Artificial Intelligence Applications for MEMS-Based Sensors and Manufacturing Process Optimization

Abstract

1. Introduction

2. MEMS Background

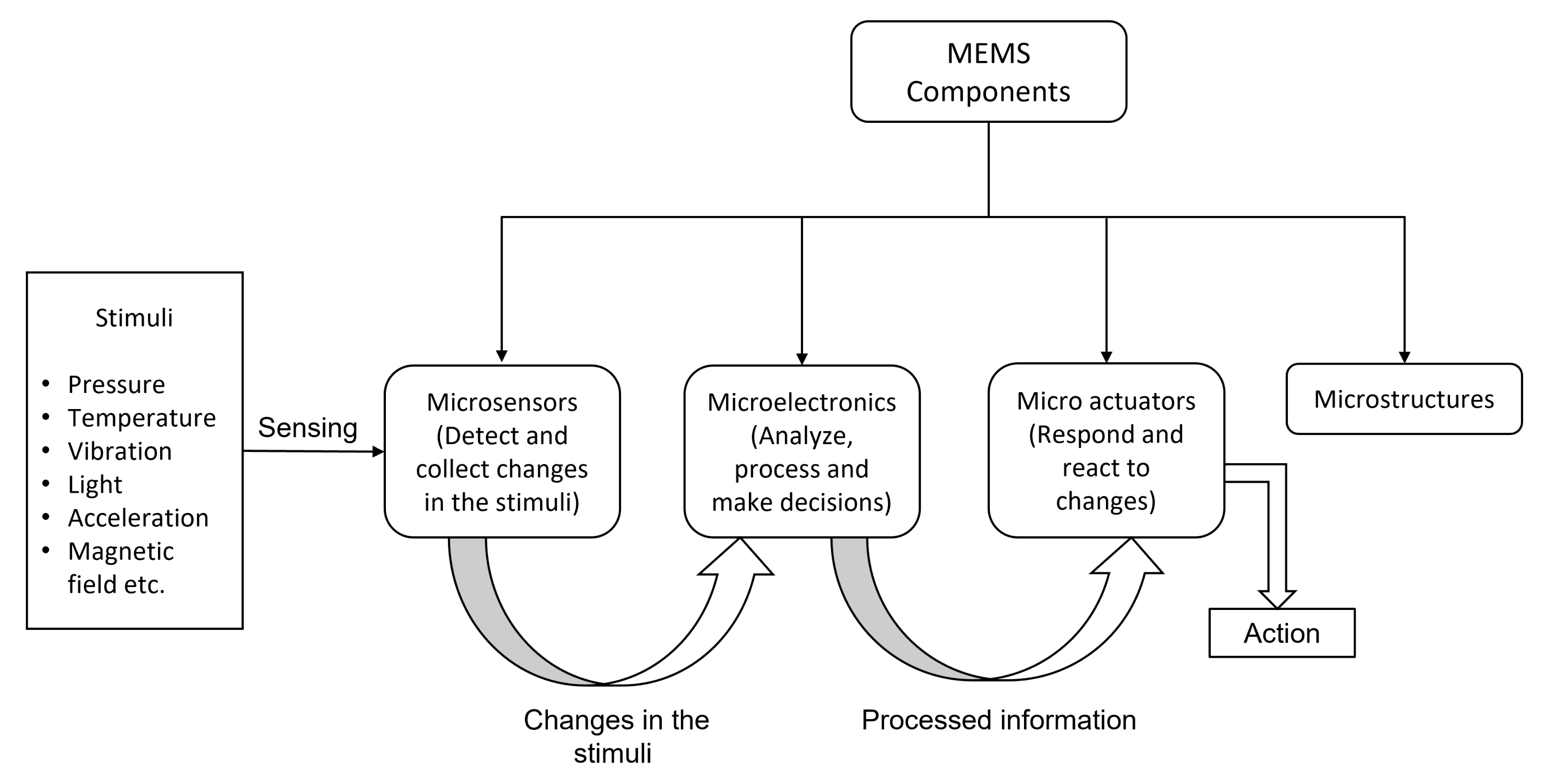

2.1. MEMS Components

Types of MEMS Sensors and Applications

- Accelerometers

- Gyroscopes

- Pressure sensors

- Temperature sensors

- Inertial Measurement Units (IMU)

- Proximity sensors etc.

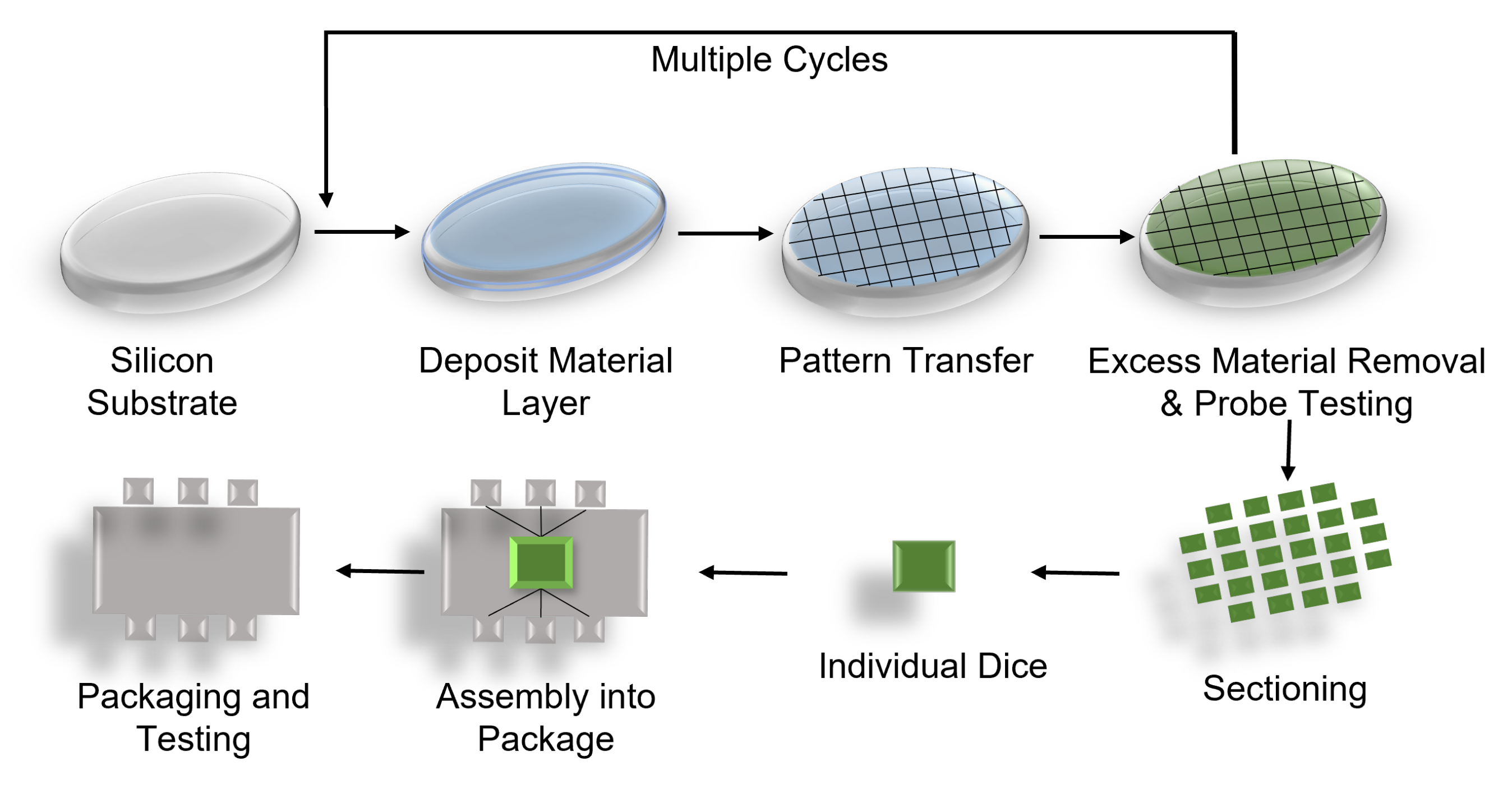

2.2. MEMS Manufacturing Process

- Type A defects: These types of defects are evenly random with a stable mean density. There is no repeated occurrence or visible systematic pattern, i.e., the probability of a dice being good or bad is equal. Thus, the root-cause analysis of such defects is not straightforward. Only an accurate and stable process can help reduce these kinds of defects.

- Type B defects: These types of defects are repeatable and of systematic pattern from wafer to wafer. These defects’ source can be generated from anomalies in the process or machine, such as mask induced or during the variation while applying films.

- Type C defects: The most common type of defect seen in semiconductor manufacturing is Type C defect, a combination of Type A and Type B defects. It is essential to eliminate random defects to recognize and eradicate systemic flaws. There can be multiple causes, such as structural defects coming from the raw material, asymmetrical presence of contaminants, irregular presence of defect generation particles, etc.

3. Research Methodology

3.1. Research Questions

- Q1: What are the most researched areas of AI implementation for MEMS sensors?

- Q2: What are the advantages of AI-based solutions compared to state-of-the-art ones?

- Q3: What are the open issues of incorporating AI-based solutions in the MEMS sensors production process? Does there exist any standardized framework to integrate AI solutions?

3.2. Search Strategy

- Articles in the MEMS sensor domain should be related to AI, ML, NN, CNN, etc.

- Publications until 2022, November, were considered.

- Original publications were selected.

- The publication language was restricted to English only.

- Duplicate works were rejected.

| Category | Sources |

|---|---|

| Databases | IEEEXplore, SpringerLink, ACM Digital Library, ScienceDirect, Elsevier, Web of Science, Google Scholar |

3.3. Search Result

4. Artificial Intelligence Application in MEMS System: Current Trends

4.1. AI Implementation Workflow

4.2. AI Application in MEMS-Based Sensors

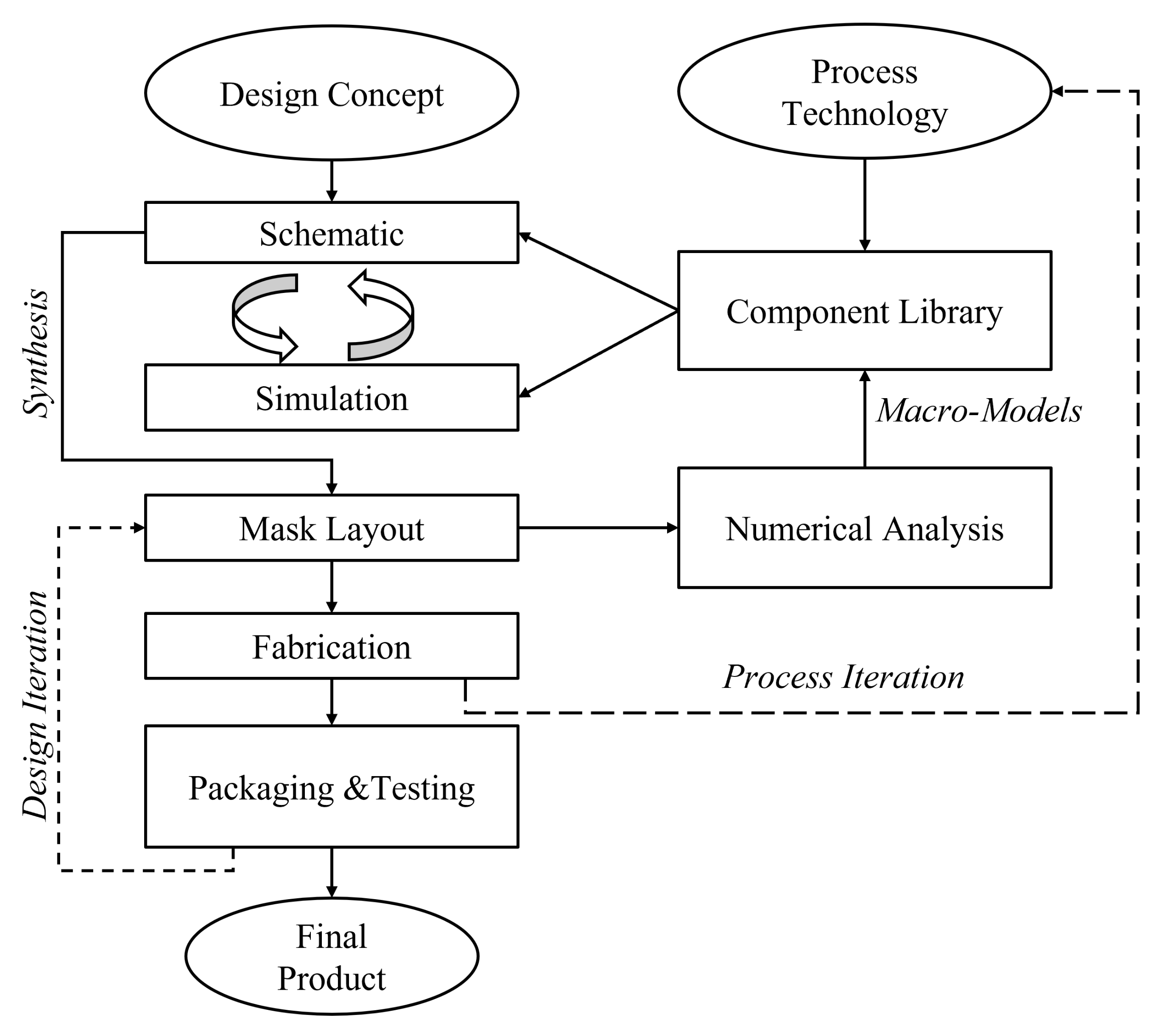

4.3. AI Applications in the MEMS Manufacturing and Design Process

5. Review Summary

- Year: The year of research publication.

- Algorithm Type: This refers to the subfields of AI used by researchers to conduct their analysis.

- Category: This refers to the types of the problem from the AI perspective, i.e., whether the problem was related to classification, regression, clustering, etc. It can be either one or multiple.

- Data Type: Types of data used for the algorithm, i.e., whether the data used to train the model were real or synthetic.

- Data Size: Total amount of data used to train, test, and validate the model’s performance.

- Problem Type: This refers to the goal of AI usage in MEMS sensors. It answers the question, ’Why was AI used?’. Some examples are thermal calibration, fault diagnosis, noise modeling, etc. All over, both product usage improvement and manufacturing process optimization are covered.

- MEMS Sensors: The types of MEMS data used for the analysis are described here, such as data retrieved from gyroscopes, accelerometers, etc. If the paper is related to MEMS design, this part refers to the process steps, such as FEA, simulation, and design for which AI was used.

- Key Findings: The main contribution of each article is highlighted here.

- Ref.: Reference to the related article analyzed.

| Year | Algorithm Type | Category | Data Type | Data Size | Problem Type | MEMS Sensor | Key Findings | Ref. |

|---|---|---|---|---|---|---|---|---|

| 2019 | MLP | Regression | Real | 153,000 | Conditional Maintenance | Accelerometer (MMA8452Q) | MLP was used to detect and predict motor failure for conditional-based maintenance. | [32] |

| 2022 | XGBoost, DT, SVM, GNB | Classification | Real | 1.5 million | Feature Estimation, FDD | IMU data | XGBoost classifier outperformed other tree based algorithms with 95% accuracy. | [34] |

| 2022 | KNN, DT, RF, Adaboost | Classification | Real | 993 | FDD | Accelerometers | RF achieved 100% accuracy compared to other algorithms used to detect leaks in the real pipe networks. | [35] |

| 2017 | NB, LR, Linear SVC, SGD | Classification | Real | 20,000 | Predictive Maintenance | Humidity Sensor | Intel Lab Data were used for this analysis to classify different humidity sensor data where GNB outperformed others. | [36] |

| 2018 | LSTM-RNN | Time-series | Real | 48,000 | Noise Modeling | Gyroscope (MEMS IMU MSI3200) | LSTM-RNN outperformed ARMA with an improvement of 42.3%, 21.4%, and 26.2% for the three-axis gyroscope. | [40] |

| 2019 | Mixed LSTM and GRU | Time Series | Real | 10,000 | Noise Modeling | Gyroscope | A mix of LSTM and GRU architecture was used for the three-axis MEMS gyroscope noise modeling, | [41] |

| 2019 | NAS-RNN | Time-Series | Real | 15 | Noise Modeling | Gyroscope (MEMS IMU STIM300) | The proposed NAS-RNN was used to de-noise and decrease the standard deviation of the three-axis gyroscope compared to the raw signal. NAS-RNN also outperformed LSTM-RNN. | [42] |

| 2018 | SRU-RNN | Time Series | Real | 10,000 | Noise Modeling | Gyroscope | A single-layer SRU-RNN was used to de-noise the three-axis MEMS gyroscope. | [43] |

| 2018 | BP-NN | Regression | Real | - | Thermal Calibration | Gyroscope | Alternate to the traditional polynomial fitting for temperature compensation, the BPNN increased the performance by 20%. | [44] |

| 2009 | BP-NN | Regression | Real | - | Thermal Calibration | Micro-gyroscope | For the temperature compensation, BP-NN was used, and an integral-separated PID (Proportion Integration Differentiation) system was used for the temperature control system design. | [45] |

| 2011 | BP-NN | Regression | Real | (−35 C)–(+80 C) temp. range | Temperature Drift Compensation | Gyroscope | The study aimed to understand the effect of temp. on gyroscope signal drift. | [47] |

| 2017 | RBF-NN | Function approximation | Real | - | Adaptive Control | Gyroscope | Fully tuned RBF-NN was proposed to remove model uncertainty and external disturbances. | [48] |

| 2017 | PSR, C-C, CPSO-LSSVM | Regression | Real | 15,000 | Temperature Drift Compensation | Gyroscope | MEMS gyroscope random drift reconstruction was performed using PSR and C-C method, which helps with dimensionality reduction. CSPO-LSSVM was used to model the MEMS gyroscope random drift that outperformed BP-ANN. | [49] |

| 2019 | GA, SVM | Regression | Real | 600 | Temperature Drift Compensation | Gyroscope | The temperature drift compensation of the gyroscope was performed using SVM that is optimized using GA. This is a simple, exquisite, and powerful solution. | [50] |

| 2020 | GA, BPNN | Regression | Real | 6360 | Temperature Drift Compensation | Accelerometer | BPNN, optimized using GA, performed 173 times better than traditional polynomial fitting for MEMS resonant accelerometer. | [51] |

| 2020 | IPSO-VMD, BP-Adaboost | Cluster, Regression | Real | (−32 C)–(+55 C) temp. range | Temperature Drift Compensation, Noise Modeling | Gyroscope | MEMS, gyroscope drift compensation, and de-noising were performed. The authors used IPSO-VMD to decompose the signal and discard the noise. | [52] |

| 2020 | CNN | Classification | Real & Synthetic | 42,368 (real) 20,000 (synthetic) | Monitoring System | Accelerometer & Gyroscope | Ground vibration monitoring system was proposed using CNN, which achieved 98.82% accuracy on synthetic data and an accuracy of 81.64% on real data. | [54] |

| 2020 | MLP, K-Means | Clustering, Time Series, Feature extraction | Real | 25,126 (static) 46,558 (dynamic) | Seismic Detection | Accelerometer | ANN model was used to detect earthquakes for both static and dynamic environments with low false alarms. | [55] |

| 2018 | ConvNet | Classification, Time Series | Real | 4.5 million | Seismic Phase Detection | Seismic Sensors | ConvNet was used for generalized phased detection of continuous seismic waves classified as P, S, or noise from a small to large range. | [56] |

| 2017 | CC-RCNN | Classification, Time Series | Real | 1000 | Seismic event Detection | Seismic Sensors | State-of-the-art 1D seismic data detection event-wise was proposed using robust CC-RCNN, which is inspired by the densely connected network. | [57] |

| 2021 | EQGAN | Regression | Real | 3600 | Data Augmentation | Accelerometer | Short Seismic wave data generation using unsupervised EQGAN (proposed), GAN, LSTM, and NN, where EQGAN achieved the highest performance, which is 81%. | [59] |

| 2020 | LSTM, CNN | Classification | Real | 9299 | Human Activity Recognition | Accelerometer, Gyroscope, Magnetometer, Light | Trained LSTM and CNN could recognize different activities such as walking, standing, and jogging with more than 90% accuracy. | [62] |

| 2015 | CNN | Classification, Feature extraction | Real | 169,335 | Human Activity Recognition | Mixed | CNN had superior performance with efficient feature extraction. | [64]. |

| 2020 | Multi-scale CNN | Classification | Real | 32,000 | FDD | MEMS Device Design | A fault diagnosis method where the time domain feature of faults occurring due to temperature was used. | [65] |

| 2018 | MLP, DWT | Classification, Function approximation, Feature extraction | Real & Synthetic | 1000 | FDD | Actuator | Fusion method to detect faults such as internal leakage, actuator leakage, and null bias current in the multi-functional spoiler system used in aircraft navigation. | [66] |

| 2017 | SSAE, DN | Classification, Signal reconstruction | Real | 12,000 | FDD | Accelerometer | SSAE-based DNN was used to overcome the dynamic and non-linear characteristics of the vibration signals by effectively extracting the features to detect faults in rotary machine bearing and identify the size of the cracks with an average accuracy of 100%. | [67] |

| 2014 | LS-SVM | Regression | Real | 50 | FDD | Pressure | LS-SVM was used for fault diagnosis using aircraft engine sensor data. | [68] |

| 2017 | SVM, PCA | Classification, Feature elimination | Synthetic | - | FDD | Gyroscope, Accelerometer | SVM was used to detect actuator faults of drones to ensure safe flight. | [69] |

| 2021 | Faster R-CNN Inception v2 COCO | Classification | Real | 419 | Surface defect | Light rays | Proposed automated defect recognition system can be used for both a single component or whole wafer at any stage of the production and assembly process. | [72] |

| 2007 | LVQ RHPNN | Classification | Real | - | FDD | Data Simulation | Improved fault detection and classification by combining LVQ with RHPNN. | [77] |

| 2022 | ADCNN | Classification | Real | 6707 | FDD | Pressure | An overall process was described to detect and classify defects of various sizes and scales using image analysis for pressure sensors chip packaging with a map of 92.39% and the defection mean accuracy was 97.2%. | [78] |

| 2021 | Transfer learning, DNN | Regression | Synthetic | 660 | FDD | Accelerometer | Transfer learning was used with DNN to detect faulty parameters that can be directly measured during MEMS manufacturing final tests. | [79] |

| 2001 | GHA | Time Series | Synthetic | 25 | MEMS Design | Modeling of micro-systems | Formulation of the dynamic behavior using GHA for model reduction to analyze transient system behaviors. | [82] |

| 2000 | NN | Regression | Real | 787 | MEMS Design | Microengine failure data | Reliability estimation to guide MEMS process development using NN, which can provide insights into different phases, such as fabrication, packaging, etc. | [84] |

| 2022 | DL | Regression | Synthetic | 29,984 | MEMS Design | FEA | DL-based model to effectively, quickly, and accurately predict MEMS structural design pattern. The data were captured from MEMS resonators. | [85] |

| 2020 | Transfer learning, Faster R-CNN | Classification | Real | 25,464 | Surface Defect | Fabrication process | The authors proposed a classification-based approach for automatic inspection using CNN models to identify the wafer surface defects with an accuracy ranging from 98% to 99%. | [86] |

| 2018 | RGRN and DSCN | Classification | Real and Synthetic | - | Surface Defect | Fabrication process | The authors proposed deep ML-based model to find mixed and single pattern defects separately with an overall accuracy of 86.17%. | [88] |

| 2005 | EASYMEMS | - | - | - | MEMS Design | Simulation and Design | A computer-based expert system for design suggestion to the engineers. It supports both the dynamic and static analysis of MEMS. | [90] |

| 2021 | Resnet | Classification | Synthetic | 11,250 | MEMS Design | FEA | NN-based analyzer performed faster than the FEA computations in less than 1/4000 of the time with an accuracy of 98%. | [91] |

6. Discussion

6.1. Q1: What Are the Most Researched Areas of AI Implementation for MEMS Sensors?

6.2. Q2: What Are the Advantages of AI-Based Solutions Compared to State-of-the-Art Solutions?

- Hidden patterns, such as cross-correlation, in the data that are impossible with traditional methods can be discovered and visualized.

- Feature estimation can be enhanced in combination with traditional methods.

- Automated monitoring systems can be built for FDD and predictive maintenance without any human in the loop. This reduces manual error and improves process accuracy.

- Elimination of prior knowledge dependency.

- MEMS manufacturing process improvement by eliminating iterative calibration steps with AI predictions.

- In the case of MEMS manufacturing, the sensing element fabrication process is subjected to different kinds of failures. AI methods can accurately perform image classification. it has proven to be useful for fault detection and recognizing substrate defects.

- Transfer learning helps apply previously gained knowledge to identify and detect features related to defects before the final test.

- AI-based models can replace conventional design tools such as FEA for predicting MEMS structural design steps with higher accuracy in less time.

- Overall, time-saving and process optimization can be achieved by incorporating AI.

6.3. Q3: What Are the Open Issues of Incorporating AI-Based Solutions in the MEMS Production Process? Does There Exist Any Standardized Framework to Integrate AI Solutions?

- Most AI-based algorithms are data-driven. A larger amount of data provides a better-trained and more robust model. Insufficient and unreliable data can degrade model performance during implementation.

- Data prepossessing is a crucial step to ensure data quality, i.e., the availability of labeled, noise-free data can ensure good training of the AI algorithm for higher accuracy. This can be a time-consuming and challenging task.

- More computational power is required compared to the traditional methods.

- Some algorithms suffer from over-fitting and bias.

- Explainability does not always exist.

- Plethora of algorithm availability can be challenging and cumbersome in finding the fitting solution.

- Cross-domain knowledge is required.

- Infrastructure compatibility poses one of the biggest challenges as sometimes small implementations may need huge changes in the production process, which can be time-consuming.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| MEMS | Micro-electromechanical Systems |

| IMU | Inertial Measurement Unit |

| FDD | Fault Detection and Diagnosis |

| RF | Random Forest |

| DT | Decision Tree |

| DL | Deep Learning |

| ML | Machine Learning |

| NN | Neural Network |

| DNN | Deep Neural Network |

| ANN | Artificial Neural Network |

| RNN | Recurrent Neural Network |

| LSTM | Long Short-Term Memory |

| CNN | Convolutional Neural Network |

| PCA | Principle Component Analysis |

| GAN | Generative adversarial networks |

References

- Shaeffer, D.K. MEMS inertial sensors: A tutorial overview. IEEE Commun. Mag. 2013, 51, 100–109. [Google Scholar] [CrossRef]

- Laermer, F. MEMS at Bosch — Invented for life. In Proceedings of the 2018 IEEE Micro Electro Mechanical Systems (MEMS), Belfast, UK, 21–25 January 2018; pp. 237–240. [Google Scholar] [CrossRef]

- Ru, X.; Gu, N.; Shang, H.; Zhang, H. MEMS Inertial Sensor Calibration Technology: Current Status and Future Trends. Micromachines 2022, 13, 879. [Google Scholar] [CrossRef] [PubMed]

- Martínez, J.; Asiain, D.; Beltrán, J.R. Lightweight thermal compensation technique for MEMS capacitive accelerometer oriented to quasi-static measurements. Sensors 2021, 21, 3117. [Google Scholar] [CrossRef] [PubMed]

- Łuczak, S.; Zams, M.; Dąbrowski, B.; Kusznierewicz, Z. Tilt Sensor with Recalibration Feature Based on MEMS Accelerometer. Sensors 2022, 22, 1504. [Google Scholar] [CrossRef]

- Aydemir, G.A.; Saranlı, A. Characterization and calibration of MEMS inertial sensors for state and parameter estimation applications. Measurement 2012, 45, 1210–1225. [Google Scholar] [CrossRef]

- Łuczak, S.; Zams, M.; Bagiński, K. Selected aging effects in triaxial MEMS accelerometers. J. Sens. 2019, 2019, 5184907. [Google Scholar]

- Maudie, T.; Hardt, A.; Nielsen, R.; Stanerson, D.; Bieschke, R.; Miller, M. MEMS manufacturing testing: An accelerometer case study. In Proceedings of the International Test Conference, Charlotte, NC, USA, 28 September–3 October 2003; pp. 843–849. [Google Scholar]

- Eloy, J.C.; Mounier, E. Status of the MEMS industry. In MEMS/MOEMS Components and Their Applications, II; SPIE: Bellingham, WA, USA, 2005; Volume 5717, pp. 43–49. [Google Scholar]

- Lawes, R. Manufacturing costs for microsystems/MEMS using high aspect ratio microfabrication techniques. Microsyst. Technol. 2007, 13, 85–95. [Google Scholar] [CrossRef]

- Global MEMS Market Revenues by Industry 2014–2024. Available online: https://www.statista.com/statistics/796333/worldwide-mems-market-revenues-by-revenue/ (accessed on 16 November 2022).

- Strong, A. Applications of artificial intelligence & associated technologies. In Proceedings of the International Conference on Emerging Technologies in Engineering, Biomedical, Management and Science [ETEBMS-2016], Jodhpur, India, 5–6 March 2016; Volume 5. [Google Scholar]

- Beck, J.; Stern, M.; Haugsjaa, E. Applications of AI in Education. XRDS Crossroads ACM Mag. Stud. 1996, 3, 11–15. [Google Scholar] [CrossRef]

- Smith, R.G.; Eckroth, J. Building AI applications: Yesterday, today, and tomorrow. AI Mag. 2017, 38, 6–22. [Google Scholar] [CrossRef]

- Chan, K.Y.; Yuen, K.K.F.; Palade, V.; Yue, Y. Artificial intelligence techniques in product engineering. Eng. Appl. Artif. Intell. 2015. [Google Scholar] [CrossRef]

- Regona, M.; Yigitcanlar, T.; Xia, B.; Li, R. Opportunities and Adoption Challenges of AI in the Construction Industry: A PRISMA Review. J. Open Innov. Technol. Mark. Complex. 2022, 8, 45. [Google Scholar] [CrossRef]

- Allen, J.J. Introduction to MEMS (MicroElectroMechanical Systems); Technical Report; Sandia National Lab. (SNL-NM): Albuquerque, NM, USA, 2007. [Google Scholar]

- MEMS Sensor Market Outlook (2022-2032). Available online: https://www.factmr.com/report/4528/mems-sensor-market (accessed on 18 November 2022).

- Tai, Y.C. Introduction to MEMS. In Microsystems and Nanotechnology; Zhou, Z., Wang, Z., Lin, L., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 187–206. [Google Scholar] [CrossRef]

- Malayappan, B.; Lakshmi, U.P.; Rao, B.P.; Ramaswamy, K.; Pattnaik, P.K. Sensing Techniques and Interrogation Methods in Optical MEMS Accelerometers: A Review. IEEE Sens. J. 2022, 22, 6232–6246. [Google Scholar] [CrossRef]

- Zhai, Y.; Li, H.; Tao, Z.; Cao, X.; Yang, C.; Che, Z.; Xu, T. Design, fabrication and test of a bulk SiC MEMS accelerometer. Microelectron. Eng. 2022, 260, 111793. [Google Scholar] [CrossRef]

- Passaro, V.M.; Cuccovillo, A.; Vaiani, L.; De Carlo, M.; Campanella, C.E. Gyroscope technology and applications: A review in the industrial perspective. Sensors 2017, 17, 2284. [Google Scholar] [CrossRef] [PubMed]

- Saile, V.; Wallrabe, U.; Tabata, O.; Korvink, J.G. LIGA and Its Applications; Hoboken, NJ, USA, 2009; Volume 7. [Google Scholar]

- Su, Y.C.; Lin, L. MEMS Design. In Microsystems and Nanotechnology; Zhou, Z., Wang, Z., Lin, L., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 261–285. [Google Scholar] [CrossRef]

- Fan, Z.; Seo, K.; Hu, J.; Rosenberg, R.C.; Goodman, E.D. System-level synthesis of MEMS via genetic programming and bond graphs. In Proceedings of the Genetic and Evolutionary Computation Conference, Chicago, IL, USA, 12–16 July 2003; pp. 2058–2071. [Google Scholar]

- Antonsson, E.; Cavallaro, J.; Mcnc, R.; Ann, M.; Intellisense, F. Structured Design Methods for MEMS Final Report; California Inst. Technology: Pasadena, CA, USA, 1997. [Google Scholar]

- Pattanaik, P.; Ojha, M. Review on challenges in MEMS technology. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Qin, Y.; Brockett, A.; Ma, Y.; Razali, A.; Zhao, J.; Harrison, C.; Pan, W.; Dai, X.; Loziak, D. Micro-manufacturing: Research, technology outcomes and development issues. Int. J. Adv. Manuf. Technol. 2010, 47, 821–837. [Google Scholar] [CrossRef]

- Kaempf, U. The binomial test: A simple tool to identify process problems. IEEE Trans. Semicond. Manuf. 1995, 8, 160–166. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; The PRISMA Group. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. Ann. Intern. Med. 2009, 151, 264–269. [Google Scholar] [CrossRef]

- World Intellectual Property Organization. WIPO IP Portal. Available online: https://patentscope.wipo.int/ (accessed on 11 October 2012).

- Scalabrini Sampaio, G.; Vallim Filho, A.R.d.A.; Santos da Silva, L.; Augusto da Silva, L. Prediction of motor failure time using an artificial neural network. Sensors 2019, 19, 4342. [Google Scholar] [CrossRef]

- Çınar, Z.M.; Abdussalam Nuhu, A.; Zeeshan, Q.; Korhan, O.; Asmael, M.; Safaei, B. Machine learning in predictive maintenance towards sustainable smart manufacturing in industry 4.0. Sustainability 2020, 12, 8211. [Google Scholar] [CrossRef]

- Podder, I.; Fischl, T.; Bub, U. Smart Feature Selection for Fault Detection in the MEMS Sensor Production Process Using Machine Learning Methods. In Proceedings of the 2nd International Conference on Industry 4.0 and Artificial Intelligence (ICIAI 2021), Sousse, Tunisia, 29–31 May 2022; pp. 21–25. [Google Scholar]

- Tariq, S.; Bakhtawar, B.; Zayed, T. Data-driven application of MEMS-based accelerometers for leak detection in water distribution networks. Sci. Total Environ. 2022, 809, 151110. [Google Scholar] [CrossRef]

- Gupta, S.; Mittal, M.; Padha, A. Predictive analytics of sensor data based on supervised machine learning algorithms. In Proceedings of the 2017 International Conference on Next Generation Computing and Information Systems (ICNGCIS), Jammu, India, 11–12 December 2017; pp. 171–176. [Google Scholar]

- Li, K.Q.; Liu, Y.; Kang, Q. Estimating the thermal conductivity of soils using six machine learning algorithms. Int. Commun. Heat Mass Transf. 2022, 136, 106139. [Google Scholar] [CrossRef]

- Li, K.Q.; Kang, Q.; Nie, J.Y.; Huang, X.W. Artificial neural network for predicting the thermal conductivity of soils based on a systematic database. Geothermics 2022, 103, 102416. [Google Scholar] [CrossRef]

- Shen, S.L.; Zhang, N.; Zhou, A.; Yin, Z.Y. Enhancement of neural networks with an alternative activation function tanhLU. Expert Syst. Appl. 2022, 199, 117181. [Google Scholar] [CrossRef]

- Jiang, C.; Chen, S.; Chen, Y.; Zhang, B.; Feng, Z.; Zhou, H.; Bo, Y. A MEMS IMU de-noising method using long short term memory recurrent neural networks (LSTM-RNN). Sensors 2018, 18, 3470. [Google Scholar] [CrossRef] [PubMed]

- Jiang, C.; Chen, Y.; Chen, S.; Bo, Y.; Li, W.; Tian, W.; Guo, J. A mixed deep recurrent neural network for MEMS gyroscope noise suppressing. Electronics 2019, 8, 181. [Google Scholar] [CrossRef]

- Zhu, Z.; Bo, Y.; Jiang, C. A MEMS gyroscope noise suppressing method using neural architecture search neural network. Math. Probl. Eng. 2019, 2019, 5491243. [Google Scholar] [CrossRef]

- Jiang, C.; Chen, S.; Chen, Y.; Bo, Y.; Han, L.; Guo, J.; Feng, Z.; Zhou, H. Performance analysis of a deep simple recurrent unit recurrent neural network (SRU-RNN) in MEMS gyroscope de-noising. Sensors 2018, 18, 4471. [Google Scholar] [CrossRef]

- Fontanella, R.; Accardo, D.; Moriello, R.S.L.; Angrisani, L.; De Simone, D. MEMS gyros temperature calibration through artificial neural networks. Sens. Actuators Phys. 2018, 279, 553–565. [Google Scholar] [CrossRef]

- Xia, D.; Chen, S.; Wang, S.; Li, H. Temperature effects and compensation-control methods. Sensors 2009, 9, 8349–8376. [Google Scholar] [CrossRef]

- Zhang, Q.; Tan, Z.; Guo, L. Compensation of temperature drift of MEMS gyroscope using BP neural network. In Proceedings of the 2009 International Conference on Information Engineering and Computer Science, Wuhan, China, 9–20 December 2009; pp. 1–4. [Google Scholar]

- Shiau, J.K.; Ma, D.M.; Huang, C.X.; Chang, M.Y. MEMS gyroscope null drift and compensation based on neural network. In Proceedings of the Advanced Materials Research. Trans. Tech. Publ. 2011, 255, 2077–2081. [Google Scholar]

- Fei, J.; Wu, D. Adaptive control of MEMS gyroscope using fully tuned RBF neural network. Neural Comput. Appl. 2017, 28, 695–702. [Google Scholar] [CrossRef]

- Xing, H.; Hou, B.; Lin, Z.; Guo, M. Modeling and compensation of random drift of MEMS gyroscopes based on least squares support vector machine optimized by chaotic particle swarm optimization. Sensors 2017, 17, 2335. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, Y.; Liu, Y.; Zhao, X. Temperature compensation of MEMS gyroscope based on support vector machine optimized by GA. In Proceedings of the 2019 IEEE Symposium Series on Computational Intelligence (SSCI), Xiamen, China, 6–9 December 2019; pp. 2989–2994. [Google Scholar]

- Wang, S.; Zhu, W.; Shen, Y.; Ren, J.; Gu, H.; Wei, X. Temperature compensation for MEMS resonant accelerometer based on genetic algorithm optimized backpropagation neural network. Sens. Actuators A Phys. 2020, 316, 112393. [Google Scholar] [CrossRef]

- Ma, T.; Cao, H.; Shen, C. A temperature error parallel processing model for MEMS gyroscope based on a novel fusion algorithm. Electronics 2020, 9, 499. [Google Scholar] [CrossRef]

- Suykens, J.A.; Vandewalle, J. Least squares support vector machine classifiers. Neural Process. Lett. 1999, 9, 293–300. [Google Scholar] [CrossRef]

- Kang, J.M.; Kim, I.M.; Lee, S.; Ryu, D.W.; Kwon, J. A Deep CNN-Based Ground Vibration Monitoring Scheme for MEMS Sensed Data. IEEE Geosci. Remote Sens. Lett. 2020, 17, 347–351. [Google Scholar] [CrossRef]

- Khan, I.; Choi, S.; Kwon, Y.W. Earthquake detection in a static and dynamic environment using supervised machine learning and a novel feature extraction method. Sensors 2020, 20, 800. [Google Scholar] [CrossRef]

- Ross, Z.E.; Meier, M.A.; Hauksson, E.; Heaton, T.H. Generalized seismic phase detection with deep learningshort note. Bull. Seismol. Soc. Am. 2018, 108, 2894–2901. [Google Scholar] [CrossRef]

- Wu, Y.; Lin, Y.; Zhou, Z.; Bolton, D.C.; Liu, J.; Johnson, P. DeepDetect: A cascaded region-based densely connected network for seismic event detection. IEEE Trans. Geosci. Remote Sens. 2018, 57, 62–75. [Google Scholar] [CrossRef]

- Wang, J.; Teng, T.l. Identification and picking of S phase using an artificial neural network. Bull. Seismol. Soc. Am. 1997, 87, 1140–1149. [Google Scholar] [CrossRef]

- Wu, A.; Shin, J.; Ahn, J.K.; Kwon, Y.W. Augmenting Seismic Data Using Generative Adversarial Network for Low-Cost MEMS Sensors. IEEE Access 2021, 9, 167140–167153. [Google Scholar] [CrossRef]

- Fan, L.; Wang, Z.; Wang, H. Human Activity Recognition Model Based on Decision Tree. In Proceedings of the 2013 International Conference on Advanced Cloud and Big Data, Nanjing, China, 13–15 December 2013; pp. 64–68. [Google Scholar] [CrossRef]

- Nweke, H.F.; Teh, Y.W.; Al-Garadi, M.A.; Alo, U.R. Deep learning algorithms for human activity recognition using mobile and wearable sensor networks: State of the art and research challenges. Expert Syst. Appl. 2018, 105, 233–261. [Google Scholar] [CrossRef]

- Ye, J.; Li, X.; Zhang, X.; Zhang, Q.; Chen, W. Deep learning-based human activity real-time recognition for pedestrian navigation. Sensors 2020, 20, 2574. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Shirahama, K.; Nisar, M.A.; Köping, L.; Grzegorzek, M. Comparison of feature learning methods for human activity recognition using wearable sensors. Sensors 2018, 18, 679. [Google Scholar] [CrossRef]

- Yang, J.; Nguyen, M.N.; San, P.P.; Li, X.L.; Krishnaswamy, S. Deep convolutional neural networks on multichannel time series for human activity recognition. In Proceedings of the Twenty-Fourth International Joint Conference on Artificial Intelligence, Buenos Aires, Argentina, 25–31 July 2015. [Google Scholar]

- Gao, T.; Sheng, W.; Zhou, M.; Fang, B.; Zheng, L. MEMS inertial sensor fault diagnosis using a cnn-based data-driven method. Int. J. Pattern Recognit. Artif. Intell. 2020, 34, 2059048. [Google Scholar] [CrossRef]

- Kordestani, M.; Samadi, M.F.; Saif, M.; Khorasani, K. A new fault diagnosis of multifunctional spoiler system using integrated artificial neural network and discrete wavelet transform methods. IEEE Sens. J. 2018, 18, 4990–5001. [Google Scholar] [CrossRef]

- Sohaib, M.; Kim, C.H.; Kim, J.M. A hybrid feature model and deep-learning-based bearing fault diagnosis. Sensors 2017, 17, 2876. [Google Scholar] [CrossRef]

- Zhu, T.B.; Lu, F. A Data-Driven Method of Engine Sensor on Line Fault Diagnosis and Recovery. Appl. Mech. Mater. 2014, 490, 1657–1660. [Google Scholar] [CrossRef]

- Baskaya, E.; Bronz, M.; Delahaye, D. Fault detection & diagnosis for small UAVs via machine learning. In Proceedings of the 2017 IEEE/AIAA 36th Digital Avionics Systems Conference (DASC), St. Petersburg, FL, USA, 17–21 September 2017; pp. 1–6. [Google Scholar]

- Ding, X.; He, Q. Energy-fluctuated multiscale feature learning with deep convnet for intelligent spindle bearing fault diagnosis. IEEE Trans. Instrum. Meas. 2017, 66, 1926–1935. [Google Scholar] [CrossRef]

- Lu, C.; Wang, Z.; Zhou, B. Intelligent fault diagnosis of rolling bearing using hierarchical convolutional network based health state classification. Adv. Eng. Inform. 2017, 32, 139–151. [Google Scholar] [CrossRef]

- Amini, A.; Kanfoud, J.; Gan, T.H. An Artificial-Intelligence-Driven Predictive Model for Surface Defect Detections in Medical MEMS. Sensors 2021, 21, 6141. [Google Scholar] [CrossRef] [PubMed]

- Kotzar, G.; Freas, M.; Abel, P.; Fleischman, A.; Roy, S.; Zorman, C.; Moran, J.M.; Melzak, J. Evaluation of MEMS materials of construction for implantable medical devices. Biomaterials 2002, 23, 2737–2750. [Google Scholar] [CrossRef] [PubMed]

- Maluf, N.I.; Kovacs, G.; Gee, D. Recent advances in medical applications of MEMS. In Proceedings of the Wescon/96, Anaheim, CA, USA, 22–24 October 1996; pp. 60–63. [Google Scholar]

- Vashistha, R.; Chhabra, D.; Shukla, P. Integrated artificial intelligence approaches for disease diagnostics. Indian J. Microbiol. 2018, 58, 252–255. [Google Scholar] [CrossRef] [PubMed]

- Yadav, D.; Garg, R.K.; Chhabra, D.; Yadav, R.; Kumar, A.; Shukla, P. Smart diagnostics devices through artificial intelligence and mechanobiological approaches. 3 Biotech 2020, 10, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Asgary, R.; Mohammadi, K.; Zwolinski, M. Using neural networks as a fault detection mechanism in MEMS devices. Microelectron. Reliab. 2007, 47, 142–149. [Google Scholar] [CrossRef]

- Deng, M.; Zhang, Q.; Zhang, K.; Li, H.; Zhang, Y.; Cao, W. A Novel Defect Inspection System Using Convolutional Neural Network for MEMS Pressure Sensors. J. Imaging 2022, 8, 268. [Google Scholar] [CrossRef]

- Heringhaus, M.E.; Müller, J.; Messner, D.; Zimmermann, A. Transfer Learning for Test Time Reduction of Parameter Extraction in MEMS Accelerometers. J. Microelectromechanical Syst. 2021, 30, 401–410. [Google Scholar] [CrossRef]

- Bajaj, N.; Patange, A.; R, J.; Kulkarni, K.; Ghatpande, R.; Kapadnis, A. A Bayesian Optimized Discriminant Analysis Model for Condition Monitoring of Face Milling Cutter Using Vibration Datasets. J. Nondestruct. Eval. Diagn. Progn. Eng. Syst. 2021, 5, 1–12. [Google Scholar] [CrossRef]

- Patange, A.; R, J.; Bajaj, N.; Khairnar, A.; Gavade, N. Application of Machine Learning for Tool Condition Monitoring in Turning. Sound Vib. 2022, 56, 127–145. [Google Scholar] [CrossRef]

- Liang, Y.; Lin, W.; Lee, H.; Lim, S.; Lee, K.; Feng, D. A neural-network-based method of model reduction for the dynamic simulation of MEMS. J. Micromechanics Microeng. 2001, 11, 226. [Google Scholar] [CrossRef]

- Sanger, T.D. Optimal unsupervised learning in a single-layer linear feedforward neural network. Neural Netw. 1989, 2, 459–473. [Google Scholar] [CrossRef]

- Perera, J.S. Reliability Modeling of Micro-Electromechanical Systems Using Neural Networks; University of Houston: Houston, TX, USA, 2000. [Google Scholar]

- Guo, R.; Sui, F.; Yue, W.; Wang, Z.; Pala, S.; Li, K.; Xu, R.; Lin, L. Deep learning for non-parameterized MEMS structural design. Microsyst. Nanoeng. 2022, 8, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Chien, J.C.; Wu, M.T.; Lee, J.D. Inspection and classification of semiconductor wafer surface defects using CNN deep learning networks. Appl. Sci. 2020, 10, 5340. [Google Scholar] [CrossRef]

- Raveendran, S.; Chandrasekhar, A. Inspecting and classifying physical failures in MEMS substrates during fabrication using computer vision. Microelectron. Eng. 2022, 254, 111696. [Google Scholar] [CrossRef]

- Tello, G.; Al-Jarrah, O.Y.; Yoo, P.D.; Al-Hammadi, Y.; Muhaidat, S.; Lee, U. Deep-structured machine learning model for the recognition of mixed-defect patterns in semiconductor fabrication processes. IEEE Trans. Semicond. Manuf. 2018, 31, 315–322. [Google Scholar] [CrossRef]

- Hoppensteadt, F.C.; Izhikevich, E.M. Synchronization of MEMS resonators and mechanical neurocomputing. IEEE Trans. Circuits Syst. I Fundam. Theory Appl. 2001, 48, 133–138. [Google Scholar] [CrossRef]

- Liu, T.I.; Oh, C. An artificial intelligence approach for the design and manufacturing of micro electro mechanical systems. Int. J. Knowl.-Based Intell. Eng. Syst. 2005, 9, 159–171. [Google Scholar] [CrossRef]

- Guo, R.; Xu, R.; Wang, Z.; Sui, F.; Lin, L. Accelerating MEMS design process through machine learning from pixelated binary images. In Proceedings of the 2021 IEEE 34th International Conference on Micro Electro Mechanical Systems (MEMS), Virtual, 25–29 January 2021; pp. 153–156. [Google Scholar]

- Steinkraus, D.; Buck, I.; Simard, P. Using GPUs for machine learning algorithms. In Proceedings of the Eighth International Conference on Document Analysis and Recognition (ICDAR’05), Seoul, Republic of Korea, 29 August–1 September 2005; pp. 1115–1120. [Google Scholar]

- Baldini, I.; Fink, S.J.; Altman, E. Predicting GPU Performance from CPU Runs Using Machine Learning. In Proceedings of the 2014 IEEE 26th International Symposium on Computer Architecture and High Performance Computing, Paris, France, 22–24 October 2014; pp. 254–261. [Google Scholar] [CrossRef]

- Mijwel, M.M. Artificial Neural Networks Advantages and Disadvantages, 2018. Available online: https//www.linkedin.com/pulse/artificial-neuralnet (accessed on 13 January 2023).

- Intel Lab Data, 2004. Available online: http://db.csail.mit.edu/labdata/labdata.html. (accessed on 19 February 2023).

- Kopáčik, A.; Kajánek, P.; Lipták, I. Systematic Error Elimination Using Additive Measurements and Combination of Two Low Cost IMSs. IEEE Sens. J. 2016, 16, 6239–6248. [Google Scholar] [CrossRef]

- Chung, J.; Gulcehre, C.; Cho, K.; Bengio, Y. Gated feedback recurrent neural networks. In Proceedings of the International Conference on Machine Learning. PMLR, Lille, France, 7–9 July 2015; pp. 2067–2075. [Google Scholar]

- Rofooei, F.; Aghababaie Mobarake, A.; Ahmadi, G. Generation of artificial earthquake records with a nonstationary Kanai–Tajimi model. Eng. Struct. 2001, 23, 827–837. [Google Scholar] [CrossRef]

- Center for Engineering Strong Motion Data. Available online: https://www.strongmotioncenter.org/ (accessed on 18 February 2023).

- Qingyi. WM-811K Wafer Map, Kaggle. Available online: https://www.kaggle.com/datasets/qingyi/wm811k-wafer-map (accessed on 18 February 2023).

- Figueira, A.; Vaz, B. Survey on synthetic data generation, evaluation methods and GANs. Mathematics 2022, 10, 2733. [Google Scholar] [CrossRef]

- Wirth, R.; Hipp, J. CRISP-DM: Towards a standard process model for data mining. In Proceedings of the 4th International Conference on the Practical Applications of Knowledge Discovery and Data Mining. Manchester, UK, 11–13 April 2000; Volume 1, pp. 29–39. [Google Scholar]

- SAS Help Center. Introduction to SEMMA. Available online: https://documentation.sas.com/doc/en/emref/14.3/n061bzurmej4j3n1jnj8bbjjm1a2.htm. (accessed on 19 February 2023).

- Fayyad, U.; Piatetsky-Shapiro, G.; Smyth, P. The KDD process for extracting useful knowledge from volumes of data. Commun. ACM 1996, 39, 27–34. [Google Scholar] [CrossRef]

- Mäkinen, S.; Skogström, H.; Laaksonen, E.; Mikkonen, T. Who needs MLOps: What data scientists seek to accomplish and how can MLOps help? In Proceedings of the 2021 IEEE/ACM 1st Workshop on AI Engineering-Software Engineering for AI (WAIN), Madrid, Spain, 30–31 May 2021; pp. 109–112. [Google Scholar]

- Alla, S.; Adari, S.K. What is mlops? In Beginning MLOps with MLFlow; Springer: Berkeley, CA, USA, 2021; pp. 79–124. [Google Scholar]

- Heuvel, W.J.v.d.; Tamburri, D.A. Model-driven ML-Ops for intelligent enterprise applications: Vision, approaches and challenges. In Proceedings of the International Symposium on Business Modeling and Software Design, Berlin, Germany, 6–8 July 2020; pp. 169–181. [Google Scholar]

| Sensor Types | Input Signal Type | Measured quantity |

|---|---|---|

| Physical | Mechanical, Electric, Magnetic, Optical, Thermal, etc. | Acceleration, Force, Pressure, Charge, Magnetic field |

| Chemical | Gas, Humidity, etc. | Toxic gases, Flammable gases, pH, H+, Metallic ions, etc. |

| Biological | Enzyme, Immuno, etc. | Glucose, Lactic acid, Protein, Virus, etc. |

| Ref. | Data Features and Attributes | Data Availability | Performance Metrics | Implemented AI Algorithm Advantage |

|---|---|---|---|---|

| [32] | Raw data were obtained from An Akasa AK-FN059 12 cm Viper cooling fan and an MMA8452Q accelerometer. Different vibration measurements were obtained with 3 weight distributions and 17 rotation speeds at a frequency of 20 ms for 1 min. | Public | RMSE | ANN-based MLP algorithms could efficiently model complex systems consisting of non-linear data. The benefits of MLP are easy implementation for large-scale problems, good generalizability, and provides efficient computation. |

| [34] | Data used were highly imbalanced. They contained information on yaw rate sensors, inertial sensors, process measurements, temperature measurements, and infrastructure measurements. | Confidential | ROC-curve, Precision, Recall, F1 Score | XGBoost Classifier could handle data imbalance efficiently. Tree-based feature importance helped with root-cause analysis, and production implementation was easy. |

| [35] | Five triple-axis MEMS-based accelerometers (model AX3D with a sensitivity of ±2 g) were used for collecting information on leak and no-leak in different pipe types. A high time synchronized data-collecting system from the manufacturer “Beanair” was utilized. SMOTE was used to balance the data. | Confidential | Accuracy, Precision, Recall, F1 Score, ROC | Ensemble-based algorithms provided a good performance on large data, and these are resilient to outliers providing an easy interpretation of results obtained. KNN is less prone to overfitting. |

| [36] | Monitored humidity data were collected from Intel indoor sensor data [95] for four different sensors. | Public | Accuracy | GNB achieved the highest accuracy 90%. The naive bayes-based algorithm is fast, does not require much training data, and is insensitive to irrelative features. |

| [40] | Data were collected from a MEMS IMU (MSI3200) manufactured by MT Microsystems Company, Shijiazhuang, China [96]. Raw static data contained three-axis gyroscope information (pitch, roll, yaw) and was noisy. | Public | Accuracy | LSTM-RNN performance was superior due to its effectiveness for time-series-related problems and better generation ability. |

| [41] | Three-axis gyroscope noisy data were collected from a MSI3200 MEMS IMU [97] containing pitch, roll, and yaw information. Training data were limited, and only static data were used. | Public | Attitude errors | Mixed deep recurrent neural networks outperformed two-layer long short-term memory recurrent neural networks and two-layer gated recurrent units with the benefits of faster convergence and quicker training procedure. |

| [42] | Three-axis gyroscope noisy data were collected from a MEMS IMU STIM300 to detect yaw, raw, and pitch error. The data availability was limited. | Public | Attitude errors | The advantages of NAS-RNN include superior sequence data processing, noise suppression, and efficient application-specific neural architecture. |

| [43] | The IMU data were composed of three-orthogonal gyroscopes and three-orthogonal accelerometers collected from a MEMS IMU MSI3200 manufactured by MT Microsystems Company. The length of the training data and the de-noising performance were traded off. The training was performed with a fixed learning rate and batch size. | Public | Attitude errors | DL has a better learning capacity than SVM or other NN. RNN always has better performance for time-series problems. |

| [44,45,47] | MEMS IMU consists of a triaxial accelerometer sensor, a triaxial gyroscope sensor, a triaxial magnetometer, and a temperature sensor. The data points were obtained at different temperature ranges for gyroscopes. | Confidential | Authors’ defined performance factor | BP-NN provided improved and adaptive polynomial fitting for detecting abrupt bias changes in small temperature change windows. |

| [48] | The aim was to have the mass proof follow the intended reference trajectory while estimating and compensating for unknown parameter errors and outside disturbances using the fully tuned RBF network. | Confidential | Authors’ defined error tracking | To account for the impact of external disturbances and model errors, an adaptive, stable, and fully tuned RBF neural network controller was used as it provides non-linear approximation and adaptive nominal control. Further, it enhanced the MEMS gyroscope’s dynamic properties and robustness. |

| [49] | Three-axis MEMS IMU was used, and the X-axis gyroscope was analyzed. Wavelet filtering was used to remove the noise. The data type was chaotic time series. The dimension of the data was improved one-dimensional time series into an auxiliary phase space using PSR. | Confidential | MAE, RMSE, ARE | Combining LSSVM model with CSPO provided advantages, such as faster computation, parameter optimization, suitable for parallel computing, and chaos mapping. |

| [50] | Creating a temperature compensation model that fits the function is the key challenge for MEMS gyroscope temperature correction due to the non-linear characteristics. The three-axis gyroscope data were collected within a temperature range of −30–+70 °C, with seven temperature points. | Confidential | Variance, Maximum error | SVM provided the following advantages: good generalization ability, easy training, can fit the non-linear temperature changes, and a globally optimal solution. The issue of parameter optimization was solved by using GA. |

| [51] | Six-axis MEMS accelerometer, high-precision rotary table, a thermostat, a resonant accelerometer, and the testing circuit were used to build the thermal calibration system. The sensor chip was mounted on a side-brazed ceramic package through the silver conductive epoxy adhesive to collect the data. The model’s inertial temperature was 293.15 K, and it was assumed that the structure had no internal tension at this temperature. The materials expanded or contracted as the temperature changed, putting the six DETFs under uneven thermal stress. | Confidential | Maximum percentage error | The accuracy of the polynomial fitting method is still lacking when used with MEMS accelerometers and results in a systematic error without considering the high-order non-linearities in the sensor errors. NN can handle these issues efficiently. Combining GA with the BP-NN network helped find the global optima with a faster convergence rate and low error. |

| [52] | Temperature signal data were collected from a MEMS gyroscope. IPSO-VMD decomposed the gyro signal and obtained the ideal VMD parameters. Using SE, the sequence complexity was calculated and divided into three categories: noise, mixed, and feature. | Confidential | Sample entropy, Allan variance | The fusion algorithm helped with strong learning, better model building, efficient global search ability, and faster convergence speed. |

| [54] | The authors used both synthetic [98] and real ground vibration data [99] with two different labels assigned to it as peak acceleration and earthquake magnitude, respectively. For the synthetic data, artificial noise was introduced in a controlled manner. | Mixed | Accuracy | CNN models can handle non-linear, erroneous, and nonconvex issues. |

| [55] | The earthquake dataset used was highly imbalanced and heavily noisy. It was collected from the National Research Institute of Earth Science and Disaster Prevention (NIED) and USGS (United States Geological Survey). The time-series non-earthquake-related data were captured using a mobile device for several hours. The final dataset contained earthquake, noise, and walk-and-wait data. | Public | Accuracy, ROC curve, Precision, Recall, F1 score | Imbalanced, the noisy dataset can be efficiently handled by ANN with very low false prediction. |

| [56] | Earthquake data containing P and S wave picks were considered. It was collected from Southern California Seismic Network (SCCN). The data were continuous with a 4-second window with noise present. A high pass filter was used to remove the noise. | Public | Precision, Recall | DL is efficient for object recognition tasks due to its robust generalization representation. No explicit characteristic recognition over millions of data helps detect objects better and make a reliable earthquake warning system. |

| [57] | Time series signals were used to detect events. The first difficulty of the data was that the length of an earthquake occurrence varied greatly; the second was that the generated proposals were temporally correlated; Not all the positive events were annotated correctly, which increased the noise in the data. | Confidential | AP | Using CC-RCNN helped find an optimized multi-scale temporal correlation of time series data to detect events of various lengths. The deep neural network has considerably improved object detection in 2D picture data. |

| [59] | Data were obtained from the National Research Institute for Earth Science and Disaster Resilience (NIED), the United States Geological Survey (USGS), along with the authors’ data. Noise data and human activity data were collected by using low-cost MEMS sensors. | Mixed | MSE, MAPE, WD error | EQGAN efficiently analyzed complex high-dimensional, time-series data structures to generate high-quality seismic sequences in terms of quality and quantity. |

| [62] | Data were obtained from the UCI website with six pedestrian motion mode recognition activities. The testers recorded three axial linear accelerations and three axial angular velocities at a constant rate of 50 Hz using the smartphone’s integrated accelerometer and gyroscope. The data contained noise. The Butterworth low-pass filter was used to separate acceleration signal components. | Public | Accuracy, Recall, F-measure, Precision | The effectiveness of CNN in deep learning is huge due to the utilization of convolutional filter hierarchies, which sequentially extracted feature representations of increasing complexity from raw sensor measurement. The unique internal structure of LSTM models provided a memory with a forget function to efficiently and selectively focus on those sensory data that were important to the recognition process. |

| [64] | Dataset contained information on whole-body movement and hand gesture information retrieved. The whole-body movement data were retrieved from 10 modality sensors with 18 classes. Hand gesture data contained 12 classes and were collected from body sensors containing a three-axis accelerometer and a two-axis gyroscope | Public | Accuracy, Average F-measure, Normalized F-measure | The challenge of obtaining useful information for activity identification was difficult as it was mostly handcrafted. It was avoided by utilizing the task-depended feature extraction property of the CNN model. The advantages were: extracted features had a stronger ability to distinguish across different categories of human activity, unified feature extraction, and classification. |

| [65] | One-dimensional MEMS inertial data were used and converted into 2D gray images after feature extraction with a sliding window. The sampling was performed non-uniformly with different temperature points for MEMS gyroscopes and accelerometers. | Confidential | Accuracy, Confusion matrix | CNN improved the fault diagnosis problem in UAV manufacturing according to the correct sensor temperature. The convergence rate of the proposed algorithm was faster, which helped to train the model with a low amount of data available. |

| [66] | Data were obtained from a LDVT sensor and control feedback signals are accessible with a limited number of precise measurements. An additional 2% white noise was introduced in the data. Three parallel blocks with new data fusion integrated with ANN and discrete wavelet transform methods were used to detect three major faults: null bias current, actuator leakage coefficient, and internal leakage. Data fusion is important to increase the decision-making process’ accuracy. | Confidential | MSE | Discrete wavelet transform can retrieve information from both frequency and location signals, making it an efficient fault detection tool. Low data availability does not impact the performance of ANN for estimating complicated non-linear functions. |

| [67] | Seeded fault data were obtained from Case Western Reserve University, which consisted of a two-horsepower (hp) electric motor, a dynamometer, and a torque transducer. The dataset includes vibration acceleration signals for bearings with no flaws and bearings with faults in the inner raceway, outer raceway, and rolling element. The dataset comprises signals recorded for bearings with three fault severity levels at four different shaft loads for each fault condition. | Public | Accuracy | To counteract the non-stationary behavior of the signals brought on by various crack sizes, the hybrid feature pool extracted more discriminating information from the raw vibration signals. More discriminating data enabled the next classifier to divide data into appropriate groupings. |

| [68] | Sensor data contained information related to high and low-pressure turbine speed, compressor outlet temperature and pressure, low-pressure turbine outlet temperature, and pressure. | Confidential | MSE | LS-SVM could implement the structural risk minimization principle with a new learning method with low risk and good generalization ability for unseen samples. |

| [69] | Gyroscope and accelerometer data were synthetically generated with two label classes, such as faulty and nominal flight conditions. The training was performed offline, but the prediction was made online. | Confidential | Posterior probabilities | SVM offer good generalization without the risk of over-fitting and avoiding global minima. It is useful for high-dimensional, non-linear systems. |

| [72] | To address the less availability of training data, the authors employed transfer learning to train their model on top of the already learned Common Objects in Context (COCO) model, which was previously trained and made publicly available. The captured images contained information related to MEMS wafer surface defects. | Confidential | Confusion matrix | Faster R-CNN was able to perform detection, classification, and localization altogether |

| [77] | A MEMS simulator called EM3DS6.2.14 has been used to simulate faults using RF MEMS and an Opamp. Faults related to stiction, curvature, fatigue and brittle, etch variation, and contamination were generated. | Confidential | Confusion matrix | LVQ was used for finding the optimum kernel number automatically with provided faster learning speed to overcome the drawback of the RHPNN algorithm finding the optimum kernel number in the second layer and improving the performance. |

| [78] | The defects obtained from the MEMS pressure-sensor chips were of different sizes and scales, and the amount of data was limited, containing an unequal distribution. The defect images were annotated manually. In terms of defects, chip scratch, chip damage, gold-wire bonding, glue-surface wrinkles, and aluminum-wire bonding were considered targets. | Confidential | AP, MAP | ADCNN can detect small changes in the MEMS pressure-sensor chip-packaging process from noisy image data by using random-data augmentation and defect classifiers, which are not possible using the traditional RCNN. |

| [79] | The data were generated containing non-linear relationships among the damping factor, resonance frequency, Brownian noise, mass, and epitaxial layer thickness. Training samples were generated using Monte Carlo simulations that contained varying epitaxy edge loss, epitaxy thickness, offset, and cavity pressure. | Confidential | RMSE | DNN is useful for the detection relationship among non-linear data. Using simulated data for offline training of DNN helped with accurate parameter extraction and was less time-consuming than ML methods. A single time-efficient forward pass was able to identify different system parameters. |

| [82] | Snapshots of the microbeam were obtained at fixed intervals with two different step-voltages, from which eigenvectors were obtained. | Confidential | Author defined error | GHA did not require to compute the input correlation matrix. The method posed potential advantages when the measured data were huge because it only had to determine a small number of necessary basis functions, which could be learned directly from the input data. |

| [84] | MEMS micro-engine data containing attributes, such as humidity, operating frequency, resonant frequency, spring quotient, and force component, were collected. Data were limited and contained both bi-modal and uni-modal distribution. | Confidential | MAE, SD, R-squared, MSE, RMSE | Trained NN could accurately estimate the reliability by mapping the attributes to a reference value and minimizing the error. As a result, it could optimize the process by sensitivity analysis of the process parameters. |

| [85] | Simulated MEMS resonator image data contained several unique resonator patterns. | Confidential | Authors’ defined RA | DL model could effectively create non-linear combinations of the target structure voxel by voxel faster and automatically without any constraints. |

| [86] | Raw visible surface defect images were collected [100] containing eight defect types and did not contain a uniform definition for defects. Only a few wafers contained multiple defects, whereas a single defect type was present in others. | Public | Accuracy, Precision, Recall, F-measure, AUC | Transfer-learning was used for efficient parameter estimation for faster training of the CNN model to detect wafer defects on a training subset. |

| [88] | The data contained multiple defect patterns and noise. The data type used contained both real and synthetic data, and the splitter segregated single and missed defects. | Confidential | Accuracy, SD, ROC, RMSE, | The advantage of the proposed method was that it could generate high-level features using low-level features with mixed patterns, which is impossible using shallow ML models. RGRN was used to detect single defects, and DSCN was used to detect mixed defect patterns. |

| [91] | Circular disk resonator two-dimensional images of 100 pixels by 100 pixels were used where the void represented the resonator body and the black-and-white part contained structural information. Four vibrational modes were the topic of interest: two torsional, one flexural, and one in-plane rotational mode. | Confidential | Accuracy, Run-time | The Resnet model could learn from the complex physical, structural patterns, which cannot be represented explicitly. The model provided an accurate and much faster analysis than the traditional FEA. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Podder, I.; Fischl, T.; Bub, U. Artificial Intelligence Applications for MEMS-Based Sensors and Manufacturing Process Optimization. Telecom 2023, 4, 165-197. https://doi.org/10.3390/telecom4010011

Podder I, Fischl T, Bub U. Artificial Intelligence Applications for MEMS-Based Sensors and Manufacturing Process Optimization. Telecom. 2023; 4(1):165-197. https://doi.org/10.3390/telecom4010011

Chicago/Turabian StylePodder, Itilekha, Tamas Fischl, and Udo Bub. 2023. "Artificial Intelligence Applications for MEMS-Based Sensors and Manufacturing Process Optimization" Telecom 4, no. 1: 165-197. https://doi.org/10.3390/telecom4010011

APA StylePodder, I., Fischl, T., & Bub, U. (2023). Artificial Intelligence Applications for MEMS-Based Sensors and Manufacturing Process Optimization. Telecom, 4(1), 165-197. https://doi.org/10.3390/telecom4010011