Advanced Thermogravimetric Analyses of Stem Wood and Straw Devolatilization: Torrefaction through Combustion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Preparation

2.2. Apparatus and Procedure

2.3. Overview of Pertinent Kinetics

3. Results

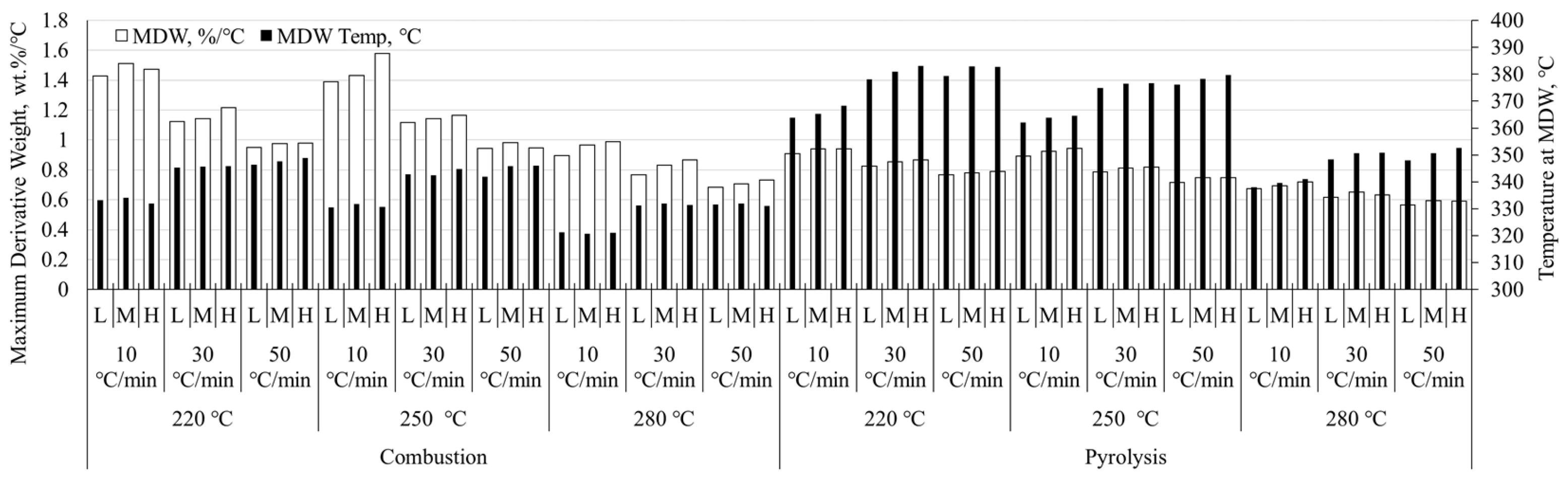

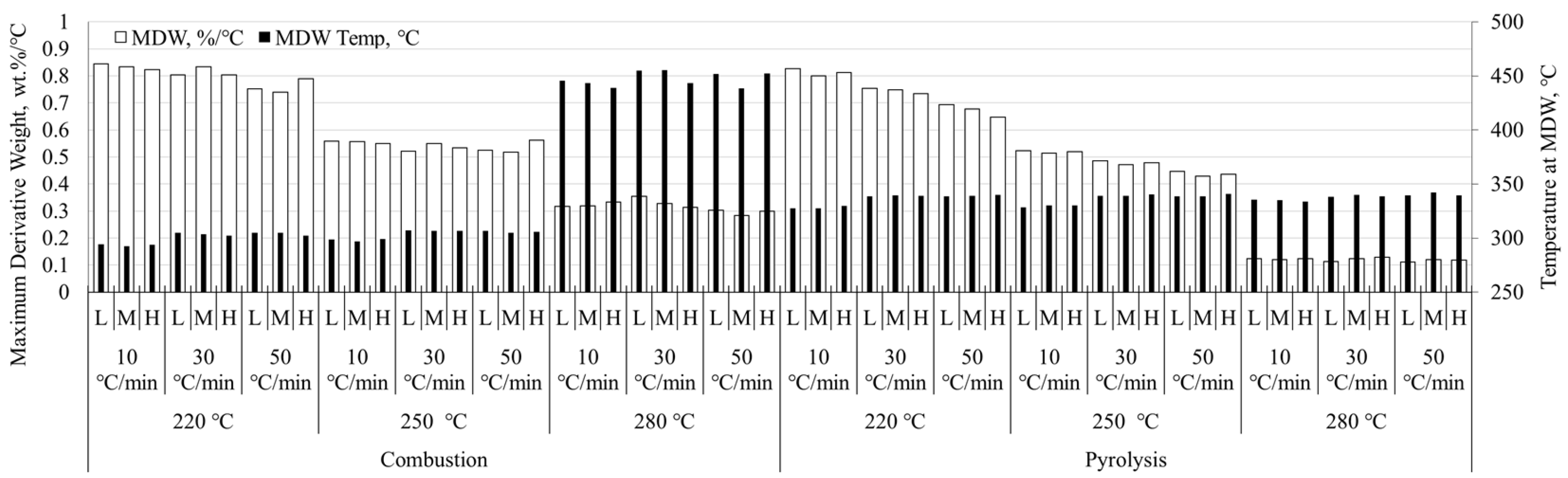

3.1. Maximum Derivative Weight Comparisons of Linearly Heated Samples

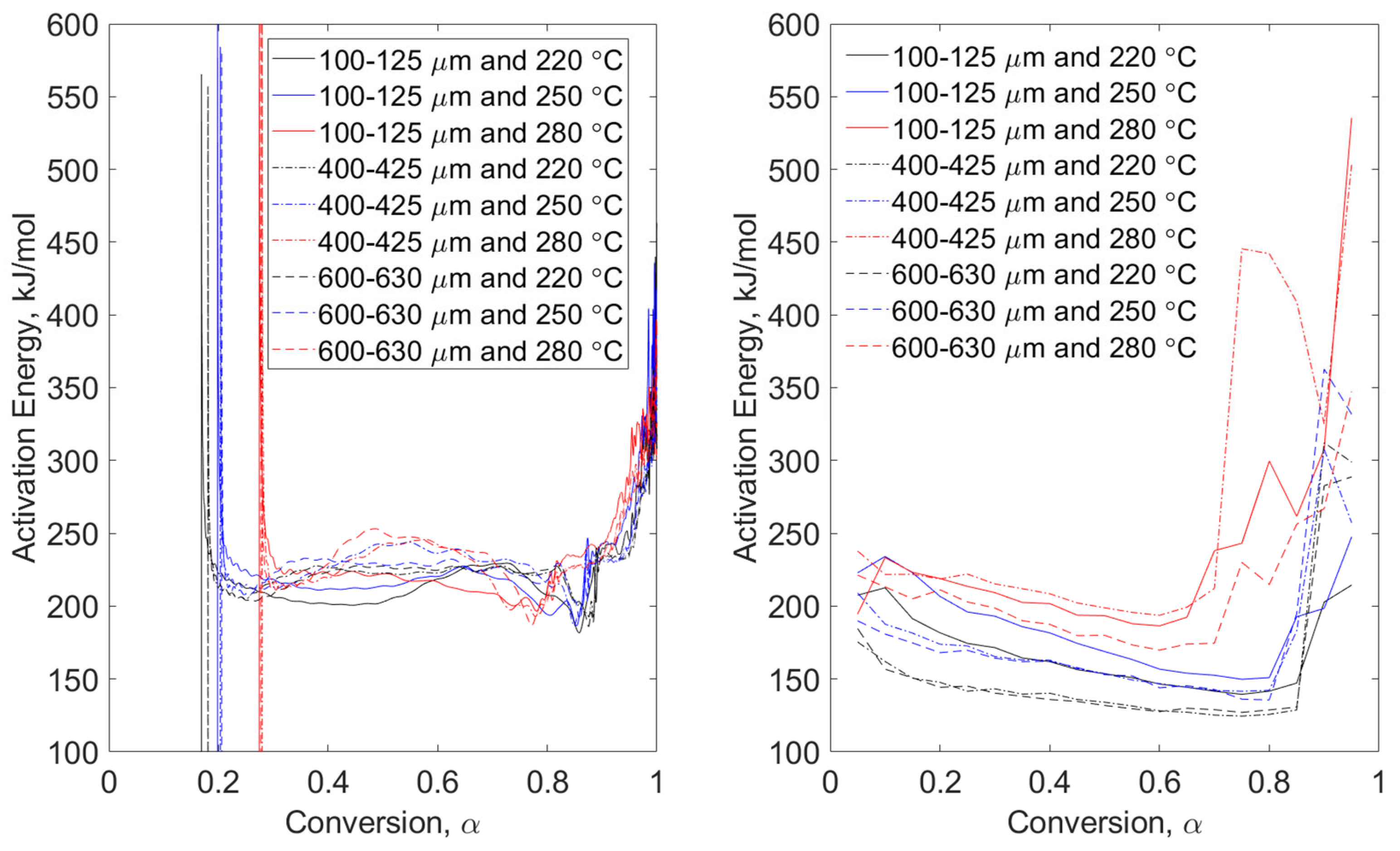

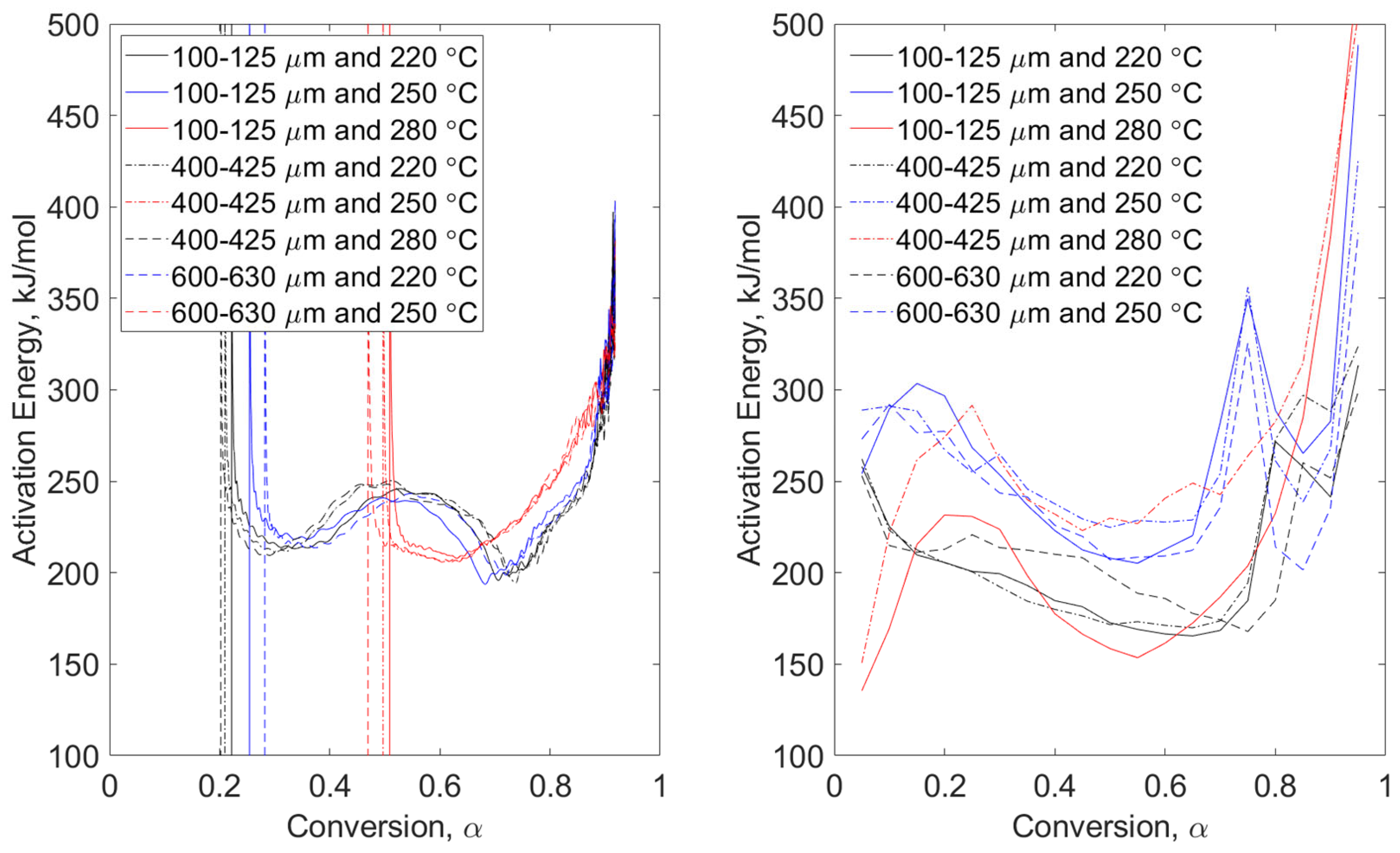

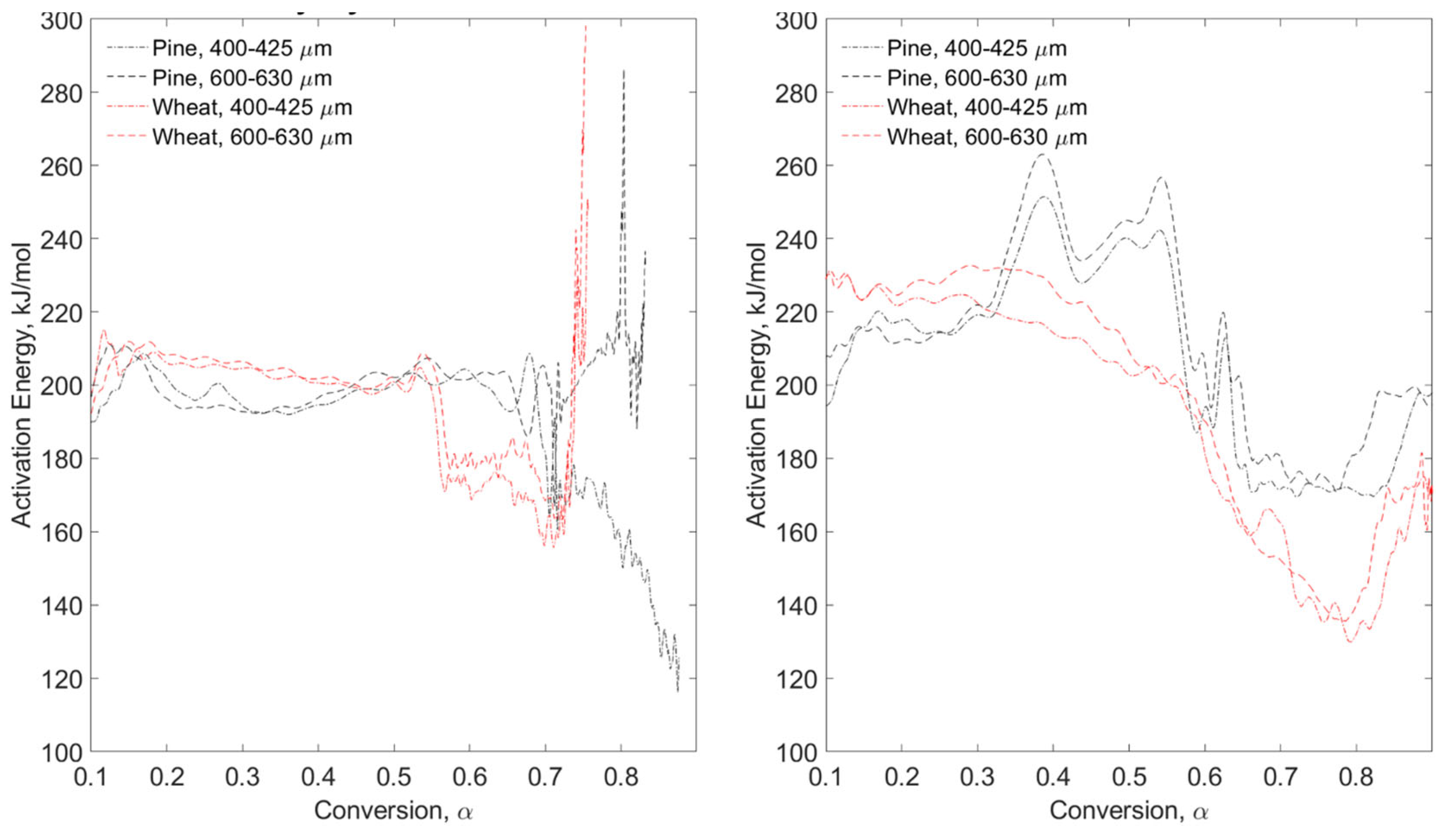

3.2. Comparison of Modulated TGA and OFW Methods

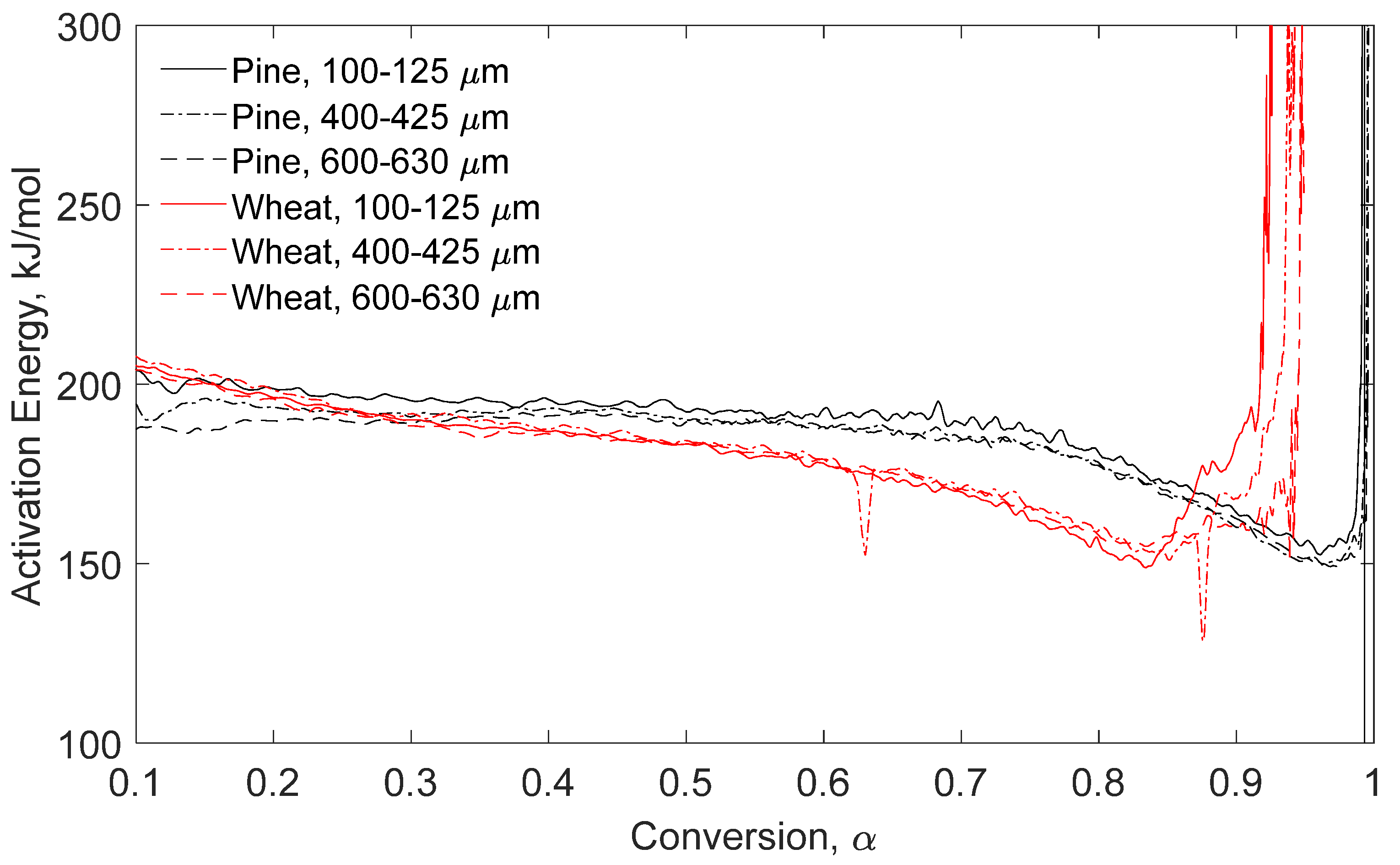

3.3. Modulated and Hi-Res™ Thermogravimetry

4. Discussion

5. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Haines, P.J. (Ed.) Principles of Thermal Analysis and Calorimetry; The Royal Society of Chemistry: London, UK, 2002. [Google Scholar]

- Mao, Z.; Campbell, C.T. Apparent Activation Energies in Complex Reaction Mechanisms: A Simple Relationship via Degrees of Rate Control. ACS Catal. 2019, 9, 9465–9473. [Google Scholar] [CrossRef]

- Peterson, C.A.; Hornbuckle, M.K.; Brown, R.C. Biomass pyrolysis devolatilization kinetics of herbaceous and woody feedstocks. Fuel Process Technol. 2022, 226, 107068. [Google Scholar] [CrossRef]

- Hu, M.; Chen, Z.; Wang, S.; Guo, D.; Ma, C.; Zhou, Y.; Chen, J.; Laghari, M.; Fazal, S.; Xiao, B.; et al. Thermogravimetric kinetics of lignocellulosic biomass slow pyrolysis using distributed activation energy model, Fraser–Suzuki deconvolution, and iso-conversional method. Energy Convers. Manag. 2016, 118, 1–11. [Google Scholar] [CrossRef]

- Dirion, J.-L.; Reverte, C.; Cabassud, M. Kinetic parameter estimation from TGA: Optimal design of TGA experiments. Chem. Eng. Res. Des. 2008, 86, 618–625. [Google Scholar] [CrossRef]

- TA Instruments. High Resolution Thermogravimetric Analysis—A New Technique for Obtaining Superior Analytical Results; TA Instruments: New Castle, DE, USA, 1992. [Google Scholar]

- Gill, P.S.; Sauerbrunn, S.R.; Crowe, B.S. High resolution thermogravimetry. J. Therm. Anal. 1992, 38, 255–266. [Google Scholar] [CrossRef]

- Blaine, R.L. Method and Apparatus of Modulated-Temperature Thermogravimetry. US6113261A, 5 September 2000. [Google Scholar]

- Crowe, B.S.; Sauerbrunn, S.R. Method and Apparatus for High Resolution Analysis. US5165792A, 24 November 1992. [Google Scholar]

- Teh, J.S.; Teoh, Y.H.; How, H.G.; Sher, F. Thermal Analysis Technologies for Biomass Feedstocks: A State-of-the-Art Review. Processes 2021, 9, 1610. [Google Scholar] [CrossRef]

- Grycova, B.; Pryszcz, A.; Krzack, S.; Klinger, M.; Lestinsky, P. Torrefaction of biomass pellets using the thermogravimetric analyser. Biomass Conv. Bioref. 2021, 11, 2837–2842. [Google Scholar] [CrossRef]

- Chen, W.H.; Kuo, P.C. A study on torrefaction of various biomass materials and its impact on lignocellulosic structure simulated by a thermogravimetry. Energy 2010, 35, 2580–2586. [Google Scholar] [CrossRef]

- Strandberg, A.; Holmgren, P.; Wagner, D.R.; Molinder, R.; Wiinikka, H.; Umeki, K.; Broström, M. Effects of Pyrolysis Conditions and Ash Formation on Gasification Rates of Biomass Char. Energy Fuels 2017, 31, 6507–6514. [Google Scholar] [CrossRef]

- Holmgren, P.; Wagner, D.R.; Strandberg, A.; Molinder, R.; Wiinikka, H.; Umeki, K.; Broström, M. Size, shape, and density changes of biomass particles during rapid devolatilization. Fuel 2017, 206, 342–351. [Google Scholar] [CrossRef]

- Wagner, D.R.; Broström, M. Time-dependent variations of activation energy during rapid devolatilization of biomass. J. Anal. Appl. Pyrolysis 2016, 118, 98–104. [Google Scholar] [CrossRef]

- TA Instruments. Modulated Thermogravimetric Analysis: A New Approach for Obtaining Kinetic Parameters; TA Instruments: New Castle, DE, USA, 1992. [Google Scholar]

- Hindmarsh, C.; Thomas, K.; Wang, W.; Cai, H.; Güell, A.; Dugwell, D.; Kandiyoti, R. A comparison of the pyrolysis of coal in wire-mesh and entrained-flow reactors. Fuel 1995, 74, 1185–1190. [Google Scholar] [CrossRef]

- Gibbins, J.R.; King, R.A.V.; Wood, R.J.; Kandiyoti, R. Variable-heating-rate wire-mesh pyrolysis apparatus. Rev. Sci. Instrum. 1989, 60, 1129–1139. [Google Scholar] [CrossRef]

- Guell, A.J.; Kandiyoti, R. Development of a gas-sweep facility for the direct capture of pyrolysis tars in a variable heating rate high-pressure wire-mesh reactor. Energy Fuels 1993, 7, 943–952. [Google Scholar] [CrossRef]

- E1641-16; Standard Test Method for Decomposition Kinetics by Thermogravimetry Using the Ozawa/Flynn/Wall Method. International ASTM: West Conshohocken, PA, USA, 2013; pp. 1–7.

- Aburto, J.; Moran, M.; Galano, A.; Torres-García, E. Non-isothermal pyrolysis of pectin: A thermochemical and kinetic approach. J. Anal. Appl. Pyrolysis 2015, 112, 94–104. [Google Scholar] [CrossRef]

- Budrugeac, P. Critical study concerning the use of sinusoidal modulated thermogravimetric data for evaluation of activation energy of heterogeneous processes. Thermochim. Acta 2020, 690, 178670. [Google Scholar] [CrossRef]

- Cai, J.; Xu, D.; Dong, Z.; Yu, X.; Yang, Y.; Banks, S.W.; Bridgwater, A.V. Processing thermogravimetric analysis data for isoconversional kinetic analysis of lignocellulosic biomass pyrolysis: Case study of corn stalk. Renew. Sustain. Energy Rev. 2018, 82, 2705–2715. [Google Scholar] [CrossRef]

- Keuleers, R.R.; Janssens, J.F.; Desseyn, H.O. Comparison of some methods for activation energy determination of thermal decomposition reactions by thermogravimetry. Thermochim. Acta 2002, 385, 127–142. [Google Scholar] [CrossRef]

- Mishra, G.; Bhaskar, T. Non isothermal model free kinetics for pyrolysis of rice straw. Bioresour. Technol. 2014, 169, 614–621. [Google Scholar] [CrossRef]

- Mishra, G.; Kumar, J.; Bhaskar, T. Kinetic studies on the pyrolysis of pinewood. Bioresour. Technol. 2015, 182, 282–288. [Google Scholar] [CrossRef]

- Vyazovkin, S.; Burnham, A.K.; Favergeon, L.; Koga, N.; Moukhina, E.; Pérez-Maqueda, L.A.; Sbirrazzuoli, N. ICTAC Kinetics Committee recommendations for analysis of multi-step kinetics. Thermochim. Acta 2020, 689, 178597. [Google Scholar] [CrossRef]

- Koga, N.; Vyazovkin, S.; Burnham, A.K.; Favergeon, L.; Muravyev, N.; Pérez-Maqueda, L.A.; Saggese, C.; Sánchez-Jiménez, P.E. ICTAC Kinetics Committee recommendations for analysis of thermal decomposition kinetics. Thermochim. Acta 2023, 719, 179384. [Google Scholar] [CrossRef]

- Mamleev, V.; Bourbigot, S. Modulated thermogravimetry in analysis of decomposition kinetics. Chem. Eng. Sci. 2005, 60, 747–766. [Google Scholar] [CrossRef]

- Blaine, R.L.; Hahn, B.K. Obtaining kinetic parameters by modulated thermogravimetry. J. Therm. Anal. Calorim. 1998, 54, 695–704. [Google Scholar] [CrossRef]

- Flynn, J.H.; Wall, L.A. A quick, direct method for the determination of activation energy from thermogravimetric data. J. Polym. Sci. Part. B Polym. Lett. 1966, 4, 323–328. [Google Scholar] [CrossRef]

- Kubo, S.; Kadla, J.F. Thermal decomposition study of isolated lignin using temperature modulated TGA. J. Wood Chem. Technol. 2008, 28, 106–121. [Google Scholar] [CrossRef]

- Schawe, J.E.K. A general approach for temperature modulated thermogravimetry: Extension to non-periodical and event-controlled modulation. Thermochim. Acta 2014, 593, 65–70. [Google Scholar] [CrossRef]

- Slough, C.G. Parameter dependency of activation energy in modulated thermogravimetry. J. Test. Eval. 2014, 42, 1343–1354. [Google Scholar] [CrossRef]

- Cheng, K.; Winter, W.T.; Stipanovic, A.J. A modulated-TGA approach to the kinetics of lignocellulosic biomass pyrolysis/combustion. Polym. Degrad. Stab. 2012, 97, 1606–1615. [Google Scholar] [CrossRef]

| Analysis | Pine [wt.%] | Wheat Straw [wt.%] |

|---|---|---|

| Ash Content | 0.4 | 8.2 |

| Volatile Matter | 84.8 | 73.4 |

| Carbon | 50.6 | 45.2 |

| Hydrogen | 6.2 | 5.7 |

| Nitrogen | 0.2 | 0.8 |

| Oxygen (diff.) | 42.6 | 40.1 |

| Factor | Levels | ||

|---|---|---|---|

| Low | Mid | High | |

| Pretreatment Temperature [°C] | 220 | 250 | 280 |

| Particle Size Ranges [micron] | 125–150 | 400–425 | 600–630 |

| Heating Rate [°C/min] | 10 | 30 | 50 |

| Gas-phase O2 [vol%] | 0 | - | 21 |

| Increase in | Directional Effect |

|---|---|

| Pretreatment (Torrefaction) Temperature |

|

| Particle Size Range |

|

| Heating Rate |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wagner, D.R. Advanced Thermogravimetric Analyses of Stem Wood and Straw Devolatilization: Torrefaction through Combustion. Reactions 2024, 5, 350-360. https://doi.org/10.3390/reactions5020018

Wagner DR. Advanced Thermogravimetric Analyses of Stem Wood and Straw Devolatilization: Torrefaction through Combustion. Reactions. 2024; 5(2):350-360. https://doi.org/10.3390/reactions5020018

Chicago/Turabian StyleWagner, David R. 2024. "Advanced Thermogravimetric Analyses of Stem Wood and Straw Devolatilization: Torrefaction through Combustion" Reactions 5, no. 2: 350-360. https://doi.org/10.3390/reactions5020018