Effect of Gravel Size, Microwave Irradiation (1 to 2.5 min), Moisture, and Quenching on Aggregate Properties of Chert Gravel: Valorizing a “Waste” Byproduct of Sand Quarrying

Abstract

:1. Introduction

1.1. State of the Art—The Methods of Rock Treatment

1.2. State of the Art—Microwave Irradiation as the Method of Rock Treatment

2. Materials and Methods

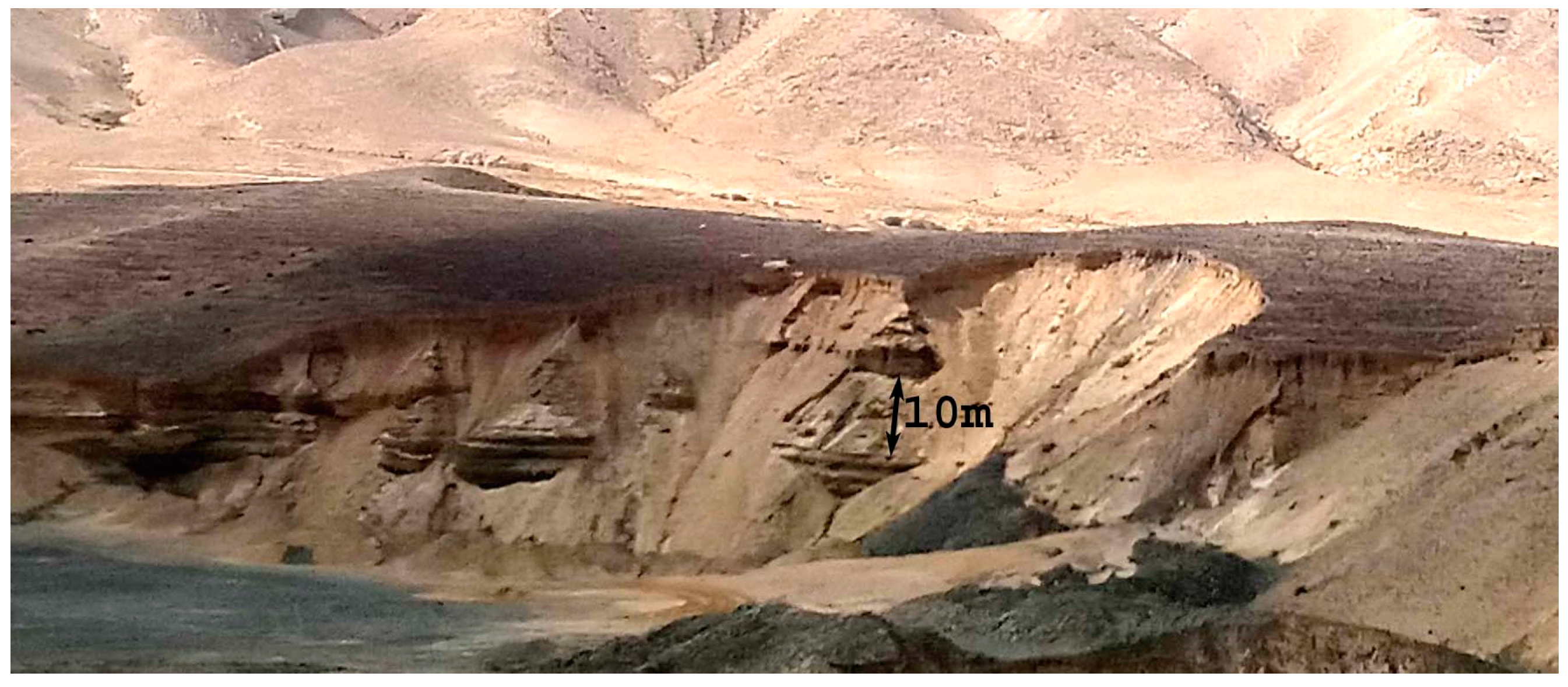

2.1. Geological Background

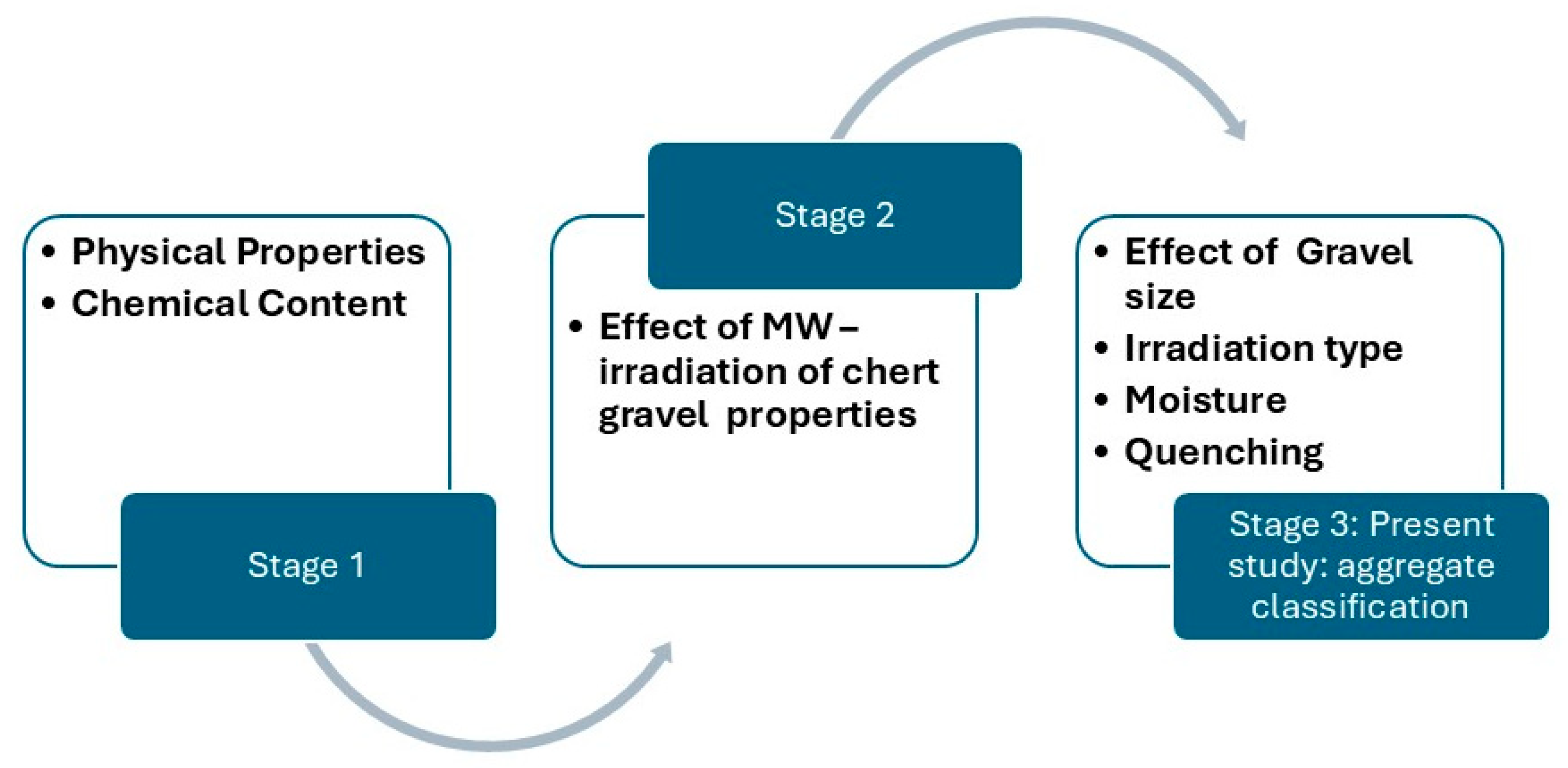

2.2. Method

- (1)

- Samples drying to avoid free water from the pores’ space–24 h, 110 °C);

- (2)

- Preparation for irradiation exposure, including preparation for weighting, when half of the samples were prewetted on their surface before weighting (Groups C, D—see below);

- (3)

- Weighting;

- (4)

- Microwave (MW) treatment;

- (5)

- Air and water cooling (Groups A,C, B,D, respectively—see below);

- (6)

- Preparation for crushing test;

- (7)

- Crushing test;

- (8)

- Aggregate sieving;

- (9)

- Classification.

- a.

- Sample preparation: The hollow cylinder was filled with aggregate to an average height of 95 mm and compacted manually.

- b.

- Machine activation: The press machine was operated at 0.025 MPa/s.

- c.

- Seating stage: The press was stopped once a deformation of 3 mm was achieved.

- d.

- Piston alignment: The loading piston was adjusted as needed.

- e.

- Progressive loading: Steps 3 and 4 were repeated for 5 mm, 10 mm, and 15 mm deformation values.

- f.

- Termination: The crushing process concluded upon reaching 15 mm deformation.

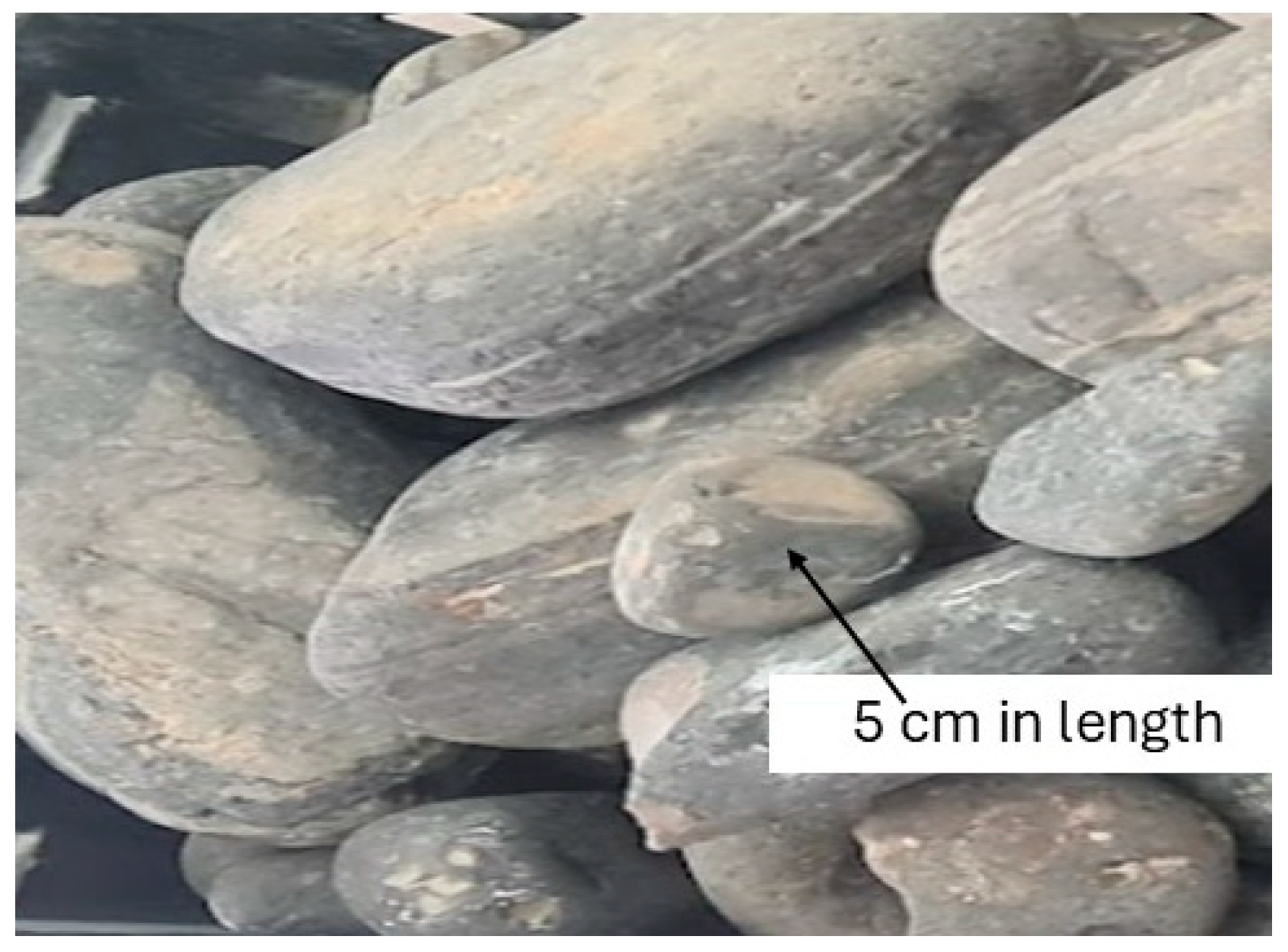

2.3. Materials

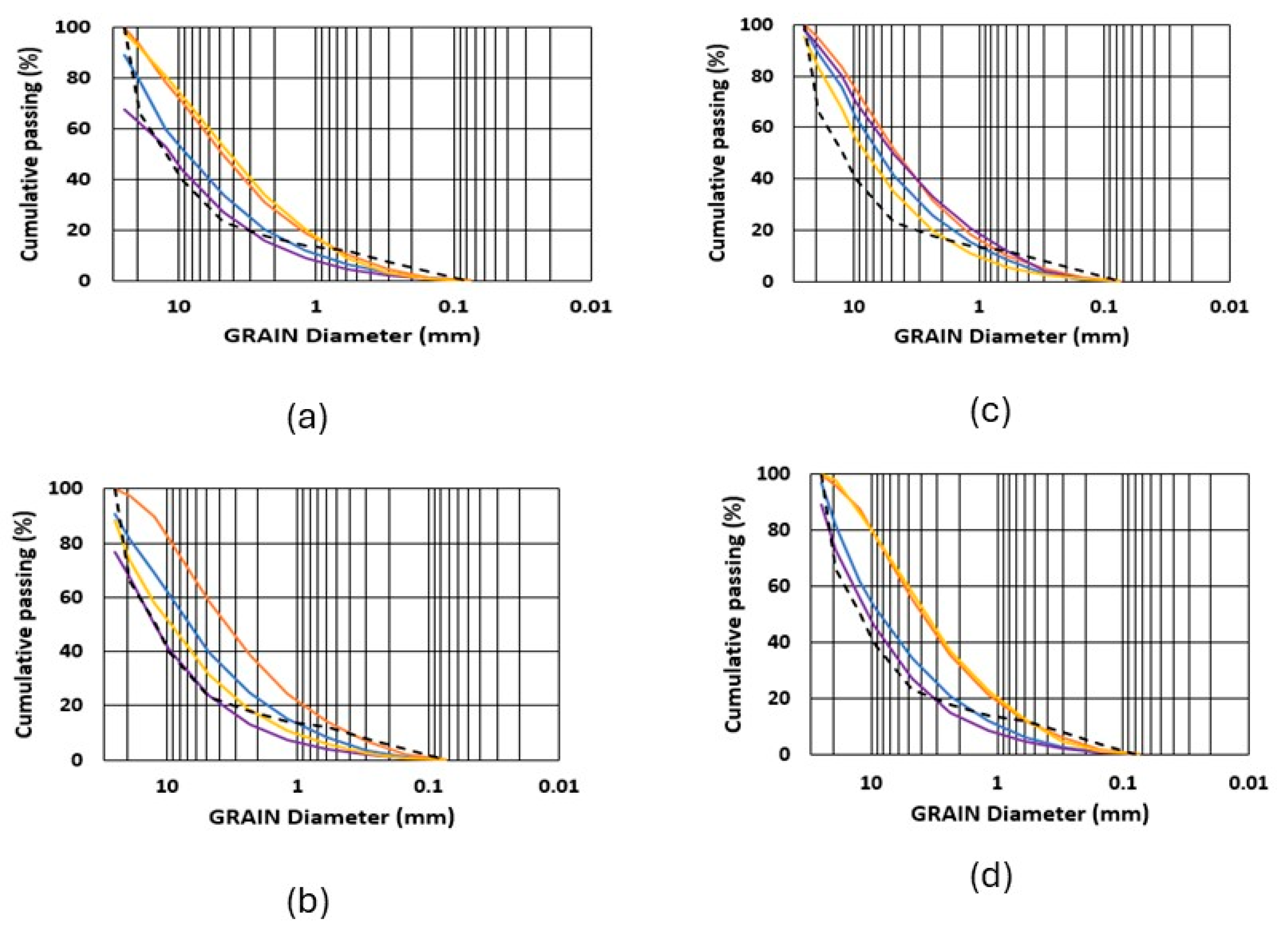

3. Results

- a.

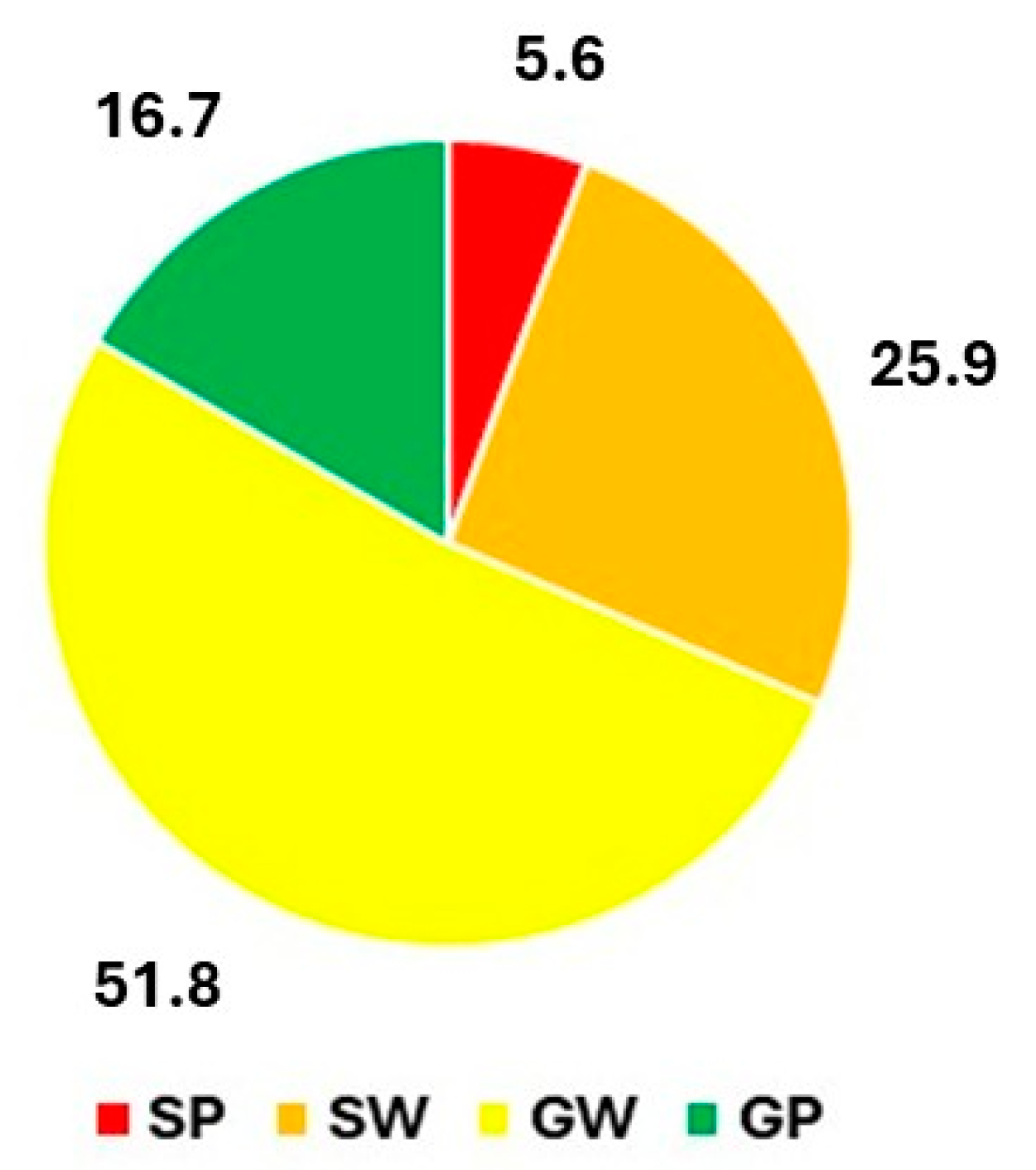

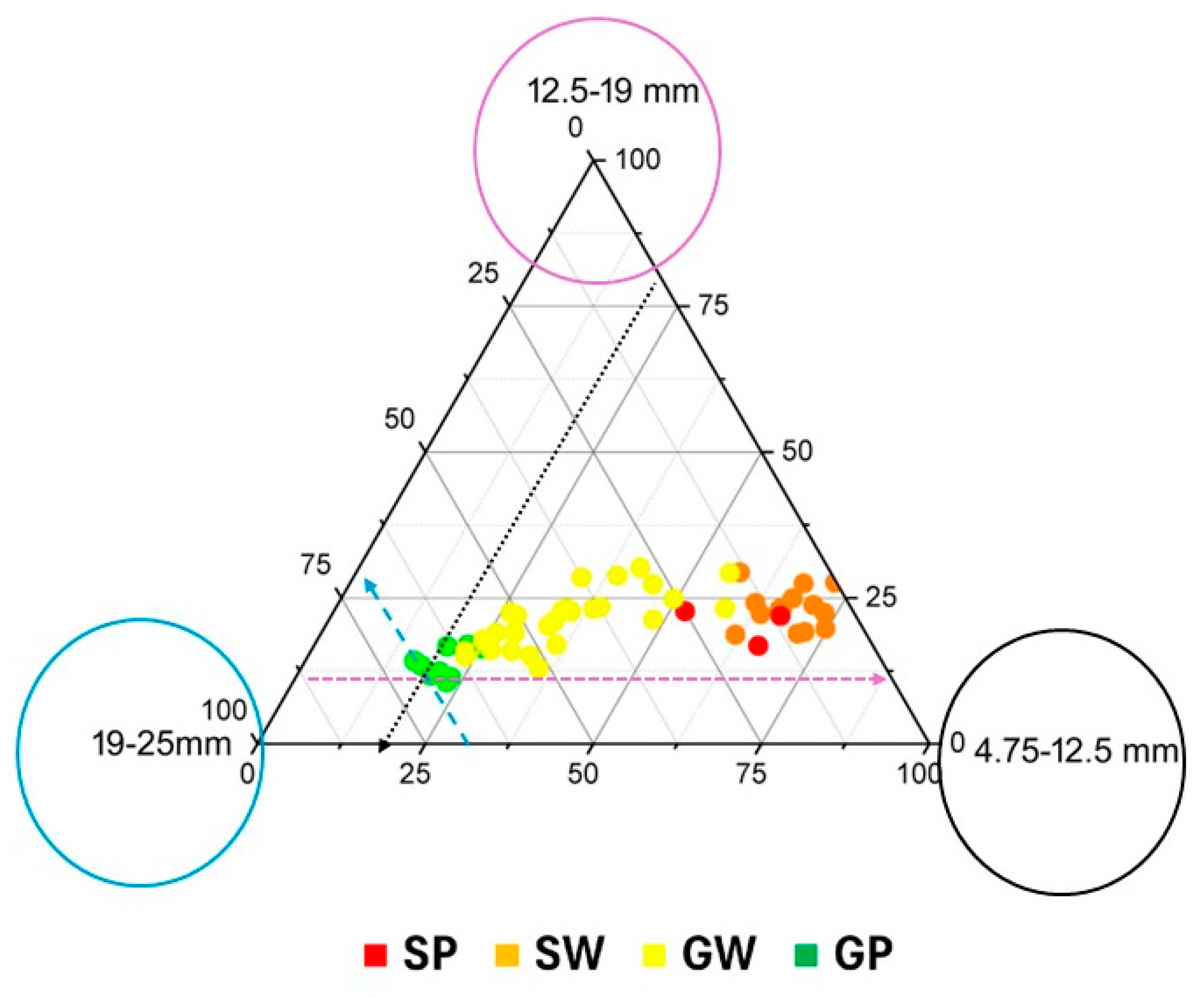

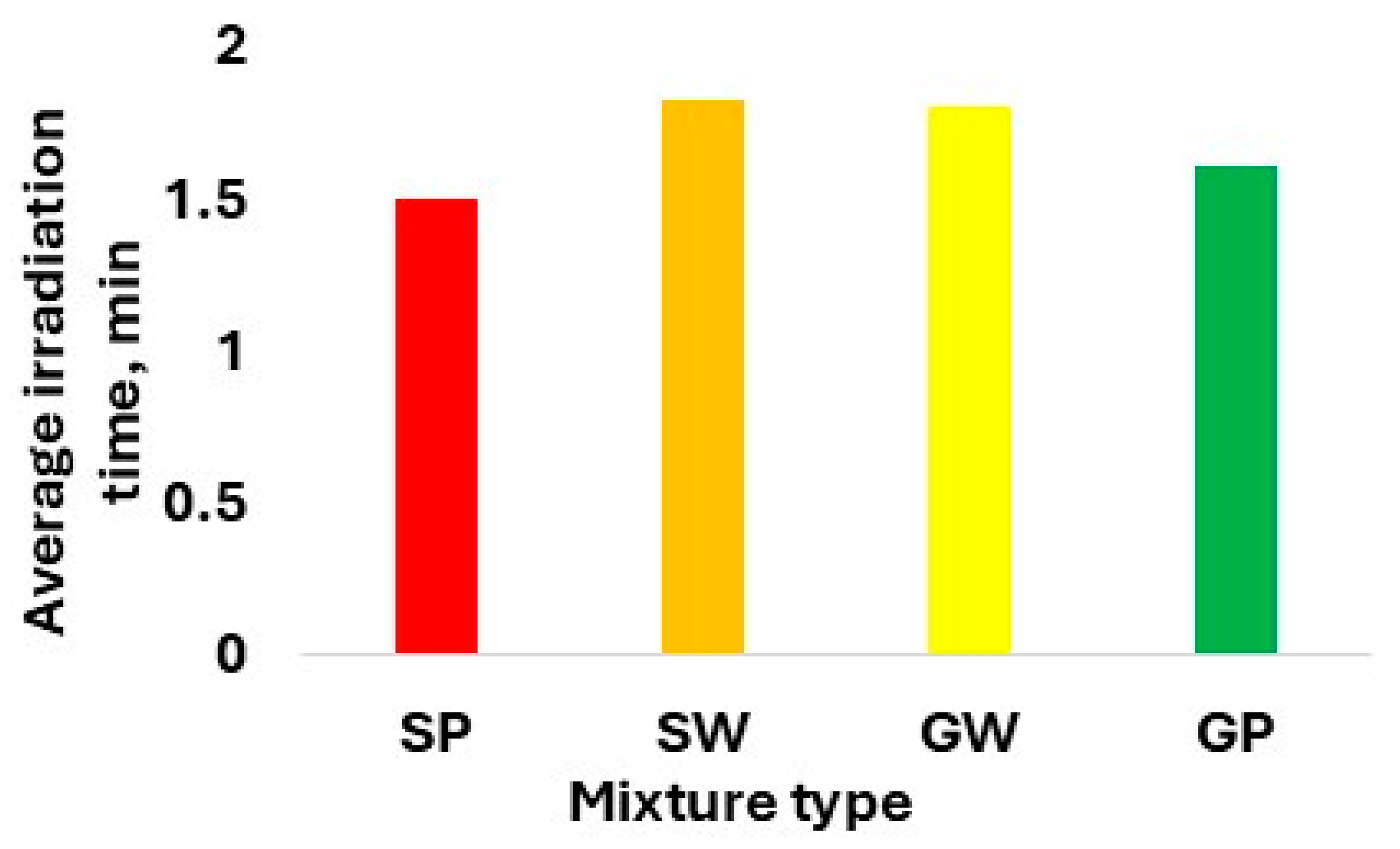

- The results show that the GW mixture is the most frequently obtained aggregate type.

- b.

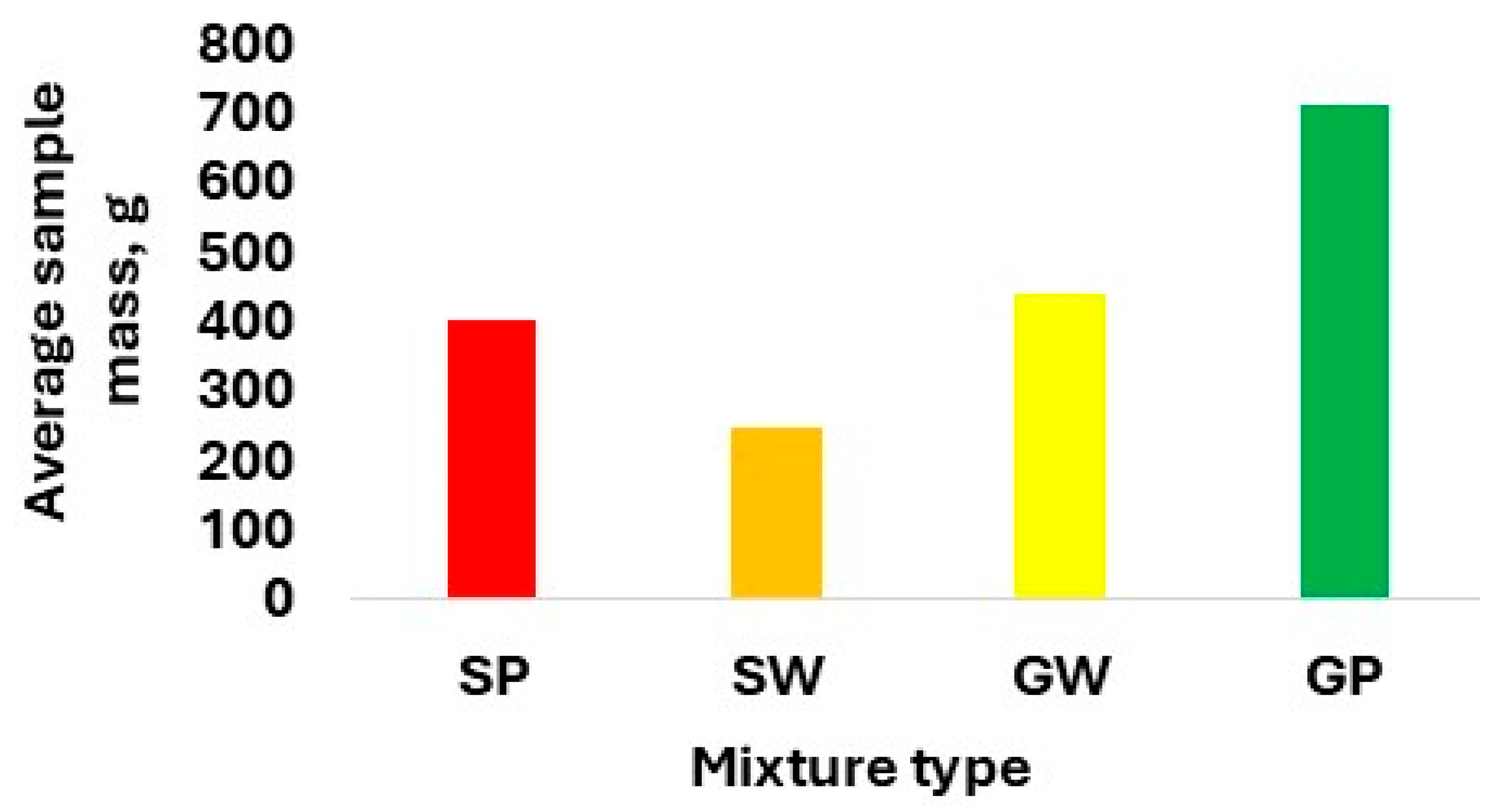

- Different pre-treatment methods (dry vs. wet, air vs. water cooling) influenced the resulting aggregate types.

- c.

- The larger samples (600–800 g) produced coarser, less uniform particles.

- d.

- The prolonged MW exposure time led to finer and more uniform aggregates.

- e.

- The quenching induces intense fracturing, creating irregular, highly fragmented aggregates.

- f.

- Pre-wetted samples exhibited finer and more uniform fragmentation than dry ones.

4. Discussion

5. Conclusions

- ✓

- Optimal MW exposure duration: At ≥2 min, significant micro-fracturing occurs, leading to finer, well-graded aggregates.

- ✓

- Influence of initial rock size: Larger samples (600–800 g) result in coarser, less uniform aggregates, while smaller samples (≤300 g) fragment more efficiently into well-graded materials.

- ✓

- Effect of moisture conditions: Pre-wetted samples exhibit finer, more uniform breakage than dry samples, improving fragmentation efficiency.

- ✓

- Cooling method impact: Air cooling produces well-graded gravel (GW), while water quenching results in poorly graded sand (SP) due to thermal shock effects.

- ✓

- Future research should focus on the following areas to enhance the practical adoption of MW-assisted chert gravel processing:

- ✓

- Flakiness Evaluation: Investigating the effects of MW exposure on aggregate flakiness and its implications for mechanical performance.

- ✓

- Industrial-Scale Feasibility: Conducting cost-benefit analyses and energy efficiency comparisons with conventional crushing methods.

- ✓

- Regulatory Compliance: Assessing whether MW-treated chert gravel meets physical and chemical standards for construction applications.

- ✓

- Long-Term Performance: Evaluating the durability of MW-treated aggregates under various environmental and load conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Somani, A.; Nandi, T.K.; Pal, S.K.; Majumder, A.K. Pre-treatment of rocks before comminution—A critical review of present practices. Int. J. Min. Sci. Technol. 2017, 27, 339–348. [Google Scholar] [CrossRef]

- Adewuyi, S.; Ahmed, H. Methods of Ore Pretreatment for Comminution Energy Reduction. Minerals 2020, 10, 423. [Google Scholar] [CrossRef]

- Jones, D.A.; Kingman, S.W.; Whittles, D.N.; Lowndes, I.S. The influence of microwave energy delivery method on strength reduction in ore samples. Chem. Eng. Process. 2007, 46, 291–299. [Google Scholar] [CrossRef]

- Bradshaw, S.; Louw, W.; van der Merwe, C.; Reader, H.; Kingman, S.; Celuch, M.; Kijewska, W. Techno-Economic Considerations in the Commercial Microwave Processing of Mineral Ores. J. Microw. Power Electromagn. Energy 2005, 40, 228–240. [Google Scholar] [CrossRef]

- Zhang, S.; Qiu, Q.; Zeng, C.; Paik, K.-W.; He, P.; Zhang, S. A review on the heating mechanism, materials and heating parameters of microwave hybrid heated joining technique. J. Manuf. Process. 2024, 116, 176–191. [Google Scholar] [CrossRef]

- Zhang, S.; Zhou, H.; Ding, T.; Long, W.; Zhong, S.; Paik, K.-W.; He, P.; Zhang, S. Impact of embedded susceptor mass and exposure time on morphological and property alterations in SAC305 joints using microwave hybrid heating. Mater. Lett. 2024, 357, 135736. [Google Scholar] [CrossRef]

- Zhang, S.; Zhou, H.; Ding, T.; Long, W.; Zhong, S.; Paik, K.-W.; He, P.; Zhang, S. Effect of microwave hybrid susceptors on the interface morphology, mechanical properties and fracture morphology of Cu/nano-Sn-3.0Ag-0.5Cu/Cu joints. J. Mater. Res. Technol. 2024, 28, 1743–1751. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, S.; Zhou, H.; Paik, K.-W.; Ding, T.; Long, W.; Zhong, S.; He, P. Preparation and characterization of Sn-3.0Ag-0.5Cu nano-solder paste and assessment of the reliability of joints fabricated by microwave hybrid heating. Mater. Charact. 2024, 207, 113512. [Google Scholar] [CrossRef]

- Lovas, M.; Znamenáčková, I.; Zubrik, A.; Kováčová, M.; Dolinská, S. The Application of Microwave Energy in Mineral Processing—A Review. Acta Montan. Slovaca 2011, 16, 137–148. [Google Scholar]

- Koleini, S.M.J.; Barani, K. Microwave Heating Applications in Mineral Processing; InTech: Houston, TX, USA, 2012; Volume ch4, pp. 79–104. [Google Scholar] [CrossRef]

- Bai, G.; Sun, Q.; Jia, H.; Ge, Z.; Tang, L.; Xue, S. Mechanical responses of igneous rocks to microwave irradiation: A review. Acta Geophys. 2022, 70, 1183–1192. [Google Scholar] [CrossRef]

- Qin, L.; Dai, J. Meso-mechanics simulation analysis of microwave-assisted mineral liberation. Frat. Integrità Strutt. 2015, 34, 543–553. [Google Scholar] [CrossRef]

- Shadi, A.; Samea, P.; Rabiei, M.; Ghoreishi-Madiseh, S.A. Energy Efficiency of Microwave-Induced Heating of Crushed Rocks/Ores. Minerals 2023, 13, 924. [Google Scholar] [CrossRef]

- Kumar, P.; Sahoo, B.K.; De, S.; Kar, D.D.; Chakraborty, S.; Meikap, B.C. Iron ore grindability improvement by microwave pre-treatment. J. Ind. Eng. Chem. 2010, 16, 805–812. [Google Scholar]

- Li, Q.; Li, X.; Yin, T. Effect of microwave heating on fracture behavior of granite: An experimental investigation. Eng. Fract. Mech. 2021, 250, 107758. [Google Scholar] [CrossRef]

- Kafashi, S.; Kuhar, L.; Bóna, A.; Nikoloski, A.N. Review of Fracturing Techniques (Microwaves, High-Voltage Pulses, and Cryogenic Fluids) for Application as Access Creation Method in Low-Permeability Hard Rocks for Potential in situ Metal Recovery. Miner. Process. Extr. Metall. Rev. 2023, 45, 522–537. [Google Scholar] [CrossRef]

- Adewuyi, S.; Ahmed, H. Grinding Behavior of Microwave-Irradiated Mining Waste. Energies 2021, 14, 3991. [Google Scholar] [CrossRef]

- Zheng, Y.L.; Ma, Z.J.; Yang, S.Q.; Zhao, X.B.; He, L.; Li, J.C. A microwave tractability index (MFI) of hard igneous rocks. Int. J. Rock Mech. Min. Sci. 2021, 138, 104566. [Google Scholar] [CrossRef]

- Zheng, Y.L.; Zhao, X.B.; Zhao, Q.H.; Li, J.C.; Zhang, Q.B. Dielectric properties of hard rock minerals and implications for microwave-assisted rock fracturing. Geomech. Geophys. Geo-Energy Geo-Resour. 2020, 6, 22. [Google Scholar] [CrossRef]

- Gao, F.; Shao, Y.; Zhou, K. Analysis of Microwave Thermal Stress Fracture Characteristics and Size Effect of Sandstone under Microwave Heating. Energies 2020, 13, 3614. [Google Scholar] [CrossRef]

- Qin, L.; Dai, J. Analysis on the growth of different shapes of mineral microcracks in the microwave field. Frat. Integrità Strutt. 2016, 37, 342–351. [Google Scholar] [CrossRef]

- Li, X.; Wang, S.; Xia, K.; Tong, T. Dynamic tensile response of a microwave-damaged granitic rock. Exp. Mech. 2021, 61, 461–468. [Google Scholar] [CrossRef]

- Deng, H.; Yang, B.; Gao, Y.; Xie, J.; Tang, R.; Ye, S. Mechanical weakening behavior and energy evolution characteristics of shale with different bedding angles after microwave irradiation. J. Geosci. Eng. 2023, 119, 205141. [Google Scholar] [CrossRef]

- Li, D.; Lyu, X.; Zhou, A.; Ru, W.; Su, X. Mechanical properties and damage constitutive relationship of microwave irradiation of granite under uniaxial compression. J. Therm. Stress. 2024, 47, 1519–1538. [Google Scholar] [CrossRef]

- Wang, S.; Lei, B.; Yao, P.; Xi, J.; Zhang, T.; Guo, Y.; Wu, X.; Sun, Y. The influences of microwave irradiation and heat treatment on the dynamic tensile response of granite. Engineering 2024, 6, 3. [Google Scholar] [CrossRef]

- Xu, T.; He, L.; Zheng, Y.; Zou, X.; Badrkhani, V.; Schillinger, D. Experimental and numerical investigations of microwave-induced damage and fracture formation in rock. J. Therm. Stress. 2021, 44, 513–528. [Google Scholar] [CrossRef]

- Xu, T.; Yuan, Y.; Heap, M.J.; Zhou, G.-L.; Perera, A.; Ranjith, P.G. Microwave-assisted damage and fracturing of hard rocks and its implications for effective mineral resources recovery. Miner. Eng. 2021, 160, 106663. [Google Scholar] [CrossRef]

- Lu, G.; Ding, C.; Zhou, J.; Liu, H.; Liu, C. Influences of microwave irradiation on rock-breaking efficiency of a reduced-scale TBM cutter. Appl. Sci. 2023, 13, 4713. [Google Scholar] [CrossRef]

- Lu, G.; Ding, C.; Hong, K.; Zhou, J.; Liu, H.; Yan, C. Influences of microwave irradiation on the physicomechanical properties and Cerchar abrasive index of rocks. Geofluids 2023, 2023, 3889083. [Google Scholar] [CrossRef]

- Ge, Z.; Sun, Q.; Hu, J.; Guan, Y.; Liu, W.; Wang, S.; Geng, J.; Hu, J. Fracture characteristics and thermal damage mechanism of shale under microwave radiation. J. Therm. Anal. Calorim. 2024, 149, 13147–13160. [Google Scholar] [CrossRef]

- Ge, Z.; Guan, Y.; Lyu, C. Variation in the electrical properties of gabbro after microwave heating. Heat Mass Transf. 2024, 60, 1485–1495. [Google Scholar] [CrossRef]

- Sun, B.-W.; Yang, S.-Q.; Huang, M.; Li, H.; Tian, W.-L.; Huang, Y.-H. Response mechanism of dynamic tensile mechanics in granite under microwave irradiation: Insights from experiments and simulations. Int. J. Rock Mech. Min. Sci. 2024, 57, 9165–9182. [Google Scholar] [CrossRef]

- Rasyid, M.A.; Aslam, A.; Rafiei, A.; Hassani, F.; Sasmito, A.P. Application of instantaneous power draw analysis to investigate the impact of microwave heating on kimberlite ore crushing. Appl. Energy 2023, 352, 121900. [Google Scholar] [CrossRef]

- Shadi, A.; Ahmadihosseini, A.; Rabiei, M.; Samea, P.; Hassani, F.; Sasmito, A.P.; Ghoreishi-Madiseh, S.A. Numerical and experimental analysis of fully coupled electromagnetic and thermal phenomena in microwave heating of rocks. Miner. Eng. 2022, 178, 107406. [Google Scholar] [CrossRef]

- Li, Q.; Cheng, B.; Li, X.; Yin, T.; Huang, L. Fracture behavior of microwave-heated granite under indentation: Experimental and numerical investigation. Eng. Fract. Mech. 2022, 269, 108535. [Google Scholar] [CrossRef]

- Wang, S.; Xu, Y.; Xia, K.; Tong, T. Dynamic fragmentation of microwave irradiated rock. J. Rock Mech. Geotech. Eng. 2021, 13, 300–310. [Google Scholar] [CrossRef]

- Yao, H.; Fang, Q.; Jia, Y.; Liu, J.C.; Lu, G.; Yang, F. Mechanical and fracture characteristics of weak microwave-absorbing sandstone under microwave irradiation: Influence of pore water. J. Microw. Power Electromagn. Energy 2024, 58, 370–384. [Google Scholar] [CrossRef]

- Zhao, Q.H.; Zhao, X.B.; Zheng, Y.L.; Li, J.C.; He, L.; Zou, C.J. Microwave fracturing of water-bearing sandstones: Heating character-istics and bursting. Int. J. Rock Mech. Min. Sci. 2020, 136, 104495. [Google Scholar] [CrossRef]

- Tang, M.-Y.; Gao, M.-Z.; Li, S.-W.; Yang, B.-G.; Tang, R.-F.; Li, F.; Liu, J.-J. Deep roadway sandstone’s failure behavior and energy evolution characteristics under different microwave irradiation modes. J. Cent. South Univ. 2023, 30, 214–226. [Google Scholar] [CrossRef]

- Yang, Z.; Tao, M.; Memon, M.B.; Zhuang, D.; Zhao, Y. Microwave irradiation-induced deterioration of rock mechanical properties and implications for mechanized hard rock excavation. J. Rock Mech. Geotech. Eng. 2025, 17, 275–290. [Google Scholar] [CrossRef]

- Yang, Z.; Tao, M.; Memon, M.B.; Zhuang, D.; Zhao, J. Effect of microwave treatment on thermal and ultrasonic properties of gabbro. Appl. Therm. Eng. 2017, 127, 359–369. [Google Scholar] [CrossRef]

- Teng, T.; Yi, P.; Jia, W.-J.; Wu, X.-Y. Experimental observation on rock damage under microwave thermal shock. Therm. Sci. 2024, 28, 3457–3463. [Google Scholar] [CrossRef]

- Ning, B.; Liu, F.; Liu, H.; Xia, Y. Experimental study on rock breaking using a microwave-assisted tunnel boring machine cutter. Int. J. Rock Mech. Min. Sci. 2024, 83, 114. [Google Scholar] [CrossRef]

- Yin, T.; Wu, B.; Wang, C.; Wu, Y. Determination of dynamic tensile strength of microwave-induced basalt using Brazilian test. Int. J. Rock Mech. Min. Sci. 2022, 55, 1429–1443. [Google Scholar] [CrossRef]

- Yang, Z.; Yin, T.; Wu, Y.; Zhuang, D.; Yin, J.; Ma, J. Mixed-mode I/II fracture properties and failure characteristics of microwave-irradiated basalt: An experimental study. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 814–834. [Google Scholar] [CrossRef]

- Lu, G.; Sun, J.; Zhou, K.; Chen, F.; Li, G. Effect of microwave irradiation on hard rock’s computed tomography and acoustic emission characteristics. Rock Mech. Rock Eng. 2021, 39, 411–424. [Google Scholar] [CrossRef]

- Tzibulsky, M.; Frid, V. Features of the Physical-Mechanical Properties and Chemical Composition of Chert Gravels. Minerals 2023, 13, 455. [Google Scholar] [CrossRef]

- Tzibulsky, M.; Frid, V. The Comminution of Chert Gravel by Microwave Irradiation. Resources 2024, 13, 63. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, S.; Ni, J.; Azzam, R.; Fernandez-Steeger, T.M. An experimental study of the mechanical properties of granite after high-temperature exposure based on mineral characteristics. Eng. Geol. 2017, 220, 234–242. [Google Scholar]

- Peng, J.; Rong, G.; Cai, M.; Yao, M.; Zhou, C. Physical and mechanical behaviors of a thermal-damaged coarse marble under uniaxial compression. Eng. Geol. 2016, 200, 88–93. [Google Scholar]

- Zhang, Q.; Li, X.; Bai, B.; Hu, H. The shear behavior of sandstone joints under different fluid and temperature conditions. Eng. Geol. 2019, 257, 105143. [Google Scholar]

- Lu, C.; Sun, Q.; Zhang, W.; Geng, J.; Qi, Y.; Lu, L. The effect of high temperature on tensile strength of sandstone. Appl. Therm. Eng. 2017, 111, 573–579. [Google Scholar] [CrossRef]

- Wang, P.; Xu, J.; Fang, X.; Wen, M.; Zheng, G.; Wang, P. Dynamic splitting tensile behaviors of red-sandstone subjected to repeated thermal shocks: Deterioration and micro-mechanism. Eng. Geol. 2017, 223, 1–10. [Google Scholar]

- Wang, P.; Xu, J.; Liu, S.; Wang, H. Dynamic mechanical properties and deterioration of red sandstone subjected to repeated thermal shocks. Eng. Geol. 2016, 212, 44–52. [Google Scholar]

- Yin, T.; Li, Q.; Li, X. Experimental investigation on mode I fracture characteristics of granite after cyclic heating and cooling treatments. Eng. Fract. Mech. 2019, 222, 106740. [Google Scholar]

- Sun, Q.; Zhang, W.; Zhu, Y.; Huang, Z. Effect of High Temperatures on the Thermal Properties of Granite. Rock Mech. Rock Eng. 2019, 52, 2691–2699. [Google Scholar]

- Sun, H.; Sun, Q.; Deng, W.; Zhang, W.; Lü, C. Temperature effect on microstructure and P-wave propagation in Linyi sandstone. Appl. Therm. Eng. 2017, 115, 913–922. [Google Scholar]

- Mahanta, B.; Singh, T.N.; Ranjith, P.G. Influence of thermal treatment on mode I fracture toughness of certain Indian rocks. Eng. Geol. 2016, 210, 103–114. [Google Scholar]

- Zuo, J.; Li, Y.; Zhang, X.; Zhao, Z.; Wang, T. The effects of thermal treatments on the subcritical crack growth of Pingdingshan sandstone at elevated high temperatures. Rock Mech. Rock Eng. 2018, 51, 3439–3454. [Google Scholar]

- Yin, T.; Wu, Y.; Li, Q.; Wang, C.; Wu, B. Determination of double-K fracture toughness parameters of thermally treated granite using notched semi-circular bending specimen. Eng. Fract. Mech. 2019, 226, 106865. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, Y. Combined effects of salt, cyclic wetting, and drying cycles on sandstone’s physical and mechanical properties. Eng. Geol. 2019, 248, 70–79. [Google Scholar]

- Borinaga-Trevino, R.; Orbe, A.; Norambuena-Contreras, J.; Canales, J. Effect of microwave heating damage on fiber-reinforced cement mortars’ electrical, thermal and mechanical properties. Constr. Build. Mater. 2018, 186, 31–41. [Google Scholar] [CrossRef]

- Yin, T.; Wang, P.; Li, X.; Wu, B.; Tao, M.; Shu, R. Determination of Dynamic Flexural Tensile Strength of Thermally Treated Laurentian Granite Using Semi-Circular Specimens. Rock Mech. Rock Eng. 2016, 49, 3887–3898. [Google Scholar] [CrossRef]

- Wang, P.; Yin, T.; Li, X.; Zhang, S.; Bai, L. Dynamic Properties of Thermally Treated Granite Subjected to Cyclic Impact Loading. Rock Mech. Rock Eng. 2019, 52, 991–1010. [Google Scholar] [CrossRef]

- Teimoori, K.; Hassani, F.; Sasmito, A.P.; Ghoreishi-Madiseh, S.A. Experimental investigations of microwave effects on rock breakage using SEM analysis. In Proceedings of the 17th International Conference on Microwave and High-Frequency Heating, Valencia, Spain, 9–12 September 2019. [Google Scholar] [CrossRef]

- Hartlieb, P.; Grafe, P.H. Experimental Study on Microwave Assisted Hard Rock Cutting of Granite. BHM 2017, 162, 77–81. [Google Scholar] [CrossRef]

- Hassani, F.; Nekoovaght, P.M.; Gharib, N. The influence of microwave irradiation on rocks for microwave-assisted underground excavation. J. Rock Mech. Geotech. Eng. 2015, 8, 1–15. [Google Scholar] [CrossRef]

- Kim, S.; Santamarina, J.K. Rock Crushing using Microwave Pre-treatment. In Geo-Chicago 2016 Session: D53/Modeling and Simulations, Part II; ASCE: Reston, VA, USA, 2016. [Google Scholar] [CrossRef]

- Jones, D.A.; Kingman, S.W.; Whittles, D.N.; Lowndes, I.S. Understanding microwave assisted breakage. Miner. Eng. 2005, 18, 659–669. [Google Scholar] [CrossRef]

- Lu, G.M.; Feng, X.-T.; Li, Y.-H.; Hassani, F.; Zhang, X. Experimental Investigation on the Effects of Microwave Treatment on Basalt Heating, Mechanical Strength, and Fragmentation. Rock Mech. Rock Eng. 2019, 52, 2535–2549. [Google Scholar] [CrossRef]

- Zhao, Q.; Zheng, Y.; Li, J.; Che, P.; Zhao, X. Heating and water transport behavior of sandstones under microwave irradiation. Int. J. Rock Mech. Min. Sci. 2024, 57, 4755–4770. [Google Scholar] [CrossRef]

- Su, X.L.; Li, D.Y.; Zhou, A.H.; Zhang, C.X.; Tao, J. Experimental studies on mechanical properties and brittleness of granite treated with different microwave heating times. J. Cent. South Univ. 2023, 30, 4052–4065. [Google Scholar] [CrossRef]

- Zhang, Y.; Gu, Y.; Sun, Q.; Rui, F.; Ge, Z.; Jia, H. Influence of microwave irradiation and water-based cooling on the fracturing behavior and failure mode transition of CSTBD granite. Eng. Fract. Mech. 2024. [Google Scholar] [CrossRef]

- Li, J.; Kaunda, R.B.; Arora, S.; Hartlieb, P.; Nelson, P.P. Fully-coupled simulations of thermally-induced cracking in pegmatite due to microwave irradiation. J. Rock Mech. Geotech. Eng. 2019, 11, 242–250. [Google Scholar] [CrossRef]

- Kahraman, S.; Ahmet, N.; Canpolat, C.; Mustafa, F.; Ozcan, C.; Kilic, A.N.C.; Kilic, Á.C.O. The assessment of the factors affecting the microwave heating of magmatic rocks. J. Sustain. Min. 2020, 6, 66. [Google Scholar] [CrossRef]

- Kahraman, S.; Canpolat, A.N.; Fener, M. The influence of microwave treatment on igneous rocks’ compressive and tensile strength. Int. J. Rock Mech. Min. Sci. 2020, 129, 104303. [Google Scholar] [CrossRef]

- Buttress, A.J.; Katrib, J.; Jones, D.A.; Batchelor, A.R.; Craig, D.A.; Royal, T.A.; Dodds, C.; Kingman, S.W. Towards large scale microwave treatment of ores: Part 1—Basis of design, construction, and commissioning. Miner. Eng. 2017, 109, 169–183. [Google Scholar]

- Batchelor, A.R.; Buttress, A.J.; Jones, D.A.; Katrib, J.; Way, D.; Chenje, T.; Stoll, D.; Dodds, C.; Kingman, S.W. Towards large scale microwave treatment of ores: Part 2–2—Metallurgical testing. Miner. Eng. 2017, 111, 5–24. [Google Scholar]

- Shahar, Y. The Hazeva Formation in the Oron-Ef’e syncline. Isr. J. Earth Sci. 1973, 22, 31–49. [Google Scholar]

- Calvo, R.; Bartov, Y. Hazeva Group, southern Israel: New observations, and their implications for its stratigraphy, paleogeography, and tectonic-sedimentary regime. Isr. J. Earth Sci. 2001, 50, 71–99. [Google Scholar]

- Shirav, M.; Shiloni, I.; Minster, Z. Sands from Mishor Rotem Region; Report GSI 11/97, Geological Survey of Israel, The Ministry of National Infrastructure, 30 Malkhe Israel St., 95501 Jerusalem, 1997. Available online: https://www.gov.il/BlobFolder/reports/reports-1997/he/report_1997_Shirav-M-Mishor-Rotem-Sands-Volumetric-Computations-Based-Boreholes-GSI-20-1997.pdf (accessed on 1 January 2023). (In Hebrew)

- Shahar, J. Note on stratigraphic relations of Zefa, Hazeva, and Hufeira formations in southern Israel. Isr. J. Earth Sci. 2008, 57, 33–34. [Google Scholar]

- BS 812-112:1990; British Standards Institution. Testing Aggregates. Method for Determination of Aggregate Impact Value (AIV). BSI: London, UK, 1990.

- ISO 3310-1:2016; Test Sieves-Technical Requirements and Testing—Part 1: Test Sieves of Metal Wire Cloth. International Organization for Standardization: Geneva, Switzerland, 2016.

- ASTM D2487; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ANSI: Washington, DC, USA, 2018.

- Strzałkowski, P.; Duchnowska, M.; Kazmierczak, U.; Bakalarz, A.; Wolny, M.; Karwowski, P.; Stepien, T. Evaluation of the Structure and Geometric Properties of Crushed Igneous Rock Aggregates. Materials 2021, 14, 7202. [Google Scholar] [CrossRef]

- Sattar, O.; Khalid, U.; Rehman, Z.; Kayani, W.I.; Haider, A. Impact of crushing shape and geopolymerization on reclaimed concrete aggregate for recycling in the flexible pavement: An enhanced circular economy solution. Road Mater. Pavement Des. 2024, 25, 1910–1932. [Google Scholar] [CrossRef]

- Pham, A.M.; Descantes, Y.; de Larrard, F. Determination of sieve grading curves using an optical device. Mechatronics 2011, 21, 298–309. [Google Scholar] [CrossRef]

- Hassan, H.M.Z.; Wu, K.; Huang, W.; Chen, S.; Zhang, Q.; Xie, J.; Cai, X. Study on the influence of aggregate strength and shape on the performance of asphalt mixture. Constr. Build. Mater. 2021, 294, 123599. [Google Scholar] [CrossRef]

- Bouquety, M.N.; Descantes, Y.; Barcelo, L.; de Larrard, F.; Clavaud, B. Experimental study of crushed aggregate shape. Constr. Build. Mater. 2007, 21, 865–872. [Google Scholar] [CrossRef]

| Properties | Value |

|---|---|

| Density (g/cm3) | 2.57 ± 0.04 |

| Porosity (%) | 0.34 ± 0.3 |

| Mass water absorption (%) | 0.13 ± 0.13 |

| Point Load index–Is(50), MPa | 12.5± 5.2 |

| The mean value of uniaxial compression strength, MPa | 321.0 ± 118.5 |

| Tension strength, MPa | 10.8 ± 3.3 |

| The value of ultrasonic wave speed, km/s | 4.38 ± 0.72 |

| Electrical resistivity, kOhm*m | 23 ± 1.9 |

| Dielectric constant | 2.53 ± 0.25 |

| Magnetic susceptibility | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tzibulsky, M.; Frid, V. Effect of Gravel Size, Microwave Irradiation (1 to 2.5 min), Moisture, and Quenching on Aggregate Properties of Chert Gravel: Valorizing a “Waste” Byproduct of Sand Quarrying. Clean Technol. 2025, 7, 29. https://doi.org/10.3390/cleantechnol7020029

Tzibulsky M, Frid V. Effect of Gravel Size, Microwave Irradiation (1 to 2.5 min), Moisture, and Quenching on Aggregate Properties of Chert Gravel: Valorizing a “Waste” Byproduct of Sand Quarrying. Clean Technologies. 2025; 7(2):29. https://doi.org/10.3390/cleantechnol7020029

Chicago/Turabian StyleTzibulsky, Mark, and Vladimir Frid. 2025. "Effect of Gravel Size, Microwave Irradiation (1 to 2.5 min), Moisture, and Quenching on Aggregate Properties of Chert Gravel: Valorizing a “Waste” Byproduct of Sand Quarrying" Clean Technologies 7, no. 2: 29. https://doi.org/10.3390/cleantechnol7020029

APA StyleTzibulsky, M., & Frid, V. (2025). Effect of Gravel Size, Microwave Irradiation (1 to 2.5 min), Moisture, and Quenching on Aggregate Properties of Chert Gravel: Valorizing a “Waste” Byproduct of Sand Quarrying. Clean Technologies, 7(2), 29. https://doi.org/10.3390/cleantechnol7020029