Design and Implementation of a Low-Pressure Briquetting Machine for the Use of Pinus spp. Wood Residues: An Approach to Appropriate Rural Technology

Abstract

1. Introduction

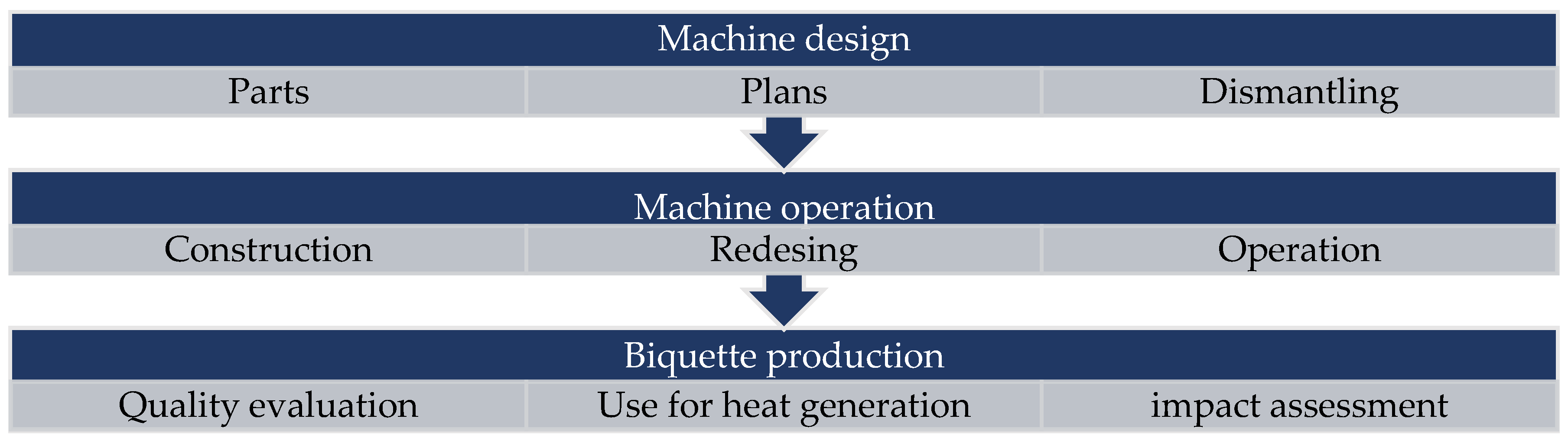

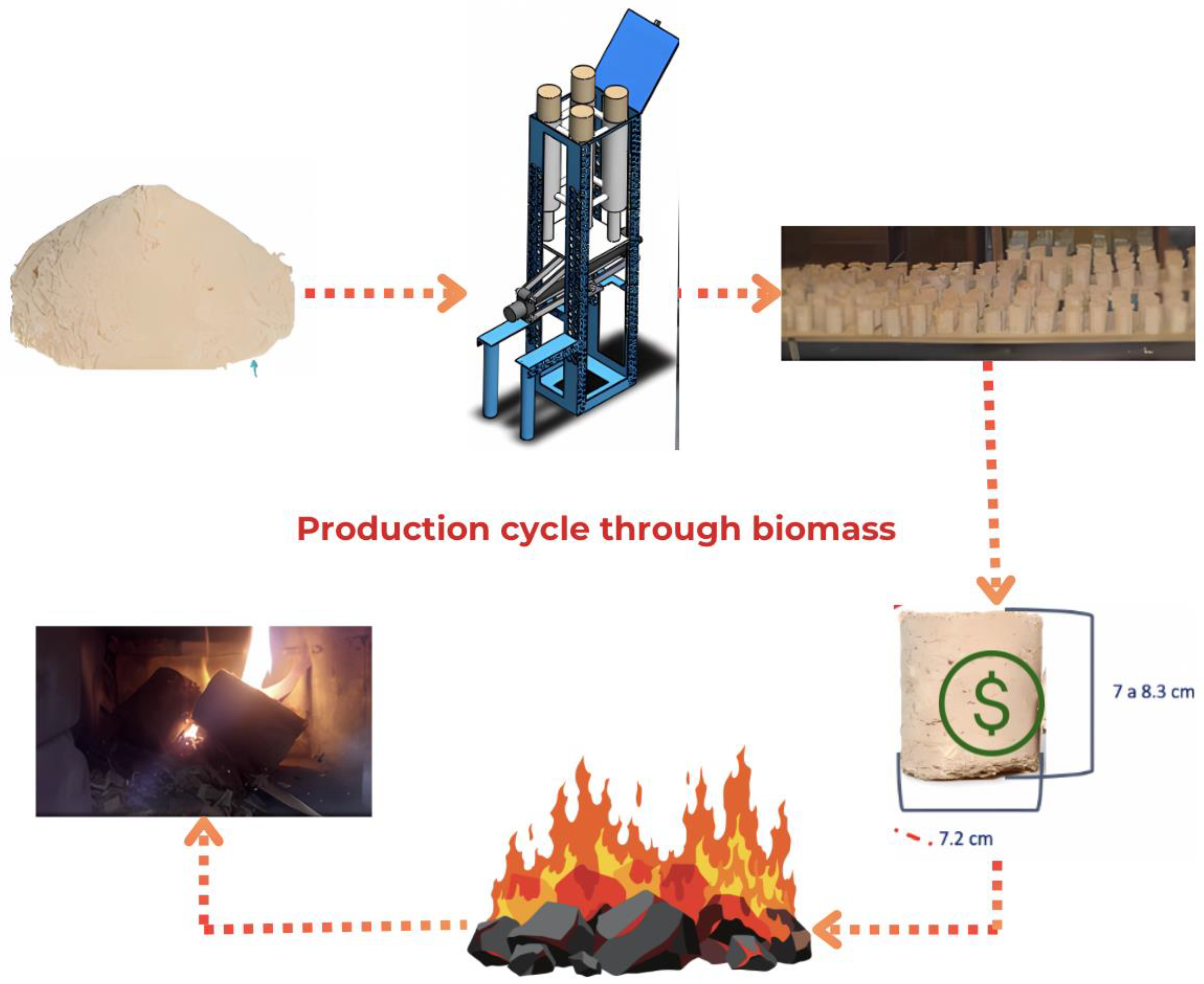

2. Materials and Methods

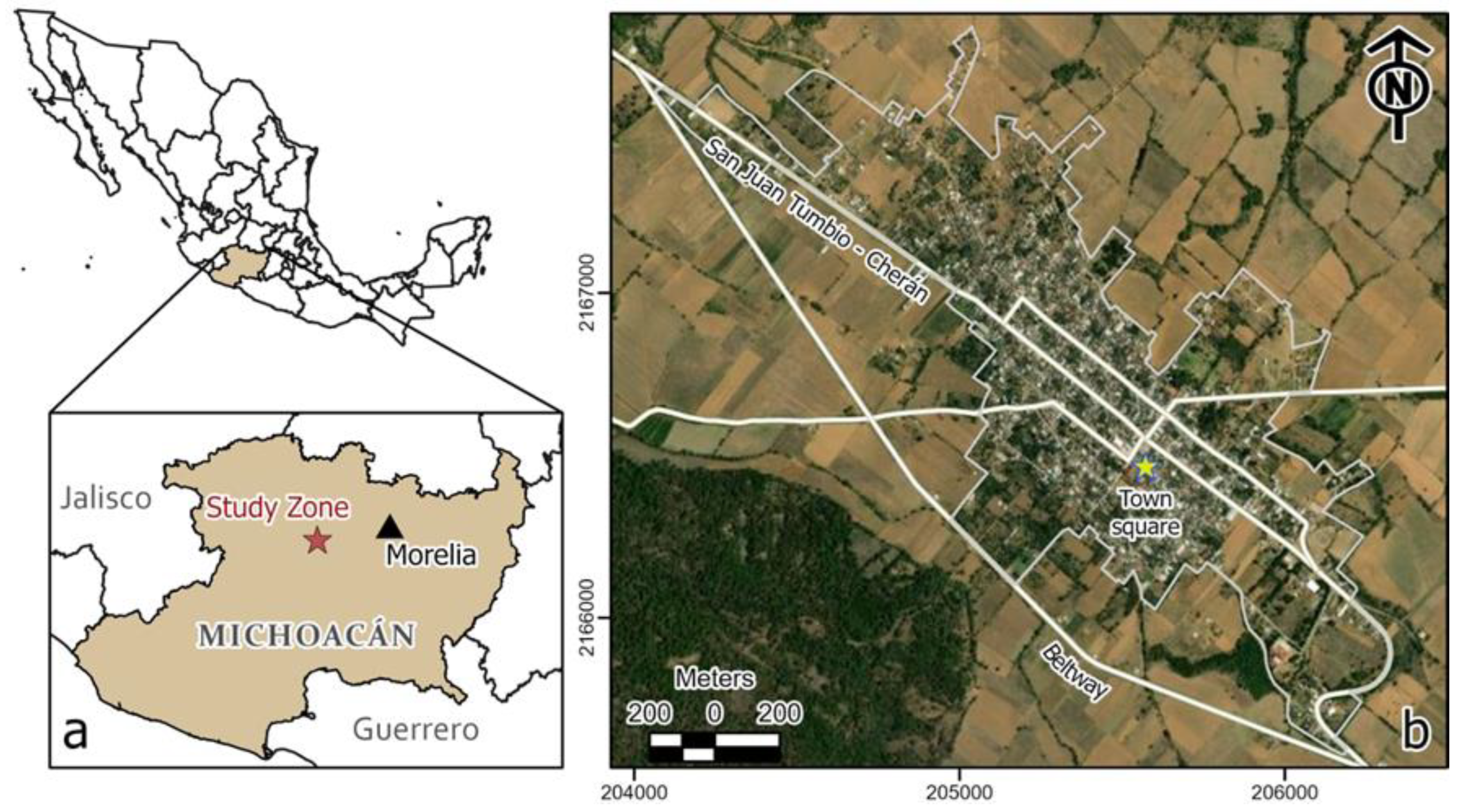

2.1. Area of Study

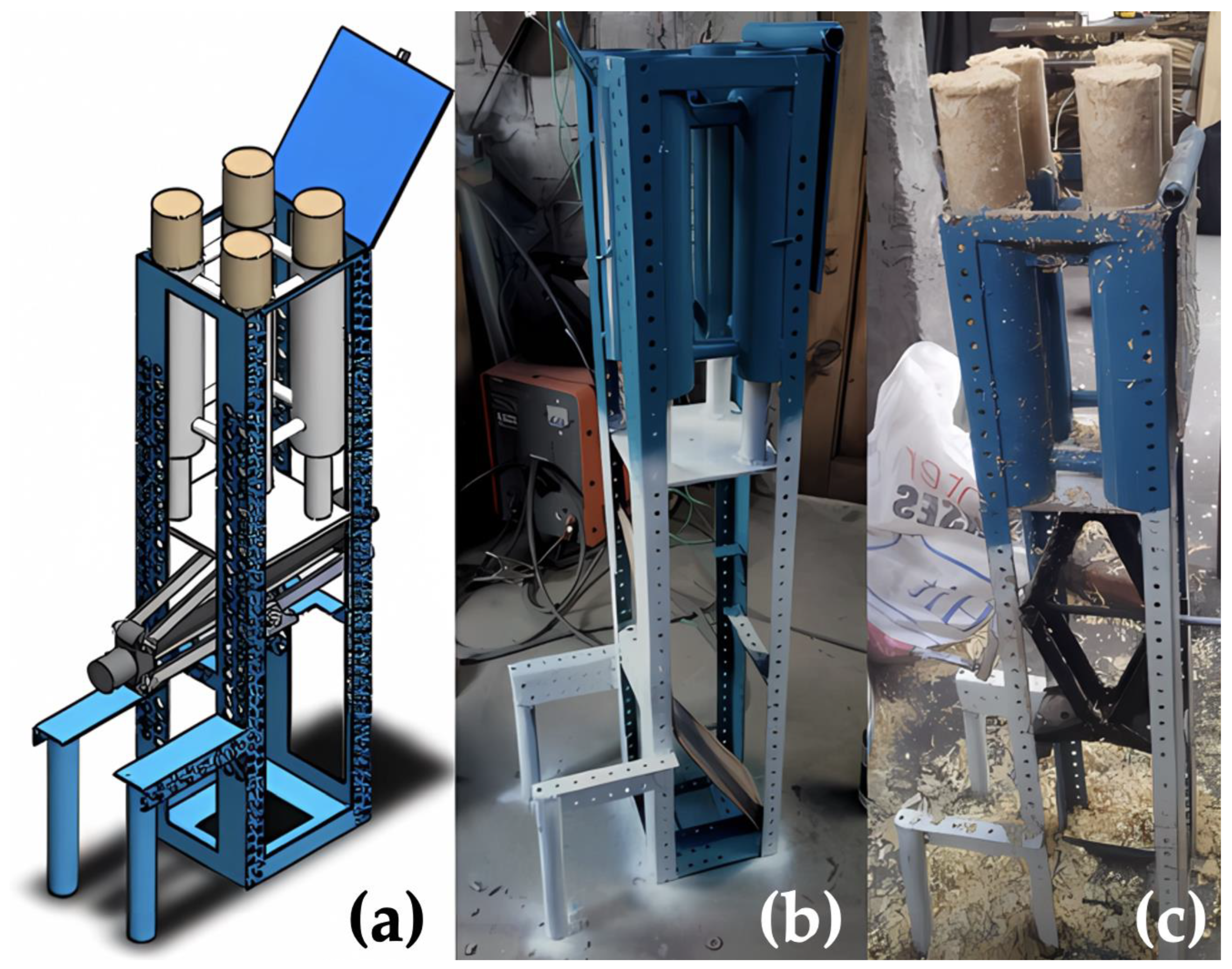

2.2. Briquetting Machine Design

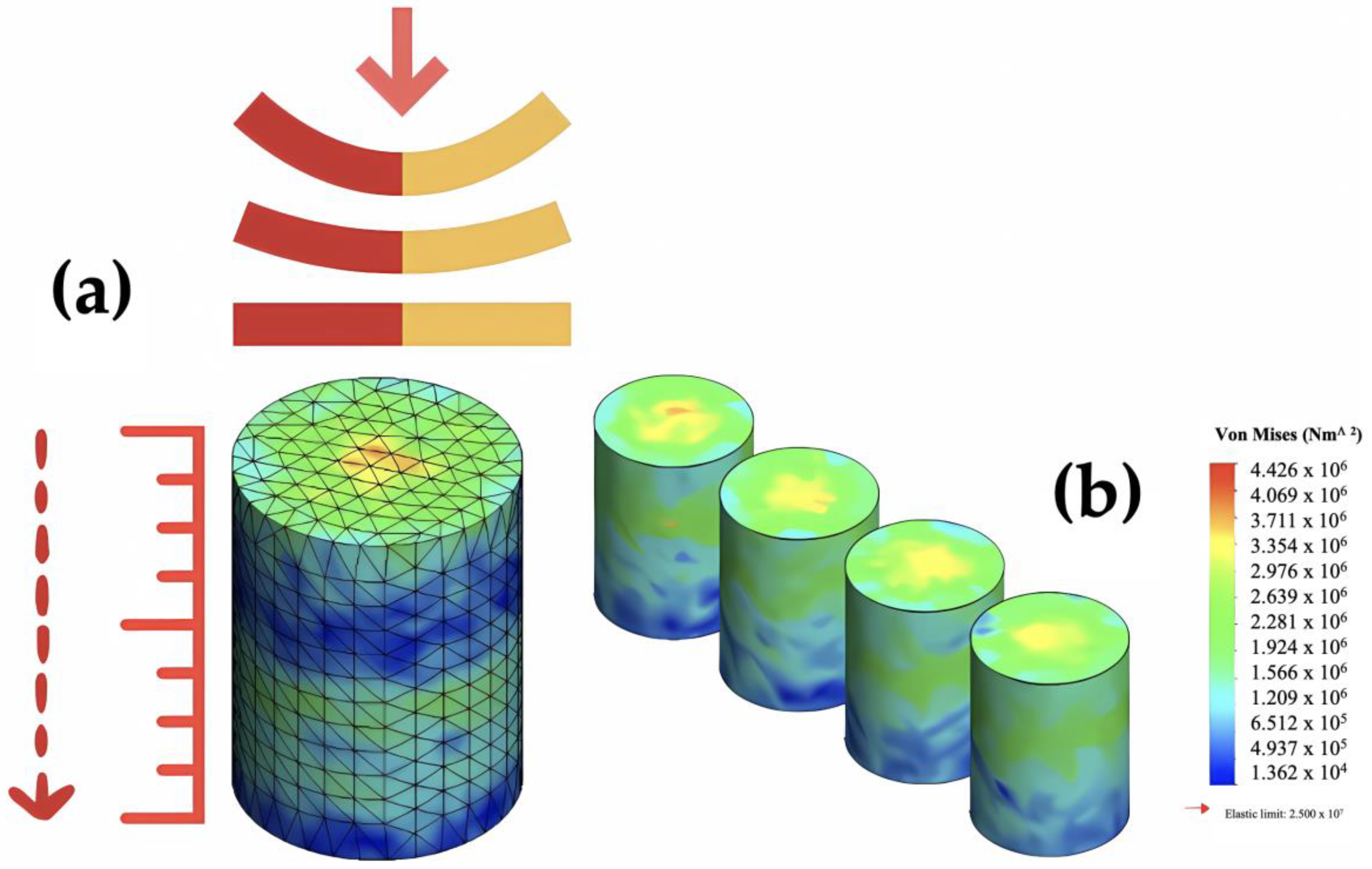

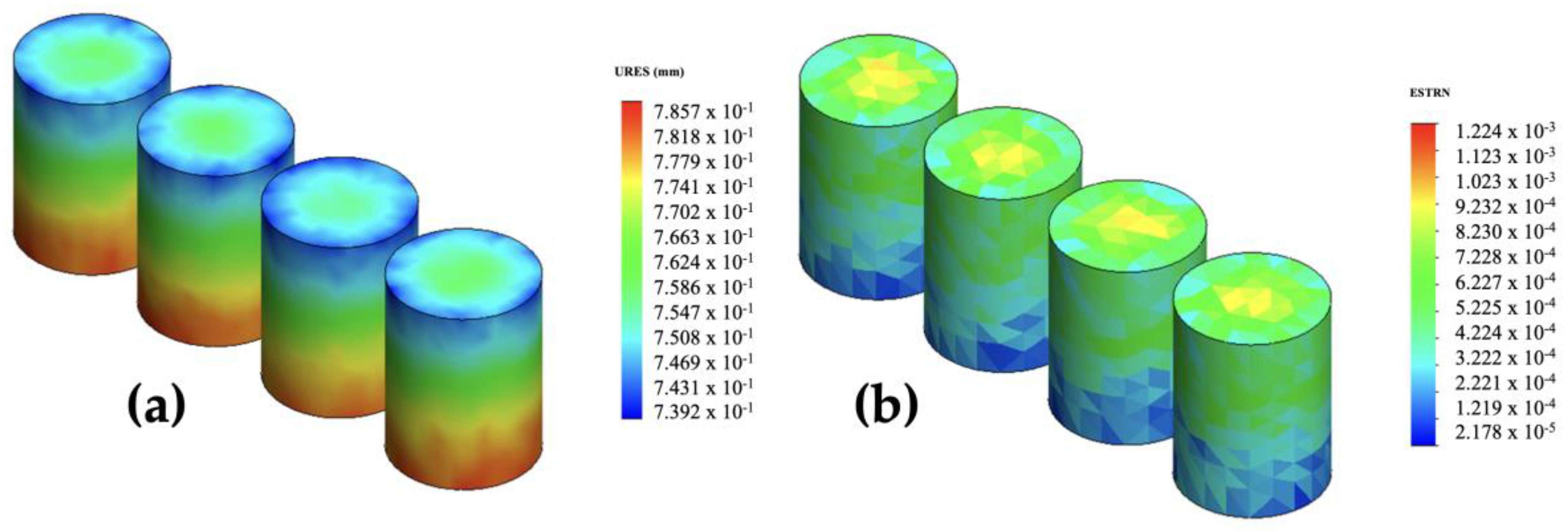

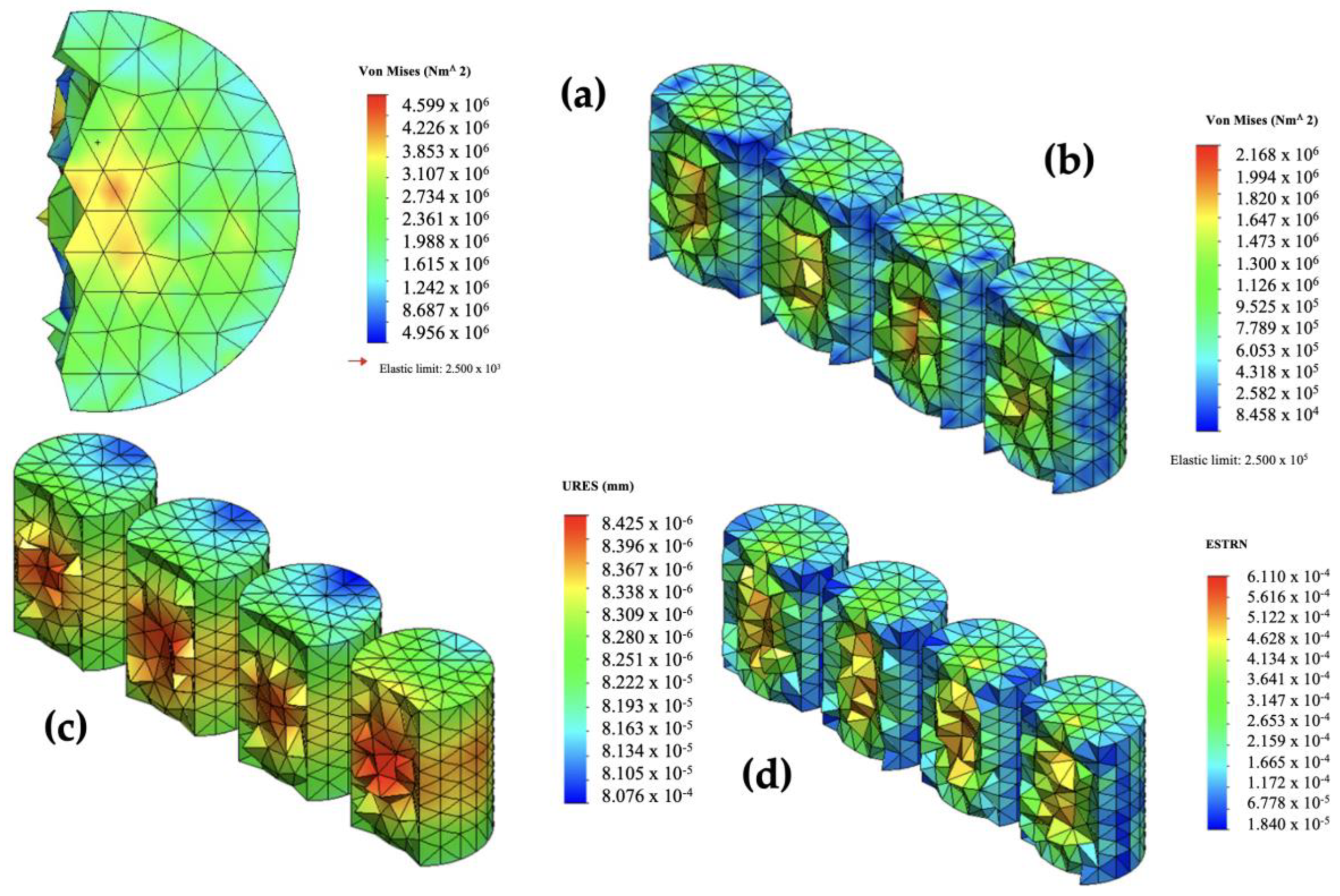

2.3. Model for Computational Simulation of the Briquetting Machine

2.4. Technology Used

2.5. Preparation of the Mixture for Densification and Economic Cost of the Materials

2.6. Production of Briquettes

- s = is the level of compaction;

- Hp = is the initial height of the compacted material;

- x = is the displacement of the axis.

2.7. Final Use of Briquettes

2.8. Identification of Polluting Gases

3. Results and Discussion

3.1. Briquetting Machine Design

3.2. Construction of the Briquetting Machine

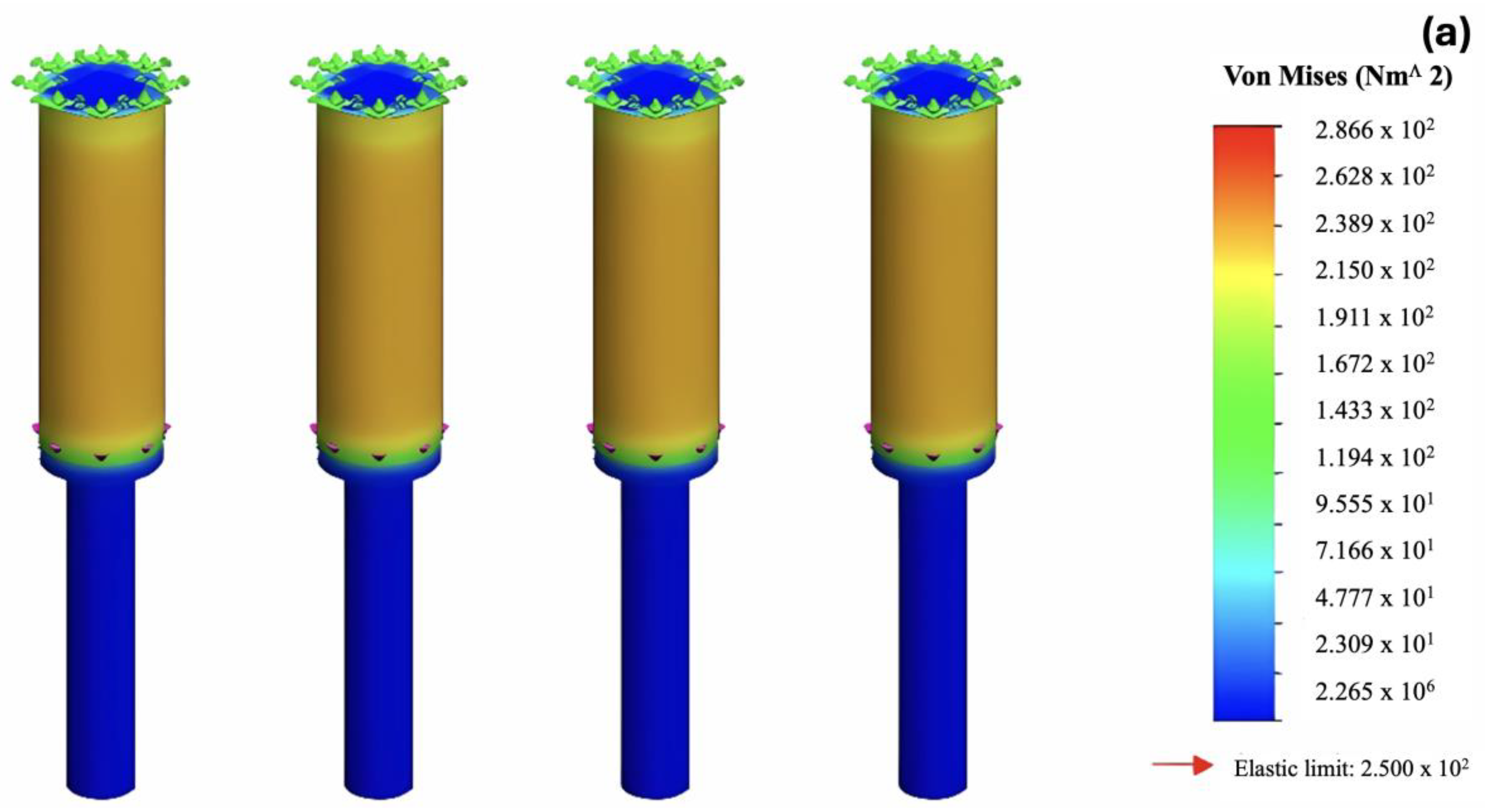

3.3. Analysis of the Compaction Process and Simulation of the Briquetting Machine

3.4. Production of Briquettes

3.5. Cost Analysis of Briquettes

3.6. Operation of the Device for Generating Briquettes

3.7. Evaluation of Food Cooking on a Three-Stone Stove

3.8. Greenhouse Gas Emissions

3.9. Application of Technology

4. Conclusions

- The machine is suitable for local production of briquettes. It uses low-cost materials for its construction; the cost of the machine is USD 75.44, three times less than a conventional machine purchased abroad;

- In the simulation performed with SolidWorks, the Von Mises stress presented a deformation range that varied between a minimum value of 2.628 × 10−3 N/m2 and a maximum of 2.500 × 108 N/m2. On the other hand, the calculated equivalent unitary strain (ESTRN) showed minimum values of 1.019 × 10−14 and maximum values of 1.845 × 10−8;

- A briquette machine operator generates, on average, 94 briquettes in a 6-hour workday, with a maximum operating pressure of 2.40 MPa;

- Briquettes, with carbon dioxide equivalent emissions of 77 g CO2e/kg, are presented as a viable and balanced alternative among traditional fuels. Although their emissions are higher than those of oak and eucalyptus firewood, they are significantly lower than those of pine firewood and comparable to those of coal. This combination of moderate environmental impact and energy efficiency positions briquettes as a sustainable option, especially in contexts where CO2e emissions are sought to be reduced without compromising energy performance.

- Environmental: There is a positive perception among users when using community biomass waste to reduce firewood consumption and, thus, reduce the pressure of firewood extraction from forests.

- Social: Participatory processes promoted local innovation focused on solving the energy needs of the region. These processes included the active participation of women;

- Economic: The design of a local machine encourages the beginning of a densified biofuel market in the region, with supply chains served by members of the same community of this study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jekayinfa, S.O.; Orisaleye, J.I.; Pecenka, R. An Assessment of Potential Resources for Biomass Energy in Nigeria. Resources 2020, 9, 92. [Google Scholar] [CrossRef]

- Kpalo, S.Y.; Zainuddin, M.F.; Manaf, L.A.; Roslan, A.M. A Review of Technical and Economic Aspects of Biomass Briquetting. Sustainability 2020, 12, 4609. [Google Scholar] [CrossRef]

- Miranda de Lima, A.J.; Iwakiri, S.; Satyanarayana, K.G.; Lomelí-Ramírez, M.G. Preparation and Characterization of Wood-Cement Particleboards Produced Using Metakaolin, Calcined Ceramics and Residues of Pinus Spp. J. Build. Eng. 2020, 32, 101722. [Google Scholar] [CrossRef]

- Cozzolino, R.; Chiappini, D.; Tribioli, L. Off-Grid PV/URFC Power Plant Fueled with Biogas from Food Waste: An Energetic and Economic Analysis. Energy 2021, 219, 119537. [Google Scholar] [CrossRef]

- Kaplan, P.O.; Witt, J.W. What Is the Role of Distributed Energy Resources under Scenarios of Greenhouse Gas Reductions? A Specific Focus on Combined Heat and Power Systems in the Industrial and Commercial Sectors. Appl. Energy 2019, 235, 83–94. [Google Scholar] [CrossRef]

- Sinsel, S.R.; Riemke, R.L.; Hoffmann, V.H. Challenges and Solution Technologies for the Integration of Variable Renewable Energy Sources—A Review. Renew. Energy 2020, 145, 2271–2285. [Google Scholar] [CrossRef]

- da Luz, T.; Moura, P. Power Generation Expansion Planning with Complementarity between Renewable Sources and Regions for 100% Renewable Energy Systems. Int. Trans. Electr. Energy Syst. 2019, 29, e2817. [Google Scholar] [CrossRef]

- Jafari, A.; Khalili, T.; Ganjehlou, H.G.; Bidram, A. Optimal Integration of Renewable Energy Sources, Diesel Generators, and Demand Response Program from Pollution, Financial, and Reliability Viewpoints: A Multi-Objective Approach. J. Clean. Prod. 2020, 247, 119100. [Google Scholar] [CrossRef]

- Jurasz, J.; Canales, F.A.; Kies, A.; Guezgouz, M.; Beluco, A. A Review on the Complementarity of Renewable Energy Sources: Concept, Metrics, Application and Future Research Directions. Sol. Energy 2020, 195, 703–724. [Google Scholar] [CrossRef]

- Rahman, M.M.; Velayutham, E. Renewable and Non-Renewable Energy Consumption-Economic Growth Nexus: New Evidence from South Asia. Renew. Energy 2020, 147, 399–408. [Google Scholar] [CrossRef]

- Samadi, S.H.; Ghobadian, B.; Nosrati, M. Prediction and Estimation of Biomass Energy from Agricultural Residues Using Air Gasification Technology in Iran. Renew. Energy 2020, 149, 1077–1091. [Google Scholar] [CrossRef]

- Irfan, M.; Zhao, Z.-Y.; Panjwani, M.K.; Mangi, F.H.; Li, H.; Jan, A.; Ahmad, M.; Rehman, A. Assessing the Energy Dynamics of Pakistan: Prospects of Biomass Energy. Energy Rep. 2020, 6, 80–93. [Google Scholar] [CrossRef]

- Shah, S.A.R.; Naqvi, S.A.A.; Riaz, S.; Anwar, S.; Abbas, N. Nexus of Biomass Energy, Key Determinants of Economic Development and Environment: A Fresh Evidence from Asia. Renew. Sustain. Energy Rev. 2020, 133, 110244. [Google Scholar] [CrossRef]

- González-Arias, J.; Sánchez, M.E.; Martínez, E.J.; Covalski, C.; Alonso-Simón, A.; González, R.; Cara-Jiménez, J. Hydrothermal Carbonization of Olive Tree Pruning as a Sustainable Way for Improving Biomass Energy Potential: Effect of Reaction Parameters on Fuel Properties. Processes 2020, 8, 1201. [Google Scholar] [CrossRef]

- Artemio, C.P.; Maginot, N.H.; Serafín, C.-U.; Rahim, F.P.; Guadalupe, R.Q.J.; Fermín, C.-M. Physical, Mechanical and Energy Characterization of Wood Pellets Obtained from Three Common Tropical Species. PeerJ 2018, 6, e5504. [Google Scholar] [CrossRef]

- Chávez-Rosales, J.S.; Pintor-Ibarra, L.F.; González-Ortega, N.; Orihuela-Equihua, R.; Ruiz-Aquino, F.; Lujan-Álvarez, C.; Rutiaga-Quiñones, J.G. Basic Chemical Composition of Pinus Spp. Sawdust from Five Regions of Mexico, for Bioenergetic Purposes. BioResources 2021, 16, 816–824. [Google Scholar] [CrossRef]

- Morales-Máximo, M. Aprovechamiento Del Aserrín y Viruta de Pino (Pinus Spp.) Para La Producción y Evaluación de Briquetas, Como Energía Alterna En La Comunidad de San Francisco Pichátaro, Michoacán. Master’s Thesis, Universidad Michoacana de San Nicólas de Hidalgo, Morelia, Mexico, 2019. [Google Scholar]

- Mario, J.; Fandiño, M.; Enrique, Y.; Doria, G.; David, R.; Vasquez, G. Elaboración de Biocombustibles Sólidos Densificados a Partir de Tusa de Maíz, Bioaglomerante de Yuca y Carbón Mineral Del Departamento de Córdoba. Ingeniare Rev. Chil. Ing. 2017, 25, 643–653. [Google Scholar] [CrossRef]

- Espinoza-Tellez, T.; Montes, J.B.; Quevedo-León, R.; Valencia-Aguilar, E.; Vargas, H.A.; Díaz-Guineo, D.; Ibarra-Garnica, M.; Díaz-Carrasco, O. Agricultural, Forestry, Textile and Food Waste Used in the Manufacture of Biomass Briquettes: A Review. Sci. Agropecu. 2020, 11, 427–437. [Google Scholar] [CrossRef]

- Orisaleye, J.I.; Jekayinfa, S.O.; Dittrich, C.; Obi, O.F.; Pecenka, R. Effects of Feeding Speed and Temperature on Properties of Briquettes from Poplar Wood Using a Hydraulic Briquetting Press. Resources 2023, 12, 12. [Google Scholar] [CrossRef]

- Oladeji, J.T. Theoretical Aspects of Biomass Briquetting: A Review Study. J. Energy Technol. Policy 2015, 5, 72–82. [Google Scholar]

- Okwu, M.O.; Samuel, O.D. Adapted Hyacinth Briquetting Machine for Mass Production of Briquettes. Energy Sources Part Recovery Util. Environ. Eff. 2018, 40, 2853–2866. [Google Scholar] [CrossRef]

- Toan, P.K.; Cuong, N.D.; Sinh, N.T.Q.; Kim, P. Application of Briquetting Technology to Produce Briquettes from Agricultural Residues and By-Products. World Renew. Energy Congr. 2000, VI, 1416–1419. [Google Scholar]

- Romallosa, A.R.D.; Kraft, E. Feasibility of Biomass Briquette Production from Municipal Waste Streams by Integrating the Informal Sector in the Philippines. Resources 2017, 6, 12. [Google Scholar] [CrossRef]

- Fajfrlíková, P.; Brunerová, A.; Roubík, H. Analyses of Waste Treatment in Rural Areas of East Java with the Possibility of Low-Pressure Briquetting Press Application. Sustainability 2020, 12, 8153. [Google Scholar] [CrossRef]

- Kayode, O.P.; Gideon, O.N. Development of an Improved Pressure Varying Hydraulically Operated Agricultural Waste Briquetting Machine. AU E-J. Interdiscip. Res. 2019, 130–137. [Google Scholar]

- Green, P.M.; Mabaso, M.C. The Economic Viability of a Locally Fabricated Honeycomb Briquetting Machine for Small and Medium Entrepreneurship. In Proceedings of the 2017 International Conference on the Domestic Use of Energy (DUE), Cape Town, South Africa, 4–5 April 2017; pp. 89–95. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; wright, C.T. A review on Biomass Densification Technologie for Energy Application; Idaho National Lab. (INL): Idaho Falls, ID, USA, 2010. [Google Scholar] [CrossRef]

- Green, D. Cross Cultural Technology Transfer of Sustainable Energy Systems: A Critical Analysis. Renew. Energy 1999, 16, 1133–1137. [Google Scholar] [CrossRef]

- Gavito, M.E.; van der Wal, H.; Aldasoro, E.M.; Ayala-Orozco, B.; Bullén, A.A. Ecología, tecnología e innovación para la sustentabilidad: Retos y perspectivas en México. Rev. Mex. Biodivers. 2017, 88, 150–160. [Google Scholar] [CrossRef]

- Assefa, G.; Frostell, B. Social Sustainability and Social Acceptance in Technology Assessment: A Case Study of Energy Technologies. Technol. Soc. 2007, 29, 63–78. [Google Scholar] [CrossRef]

- Francisco-Arriaga, F.; Guerrero García-Rojas, H.R.; Kido-Cruz, A.; Cortés-Zavala, M.T. Ingreso generado por la recolección de recursos forestales en Pichátaro, Michoacán, México. Agric. Soc. Desarro. 2011, 8, 107–117. [Google Scholar]

- Orozco, S.; López-Sosa, L.B.; Montiel, E.; Espino, J.; Guerra, R.; Vargas, J.; Alfonso, I.; Rivero, M. Green Practices in Wastewater Treatment: Upcycling Avocado Waste for Enhanced Water Sanitation. Case Study: WWTP in San Francisco Pichátaro, Michoacán. Results Eng. 2024, 24, 103347. [Google Scholar] [CrossRef]

- Wessapan, T.; Somsuk, N.; Borirak, T. Design and Development of a Compact Screw-Press Biomass Briquetting Machine for Productivity Improvement and Cost Reduction. In Proceedings of the First TSME International Conference on Mechanical Engineering, Ubon Ratchathani, Thailand, 20–22 October 2010; p. 6. [Google Scholar]

- Obi, O.F.; Akubuo, C.O.; Okonkwo, W.I. Development of an Appropriate Briquetting Machine for Use in Rural Communities. Int. J. Eng. Adv. Technol. IJEAT 2013, 2, 578–582. [Google Scholar]

- Bembenek, M. Exploring Efficiencies: Examining the Possibility of Decreasing the Size of the Briquettes Used as the Batch in the Electric Arc Furnace Dust Processing Line. Sustainability 2020, 12, 6393. [Google Scholar] [CrossRef]

- Shi, L.; Chew, M.Y.L. A Review on Sustainable Design of Renewable Energy Systems. Renew. Sustain. Energy Rev. 2012, 16, 192–207. [Google Scholar] [CrossRef]

- Massaro, M.M.; Son, S.F.; Groven, L.J. Mechanical, Pyrolysis, and Combustion Characterization of Briquetted Coal Fines with Municipal Solid Waste Plastic (MSW) Binders. Fuel 2014, 115, 62–69. [Google Scholar] [CrossRef]

- Gesase, L.E.; King’ondu, C.K.; Jande, Y.A.C. Manihot Glaziovii-Bonded and Bioethanol-Infused Charcoal Dust Briquettes: A New Route of Addressing Sustainability, Ignition, and Food Security Issues in Briquette Production. Bioenergy Res. 2020, 13, 378–386. [Google Scholar] [CrossRef]

- Morales-Máximo, M.; Ruíz-García, V.M.; López-Sosa, L.B.; Rutiaga-Quiñones, J.G. Exploitation of Wood Waste of Pinus Spp for Briquette Production: A Case Study in the Community of San Francisco Pichátaro, Michoacán, Mexico. Appl. Sci. 2020, 10, 2933. [Google Scholar] [CrossRef]

- García-Frapolli, E.; Schilmann, A.; Berrueta, V.M.; Riojas-Rodríguez, H.; Edwards, R.D.; Johnson, M.; Guevara-Sanginés, A.; Armendariz, C.; Masera, O. Beyond Fuelwood Savings: Valuing the Economic Benefits of Introducing Improved Biomass Cookstoves in the Purépecha Region of Mexico. Ecol. Econ. 2010, 69, 2598–2605. [Google Scholar] [CrossRef]

- Ruiz-Mercado, I.; Masera, O. Patterns of Stove Use in the Context of Fuel–Device Stacking: Rationale and Implications. EcoHealth 2015, 12, 42–56. [Google Scholar] [CrossRef]

- Medina, P.; Berrueta, V.; Martínez, M.; Ruiz, V.; Edwards, R.D.; Masera, O. Comparative Performance of Five Mexican Plancha-Type Cookstoves Using Water Boiling Tests. Dev. Eng. 2017, 2, 20–28. [Google Scholar] [CrossRef]

- Serrano-Medrano, M.; García-Bustamante, C.; Berrueta, V.M.; Martínez-Bravo, R.; Ruiz-García, V.M.; Ghilardi, A.; Masera, O. Promoting LPG, Clean Woodburning Cookstoves or Both? Climate Change Mitigation Implications of Integrated Household Energy Transition Scenarios in Rural Mexico. Environ. Res. Lett. 2018, 13, 115004. [Google Scholar] [CrossRef]

- IPCC. Part A: Global and Sectoral Aspects. (Contribution of Working Group II to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change). Climate Change 2014: Impacts, Adaptation, Vulnerability. 2014, p. 1132. Available online: https://www.ipcc.ch/report/ar5/wg2/ (accessed on 18 December 2024).

- IPCC. Cambio Climático 2007: Informe de Síntesis de Expertos Sobre El Cambio Climático; IPCC: Ginebra, Switzerland, 2007. [Google Scholar]

- Edwards, R.D.; Smith, K.R. Carbon Balances, Global Warming Commitments, and Health Implications of Avoidable Emissions from Residential Energy Use in China. Evid. Emiss. Database. Available online: https://pubs.giss.nasa.gov (accessed on 2 May 2024).

- MacCarty, N.; Ogle, D.; Still, D.; Bond, T.; Roden, C. A Laboratory Comparison of the Global Warming Impact of Five Major Types of Biomass Cooking Stoves. Energy Sustain. Dev. 2008, 12, 56–65. [Google Scholar] [CrossRef]

- Bailis, R.; Drigo, R.; Ghilardi, A.; Masera, O. The Carbon Footprint of Traditional Woodfuels. Nat. Clim. Change 2015, 5, 266–272. [Google Scholar] [CrossRef]

- Morales-Máximo, M.; Rutiaga-Quiñones, J.G.; Masera, O.; Ruiz-García, V.M. Briquettes from Pinus Spp. Residues: Energy Savings and Emissions Mitigation in the Rural Sector. Energies 2022, 15, 3419. [Google Scholar] [CrossRef]

- Sinha, Y.; Sahu, P.; Biswas, S. Development of Manually Operated Piston Press Type Briquetting Machine. Int. J. Curr. Microbiol. Appl. Sci. 2019, 8, 2932–2939. [Google Scholar] [CrossRef]

- Spirchez, C.; Lunguleasa, A.; Șova, D.; Gorbacheva, G. On the Rheological Behavior of Pine (Pinus sylvestris L.) Shavings and the Briquettes Obtained from Them. Forests 2025, 16, 267. [Google Scholar] [CrossRef]

- Gendek, A.; Aniszewska, M.; Malaťák, J.; Velebil, J. Evaluation of Selected Physical and Mechanical Properties of Briquettes Produced from Cones of Three Coniferous Tree Species. Biomass Bioenergy 2018, 117, 173–179. [Google Scholar] [CrossRef]

- Member, E.A.S.; Pasache, M.B.; García, M.E. Development of Briquettes from Waste Wood (Sawdust) for Use in Low-Income Households. In Proceedings of the World Congress on Engineering 2014, WCE 2014, London, UK, 2–4 July 2014; Volume II, p. 5. [Google Scholar]

- Stolarski, M.J.; Szczukowski, S.; Tworkowski, J.; Krzyżaniak, M.; Gulczyński, P.; Mleczek, M. Comparison of Quality and Production Cost of Briquettes Made from Agricultural and Forest Origin Biomass. Renew. Energy 2013, 57, 20–26. [Google Scholar] [CrossRef]

- Nyemba, W.R.; Hondo, A.; Mbohwa, C.; Madiye, L. Unlocking Economic Value and Sustainable Furniture Manufacturing through Recycling and Reuse of Sawdust. Procedia Manuf. 2018, 21, 510–517. [Google Scholar] [CrossRef]

- Velasquez, A.V. Diseño de Briquetas Ecologicas Para La Generacion de Energia Calorifica y Mejoramiento de Ecosistemas En El Corregimiento de Nabusimake, Municipio de Pueblo Bello-Cesar. Ph.D. Thesis, Universidad Nacional Abierta y a Distancia UNAD de Colombia, Bogotá, Colombia, 2014. Volume 6. [Google Scholar]

- Orisaleye, J.I.; Jekayinfa, S.O.; Braimoh, O.M.; Edhere, V.O. Empirical Models for Physical Properties of Abura (Mitragyna Ciliata) Sawdust Briquettes Using Response Surface Methodology. Clean. Eng. Technol. 2022, 7, 100447. [Google Scholar] [CrossRef]

- Kabaş, Ö.; Ünal, İ.; Sözer, S.; Selvi, K.C.; Ungureanu, N. Quality Assessment of Biofuel Briquettes Obtained from Greenhouse Waste Using a Mobile Prototype Briquetting Machine with PTO Drive. Energies 2022, 15, 8371. [Google Scholar] [CrossRef]

- Thabuot, M.; Pagketanang, T.; Panyacharoen, K.; Mongkut, P.; Wongwicha, P. Effect of Applied Pressure and Binder Proportion on the Fuel Properties of Holey Bio-Briquettes. Energy Procedia 2015, 79, 890–895. [Google Scholar] [CrossRef]

- Yank, A.; Ngadi, M.; Kok, R. Physical Properties of Rice Husk and Bran Briquettes under Low Pressure Densification for Rural Applications. Biomass Bioenergy 2016, 84, 22–30. [Google Scholar] [CrossRef]

- Rahaman, S.A.; Salam, P.A. Characterization of Cold Densified Rice Straw Briquettes and the Potential Use of Sawdust as Binder. Fuel Process. Technol. 2017, 158, 9–19. [Google Scholar] [CrossRef]

- Bello, R.S.; Onilude, M.A. Effects of Critical Extrusion Factors on Quality of High-Density Briquettes Produced from Sawdust Admixture. Mater. Today Proc. 2021, 38, 949–957. [Google Scholar] [CrossRef]

- Orisaleye, J.I.; Jekayinfa, S.O.; Adebayo, A.O.; Ahmed, N.A.; Pecenka, R. Effect of Densification Variables on Density of Corn Cob Briquettes Produced Using a Uniaxial Compaction Biomass Briquetting Press. Energy Sources Part Recovery Util. Environ. Eff. 2018, 40, 1–10. [Google Scholar] [CrossRef]

- Gonçalves, C.; Alves, C.; Pio, C. Inventory of Fine Particulate Organic Compound Emissions from Residential Wood Combustion in Portugal. Atmos. Environ. 2012, 50, 297–306. [Google Scholar] [CrossRef]

- Reisen, F.; Meyer, C.P.; Weston, C.J.; Volkova, L. Ground-Based Field Measurements of PM2.5 Emission Factors from Flaming and Smoldering Combustion in Eucalypt Forests. J. Geophys. Res. Atmos. 2018, 123, 8301–8314. [Google Scholar] [CrossRef]

- Day, S.J.; Carras, J.N.; Fry, R.; Williams, D.J. Greenhouse Gas Emissions from Australian Open-Cut Coal Mines: Contribution from Spontaneous Combustion and Low-Temperature Oxidation. Environ. Monit. Assess. 2010, 166, 529–541. [Google Scholar] [CrossRef]

- Magnone, E.; Park, S.-K.; Park, J.H. Effects of Moisture Contents in the Common Oak on Carbonaceous Aerosols Generated from Combustion Processes in an Indoor Wood Stove. Combust. Sci. Technol. 2016, 188, 982–996. [Google Scholar] [CrossRef]

- Calvo, A.I.; Tarelho, L.A.C.; Alves, C.A.; Duarte, M.; Nunes, T. Characterization of Operating Conditions of Two Residential Wood Combustion Appliances. Fuel Process. Technol. 2014, 126, 222–232. [Google Scholar] [CrossRef]

- Mohalik, N.K.; Lester, E.; Lowndes, I.S.; Singh, V.K. Estimation of Greenhouse Gas Emissions from Spontaneous Combustion/Fire of Coal in Opencast Mines—Indian Context. Carbon Manag. 2016, 7, 317–332. [Google Scholar] [CrossRef]

- Quiñones-Reveles, M.A.; Ruiz-García, V.M.; Ramos-Vargas, S.; Vargas-Larreta, B.; Masera-Cerutti, O.; Ngangyo-Heya, M.; Carrillo-Parra, A. Assessment of Pellets from Three Forest Species: From Raw Material to End Use. Forests 2021, 12, 447. [Google Scholar] [CrossRef]

- Wang, H.; van Eyk, P.J.; Medwell, P.R.; Birzer, C.H.; Tian, Z.F.; Possell, M.; Huang, X. Smouldering Fire and Emission Characteristics of Eucalyptus Litter Fuel. Fire Mater. 2022, 46, 576–586. [Google Scholar] [CrossRef]

- Alves, C.; Gonçalves, C.; Fernandes, A.P.; Tarelho, L.; Pio, C. Fireplace and Woodstove Fine Particle Emissions from Combustion of Western Mediterranean Wood Types. Atmos. Res. 2011, 101, 692–700. [Google Scholar] [CrossRef]

- Zhao, H.; Yang, G.; Tong, D.Q.; Zhang, X.; Xiu, A.; Zhang, S. Interannual and Seasonal Variability of Greenhouse Gases and Aerosol Emissions from Biomass Burning in Northeastern China Constrained by Satellite Observations. Remote Sens. 2021, 13, 1005. [Google Scholar] [CrossRef]

- Tschaplinski, T.J.; Simpson, S.D. Development of a Sustainable Green Chemistry Platform for Production of Acetone and Downstream Drop-in Fuel and Commodity Products Directly from Biomass Syngas Via a Novel Energy Conserving Route in Engineered Acetogenic Bacteria; U.S. Department of Energy: Washington, DC, USA, 2019.

- Lan, S. Assessing Textile Raw Materials and Exploring Sustainable Sources for Future Renewable Textile Materials for IKEA of Sweden; Swedish Un.; Department of Biosystems and Technology: Alnarp, Sweden, 2023. [Google Scholar]

- Liu, W.; Wang, J.; Bhattacharyya, D.; Jiang, Y.; DeVallance, D. Economic and Environmental Analyses of Coal and Biomass to Liquid Fuels. Energy 2017, 141, 76–86. [Google Scholar] [CrossRef]

| Average Amount of Material Used | Cost Per Briquette (USD) |

|---|---|

| 0.25 L | 0.053 |

| 75 g Shavings of sawdust | 0.0050 |

| 77.5 g Cornstarch | 0.0075 |

| Cost per briquette | (USD) 0.065 |

| Participant | Height (m) | Briquettes Produced (Quantity) |

|---|---|---|

| 1 | 1.75 | 108 |

| 2 | 1.70 | 92 |

| 3 | 1.70 | 84 |

| 4 | 1.65 | 98 |

| 5 | 1.85 | 96 |

| 6 | 1.70 | 102 |

| 7 | 1.78 | 80 |

| Food (1 kg) | Cooking Time with Briquettes (min) | Number of Briquettes Used |

|---|---|---|

| Cauliflower cooking | 48 | 17 |

| Cooking eggs | 55 | 21 |

| Chicken broth cooking | 67 | 25 |

| Quelites cooking | 50 | 19 |

| Fish broth cooking | 62 | 22 |

| Emission Factors per Dry Fuel Consumed | |||||

|---|---|---|---|---|---|

| Parameters | Briquette | Pine Firewood | Oak Firewood | Eucalyptus | Coal |

| gCO2/kg | 309 ± 75 | 1129 ± 118 | 1632 ± 315 [65] | 1726 ± 28 [66] | 264 ± 69 [67] |

| gCO/kg | 12 ± 5 | 39 ± 12 | 1.12 ± 0.09 [68] | 63.33 ± 6.18 [69] | 17.746 ± 0.01 [70] |

| mg CH4/kg | 233 ± 124 | 852 ± 324 | 101± 9 [71] | 16 ± 0.05 [72] | 40.3361 ± 0.03 [70] |

| mg PM2.5/kg | 1204 ± 579 | 3375 1293 | 5.8 ± 3.9 [73] | 10 ± 6.7 [73] | 543.2 ± ND [74] |

| g CO2e/kg | 77 ± 19 | 285 ± 31 | 4.62 ± ND [75] | 0.74 ± ND [76] | 80.62 ± ND [77] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morales-Máximo, M.; Ruíz-García, V.M.; Rutiaga-Quiñones, J.G.; López-Sosa, L.B. Design and Implementation of a Low-Pressure Briquetting Machine for the Use of Pinus spp. Wood Residues: An Approach to Appropriate Rural Technology. Clean Technol. 2025, 7, 22. https://doi.org/10.3390/cleantechnol7010022

Morales-Máximo M, Ruíz-García VM, Rutiaga-Quiñones JG, López-Sosa LB. Design and Implementation of a Low-Pressure Briquetting Machine for the Use of Pinus spp. Wood Residues: An Approach to Appropriate Rural Technology. Clean Technologies. 2025; 7(1):22. https://doi.org/10.3390/cleantechnol7010022

Chicago/Turabian StyleMorales-Máximo, Mario, Víctor Manuel Ruíz-García, José Guadalupe Rutiaga-Quiñones, and Luis Bernado López-Sosa. 2025. "Design and Implementation of a Low-Pressure Briquetting Machine for the Use of Pinus spp. Wood Residues: An Approach to Appropriate Rural Technology" Clean Technologies 7, no. 1: 22. https://doi.org/10.3390/cleantechnol7010022

APA StyleMorales-Máximo, M., Ruíz-García, V. M., Rutiaga-Quiñones, J. G., & López-Sosa, L. B. (2025). Design and Implementation of a Low-Pressure Briquetting Machine for the Use of Pinus spp. Wood Residues: An Approach to Appropriate Rural Technology. Clean Technologies, 7(1), 22. https://doi.org/10.3390/cleantechnol7010022