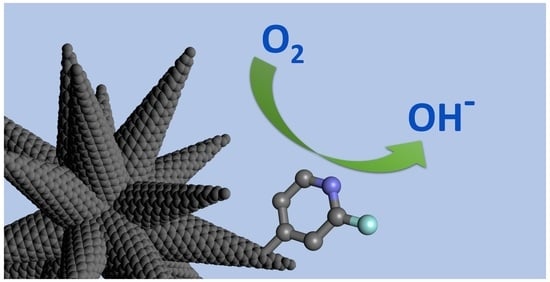

Nitrogen- and Fluorine-Doped Carbon Nanohorns as Efficient Metal-Free Oxygen Reduction Catalyst: Role of the Nitrogen Groups

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Functionalized Carbon Nanohorns (CNHs)

2.3. Physicochemical Characterization

2.4. Electrochemical Characterization

2.5. In-Line Photoemission and Electrochemical Measurements

3. Results and Discussion

3.1. Synthesis and Physicochemical Characterization of CNH Derivatives

3.2. Electrochemical Characterization

3.3. In-Line Photoemission and Electrochemical Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ferriday, T.B.; Middleton, P.H. Alkaline fuel cell technology—A review. Int. J. Hydrogen Energy 2021, 46, 18489–18510. [Google Scholar] [CrossRef]

- Vijayakumar, V.; Nam, S.Y. Recent advancements in applications of alkaline anion exchange membranes for polymer electrolyte fuel cells. J. Ind. Eng. Chem. 2019, 70, 70–86. [Google Scholar] [CrossRef]

- Olabi, A.G.; Sayed, E.T.; Wilberforce, T.; Jamal, A.; Alami, A.H.; Elsaid, K.; Rahman, S.M.A.; Shah, S.K.; Abdelkareem, M.A. Metal-Air Batteries—A Review. Energies 2021, 14, 7373. [Google Scholar] [CrossRef]

- Liu, Q.; Pan, Z.; Wang, E.; An, L.; Sun, G. Aqueous metal-air batteries: Fundamentals and applications. Energy Storage Mater. 2020, 27, 478–505. [Google Scholar] [CrossRef]

- Zhang, L.; Li, L.; Chen, H.; Wei, Z. Recent Progress in Precious Metal-Free Carbon-Based Materials towards the Oxygen Reduction Reaction: Activity, Stability, and Anti-Poisoning. Chemistry 2020, 26, 3973–3990. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Lin, C.Y.; Zhang, D.; Gong, L.; Zhu, Y.; Zhao, Z.; Xu, Q.; Li, H.; Xia, Z. Guiding Principles for Designing Highly Efficient Metal-Free Carbon Catalysts. Adv. Mater. 2019, 31, e1805252. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Tong, Y.; Peng, F. Metal-free carbocatalysis for electrochemical oxygen reduction reaction: Activity origin and mechanism. J. Energy Chem. 2020, 48, 308–321. [Google Scholar] [CrossRef]

- Gao, R.; Dai, Q.; Du, F.; Yan, D.; Dai, L. C(60)-Adsorbed Single-Walled Carbon Nanotubes as Metal-Free, pH-Universal, and Multifunctional Catalysts for Oxygen Reduction, Oxygen Evolution, and Hydrogen Evolution. J. Am. Chem. Soc. 2019, 141, 11658–11666. [Google Scholar] [CrossRef]

- Begum, H.; Ahmed, M.S.; Kim, Y.B. Nitrogen-rich graphitic-carbon@graphene as a metal-free electrocatalyst for oxygen reduction reaction. Sci. Rep. 2020, 10, 12431. [Google Scholar] [CrossRef]

- Gao, Y.; Xiao, Z.; Kong, D.; Iqbal, R.; Yang, Q.-H.; Zhi, L. N,P co-doped hollow carbon nanofiber membranes with superior mass transfer property for trifunctional metal-free electrocatalysis. Nano Energy 2019, 64, 103879. [Google Scholar] [CrossRef]

- Al-Hajri, W.; De Luna, Y.; Bensalah, N. Review on Recent Applications of Nitrogen-Doped Carbon Materials in CO2 Capture and Energy Conversion and Storage. Energy Technol. 2022, 10, 2200498. [Google Scholar] [CrossRef]

- Gutru, R.; Turtayeva, Z.; Xu, F.; Maranzana, G.; Thimmappa, R.; Mamlouk, M.; Desforges, A.; Vigolo, B. Recent progress in heteroatom doped carbon based electrocatalysts for oxygen reduction reaction in anion exchange membrane fuel cells. Int. J. Hydrogen Energy 2023, 48, 3593–3631. [Google Scholar] [CrossRef]

- Tuci, G.; Zafferoni, C.; Rossin, A.; Milella, A.; Luconi, L.; Innocenti, M.; Truong Phuoc, L.; Duong-Viet, C.; Pham-Huu, C.; Giambastiani, G. Chemically Functionalized Carbon Nanotubes with Pyridine Groups as Easily Tunable N-Decorated Nanomaterials for the Oxygen Reduction Reaction in Alkaline Medium. Chem. Mater. 2014, 26, 3460–3470. [Google Scholar] [CrossRef]

- Wee, J.-H.; Kim, C.H.; Lee, H.-S.; Choi, G.B.; Kim, D.-W.; Yang, C.-M.; Kim, Y.A. Enriched Pyridinic Nitrogen Atoms at Nanoholes of Carbon Nanohorns for Efficient Oxygen Reduction. Sci. Rep. 2019, 9, 20170. [Google Scholar] [CrossRef]

- Guo, D.; Shibuya, R.; Akiba, C.; Saji, S.; Kondo, T.; Nakamura, J. Active sites of nitrogen-doped carbon materials for oxygen reduction reaction clarified using model catalysts. Science 2016, 351, 361–365. [Google Scholar] [CrossRef]

- Rao, C.V.; Cabrera, C.R.; Ishikawa, Y. In Search of the Active Site in Nitrogen-Doped Carbon Nanotube Electrodes for the Oxygen Reduction Reaction. J. Phys. Chem. Lett. 2010, 1, 2622–2627. [Google Scholar] [CrossRef]

- Haque, E.; Zavabeti, A.; Uddin, N.; Wang, Y.; Rahim, M.A.; Syed, N.; Xu, K.; Jannat, A.; Haque, F.; Zhang, B.Y.; et al. Deciphering the Role of Quaternary N in O2 Reduction over Controlled N-Doped Carbon Catalysts. Chem. Mater. 2020, 32, 1384–1392. [Google Scholar] [CrossRef]

- Duan, Z.; Henkelman, G. Identification of Active Sites of Pure and Nitrogen-Doped Carbon Materials for Oxygen Reduction Reaction Using Constant-Potential Calculations. J. Phys. Chem. C 2020, 124, 12016–12023. [Google Scholar] [CrossRef]

- Liu, R.; Wu, D.; Feng, X.; Müllen, K. Nitrogen-Doped Ordered Mesoporous Graphitic Arrays with High Electrocatalytic Activity for Oxygen Reduction. Angew. Chem.-Int. Edit. 2010, 49, 2565–2569. [Google Scholar] [CrossRef]

- Kagkoura, A.; Tagmatarchis, N. Carbon Nanohorn-Based Electrocatalysts for Energy Conversion. Nanomaterials 2020, 10, 1407. [Google Scholar] [CrossRef]

- Jung, J.Y.; Kim, S.; Kim, J.-G.; Kim, M.J.; Lee, K.-S.; Sung, Y.-E.; Kim, P.; Yoo, S.J.; Lim, H.-K.; Kim, N.D. Hierarchical porous single-wall carbon nanohorns with atomic-level designed single-atom Co sites toward oxygen reduction reaction. Nano Energy 2022, 97, 107206. [Google Scholar] [CrossRef]

- Montiel Macias, E.; Valenzuela-Muñiz, A.M.; Alonso-Núñez, G.; Farías Sánchez, M.H.; Gauvin, R.; Verde Gómez, Y. Sulfur doped carbon nanohorns towards oxygen reduction reaction. Diam. Relat. Mat. 2020, 103, 107671. [Google Scholar] [CrossRef]

- Bahr, J.L.; Yang, J.P.; Kosynkin, D.V.; Bronikowski, M.J.; Smalley, R.E.; Tour, J.M. Functionalization of carbon nanotubes by electrochemical reduction of aryl diazonium salts: A bucky paper electrode. J. Am. Chem. Soc. 2001, 123, 6536–6542. [Google Scholar] [CrossRef]

- Fresco-Cala, B.; López-Lorente, Á.I.; Cárdenas, S. Monolithic Solid Based on Single-Walled Carbon Nanohorns: Preparation, Characterization, and Practical Evaluation as a Sorbent. Nanomaterials 2018, 8, 370. [Google Scholar] [PubMed]

- Zięba, W.; Jurkiewicz, K.; Burian, A.; Pawlyta, M.; Boncel, S.; Szymański, G.S.; Kubacki, J.; Kowalczyk, P.; Krukiewicz, K.; Furuse, A.; et al. High-Surface-Area Graphene Oxide for Next-Generation Energy Storage Applications. ACS Appl. Nano Mater. 2022, 5, 18448–18461. [Google Scholar] [CrossRef]

- Vicentini, N.; Gatti, T.; Salerno, N.; Hernandez Gomez, Y.S.; Bellon, M.; Gallio, S.; Marega, C.; Filippini, F.; Menna, E. Effect of different functionalized carbon nanostructures as fillers on the physical properties of biocompatible poly(L-lactic acid) composites. Mater. Chem. Phys. 2018, 214, 265–276. [Google Scholar] [CrossRef]

- Salice, P.; Fabris, E.; Sartorio, C.; Fenaroli, D.; Figà, V.; Casaletto, M.P.; Cataldo, S.; Pignataro, B.; Menna, E. An Insight into the Functionalisation of Carbon Nanotubes by Diazonium Chemistry: Towards a Controlled Decoration. Carbon 2014, 74, 73–82. [Google Scholar] [CrossRef]

- Vicentini, N.; Gatti, T.; Salice, P.; Scapin, G.; Marega, C.; Filippini, F.; Menna, E. Covalent functionalization enables good dispersion and anisotropic orientation of multi-walled carbon nanotubes in a poly(L-lactic acid) electrospun nanofibrous matrix boosting neuronal differentiation. Carbon 2015, 95, 725–730. [Google Scholar] [CrossRef]

- Pagona, G.; Karousis, N.; Tagmatarchis, N. Aryl diazonium functionalization of carbon nanohorns. Carbon 2008, 46, 604–610. [Google Scholar] [CrossRef]

- Gatti, T.; Manfredi, N.; Boldrini, C.; Lamberti, F.; Abbotto, A.; Menna, E. A D-π-A organic dye-reduced graphene oxide covalent dyad as a new concept photosensitizer for light harvesting applications. Carbon 2017, 115, 746–753. [Google Scholar] [CrossRef]

- Artyushkova, K. Misconceptions in interpretation of nitrogen chemistry from X-ray photoelectron spectra. J. Vac. Sci. Technol. A 2020, 38, 031002. [Google Scholar] [CrossRef]

- Bulusheva, L.G.; Okotrub, A.V.; Kudashov, A.G.; Yudanov, N.F.; Pazhetnov, E.M.; Boronin, A.I.; Abrosimov, O.G.; Rudina, N.A. Fluorination of multiwall nitrogen-doped carbon nanotubes. Russ. J. Inorg. Chem. 2006, 51, 613–618. [Google Scholar] [CrossRef]

- Takeyasu, K.; Furukawa, M.; Shimoyama, Y.; Singh, S.K.; Nakamura, J. Role of Pyridinic Nitrogen in the Mechanism of the Oxygen Reduction Reaction on Carbon Electrocatalysts. Angew. Chem.-Int. Edit. 2021, 60, 5121–5124. [Google Scholar] [CrossRef]

| Sample | Py-N (398.6 eV) | Py-NH (399.7 eV) | N-F (400.4 eV) | Py-NH+ (401.2 eV) | NOx (402.3 eV) |

|---|---|---|---|---|---|

| CNH-Py-F (as prepared) | 31.7% | 44.8% | --- | 18.4% | 5.1% |

| CNH-Py-F + Nafion | 5.6% | 26.6% | 30.7% | 24.0% | 13.1% |

| −0.10 V 1 | 12.2% | 28.9% | 29.5% | 22.6% | 6.8% |

| −0.35 V 1 | 17.2% | 30.7% | 29.1% | 20.5% | 2.5% |

| −0.60 V 1 | 15.7% | 33.9% | 30.0% | 18.1% | 2.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tosin, E.; Gatti, T.; Agnoli, S.; Calvillo, L.; Menna, E. Nitrogen- and Fluorine-Doped Carbon Nanohorns as Efficient Metal-Free Oxygen Reduction Catalyst: Role of the Nitrogen Groups. Surfaces 2023, 6, 227-238. https://doi.org/10.3390/surfaces6030015

Tosin E, Gatti T, Agnoli S, Calvillo L, Menna E. Nitrogen- and Fluorine-Doped Carbon Nanohorns as Efficient Metal-Free Oxygen Reduction Catalyst: Role of the Nitrogen Groups. Surfaces. 2023; 6(3):227-238. https://doi.org/10.3390/surfaces6030015

Chicago/Turabian StyleTosin, Elisa, Teresa Gatti, Stefano Agnoli, Laura Calvillo, and Enzo Menna. 2023. "Nitrogen- and Fluorine-Doped Carbon Nanohorns as Efficient Metal-Free Oxygen Reduction Catalyst: Role of the Nitrogen Groups" Surfaces 6, no. 3: 227-238. https://doi.org/10.3390/surfaces6030015

APA StyleTosin, E., Gatti, T., Agnoli, S., Calvillo, L., & Menna, E. (2023). Nitrogen- and Fluorine-Doped Carbon Nanohorns as Efficient Metal-Free Oxygen Reduction Catalyst: Role of the Nitrogen Groups. Surfaces, 6(3), 227-238. https://doi.org/10.3390/surfaces6030015