Abstract

The increasing demand for sustainable materials in the coatings industry is driving the replacement of synthetic components with bio-based alternatives. In this study, Tagua powder, derived from the seeds of Phytelephas macrocarpa, was incorporated as a filler in a waterborne acrylic-based coating to evaluate its effects on abrasion and protective properties. Two different particle size ranges (40–63 µm and ≤40 µm) and concentrations (1 wt% and 3 wt%) were tested. Morphological analyses confirmed a homogeneous dispersion of the filler within the coating matrix, with larger particles inducing surface roughness. The results demonstrated that the addition of Tagua powder significantly improved abrasion resistance, with the coating containing 3 wt% of larger particles (40–63 µm), reducing mass loss by 24.5% after 1000 Taber abrasion cycles compared to the reference coating. However, due to its lignocellulosic nature, the filler increased water uptake, leading to a decrease in barrier properties. Coatings with 3 wt% filler exhibited a reduction in electrochemical impedance modulus by approximately one order of magnitude after 670 h of immersion in a 3.5 wt% NaCl solution, indicating lower corrosion protection. Despite this, the performance in filiform corrosion resistance remained comparable to the reference, suggesting that Tagua powder does not critically affect adhesion properties. These findings highlight the potential of Tagua powder as a functional bio-based filler, offering enhanced mechanical durability while requiring a strategic coating design, such as a multilayer system, to mitigate moisture sensitivity. This study provides valuable insights into the development of environmentally friendly coatings with improved wear resistance.

1. Introduction

During the past century, the prices of raw materials have been consistently climbing as a result of the unsustainable linear economic model. This system has made resources less available and more expensive while also inflicting irreversible damage on the environment and leading to a growing accumulation of waste [1,2,3]. One possible solution to this problem is a production aimed at the minimization of the impact on the environment. In this scenario, sustainable sources, such as bio-based materials, are applied to replace the products derived from fossil fuels in order to optimize waste management systems [4]. For example, in the paints field, researchers are increasingly focused on ecological and multifunctional alternatives to standard synthetic fillers because their production typically does not consider characteristics of environmental sustainability [5]. A sustainable approach is to use pigments that can be produced without chemical reactions, with reduced energy consumption and zero waste.

Recent research indicates that fillers derived from food and natural waste materials can significantly enhance the value of composite materials by reducing production costs and repurposing recycled resources effectively [6]. For example, the use of bio-based feedstock in material production grew from 5% in 2004 to 12% in 2010, reaching around 18% in 2020. Forecasts predict this could rise to 25% by 2030 [7]. These aspects have driven the research and the industrial sector toward the adoption of polymeric matrices added with bio-based fillers, in particular, those sourced from natural materials or derived from agricultural and food waste. One promising example of a natural bio-based filler is CaCO3 powder from chicken eggshells tested in several organic coatings [8,9,10]. All these studies highlighted that thanks to their high content of CaCO3, about 95%, chicken eggshells can replace commercial CaCO3 without compromising the protective performances of the coating. Similarly, seashell waste from various mollusks provides an abundant supply of CaCO3 that can be used to enhance the mechanical and thermal properties of bio-composites. In coatings, this natural filler also improves flame retardancy and reduces smoke emissions [11]. Additionally, agro-industrial waste offers a low-cost and valuable option as a filler. Materials like pistachio nutshells [12], cherry seeds, olive pits [6], peanut shells [13], avocado seeds [14], and groundnut and coconut shells [15] have been studied and utilized to improve mechanical, thermal, and wear-resistant properties of polymer composites.

An intriguing alternative filler material emerges in the form of Tagua, often referred to as “natural ivory”. This remarkable material is derived from the seeds found within the fruits of the Phytelephas Macrocarpa tree, a palm species native to tropical regions of South America [16,17]. Known for its exceptional hardness and dense, ivory-like texture, Tagua has been prized for centuries in both artisanal and industrial applications [18]. Historically, it has been extensively used in the production of jewelry, chess pieces, billiard balls, buttons, and various decorative items [19]. During its peak industrial usage, this material constituted up to 20% of all buttons manufactured in the United States, underscoring its importance as a sustainable and versatile resource. It is naturally available and only needs to be pulverized. Its production does not lead to deforestation; on the contrary, it supports the sustainable development of local communities. Tagua is harvested in Ecuador when it naturally falls from wild trees, contributing to forest conservation and preventing deforestation risks. The collectors are independent farmers who supply Tagua to local wholesalers. Drying and initial processing stages are carried out locally, further supporting the regional economy [20].

Despite its long history and recognized potential, the use of Tagua in advanced materials remains underexplored. In particular, no studies have investigated the incorporation of Tagua powder as a functional filler in organic coatings. Leveraging its inherent hardness and unique physical properties, this work seeks to fill that gap by evaluating the impact of Tagua powder on the aesthetic qualities, durability, and mechanical performance of waterborne paints. In the current context of environmental concerns and stricter volatile organic compounds (VOCs) regulations, the coatings industry has been driven toward more sustainable alternatives, with waterborne paints emerging as a key solution. Widely adopted in the DIY and residential markets, these coatings offer advantages such as low VOC content [21], reduced odor, non-flammability [22], and easy cleanup with water. Their formulation has evolved to replicate the application and processing properties of traditional solvent-based systems through the use of water-dispersible or -emulsifiable resins.

The challenges of water sensitivity in waterborne paints, primarily linked to the use of hydrophilic additives, highlight the need for innovative solutions to enhance their protective properties [21]. Natural fillers such as Tagua could be interesting as sustainable alternatives to synthetic components, offering potential benefits in improved wear performance of the outer layer of the coating system.

This study explores the potential of Tagua as a filler in waterborne acrylic paints, evaluating its impact on water absorption, film integrity, and overall coating performance. The findings aim to advance the development of eco-friendly, high-performance waterborne coatings on steel substrates while leveraging the sustainable attributes of natural materials.

The paint was prepared by adding two different amounts of Tagua powder for two different particle size ranges to assess how the filler concentration and the granulometry influence the coatings’ performance. The morphology and the aesthetic characteristics of the coatings were characterized by scanning electron microscope (SEM), optical microscope, gloss and roughness analysis, and contact angle to study the influence of the Tagua powder. The influence of bio-filler on the corrosion resistance and performance of composite coatings in aggressive environments was investigated through neutral salt spray chamber exposure (NSST), humidostatic chamber, and electrochemical impedance spectroscopy (EIS). Moreover, it was possible to study the promising mechanical wear improvement of the different coatings by exploiting the Taber test [23] and the Scrub test [24].

2. Materials and Methods

2.1. Samples Preparation

Natural ivory in the form of Tagua buttons was supplied by Mabo (Telgate, BG, Italy). The buttons were ground using a batch mill (IKA® WERKE M20, Staufen, Germany) to produce a fine powder. The resulting powder was sieved, yielding two distinct particle size distributions: one containing particles with sizes between 63 μm and 40 μm and the other containing particles smaller than 40 μm. The white waterborne 2K acrylic-based paint, AQUACRIL SATIN DTM, was supplied by FRANCHI & KIM (Castenedolo, BS, Italy). The Tagua powder was added to the paint at concentrations of 1 wt% and 3 wt% for each particle size range. The resulting formulations were mixed for 5 min using a high-speed homogenizer (IKA® ULTRA TURRAX T18, Staufen, Germany) to ensure homogeneous dispersion of the bio-filler particles. The paints were then applied onto the carbon steel substrates using a spray deposition technique. Five different coating types were prepared, including four bio-filler-enriched paints (two particle size ranges at two concentrations each) and the reference paint, free of bio-filler. Table 1 summarizes the coating types. Carbon steel substrates (Q-panel type R; composition: 0.15% C, Fe bal.) were used in three different dimensions: 76 mm × 152 mm × 0.81 mm, 102 mm × 102 mm × 0.81 mm, and 102 mm × 203 mm × 0.81 mm. These substrates were provided by Q-Lab (Westlake, OH, USA). After deposition, the coated samples were dried at room temperature for 15 min, followed by oven curing at 60 °C for 40 min.

Table 1.

Coatings formulation considered. Different particle content and particle size were evaluated.

2.2. Characterization Methods

The morphology and composition of the Tagua powder and acrylic-based white paint, as well as the cross-sections of the coatings, were analyzed using a low-vacuum scanning electron microscope (SEM, JEOL IT 300, Tokyo, Japan). Powder size distribution was determined from SEM images using ImageJ software 1.53t. The gloss at 60° incident light rays of the coatings, influenced by different amounts of Tagua powder, was measured with an Erichsen 503 glossmeter (Milan, Italy) according to ASTM D523-14 [25]. Measurements were performed on three specimens per coating type, with five measurements per specimen for a total of 15 readings per coating. Coating roughness was assessed using a MAHR MarSurf PS1 profilometer (Mahr Gruppe, Göttingen, Germany) to evaluate Ra and Rz parameters. The coating thickness was measured with a Phynix Surfix FN thickness gauge (Phynix Sensortechnik, Neuss, Germany). To evaluate the effect of the filler on the surface wettability of the coatings, contact angle measurements were performed following the ASTM D7334/08 standard [26]. A Nikon 60 mm lens f/2.8 (Nikon Instruments, Tokyo, Japan) for macro pictures was used, and the wetting angle was measured by using the NIS-Elements Microscope Imaging software. The drops were formed with a syringe and dropped from a height of about 2 cm. Once the drop was focused, the picture was captured, and the wetting angle was measured by imaging software. In total, 10 measurements were performed for each sample to obtain statistical validity. Abrasion resistance was evaluated using the Taber and Scrub tests. The Taber test, performed following ASTM D4060–19 [23], utilized a Taber Abraser 5135 (Taber Industries, Tonawanda, NY, USA) with CS10 abrasive wheels loaded with 250 g each. Samples underwent 1.000 cycles at 60 rpm, with mass loss measured every 100 cycles. The wheels were cleaned and resurfaced every 250 cycles as per the standard. The Scrub test was conducted with an Elcometer 1720 Abrasion and Washability Tester (Elcometer, Manchester, U.K.) in accordance with ASTM D4213-24 [24]. Samples were subjected to 2000 cycles using an abrasive pad (90.0 ± 0.5 mm × 39.0 ± 0.5 mm) weighing 400 g, moving at 37 cycles per minute. Weight loss was evaluated every 500 cycles. The test was performed in dry mode to prevent solution absorption into the coatings. The NSST was performed to assess the corrosion protection provided by the coatings in accordance with ASTM B117-19 [27]. Images of the tested samples before aging is reported in Appendix A. Samples were exposed to a 5 wt.% sodium chloride solution in a salt spray chamber (Ascott Analytical Equipment Limited, Tamworth, U.K.) for 1.000 h. Since the NSST does not provide a complete characterization of the common failure mechanism [28], filiform corrosion (FFC) resistance was performed at a constant humidity of 80% at 40 °C after a 5 h chlorides contamination stage in the salt spray chamber [29]. Observations were made periodically to identify defects such as pores, blisters, and rust [30]. EIS was employed to evaluate coating defect levels and resistance to water and aggressive ion absorption. Measurements were conducted using an Autolab PGSTAT302N potentiostat (Metrohm, Herisau, Switzerland) controlled by Nova 1.11 software. A sinusoidal signal with a 20 mV peak-to-peak amplitude was applied over a frequency range of 100 kHz to 10 mHz. The setup included an electrochemical cell with a 15 cm2 area in contact with a 3.5 wt.% sodium chloride solution. The cell housed an Ag/AgCl/3M KCl reference electrode and a platinum counter electrode. Impedance measurements were taken at different immersion periods.

3. Results

3.1. Filler and Coating Characterization

The initial analysis conducted was Energy-Dispersive X-ray Spectroscopy to determine the composition of the Tagua powder. The results, presented in Table 2, reveal that the powder is primarily composed of carbon (51 wt.%) and oxygen (46 wt.%), with trace amounts of other elements, including Al, K, Cl, Cu, Ca, P, S, Mg, and Si.

Table 2.

Composition of Tagua powder.

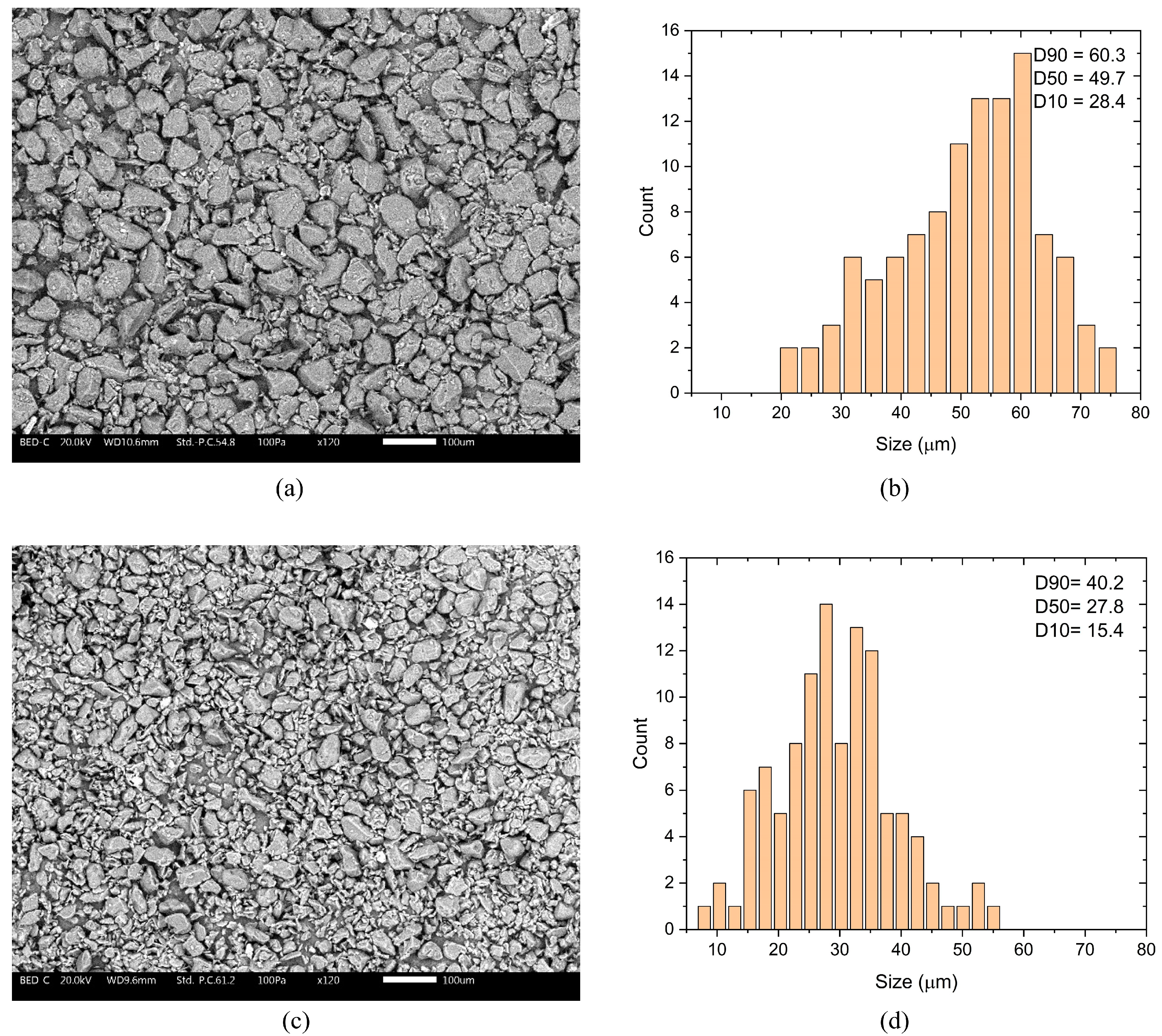

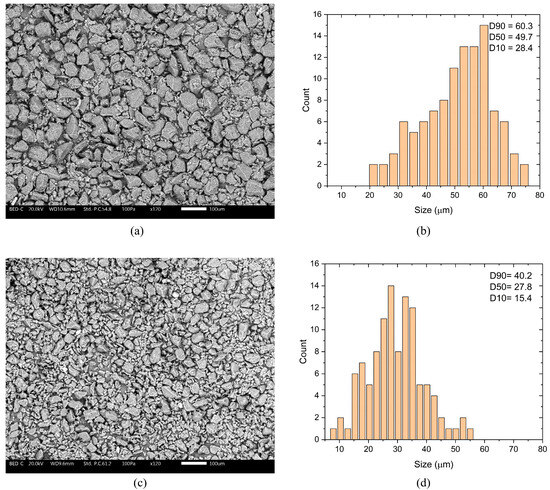

The SEM images of the two powders differently sieved are reported in Figure 1a and Figure 1c, respectively, and for both images, the size distribution of the powders, determined with the aid of ImageJ software, was extracted (Figure 1b,d). The particle size was measured considering the maximum dimension of the particles. As a result, elongated particles with a major dimension larger than the sieve aperture may still pass through it due to their shape. However, the dimension of the maximum dimension for 90% of the particles (D90) for the coarse powder, 60.3 µm, indicates that nearly all granules are smaller than the sieve aperture size (63 µm). For the other type of powder, D90 is calculated at around 40.2 µm.

Figure 1.

SEM-BED images of Tagua particles sieved through 60 µm mesh (a) and its particle size distribution (b). SEM-BED image of Tagua particles sieved through 40 µm mesh (c) at 120 and its particle size distribution (d).

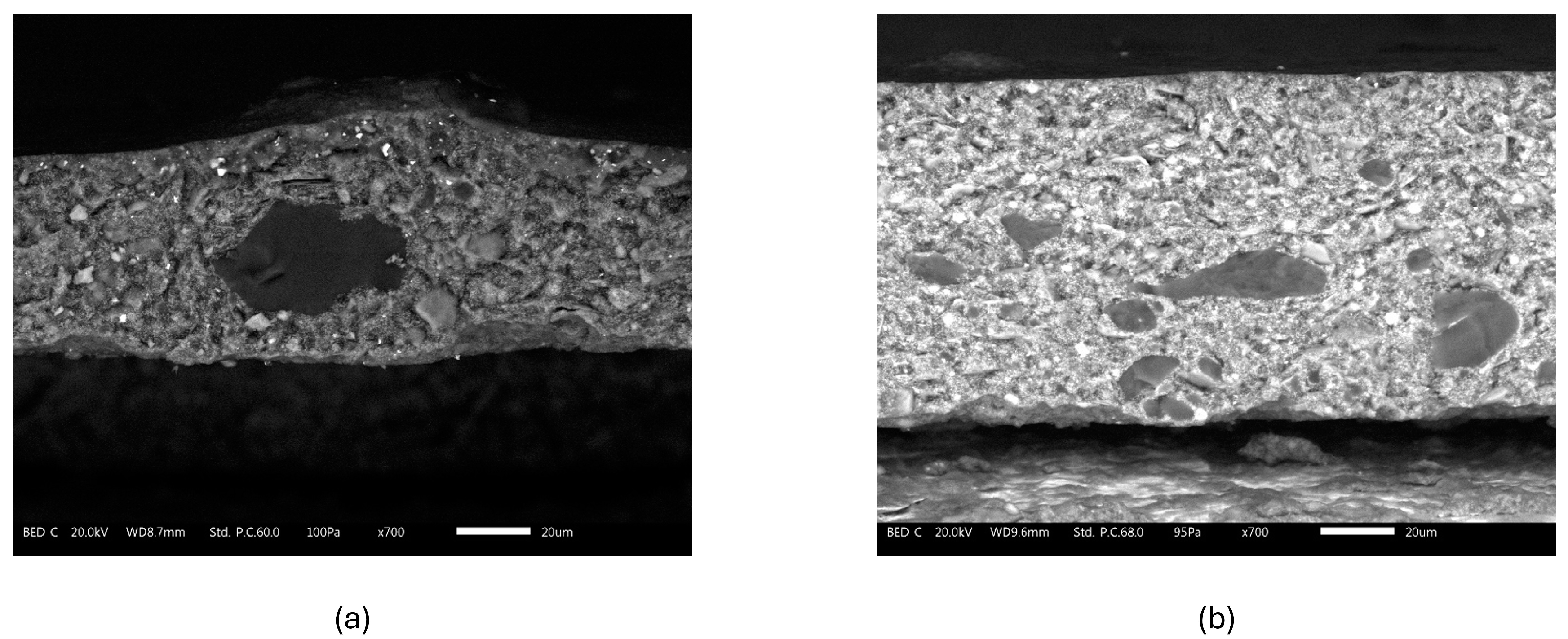

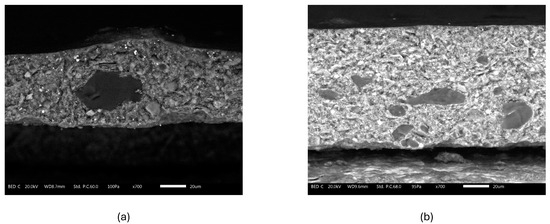

In addition to evaluating the morphology and particle size distribution, their adhesion to the matrix was also observed. To evaluate the compatibility between the paint matrix and the bio-based filler, the samples underwent a brittle fracture process by means of liquid nitrogen, allowing investigation of the cross-sectional structure through SEM analysis. In Figure 2, the cross-section of samples C3S63 and C3S40 is shown, and the images reveal the presence of Tagua granules well embedded within the paint layer. Despite the brittle fracture process, the bio-based filler remains firmly integrated into the matrix. This observation confirms strong compatibility between the filler and the polymeric matrix for both the bigger and the smaller particles. Interestingly, larger particles, as shown in Figure 2a, induce the formation of surface bulges, which increase surface roughness. In contrast, smaller particles, depicted in Figure 2b, result in a less pronounced effect on the surface texture.

Figure 2.

SEM-BED-C images of cross-sections for (a) C3S63 and (b) C3S40.

Regarding the coating surface properties, the gloss values of the coating change not only as a function of the filler concentration but also as a function of its granulometry. The presence of the Tagua determines a decrease in the gloss value, providing a matt effect. This feature is in agreement with the higher roughness detected on the loaded paint with respect to the reference one (C0) in Table 3. Furthermore, a greater amount of Tagua added determines lower gloss together with higher roughness regardless of the particle size. The most relevant change is reached by adding 3.0 wt% of powder in coating type C3S63, which shows a decrease in gloss of around 30% with respect to the reference sample C0. Therefore, the introduction of the bio-based filler causes a gradual opacification of the coating. This trend is more evident when increasing the dimension of the filler. This bio-based filler influences both the surface morphology and texture of the coating, demonstrating its potential to provide aesthetic multifunctionality. Regarding the modification of the wettability of the coating, the contact angle is reported in Table 3 as being hydrophilic, which leads to an increase in the contact angle. So, increasing the content and the dimension of the particles increases the contact angle of the droplets deposited on the coating.

Table 3.

Thickness and surface properties of the analyzed coatings.

3.2. Wear Resistance

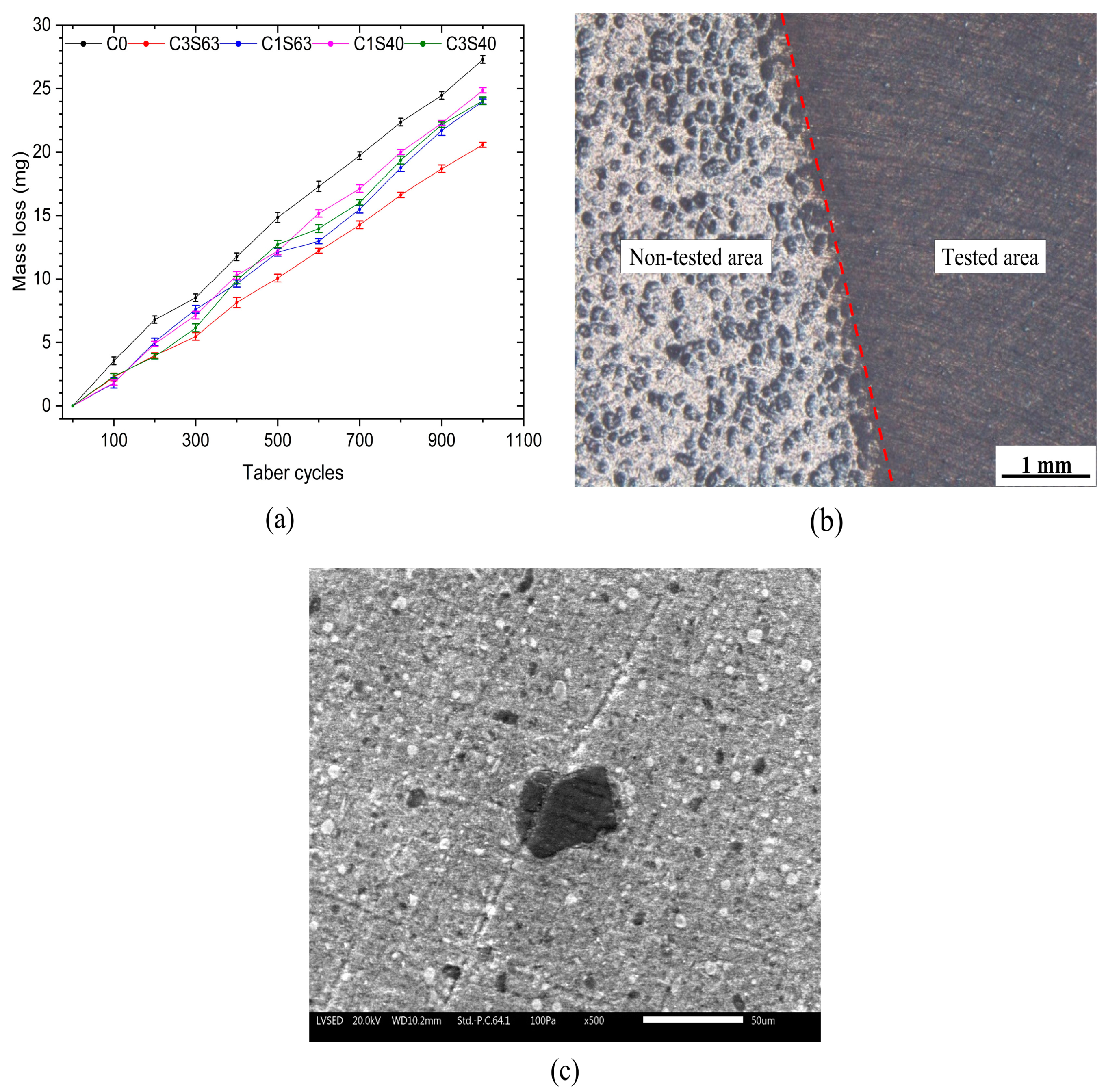

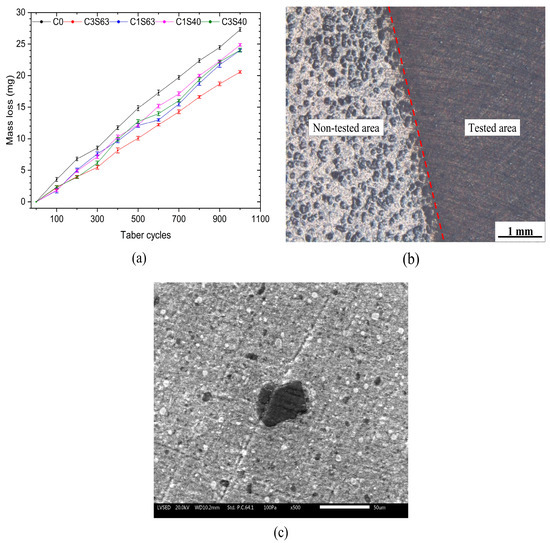

The graph in Figure 3a illustrates the mass loss recorded for each coating type as a function of the number of Taber test abrasion cycles. As the test progresses, the mass loss consistently increases due to the continuous removal of the surface wear by the rotating wheels. The hardness of the Tagua particles in all the concentrations and granulometries leads to a reduction in mass loss. However, the paint added with the 3 wt% of particles having bigger particles appears to be the best choice for optimizing the abrasion resistance of the paint. Indeed, C3S63 shows a saved mass loss of 24.5% after 1000 cycles compared to the reference C0. The behavior during abrasion of the coating charged with smaller particles in higher amounts gives a similar result to the one of the coating charged with bigger particles but in lower amounts. A slight improvement in wear resistance is observed when tripling the amount of smaller particles; however, their tendency to remain embedded within the matrix reduces their effectiveness in reinforcing the coating. In contrast, larger particles protrude more from the surface, providing greater mechanical resistance against abrasion, while smaller particles are more easily detached during wear. On the other hand, the difference in mass loss between C3S63 and C3S40 is much more pronounced, indicating that the influence of filler size is less significant when particle content is small but becomes considerably more impactful as particle content increases.

Figure 3.

Mass loss evolution during 1000 cycles of Taber test (a). SEM-BED images (b,c) highlight the different morphologies on the tested coating surface for the C3S63 sample at different magnifications.

It is noticeable that the damage after 1000 cycles on the C3S63 surface in the right region of Figure 3b. In contrast, the left portion of the image, which represents the region of the sample not subjected to abrasion, displays bulges caused by particles coated with paint. A detail of the same specimen is displayed in Figure 3c.

It can be observed that the motion of the wheels during the 1000 Taber cycles has removed the outer layer of the coating composed of paint, and it seems that the Tagua particles are well anchored to the polymer matrix, and no signs of pull-off were observed. During the cycles, the surrounding polymer was removed, while the filler remained attached to the paint, leading to a reduction in material loss thanks to the good wear resistance of the granules. Referring to Figure 3c, it is possible to see a sort of cut in the particle, so it is clear that the Tagua also gets abraded, and it is unable to provide complete shielding to the paint. However, by observing the edges of the particle, it is possible to see that the particle is slightly elevated compared to the matrix. These kinds of “steps” created between these granules may serve as resistance points against the grinding wheel’s movement. As a result, the wheels tend to glide over these steps, reducing the removal of the polymeric matrix in the coating. Indeed, it can be seen how the mark left by the wheel stops above the particle and then starts again in a region slightly distant from it. Therefore, for this type of superficial abrasive process, Tagua powder effectively reduces the removal of the polymer matrix, thereby enhancing the durability of the coating in repeated abrasive contact.

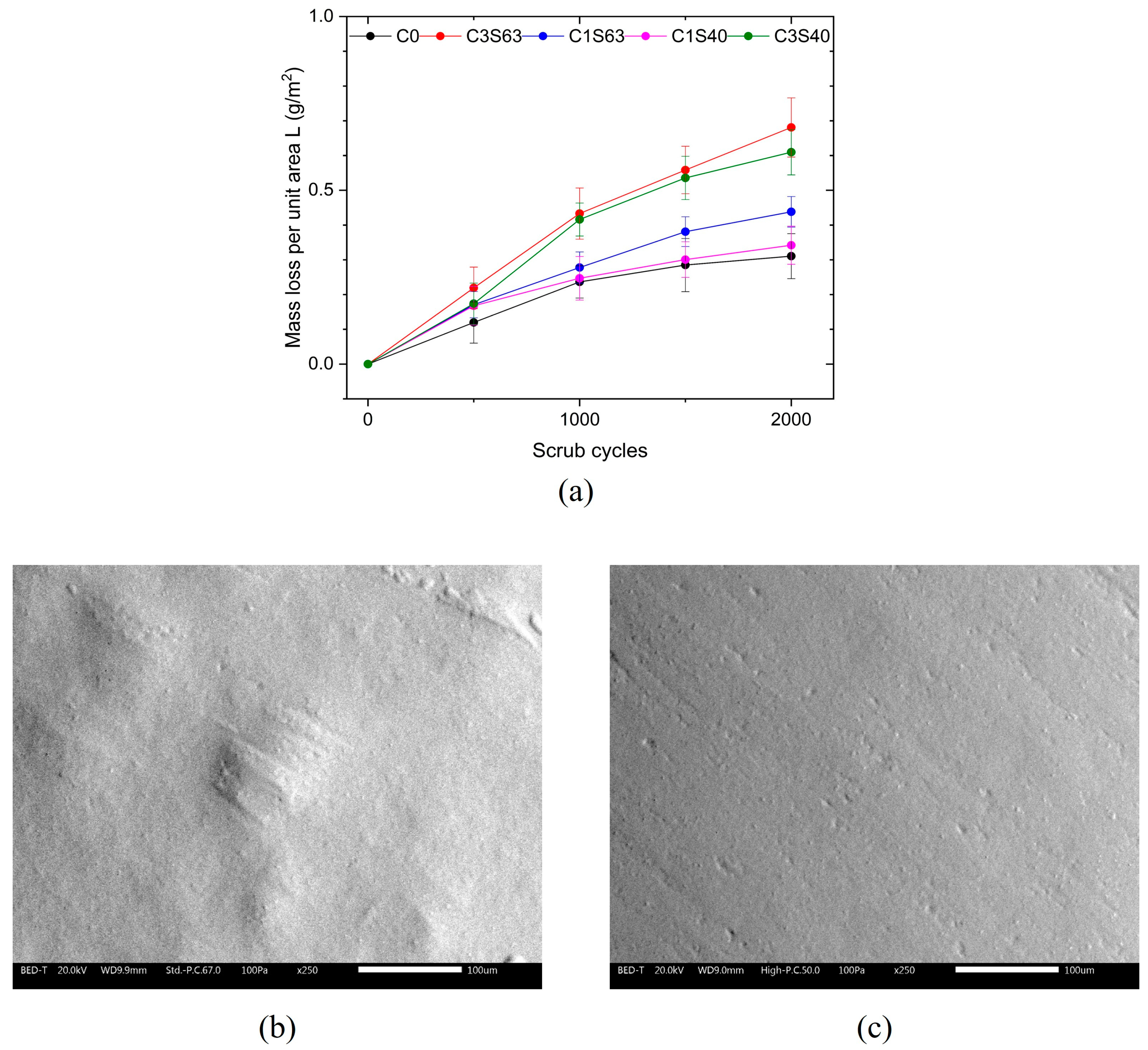

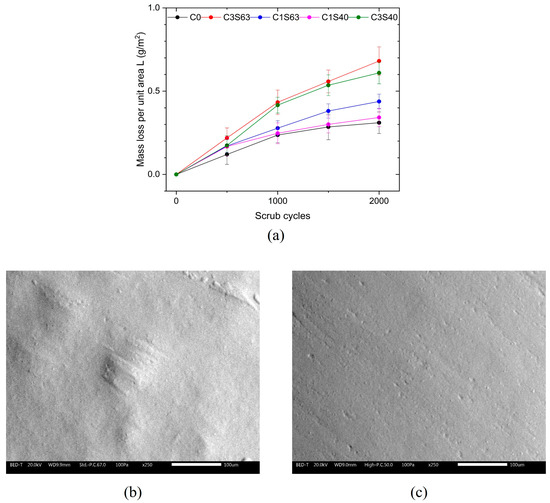

The Scrub test is one reliable method exploited for the characterization of the mechanical properties of organic-based composite coatings. It provides valuable insights into the reinforcing effects of pigments and both inorganic and organic fillers on the mechanical strength of coatings. The abrasion resistance of the coatings was assessed by subjecting the samples to wear cycles caused by an abrasive pad. The weight loss of the samples was monitored every 500 abrasion cycles, and then it is necessary to calculate L, which is the loss in coating mass per unit area, following Equation (1) in which it is possible to find the sample’s initial weight () and the weight after the cycle (). Additionally, A is the area of the sample occupied by the pad during the test [31].

By observing the trend of mass loss per unit area (L) as a function of abrasion cycles in the graph shown in Figure 4a, it is possible to evaluate the contribution of the concentration and the granulometry of the filler on the abrasion of the composite coating. It is noted that under such testing conditions, the addition of Tagua particles in all granulometries and concentrations increases the mass loss during the entire sequence of abrasion cycles compared to the sample coated with paint free of filler. In particular, for coatings containing the same concentrations of particles, the bigger size of the filler causes an increase in mass loss. In addition, also the measures of roughness reported in Table 3 corroborate the outcome of the mass losses. C3S63 contains big particles, resulting in higher roughness than the other samples. This means offering many protruding points where the pad can exert its abrasive action in a severe manner by removing the paint that covers the particles, and sometimes, it is also able to remove some of them, which results in a significant mass loss. The explanation of these data can be found by comparing the images of the area subjected to the abrasion for C3S63 and C0 taken after 2000 cycles and reported in Figure 4b,c. The C3S63 surface shows that the pad performs strong abrasive action on the raised areas corresponding to the places where are present the particles covered by paint, while the surface of C0 is smoother than C3S63, and it seems that the pad exerted less abrasive action. However, for this type of test, as was found for the Taber test, no cases of pull-off were detected.

Figure 4.

Mass loss evolution during 2000 cycles of the Scrub test (a). SEM-BED images (b) and (c) highlight the different roughness morphologies on the tested coating surface for C3S63 and C0 samples, respectively.

Lowering the particle concentration to 1 wt% leads to smaller mass losses after 2000 Scrub cycles, likely because the elevated points are less numerous. Additionally, the lower amount of filler reduces the contribution of cut particle pieces to the mass loss. This test involved a different type of abrasive action compared to the Taber test, and as a result, the findings differ significantly from those of the Taber test, which identified C3S63 as the best option.

3.3. Aging Tests

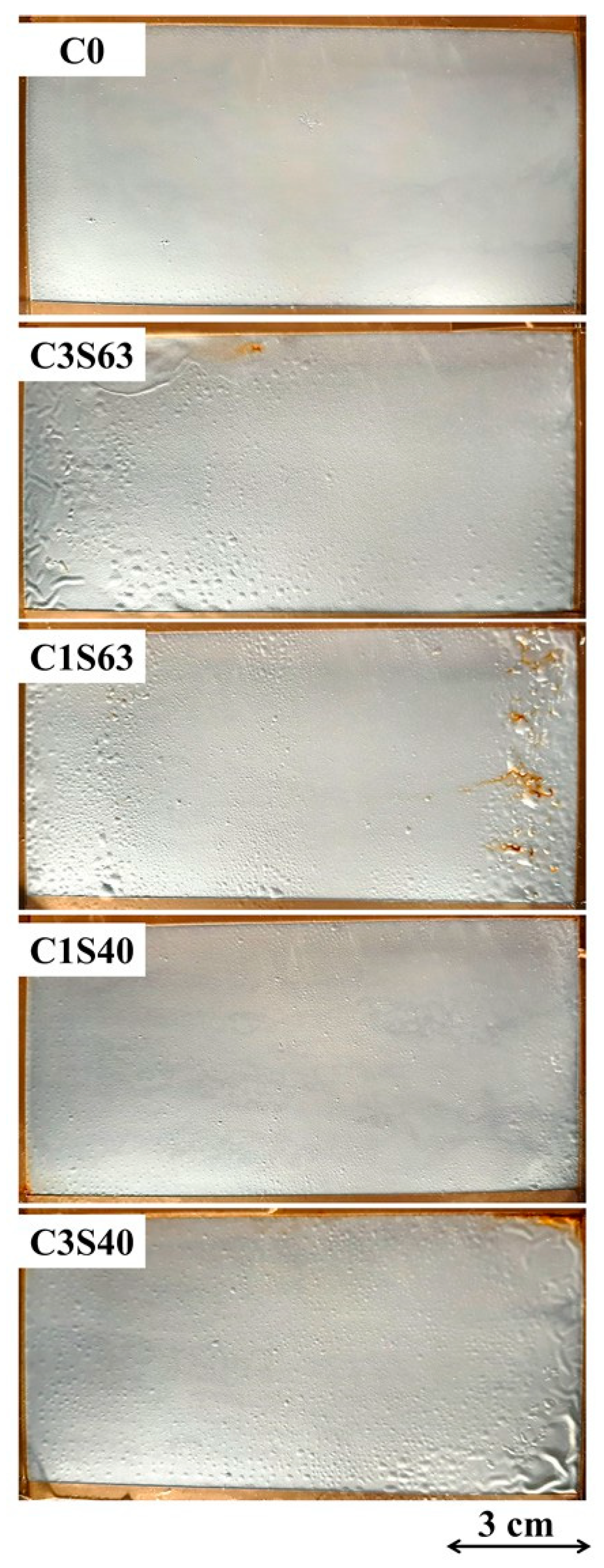

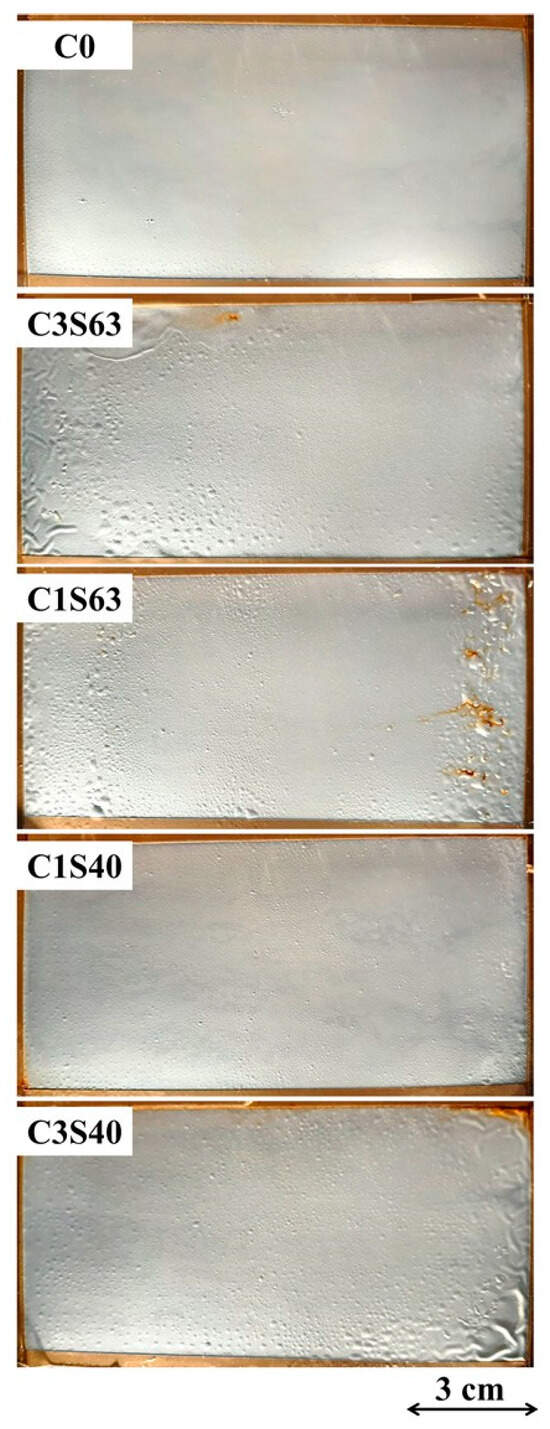

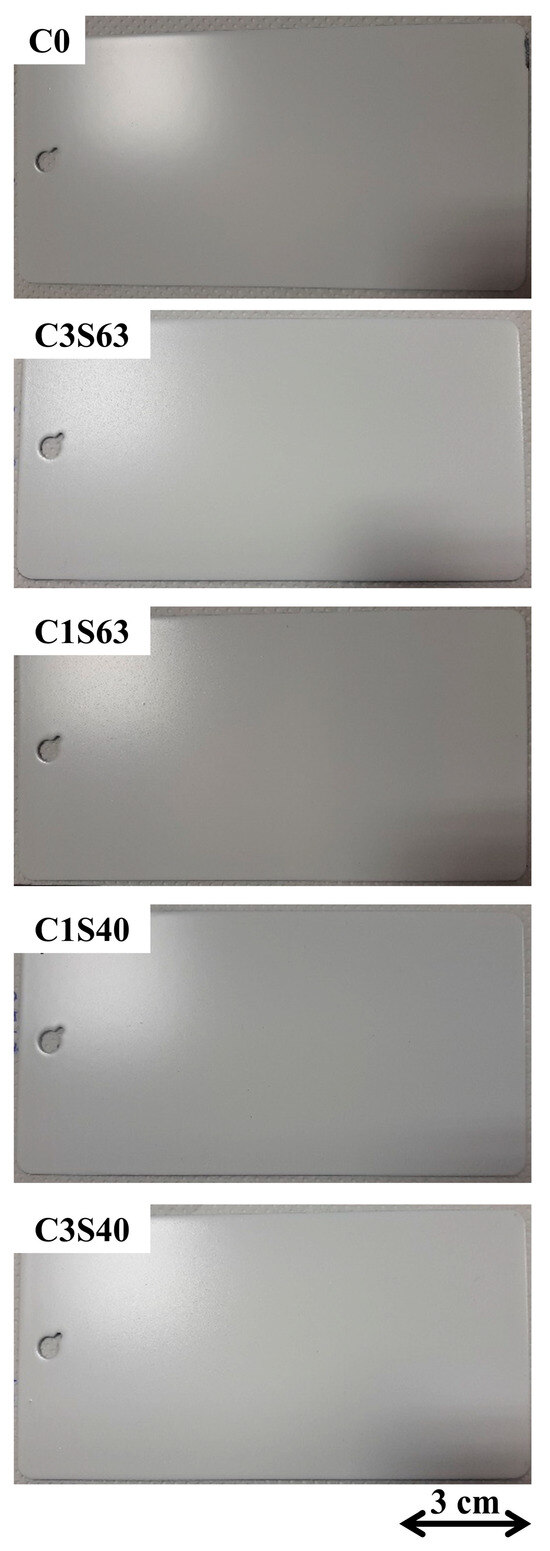

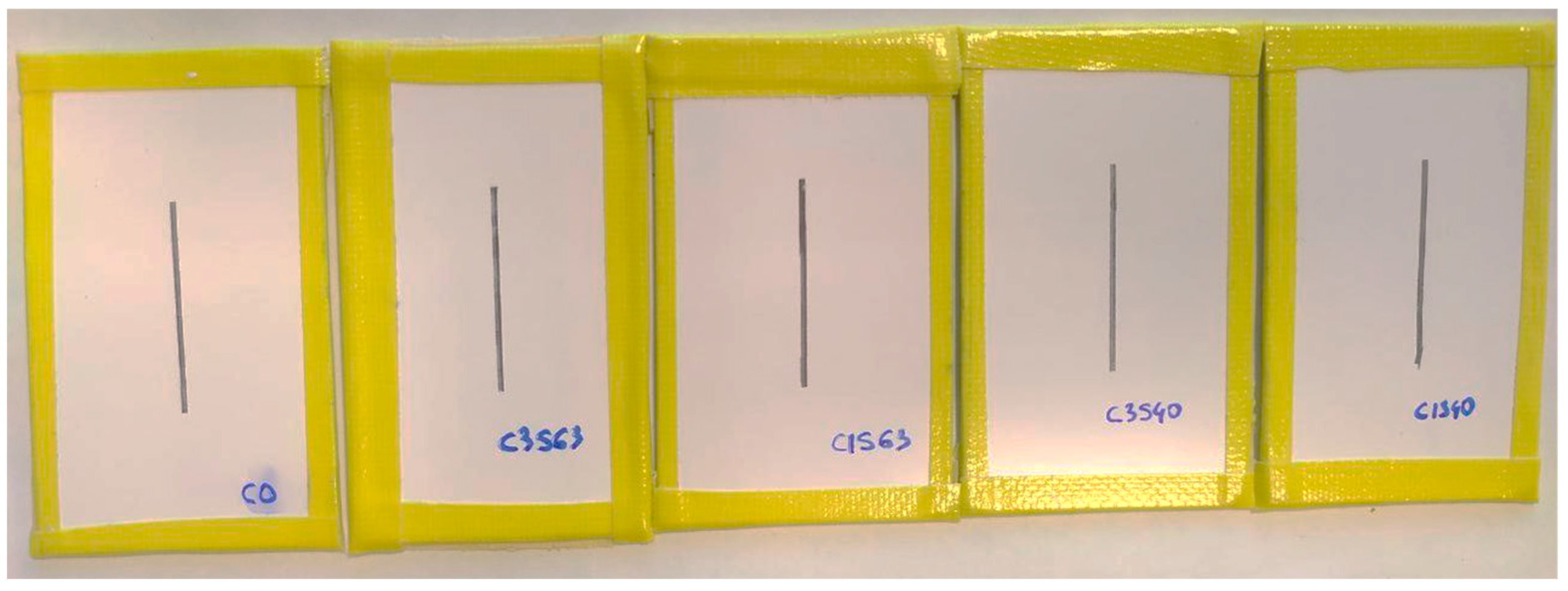

The coated samples were placed in the NSST for a total duration of 1000 h, and the samples were observed after 24, 72, 150, 300, 500, and 1000 h. The blister formation caused by water uptake was visually inspected during each monitoring session. After 300 h, some blisters became visible in the area for samples C3S40 and C3S63. The appearance of the coated steel panels after 1000 h is displayed in Figure 5. The inclusion of the bio-based filler does not enhance the protective properties of the coating; rather, it appears to influence them by promoting water uptake by its hygroscopic tendency. Tagua is composed of lignocellulose and is characterized by a hygroscopic behavior, which is already highlighted in several works [32,33,34,35].

Figure 5.

Coated samples after 1000 of NSST exposure.

After 1000 h in the salt spray chamber, the samples loaded with 3% Tagua powder (C3S63 and C3S40) exhibit blisters evenly distributed across the tested surface, accompanied by visible delamination. In the case of sample C1S40, the blisters are fewer and smaller in size, with better durability. Conversely, sample C1S63 might initially appear to be the most damaged. According to [36] ISO 4628-2, a blistering grade can be assigned based on the density and size of the blisters for each sample, focusing on the area reasonably far from the edges. These evaluations are summarized in Table 4. A higher amount of filler translates to a wider area damaged by blisters, while bigger particles cause a reduced number of blisters but have bigger dimensions. In the NSST, the higher absorption of water caused by the presence of Tagua particles is aggravated by the humidity set at 100 r.h.%, which may not be fully representative of the real durability performances.

Table 4.

Percentage of area covered by blisters, number of blisters, and blistering grade.

Furthermore, the comparison between C3S63 and C3S40 underscores the impact of particle size. Larger particles appear to exacerbate water absorption, potentially creating pathways that facilitate water transport through capillary action. Meanwhile, for the samples containing 1 wt% of particles, it is observed that the blistering is less noticeable, and the effect of particle size is less pronounced. The barrier properties of the composite layers are weakened by the presence of these fillers, as their interface with the polymer matrix creates pathways that allow moisture and aggressive ions to penetrate. Larger particles, due to their hydrophilic nature and increased likelihood of surface exposure with incomplete matrix coverage (see Figure 2), create preferential pathways for electrolyte infiltration. This effect, combined with the expanded interface between the polymer matrix and the filler, promotes higher water uptake and reduces the overall barrier performance of the coating. Similar behavior has been reported in previous studies [6], where lignocellulose-based fillers increased water absorption by forming percolating pathways that facilitate water transport through capillary action within the filler.

A similar aging campaign was performed on similar samples where a longitudinal scratch in the coating was introduced. The results are not reported here since no differences have been detected between the coating loaded with Tagua and the reference. In the case of a damaged coating, the effect of the filler results is hidden by the macroscopic source of electrolyte from scratch, and the paint wet adhesion seems not altered.

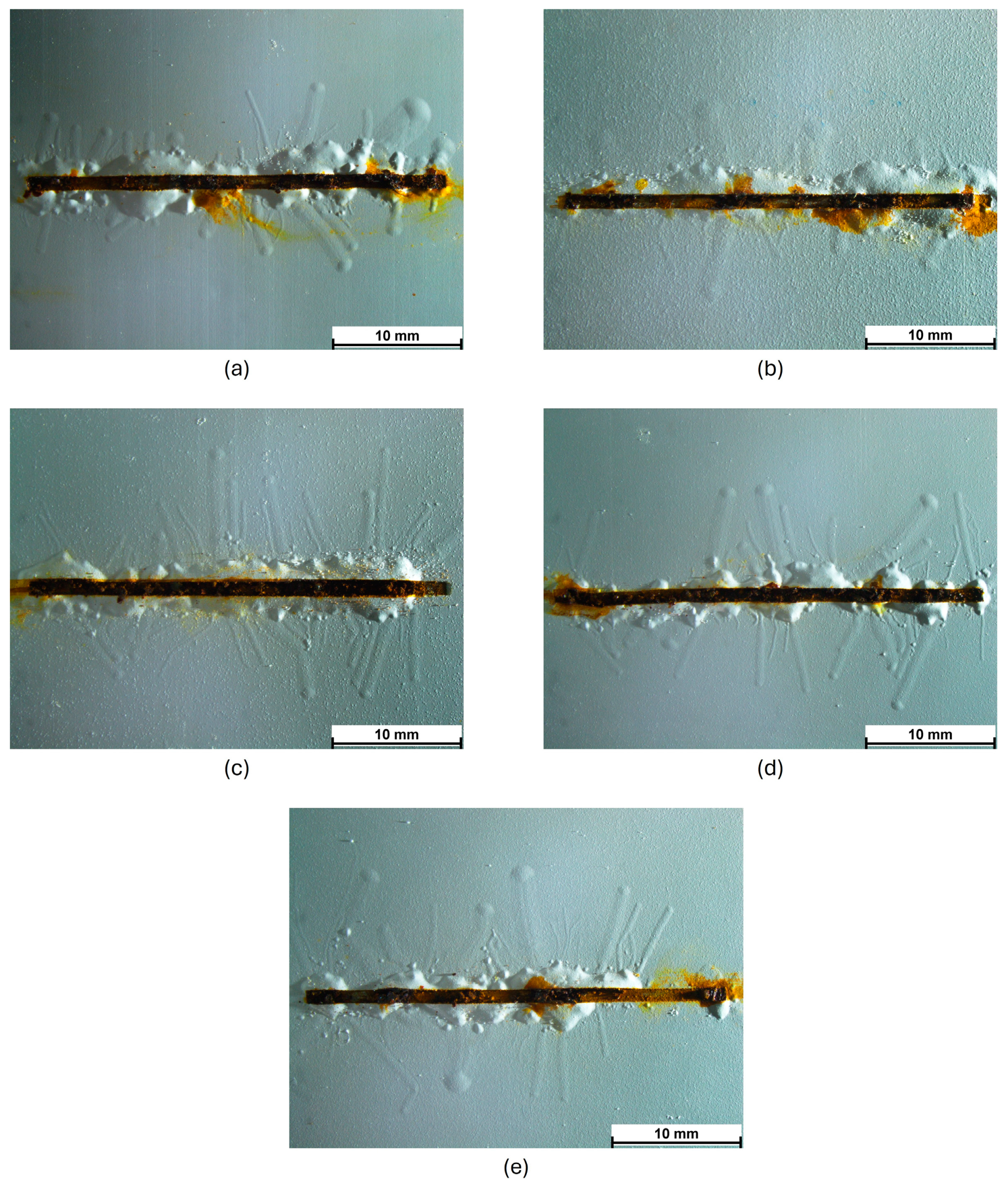

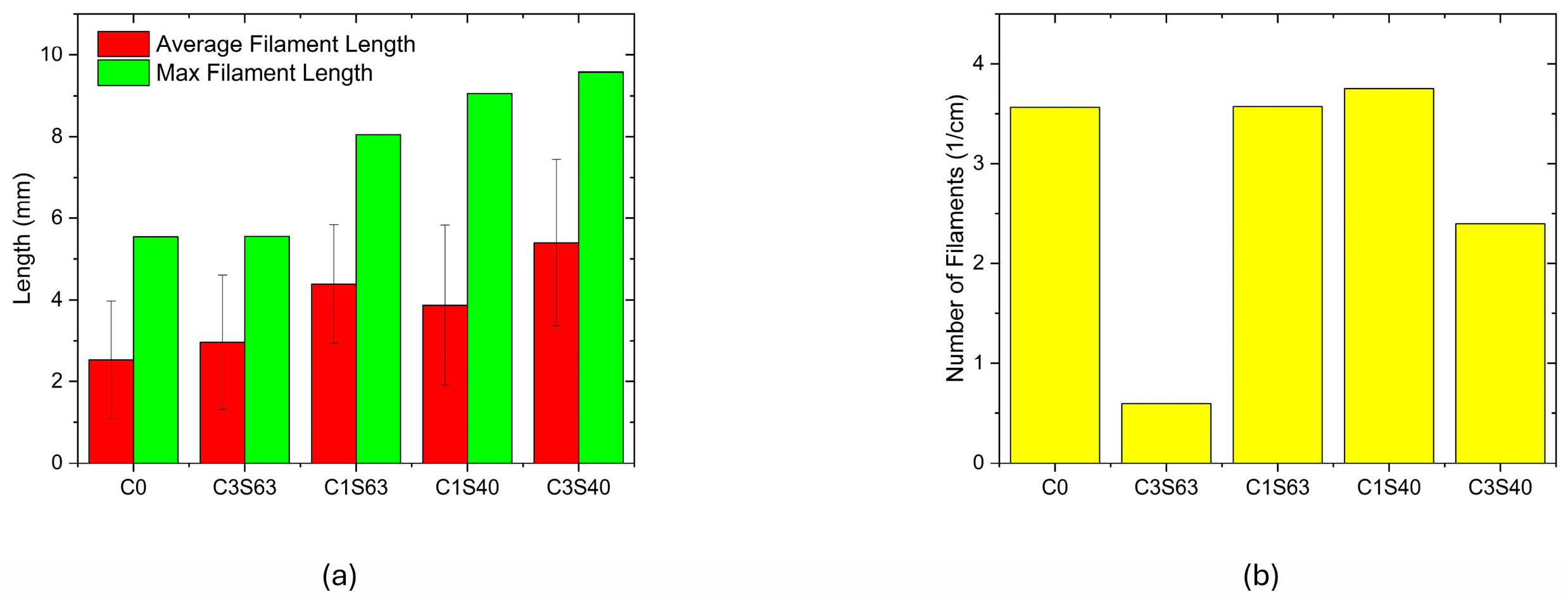

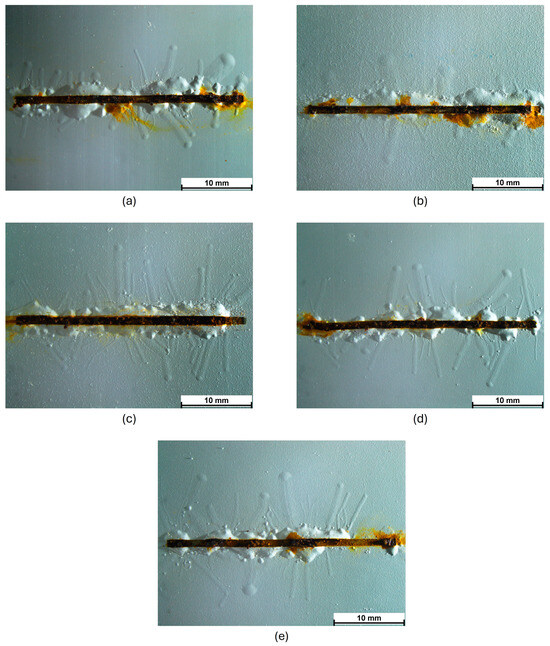

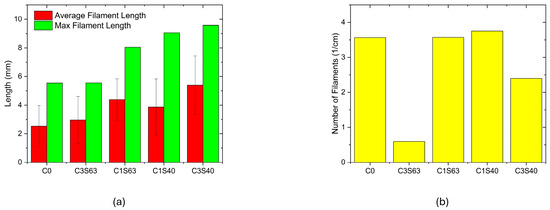

To evaluate durability not only against cathodic delamination but also in relation to a similarly common yet less frequently considered failure mechanism, FFC resistance was tested in a humidostatic chamber at 80 r.h.% (FFC test). This setup favors the electrochemical processes driving FFC over those responsible for cathodic delamination. In this scenario, closer to natural exposure in a continental environment, low chloride contamination and relatively lower humidity compared to NSST conditions were simulated. Under these conditions, delamination driven by the nucleation and propagation of filaments through an advancing anodic front showed less critical results regarding the use of Tagua powder. In fact, no significant worsening was observed with the introduction of the filler with respect to the reference (Figure 6a). As already reported in the literature [28,37,38], different aging conditions could lead to opposite performance in coatings durability. In the case at hand, the sample with the higher amount of particles loaded and the biggest size (C3S63) displays after 500 h of cabinet FFC test the minor degradation in terms of fewer filaments nucleated (Figure 7b), focusing on the average and maximum threads length this sample presents feature fully comparable with the blank one (Figure 7a). The increased water uptake due to the presence of Tagua particles does not exacerbate FFC as observed with cathodic disbonding. Instead, it appears to alter the typical propagation pattern, leading to fewer but wider threads rather than the characteristic fine filaments. This suggests that the presence of the bio-based filler and the resulting modification of the barrier layer may disrupt the formation of the differential aeration cells necessary to sustain the conventional anodic undermining mechanism. As a general consideration, the FFC degradation was comparable to the reference and aligned with propagation rates reported in the literature [39]. Thus, in the tested humidity range, it is estimated to be a more frequent exposure condition rather than the NSST [40,41].

Figure 6.

Coated samples after 500 h of FFC test. Samples C0 (a), C3S63 (b), C1S63 (c), C1S40 (d), and C3S40 (e) are displayed.

Figure 7.

FFC degradation parameters after 500 h of humidostatic test at 80 r.h.% and 40 °C. (a) reports the mean and maximum filament length, while (b) displays the specific number of nucleated threads per unit length.

Moreover, considering the results obtained, Tagua powder emerges as an excellent filler for enhancing abrasion resistance. Its strategic application in the topcoat layer, where wear resistance is crucial, could improve the durability of the coating. When combined with a protective system design featuring a thinner primer layer, this approach may offer a well-balanced solution, ensuring both mechanical durability and effective corrosion protection.

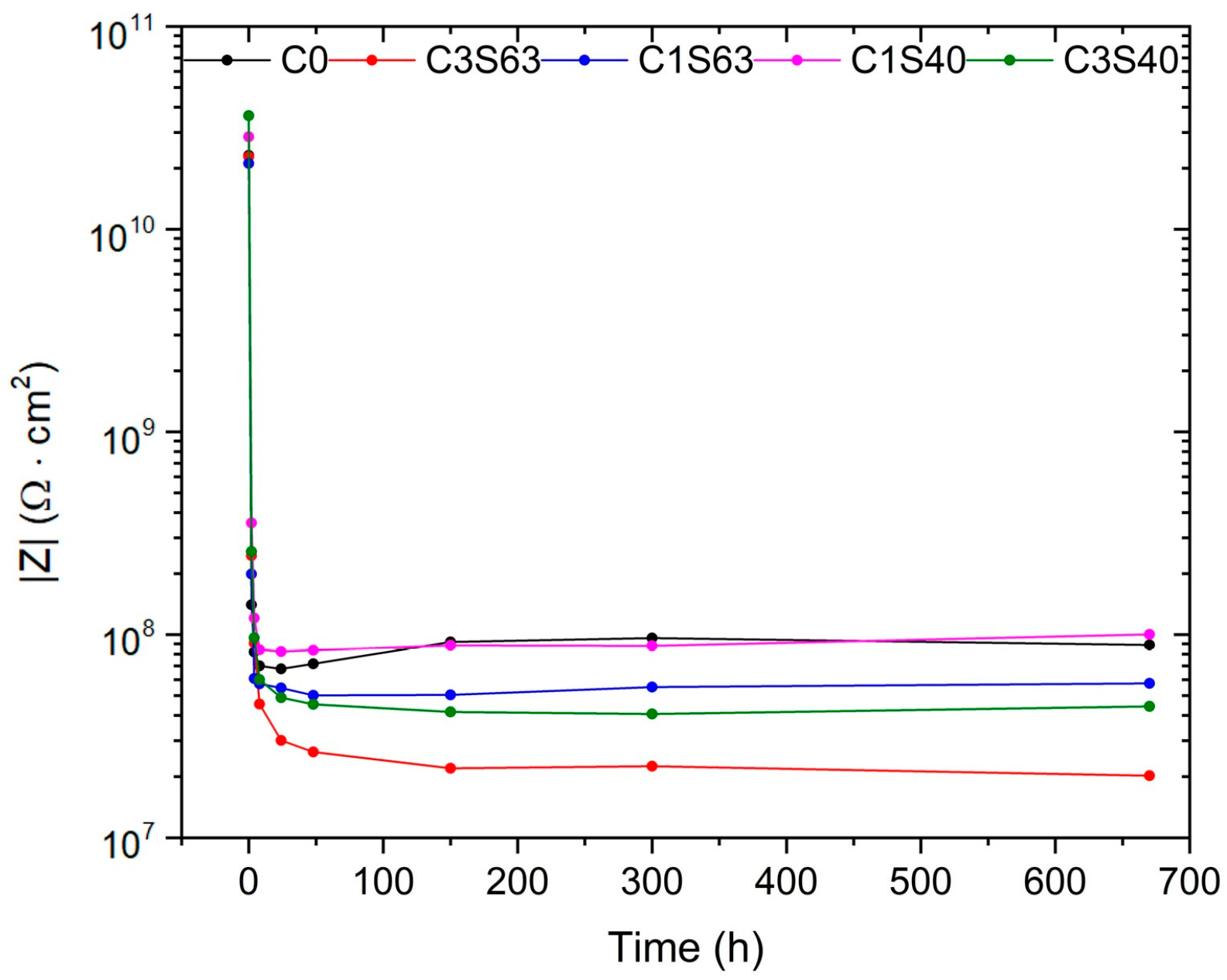

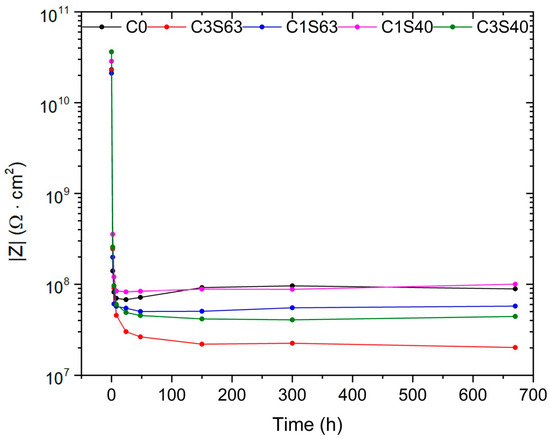

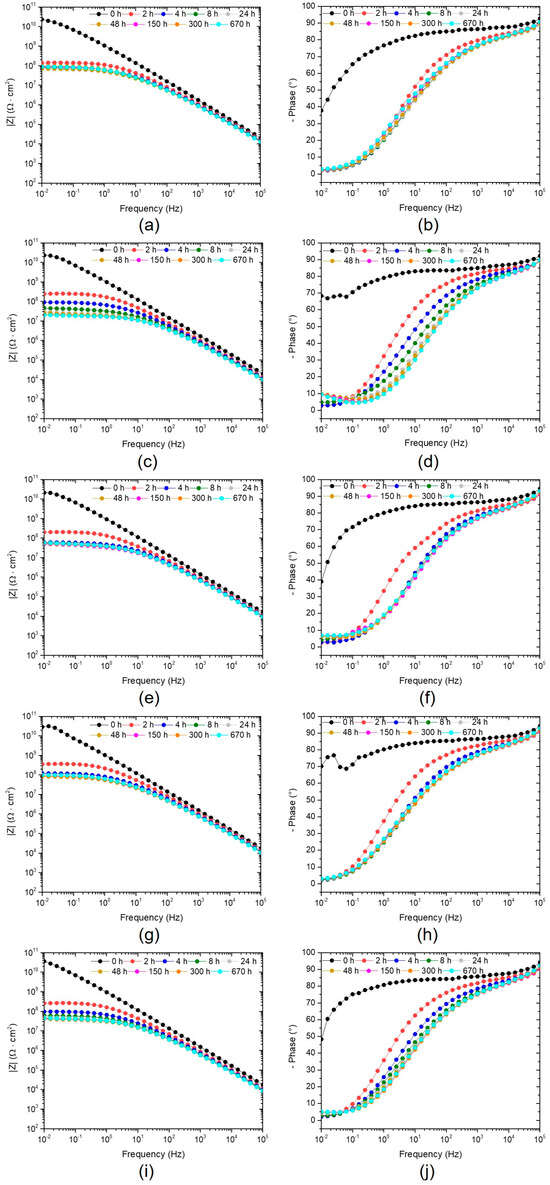

3.4. Electrochemical Impedance Spectroscopy

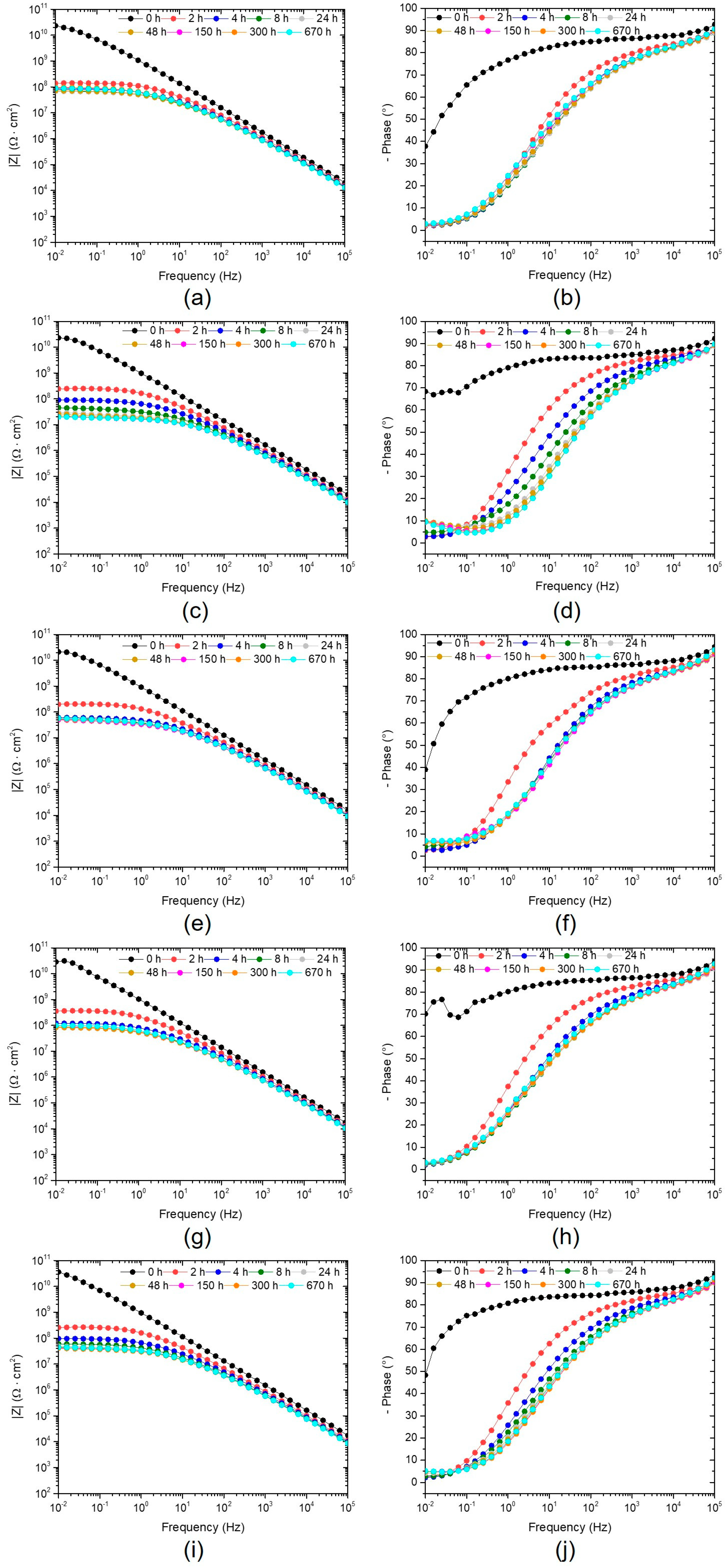

EIS monitoring during electrolyte immersion is commonly employed to evaluate the protective performance of paints, including their adhesion properties, barrier properties, and potential defects. The impedance modulus in the Bode plot at low frequencies (10−2 Hz), denoted as |Z|(0.01), in some cases, could serve as a key parameter for approximating the overall coating’s level of protection. This is commonly recognized as a potential source of misinterpretation in the case of organic coatings with a high level of barrier properties [42]. However, in the present study, the waterborne nature of the paints and the increased permeability introduced by the addition of Tagua powder provide suitable boundary conditions for a reliable evaluation of these parameters as a representative index of the coating’s protective performance. According to various authors [43,44], a |Z|(0.01) value of 106 Ω·cm2 is generally considered the minimum threshold for classifying a coating as “protective”. The performance of the coatings was assessed by monitoring the evolution of their impedance modulus, |Z|(0.01), over time. The results, depicted in Figure 8, show the variation in |Z|(0.01) throughout the 670 h exposure to the test solution. Initially, all samples exhibited similar values for |Z|(0.01) around 1010 Ω·cm2. In the following 8 h after, the low-frequency impedance continues to decrease significantly reaching a value around 108 Ω·cm2 for all the samples, and this is due to the water uptake typical of the waterborne paint [45]. This type of coating containing additives like wetting and dispersing agents, stabilizers, and thickeners having hydrophilic characteristics makes the films more susceptible to water absorption. However, after 24 h of immersion, all samples appear to stabilize, with for |Z|(0.01) remaining relatively constant for the remainder of the test. As indicated in the NSST, the presence of Tagua particles in the paint, due to their hydrophilic tendency, leads to a general decrease in the impedance modulus at the end of the test, compared to the paint without particles, which retains the highest impedance modulus. C3S63 shows the lowest for |Z|(0.01) after 670 h of exposure to the electrolyte, while C3S40 containing the same amount of filler shows a higher value, also highlighting this time the negative effect of bigger particles, which favor the formation of detrimental pathways that allow the electrolyte to reach the substrate.

Figure 8.

Bode impedance modulus |Z|0.01 evolution with time.

Figure 9 displays the Bode spectra of the monitored samples in time. In Figure 9d, it is possible to see that after 24 h for the extreme case of C3S63, a shoulder at a low frequency (0.1 Hz) develops, and the impedance drops at higher frequencies at increasing times. The outcome at low frequencies is representative of a second low-frequency time constant appearance that is typical of the electrochemical reactions at the coating–substrate interface. Instead, for sample C3S40 (Figure 9j), there is the evolution of the Bode phase spectrum, and the second low-frequency time constant is less visible in the sampled range and likely starts at lower frequencies. Regarding the other samples, reference C0, low-loaded C1S40, and C1S63, their spectra exhibit a single time constant curve at high frequencies that gradually shifts toward higher frequencies over time.

Figure 9.

Bode impedance modulus and the Bode phase spectra for C0 (a,b), C3S63 (c,d), C1S63 (e,f), C1S40 (g,h), and C3S40 (i,j).

4. Discussion

The incorporation of Tagua powder as a bio-based filler significantly influences the aesthetic, mechanical, and protective properties of the waterborne acrylic paint. The addition of this filler effectively reduces gloss and increases surface roughness compared to the unfilled paint. Notably, filler concentration plays a more significant role in altering these properties than particle size. While variations in particle size do impact gloss and roughness, their effect is less pronounced compared to differences in filler content. When comparing coatings with the same filler concentration but different particle sizes, the changes in surface characteristics are minimal, whereas coatings with different filler concentrations exhibit more substantial variations in gloss and roughness.

Mechanical performance results show contrasting trends depending on the type of abrasion stress. In the Taber test, which evaluates resistance to abrasive forces, Tagua powder enhances durability due to its compact structure. A higher filler concentration and larger particle size contribute to lower mass loss, with the best performance observed in the coating containing 3 wt% of the largest particles, showing a 24.5% reduction in mass loss compared to the unmodified acrylic matrix. This highlights the potential of Tagua powder as an effective reinforcement for applications requiring high abrasion resistance. However, in the Scrub test, which involves another type of abrasion, the results differ. Here, the best-performing coating is the one with the lower concentration of the smallest particles. The increase in surface roughness caused by the filler creates more protruding points where the abrasive pad can exert force, leading to greater mass loss at higher filler concentrations. While the Taber test provides valuable insights into the mechanical wear resistance of coatings, it does not always fully reflect real-world performance across all applications. For instance, in the automotive industry, discrepancies have been observed between Taber test results and actual service conditions, where factors such as delamination and chipping play a significant role [46]. This highlights the importance of considering multiple evaluation methods. Scrub tests, for example, can offer complementary data, particularly for coatings exposed to frequent cleaning cycles. Therefore, selecting the most appropriate test method requires a thorough understanding of the specific environmental and mechanical stresses the coating will face in its intended application.

Regarding protective properties, despite good compatibility between the filler and the polymer matrix, the lignocellulosic nature of Tagua powder introduces challenges related to water absorption. Both NSST and EIS measurements indicate that the addition of the filler negatively affects the barrier properties of the coating in saturated, humid environments. Higher filler concentrations and larger particle sizes exacerbate this issue, leading to reduced protective performance. This effect is less pronounced when the coating is exposed to lower humidity levels, where FFC may become the primary failure mechanism for this type of coating [47]. The hydrophilic nature of lignocellulosic materials represents a key industrial concern, and ongoing research aims to address this limitation [48]. Promising advancements have been reported by successfully enhancing the water resistance of bio-filled coatings by functionalizing olive pit powder with silane and wax [6]. The functionalization processes applied to such fillers can significantly alter their hydrophobic properties, potentially mitigating issues related to water absorption and enhancing barrier performance in high-humidity environments.

The introduction of Tagua powder into the waterborne acrylic binder significantly increases the interfacial area between the filler and the matrix. Despite this, no voids or delamination were observed, indicating good compatibility between the two components. However, this interfacial region can represent a potential weak point in terms of coating durability, particularly concerning barrier properties and cohesion. It is important to note that the size of the Tagua particles plays a crucial role in determining the behavior of the filler within the coating system. Smaller particles provide a greater interfacial area, leading to better dispersion and stronger interactions with the binder. In contrast, larger particles often result in incomplete coverage by the binder, leaving the filler partially exposed to the environment. This effect may negatively influence the coating’s protective performance, especially in terms of moisture and corrosion resistance. Thus, particle size is a key factor in optimizing the interfacial properties and overall performance of bio-based filled coatings.

This technology could also be implemented in the case at hand. However, the most promising strategy appears to be the design of a multilayer organic coating consisting of an unfilled primer ensuring strong adhesion to the substrate, a thicker barrier layer, and a topcoat functionalized with Tagua particles to enhance wear resistance [49]. Furthermore, the increased water uptake resulting from the porous or hydrophilic nature of bio-fillers used for wear resistance can be mitigated by integrating hybrid fillers. A dual-filler strategy, combining bio-fillers to enhance mechanical properties with hydrophobic additives to improve water resistance, offers a balanced solution [50,51]. This synergistic approach not only enhances durability in humid environments but may also contribute to improved fire resistance, making it a promising strategy for high-performance protective coatings.

This paper, for the first time, explores the potential of Tagua as a coating additive. To assess its fundamental properties, a single-layer system was adopted. At this stage, the objective was not to develop a fully formulated multilayer coating system but rather to establish a fundamental understanding of the effects of Tagua powder as a bio-based filler in coatings. By adopting a single-layer configuration, we aimed to accurately assess its influence on key properties such as abrasion resistance, gloss, and water uptake without the interference of additional layers. The findings confirmed that while Tagua powder improves wear resistance, its hydrophilic nature increases water absorption, making it unsuitable for direct application in a layer in contact with a metallic substrate. Based on these results, a more practical and effective two-layer coating system is proposed, where a primer ensures adhesion and corrosion protection while a Tagua-containing topcoat enhances mechanical durability. This study lays the groundwork for further optimization, aligning with the growing interest in sustainable coatings for environmentally oriented engineering applications.

5. Conclusions

This study demonstrated the potential of Tagua powder as a bio-based additive for acrylic coatings, particularly in improving abrasion durability. One of the key findings is its significant contribution to wear resistance, a fundamental parameter for the long-term performance of organic coatings. The incorporation of Tagua particles effectively reduced mass loss in abrasion tests, confirming its role in enhancing the mechanical strength of the polymeric matrix. In particular, coatings containing 3 wt% of larger particles (40–63 µm) exhibited a 24.5% reduction in mass loss after 1000 Taber abrasion cycles compared to the reference coating, while coatings with smaller particles (≤40 µm) at the same concentration showed a more modest improvement of approximately 10%.

However, the lignocellulosic nature of Tagua also introduces hydrophilic characteristics, leading to increased water uptake. EIS revealed that coatings with 3 wt% Tagua powder, especially with larger particles, experienced a reduction in impedance modulus by approximately one order of magnitude after 670 h of immersion in a 3.5 wt% NaCl solution, indicating a decrease in barrier properties. Despite this, filiform corrosion resistance tests showed comparable performance to the reference, suggesting that the adhesion properties of the coatings were not significantly affected by the presence of the bio-based filler.

These results highlight the need for an optimized coating design to balance the benefits of increased wear resistance with the challenges of water sensitivity. A multilayer approach, where a topcoat reinforced with Tagua powder is combined with a dedicated barrier layer, could provide a viable solution for applications requiring both durability and environmental sustainability. This study provides a foundation for further research aimed at optimizing formulation strategies and evaluating long-term performance in real-world conditions.

Author Contributions

Conceptualization, S.R. and A.C.; methodology, S.R.; validation, S.R. and A.C.; investigation, L.D.; resources, S.R.; data curation, L.D. and A.C.; writing—original draft preparation, A.C. and L.D.; writing—review and editing, S.R. and A.C.; supervision, S.R.; project administration, S.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available upon request.

Acknowledgments

The authors would like to thank Mabo, Telgate (BG), for providing the Tagua, and Stefano Tonini from Estalia, Castenedolo (BS), for supplying the waterborne coating.

Conflicts of Interest

The authors declare no conflicts of interest.

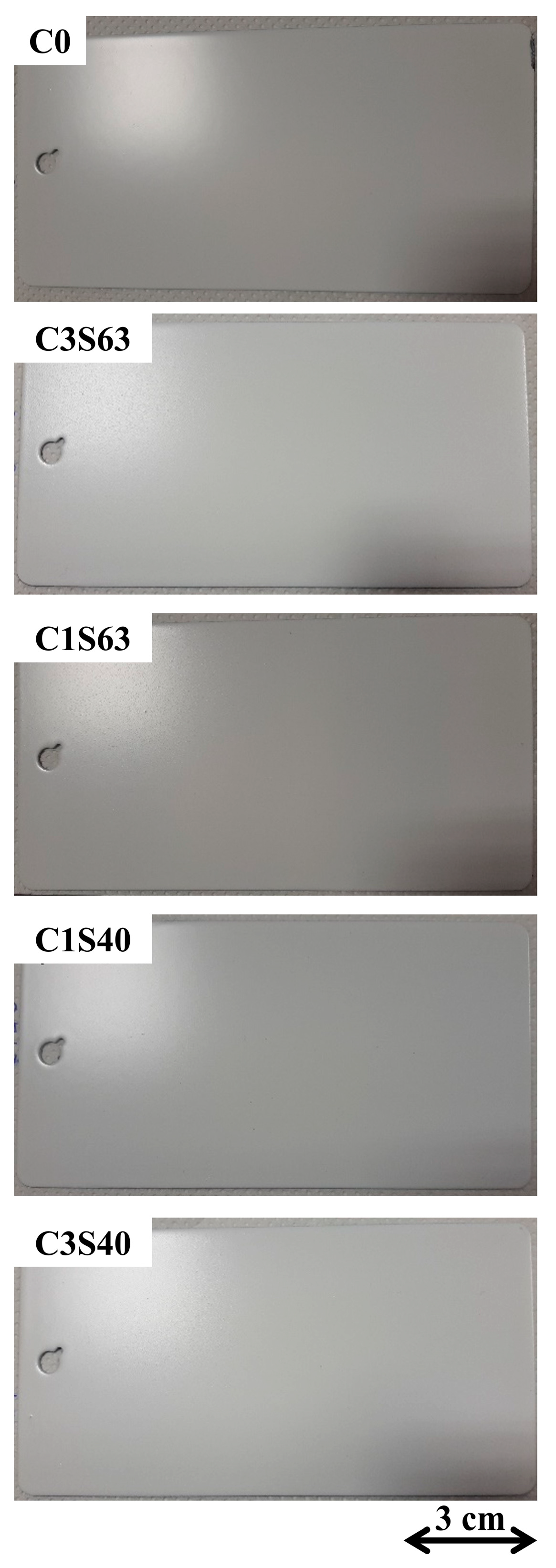

Appendix A

Figure A1.

Coated samples before NSST exposure.

Figure A1.

Coated samples before NSST exposure.

Figure A2.

Coated samples before the FFC test. A 3 cm longitudinal scratch is introduced in the organic layer.

Figure A2.

Coated samples before the FFC test. A 3 cm longitudinal scratch is introduced in the organic layer.

References

- Huttmanová, E.; Chovancová, J.; Petruška, I.; Sallaku, K. Circular Economy in Action: Examining the Decoupling of Economic Growth and Material Use across EU Countries. EJSD 2024, 13, 13. [Google Scholar] [CrossRef]

- Fellner, J.; Lederer, J.; Scharff, C.; Laner, D. Present Potentials and Limitations of a Circular Economy with Respect to Primary Raw Material Demand. J. Ind. Ecol. 2017, 21, 494–496. [Google Scholar] [CrossRef]

- Schüpfer, D.; Wagner-Wenz, R.; Hendrich, K.; Weidenkaff, A. Materials Come around and Go around: Adapting to Nature’s Circularity. MRS Bull. 2023, 48, 1184–1189. [Google Scholar] [CrossRef]

- Proskurina, S. Carbon Neutrality in the Finnish Energy Sector: Prospects for a Fossil-Fuel Phase Out. Biofuels Bioprod. Biorefining 2024, 18, 1065–1076. [Google Scholar] [CrossRef]

- Calovi, M.; Rossi, S. Synergistic Contribution of Bio-Based Additives in Wood Paint: The Combined Effect of Pigment Deriving from Spirulina and Multifunctional Filler Based on Carnauba Wax. Prog. Org. Coat. 2023, 182, 107713. [Google Scholar] [CrossRef]

- Calovi, M.; Rossi, S. Functional Olive Pit Powders: The Role of the Bio-Based Filler in Reducing the Water Uptake Phenomena of the Waterborne Paint. Coatings 2023, 13, 442. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A Review of the Recent Developments in Biocomposites Based on Natural Fibres and Their Application Perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Yew, M.C.; Ramli Sulong, N.H.; Yew, M.K.; Amalina, M.A.; Johan, M.R. The Formulation and Study of the Thermal Stability and Mechanical Properties of an Acrylic Coating Using Chicken Eggshell as a Novel Bio-Filler. Prog. Org. Coat. 2013, 76, 1549–1555. [Google Scholar] [CrossRef]

- Toro, P.; Quijada, R.; Yazdani-Pedram, M.; Arias, J.L. Eggshell, a New Bio-Filler for Polypropylene Composites. Mater. Lett. 2007, 61, 4347–4350. [Google Scholar] [CrossRef]

- Yew, M.C.; Yew, M.K.; Saw, L.H.; Ng, T.C.; Durairaj, R.; Beh, J.H. Influences of Nano Bio-Filler on the Fire-Resistive and Mechanical Properties of Water-Based Intumescent Coatings. Prog. Org. Coat. 2018, 124, 33–40. [Google Scholar] [CrossRef]

- Sienkiewicz, N.; Dominic, M.; Parameswaranpillai, J. Natural Fillers as Potential Modifying Agents for Epoxy Composition: A Review. Polymers 2022, 14, 265. [Google Scholar] [CrossRef] [PubMed]

- Balasundar, P.; Narayanasamy, P.; Senthil, S.; Abdullah Al-Dhabi, N.; Prithivirajan, R.; Shyam Kumar, R.; Ramkumar, T.; Subrahmanya Bhat, K. Physico-Chemical Study of Pistachio (Pistacia Vera) Nutshell Particles as a Bio-Filler for Eco-Friendly Composites. Mater. Res. Express 2019, 6, 105339. [Google Scholar] [CrossRef]

- Prabhakar, M.N.; Shah, A.U.R.; Rao, K.C.; Song, J.-I. Mechanical and Thermal Properties of Epoxy Composites Reinforced with Waste Peanut Shell Powder as a Bio-Filler. Fibers Polym. 2015, 16, 1119–1124. [Google Scholar] [CrossRef]

- Zuluaga-Parra, J.D.; Ramos-deValle, L.F.; Sánchez-Valdes, S.; Torres-Lubián, J.R.; Rodriguez-Fernadez, O.S.; Hernández-Hernández, E.; da Silva, L.; Rodríguez-Gonzalez, J.A.; Borjas-Ramos, J.J.; Vázquez-Rodríguez, S.; et al. Phosphorylated Avocado Seed: A Renewable Biomaterial for Preparing a Flame Retardant Biofiller. Fire Mater. 2022, 46, 968–980. Available online: https://onlinelibrary-wiley-com.ezp.biblio.unitn.it/doi/10.1002/fam.3044 (accessed on 13 January 2025). [CrossRef]

- Suthan, R.; Jayakumar, V.; Bharathiraja, G. Wear Analysis of Bio-Fillers Reinforced Epoxy Composites. Mater. Today Proc. 2020, 22, 793–798. [Google Scholar] [CrossRef]

- Smith, N. Phytelephas Macrocarpa. In Palms and People in the Amazon; Smith, N., Ed.; Springer International Publishing: Cham, Switzerland, 2015; pp. 429–444. ISBN 978-3-319-05509-1. [Google Scholar]

- Acosta-Solis, M. Tagua or Vegetable Ivory: A Forest Product of Ecuador. Econ. Bot. 1948, 2, 46–57. [Google Scholar] [CrossRef]

- Cooper, D. On the Structure of the Nut Known as Vegetable Ivory. Trans. Microsc. Soc. J. 1842, 1, 97–99. [Google Scholar] [CrossRef]

- Barfod, A.S.; Bergmann, B.; Pedersen, H.B. The Vegetable Ivory Industry: Surviving and Doing Well in Ecuador. Econ. Bot. 1990, 44, 293–300. [Google Scholar] [CrossRef]

- MABO Website. Available online: https://mabo.it/it (accessed on 15 February 2025).

- Chek, Y.W.; Ang, D.T.-C. Progress of Bio-Based Coatings in Waterborne System: Synthesis Routes and Monomers from Renewable Resources. Prog. Org. Coat. 2024, 188, 108190. [Google Scholar] [CrossRef]

- Zhan, W.; Li, L.; Chen, L.; Kong, Q.; Chen, M.; Chen, C.; Zhang, Q.; Jiang, J. Biomaterials in Intumescent Fire-Retardant Coatings: A Review. Prog. Org. Coat. 2024, 192, 108483. [Google Scholar] [CrossRef]

- ASTM F1978-22; Standard Test Method for Measuring Abrasion Resistance of Metallic Thermal Spray Coatings by Using the Taber Abraser. ASTM International: West Conshohocken, PA, USA, 2022.

- D01 Committee ASTM International. Test Method for Scrub Resistance of Paints by Abrasion Weight Loss; ASTM International: West Conshohocken, PA, USA, 2024. [Google Scholar] [CrossRef]

- E12 Committee ASTM International. Test Method for Specular Gloss; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar] [CrossRef]

- D01 Committee ASTM International. Practice for Surface Wettability of Coatings, Substrates and Pigments by Advancing Contact Angle Measurement; ASTM International: West Conshohocken, PA, USA, 2022. [Google Scholar] [CrossRef]

- ASTM B117-19; Standard Practice for Operating Salt Spray (Fog) Apparatus. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- Cristoforetti, A.; Deflorian, F.; Rossi, S.; Fedel, M. On the Occurrence of Filiform Corrosion on Organic Coated Carbon Steel Exposed to Cyclic Aging Test. Corrosion 2023, 79, 1339–1344. [Google Scholar] [CrossRef] [PubMed]

- ASTM D2803-09; Standard Guide for Testing Filiform Corrosion Resistance of Organic Coatings on Metal. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- D01 Committee ASTM International. Test Method for Evaluating Degree of Blistering of Paints; ASTM International: West Conshohocken, PA, USA, 2025. [Google Scholar] [CrossRef]

- Calovi, M.; Rossi, S.; Deflorian, F.; Dirè, S.; Ceccato, R.; Guo, X.; Frankel, G.S. Effects of Graphene-Based Fillers on Cathodic Delamination and Abrasion Resistance of Cataphoretic Organic Coatings. Coatings 2020, 10, 602. [Google Scholar] [CrossRef]

- Gašparovič, L.; Koreňová, Z.; Jelemenský, Ľ. Kinetic Study of Wood Chips Decomposition by TGA. Chem. Pap. 2010, 64, 174–181. [Google Scholar] [CrossRef]

- Mansour, O.Y. Lignocellulose–Polymer Composite. III. J. Appl. Polym. Sci. 1993, 47, 839–846. [Google Scholar] [CrossRef]

- Najafi, S.K.; Tajvidi, M.; Chaharmahli, M. Long-Term Water Uptake Behavior of Lignocellulosic-High Density Polyethylene Composites. J. Appl. Polym. Sci. 2006, 102, 3907–3911. [Google Scholar] [CrossRef]

- Yang, X.F.; Vang, C.; Tallman, D.E.; Bierwagen, G.P.; Croll, S.G.; Rohlik, S. Weathering Degradation of a Polyurethane Coating. Polym. Degrad. Stab. 2001, 74, 341–351. [Google Scholar] [CrossRef]

- ISO 4628-2:2016; Paints and Varnishes—Evaluation of Degradation of Coatings—Designation of Quantity and Size of Defects, Part 2: Designation of Degree of Blistering. International Organization for Standardization: Geneva, Switzerland, 2016.

- Cambier, S.M.; Posner, R.; Frankel, G.S. Coating and Interface Degradation of Coated Steel, Part 1: Field Exposure. Electrochim. Acta 2014, 133, 30–39. [Google Scholar] [CrossRef]

- Cambier, S.M.; Frankel, G.S. Coating and Interface Degradation of Coated Steel, Part 2: Accelerated Laboratory Tests. Electrochim. Acta 2014, 136, 442–449. [Google Scholar] [CrossRef]

- Cristoforetti, A.; Rossi, S.; Deflorian, F.; Fedel, M. Recent Progress in Understanding Filiform Corrosion on Organic Coated Steel: A Comprehensive Review. Prog. Org. Coat. 2024, 192, 108469. [Google Scholar] [CrossRef]

- Cristoforetti, A.; Rossi, S.; Deflorian, F.; Fedel, M. An Electrochemical Study on the Mechanism of Filiform Corrosion on Acrylic-Coated Carbon Steel. Prog. Org. Coat. 2023, 179, 107525. [Google Scholar] [CrossRef]

- Cristoforetti, A.; Rossi, S.; Deflorian, F.; Fedel, M. Comparative Study between Natural and Artificial Weathering of Acrylic-coated Steel, Aluminum, and Galvanized Steel. Mater. Corros. 2023, 74, 1429–1438. [Google Scholar] [CrossRef]

- Cristoforetti, A.; Deflorian, F.; Rossi, S.; Fedel, M. On the Limits of the EIS Low-Frequency Impedance Modulus as a Tool to Describe the Protection Properties of Organic Coatings Exposed to Accelerated Aging Tests. Coatings 2023, 13, 598. [Google Scholar] [CrossRef]

- Amirudin, A.; Thieny, D. Application of Electrochemical Impedance Spectroscopy to Study the Degradation of Polymer-Coated Metals. Prog. Org. Coat. 1995, 26, 1–28. [Google Scholar] [CrossRef]

- Rossi, S.; Deflorian, F.; Fontanari, L.; Cambruzzi, A.; Bonora, P.L. Electrochemical Measurements to Evaluate the Damage Due to Abrasion on Organic Protective System. Prog. Org. Coat. 2005, 52, 288–297. [Google Scholar] [CrossRef]

- Lendvay-Győrik, G.; Pajkossy, T.; Lengyel, B. Water Uptake of Water-Borne Paint Resin Films as Studied by Impedance Spectroscopy and Gravimetry. Prog. Org. Coat. 2007, 59, 95–99. [Google Scholar] [CrossRef]

- Sun, J.; Mukamal, H.; Liu, Z.; Shen, W. Analysis of the Taber Test in Characterization of Automotive Side Windows. Tribol. Lett. 2002, 13, 49–54. [Google Scholar] [CrossRef]

- Bautista, A. Filiform Corrosion in Polymer-Coated Metals. Prog. Org. Coat. 1996, 28, 49–58. [Google Scholar] [CrossRef]

- Randis, R.; Darmadi, D.B.; Gapsari, F.; Sonief, A.A.; Akpan, E.D.; Ebenso, E.E. The Potential of Nanocomposite-Based Coatings for Corrosion Protection of Metals: A Review. J. Mol. Liq. 2023, 390, 123067. [Google Scholar] [CrossRef]

- Przystupa, K. Research on the Durability and Reliability of Industrial Layered Coatings on Metal Substrate Due to Abrasive Wear. Materials 2023, 16, 1779. [Google Scholar] [CrossRef]

- Mustapa, S.A.S.; Ramli Sulong, N.H. Performance of Palm Oil Clinker as a Bio-Filler with Hybrid Fillers in Intumescent Fire Protective Coatings for Steel. JSM 2017, 46, 2489–2496. [Google Scholar] [CrossRef]

- Pei, X.-Q.; Bennewitz, R.; Kasper, C.; Tlatlik, H.; Bentz, D.; Becker-Willinger, C. Tribological Synergy of Filler Components in Multifunctional Polyimide Coatings. Adv. Eng. Mater. 2017, 19, 1600363. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).