Wilcoxon-Type Control Charts Based on Multiple Scans

Abstract

1. Introduction

2. The Proposed Nonparametric Control Charts Based on Rank Sum Statistics and Multiple Scans

3. Main Results

- An chart with design parameters . In other words, the practitioner should select the 30th and the 32nd ordered reference observations as the control limits and determine the remaining parameters as . The resulting chart achieves an in-control ARL equal to 379.95.

- An chart with design parameters . In other words, the practitioner should select the 27th and the 29th ordered reference observations as the control limits and determine the remaining parameters as . The resulting chart achieves an in-control ARL equal to 356.25.

- An chart with design parameters . In other words, the practitioner should select the 24th and the 26th ordered reference observations as the control limits and determine the remaining parameters as . The resulting chart achieves an in-control ARL equal to 370.99.

- An chart with design parameters (with exact in-control ARL equal to 493.02);

- An chart with design parameters (with exact in-control ARL equal to 484.68);

- An chart with design parameters (with exact in-control ARL equal to 511.04).

4. Numerical Comparisons

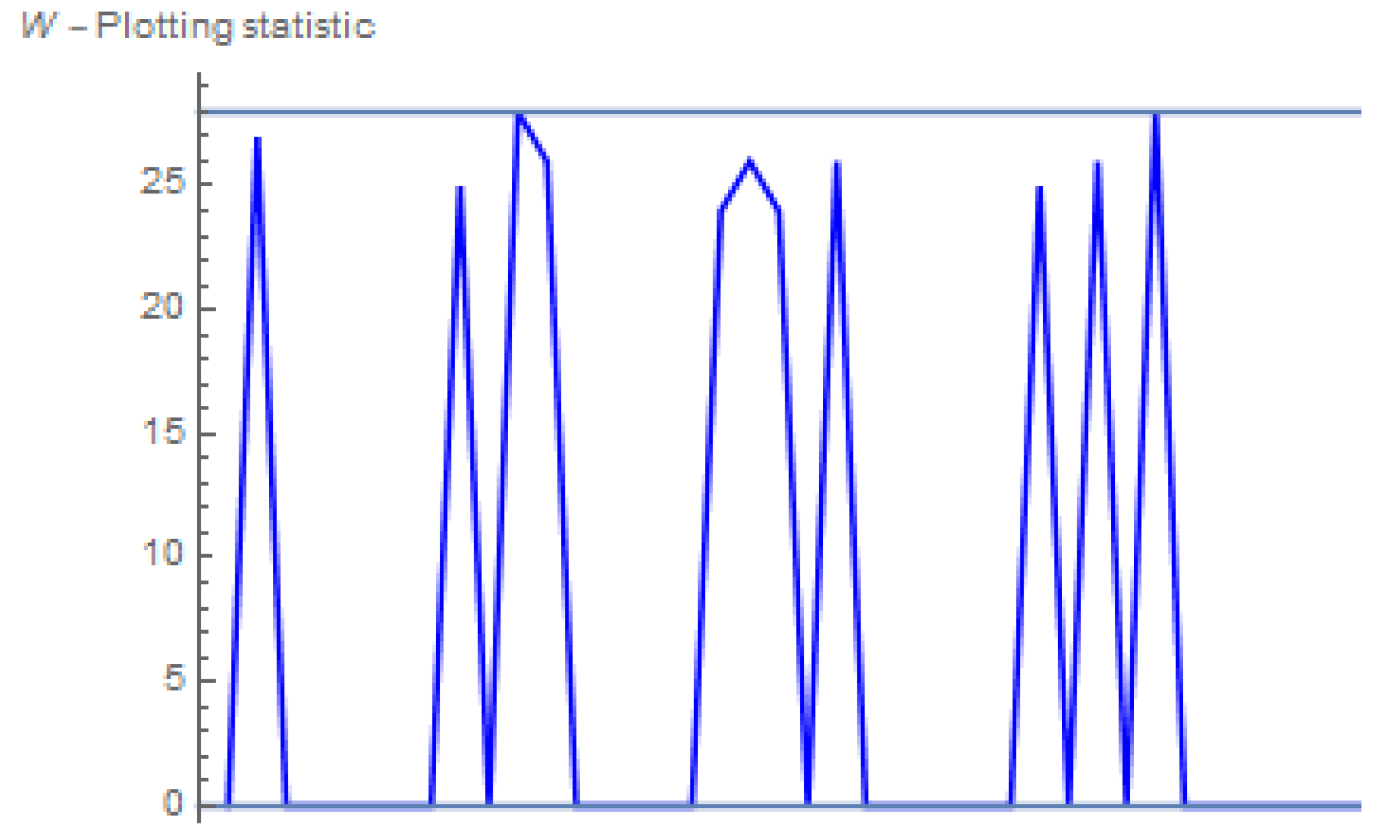

5. An Illustrative Real-Life Example

6. Discussion

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tang, A.; Sun, J.; Hu, X.; Castagliola, P. A new nonparametric adaptive EWMA control chart with exact run length properties. Comput. Ind. Eng. 2019, 130, 404–419. [Google Scholar] [CrossRef]

- Hu, X.; Castagliola, P.; Xhong, J.; Tang, A.; Qiao, Y. On the performance of the adaptive EWMA chart for monitoring time between events. J. Stat. Comput. Simul. 2021, 91, 1175–1211. [Google Scholar] [CrossRef]

- Xie, F.; Castagliola, P.; Sun, J.; Tang, A.; Hu, Y. A one-sided adaptive truncated exponentially weighted moving average scheme for time between events. Comput. Ind. Eng. 2022, 168, 108052. [Google Scholar] [CrossRef]

- Alevizakos, V.; Chatterjee, K.; Koukouvinos, C. A nonparametric triple exponentially weighted moving average sign control chart. Qual. Reliab. Eng. Int. 2021, 37, 1504–1523. [Google Scholar] [CrossRef]

- Alevizakos, V.; Koukouvinos, C.; Chatterjee, K. A nonparametric double generally weighted moving average signed-rank control chart for monitoring process location. Qual. Reliab. Eng. Int. 2020, 36, 2441–2458. [Google Scholar] [CrossRef]

- Tang, A.; Mukherjee, A.; Wang, X. Distribution-free Phase-II monitoring of high-dimensional industrial processes via origin and modified interpoint distance based algorithms. Comput. Ind. Eng. 2023, 179, 109161. [Google Scholar] [CrossRef]

- Perdikis, T.; Psarakis, S.; Castagliola, P.; Giner-Bosch, V.; Maravelakis, P.; Rakitzis, A.C. An EWMA sign chart for dispersion with exact run length properties. J. Stat. Comput. Simul. 2023, 93, 1799–1829. [Google Scholar] [CrossRef]

- Perdikis, T.; Psarakis, S.; Castagliola, P.; Maravelakis, P. An EWMA signed ranks control chart with reliable run length performances. Qual. Reliab. Eng. Int. 2021, 37, 1266–1284. [Google Scholar] [CrossRef]

- Chakraborti, S.; Graham, M. Nonparametric (distribution-free) control charts: An updated overview and some results. Qual. Eng. 2019, 31, 523–544. [Google Scholar] [CrossRef]

- Xue, L.; Qiu, P. A nonparametric CUSUM chart for monitoring multivariate serially correlated processes. J. Qual. Technol. 2021, 53, 396–409. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, Q.; Qiu, P. Novel nonparametric control charts for monitoring dispersion of count data. Qual. Reliab. Eng. Int. 2023; to appear. [Google Scholar] [CrossRef]

- Tang, L.; Li, J. A nonparametric control chart for monitoring count data mean. Qual. Reliab. Eng. Int. 2024, 40, 722–736. [Google Scholar] [CrossRef]

- Tang, A.; Mukherjee, A.; Ma, Y. An optimally designed distribution-free CUSUM procedure for tri-aspect surveillance of continuous processes. Qual. Reliab. Eng. Int. 2023, 39, 2537–2557. [Google Scholar] [CrossRef]

- Triantafyllou, I.S.; Ram, M. Distribution-free CUSUM-type control charts for monitoring process location and scale: An overview and some results. Int. J. Math. Eng. Manag. Sci. 2021, 6, 975–1008. [Google Scholar]

- Balakrishnan, N.; Triantafyllou, I.S.; Koutras, M.V. Nonparametric control charts based on runs and Wilcoxon-type rank-sum statistics. J. Stat. Plan. Inference 2009, 139, 3177–3192. [Google Scholar] [CrossRef]

- Mukherjee, A.; Chakraborti, S. A distribution-free control chart for the joint monitoring of location and scale. Qual. Reliab. Eng. Int. 2012, 28, 335–352. [Google Scholar] [CrossRef]

- Malela-Majika, J.C.; Graham, M.A.; Chakraborti, S. Distribution-free Phase II Mann-Whitney control charts with runs-rules. Int. J. Adv. Manuf. Technol. 2016, 86, 723–735. [Google Scholar] [CrossRef]

- Chakraborti, S.; van de Wiel, M.A. A nonparametric control chart based on the Mann-Whitney statistic. In IMS Collections; Beyond parametrics in interdisciplinary research: Festschrift in Honour of Professor Pranab K. Sen; Institute of Mathematical Statistics: Waite Hill, OH, USA, 2008; Volume 1, pp. 156–172. [Google Scholar]

- Koutras, M.V.; Triantafyllou, I.S. A general class of nonparametric control charts. Qual. Reliab. Eng. Int. 2018, 34, 427–435. [Google Scholar] [CrossRef]

- Triantafyllou, I.S.; Panayiotou, N. A new distribution-free monitoring scheme based on ranks. Commun. Stat. Simul. Comput. 2022, 51, 6456–6478. [Google Scholar] [CrossRef]

- Qiu, P. Some perspectives on nonparametric statistical process control. J. Qual. Technol. 2018, 50, 49–65. [Google Scholar] [CrossRef]

- Qiu, P. Some recent studies in Statistical Process Control. In Statistical Quality Technologies; Springer: Cham, Switzerland, 2019; pp. 3–19. [Google Scholar]

- Chakraborti, S.; Graham, M. Nonparametric Statistical Process Control; John Wiley & Sons: Hoboken, NJ, USA, 2019. [Google Scholar]

- Qiu, P. Introduction to Statistical Process Control; Chapman and Hall/CRC: New York, NY, USA, 2013. [Google Scholar]

- Qiu, P. Big Data? Statistical Process Control can help. Am. Stat. 2020, 74, 329–344. [Google Scholar] [CrossRef]

- Perdikis, T.; Celano, G.; Chakraborti, S. Distribution-free control charts for monitoring scale in finite horizon productions. Eur. J. Oper. Res. 2023, 314, 1040–1051. [Google Scholar] [CrossRef]

- Dafnis, S.D.; Perdikis, T.; Koutras, M.V. Improved Shewhart-type control charts based on weak runs in multistate trials. Qual. Technol. Quant. Manag. 2024; to appear. [Google Scholar] [CrossRef]

- Nasrollahzadeh, S.; Bameni Moghadam, M.; Farnoosh, R. A Shewhart-type nonparametric multivariate depth-based control chart for monitoring location. Comm. Stat. Theory Methods 2023, 52, 7385–7404. [Google Scholar] [CrossRef]

- Hernández-Zamudio, G.; Tercero-Gómeza, V.; Conover, W.J.; Benavides-Vázquez, L.; Beruvides, M. On the power and robustness of phase I nonparametric Shewhart-type charts using sequential normal scores. J. Ind. Prod. Eng. 2023, 41, 276–305. [Google Scholar] [CrossRef]

- Diaz Pulido, A.J.; Cordero Franco, A.E.; Tercero Gómez, V.G. A distribution-free control chart for joint monitoring of location and scale in finite horizon productions. Comput. Stat, 2023; to appear. [Google Scholar] [CrossRef]

- Balakrishnan, N.; Koutras, M.V. Runs and Scan with Applications; John Wiley & Sons: New York, NY, USA, 2002. [Google Scholar]

- Lehmann, E.L. The power of rank tests. Ann. Math. Stat. 1953, 24, 23–43. [Google Scholar] [CrossRef]

- Li, S.-Y.; Tang, L.-C.; Ng, S.-H. Nonparametric CUSUM and EWMA control charts for detecting mean shifts. J. Qual. Technol. 2010, 42, 209–226. [Google Scholar] [CrossRef]

- Montgomery, D.C. Introduction to Statistical Quality Control; John Wiley & Sons: New York, NY, USA, 2009. [Google Scholar]

| Reference Sample Size m | |||||||

|---|---|---|---|---|---|---|---|

| 50 | 100 | 200 | |||||

| ARLo | (n, r) | (a, b, w, r1) | Exact ARLin | (a, b, w, r1) | Exact ARLin | (a, b, w, r1) | Exact ARLin |

| 370 | (5, 1) | (10, 12, 36, 2) (16, 18, 39, 3) (9, 11, 37, 2) | 394.99 377.46 386.65 | (11, 13, 22, 2) (24, 26, 49, 3) (17, 19, 37, 2) | 390.87 366.74 366.47 | (27, 29, 54, 2) (30, 32, 61, 2) (37, 39, 40, 3) | 377.11 383.71 380.68 |

| (5, 2) | (9, 11, 19, 2) (5, 7, 10, 2) (8, 10, 17, 2) | 361.66 352.83 356.36 | (11, 13, 19, 2) (20, 22, 43, 2) (17, 19, 41, 2) | 385.57 392.72 345.39 | (30, 32, 44, 2) (27, 29, 45, 2) (24, 26, 30, 2) | 379.95 356.25 370.99 | |

| (5, 3) | (8, 10, 11, 3) (9, 11, 19, 2) (11, 13, 25, 2) | 399.43 381.55 359.55 | (10, 12, 18, 2) (12, 14, 23, 2) (18, 20, 37, 2) | 374.94 349.00 355.98 | (35, 37, 30, 2) (31, 33, 30, 2) (28, 30, 30, 2) | 362.63 370.13 385.39 | |

| 500 | (5, 1) | (10, 12, 42, 2) (9, 11, 41, 2) (9, 11, 38, 2) | 467.68 502.58 479.25 | (15, 17, 31, 2) (17, 19, 37, 2) (16, 18, 45, 2) | 476.19 473.51 509.30 | (43, 45, 40, 3) (37, 39, 40, 3) (27, 29, 55, 2) | 482.39 493.21 486.36 |

| (5, 2) | (10, 12, 22, 2) (7, 9, 14, 3) (9, 11, 20, 2) | 514.80 483.21 508.85 | (20, 22, 42, 2) (19, 21, 43, 2) (10, 12, 20, 2) | 462.81 516.85 517.35 | (27, 29, 44, 2) (24, 26, 45, 2) (21, 23, 31, 2) | 506.04 475.79 500.53 | |

| (5, 3) | (9, 11, 19, 2) (8, 10, 16, 3) (8, 10, 17, 2) | 524.48 524.94 504.54 | (12, 14, 24, 2) (13, 15, 26, 2) (12, 14, 24, 2) | 503.69 517.25 503.69 | (31, 33, 30, 2) (28, 30, 30, 2) (25, 27, 30, 2) | 509.32 486.52 508.66 | |

| Reference Sample Size m | |||||||

|---|---|---|---|---|---|---|---|

| 50 | 100 | 200 | |||||

| ARLo | (n, r) | ) | Exact ARLin | ) | Exact ARLin | ) | Exact ARLin |

| 370 | (5, 1) | (6, 8, 15, 17, 32, 2, 2) (5, 7, 14, 16, 29, 2, 2) (5, 7, 13, 15, 24, 2, 2) | 378.89 367.01 389.21 | (16, 18, 20, 22, 23, 2, 2) (14, 16, 20, 22, 23, 2, 2) (8, 10, 18, 20, 20, 2, 2) | 372.91 380.82 363.57 | (13, 15, 30, 32, 15, 2, 2) (12, 14, 28, 30, 15, 2, 2) (11, 13, 25, 27, 22, 2, 2) | 355.45 384.88 373.20 |

| (5, 2) | (6, 8, 13, 15, 16, 2, 2) (6, 8, 16, 18, 32, 2, 2) (6, 8, 15, 17, 27, 2, 2) | 382.10 363.38 368.12 | (13, 15, 22, 24, 39, 2, 1) (12, 14, 22, 24, 24, 2, 2) (11, 13, 21, 23, 23, 2, 2) | 377.02 381.07 359.54 | (10, 12, 28, 30, 11, 2, 2) (10, 12, 36, 38, 13, 2, 2) (10, 12, 30, 32, 13, 2, 2) | 364.96 385.78 388.40 | |

| (5, 3) | (5, 7, 15, 17, 18, 2, 2) (5, 7, 15, 17, 22, 2, 2) (5, 7, 15, 17, 24, 2, 2) | 374.41 374.20 380.89 | (13, 15, 22, 24, 23, 2, 2) (12, 14, 22, 24, 39, 2, 1) (11, 13, 24, 26, 26, 2, 2) | 374.79 361.81 383.59 | (11, 13, 26, 28, 11, 2, 2) (10, 12, 28, 30, 11, 2, 2) (12, 14, 20, 22, 13, 2, 2) | 366.81 388.65 367.68 | |

| 500 | (5, 1) | (5, 7, 13, 15, 22, 2, 2) (5, 7, 13, 15, 24, 2, 2) (5, 7, 12, 14, 22, 2, 2) | 479.21 504.69 486.43 | (16, 18, 25, 27, 27, 3, 2) (12, 14, 20, 22, 23, 2, 2) (10, 12, 20, 22, 23, 2, 2) | 509.69 509.92 492.51 | (12, 14, 30, 32, 15, 2, 2) (13, 15, 23, 25, 16, 2, 2) (8, 11, 21, 23, 19, 2, 2) | 484.80 493.11 490.41 |

| (5, 2) | (6, 8, 14, 16, 19, 2, 2) (6, 8, 15, 17, 32, 2, 2) (6, 8, 15, 17, 34, 2, 2) | 499.74 516.71 499.40 | (12, 14, 23, 25, 25, 2, 2) (11, 13, 21, 23, 23, 2, 2) (11, 13, 24, 26, 27, 2, 2) | 484.34 478.38 518.66 | (10, 12, 37, 39, 13, 2, 2) (10, 12, 30, 32, 13, 2, 2) (11, 13, 31, 33, 17, 2, 2) | 503.88 495.89 486.75 | |

| (5, 3) | (5, 7, 14, 16, 17, 2, 2) (5, 7, 15, 17, 24, 2, 2) (5, 7, 15, 17, 26, 2, 2) | 509.29 482.47 516.10 | (12, 14, 22, 24, 39, 2, 1) (13, 15, 22, 24, 39, 2, 1) (12, 14, 23, 25, 26, 2, 2) | 493.02 484.68 511.04 | (12, 14, 31, 33, 13, 2, 2) (12, 14, 16, 18, 13, 2, 2) (12, 14, 33, 35, 14, 2, 2) | 488.98 476.48 489.10 | |

| Reference Sample Size m | |||||||

|---|---|---|---|---|---|---|---|

| 50 | 100 | 200 | |||||

| ARLo | (n, r) | (a, b, w, r1) | Exact ARLout | (a, b, w, r1) | Exact ARLout | (a, b, w, r1) | Exact ARLout |

| 370 | (5, 1) | (10, 12, 36, 2) (16, 18, 39, 3) (9, 11, 37, 2) | 150.31 170.29 139.57 | (11, 13, 22, 2) (24, 26, 49, 3) (17, 19, 37, 2) | 184.88 178.44 140.31 | (27, 29, 54, 2) (30, 32, 61, 2) (37, 39, 40, 3) | 176.45 154.21 228.70 |

| (5, 2) | (9, 11, 19, 2) (5, 7, 10, 2) (8, 10, 17, 2) | 156.26 169.77 139.71 | (11, 13, 19, 2) (20, 22, 43, 2) (17, 19, 41, 2) | 218.61 167.78 143.53 | (30, 32, 44, 2) (27, 29, 44, 2) (24, 26, 30, 2) | 203.20 191.78 201.31 | |

| (5, 3) | (8, 10, 11, 3) (9, 11, 19, 2) (11, 13, 25, 2) | 269.67 170.21 154.83 | (10, 12, 18, 2) (12, 14, 23, 2) (18, 20, 37, 2) | 218.44 204.18 162.56 | (35, 37, 30, 2) (31, 33, 30, 2) (28, 30, 30, 2) | 199.73 203.92 212.75 | |

| 500 | (5, 1) | (10, 12, 42, 2) (9, 11, 41, 2) (9, 11, 38, 2) | 168.03 177.79 160.72 | (15, 17, 31, 2) (17, 19, 37, 2) (16, 18, 45, 2) | 187.42 177.64 185.83 | (43, 45, 40, 3) (37, 39, 40, 3) (27, 29, 55, 2) | 283.86 293.25 185.91 |

| (5, 2) | (10, 12, 22, 2) (7, 9, 14, 3) (9, 11, 20, 2) | 214.42 269.29 195.31 | (20, 22, 42, 2) (19, 21, 43, 2) (10, 12, 20, 2) | 195.63 211.75 256.27 | (27, 29, 44, 2) (24, 26, 45, 2) (21, 23, 31, 2) | 266.64 252.35 266.16 | |

| (5, 3) | (9, 11, 19, 2) (8, 10, 16, 3) (8, 10, 17, 2) | 234.39 317.09 209.56 | (12, 14, 24, 2) (13, 15, 26, 2) (12, 14, 24, 2) | 254.65 262.87 254.65 | (31, 33, 30, 2) (28, 30, 30, 2) (25, 27, 30, 2) | 279.25 263.34 183.99 | |

| Reference Sample Size m | |||||||

|---|---|---|---|---|---|---|---|

| 50 | 100 | 200 | |||||

| ARLo | (n,r) | ) | ARLout | ) | ARLout | ) | ARLout |

| 370 | (5, 1) | (6, 8, 15, 17, 32, 2, 2) (5, 7, 14, 16, 29, 2, 2) (5, 7, 13, 15, 24, 2, 2) | 105.60 103.45 95.35 | (16, 18, 20, 22, 23, 2, 2) (14, 16, 20, 22, 23, 2, 2) (8, 10, 18, 20, 20, 2, 2) | 71.18 72.84 88.00 | (13, 15, 30, 32, 15, 2, 2) (12, 14, 28, 30, 15, 2, 2) (11, 13, 25, 27, 22, 2, 2) | 122.89 135.70 134.31 |

| (5, 2) | (6, 8, 13, 15, 16, 2, 2) (6, 8, 16, 18, 32, 2, 2) (6, 8, 15, 17, 27, 2, 2) | 200.58 209.25 199.96 | (13, 15, 22, 24, 39, 2, 1) (12, 14, 22, 24, 24, 2, 2) (11, 13, 21, 23, 23, 2, 2) | 210.98 199.23 188.61 | (10, 12, 28, 30, 11, 2, 2) (10, 12, 36, 38, 13, 2, 2) (10, 12, 30, 32, 13, 2, 2) | 239.00 252.42 241.62 | |

| (5, 3) | (5, 7, 15, 17, 18, 2, 2) (5, 7, 15, 17, 22, 2, 2) (5, 7, 15, 17, 24, 2, 2) | 224.42 229.70 225.92 | (13, 15, 22, 24, 23, 2, 2) (12, 14, 22, 24, 39, 2, 1) (11, 13, 24, 26, 26, 2, 2) | 225.89 209.33 216.79 | (11, 13, 26, 28, 11, 2, 2) (10, 12, 28, 30, 11, 2, 2) (12, 14, 20, 22, 13, 2, 2) | 256.99 258.45 241.00 | |

| 500 | (5, 1) | (5, 7, 13, 15, 22, 2, 2) (5, 7, 13, 15, 24, 2, 2) (5, 7, 12, 14, 22, 2, 2) | 122.03 119.63 104.97 | (16, 18, 25, 27, 27, 3, 2) (12, 14, 20, 22, 23, 2, 2) (10, 12, 20, 22, 23, 2, 2) | 179.45 97.57 100.74 | (12, 14, 30, 32, 15, 2, 2) (13, 15, 23, 25, 16, 2, 2) (8, 11, 21, 23, 19, 2, 2) | 172.33 154.18 176.00 |

| (5, 2) | (6, 8, 14, 16, 19, 2, 2) (6, 8, 15, 17, 32, 2, 2) (6, 8, 15, 17, 34, 2, 2) | 273.54 283.85 258.56 | (12, 14, 23, 25, 25, 2, 2) (11, 13, 21, 23, 23, 2, 2) (11,13,24,26,27,2,2) | 249.89 236.14 262.64 | (10, 12, 37, 39, 13, 2, 2) (10, 12, 30, 32, 13, 2, 2) (11, 13, 31, 33, 17, 2, 2) | 327.24 304.58 311.87 | |

| (5, 3) | (5, 7, 14, 16, 17, 2, 2) (5, 7, 15, 17, 24, 2, 2) (5, 7, 15, 17, 26, 2, 2) | 294.09 281.34 294.85 | (12, 14, 22, 24, 39, 2, 1) (13, 15, 22, 24, 39, 2, 1) (12, 14, 23, 25, 26, 2, 2) | 287.25 268.90 248.36 | (12, 14, 31, 33, 13, 2, 2) (12, 14, 16, 18, 13, 2, 2) (12, 14, 33, 35, 14, 2, 2) | 323.14 302.00 309.04 | |

| Exponential Distribution (λ) | ||||

|---|---|---|---|---|

| Shift | Chart a = 15, b = 17, w = 31, r1 = 2 | Chart a = 17, b = 19, w = 37, r1 = 2 | Chart a = 16, b = 18, w = 45, r1 = 2 | Competitor 1 |

| 0.0 | 476.19 | 473.51 | 509.30 | 512.40 |

| 0.1 | 380.01 | 372.38 | 400.43 | 459.48 |

| 0.2 | 300.41 | 290.08 | 311.85 | 410.87 |

| 0.3 | 235.09 | 223.71 | 240.44 | 366.38 |

| 0.4 | 181.99 | 170.70 | 183.43 | 325.81 |

| 0.5 | 139.26 | 128.80 | 138.38 | 289.01 |

| 0.6 | 105.26 | 96.06 | 103.19 | 255.80 |

| 0.7 | 78.53 | 70.78 | 76.03 | 226.00 |

| 0.8 | 57.79 | 51.52 | 55.34 | 199.46 |

| 0.9 | 41.92 | 37.04 | 39.80 | 176.02 |

| 1.0 | 29.98 | 26.32 | 28.29 | 155.51 |

| 1.1 | 21.15 | 18.51 | 19.91 | 137.79 |

| 1.2 | 14.73 | 12.92 | 13.90 | 122.71 |

| 1.3 | 10.16 | 8.98 | 9.66 | 110.15 |

| 1.4 | 6.98 | 6.26 | 6.73 | 99.99 |

| 1.5 | 5.12 | 4.42 | 5.03 | 92.12 |

| Exponential Distribution (λ) | ||||

|---|---|---|---|---|

| Shift | ) | ) | ) | Competitor 2 |

| 0.0 | 378.89 | 367.01 | 389.21 | 388.40 |

| 0.1 | 305.33 | 295.83 | 311.58 | 333.57 |

| 0.2 | 244.12 | 236.62 | 247.39 | 284.41 |

| 0.3 | 193.56 | 187.74 | 194.75 | 240.55 |

| 0.4 | 152.13 | 147.69 | 151.92 | 201.67 |

| 0.5 | 118.48 | 115.18 | 117.40 | 167.41 |

| 0.6 | 91.39 | 89.01 | 89.85 | 137.46 |

| 0.7 | 69.80 | 68.14 | 68.09 | 111.48 |

| 0.8 | 52.77 | 51.69 | 51.09 | 89.17 |

| 0.9 | 39.50 | 38.85 | 37.96 | 70.21 |

| 1.0 | 29.27 | 28.95 | 27.95 | 54.30 |

| 1.1 | 21.49 | 21.40 | 20.42 | 41.13 |

| 1.2 | 15.65 | 15.72 | 14.83 | 30.39 |

| 1.3 | 11.33 | 11.51 | 10.74 | 21.82 |

| 1.4 | 8.17 | 8.41 | 7.78 | 15.15 |

| 1.5 | 5.91 | 6.18 | 5.67 | 10.09 |

| Shift | Chart | Chart | Wmin | MW | W-CUSUM | W-EWMA |

|---|---|---|---|---|---|---|

| 0.0 | 473.51 | 501.92 | 501.66 | 502.48 | 498.64 | 502.94 |

| 0.25 | 77.44 | 93.12 | 100.82 | 428.03 | 333.45 | 321.52 |

| 0.50 | 19.87 | 21.88 | 25.59 | 292.77 | 107.19 | 103.15 |

| 1.00 | 3.27 | 3.46 | 3.52 | 86.57 | 13.04 | 14.29 |

| 1.50 | 1.32 | 1.33 | 1.33 | 28.52 | 6.25 | 7.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Triantafyllou, I.S. Wilcoxon-Type Control Charts Based on Multiple Scans. Stats 2024, 7, 301-316. https://doi.org/10.3390/stats7010018

Triantafyllou IS. Wilcoxon-Type Control Charts Based on Multiple Scans. Stats. 2024; 7(1):301-316. https://doi.org/10.3390/stats7010018

Chicago/Turabian StyleTriantafyllou, Ioannis S. 2024. "Wilcoxon-Type Control Charts Based on Multiple Scans" Stats 7, no. 1: 301-316. https://doi.org/10.3390/stats7010018

APA StyleTriantafyllou, I. S. (2024). Wilcoxon-Type Control Charts Based on Multiple Scans. Stats, 7(1), 301-316. https://doi.org/10.3390/stats7010018