Aggressiveness of Different Ageing Conditions for Three Thick Marine Epoxy Systems

Abstract

:1. Introduction

2. Experimental Part

2.1. Materials

2.2. Ageing Tests

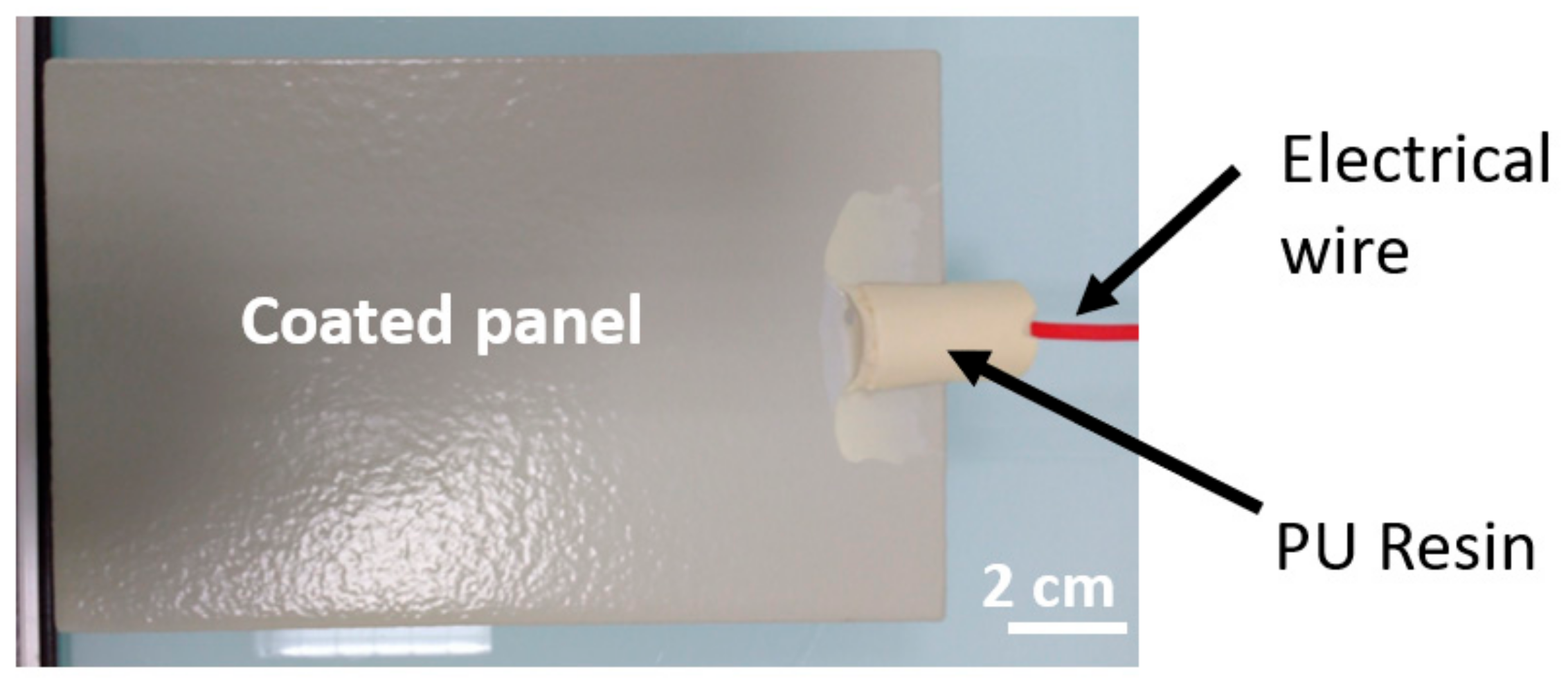

2.3. EIS Measurements

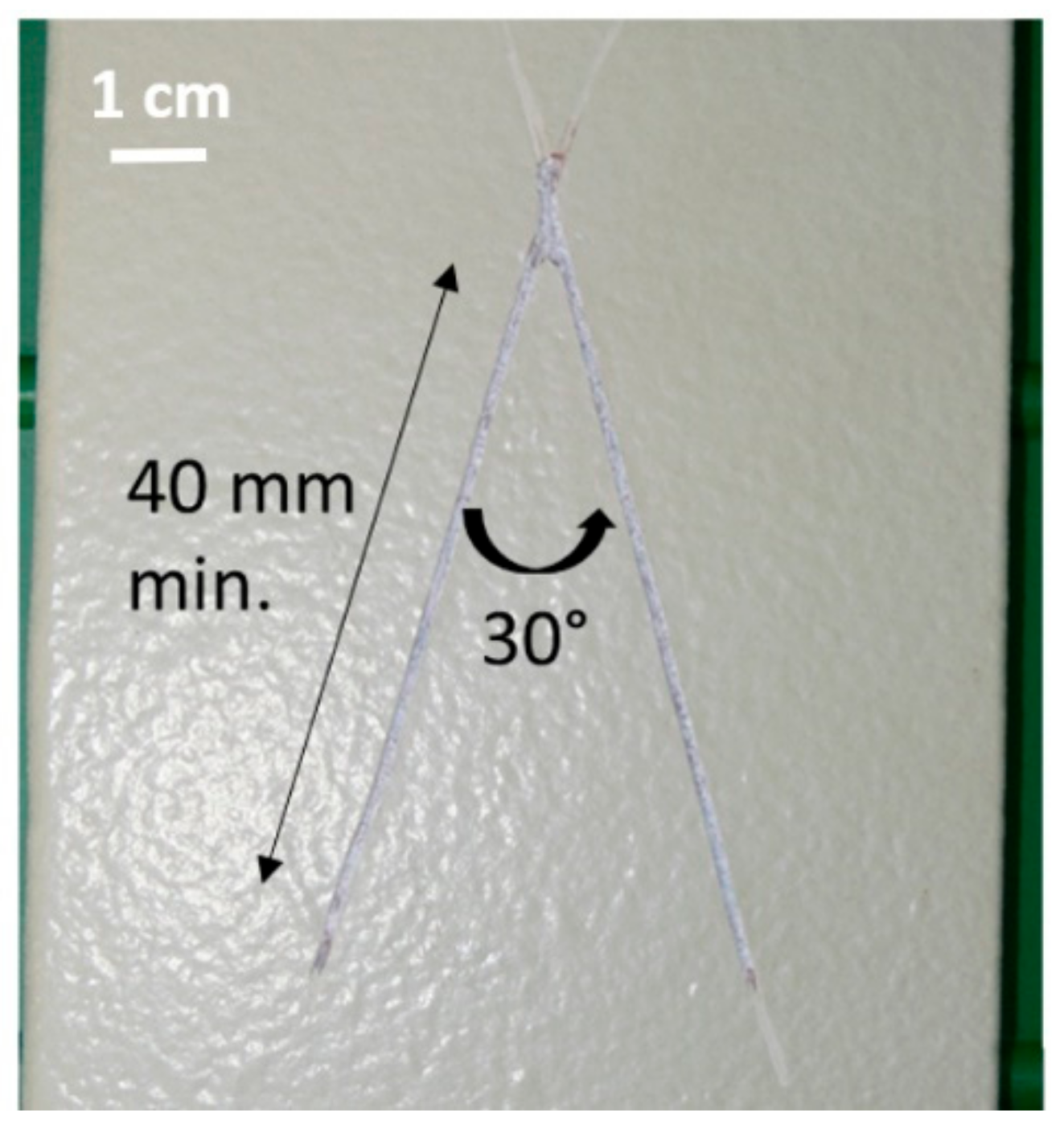

2.4. Degree of Corrosion

3. Results and Discussion

3.1. Thickness Measurements

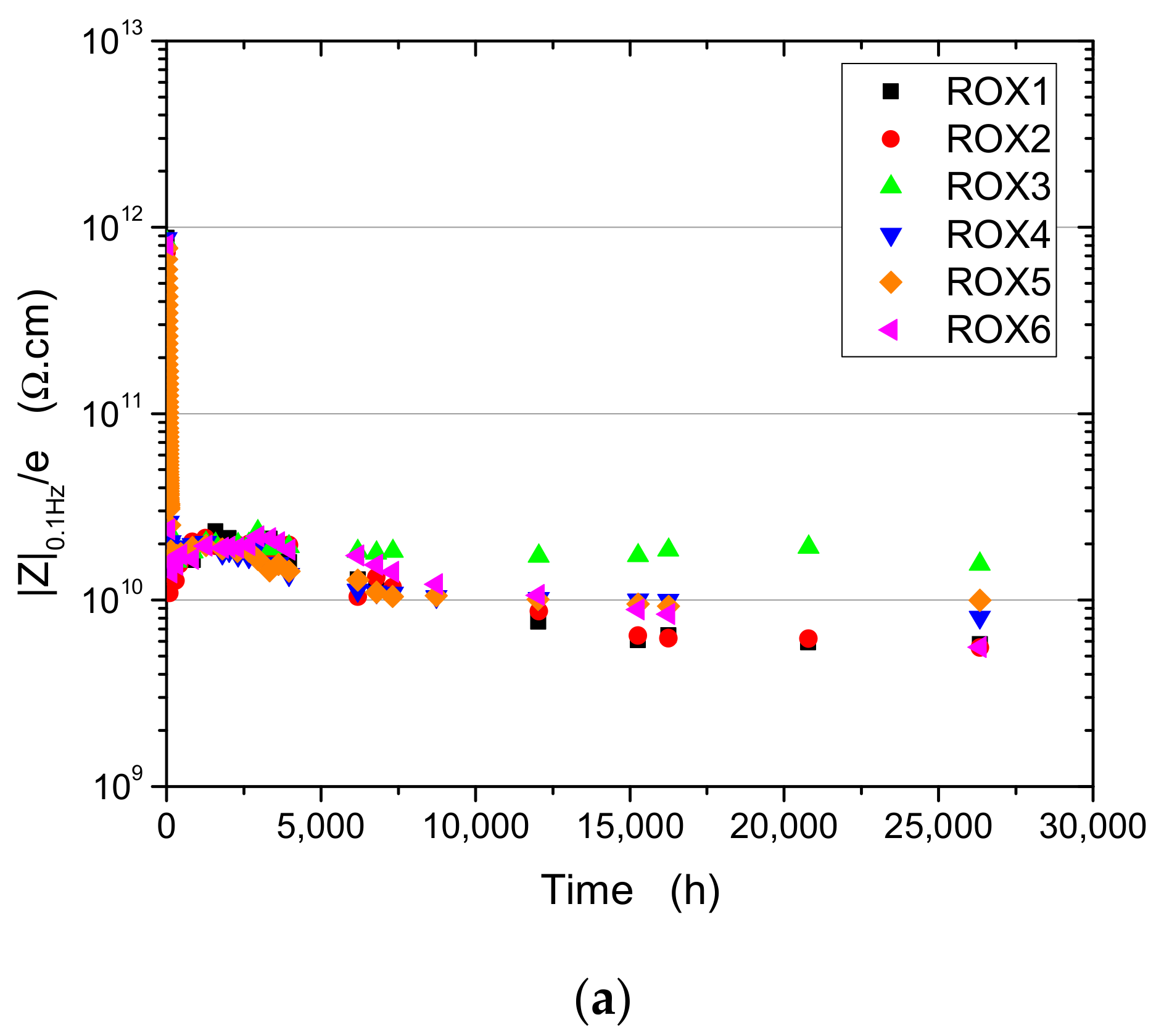

3.2. Defect-Free Samples Immersed at 35 °C

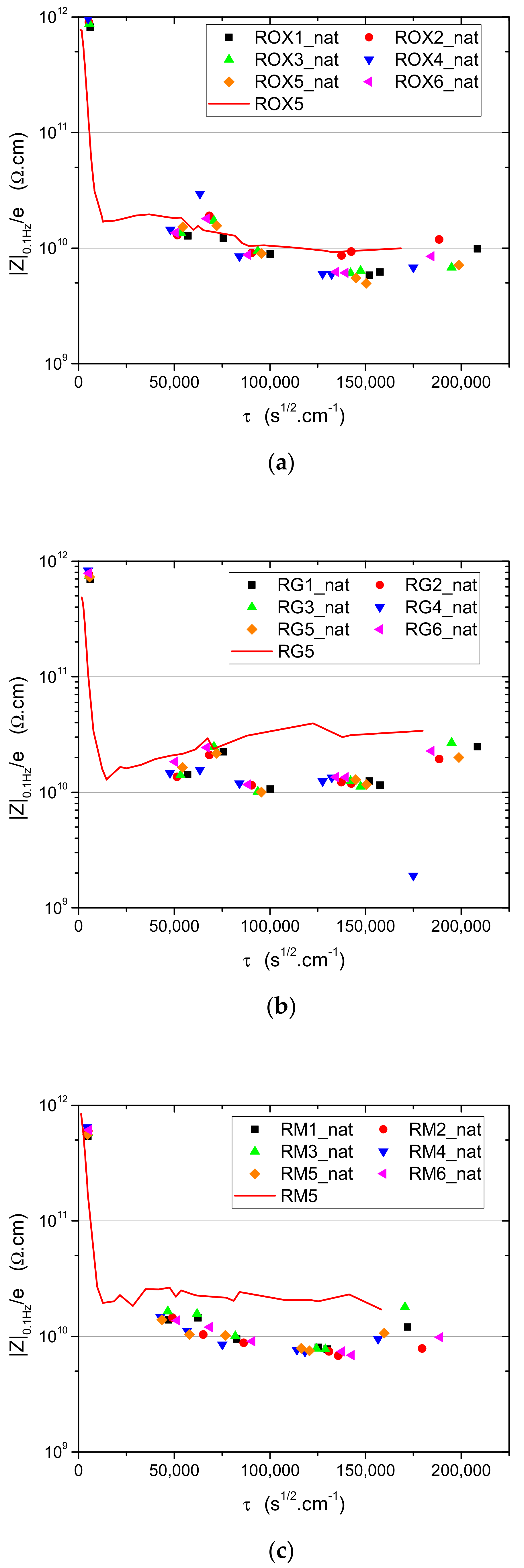

3.3. Defect-Free Samples Immersed in Natural Seawater

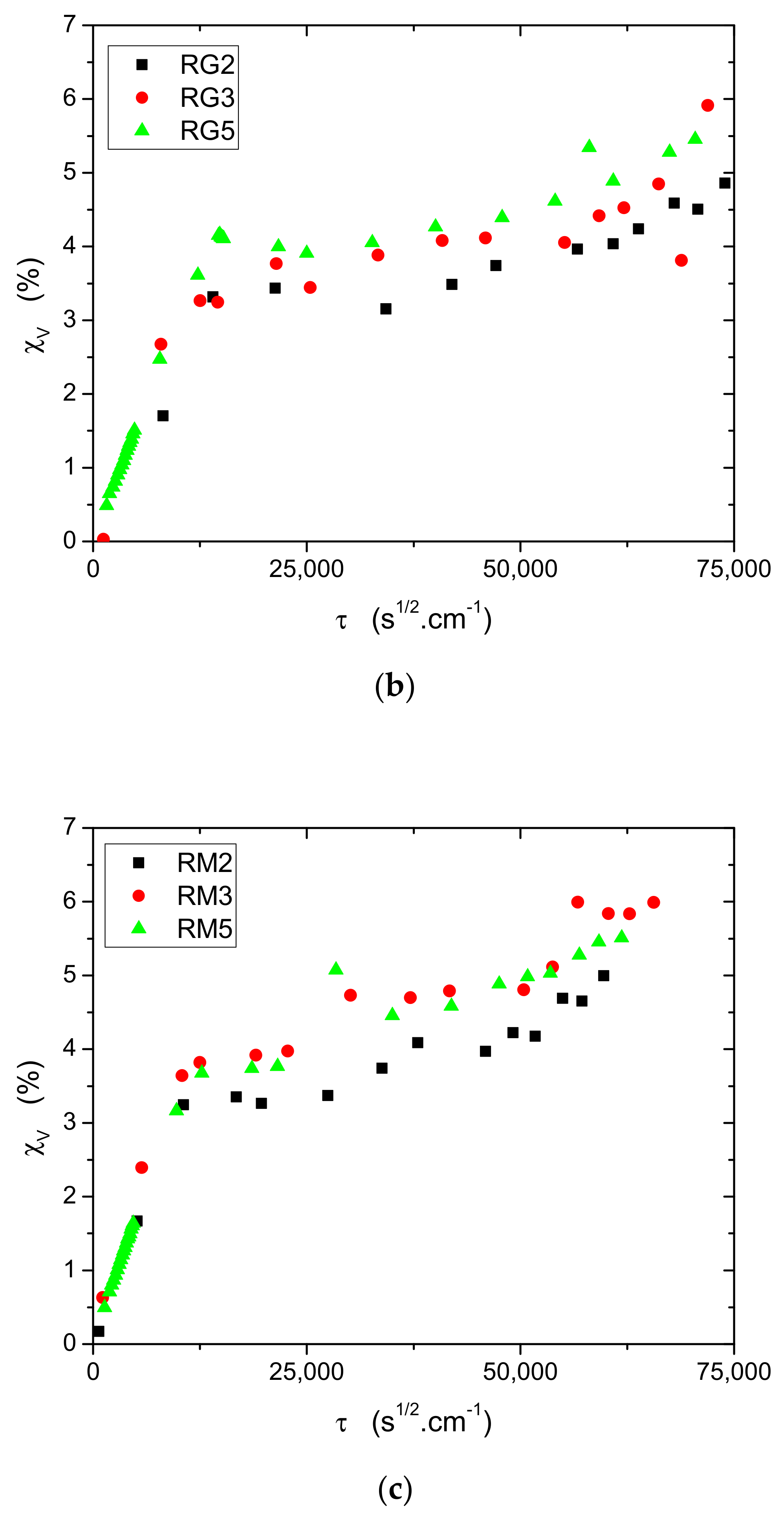

3.4. Defect-Free Samples in Cyclic NSS then Immersed at 35 °C

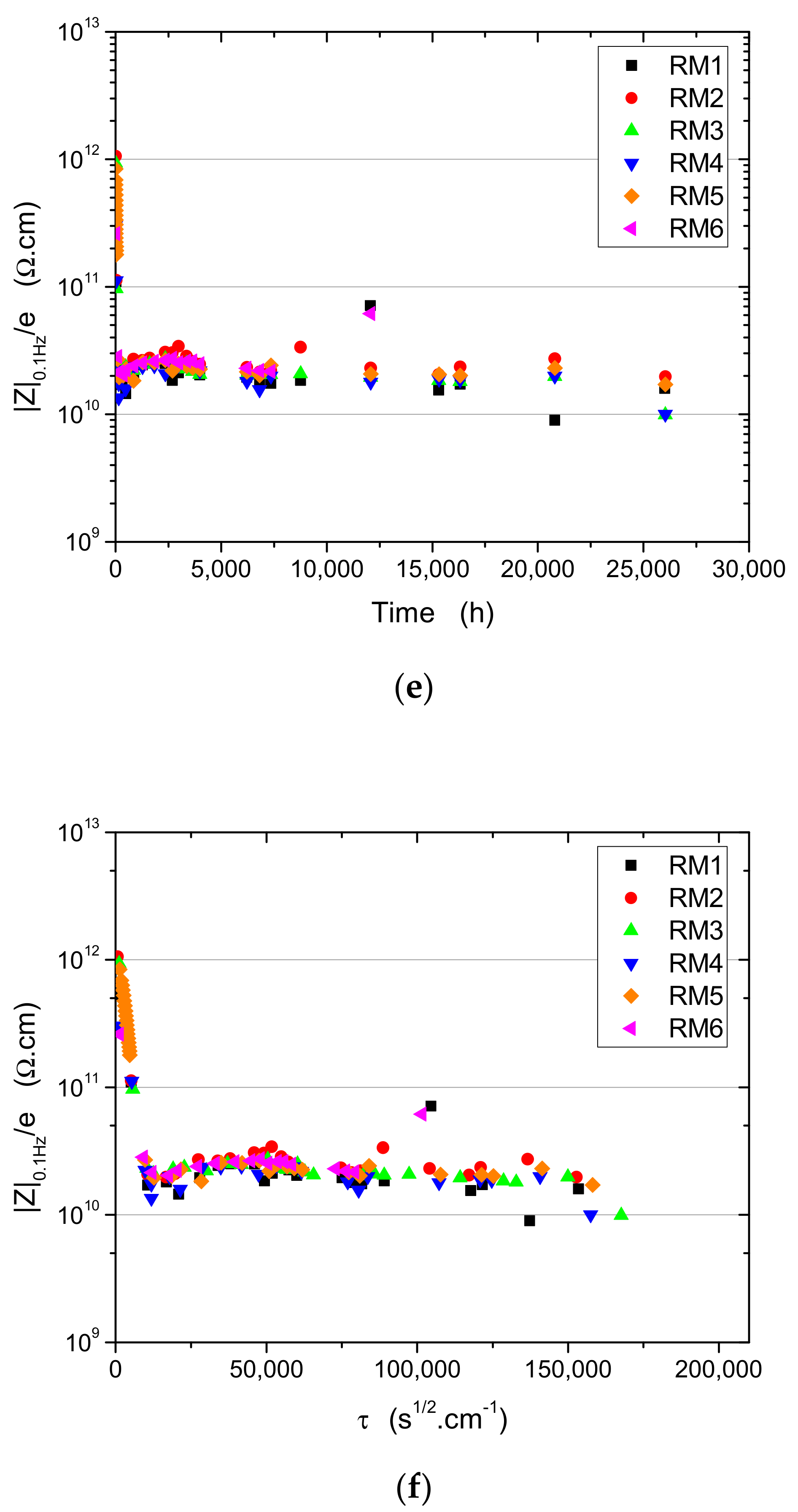

3.5. Defect-Free Samples in Alternate Cycling

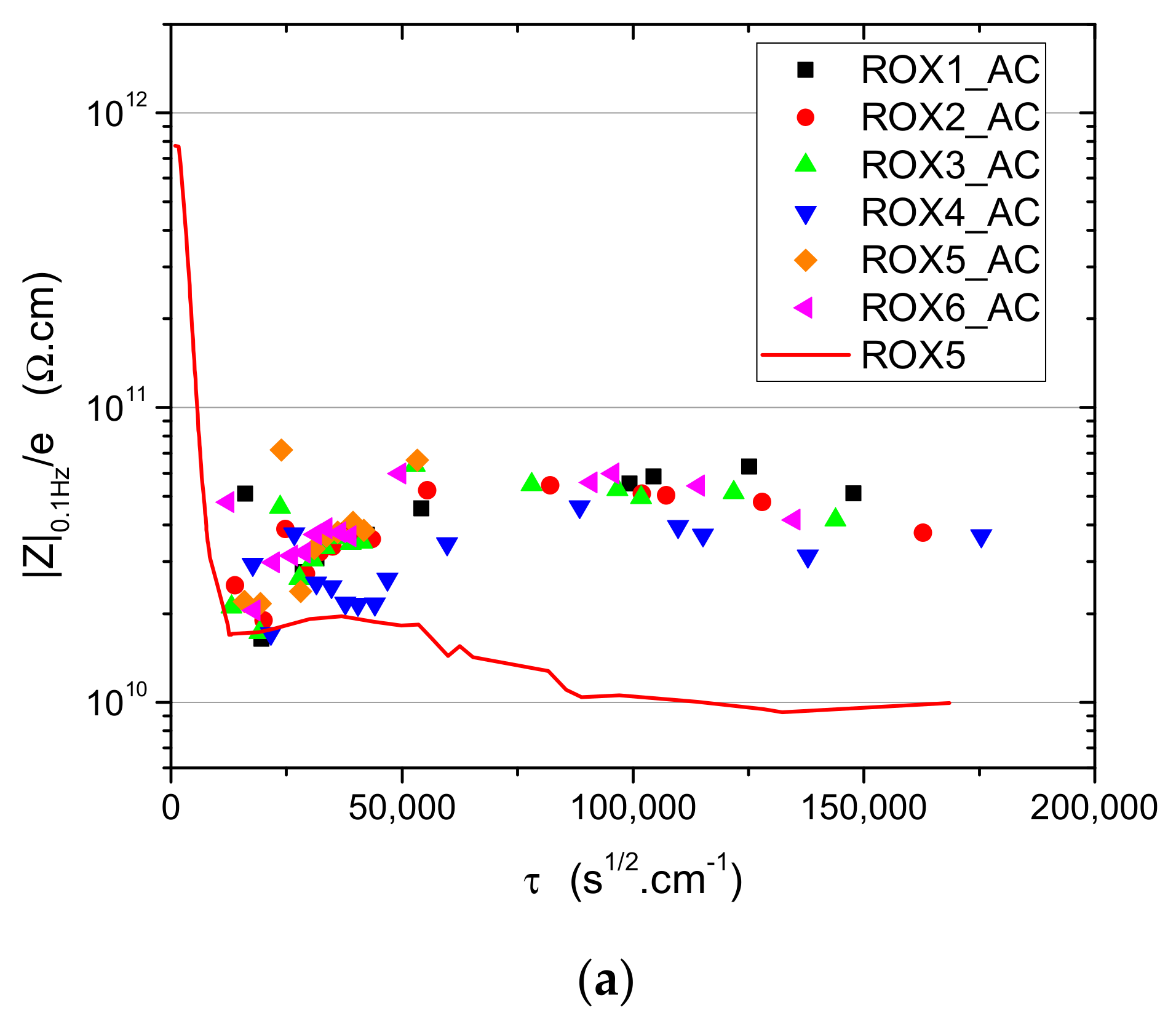

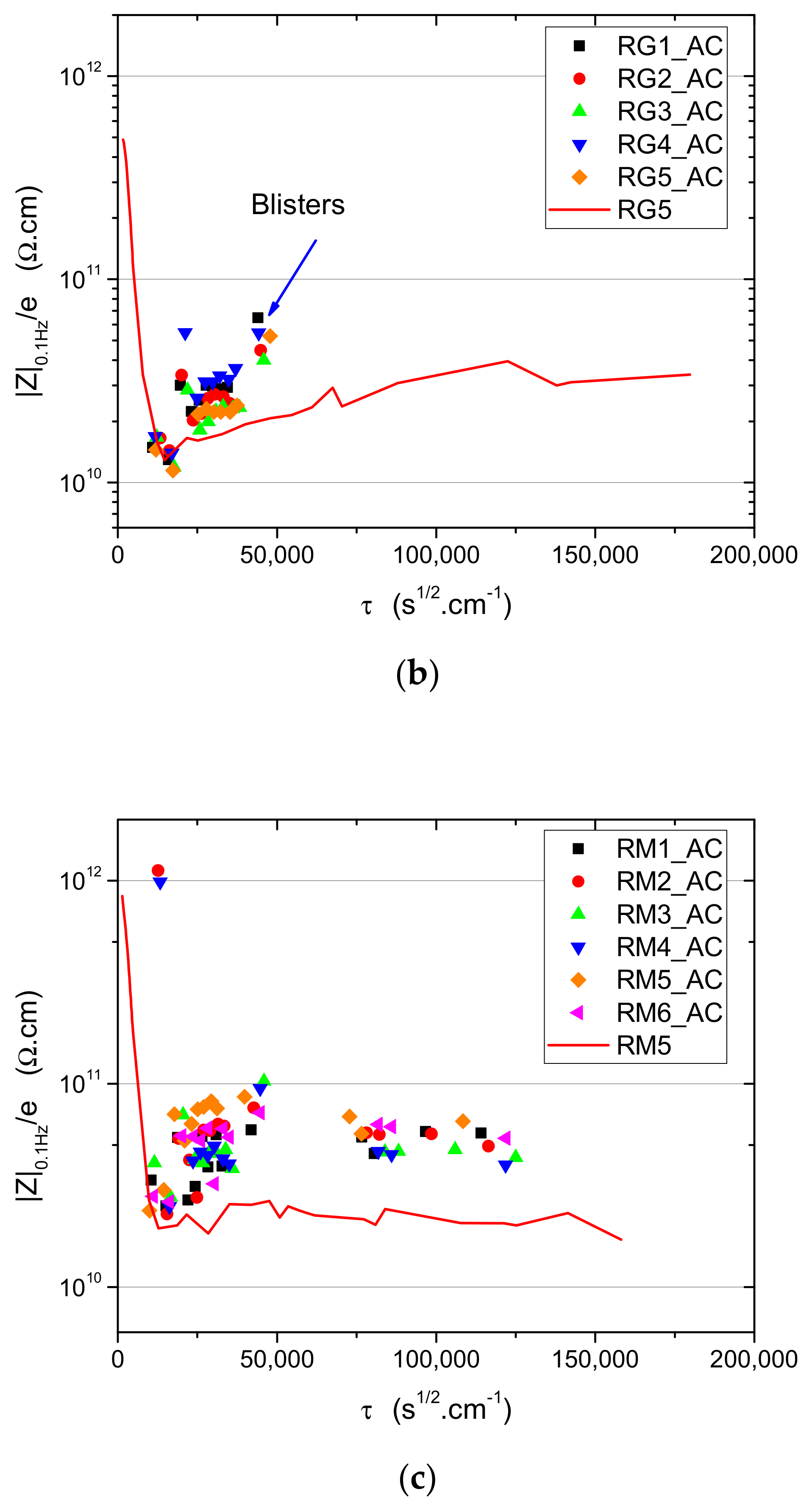

3.6. X-Cut Samples Immersed at 35 °C

3.7. X-Cut Samples in Cyclic NSS

3.8. X-Cut Samples in Alternate Cycling

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Borthwick, A.G.L. Marine Renewable Energy Seascape. Engineering 2016, 2, 69–78. [Google Scholar] [CrossRef] [Green Version]

- Fredj, N.; Cohendoz, S.; Feaugas, X.; Touzain, S. Ageing of marine coating in natural and artificial seawater under mechanical stresses. Prog. Org. Coat. 2012, 74, 391–399. [Google Scholar] [CrossRef]

- Song, G.-L.; Feng, Z. Modification, Degradation and Evaluation of a Few Organic Coatings for Some Marine Applications. Corros. Mater. Degrad. 2020, 1, 408–442. [Google Scholar] [CrossRef]

- Le Thu, Q.; Takenouti, H.; Touzain, S. EIS characterization of thick flawed organic coatings aged under cathodic protection in seawater. Electrochim. Acta 2006, 51, 2491–2502. [Google Scholar] [CrossRef]

- Funke, W. The role of adhesion in corrosion protection by organic coatings. J. Oil Colour Chem. Assoc. 1979, 68, 229–232. [Google Scholar]

- Wicks, Z.W.; Jones, F.N.; Pappas, S.P.; Wicks, A.D. Organic Coatings: Science and Technology, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1999. [Google Scholar]

- Sørensen, P.; Kiil, S.; Dam-Johansen, K.; Weinell, C. Anticorrosive coatings: A review. J. Coat. Technol. Res. 2009, 6, 135–176. [Google Scholar] [CrossRef]

- Mansfeld, F.; Xiao, H.; Han, L.T.; Lee, C.C. Electrochemical impedance and noise data for polymer coated steel exposed at remote marine test sites. Prog. Org. Coat. 1997, 30, 89–100. [Google Scholar] [CrossRef]

- Fedrizzi, L.; Bergo, A.; Fanicchia, M. Evaluation of accelerated aging procedures of painted galvanised steels by EIS. Electrochim. Acta. 2006, 51, 1864–1872. [Google Scholar] [CrossRef]

- Deflorian, F.; Rossi, S.; Fedrizzi, L.; Zanella, C. Comparison of organic coating accelerated tests and natural weathering considering meteorological data. Prog. Org. Coat. 2007, 59, 244–250. [Google Scholar] [CrossRef]

- Croll, S.G.; Shi, X.; Fernando, B.M.D. The interplay of physical aging and degradation during weathering for two crosslinked coatings. Prog. Org. Coat. 2008, 61, 136–144. [Google Scholar] [CrossRef]

- Bierwagen, G.P.; He, L.; Li, J.; Ellingson, L.; Tallman, D.E. Studies of a new accelerated evaluation method for coating corrosion resistance—Thermal cycling testing. Prog. Org. Coat. 2000, 39, 67–78. [Google Scholar] [CrossRef]

- Yang, X.F.; Li, J.; Croll, S.G.; Tallman, D.E.; Bierwagen, G.P. Degradation of low gloss polyurethane aircraft coatings under UV and prohesion alternating exposures. Polym. Degrad. Stab. 2003, 80, 51–58. [Google Scholar] [CrossRef]

- Corfias, C.; Pebere, N.; Lacabanne, C. Characterization of a thin protective coating on galvanized steel by electrochemical impedance spectroscopy and a thermostimulated current method. Corros. Sci. 1999, 41, 1539–1555. [Google Scholar] [CrossRef]

- Kendig, M.; Mansfeld, F.; Tsai, S. Determination of the long term corrosion behavior of coated steel with A.C. impedance measurements. Corros. Sci. 1983, 23, 317–329. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, X.-Z.; Yin, P.-F.; Xu, Z.-K.; Han, B.; Wang, J. EIS study on the deterioration process of organic coatings under immersion and different cyclic wet-dry ratios. Appl. Mech. Mater. 2012, 161, 58–66. [Google Scholar] [CrossRef]

- Yang, C.; Xing, X.; Li, Z.; Zhang, S. A Comprehensive Review on Water Diffusion in Polymers Focusing on the Polymer–Metal Interface Combination. Polymers 2020, 12, 138. [Google Scholar] [CrossRef] [Green Version]

- Schulz, U.; Trubiroha, P.; Schernau, U.; Baumgart, H. Effects of acid rain on the appearance of automotive paint systems studied outdoors and in a new artificial weathering test. Prog. Org. Coat. 2000, 40, 151–165. [Google Scholar] [CrossRef]

- Wernståhl, K.M. Service life prediction of automotive coatings, correlating infrared measurements and gloss retention. Polym. Degrad. Stab. 1996, 54, 57–65. [Google Scholar] [CrossRef]

- Margarit-Mattos, I.C.P. EIS and organic coatings performance: Revisiting some key points. Electrochim. Acta 2020, 354, 136725. [Google Scholar] [CrossRef]

- Da Silva, T.C.; Mallarino, S.; Touzain, S.; Margarit-Mattos, I.C.P. DMA, EIS and thermal fatigue of organic coatings. Electrochim. Acta 2019, 318, 989–999. [Google Scholar] [CrossRef]

- Olivier, M.-G.; Romano, A.-P.; Vandermiers, C.; Mathieu, X.; Poelman, M. Influence of the stress generated during an ageing cycle on the barrier properties of cataphoretic coatings. Prog. Org. Coat. 2008, 63, 323–329. [Google Scholar] [CrossRef]

- Oliveira, J.L.; Skilbred, A.W.B.; Loken, A.; Henriques, R.R.; Soares, B.G. Effect of accelerated ageing procedures and flash rust inhibitors on the anti-corrosive performance of epoxy coatings: EIS and dynamic-mechanical analysis. Prog. Org. Coat. 2021, 159, 106387. [Google Scholar] [CrossRef]

- Allahar, K.N.; Bierwagen, G.P.; Gelling, V.J. Understanding ac-dc-ac accelerated test results. Corros. Sci. 2010, 52, 1106–1114. [Google Scholar] [CrossRef]

- Bistac, S.; Vallat, M.F.; Schultz, J. Durability of steel/polymer adhesion in an aqueous environment. Int. J. Adhes. Adhes. 1998, 18, 365–369. [Google Scholar] [CrossRef]

- Hollaender, J. Rapid assessment of food/package interactions by electrochemical impedance spectroscopy (EIS). Food Addit. Contam. 1997, 14, 617–626. [Google Scholar] [CrossRef] [PubMed]

- Suay, J.J.; Rodríguez, M.T.; Izquierdo, R.; Kudama, A.M.; Saura, J.J. Rapid Assessment of Automotive Epoxy Primers by Electrochemical Techniques. J. Coat. Technol. 2003, 75, 103–111. [Google Scholar] [CrossRef]

- Miszczyk, A.; Darowicki, K. Accelerated ageing of organic coating systems by thermal treatment. Corros. Sci. 2001, 43, 1337–1343. [Google Scholar] [CrossRef]

- Zargarnezhad, H.; Asselin, E.; Wong, D.; Lam, C.N.C. A critical review of the time-dependent performance of polymeric pipeline coatings: Focus on hydration of epoxy-based coatings. Polymers 2021, 13, 1517. [Google Scholar] [CrossRef] [PubMed]

- Bierwagen, G.; Tallman, D.; Li, J.; He, L.; Jeffcoate, C. EIS studies of coated metals in accelerated exposure. Prog. Org. Coat. 2003, 46, 149–158. [Google Scholar] [CrossRef]

- Bierwagen, G.P.; Jeffcoate, C.S.; Li, J.; Balbyshev, S.; Tallman, D.E.; Mills, D.J. The use of electrochemical noise methods (ENM) to study thick, high impedance coatings. Prog. Org. Coat. 1996, 29, 21–29. [Google Scholar] [CrossRef]

- Valentinelli, L.; Vogelsang, J.; Ochs, H.; Fedrizzi, L. Evaluation of barrier coatings by cycling testing. Prog. Org. Coat. 2002, 45, 405–413. [Google Scholar] [CrossRef]

- LeBozec, N.; Thierry, D.; le Calvé, P.; Favennec, C.; Pautasso, J.-P.; Hubert, C. Performance of marine and offshore paint systems: Correlation of accelerated corrosion tests and field exposure on operating ships. Mater. Corros. 2015, 66, 215–225. [Google Scholar] [CrossRef]

- Ochs, H.; Vogelsang, J. Effect of temperature cycles on impedance spectra of barrier coatings under immersion conditions. Electrochim. Acta 2004, 49, 2973–2980. [Google Scholar] [CrossRef]

- Qu, S.; Ju, P.; Zuo, Y.; Zhao, X.; Tang, Y. The effect of various cyclic wet-dry exposure cycles on the failure process of organic coatings. Int. J. Electrochem. Sci. 2019, 14, 10754–10755. [Google Scholar] [CrossRef]

- Thirion, P. Proprietes viscoelastiques des reseaux a l’etat caoutchoutique. Eur. Polym. J. 1974, 10, 1093–1101. [Google Scholar] [CrossRef]

- Mills, D.J.; Jamali, S.S. The best tests for anti-corrosive paints. And why: A personal viewpoint. Prog. Org. Coat. 2017, 102, 8–17. [Google Scholar] [CrossRef] [Green Version]

- Apicella, A.; Tessieri, R.; De Cataldis, C. Sorption modes of water in glassy epoxies. J. Memb. Sci. 1984, 18, 211–225. [Google Scholar] [CrossRef]

- Apicella, A.; Nicolais, L. Effect of water on the properties of epoxy matrix and composite. In Epoxy Resins and Composites I; Springer: Berlin/Heidelberg, Germany, 1985; pp. 69–77. [Google Scholar] [CrossRef]

- Barchiche, C.; Deslouis, C.; Festy, D.; Gil, O.; Refait, P.; Touzain, S.; Tribollet, B. Characterization of calcareous deposits in artificial seawater by impedance techniques: 3—Deposit of CaCO3 in the presence of Mg (II). Electrochim. Acta 2003, 48, 1645–1654. [Google Scholar] [CrossRef]

- Deslouis, C.; Doncescu, A.; Festy, D.; Gil, O.; Maillot, V.; Touzain, S.; Tribollet, B. Kinetics and characterisation of calcareous deposits under cathodic protection in natural sea water. Mater. Sci. Forum 1998, 289–292, 1163–1180. [Google Scholar] [CrossRef]

- Brasher, D.M.; Kingsbury, A.H. Electrical measurements in the study of immersed paint coatings on metal. I. Comparison between capacitance and gravimetric methods of estimating water-uptake. J. Appl. Chem. 1954, 4, 62–72. [Google Scholar] [CrossRef]

- Fredj, N.; Cohendoz, S.; Mallarino, S.; Feaugas, X.; Touzain, S. Evidencing antagonist effects of water uptake and leaching processes in marine organic coatings by gravimetry and EIS. Prog. Org. Coat. 2010, 67, 287–295. [Google Scholar] [CrossRef]

- Boisseau, A.; Davies, P.; Thiebaud, F. Sea water ageing of composites for ocean energy conversion systems: Influence of glass fibre type on static behaviour. Appl. Compos. Mater. 2012, 19, 459–473. [Google Scholar] [CrossRef]

- Dang, D.N.; Cohendoz, S.; Mallarino, S.; Feaugas, X.; Touzain, S. Effects of curing program on mechanical behavior and water absorption of DGEBA/TETa epoxy network. J. Appl. Polym. Sci. 2013, 129, 2451–2463. [Google Scholar] [CrossRef]

- Cattarin, S.; Comisso, N.; Musiani, M.; Tribollet, B. The Impedance of an Electrode Coated by a Resistive Film with a Graded Thickness. Electrochem. Solid-State Lett. 2008, 11, C27–C30. [Google Scholar] [CrossRef]

- Touzain, S. Some comments on the use of the EIS phase angle to evaluate organic coating degradation. Electrochim. Acta 2010, 55, 6190–6194. [Google Scholar] [CrossRef]

- Bouvet, G.; Nguyen, D.D.; Mallarino, S.; Touzain, S. Analysis of the non-ideal capacitive behavior for high impedance organic coatings. Prog. Org. Coat. 2014, 77, 2045–2053. [Google Scholar] [CrossRef]

- Nguyen, A.S.; Musiani, M.; Orazem, M.E.; Pébère, N.; Tribollet, B.; Vivier, V. Impedance analysis of the distributed resistivity of coatings in dry and wet conditions. Electrochim. Acta 2015, 179, 452–459. [Google Scholar] [CrossRef] [Green Version]

- Mišković-Stanković, V.B.; Dražić, D.M.; Teodorović, M.J. Electrolyte penetration through epoxy coatings electrodeposited on steel. Corros. Sci. 1995, 37, 241–252. [Google Scholar] [CrossRef]

- Walter, G.W. The application of impedance methods to study the effects of water uptake and chloride ion concentration on the degradation of paint films—II. Free films and attached/free film comparisons. Corros. Sci. 1991, 32, 1085–1103. [Google Scholar] [CrossRef]

- Duval, S.; Keddam, M.; Sfaira, M.; Srhiri, A.; Takenouti, H. Electrochemical impedance spectroscopy of epoxy-vinyl coating in aqueous medium analyzed by dipolar relaxation of polymer. J. Electrochem. Soc. 2002, 149, B520. [Google Scholar] [CrossRef]

- Amirudin, A.; Thieny, D. Application of electrochemical impedance spectroscopy to study the degradation of polymer-coated metals. Prog. Org. Coat. 1995, 26, 1–28. [Google Scholar] [CrossRef]

- Zhou, J.; Lucas, J.P. Hygrothermal effects of epoxy resin. Part I: The nature of water in epoxy. Polymer 1999, 40, 5505–5512. [Google Scholar] [CrossRef]

- Irigoyen, M.; Aragon, E.; Perrin, F.X.; Vernet, J.L. Effect of UV aging on electrochemical behavior of an anticorrosion paint. Prog. Org. Coat. 2007, 59, 259–264. [Google Scholar] [CrossRef]

- Pebere, N.; Picaud, T.; Duprat, M.; Dabosi, F. Evaluation of corrosion performance of coated steel by the impedance technique. Corros. Sci. 1989, 29, 1073–1086. [Google Scholar] [CrossRef]

- Mansfeld, F. Use of electrochemical impedance spectroscopy for the study of corrosion protection by polymer coatings. J. Appl. Electrochem. 1995, 25, 187–202. [Google Scholar] [CrossRef]

- Deflorian, F.; Fedrizzi, L.; Rossi, S.; Bonora, P.L. Organic coating capacitance measurement by EIS: Ideal and actual trends. Electrochim. Acta 1999, 44, 4243–4249. [Google Scholar] [CrossRef]

- Van Westing, E.P.M.; Ferrari, G.M.; De Wit, J.H.W. The determination of coating performance with impedance measurements-II. Water uptake of coatings. Corros. Sci. 1994, 36, 957–977. [Google Scholar] [CrossRef]

- Nguyen, V.N.; Perrin, F.X.; Vernet, J.L. Water permeability of organic/inorganic hybrid coatings prepared by sol-gel method: A comparison between gravimetric and capacitance measurements and evaluation of non-Fickian sorption models. Corros. Sci. 2005, 47, 397–412. [Google Scholar] [CrossRef]

- Dang, D.N.; Peraudeau, B.; Cohendoz, S.; Mallarino, S.; Feaugas, X.; Touzain, S. Effect of mechanical stresses on epoxy coating ageing approached by Electrochemical Impedance Spectroscopy measurements. Electrochim. Acta 2014, 124, 80–89. [Google Scholar] [CrossRef]

- Mišković-Stanković, V.B.; Dražić, D.M.; Kačarević-Popović, Z. The sorption characteristics of epoxy coatings electrodeposited on steel during exposure to different corrosive agents. Corros. Sci. 1996, 38, 1513–1523. [Google Scholar] [CrossRef]

- Fedrizzi, L.; Deflorian, F.; Boni, G.; Bonora, P.L.; Pasini, E. EIS study of environmentally friendly coil coating performances. Prog. Org. Coat. 1996, 29, 89–96. [Google Scholar] [CrossRef]

- Perez, C.; Collazo, A.; Izquierdo, M.; Merino, P.; Novoa, X.R. Characterisation of the barrier properties of different paint systems. Part I. Experimental set-up and ideal Fickian diffusion. Prog. Org. Coat. 1999, 36, 102–108. [Google Scholar] [CrossRef]

- Murray, J.N.; Hack, H.P. Testing organic architectural coatings in ASTM synthetic seawater immersion conditions using EIS. Corrosion 1992, 48, 671–685. [Google Scholar] [CrossRef]

- Perera, D.Y. Effect of thermal and hygroscopic history on physical ageing of organic coatings. Prog. Org. Coat. 2002, 44, 55–62. [Google Scholar] [CrossRef]

- Perera, D.Y. Physical ageing of organic coatings. Prog. Org. Coat. 2003, 47, 61–76. Available online: http://www.sciencedirect.com/science/article/B6THD-48NC0P4-1/2/dd9b3f7922d3afe1c28c0df3162bd9a0 (accessed on 30 September 2021). [CrossRef]

- Bierwagen, G.P.; Wang, X.; Tallman, D.E. In situ study of coatings using embedded electrodes for ENM measurements. Prog. Org. Coat. 2003, 46, 163–175. [Google Scholar] [CrossRef]

- Kong, E. Physical aging in epoxy matrices and composites. In Epoxy Resins and Composites IV; Dušek, K., Ed.; Springer: Berlin/Heidelberg, Germany, 1986; pp. 125–171. [Google Scholar] [CrossRef]

- Elkebir, Y.; Mallarino, S.; Trinh, D.; Touzain, S. Effect of physical ageing onto the water uptake in epoxy coatings. Electrochim. Acta 2020, 337, 135766. [Google Scholar] [CrossRef]

- Hutchinson, J.M. Physical aging of polymers. Prog. Polym. Sci. 1995, 20, 703–760. [Google Scholar] [CrossRef]

- Le Guen-Geffroy, A.; Le Gac, P.-Y.; Habert, B.; Davies, P. Physical ageing of epoxy in a wet environment: Coupling between plasticization and physical ageing. Polym. Degrad. Stab. 2019, 168, 108947. [Google Scholar] [CrossRef]

- Thai, T.T.; Druart, M.-E.; Paint, Y.; Trinh, A.T.; Olivier, M.-G. Influence of the sol-gel mesoporosity on the corrosion protection given by an epoxy primer applied on aluminum alloy 2024 –T3. Prog. Org. Coat. 2018, 121, 53–63. [Google Scholar] [CrossRef]

- Deflorian, F.; Fedrizzi, L. Adhesion characterization of protective organic coatings by electrochemical impedance spectroscopy. J. Adhes. Sci. Technol. 1999, 13, 629–645. [Google Scholar] [CrossRef]

- Ecco, L.G.; Fedel, M.; Deflorian, F.; Becker, J.; Iversen, B.B.; Mamakhel, A. Waterborne acrylic paint system based on nanoceria for corrosion protection of steel. Prog. Org. Coat. 2016, 96, 19–25. [Google Scholar] [CrossRef]

- Bonora, P.L.; Deflorian, F.; Fedrizzi, L. Electrochemical impedance spectroscopy as a tool for investigating underpaint corrosion. Electrochim. Acta 1996, 41, 1073–1082. [Google Scholar] [CrossRef]

- Park, J.H.; Lee, G.D.; Ooshige, H.; Nishikata, A.; Tsuru, T. Monitoring of water uptake in organic coatings under cyclic wet–dry condition. Corros. Sci. 2003, 45, 1881–1894. [Google Scholar] [CrossRef]

- Fedrizzi, L.; Rodriguez, F.J.; Rossi, S.; Deflorian, F. Corrosion study of industrial painting cycles for garden furniture. Prog. Org. Coat. 2003, 46, 62–73. [Google Scholar] [CrossRef]

- Bajat, J.B.; Mišković-Stanković, V.B.; Bibić, N.; Dražić, D.M. The influence of zinc surface pretreatment on the adhesion of epoxy coating electrodeposited on hot-dip galvanized steel. Prog. Org. Coat. 2007, 58, 323–330. [Google Scholar] [CrossRef]

- Rosales, B.M.; Di Sarli, A.R.; De Rincón, O.; Rincón, A.; Elsner, C.I.; Marchisio, B. An evaluation of coil coating formulations in marine environments. Prog. Org. Coat. 2004, 50, 105–114. [Google Scholar] [CrossRef]

| System Name | Paint System | Total Dry Film Thickness |

|---|---|---|

| Organic system ROX | Hempadur 45703: 250 µm + Hempadur 45753: 250 µm | 500 µm |

| Galvanized system RG | Hempadur 15570: 50 µm + Hempadur 45703: 200 µm + Hempadur 45753: 250 µm | 500 µm |

| Thermal spray system RM | Hempadur 45703: 30 µm + Hempadur 45703: 250 µm + Hempadur 45753: 250 µm | 530 µm |

| Ageing Conditions | Panel Name | Thickness (µm) | Panel Name | Thickness (µm) | Panel Name | Thickness (µm) |

|---|---|---|---|---|---|---|

| Immersion at 35 °C in NaCl solution | ROX1 | 544 | RG1 | 555 | RM1 | 630 |

| ROX2 | 658 | RG2 | 514 | RM2 | 634 | |

| ROX3 | 618 | RG3 | 528 | RM3 | 577 | |

| ROX4 | 535 | RG4 | 479 | RM4 | 615 | |

| ROX5 | 578 | RG5 | 539 | RM5 | 612 | |

| ROX6 | 683 | RG6 | 505 | RM6 | 650 | |

| Immersion in seawater | ROX1_nat | 490 | RG1_nat | 490 | RM1_nat | 594 |

| ROX2_nat | 542 | RG2_nat | 542 | RM2_nat | 569 | |

| ROX3_nat | 524 | RG3_nat | 524 | RM3_nat | 599 | |

| ROX4_nat | 584 | RG4_nat | 584 | RM4_nat | 653 | |

| ROX5_nat | 514 | RG5_nat | 514 | RM5_nat | 640 | |

| ROX6_nat | 554 | RG6_nat | 554 | RM6_nat | 541 | |

| Cyclic NSS | ROX1_NSS | 651 | RG1_NSS | 725 | RM1_NSS | 667 |

| ROX2_NSS | 521 | RG2_NSS | 536 | RM2_NSS | 679 | |

| ROX3_NSS | 483 | RG3_NSS | 719 | RM3_NSS | 696 | |

| ROX4_NSS | 517 | RG4_NSS | 711 | RM4_NSS | 669 | |

| Alternate cycling | ROX1_AC | 594 | RG1_AC | 720 | RM1_AC | 756 |

| ROX2_AC | 571 | RG2_AC | 705 | RM2_AC | 741 | |

| ROX3_AC | 600 | RG3_AC | 648 | RM3_AC | 690 | |

| ROX4_AC | 530 | RG4_AC | 671 | RM4_AC | 708 | |

| ROX5_AC | 594 | RG5_AC | 662 | RM5_AC | 796 | |

| ROX6_AC | 640 | RG6_AC | 681 | RM6_AC | 708 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Renaud, A.; Pommier, V.; Garnier, J.; Frappart, S.; Florimond, L.; Koch, M.; Grolleau, A.-M.; Puente-Lelièvre, C.; Sebastien, T. Aggressiveness of Different Ageing Conditions for Three Thick Marine Epoxy Systems. Corros. Mater. Degrad. 2021, 2, 721-742. https://doi.org/10.3390/cmd2040039

Renaud A, Pommier V, Garnier J, Frappart S, Florimond L, Koch M, Grolleau A-M, Puente-Lelièvre C, Sebastien T. Aggressiveness of Different Ageing Conditions for Three Thick Marine Epoxy Systems. Corrosion and Materials Degradation. 2021; 2(4):721-742. https://doi.org/10.3390/cmd2040039

Chicago/Turabian StyleRenaud, Alexis, Victor Pommier, Jérémy Garnier, Simon Frappart, Laure Florimond, Marion Koch, Anne-Marie Grolleau, Céline Puente-Lelièvre, and Touzain Sebastien. 2021. "Aggressiveness of Different Ageing Conditions for Three Thick Marine Epoxy Systems" Corrosion and Materials Degradation 2, no. 4: 721-742. https://doi.org/10.3390/cmd2040039

APA StyleRenaud, A., Pommier, V., Garnier, J., Frappart, S., Florimond, L., Koch, M., Grolleau, A.-M., Puente-Lelièvre, C., & Sebastien, T. (2021). Aggressiveness of Different Ageing Conditions for Three Thick Marine Epoxy Systems. Corrosion and Materials Degradation, 2(4), 721-742. https://doi.org/10.3390/cmd2040039