Enhancing Density-Based Mining Waste Alkali-Activated Foamed Materials Incorporating Expanded Cork

Abstract

:1. Introduction

2. Experimental Work

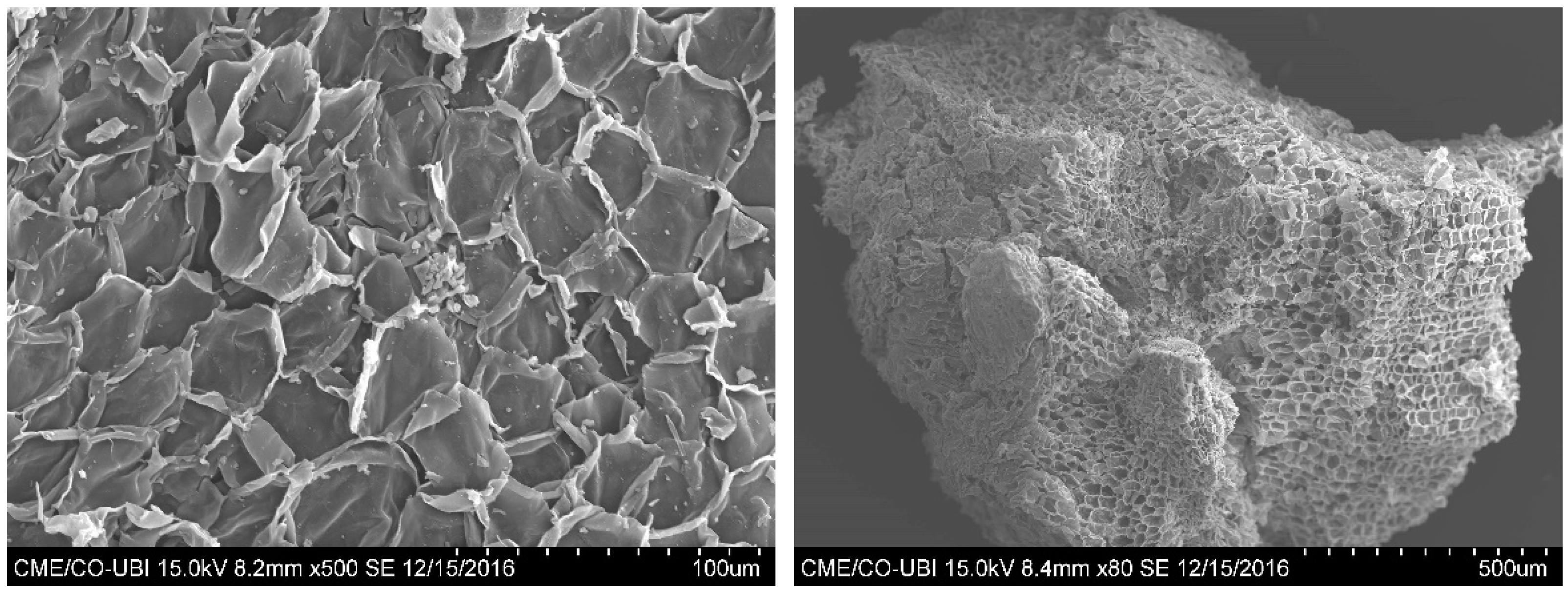

2.1. Materials

2.2. Methods

2.2.1. Mixing Alkaline Solutions

2.2.2. Mix Design

3. Results and Discussion

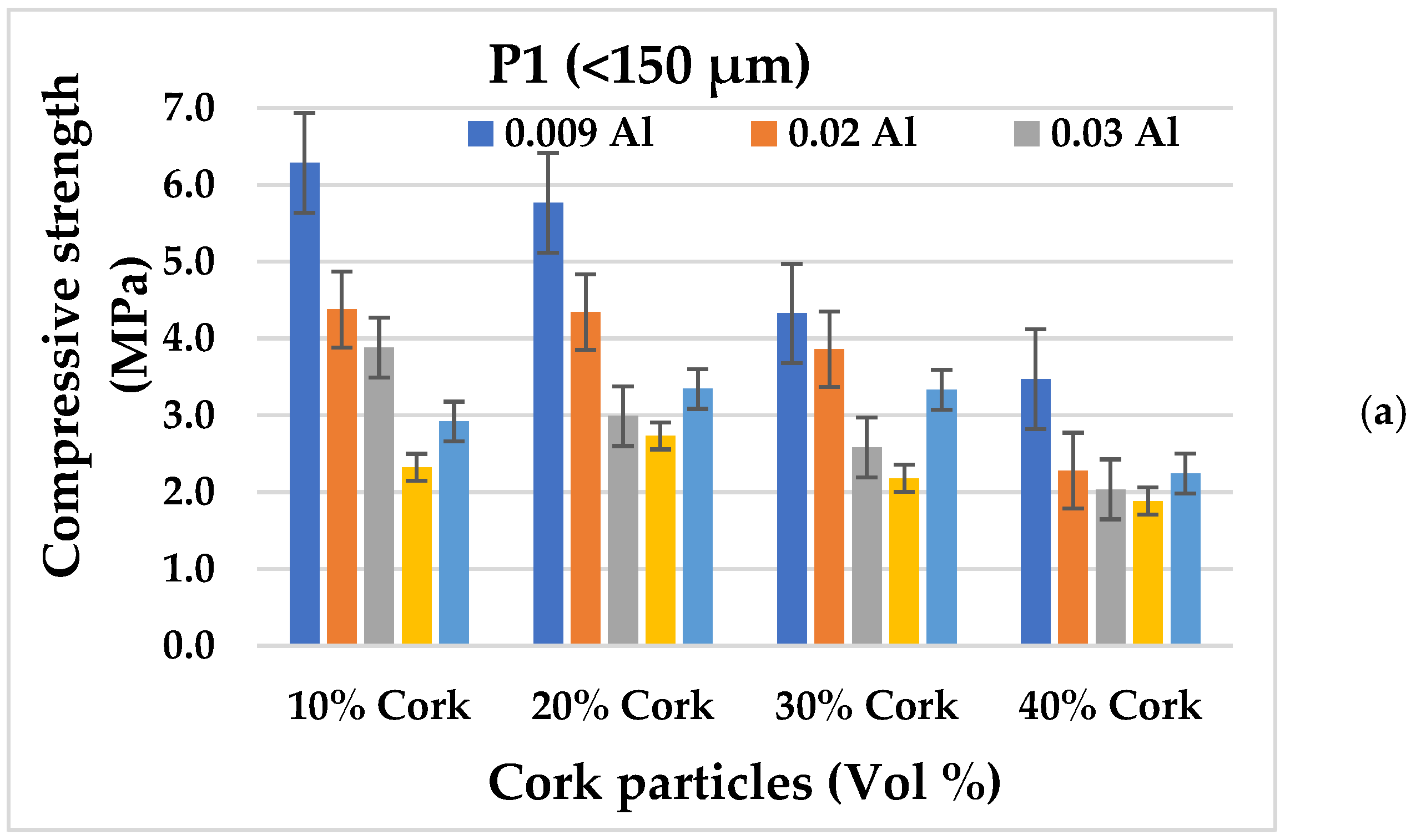

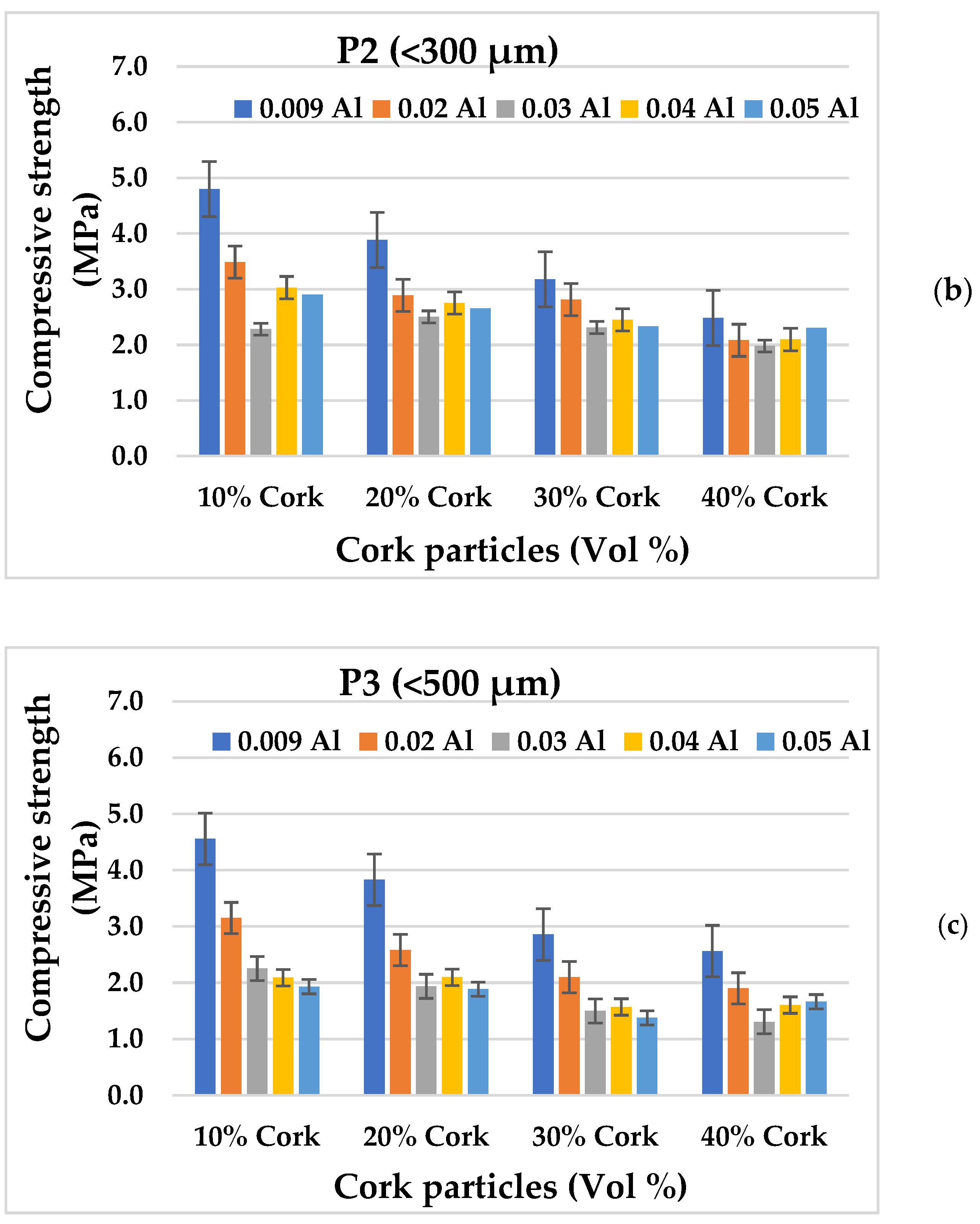

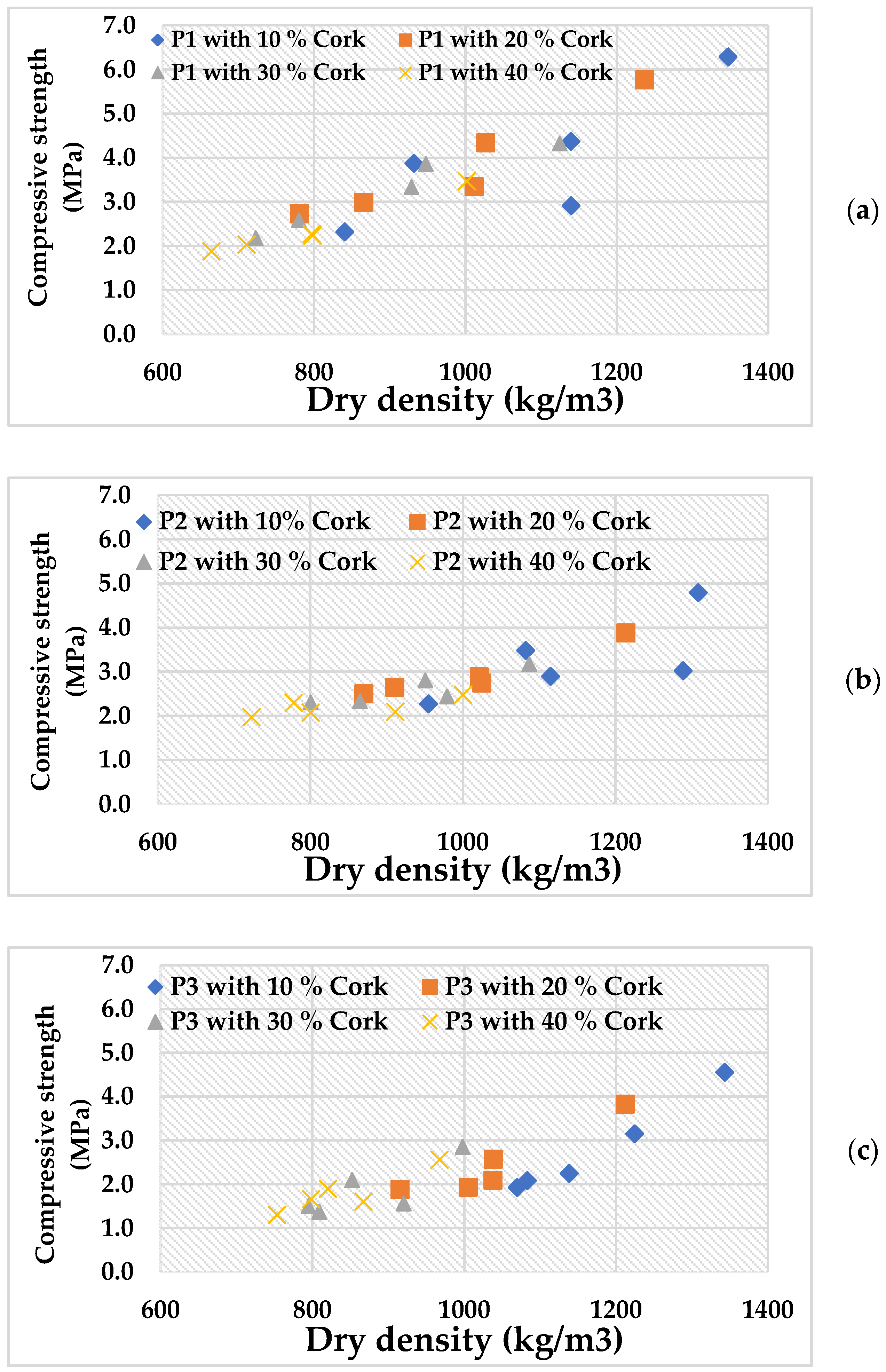

3.1. Compressive Strength

3.2. Strength Loss/Gain

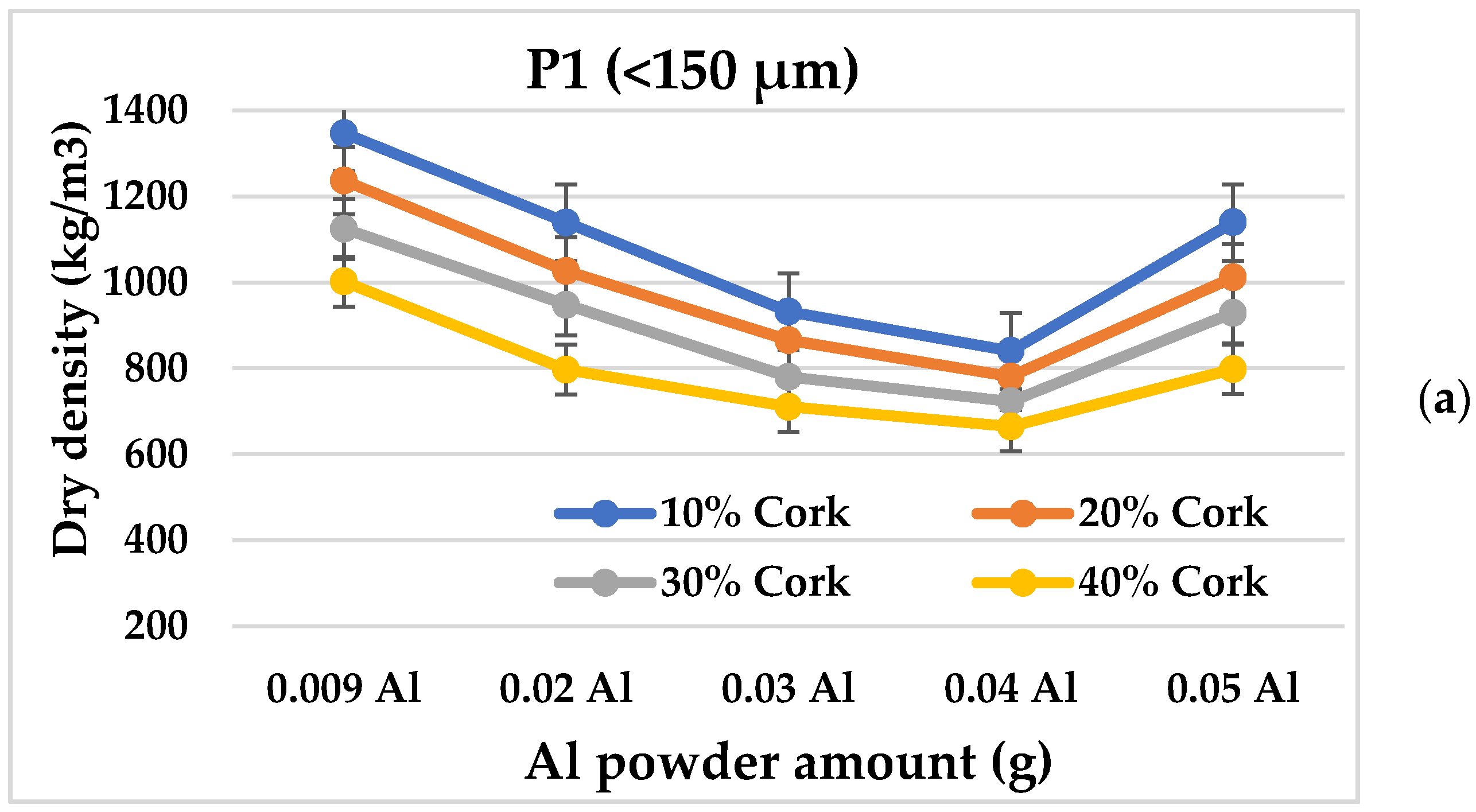

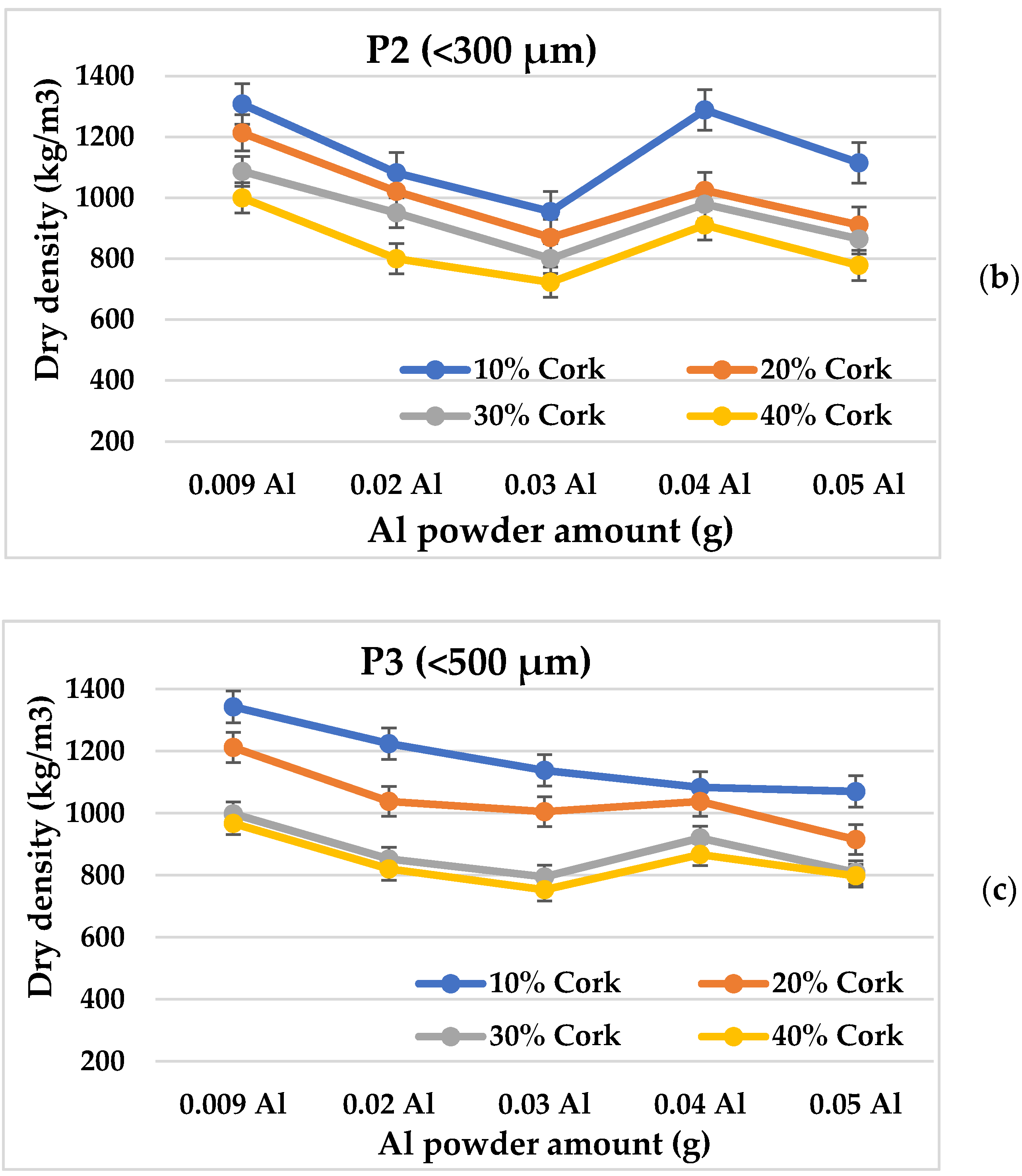

3.3. Dry Density

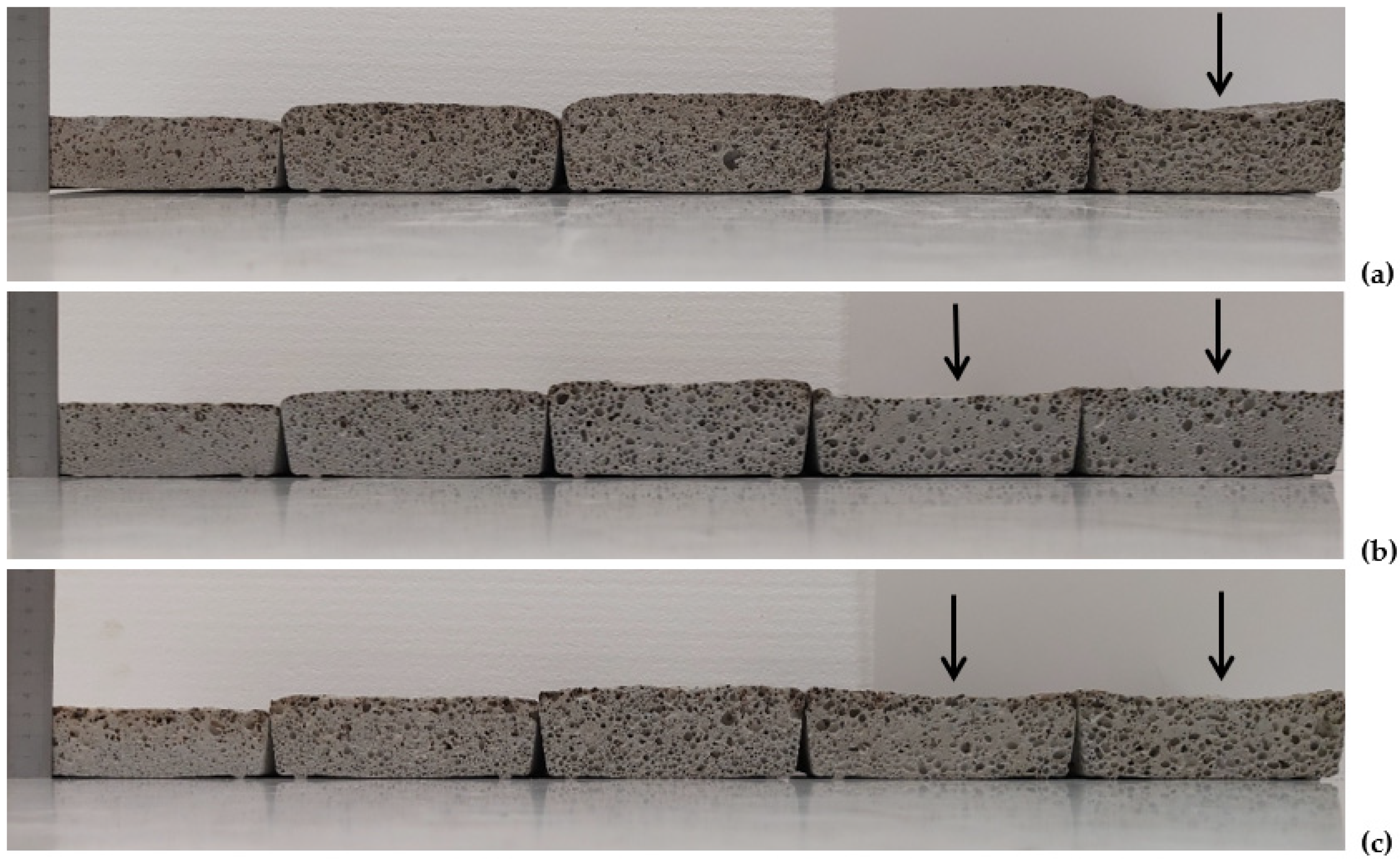

3.4. Expansion Volume

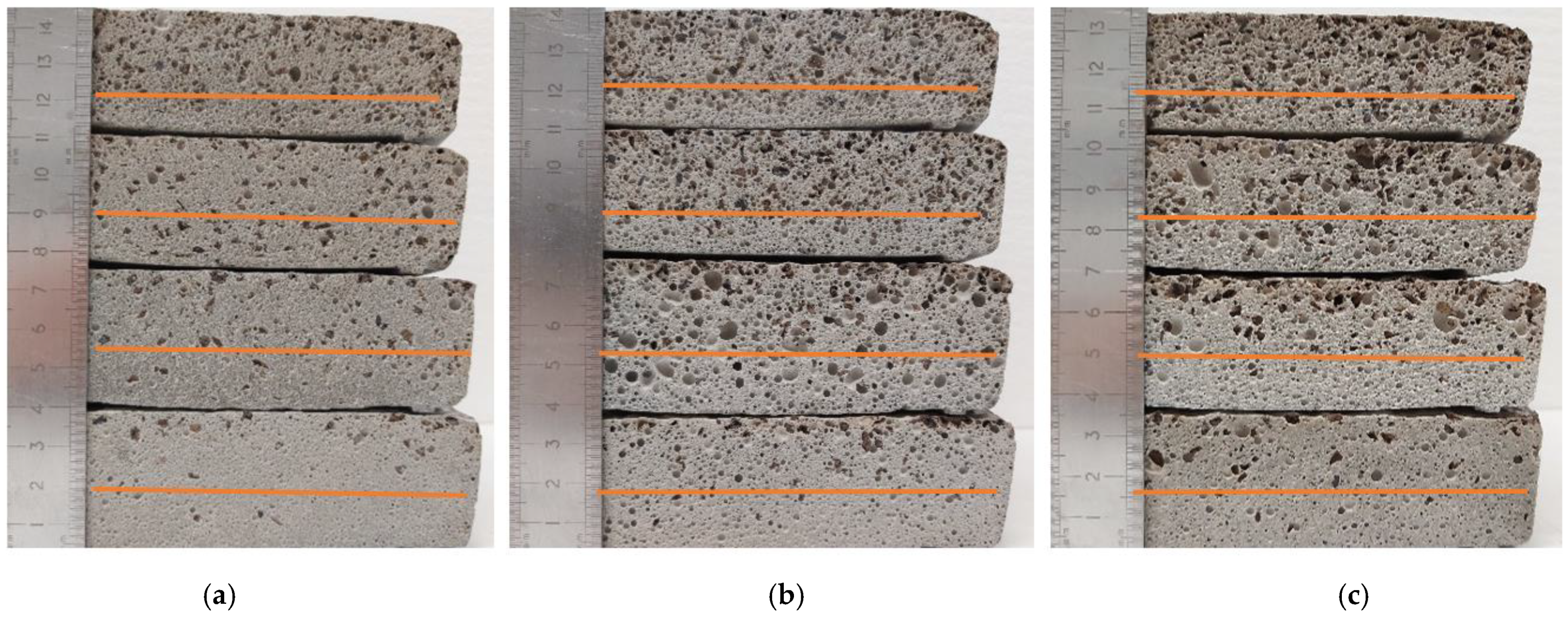

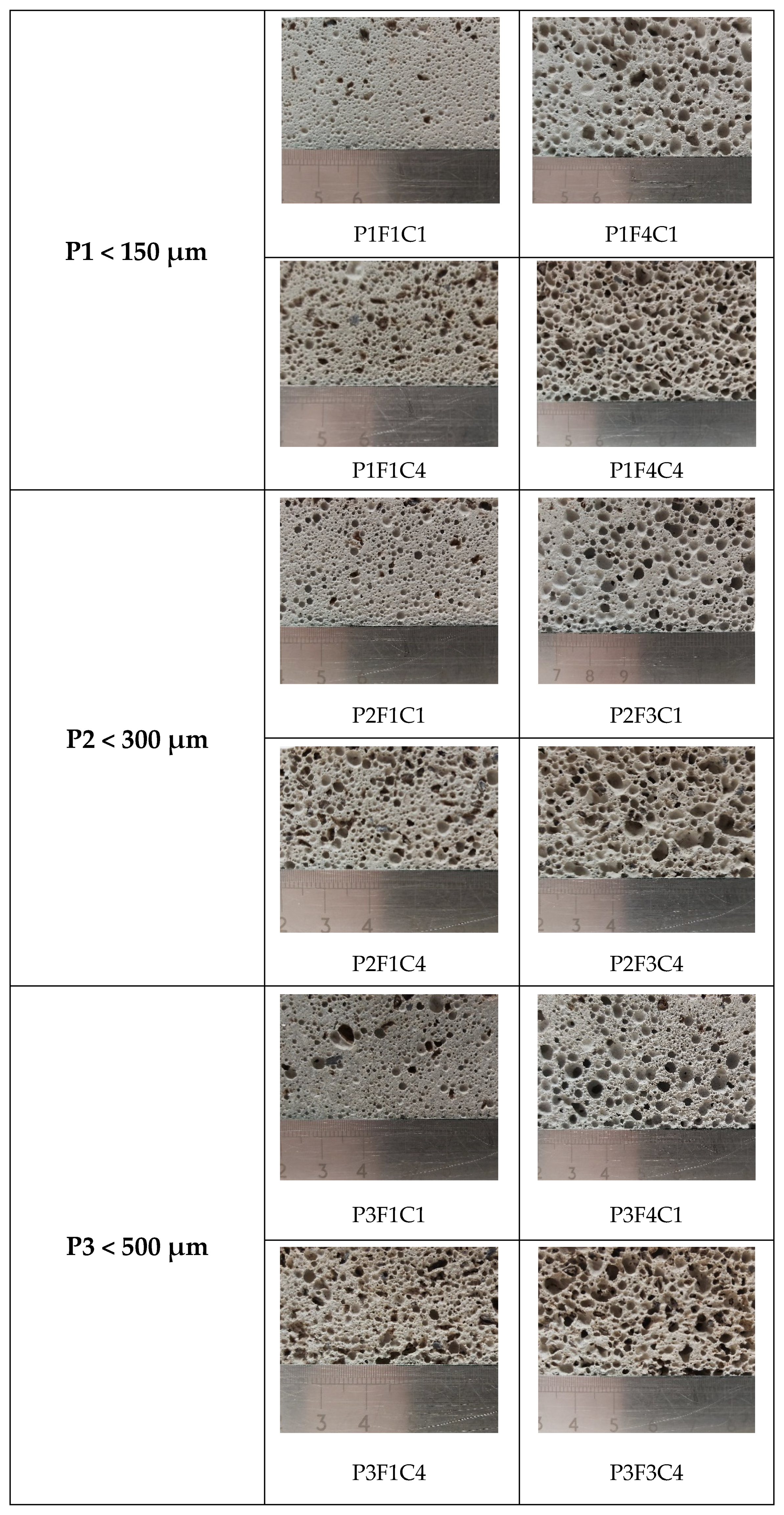

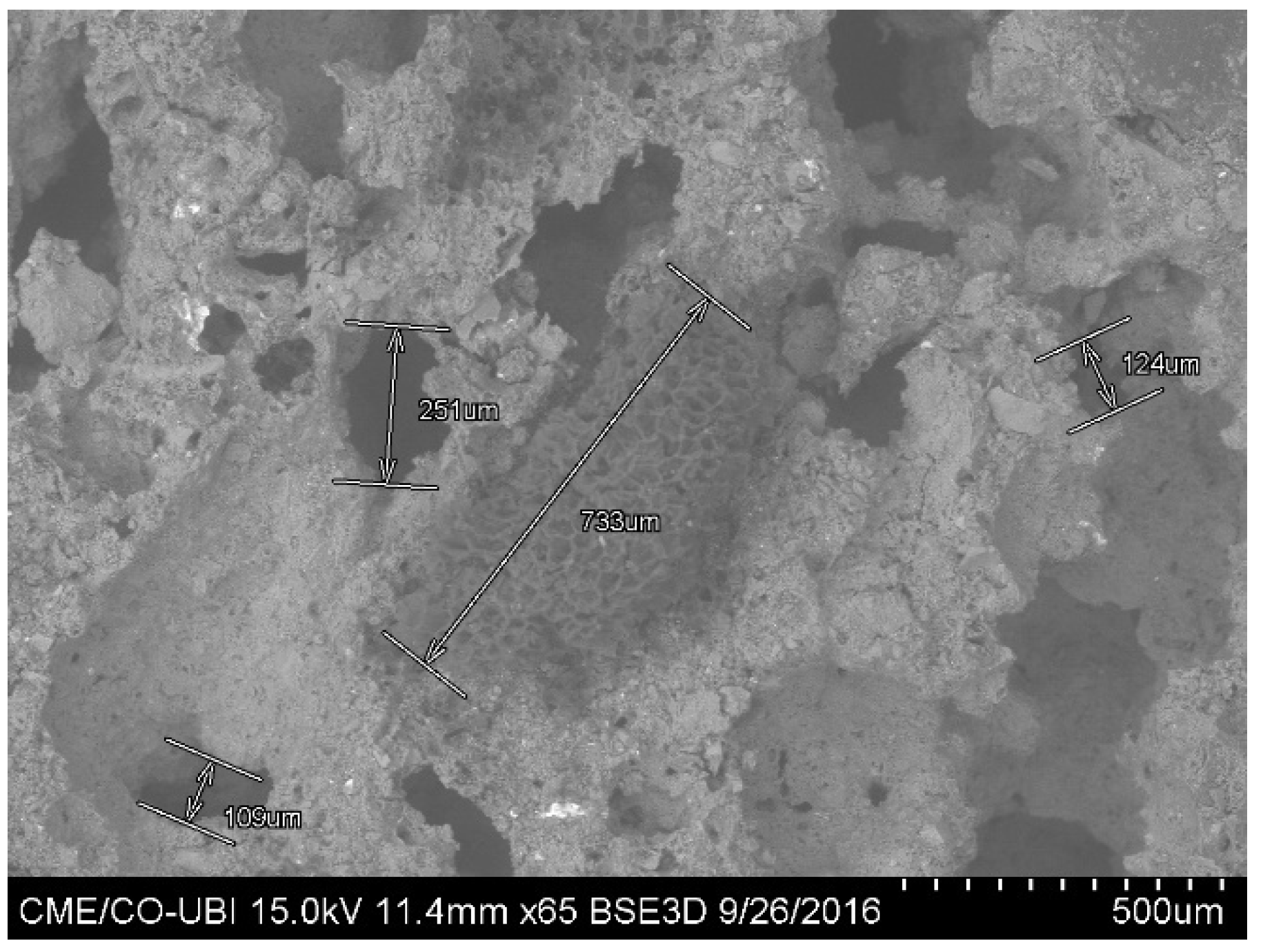

3.5. Pore Sizes and Cork Particles’ Distributions

3.5.1. Effect of Al Powder Addition

3.5.2. Effect of Cork Addition

4. Conclusions

- Compressive strength showing relatively good results of 2.04 MPa, 1.98 MPa, and 1.31 MPa for densities of 664 kg/m3, 722 kg/m3, and 753 kg/m3, with expansion volumes of 58.73%, 56.87%, and 54.16%s for P1, P2 and P3 precursors’ maximum particle size incorporating 40 vol.% of cork particles, respectively.

- The compressive strength of the AA-LFM is strongly affected by the increase of Al powder amount and slightly with the change of cork particles content.

- Highly porous foams were produced when using the Al powder as a blowing agent. It is found that the density decreases as expanded granulated cork (EGC) particles content increase due to the low density of cork particles.

- The lowest density obtained for P1, P2 and P3 is 664 kg/m3, 722 kg/m3, 753 kg/m3, respectively, using 0.04 w.% Al powder in the case of precursor P1 and 0.03 w.% Al powder for precursors P2 and P3.

- For each precursor particle size, the density obtained through the changes in the amount of Al powder and as a result of adding cork particles at 40 vol.% showed superior values when adding 0.05 w.% Al powder as in P1 and 0.04 w.% Al powder as in P2 and P3; the collapsed samples present an increase in the compressive strength because of the decrease of the porosity through the failure of the samples expansion process.

- The expansion volume obtained from Al powder catalysed by the NaOH with the ratio SS; SH = 3.1 is about 55.90%, 53.84%, 59.42%, and 58.73% for precursor P1 (<150 µm), 51.94%, 52.29%, 47.82%, and 56.87% for precursor P2 (<300 µm) and 43.45%, 52.43%, 56.62%, and 54.16% for precursor P3 (<150 µm) when incorporating 10 vol.%, 20 vol.%, 30 vol.%, and 40 vol.%, respectively.

- Typical self-foaming (chemical foaming) was observed in alkali-activation of different precursors’ particles size incorporating different cork particles’ percentage under 2 mm.

- Adding a large amount of Al powder was followed by the collapse of the samples when adding 0.05 w.% Al powder in the case of precursor P1 and when adding 0.04 w.% and 0.05 w.% of Al powder in the case of precursors P2 and P3.

Author Contributions

Funding

Conflicts of Interest

References

- Sandanayake, M.; Zhang, G.; Setunge, S. Estimation of environmental emissions and impacts of building construction—A decision making tool for contractors. J. Build. Eng. 2019, 21, 173–185. [Google Scholar] [CrossRef]

- Kappel, A.; Ottosen, L.M.; Kirkelund, G.M. Colour, compressive strength, and workability of mortars with an iron rich sewage sludge ash. Constr. Build. Mater. 2017, 157, 1199–1205. [Google Scholar] [CrossRef] [Green Version]

- Available online: https://patents.google.com/patent/US544706 (accessed on 19 June 2021).

- Li, C.; Sun, H.; Li, L. A review: The comparison between alkali-activated slag (Si + Ca) and metakaolin (Si + Al) cements. Cem. Concr. Res. 2010, 40, 1341–1349. [Google Scholar] [CrossRef]

- Roy, M.D. Alkali-activated cements Opportunities and challenges. Cem. Concr. Res. 1999, 29, 249–254. [Google Scholar] [CrossRef]

- Palomo, A.; Krivenko, P.; Kavalerova, E.; Maltseva, O. A review on alkaline activation: New analytical perspectives. Mater. Constr. 2014, 64, e022. [Google Scholar] [CrossRef] [Green Version]

- Jochens, P.R. Utilization of slags for the manufacture cement. J. S. Afr. Inst. Min. Metall. 1969, 464–474. Available online: https://www.saimm.co.za/Journal/v069n09p464.pdf (accessed on 19 June 2021).

- Davidovite, J. Synthetic Mineral Polymer Compound of the Silico-Aluminates Family and Preparation Process. U.S. Patent 4,472,199, 18 September 1984. [Google Scholar]

- Krivenko, P.; Kovalchuk, G. Achieving a heat resistance of cellular concrete based on alkali activated fly ash cements. Mater. Struct. 2015, 599–606. [Google Scholar] [CrossRef]

- Palomo, A.; Grutzeck, M.W.; Blanco, M.T. Alkali-activated fly ashes: A cement for the future. Cem. Concr. Res. 1999, 29, 1323–1329. [Google Scholar] [CrossRef]

- Shi, C.; Jiménez, A.F.; Palomo, A. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar] [CrossRef]

- Provis, J.L.; van Deventer, J. Alkali Activated Materials: State-of-the-Art Report, RILEM TC 224-AAM; Springer: Dordrecht, Switzerland, 2014; ISBN 978-94-007-7671-5. [Google Scholar]

- Krivenko, P.; Cao, H.; Petropavlovskyi, O.; Weng, L. Efficiency of alkali activated hybrid cements for immobilization of low-level radioactive anion-echange resins. East. Eur. J. Enterp. Technol. 2016, 10, 38–43. [Google Scholar] [CrossRef] [Green Version]

- Davidovits, J.; Sawyer, J.L. Early High-Strength Mineral Polymer. U.S. Patent 4509985-A, 9 April 1985. [Google Scholar]

- Davidovits, J. Mineral Polymers and Methods of Making Them. U.S. Patent 4349386, 14 September 1982. [Google Scholar]

- Davidovits, J. Geopolymer Chemistry and Applications, 3rd ed.; Geopolymer Institute: Saint-Quentin, France, 2011. [Google Scholar]

- Pacheco-Torgal, F.; Castro-Gomes, J.P.; Jalali, S. Utilization of mining wastes to produce geopolymer binders. Geopolymers Struct. Process. Prop. Ind. Appl. 2009, 267–293. [Google Scholar]

- Castro-Gomes, J.P.; Oliveira, L.A.P.; Almeida, M.D. Valorizacao de Residuos de Minas em Pavimento de Baixo Custo. 2006. Available online: https://www.academia.edu/22261036/Valoriza%C3%A7%C3%A3o_de_res%C3%ADduos_de_minas_em_pavimentos_de_baixo_custo (accessed on 19 June 2021).

- Pacheco-Torgal, F.; Castro-Gomes, J.P.; Jalali, S. Investigations of tungsten mine waste geopolymeric binder: Strength and microstructure. Constr. Build. Mater. 2008, 22, 2212–2219. [Google Scholar] [CrossRef] [Green Version]

- United States Environmental Protection Agency. Report to Congress: Wastes from the Extraction and Beneficiation of Metallic Ores, Phosphate Rock, Asbestos, Overburden from Uranium Mining and Oil Shale. 1985. Available online: https://www.epa.gov/hw/report-congress-wastes-extraction-and-beneficiation-metallic-ores-phosphate-rock-asbestos (accessed on 19 June 2021).

- Castro-Gomes, J.P.; Silva, A.P.; Cano, R.P.; Suarez, J.D.; Albuquerque, A. Potential for reuse of tungsten mining waste-rock in technical-artistic value added products. J. Clean. Prod. 2012, 25, 34–41. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Castro-Gomes, J.P.; Jalali, S. Adhesion characterization of tungsten mine waste geopolymeric binder. Influence of OPC concrete substrate surface treatment. Constr. Build. Mater. 2008, 22, 154–161. [Google Scholar] [CrossRef] [Green Version]

- Longhi, M.A.; Rodríguez, E.D.; Bernal, S.A.; Provis, J.L.; Kirchheim, A.P. Valorisation of a kaolin mining waste for the production of geopolymers. J. Clean. Prod. 2016, 115, 265–272. [Google Scholar] [CrossRef]

- Franco, A.; Vieira, R.; Geologist, C.; Bunting, R.; Executive, N. The Panasqueira Mine at a Glance, Volume 3. 2014. Available online: https://www.academia.edu/30245408/The_Panasqueira_Mine_at_a_Glance (accessed on 19 June 2021).

- Liu, G.; Florea, M.V.A.; Brouwers, H.J.H. Waste glass as binder in alkali activated slag–fly ash mortars. Mater. Struct. Constr. 2019, 52, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Pahlevani, F.; Sahajwalla, V. From waste glass to building materials—An innovative sustainable solution for waste glass. J. Clean. Prod. 2018, 191, 192–206. [Google Scholar] [CrossRef]

- Abdollahnejad, Z.; Dalvand, A.; Mastali, M.; Luukkonen, T.; Illikainen, M. Effects of waste ground glass and lime on the crystallinity and strength of geopolymers. Mag. Concr. Res. 2019, 71, 1218–1231. [Google Scholar] [CrossRef]

- European Commission Closing the Loop: Commission Adopts Ambitious New Circular Economy Package to Boost Competitiveness, Create Jobs and Generate Sustainable. 2015. Available online: http://www.lifelcip.eu/FR/fiche-actualite/60/Closing-the-loop-Commission-adopts-ambitious-new-Circular-Economy-Package-to-boost-competitiveness-create-jobs-and-generate-sustainable-growth (accessed on 19 June 2021).

- Haq, E.U.; Padmanabhan, S.K.; Licciulli, A. Microwave synthesis of thermal insulating foams from coal derived bottom ash. Fuel Process. Technol. 2015, 130, 263–267. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Geopolymer fsoam concrete: An emerging material for sustainable construction. Constr. Build. Mater. 2014, 56, 113–127. [Google Scholar] [CrossRef]

- Commission, E.; From, C.; Commission, T.H.E.; The, T.O.; Parliament, E.; Council, T.H.E.; European, T.H.E.; Committee, S.; Committee, T.H.E.; The, O.F. A Roadmap for Moving to a Competitive Low Carbon Economy in 2050. 2011. Available online: https://www.eea.europa.eu/policy-documents/com-2011-112-a-roadmap (accessed on 19 June 2021).

- Beghoura, I.; Castro-Gomes1, J.; Ihsan, H.; Estrada, N. Feasibility of alkali-activated mining waste foamed materials incorporating expanded granulated cork. Min. Sci. 2017, 24, 7–28. [Google Scholar] [CrossRef]

- Bai, C.; Colombo, P. Processing, properties, and applications of highly porous geopolymers: A review. Ceram. Int. 2018, 44, 16103–16118. [Google Scholar] [CrossRef]

- Hajimohammadi, A.; Ngo, T.; Mendis, P.; Sanjayan, J. Regulating the chemical foaming reaction to control the porosity of geopolymer foams. Mater. Des. 2017, 120, 255–265. [Google Scholar] [CrossRef]

- Wu, H.C.; Sun, P. New building materials from fly ash-based lightweight inorganic polymer. Constr. Build. Mater. 2007, 21, 211–217. [Google Scholar] [CrossRef]

- Aguilar, R.A.; Díaz, O.B.; García, J.E. Lightweight concretes of activated metakaolin-fly ash binders, with blast furnace slag aggregates. Constr. Build. Mater. 2010, 24, 1166–1175. [Google Scholar] [CrossRef]

- Beghoura, I.; Castro-Gomes, J. Development of Alkali-activated Foamed Lightweight Mortar Tungsten Mining Waste Mud-based Incorporating Expanded Cork. KnE Eng. 2020, 2020, 134–146. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, R.; Gong, L.; Li, Y.; Cao, W.; Cheng, X. Development of porous fly ash-based geopolymer with low thermal conductivity. Mater. Des. 2015, 65, 529–533. [Google Scholar] [CrossRef]

- Cheng-Yong, H.; Yun-Ming, L.; Abdullah, M.M.A.B.; Hussin, K. Thermal Resistance Variations of Fly Ash Geopolymers: Foaming Responses. Sci. Rep. 2017, 7, 45355. [Google Scholar] [CrossRef]

- Beghoura, I.; Castro-Gomes, J. Development of Porous Tungsten Mud Waste-based Alkali-activated Foams with Low Thermal Conductivity. KnE Eng. 2020, 2020, 113–125. [Google Scholar] [CrossRef]

- Vaou, V.; Panias, D. Thermal insulating foamy geopolymers from perlite. Miner. Eng. 2010, 23, 1146–1151. [Google Scholar] [CrossRef]

- Castañeda, D.; Silva, G.; Salirrosas, J.; Kim, S.; Bertolotti, B.; Nakamatsu, J.; Aguilar, R. Production of a lightweight masonry block using alkaline activated natural pozzolana and natural fibers. Constr. Build. Mater. 2020, 253, 119143. [Google Scholar] [CrossRef]

- Sanjayan, J.G.; Nazari, A.; Chen, L.; Nguyen, G.H. Physical and mechanical properties of lightweight aerated geopolymer. Constr. Build. Mater. 2015, 79, 236–244. [Google Scholar] [CrossRef]

- Beghoura, I.; Castro-Gomes, J. Design of alkali-activated aluminium powder foamed materials for precursors with different particle sizes. Constr. Build. Mater. 2019, 224, 682–690. [Google Scholar] [CrossRef]

- Narayanan, N.; Ramamurthy, K. Structure, and properties of aerated concrete: A review. Cem. Concr. Compos. 2000, 22, 321–329. [Google Scholar] [CrossRef]

- Kearsley, E.P.; Wainwright, P.J. The effect of high fly ash content on the compressive strength of foamed concrete. Cem. Concr. Res. 2001, 31, 105–112. [Google Scholar] [CrossRef]

- Masi, G.; Rickard, W.D.A.; Vickers, L.; Bignozzi, M.C.; Van Riessen, A. A comparison between different foaming methods for the synthesis of light weight geopolymers. Ceram. Int. 2014, 40, 13891–13902. [Google Scholar] [CrossRef] [Green Version]

- Hlaváček, P.; Šmilauer, V.; Škvára, F.; Kopecký, L.; Šulc, R. Inorganic foams made from alkali-activated fly ash: Mechanical, chemical, and physical properties. J. Eur. Ceram. Soc. 2015, 35, 703–709. [Google Scholar] [CrossRef]

- Beghoura, I.; Castro-Gomes, J.; Ihsan, H.; Pickstone, J.; Estrada, N. Expansion volume of alkali activated foamed cork composites from tungsten mining mud waste with aluminium. EDP Sci. 2019, 274, 03002. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Q.; Zuo, S.; Deng, D. Early-age deformation of cement emulsified asphalt mortar with aluminium powder and expansive agent. Constr. Build. Mater. 2020, 260, 120484. [Google Scholar] [CrossRef]

- João Castro-Gomes, Manuel Magrinho, Naim Sedira, Imed Beghoura, Pedro Humbert, Maria Manso, Ana Fernandes, Rafael Silva Alkali-Activation of Tungsten Mining Waste Mud Blended with Waste Glass: Reactivity, Performance, and Innovative Applications. Available online: http://hdl.handle.net/10400.6/6858 (accessed on 19 June 2021).

- Nóvoa, P.J.R.O.; Ribeiro, M.C.S.; Ferreira, A.J.M.; Marques, A.T. Mechanical characterization of lightweight polymer mortar modified with cork granulates. Compos. Sci. Technol. 2004, 64, 2197–2205. [Google Scholar] [CrossRef]

- Branco, F.G.; Reis, M.d.L.B.C.; Tadeu, B. Utilização da Cortiça Como Agregado em Betões. 2006. Available online: https://www.dec.uc.pt/~fjbranco/POCI_ECM_55889/branco_et_al_QIC_2006.pdf (accessed on 19 June 2021).

- Matos, A.M.; Nunes, S.; Sousa-Coutinho, J. Cork waste in cement based materials. JMADE 2015, 85, 230–239. [Google Scholar] [CrossRef]

- Brás, A.; Leal, M.; Faria, P. Cement-cork mortars for thermal bridges correction. Comparison with cement-EPS mortars performance. Constr. Build. Mater. 2013, 49, 315–327. [Google Scholar] [CrossRef]

- Karade, S.R.; Irle, M.; Maher, K. Influence of granule properties and concentration on cork-cement compatibility. Holz Roh Werkst. 2006, 281–286. [Google Scholar] [CrossRef]

- Sedira, N.; Castro-Gomes, J.; Magrinho, M. Red clay brick and tungsten mining waste-based alkali-activated binder: Microstructural and mechanical properties. Constr. Build. Mater. 2018, 190, 1034–1048. [Google Scholar] [CrossRef]

- Ducman, V.; Korat, L. Characterization of geopolymer fl y-ash based foams obtained with the addition of Al powder or H 2 O 2 as foaming agents. Mater. Charact. 2016, 113, 207–213. [Google Scholar] [CrossRef]

- Dembovska, L.; Bajare, D.; Ducman, V.; Korat, L.; Bumanis, G. The use of different by-products in the production of lightweight alkali activated building materials. Constr. Build. Mater. 2017, 135, 315–322. [Google Scholar] [CrossRef]

| Chemical Compound | TWM (%) | WG (%) | MK (%) |

|---|---|---|---|

| SiO2 | 46.67 | 68.13 | 52.28 |

| Al2O3 | 17.01 | 2.80 | 42.99 |

| Fe2O3 | 15.47 | 2.90 | 1.49 |

| SO3 | 7.90 | 0.23 | - |

| K2O | 4.90 | 0.86 | 0.94 |

| Na2O | 0.85 | 12.52 | 0.32 |

| CaO | 0.69 | 10.52 | - |

| MgO | 4.83 | 2.04 | 0.47 |

| Oxide/Materials | Chemical Composition of the Activators (g) | |

|---|---|---|

| Sodium Silicate (SS) | Sodium Hydroxide (SH) | |

| Na2O | 19.37 | 13.02 |

| SiO2 | 62.60 | 0.00 |

| Al2O3 | 0.90 | 0.00 |

| H2O | 142.32 | 43.27 |

| Precursors’ Particle Sizes (µm) | Precursors (%) | Cork Particles (Vol.%) | Al Powder (w.%) | (SS/SH) | (P/A) * | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| TWM | WG | MK | 0.009% | 0.02% | 0.03% | 0.04% | 0.05% | (g) | |||

| P1 | 70 | 20 | 10 | 10% | P1F1C1 | P1F2C1 | P1F3C1 | P1F4C1 | P1F5C1 | 3;1 | 2.3 |

| 20% | P1F1C2 | P1F2C2 | P1F3C2 | P1F4C2 | P1F5C2 | 3;1 | |||||

| (<150 µm) | 30% | P1F1C3 | P1F2C3 | P1F3C3 | P1F4C3 | P1F5C3 | 3;1 | ||||

| 40% | P1F1C4 | P1F2C2 | P1F3C4 | P1F4C4 | P1F5C4 | 3;1 | |||||

| P2 | 70 | 20 | 10 | 10% | P2F1C1 | P2F2C1 | P2F3C1 | P2F4C1 | P2F5C1 | 3;1 | 2.6 |

| 20% | P2F1C2 | P2F2C2 | P2F3C2 | P2F4C2 | P2F5C2 | 3;1 | |||||

| (<300 µm) | 30% | P2F1C3 | P2F2C3 | P2F3C3 | P2F4C3 | P2F5C3 | 3;1 | ||||

| 40% | P2F1C4 | P2F2C2 | P2F3C4 | P2F4C4 | P2F5C4 | 3;1 | |||||

| P3 | 70 | 20 | 10 | 10% | P3F1C1 | P3F2C1 | P3F3C1 | P3F4C1 | P3F5C1 | 3;1 | 2.6 |

| 20% | P3F1C2 | P3F2C2 | P3F3C2 | P3F4C2 | P3F5C2 | 3;1 | |||||

| (<500 µm) | 30% | P3F1C3 | P3F2C3 | P3F3C3 | P3F4C3 | P3F5C3 | 3;1 | ||||

| 40% | P3F1C4 | P3F2C2 | P3F3C4 | P3F4C4 | P3F5C4 | 3;1 | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beghoura, I.; Castro-Gomes, J. Enhancing Density-Based Mining Waste Alkali-Activated Foamed Materials Incorporating Expanded Cork. CivilEng 2021, 2, 523-540. https://doi.org/10.3390/civileng2020029

Beghoura I, Castro-Gomes J. Enhancing Density-Based Mining Waste Alkali-Activated Foamed Materials Incorporating Expanded Cork. CivilEng. 2021; 2(2):523-540. https://doi.org/10.3390/civileng2020029

Chicago/Turabian StyleBeghoura, Imed, and Joao Castro-Gomes. 2021. "Enhancing Density-Based Mining Waste Alkali-Activated Foamed Materials Incorporating Expanded Cork" CivilEng 2, no. 2: 523-540. https://doi.org/10.3390/civileng2020029

APA StyleBeghoura, I., & Castro-Gomes, J. (2021). Enhancing Density-Based Mining Waste Alkali-Activated Foamed Materials Incorporating Expanded Cork. CivilEng, 2(2), 523-540. https://doi.org/10.3390/civileng2020029