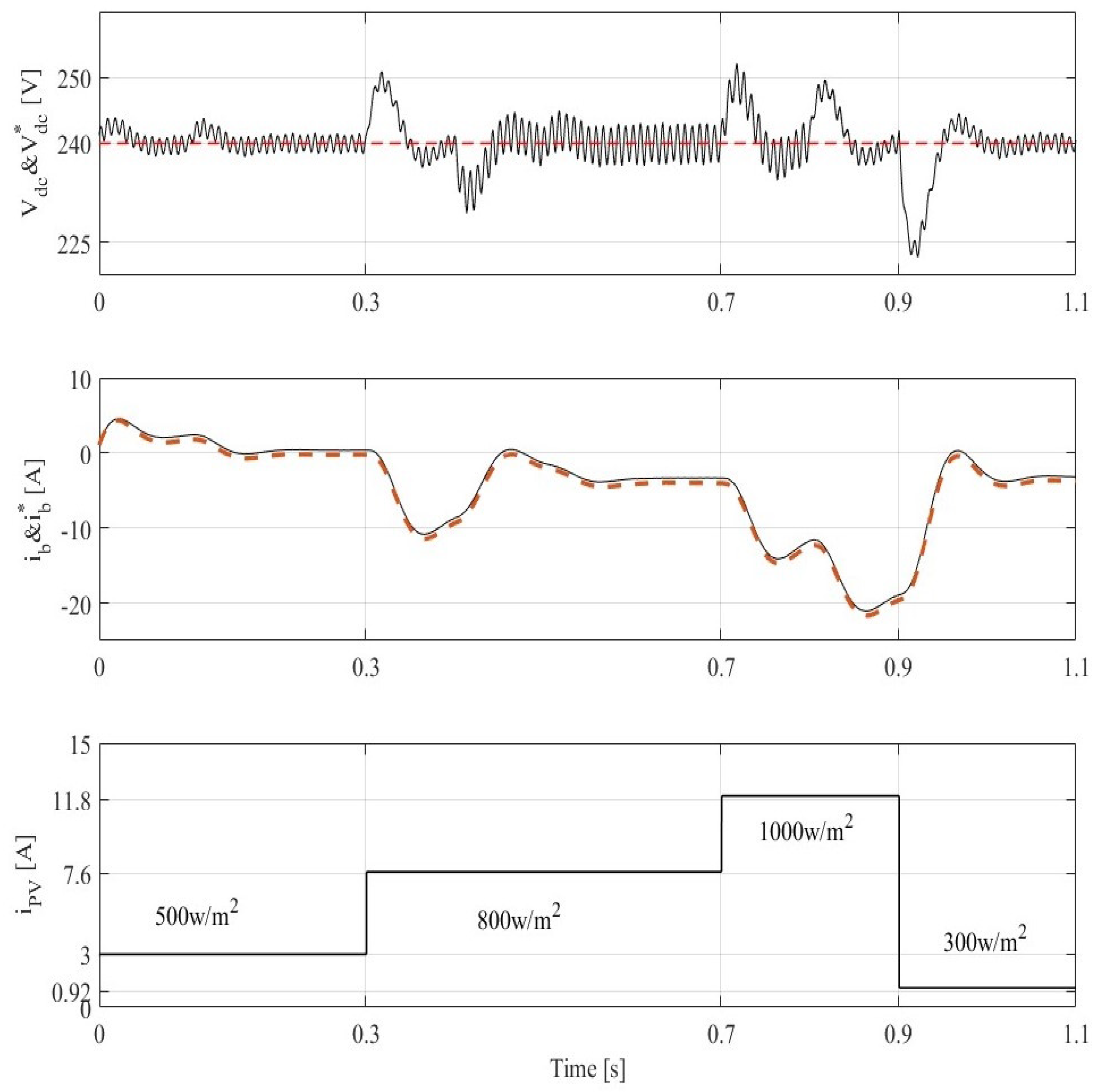

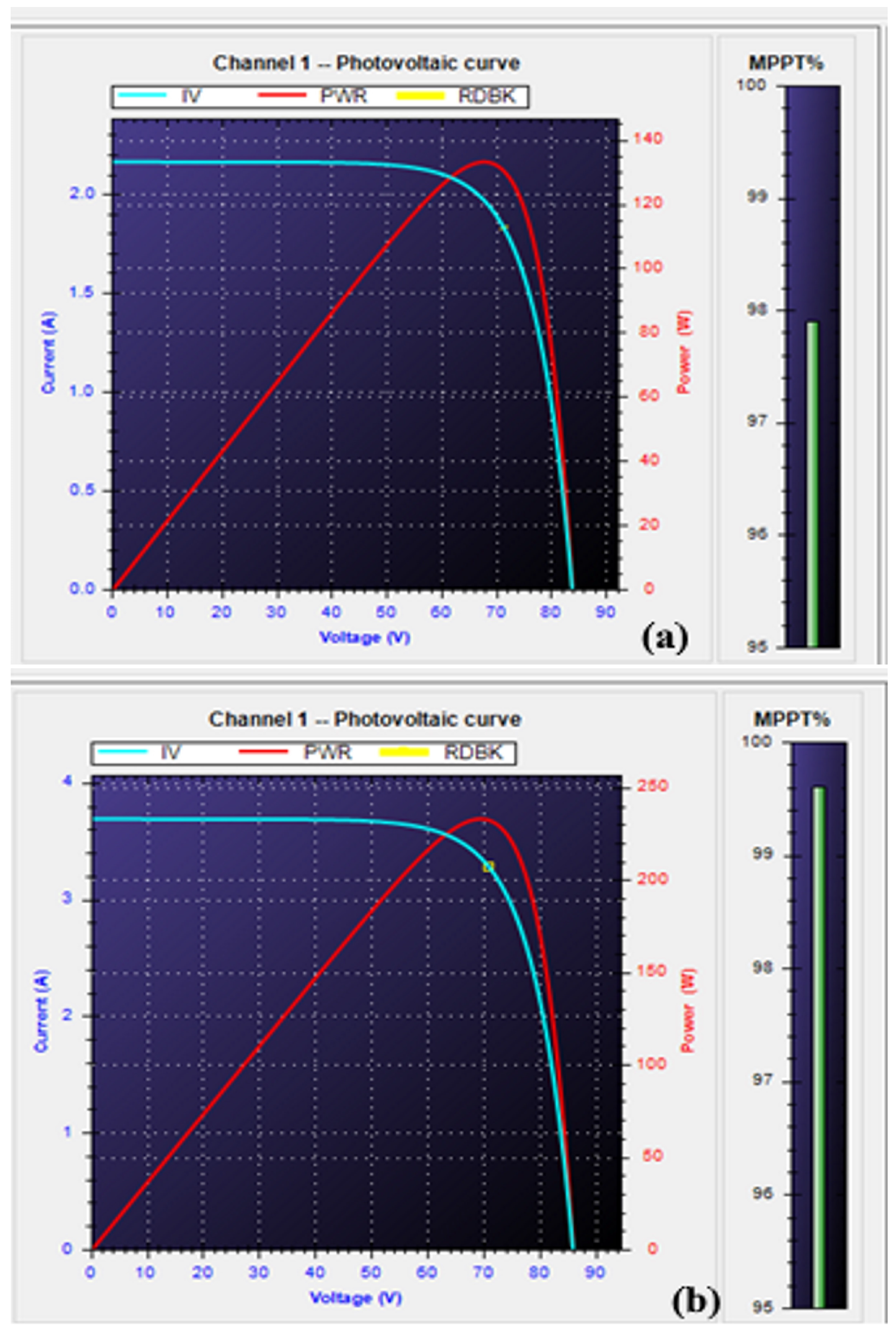

4.6. Performance Analysis under Fixed Load and during Solar Irradiation Change and Non-Existence of the Wind Speed

4.7. Performance Analysis under Fixed Load and during Solar Irradiation and Wind Speed Changes

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Observer gains | |

| Observer bandwidth in [rad/s] | |

| Disturbance terms | |

| Controller bandwidth in [rad/s] | |

| Control gains | |

| Capacitor of the common DC-link in [uF] | |

| Control signal in d-q axis | |

| Output filter capacitor current in d-q axis in [A] | |

| DC current at the input of the interfacing single-phase inverter current in [A] | |

| Output interfacing single-phase inverter current in d-q axis in [A] | |

| Battery current in [A] | |

| Load current in d-q axis in [A] | |

| Output current from PVs in [A] | |

| Generated current from PVs and WT in [A] | |

| Output current from WT in [A] | |

| Proportional gains | |

| Inductor installed between battery and the buck–boost converter [mH] | |

| s | Laplace operator |

| Mechanical torque of the WT in [N.m] | |

| Battery voltage in [V] | |

| DC-link voltage in [V] | |

| Desired common DC-link voltage in [V] | |

| Load voltage in d-q axis in [V] | |

| Tracking signals | |

| Estimated disturbances |

Appendix A

| DC-DC BOOST | |||||

| SINGLE-PHASE INVERTER | |||||

References

- Rezkallah, M.; Chandra, A.; Singh, B.; Singh, S. Microgrid: Configurations, control and applications. IEEE Trans. Smart Grid 2017, 10, 1290–1302. [Google Scholar] [CrossRef]

- Rezkallah, M.; Singh, S.; Chandra, A.; Singh, B.; Ibrahim, H. Off-grid system configurations for coordinated control of renewable energy sources. Energies 2020, 13, 4950. [Google Scholar] [CrossRef]

- Bharatee, A.; Ray, P.K.; Subudhi, B.; Ghosh, A. Power Management Strategies in a Hybrid Energy Storage System Integrated AC/DC Microgrid: A Review. Energies 2022, 15, 7176. [Google Scholar] [CrossRef]

- Liu, X.; Wang, P.; Loh, P.C. A hybrid AC/DC microgrid and its coordination control. IEEE Trans. Smart Grid 2011, 2, 278–286. [Google Scholar]

- Wang, G.; Wang, X.; Wang, F.; Han, Z. Research on hierarchical control strategy of AC/DC hybrid microgrid based on power coordination control. Appl. Sci. 2020, 10, 7603. [Google Scholar] [CrossRef]

- Unamuno, E.; Barrena, J.A. Hybrid ac/dc microgrids—Part II: Review and classification of control strategies. Renew. Sustain. Energy Rev. 2015, 52, 1123–1134. [Google Scholar] [CrossRef]

- Singh, B.; Bhalla, K.K. Reduced converter topology for integrated wind and small-hydro energy generation system. IET Renew. Power Gener. 2015, 9, 520–529. [Google Scholar] [CrossRef]

- Yadav, V.; Singh, B.; Verma, A. Robust Control for PMBLDCG Based WEC System and Seamless Grid Synchronization. In Proceedings of the 2021 International Conference on Sustainable Energy and Future Electric Transportation (SEFET), Hyderabad, India, 21–23 January 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–5. [Google Scholar]

- Pathak, G.; Singh, B.; Panigrahi, B.K. Control of wind-diesel microgrid using affine projection-like algorithm. IEEE Trans. Ind. Inform. 2016, 12, 524–531. [Google Scholar] [CrossRef]

- Sharma, R.; Singh, B. A robust control for solar and SyRG based hydro generation microgrid with grid synchronization. IEEE Trans. Ind. Appl. 2022, 58, 7595–7607. [Google Scholar] [CrossRef]

- Kalla, U.K.; Singh, B.; Murthy, S.S.; Jain, C.; Kant, K. Adaptive sliding mode control of standalone single-phase microgrid using hydro, wind, and solar PV array-based generation. IEEE Trans. Smart Grid 2017, 9, 6806–6814. [Google Scholar] [CrossRef]

- Kandari, R.; Neeraj, N.; Micallef, A. Review on recent strategies for integrating energy storage systems in microgrids. Energies 2022, 16, 317. [Google Scholar] [CrossRef]

- Singh, B.; Kushwaha, R. A PFC based EV battery charger using a bridgeless isolated SEPIC converter. IEEE Trans. Ind. Appl. 2019, 56, 477–487. [Google Scholar] [CrossRef]

- Pandey, R.; Singh, B. A power-factor-corrected LLC resonant converter for electric vehicle charger using Cuk converter. IEEE Trans. Ind. Appl. 2019, 55, 6278–6286. [Google Scholar] [CrossRef]

- Rezkallah, M.; Singh, S.; Singh, B.; Chandra, A.; Ibrahim, H.; Ghandour, M. Implementation of two-level coordinated control for seamless transfer in standalone microgrid. IEEE Trans. Ind. Appl. 2020, 57, 1057–1068. [Google Scholar] [CrossRef]

- Russo, A.; Cavallo, A. Stability and Control for Buck–Boost Converter for Aeronautic Power Management. Energies 2023, 16, 988. [Google Scholar] [CrossRef]

- Veerachary, M.; Khubchandani, V. Analysis, design, and control of switching capacitor based buck–boost converter. IEEE Trans. Ind. Appl. 2018, 55, 2845–2857. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, Q.; Wang, S.; Yue, X. Improved Repetitive Control for an LCL-Type Grid-Tied Inverter with Frequency Adaptive Capability in Microgrids. Electronics 2023, 12, 1736. [Google Scholar] [CrossRef]

- Zhu, G.r.; Wang, H.; Liang, B.; Tan, S.C.; Jiang, J. Enhanced single-phase full-bridge inverter with minimal low-frequency current ripple. IEEE Trans. Ind. Electron. 2015, 63, 937–943. [Google Scholar] [CrossRef]

- Cao, D.; Jiang, S.; Peng, F.Z.; Li, Y. Low cost transformer isolated boost half-bridge micro-inverter for single-phase grid-connected photovoltaic system. In Proceedings of the 2012 Twenty-Seventh Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Orlando, FL, USA, 5–9 February 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 71–78. [Google Scholar]

- Zeb, K.; Khan, I.; Uddin, W.; Khan, M.A.; Sathishkumar, P.; Busarello, T.D.C.; Ahmad, I.; Kim, H. A review on recent advances and future trends of transformerless inverter structures for single-phase grid-connected photovoltaic systems. Energies 2018, 11, 1968. [Google Scholar] [CrossRef]

- Bollipo, R.B.; Mikkili, S.; Bonthagorla, P.K. Hybrid, optimal, intelligent and classical PV MPPT techniques: A review. CSEE J. Power Energy Syst. 2020, 7, 9–33. [Google Scholar]

- Rezkallah, M.; Singh, S.; Chandra, A.; Singh, B.; Tremblay, M.; Saad, M.; Geng, H. Comprehensive controller implementation for wind-PV-diesel based standalone microgrid. IEEE Trans. Ind. Appl. 2019, 55, 5416–5428. [Google Scholar] [CrossRef]

- Wei, C.; Zhang, Z.; Qiao, W.; Qu, L. An adaptive network-based reinforcement learning method for MPPT control of PMSG wind energy conversion systems. IEEE Trans. Power Electron. 2016, 31, 7837–7848. [Google Scholar] [CrossRef]

- Pervez, I.; Pervez, A.; Tariq, M.; Sarwar, A.; Chakrabortty, R.K.; Ryan, M.J. Rapid and robust adaptive Jaya (Ajaya) based maximum power point tracking of a PV-based generation system. IEEE Access 2020, 9, 48679–48703. [Google Scholar] [CrossRef]

- Meng, X.; Gao, F.; Xu, T.; Zhang, C. Fast Two-Stage Global Maximum Power Point Tracking for Grid-Tied String PV Inverter Using Characteristics Mapping Principle. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 10, 564–574. [Google Scholar] [CrossRef]

- Zhang, L.; Born, R.; Gu, B.; Chen, B.; Zheng, C.; Zhao, X.; Lai, J.S. A sensorless implementation of the parabolic current control for single-phase stand-alone inverters. IEEE Trans. Power Electron. 2015, 31, 3913–3921. [Google Scholar] [CrossRef]

- Sedo, J.; Kascak, S. Control of single-phase grid connected inverter system. In Proceedings of the 2016 ELEKTRO, Strbske Pleso, Slovakia, 16–18 May 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 207–212. [Google Scholar]

- Arafat, M.N.; Palle, S.; Sozer, Y.; Husain, I. Transition control strategy between standalone and grid-connected operations of voltage-source inverters. IEEE Trans. Ind. Appl. 2012, 48, 1516–1525. [Google Scholar] [CrossRef]

- Garcia-Reyes, L.A.; Beltrán-Telles, A.; Bañuelos-Ruedas, F.; Reta-Hernández, M.; Ramírez-Arredondo, J.M.; Silva-Casarín, R. Level-shift pwm control of a single-phase full h-bridge inverter for grid interconnection, applied to ocean current power generation. Energies 2022, 15, 1644. [Google Scholar] [CrossRef]

- Yang, M.; Liu, P. Research on Sliding Mode Control of Dual Active Bridge Converter Based on Linear Extended State Observer in Distributed Electric Propulsion System. Electronics 2023, 12, 3522. [Google Scholar] [CrossRef]

- Feng, L.; Sun, X.; Tian, X.; Diao, K. Direct torque control with variable flux for an SRM based on hybrid optimization algorithm. IEEE Trans. Power Electron. 2022, 37, 6688–6697. [Google Scholar] [CrossRef]

- Ullah, F.; Ali, S.; Ying, D.; Saeed, A. Linear active disturbance rejection control approach base pitch angle control of variable speed wind turbine. In Proceedings of the 2019 IEEE 2nd International Conference on Electronics Technology (ICET), Chengdu, China, 10–13 May 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 614–618. [Google Scholar]

- Herbst, G. A simulative study on active disturbance rejection control (ADRC) as a control tool for practitioners. Electronics 2013, 2, 246–279. [Google Scholar] [CrossRef]

- Tan, W.; Fu, C. Linear active disturbance-rejection control: Analysis and tuning via IMC. IEEE Trans. Ind. Electron. 2015, 63, 2350–2359. [Google Scholar] [CrossRef]

- Gao, Z. Scaling and bandwidth-parameterization based controller tuning. In Proceedings of the 2003 American Control Conference, Denver, CO, USA, 4–6 June 2003; pp. 4989–4996. [Google Scholar]

- Cao, Y.; Zhao, Q.; Ye, Y.; Xiong, Y. ADRC-based current control for grid-tied inverters: Design, analysis, and verification. IEEE Trans. Ind. Electron. 2019, 67, 8428–8437. [Google Scholar] [CrossRef]

- Fu, C.; Tan, W. Parameters tuning of reduced-order active disturbance rejection control. IEEE Access 2020, 8, 72528–72536. [Google Scholar] [CrossRef]

- Rezkallah, M.; Ibrahim, H.; Bekbouti, Y.; Chandra, A. Performance analysis of low-cost configuration based on single-phase inverter for microgrid application. In Proceedings of the 2021 IEEE Industry Applications Society Annual Meeting (IAS), Vancouver, BC, Canada, 10–14 October 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1–5. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rezkallah, M.; Chandra, A.; Ibrahim, H. Wind–PV–Battery Hybrid Off-Grid System: Control Design and Real-Time Testing. Clean Technol. 2024, 6, 471-493. https://doi.org/10.3390/cleantechnol6020024

Rezkallah M, Chandra A, Ibrahim H. Wind–PV–Battery Hybrid Off-Grid System: Control Design and Real-Time Testing. Clean Technologies. 2024; 6(2):471-493. https://doi.org/10.3390/cleantechnol6020024

Chicago/Turabian StyleRezkallah, Miloud, Ambrish Chandra, and Hussein Ibrahim. 2024. "Wind–PV–Battery Hybrid Off-Grid System: Control Design and Real-Time Testing" Clean Technologies 6, no. 2: 471-493. https://doi.org/10.3390/cleantechnol6020024