Recovery of Vegetable Fibers from Licorice Processing Waste and a Case Study for Their Use in Green Building Products

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Used

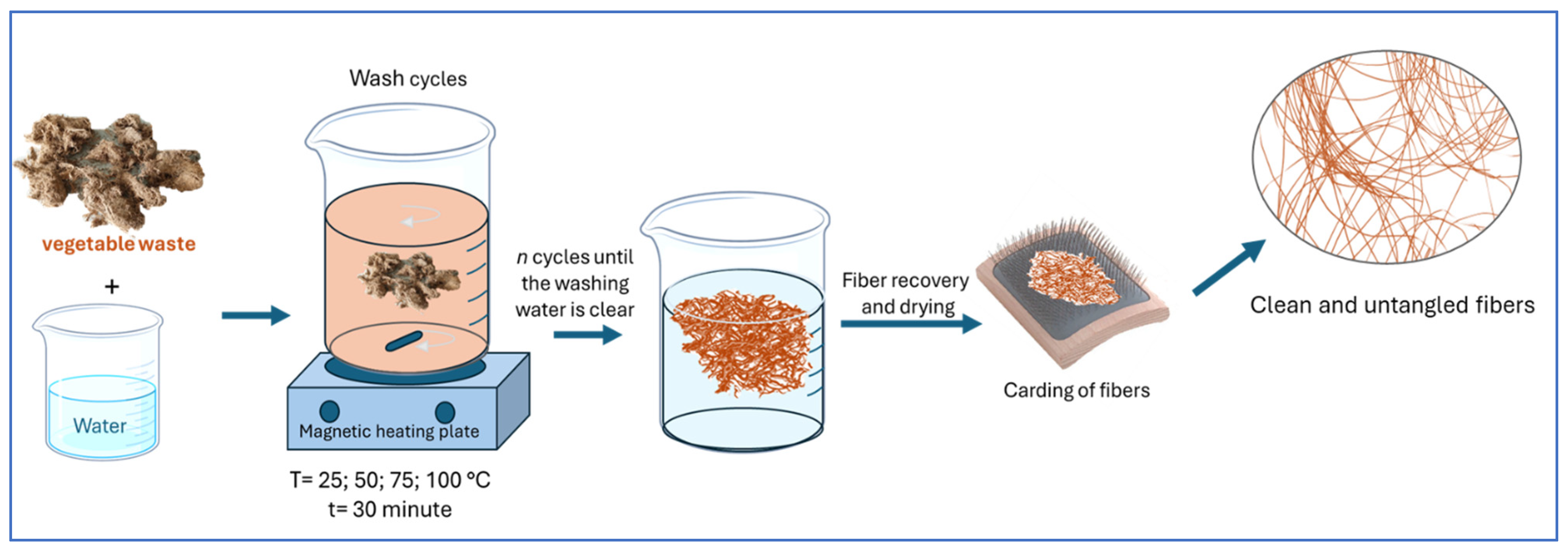

2.2. Extraction and Cleaning of Fibers Through the Thermal Process

2.3. Preparation Gypsum Matrix Samples for Mechanical Tests of Flexural Strength

2.4. Instruments

3. Results

3.1. Characterization of Waste

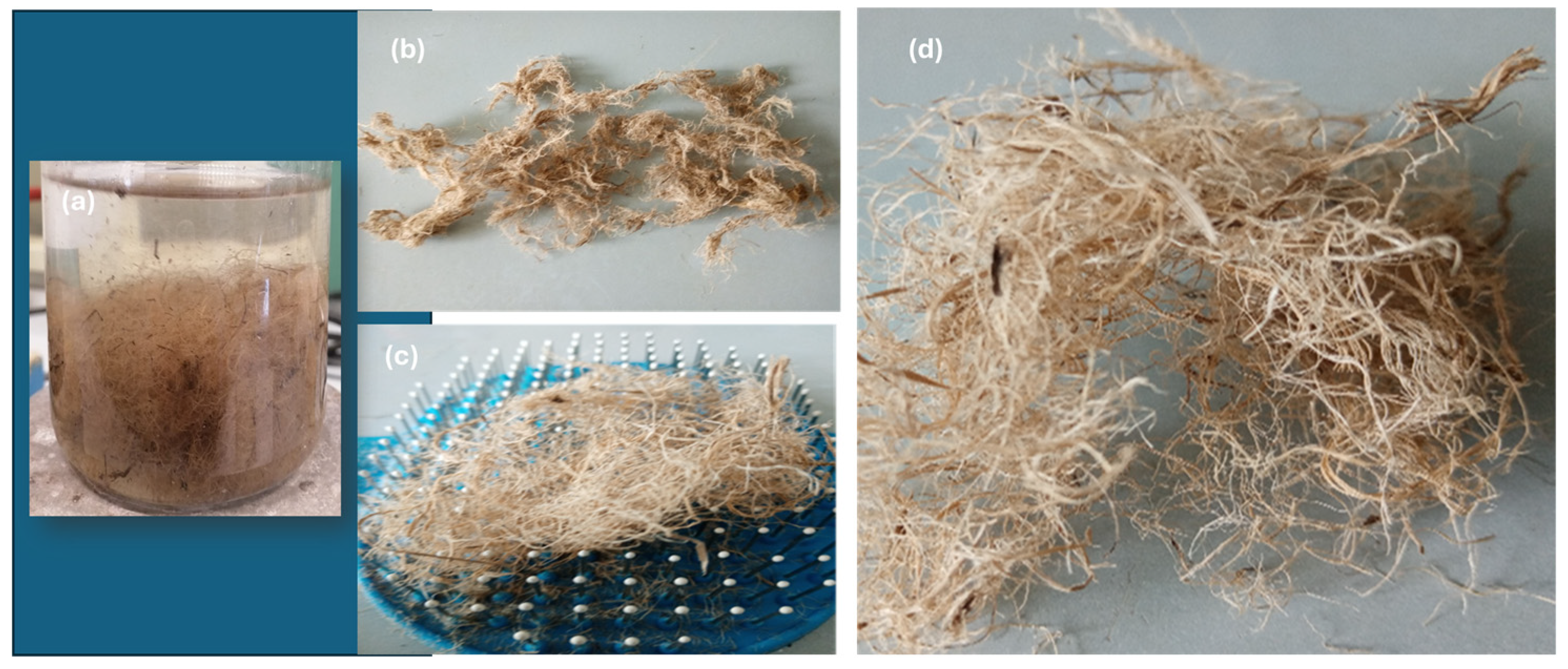

3.1.1. Macroscopic Characterization of Waste

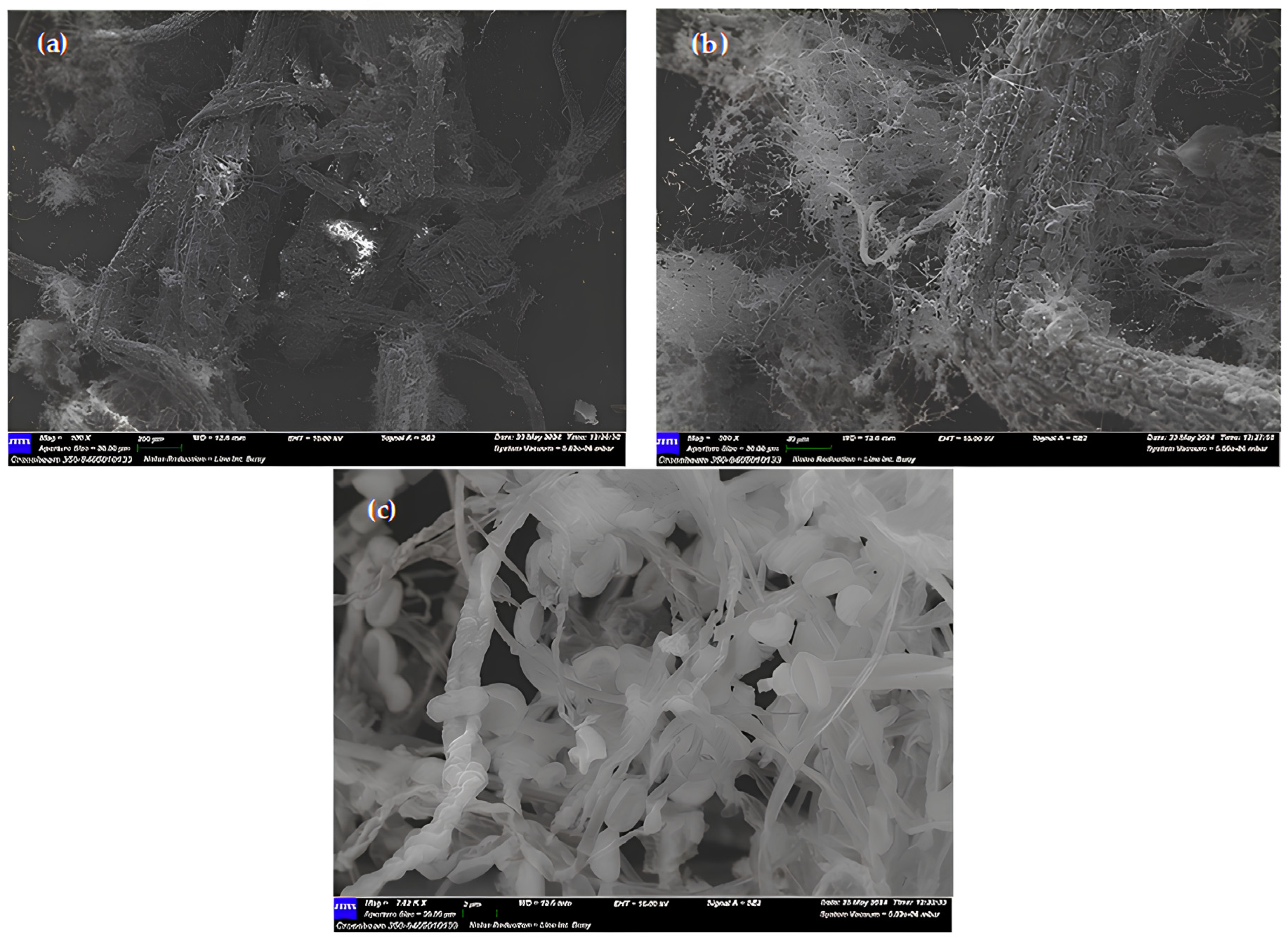

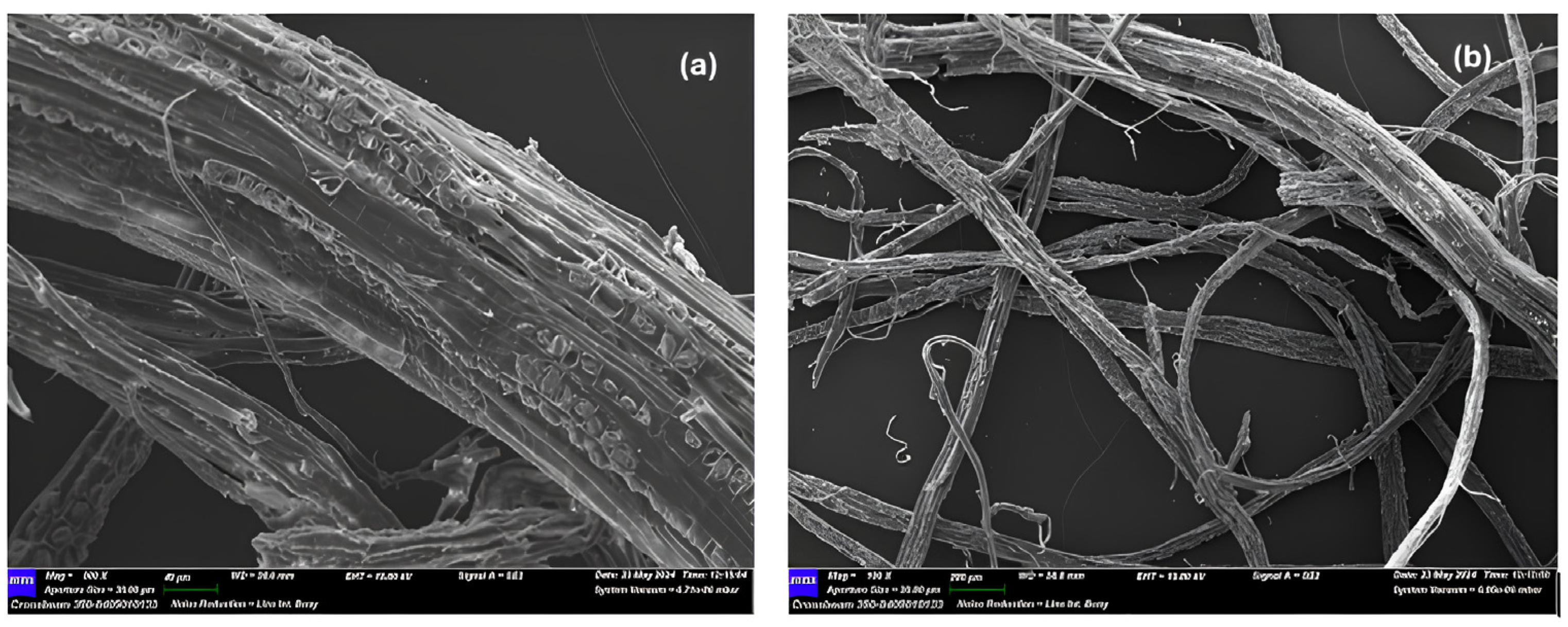

3.1.2. Characterization of the Waste by SEM (Electronic Microscope) and EDS (Energy Dispersive X-Ray Spectroscopy)

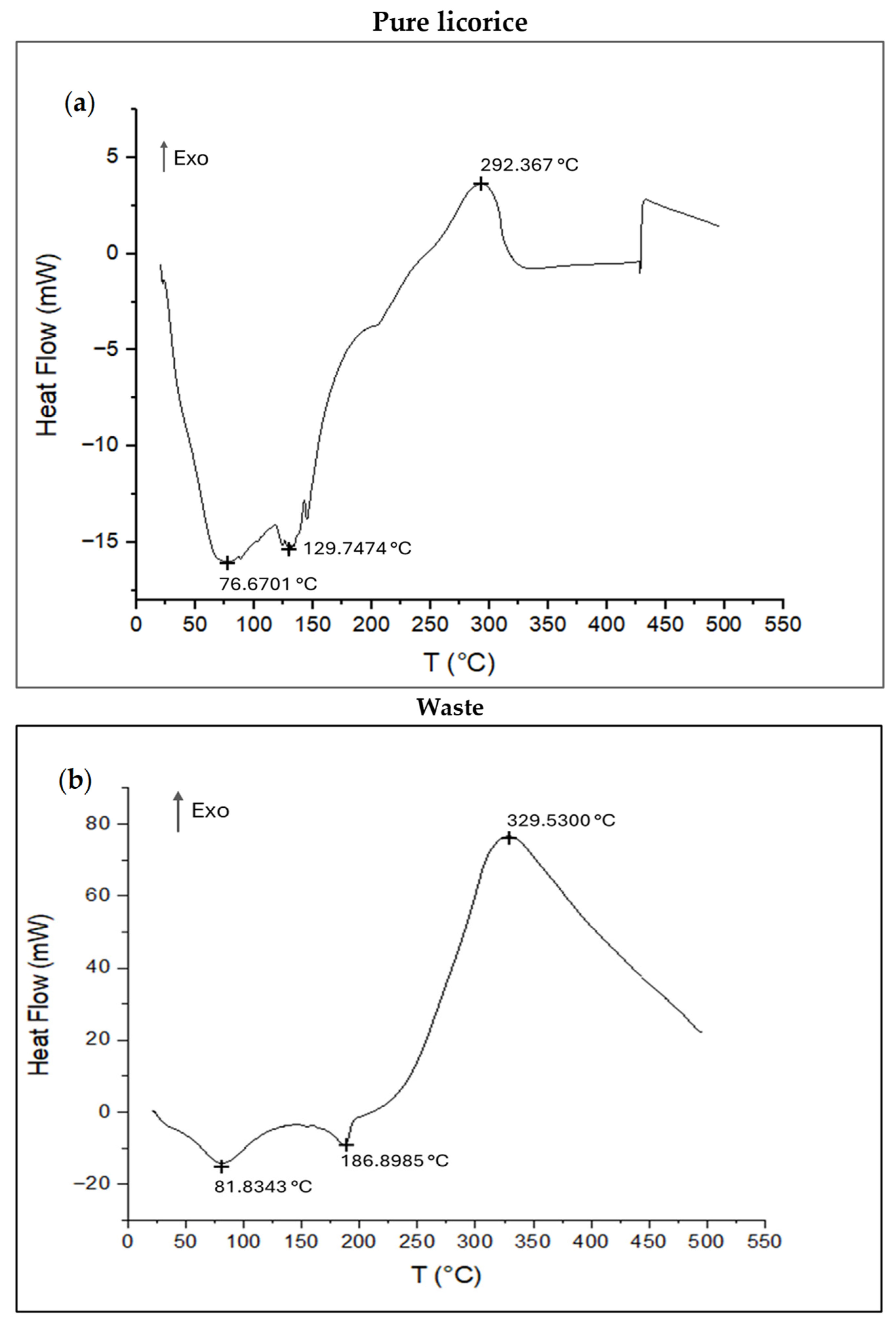

3.1.3. Thermal Characterization of Waste and Pure Licorice

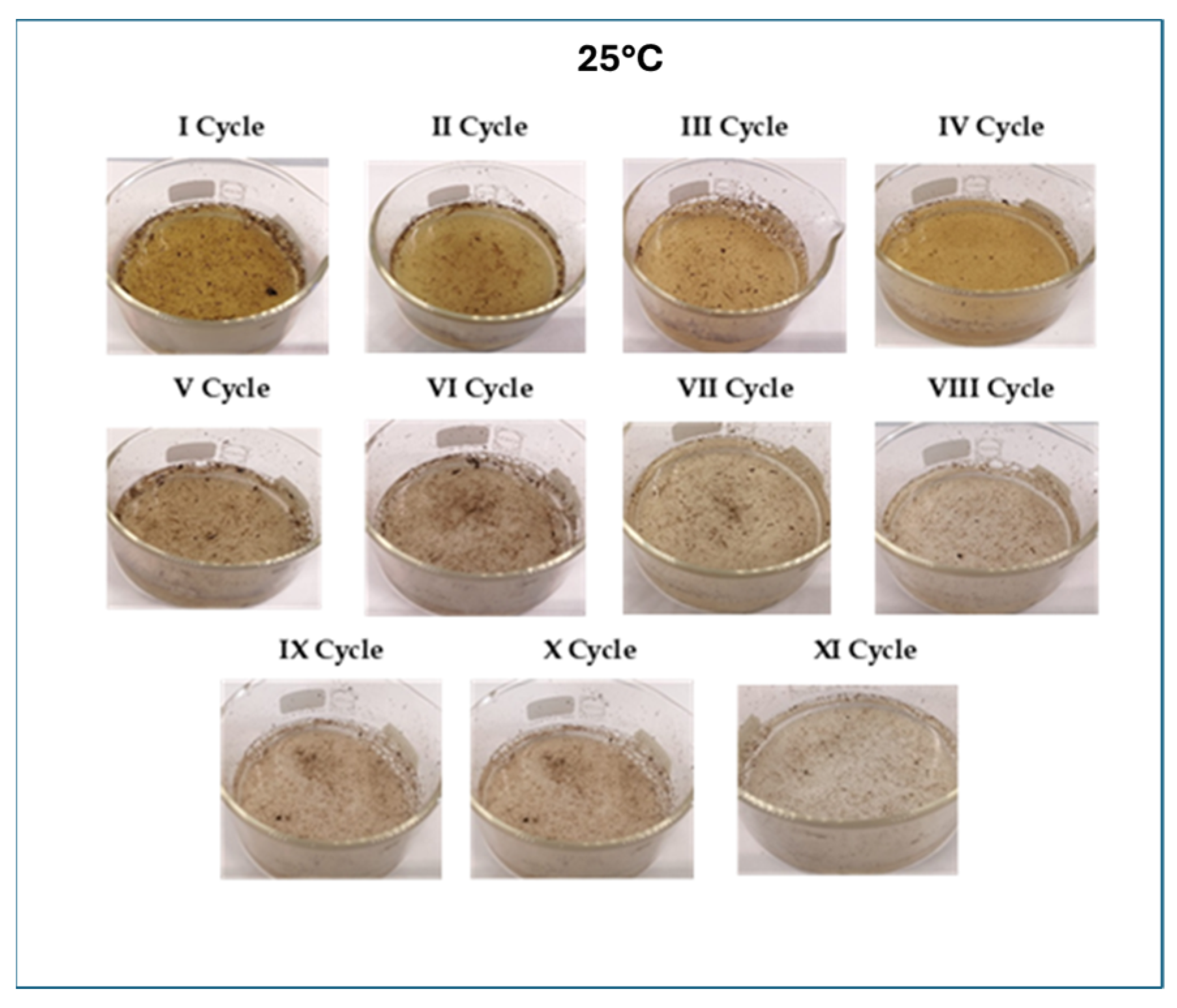

3.2. Optimization of the Fiber Recovery Process from Waste

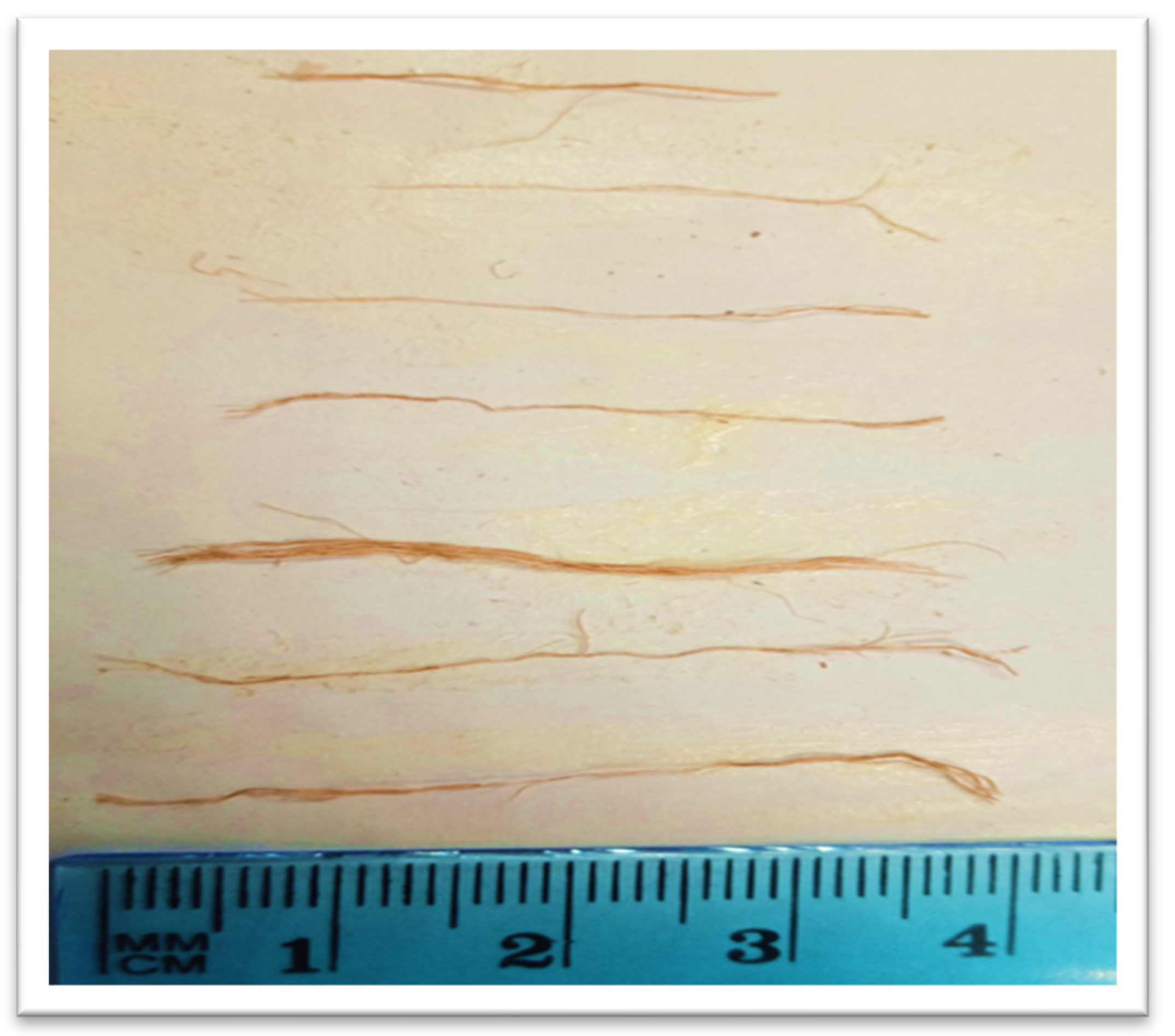

3.3. Fiber Characterization

3.3.1. Characterization of Fibers by SEM and EDS Microanalysis

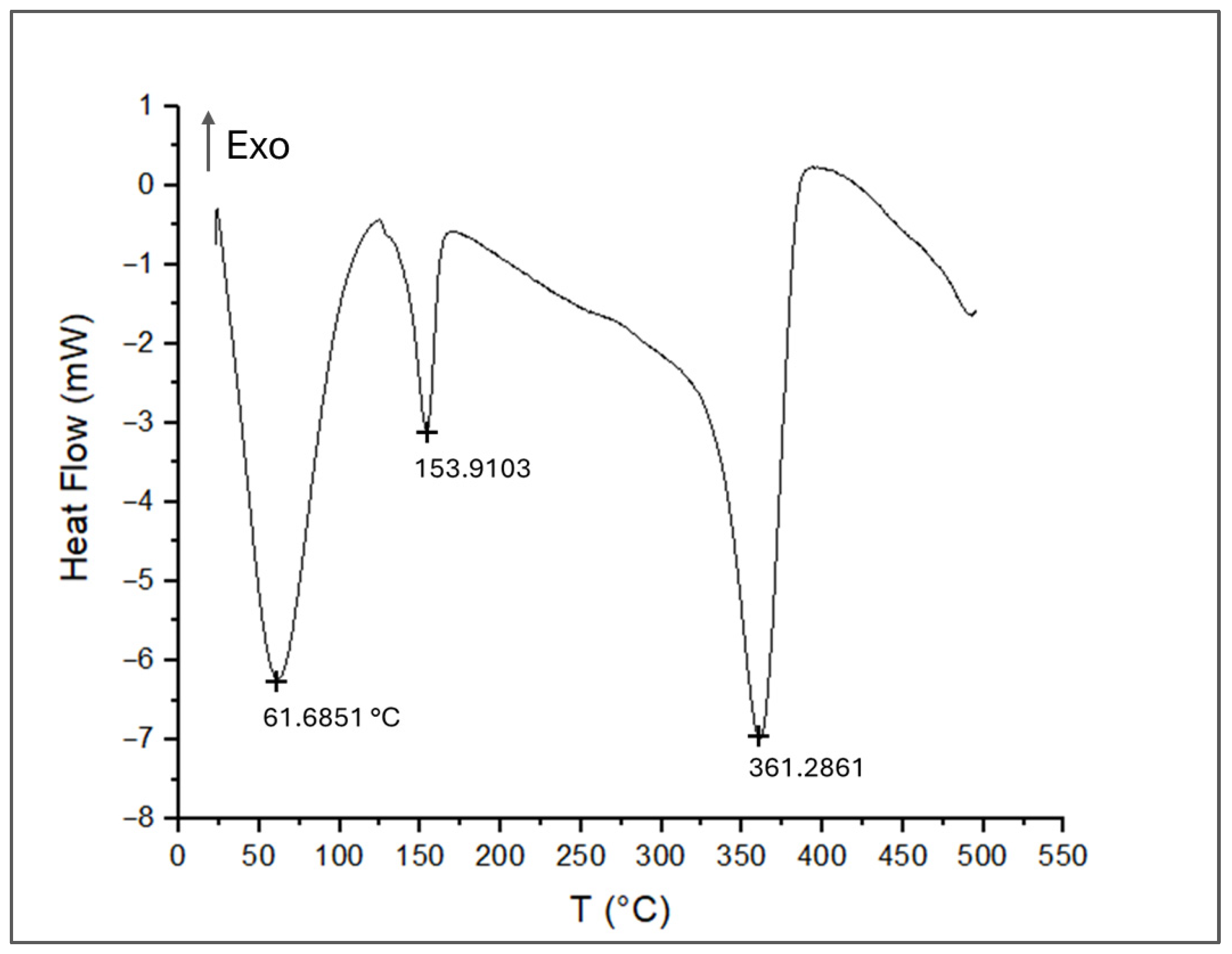

3.3.2. DSC Thermal Characterization of Fibers

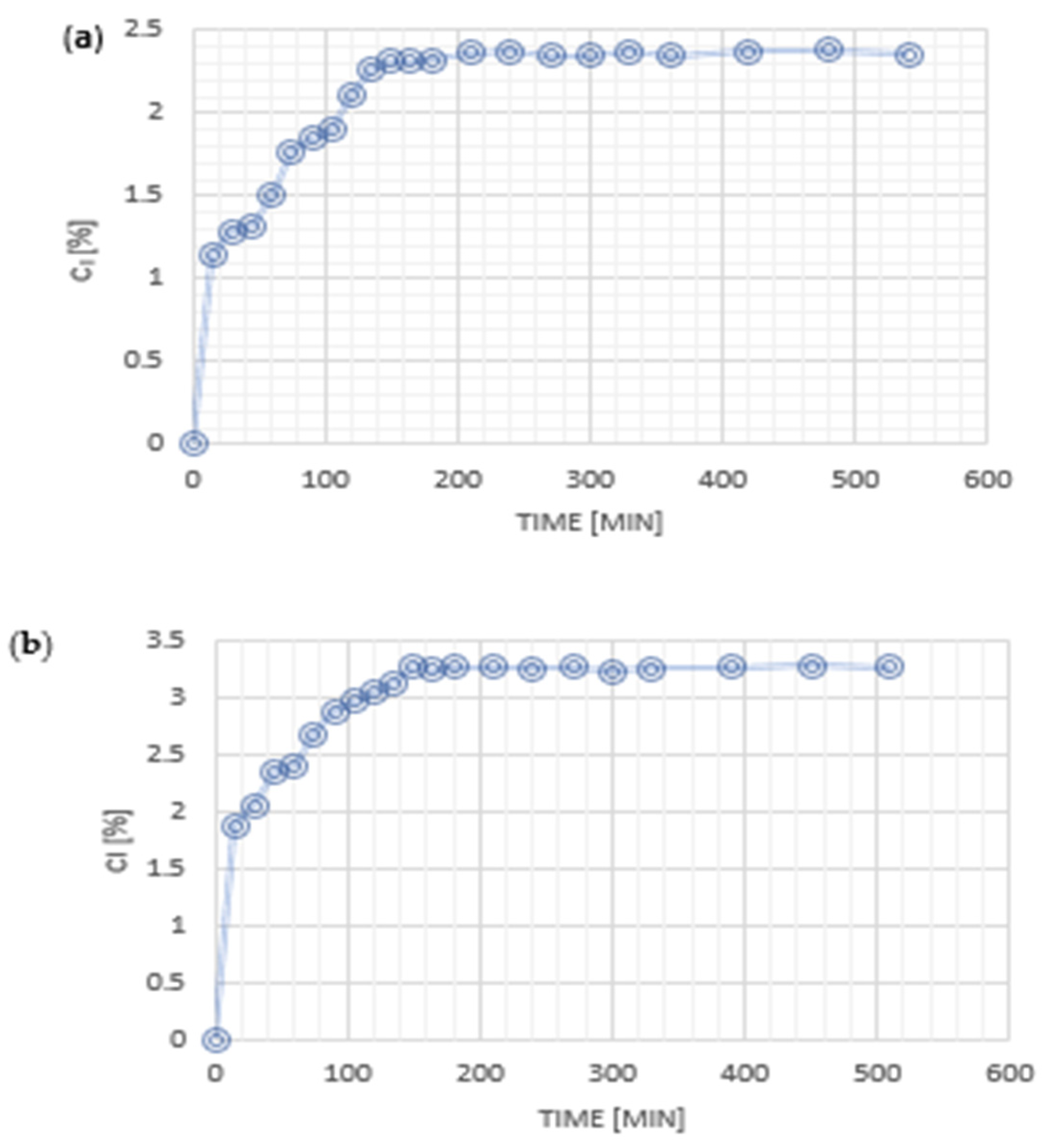

3.3.3. Absorption Tests

3.4. Characterization of Gypsum Matrix Samples

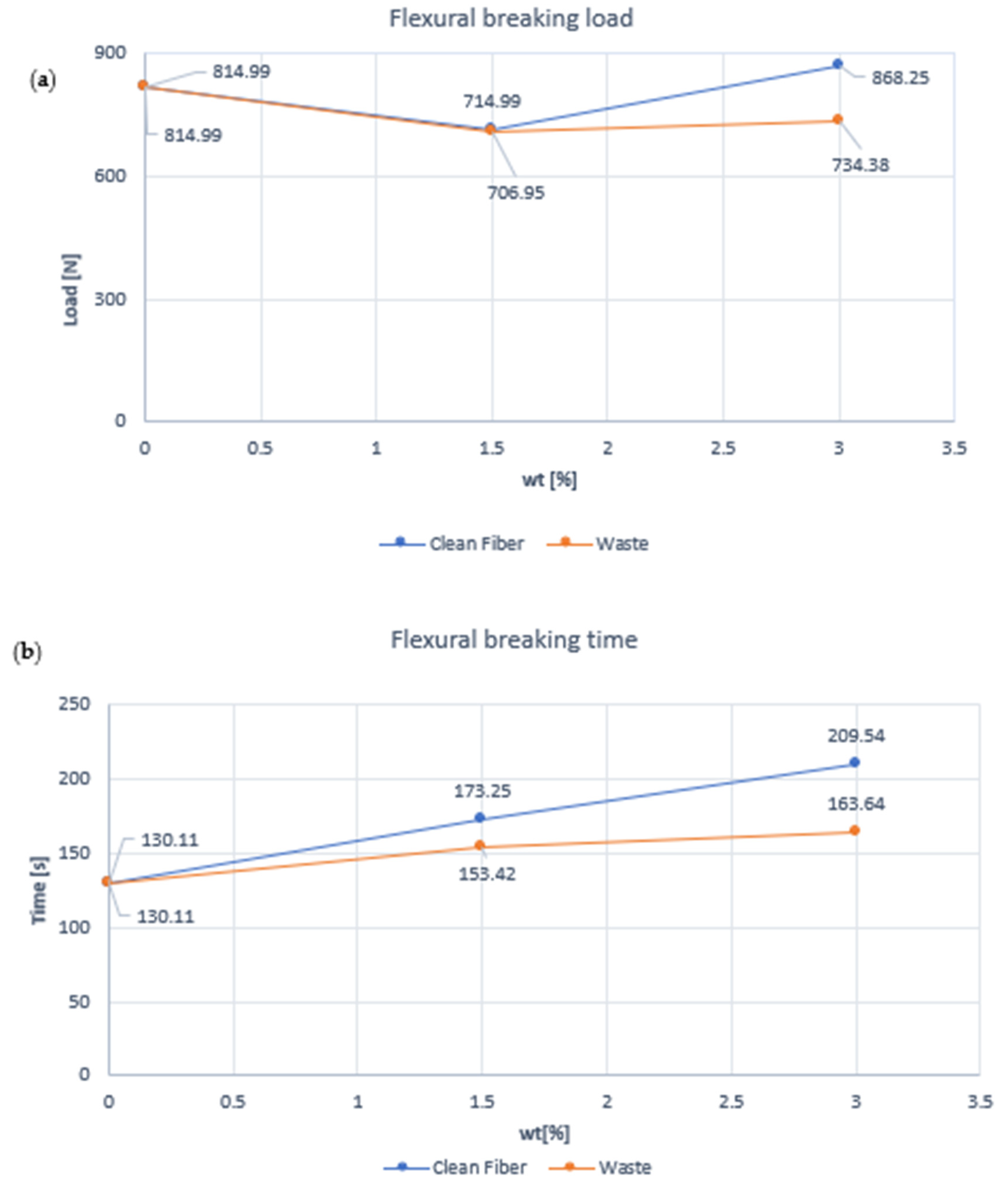

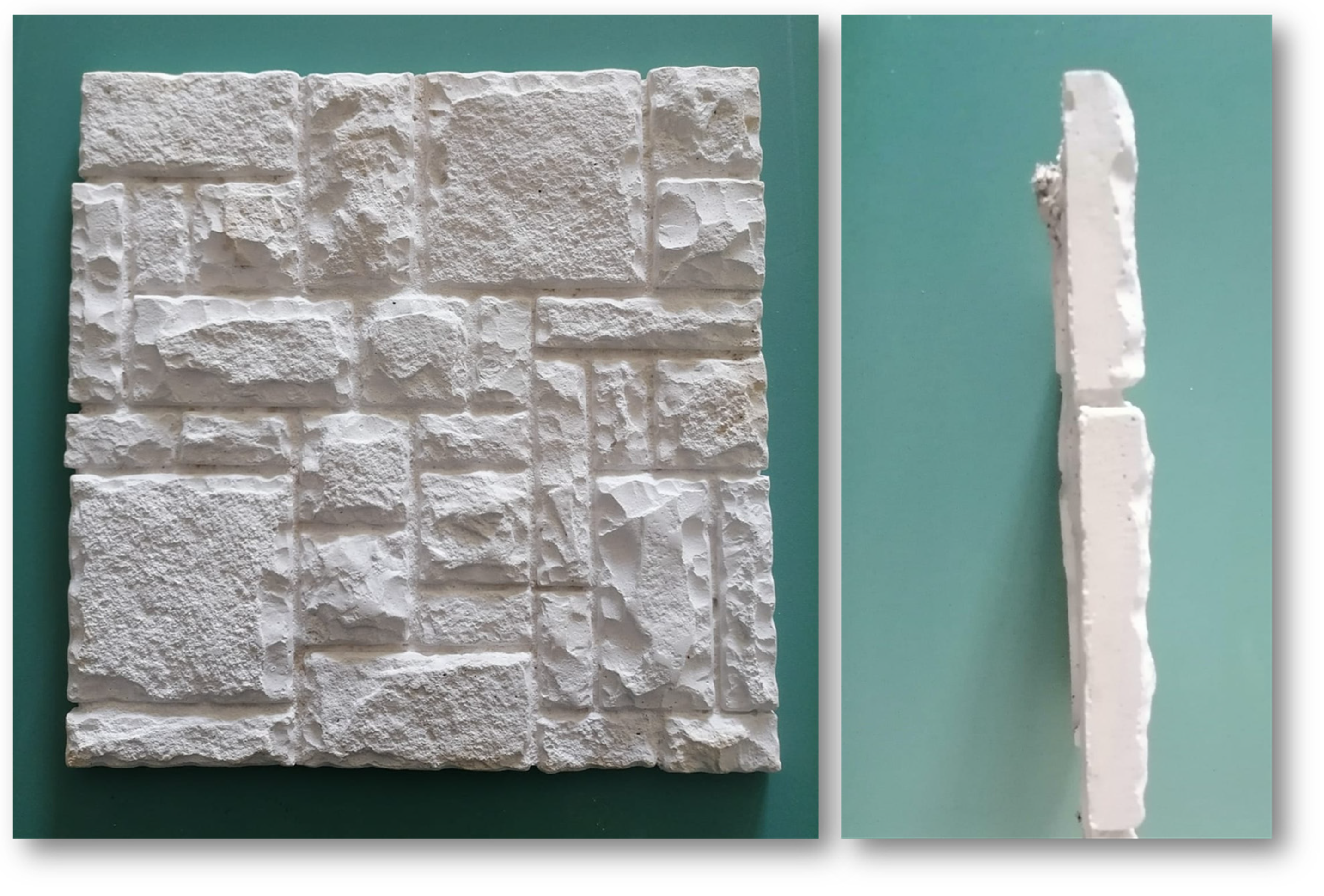

3.4.1. Flexural Strength Tests

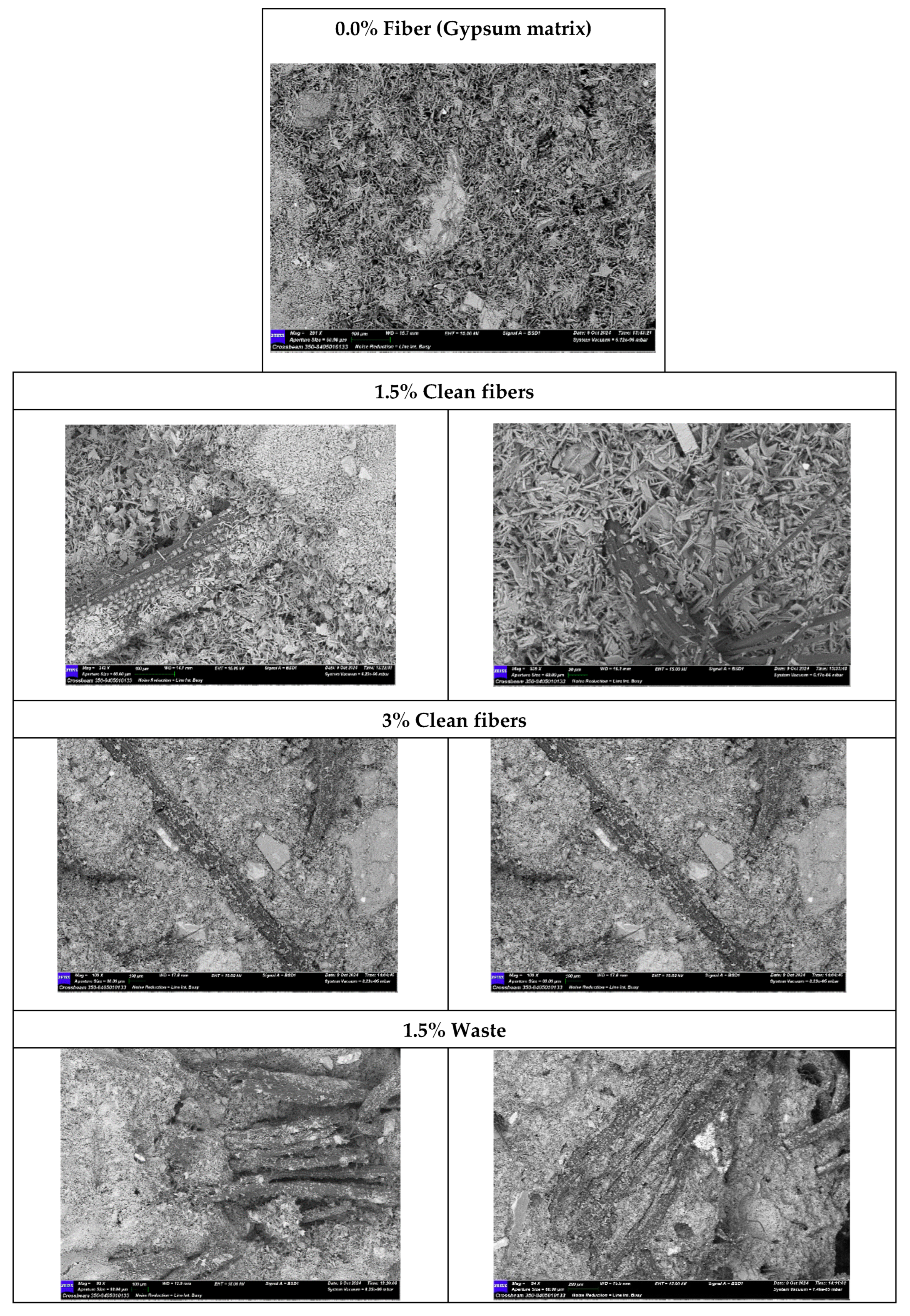

3.4.2. SEM Characterization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hartley, K.; Schülzchen, S.; Bakker, C.A.; Kirchherr, J. A Policy Framework for the Circular Economy: Lessons from the EU. J. Clean. Prod. 2023, 412, 137176. [Google Scholar] [CrossRef]

- Quarmby, S.; Santos, G.; Mathias, M. Air Quality Strategies and Technologies: A Rapid Review of the International Evidence. Sustainability 2019, 11, 2757. [Google Scholar] [CrossRef]

- Onyena, A.P.; Aniche, D.C.; Ogbolu, B.O.; Rakib, M.R.J.; Uddin, J.; Walker, T.R. Governance Strategies for Mitigating Microplastic Pollution in the Marine Environment: A Review. Microplastics 2022, 1, 15–46. [Google Scholar] [CrossRef]

- Stanitsas, M.; Kirytopoulos, K. Sustainable Energy Strategies for Power Purchase Agreements (PPAs). Sustainability 2023, 15, 6638. [Google Scholar] [CrossRef]

- Choina, J.; Duwensee, H.; Flechsig, G.-U.; Kosslick, H.; Morawski, A.W.; Tuan, V.A.; Schulz, A. Removal of Hazardous Pharmaceuticals from Water by Photocatalytic Treatment. Cent. Eur. J. Chem. 2010, 8, 1288–1297. [Google Scholar] [CrossRef]

- De Luca, P.; Macario, A.; Siciliano, C.; B.Nagy, J. Recovery of Biophenols from Olive Vegetation Waters by Carbon Nanotubes. Materials 2022, 15, 2893. [Google Scholar] [CrossRef]

- Sall, M.L.; Diaw, A.K.D.; Gningue-Sall, D.; Efremova Aaron, S.; Aaron, J.-J. Toxic Heavy Metals: Impact on the Environment and Human Health, and Treatment with Conducting Organic Polymers—A Review. Environ. Sci. Pollut. Res. 2020, 27, 29927–29942. [Google Scholar] [CrossRef]

- Kim, S.; Nam, S.-N.; Jang, A.; Jang, M.; Park, C.M.; Son, A.; Her, N.; Heo, J.; Yoon, Y. Review of Adsorption–Membrane Hybrid Systems for Water and Wastewater Treatment. Chemosphere 2022, 286, 131916. [Google Scholar] [CrossRef]

- Islam, M.T.; Iyer-Raniga, U.; Trewick, S. Recycling Perspectives of Circular Business Models: A Review. Recycling 2022, 7, 79. [Google Scholar] [CrossRef]

- Bonocore, G.; De Luca, P. Preparation and Characterization of Insulating Panels from Recycled Polylaminate (Tetra Pak) Materials. Sustainability 2022, 14, 6858. [Google Scholar] [CrossRef]

- Karimah, A.; Ridho, M.R.; Munawar, S.S.; Adi, D.S.; Damayant, R.; Subiyanto, B.; Fatriasari, W.; Fudkoli, A. A Review on Natural Fibers for Development of Eco-Friendly Bio-Composites: Characteristics and Utilizations. J. Mater. Res. Technol. 2021, 13, 2442–2458. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Alyousef, R.; Tahir, M.M. Towards Sustainable Concrete Composites through Waste Valorisation of Plastic Food Trays as Low-Cost Fibrous Materials. Sustainability 2021, 13, 2073. [Google Scholar] [CrossRef]

- Madurwar, M.V.; Ralegaonkar, R.V.; Mandavgane, S.A. Application of Agro-Waste for Sustainable Construction Materials: A Review. Constr. Build. Mater. 2013, 38, 872–878. [Google Scholar] [CrossRef]

- Ojo, A.O. An Overview of Lignocellulose and Its Biotechnological Importance in High-Value Product Production. Fermentation 2023, 9, 990. [Google Scholar] [CrossRef]

- Gil, A. Current Insights into Lignocellulose-Related Waste Valorization. Chem. Eng. J. Adv. 2021, 8, 100186. [Google Scholar] [CrossRef]

- Sharma, S.; Tsai, M.-L.; Sharma, V.; Sun, P.-P.; Nargotra, P.; Bajaj, B.K.; Chen, C.-W.; Dong, C.-D. Environment-Friendly Pretreatment Approaches for the Bioconversion of Lignocellulosic Biomass into Biofuels and Value-Added Products. Environments 2022, 10, 6. [Google Scholar] [CrossRef]

- Chandel, H.; Kumar, P.; Chandel, A.K.; Verma, M.L. Biotechnological Advances in Biomass Pretreatment for Bio-Renewable Production through Nanotechnological Intervention. Biomass Convers. Biorefin. 2024, 14, 2959–2981. [Google Scholar] [CrossRef] [PubMed]

- Chiais, E. From “Out of Fashion” to Upcycling. How Art and the Fashion Industry Have Resemantized the Word “Recycling”. ZoneModa J. 2022, 12, 135–144. [Google Scholar] [CrossRef]

- Collins, M.N.; Nechifor, M.; Tanasă, F.; Zănoagă, M.; McLoughlin, A.; Stróżyk, M.A.; Culebras, M.; Teacă, C.A. Valorization of Lignin in Polymer and Composite Systems for Advanced Engineering Applications—A Review. Int. J. Biol. Macromol. 2019, 131, 828–849. [Google Scholar] [CrossRef]

- Housemn, P.A.; Lacey, H.Y. The Licorice Root in Industry. Ind. Eng. Chem. 1929, 21, 915–917. [Google Scholar] [CrossRef]

- Schmid, C.; Dawid, C.; Peters, V.; Hofmann, T. Saponins from European Licorice Roots (Glycyrrhiza glabra). J. Nat. Prod. 2018, 81, 1734–1744. [Google Scholar] [CrossRef] [PubMed]

- Bai, M.; Yao, G.D.; Ren, Q.; Li, Q.; Liu, Q.-B.; Zhang, Y.; Wang, X.B.; Huang, X.-X.; Song, S.-J. Triterpenoid Saponins and Flavonoids from Licorice Residues with Anti-Inflammatory Activity. Ind. Crops Prod. 2018, 125, 50–58. [Google Scholar] [CrossRef]

- Fukai, T.; Marumo, A.; Kaitou, K.; Kanda, T.; Terada, S.; Nomura, T. Anti-Helicobacter pylori Flavonoids from Licorice Extract. Life Sci. 2002, 71, 1449–1463. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Yu, M.; Wang, L. Preparation and Characterization of Antioxidant Soy Protein Isolate Films Incorporating Licorice Residue Extract. Food Hydrocoll. 2018, 75, 13–21. [Google Scholar] [CrossRef]

- Kaghazchi, T.; Asasian, N.; Soleimani, K.M. Licorice Residue and Pistachio-Nut Shell Mixture: A Promising Precursor for Activated Carbon. J. Ind. Eng. Chem. 2010, 16, 368–374. [Google Scholar] [CrossRef]

- Sdykov, T.; Abduazimov, K.A. Lignins of Allochruza paniculata and Glycyrrhiza glabra. Chem. Nat. Compd. 2002, 38, 288–290. [Google Scholar]

- Santulli, C.; Rallini, M.; Puglia, D.; Gabrielli, S.; Torre, L.; Marcantoni, E. Characterization of Licorice Root Waste for Prospective Use as Filler in more Eco-Friendly Composite Materials. Processes 2020, 8, 733. [Google Scholar] [CrossRef]

- Edwards, C.S. Determination of Lignin and Cellulose in Forages by Extraction with Triethylene Glycol. J. Sci. Food Agric. 1973, 24, 381–388. [Google Scholar] [CrossRef]

- Kim, H.-S.; Lee, S.-Y.; Kim, B.-Y.; Lee, E.-K.; Ryu, J.-H.; Lim, G.-B. Effects of Modifiers on the Supercritical CO2 Extraction of Glycyrrhizin from Licorice and the Morphology of Licorice Tissue after Extraction. Biotechnol. Bioprocess Eng. 2004, 9, 447–453. [Google Scholar] [CrossRef]

- Hayashi, H.; Sudo, H. Economic Importance of Licorice. Plant Biotechnol. 2009, 26, 101–104. [Google Scholar] [CrossRef]

| Mixtures | W/G [%wt] | Clean Fibers * [%wt] | Waste * [%wt] |

|---|---|---|---|

| I | 0.57 | --- | --- |

| II | 0.57 | 1.5 | --- |

| III | 0.57 | 3.0 | --- |

| IV | 0.57 | --- | 1.5 |

| V | 0.57 | --- | 3.0 |

| Mixtures | Gypsum [g] | Clean Fibers [g] | Waste [g] | Effective Quantity of Water * [g] |

|---|---|---|---|---|

| I | 140 | --- | --- | 80.00 |

| II | 140 | 3.3 | --- | 87.75 |

| III | 140 | 6.6 | -- | 95.51 |

| IV | 140 | --- | 3.3 | 90.79 |

| V | 140 | --- | 6.6 | 101.58 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Madeo, L.; Macario, A.; Candamano, S.; De Luca, P. Recovery of Vegetable Fibers from Licorice Processing Waste and a Case Study for Their Use in Green Building Products. Clean Technol. 2025, 7, 55. https://doi.org/10.3390/cleantechnol7030055

Madeo L, Macario A, Candamano S, De Luca P. Recovery of Vegetable Fibers from Licorice Processing Waste and a Case Study for Their Use in Green Building Products. Clean Technologies. 2025; 7(3):55. https://doi.org/10.3390/cleantechnol7030055

Chicago/Turabian StyleMadeo, Luigi, Anastasia Macario, Sebastiano Candamano, and Pierantonio De Luca. 2025. "Recovery of Vegetable Fibers from Licorice Processing Waste and a Case Study for Their Use in Green Building Products" Clean Technologies 7, no. 3: 55. https://doi.org/10.3390/cleantechnol7030055

APA StyleMadeo, L., Macario, A., Candamano, S., & De Luca, P. (2025). Recovery of Vegetable Fibers from Licorice Processing Waste and a Case Study for Their Use in Green Building Products. Clean Technologies, 7(3), 55. https://doi.org/10.3390/cleantechnol7030055