Degradation of Polypropylene and Jute Fiber-Reinforced Composites Exposed to Natural and Accelerated Aging: Mechanical Properties and Wettability

Abstract

:1. Introduction

2. Materials and Methods

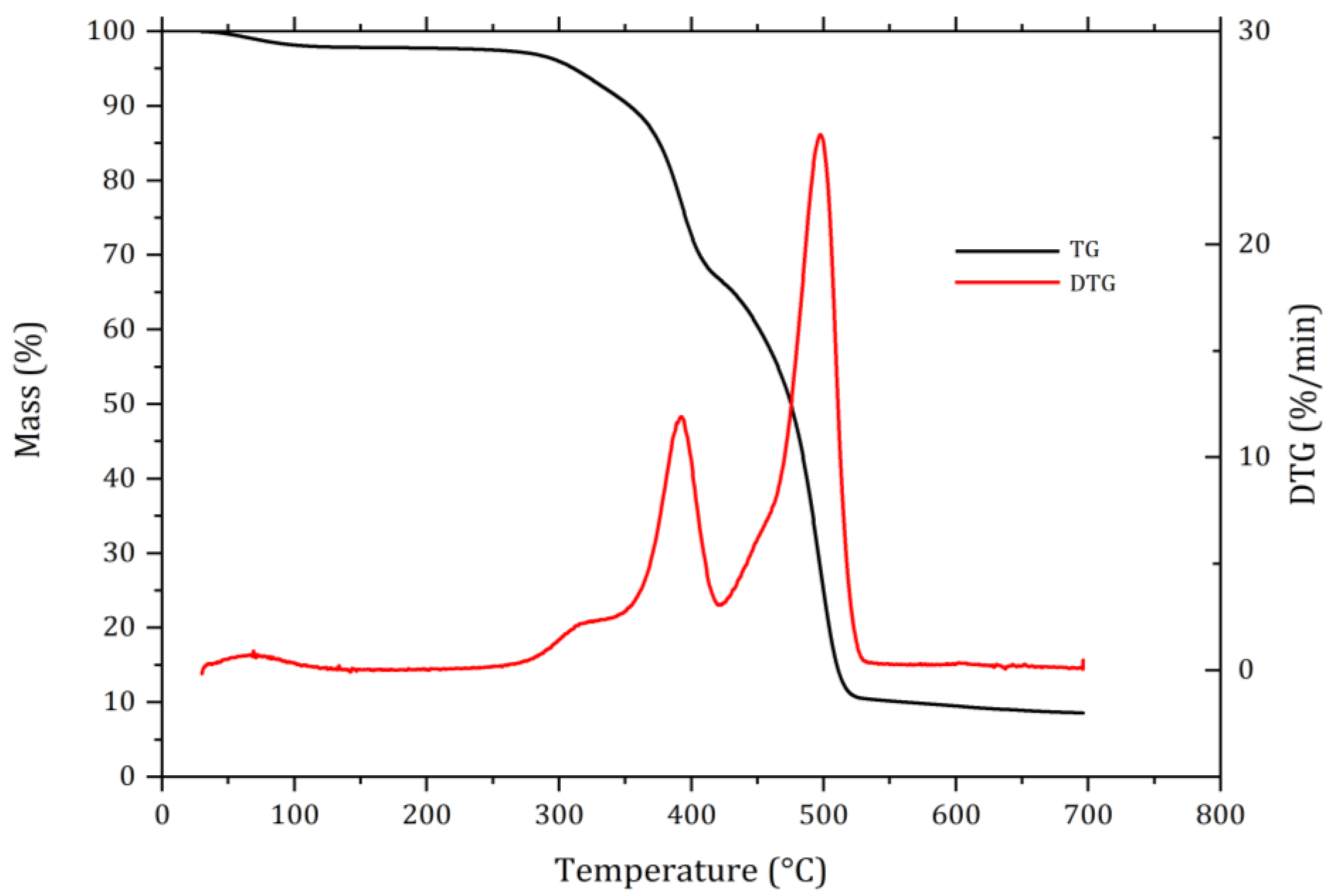

2.1. Thermogravimetric Analysis of Industrial Waste

2.2. Manufacture of Composites

2.3. Natural Aging

2.4. Accelerated Aging

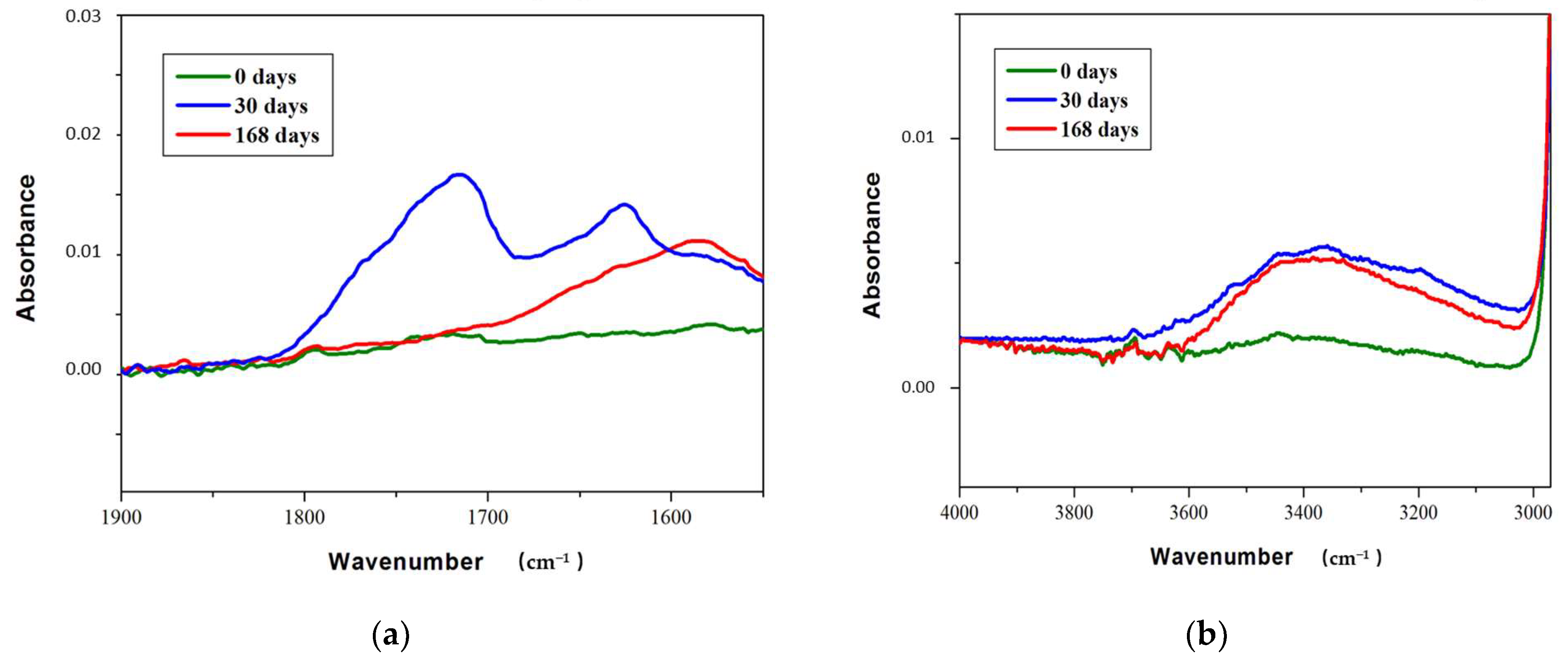

2.5. Infrared Spectroscopy

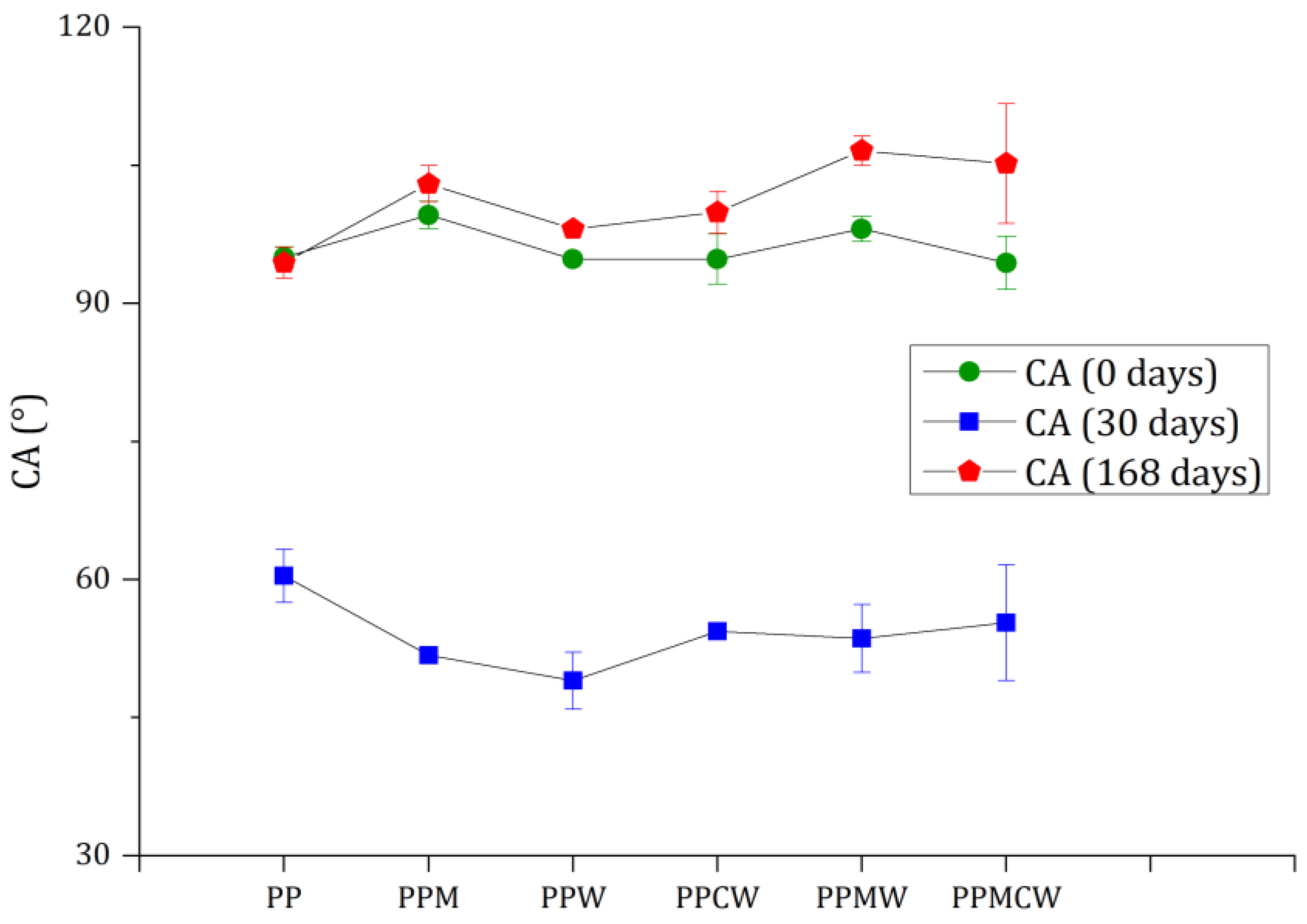

2.6. Contact Angle Measurements

2.7. Tensile Tests

3. Results and Discussion

3.1. Thermal Stability of Industrial Waste

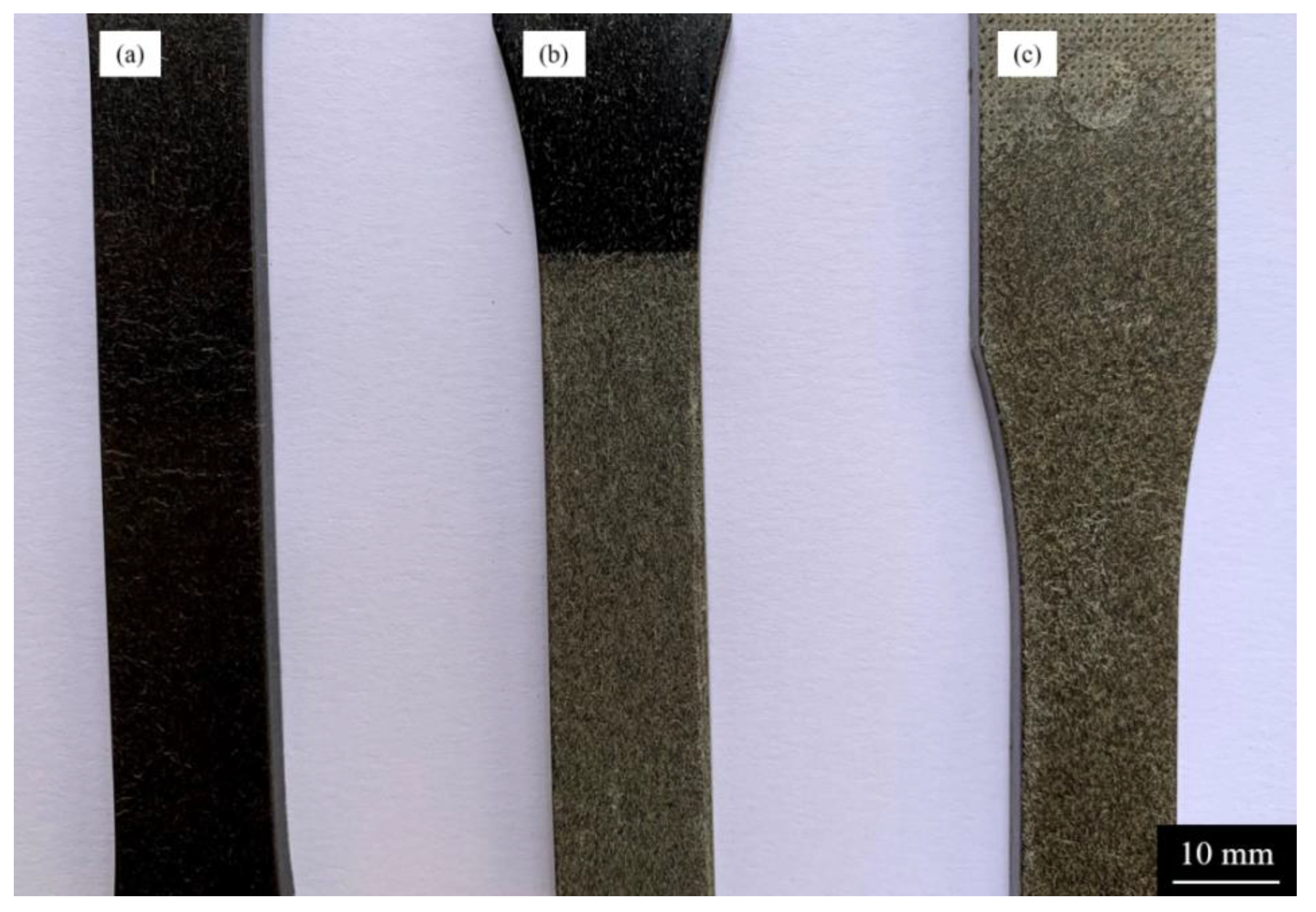

3.2. Visual Non-Destructive Test

3.3. Infrared Spectroscopy

3.4. Wettability

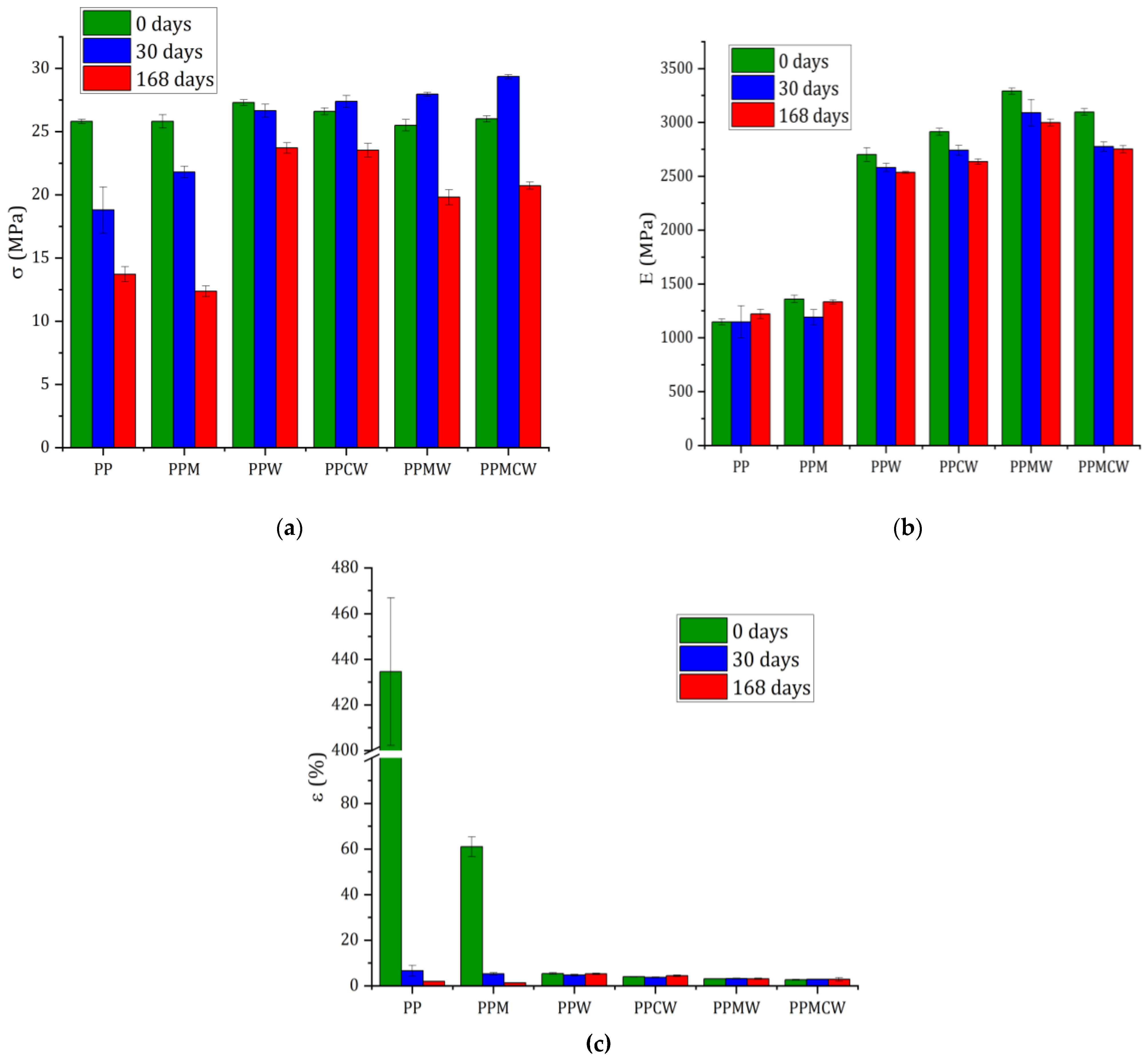

3.5. Tensile Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Global Market Insights Global Market Insights. Gmi 2016, 104. Available online: https://www.gminsights.com/industry-analysis/cellulose-fiber-market/ (accessed on 29 October 2021).

- Hassan, T.; Jamshaid, H.; Mishra, R.; Khan, M.Q.; Petru, M.; Novak, J.; Choteborsky, R.; Hromasova, M. Acoustic, mechanical and thermal properties of green composites reinforced with natural fiberswaste. Polymers 2020, 12, 654. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saad, M.; Agwa, I.S.; Abdelsalam Abdelsalam, B.; Amin, M. Improving the brittle behavior of high strength concrete using banana and palm leaf sheath fibers. Mech. Adv. Mater. Struct. 2020, 1–10. [Google Scholar] [CrossRef]

- Busuioceanu, I.I.; Enăchescu, G.-L.; Baciu, F.; Dinu, G.; Ştefănescu, M.F. Determination of mechanical behavior of new biocomposites. AIP Conf. Proc. 2018, 1932, 030004. [Google Scholar] [CrossRef]

- Bourmaud, A.; Shah, D.U.; Beaugrand, J.; Dhakal, H.N. Property changes in plant fibres during the processing of bio-based composites. Ind. Crops Prod. 2020, 154, 112705. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Madhu, P.; Jawaid, M.; Senthamaraikannan, P.; Senthil, S.; Pradeep, S. Characterization and properties of natural fiber polymer composites: A comprehensive review. J. Clean. Prod. 2018, 172, 566–581. [Google Scholar] [CrossRef]

- Prabhakaran, S.; Krishnaraj, V.; Senthil Kumar, M.; Zitoune, R. Sound and Vibration Damping Properties of Flax Fiber Reinforced Composites. Procedia Eng. 2014, 97, 573–581. [Google Scholar] [CrossRef] [Green Version]

- Sanjay, M.R.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C.I.; Khan, A. A comprehensive review of techniques for natural fibers as reinforcement in composites: Preparation, processing and characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Franciszczak, P.; Osman, Z.; Elbadawi, M. Polypropylene biocomposites reinforced with softwood, abaca, jute, and kenaf fibers. Ind. Crops Prod. 2015, 70, 91–99. [Google Scholar] [CrossRef]

- Fajardo Cabrera de Lima, P.F.C.; Santana, R.M.C.; Chamorro Rodríguez, C.D. Influence of Coupling Agent in Mechanical, Physical and Thermal Properties of Polypropylene/Bamboo Fiber Composites: Under Natural Outdoor Aging. Polymers 2020, 12, 929. [Google Scholar] [CrossRef] [PubMed]

- Vinod, A.; Sanjay, M.R.; Suchart, S.; Jyotishkumar, P. Renewable and sustainable biobased materials: An assessment on biofibers, biofilms, biopolymers and biocomposites. J. Clean. Prod. 2020, 258, 120978. [Google Scholar] [CrossRef]

- Wu, C.L.; Zhang, M.Q.; Rong, M.Z.; Friedrich, K. Tensile performance improvement of low nanoparticles filled-polypropylene composites. Compos. Sci. Technol. 2002, 62, 1327–1340. [Google Scholar] [CrossRef]

- Luthra, P.; Singh, R.; Kapur, G.S. Preparation and studies of pigeon pea stalk/polypropylene composites with and without compatibilizer. Polym. Polym. Compos. 2019, 27, 337–346. [Google Scholar] [CrossRef]

- Godara, A.; Raabe, D.; Bergmann, I.; Putz, R.; Muller, U. Influence of additives on the global mechanical behavior and the microscopic strain localization in wood reinforced polypropylene composites during tensile deformation investigated using digital image correlation. Compos. Sci. Technol. 2009, 69, 139–146. [Google Scholar] [CrossRef]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 1–14. [Google Scholar] [CrossRef]

- Sanvezzo, P.B.; Branciforti, M.C. Recycling of industrial waste based on jute fiber-polypropylene: Manufacture of sustainable fiber-reinforced polymer composites and their characterization before and after accelerated aging. Ind. Crops Prod. 2021, 168, 113568. [Google Scholar] [CrossRef]

- Cobra, R.; Sanvezzo, P.; Branciforti, M.; Mascarenhas, J. Circular technology roadmapping (TRM): Fostering sustainable material development. Sustainability 2021, 13, 7036. [Google Scholar] [CrossRef]

- de Castro Negreiros, F.P.; Sanvezzo, P.B.; Branciforti, M.C. Propriedades de compósitos fabricados com resíduo industrial, projeto e prospecção de custo de produção de mobiliário urbano com conceito de economia circular. In A Química nas Áreas Natural, Tecnológica e Sustentável; Atena Editora: Ponta Grossa, Brazil, 2020; pp. 258–276. [Google Scholar]

- Brebu, M.; Vasile, C. Thermal degredation of Lignin-A Review. Cellul. Chem. Technol. 2010, 44, 353–363. [Google Scholar] [CrossRef]

- Yao, F.; Wu, Q.; Lei, Y.; Guo, W.; Xu, Y. Thermal decomposition kinetics of natural fibers: Activation energy with dynamic thermogravimetric analysis. Polym. Degrad. Stab. 2008, 93, 90–98. [Google Scholar] [CrossRef]

- Philippart, J.-L.; Sinturel, C.; Arnaud, R.; Gardette, J.-L. Influence of the exposure parameters on the mechanism of photooxidation of polypropylene. Polym. Degrad. Stab. 1999, 2, 213–225. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, H.; Chan, C.M.; Wu, J. Effects of coating amount and particle concentration on the impact toughness of polypropylene/CaCO3 nanocomposites. Eur. Polym. J. 2011, 47, 294–304. [Google Scholar] [CrossRef]

| Sample | PP (wt.%) | W (wt.%) | N (wt.%) | C (wt.%) |

|---|---|---|---|---|

| PP | 100 | - | - | - |

| PPM | 90 | - | 10 | - |

| PPW | 50 | 50 | - | - |

| PPCW | 49 | 50 | - | 1 |

| PPMW | 40 | 50 | 10 | - |

| PPMCW | 39 | 50 | 10 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanvezzo, P.B.; Negreiros, F.P.d.C.; Branciforti, M.C. Degradation of Polypropylene and Jute Fiber-Reinforced Composites Exposed to Natural and Accelerated Aging: Mechanical Properties and Wettability. Chemistry 2021, 3, 1392-1400. https://doi.org/10.3390/chemistry3040100

Sanvezzo PB, Negreiros FPdC, Branciforti MC. Degradation of Polypropylene and Jute Fiber-Reinforced Composites Exposed to Natural and Accelerated Aging: Mechanical Properties and Wettability. Chemistry. 2021; 3(4):1392-1400. https://doi.org/10.3390/chemistry3040100

Chicago/Turabian StyleSanvezzo, Paula Bertolino, Fernanda Pereira de Castro Negreiros, and Marcia Cristina Branciforti. 2021. "Degradation of Polypropylene and Jute Fiber-Reinforced Composites Exposed to Natural and Accelerated Aging: Mechanical Properties and Wettability" Chemistry 3, no. 4: 1392-1400. https://doi.org/10.3390/chemistry3040100

APA StyleSanvezzo, P. B., Negreiros, F. P. d. C., & Branciforti, M. C. (2021). Degradation of Polypropylene and Jute Fiber-Reinforced Composites Exposed to Natural and Accelerated Aging: Mechanical Properties and Wettability. Chemistry, 3(4), 1392-1400. https://doi.org/10.3390/chemistry3040100