The Development of Continuous Connections for Multi-Span Precast Prestressed Girder Bridges: A Review

Abstract

1. Introduction

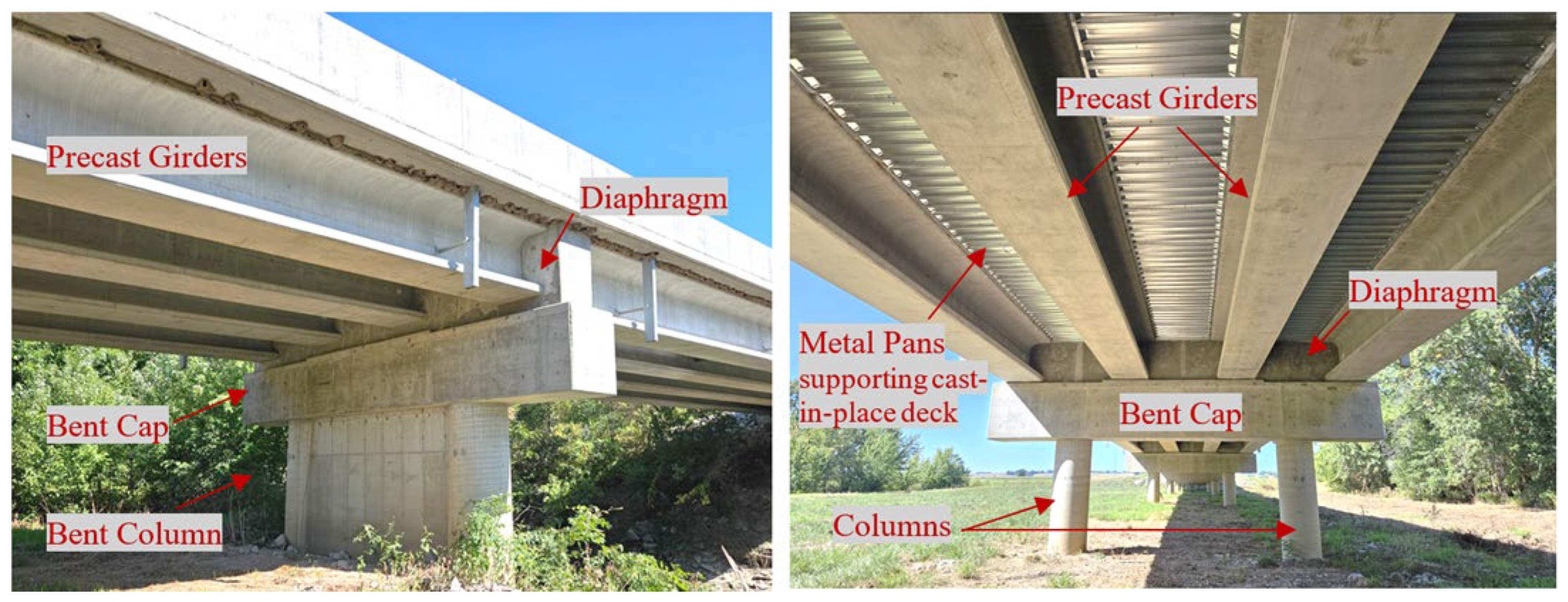

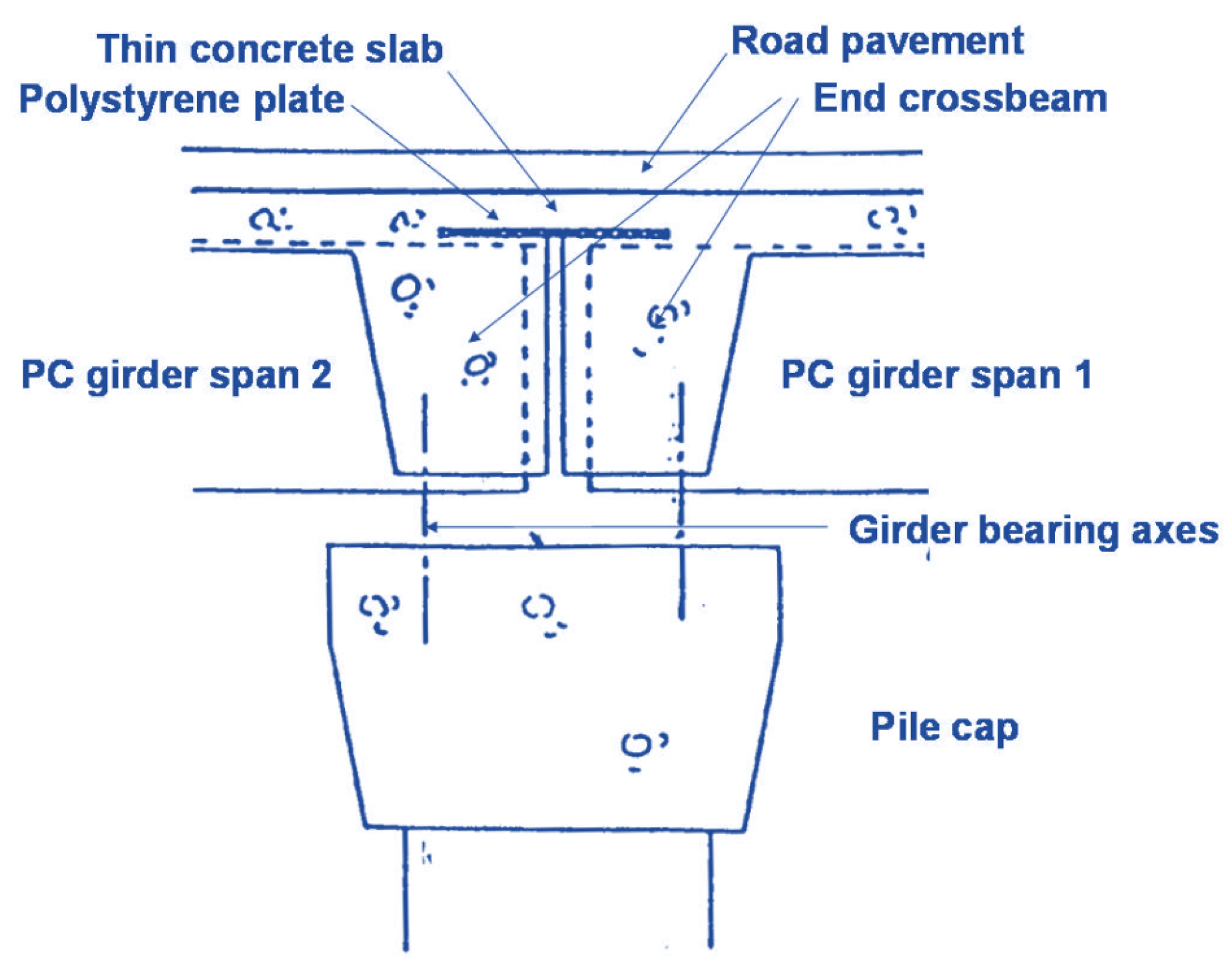

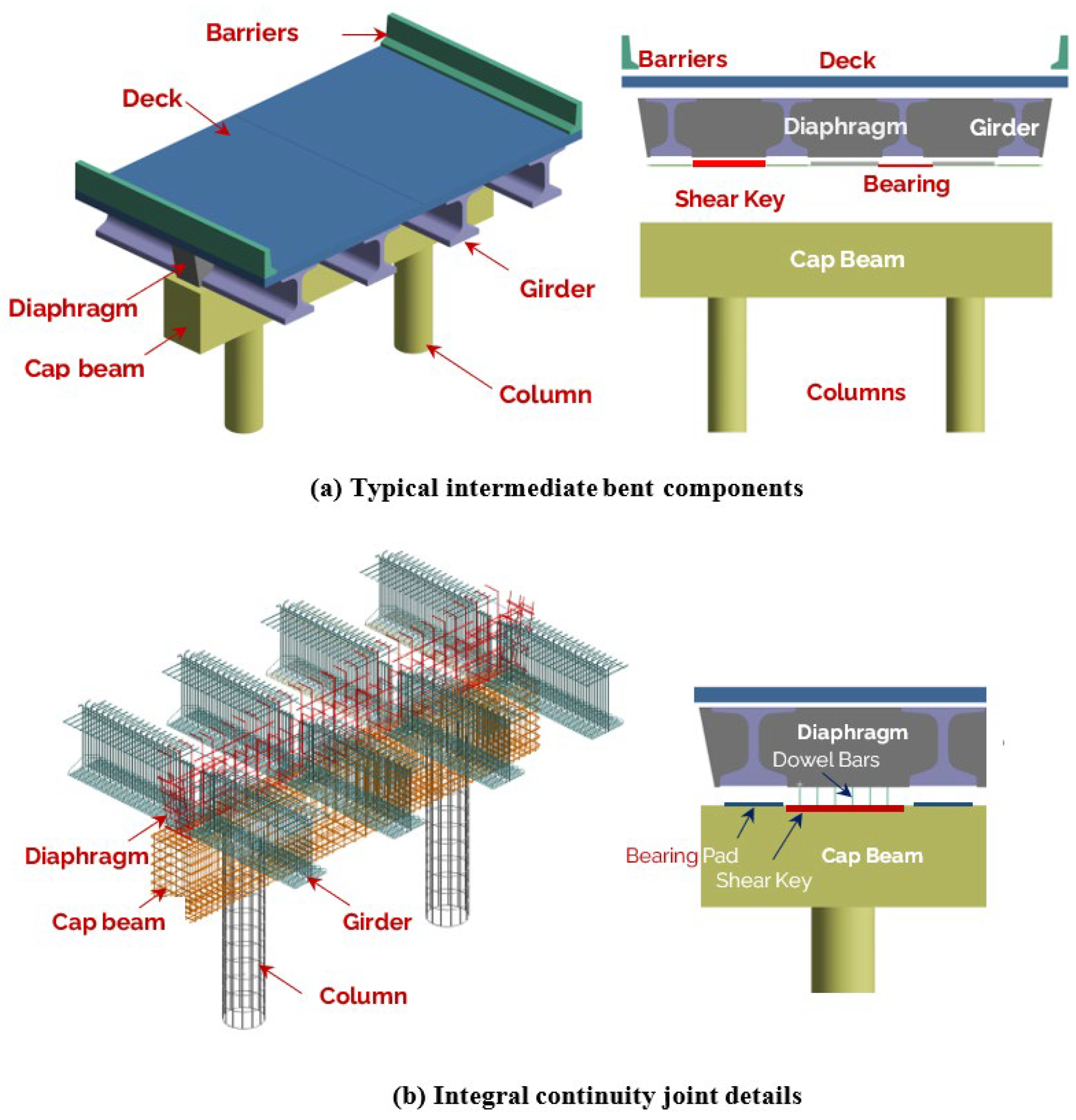

2. Partially Integrated Connection

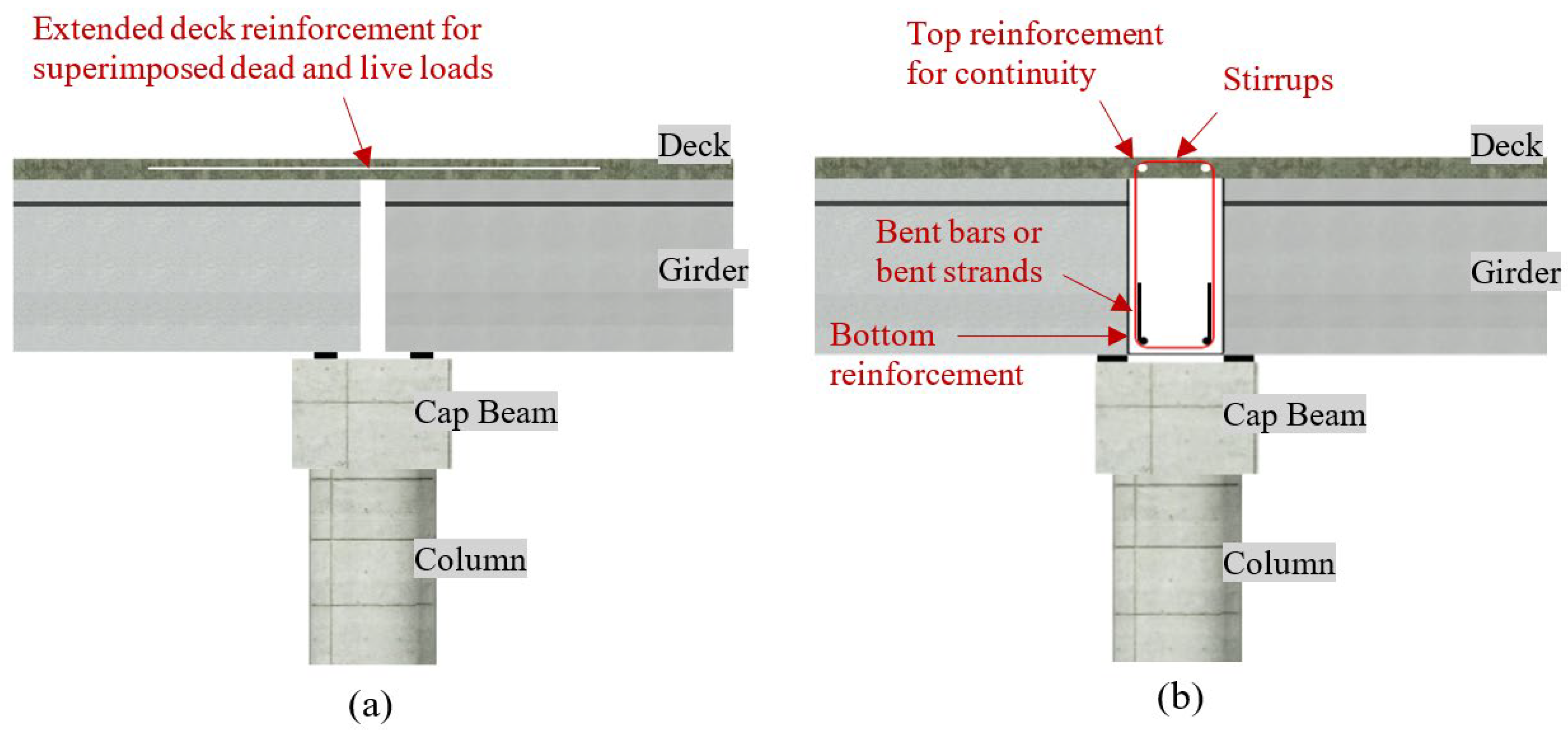

2.1. Extended Deck Reinforcement

2.2. Diaphragm with Bent Bars

2.3. Diaphragm with Bent Strands

3. Fully Integrated Connection

3.1. Girder-to-Girder Joint

3.2. Girder-to-Column Joint

3.3. Girder-to-Bent Cap Beam Joint

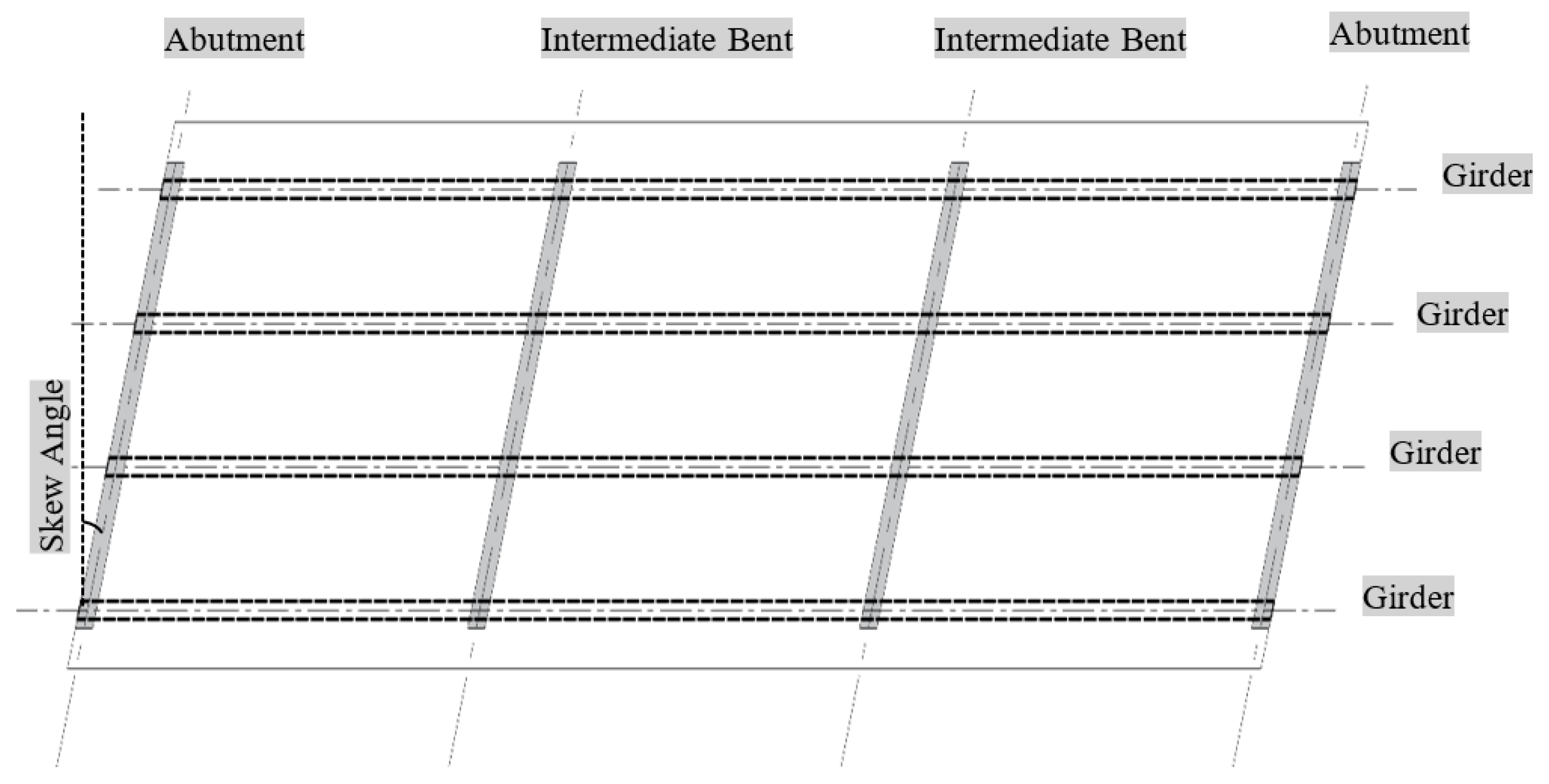

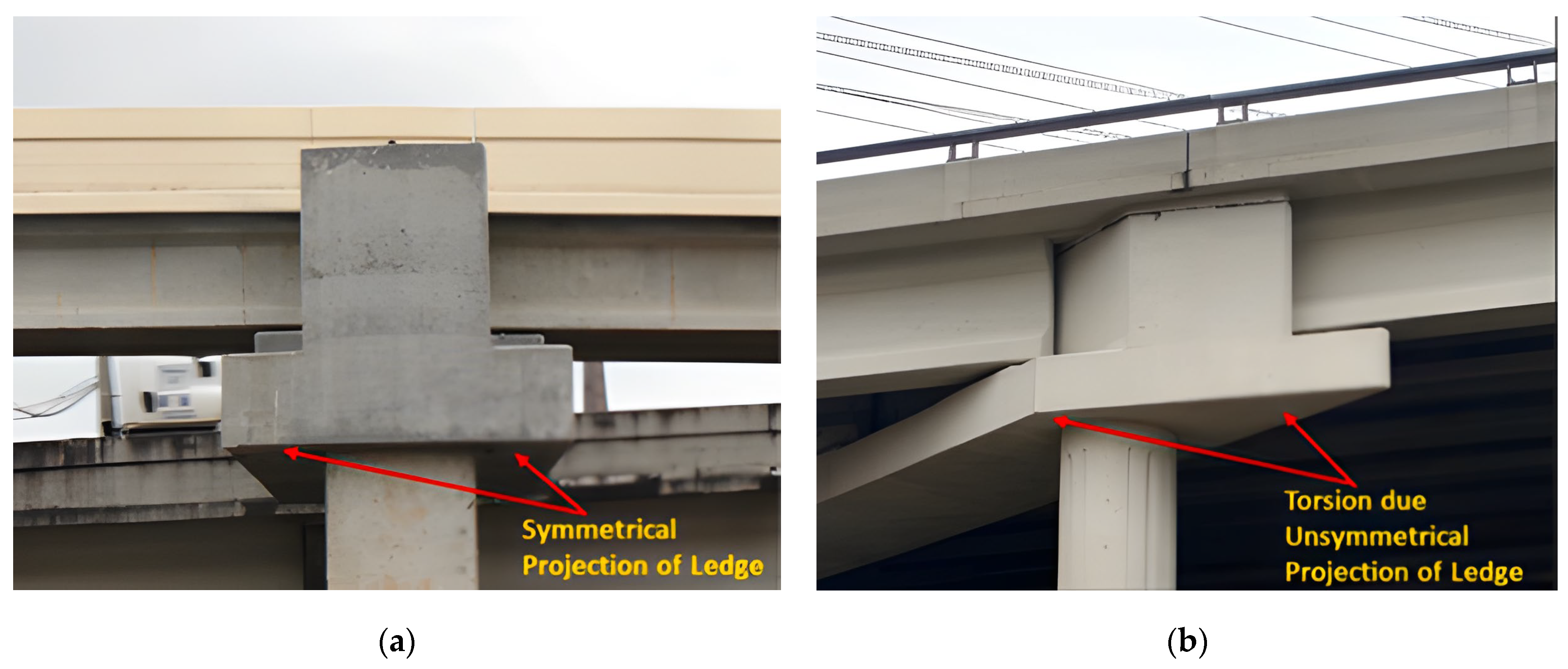

3.4. Skewed Connections in Inverted-T Bent Caps

4. Advanced Connecting Approaches

4.1. Ultra-High-Performance Concrete (UHPC)

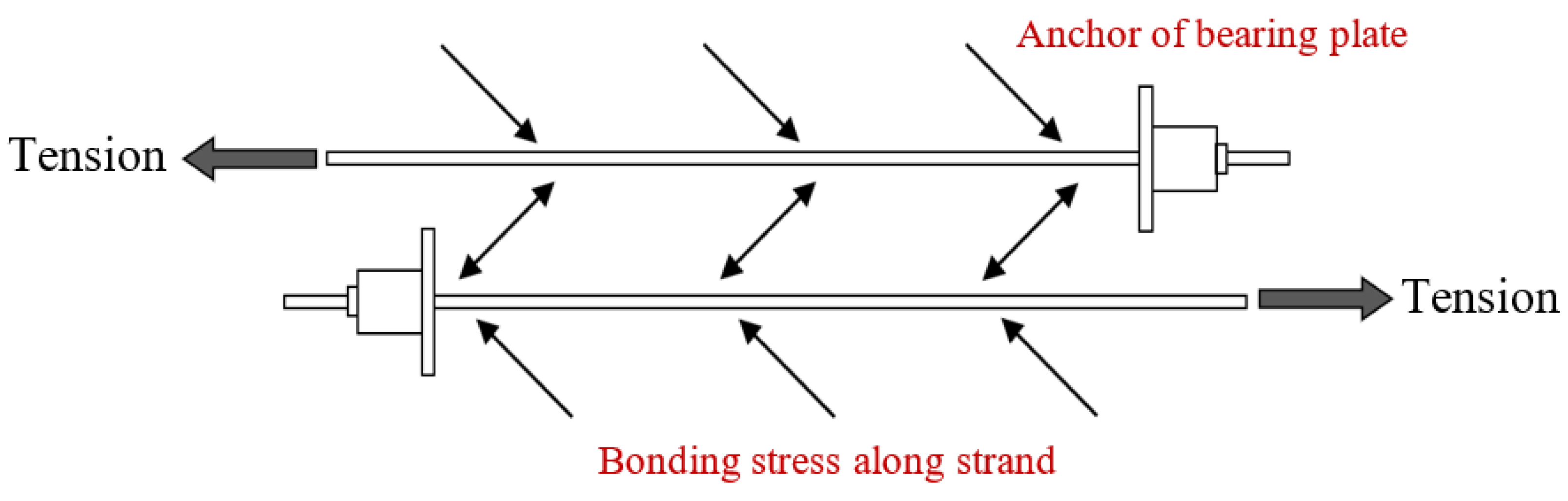

4.2. Unstressed Strands

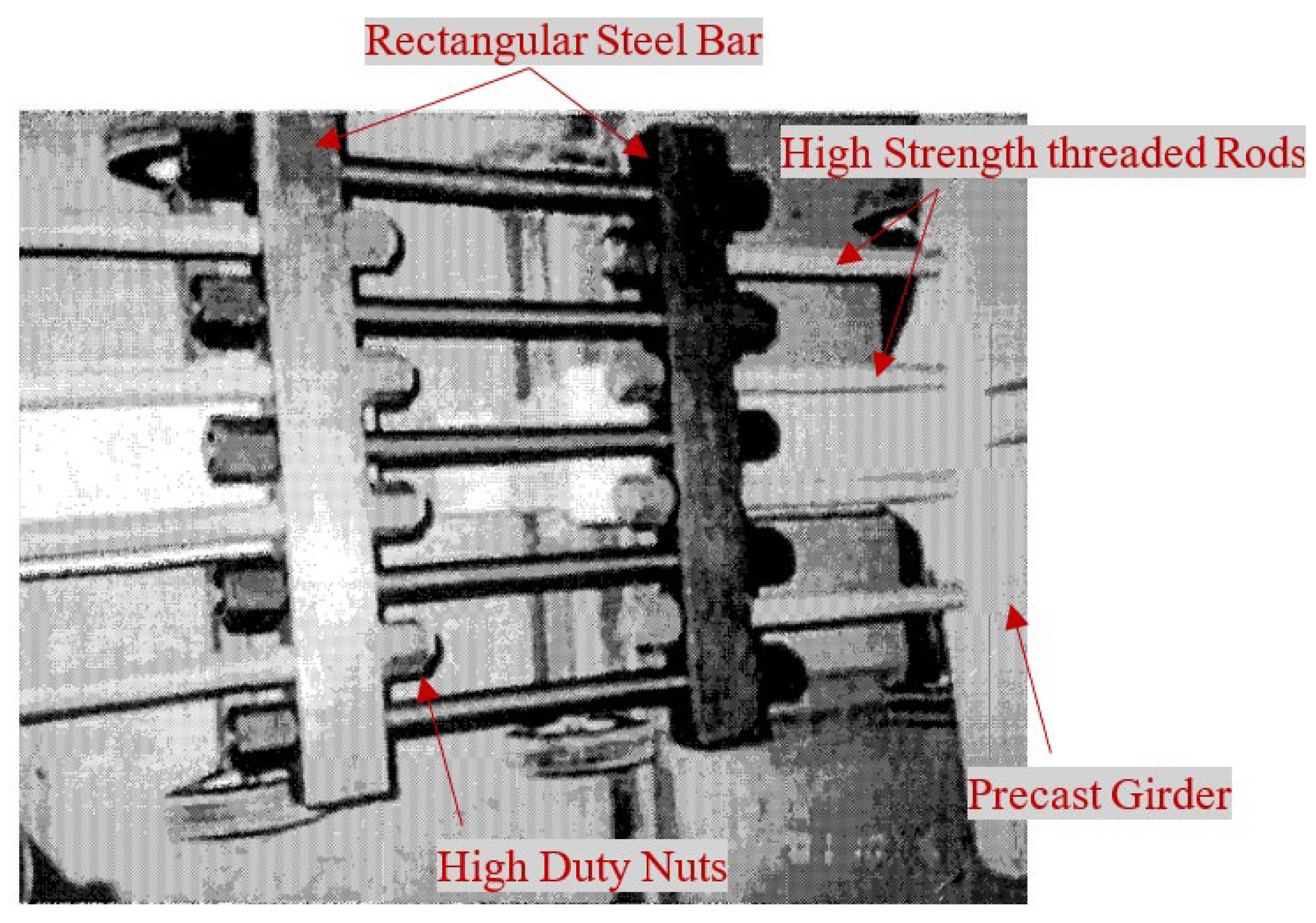

4.3. Mechanical Splices

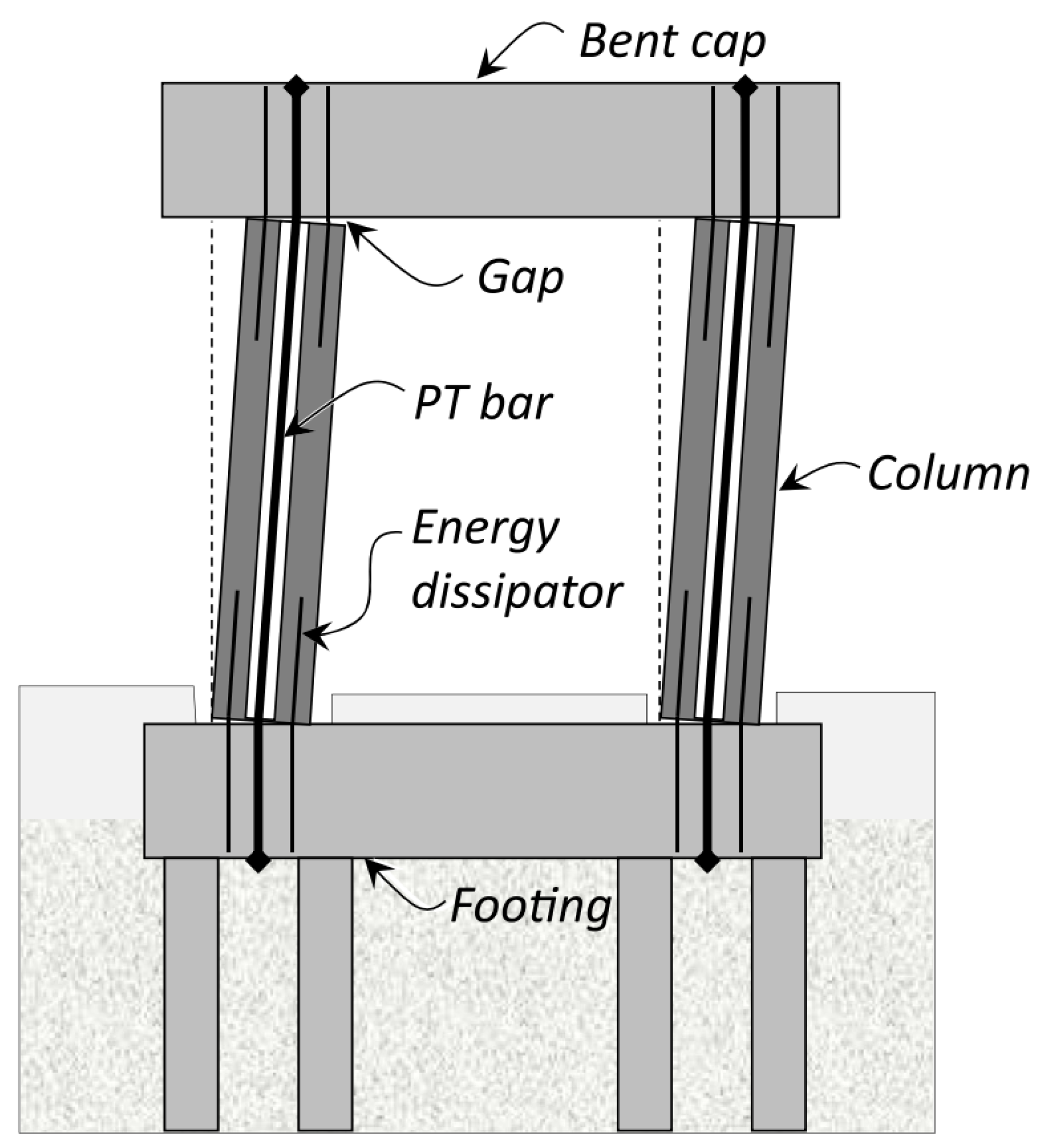

5. Seismic Performance

| Reference | Location | Approach |

|---|---|---|

| Mander et al. (1997) [90] | Column–foundation | Investigated steel plates at the joint. |

| Billington et al. (2004) [91] | Column–foundation | Substituted column ends with fiber-reinforced concrete shells, either hollow or filled with self-consolidating concrete. |

| Palermo et al. (2007) [92] | Column–foundation | Implemented steel plates at the foundation top, armored column toes with steel angles, and linked a hemispherical steel block to guarantee shear transfer. |

| Marriot et al. (2009, 2011) [93,94] | Column–foundation | Investigated replaceable external hysteretic dampers. |

| ElGawady et al. (2010) [95] | Column–foundation | Implemented thin neoprene pads at column ends, resulting in reduced lateral stiffness of the column. |

| Trono et al. (2014) [96] | Column–foundation | Researched various bedding mortars for the joint between column and cap beam and replaced column ends with fiber-reinforced concrete shells. |

| Motaref et al. (2014) [97] | Column–foundation | Utilized laminated elastomeric bearings at column ends, resulting in changes in the dynamic characteristics of the column. |

| Tazarv et al. (2015) [98] | Column–foundation | Replaced column ends with fiber-reinforced concrete shells, either hollow or filled with self-consolidating concrete. |

| Mashal et al. (2015), White et al. (2016) [99,100] | Column–foundation | Explored unbonded PT bridge columns embedded in foundation sockets, strengthened with a steel jacket. |

| Thonstad et al. (2016) [101] | Column–foundation | Employed partially debonded mild-reinforcing or stainless-steel reinforcing bars for energy dissipation in jointed bridge columns. |

| Tobolski et al. (2008) [102] | Column–cap | Investigated the types of bedding mortar that can withstand the impact and transfer shear at the joint between the column and the cap beam. |

| Cohagen et al. (2008) [103] | Column–cap | Investigated various bedding mortar types for the joint between column and cap beam and utilized spirals to confine column ends. |

| Restrepo et al. (2011) [104] | Column–cap | Explored different bedding mortars for the joint between column and cap beam and studied columns with dual steel shells (concrete cast between shells). |

| Guerrini et al. (2013) [105] | Column–cap | Investigated bedding mortars for the joint between column and cap beam and employed headed reinforcing bars at column ends for compression transfer. |

| Guerrini et al. (2014) [89] | Column–cap | Examined bedding mortars for the joint between column and cap beam, investigated columns with dual steel shells (concrete cast between shells), and used headed reinforcing bars at column ends for compression transfer. |

| Eberhard et al. (2014) [106] | Column ends | Demonstrated the feasibility of precast pretensioned bridge columns with partially debonded strands, employing a hybrid fiber-reinforced concrete shell for confinement at the critical column ends. |

6. Conclusions

- Extended deck reinforcement offers a simple and cost-effective solution for achieving partially integrated continuity in bridge decks but may have limitations for large spans and can induce challenges such as the development of cracks at the bottom of diaphragms.

- Diaphragms with bent bar connections mitigate the occurrence of cracks induced by positive moments, but weaknesses at the girder–diaphragm interface prevent the full achievement of continuity effects and may lead to spalling in the diaphragm concrete.

- Diaphragms with bent strands offer an alternative solution for mitigating spalling in diaphragms observed in those with bent bar connections, but there are concerns that crack widths under cyclic loads and inadequate development length for the bent strands may affect performance under full service and seismic conditions.

- Positive-moment connections between superstructures often involve bent bars or bent strands, with bent bars demonstrating superior performance in typical design scenarios.

- While continuity diaphragms may improve load distribution properties, their effectiveness in skewed continuous bridges is limited.

- Ultra-High-Performance Concrete (UHPC) offers several benefits for joint connections, including increased load capacity, improved durability, and enhanced resistance to seismic activity.

- Mechanical splices, such as the threaded rod continuity system, offer advantages in establishing continuity for live loads, superimposed dead loads, and the dead load of the slab itself.

- The seismic performance of PC/PS girder bridges relies heavily on the connections between precast structural components, particularly at critical joints like column–foundation and column–cap connections.

- Research efforts have focused on investigating the structural performance of column ends under seismic loads, including the use of steel plates, fiber-reinforced concrete shells, steel jackets, spirals, headed reinforcing bars, and unbonded post-tensioning, to improve shear transfer and compression transfer at column–foundation and column–cap joints.

- While this study provides a comprehensive review of continuous joints in precast prestressed girder bridges, several aspects require further research. The seismic performance of continuous joints needs additional experimental and numerical investigations to enhance resilience in highly seismic regions. Moreover, the long-term durability of these connections under environmental exposure, fatigue, and corrosion remains a critical area of study. The use of post-tensioned concrete columns in continuous bridge systems is still not widely explored, and further studies are needed to evaluate their structural feasibility and force transfer mechanisms. Additionally, future research should focus on innovative connection methods, including modular precast solutions, hybrid joints, and advanced materials, to improve constructability and performance. The integration of smart monitoring technologies and AI-based structural health assessment could further enhance the reliability and maintenance of continuous bridges.

Funding

Data Availability Statement

Conflicts of Interest

References

- Tomek, R. Advantageous bridge construction with prefabrication. In Proceedings of the Creative Construction Conference, Ljubljana, Slovenia, 30 June–3 July 2018; pp. 271–275. [Google Scholar]

- Ussenkulov, Z.A.; Shukeyeva, S.S.; Ussenkulova, S.Z. Advantage Use of Precast Concrete for Bridges. In Proceedings of the Industrial Technologies and Engineering (ICITE-2018), Singapore, 3–5 September 2018; pp. 232–236. [Google Scholar]

- Tomek, R. Advantages of precast concrete in highway infrastructure construction. Procedia Eng. 2017, 196, 176–180. [Google Scholar]

- Faraji, S.; Ting, J.M.; Crovo, D.S.; Ernst, H. Nonlinear analysis of integral bridges: Finite-element model. J. Geotech. Geoenviron. Eng. 2001, 127, 454–461. [Google Scholar]

- Greimann, L.F.; Yang, P.-S.; Wolde-Tinsae, A.M. Nonlinear analysis of integral abutment bridges. J. Struct. Eng. 1986, 112, 2263–2280. [Google Scholar]

- Okeil, A.M.; Cai, S.; Chebole, V.; Hossain, T. Evaluation of Continuity Detail for Precast Prestressed Girders; Louisiana Transportation Research Center: Baton Rouge, LA, USA, 2011. [Google Scholar]

- Pacheco, P.; Adão da Fonseca, A.P.; Resende, A.; Campos, R. Sustainability in bridge construction processes. Clean Technol. Environ. Policy 2010, 12, 75–82. [Google Scholar] [CrossRef]

- Pierrehumbert, R. There is no Plan B for dealing with the climate crisis. Bull. At. Sci. 2019, 75, 215–221. [Google Scholar] [CrossRef]

- Cao, J.; Wang, C.; Gonzalez-Libreros, J.; Wang, T.; Tu, Y.; Elfgren, L.; Sas, G. Extended applications of molecular dynamics methods in multiscale studies of concrete composites: A review. Case Stud. Constr. Mater. 2025, 22, e04153. [Google Scholar] [CrossRef]

- Burns, N.H. Development of continuity between precast prestressed concrete beams. PCI J. 1966, 11, 23–36. [Google Scholar]

- Thippeswamy, H.K.; GangaRao, H.V.S.; Franco, J.M. Performance evaluation of jointless bridges. J. Bridge Eng. 2002, 7, 276–289. [Google Scholar]

- Hosteng, T.K.; Phares, B.M. Economic Impact of Multi-Span, Prestressed Concrete Girder Bridges Designed as Simple Span Versus Continuous Span: Tech Transfer Summary; Midwest Transportation Center: Ames, IA, USA, 2016. [Google Scholar]

- Okeil, A.M.; ElSafty, A. Partial continuity in bridge girders with jointless decks. Pract. Period. Struct. Des. Constr. 2005, 10, 229–238. [Google Scholar]

- Al-Ani, M.; Murashev, A.; Palermo, A.; Andisheh, K.; Wood, J.; Goodall, D.; Lloyd, N. Criteria and guidance for the design of integral bridges. Proc. Inst. Civ. Eng. Bridge Eng. 2018, 171, 143–154. [Google Scholar]

- Gharad, A.M.; Sonparote, R.S. Influence of soil-structure interaction on the dynamic response of continuous and integral bridge subjected to moving loads. Int. J. Rail Transp. 2020, 8, 285–306. [Google Scholar] [CrossRef]

- Kim, S.-H.; Yoon, J.-H.; Kim, J.-H.; Choi, W.-J.; Ahn, J.-H. Structural details of steel girder–abutment joints in integral bridges: An experimental study. J. Constr. Steel Res. 2012, 70, 190–212. [Google Scholar] [CrossRef]

- Hulangamuwa, C.; Abeykoon, D. Behaviour of Jointless Bridge Decks with Link Slabs: A Review. In Proceedings of the International Conference of Structural Engineering & Construction Management (ICSECM-2019), Kandy, Sri Lanka, 12–14 December 2020. [Google Scholar]

- Loveall, C.L. Jointless bridge decks. Civ. Eng. 1985, 55, 64–67. [Google Scholar]

- Burke, M.P., Jr. Semi-integral bridges: Movements and forces. Transp. Res. Rec. 1994, 1460, 1–7. [Google Scholar]

- Burke, M.P., Jr. Integral bridges: Attributes and limitations. Transp. Res. Rec. 1993, 1393, 1–8. [Google Scholar]

- Oesterle, R.G.; Glikin, J.D.; Larson, S.C. Design of Precast, Prestressed Bridge Girders Made Continuous; Transportation Research Board: Washington, DC, USA, 1989. [Google Scholar]

- Miller, R.A. Connection of Simple-Span Precast Concrete Girders for Continuity; Transportation Research Board: Washington, DC, USA, 2004. [Google Scholar]

- Newhouse, C.D. Design and Behavior of Precast, Prestressed Girders Made Continuous: An Analytical and Experimental Study. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2005. [Google Scholar]

- Saber, A.; Toups, J.; Guice, L.; Tayebi, A. Continuity Diaphragm for Skewed Continuous Span Precast Prestressed Concrete Girder Bridges; Louisiana Transportation Research Center: Baton Rouge, LA, USA, 2004. [Google Scholar]

- Saber, A.; Mothukuri, A.K.; Arasangi, P. Field Verification for the Effectiveness of Continuity Diaphragms for Skewed Continuous P/CP/S Concrete Girder Bridges; Louisiana Transportation Research Center: Baton Rouge, LA, USA, 2009. [Google Scholar]

- Naseri, H.; Jahanbakhsh, H.; Foomajd, A.; Galustanian, N.; Karimi, M.M.; DWaygood, E.O. A newly developed hybrid method on pavement maintenance and rehabilitation optimization applying Whale Optimization Algorithm and random forest regression. Int. J. Pavement Eng. 2023, 24, 2147672. [Google Scholar]

- Kwon, O.S.; Kim, E.; Orton, S. Calibration of live-load factor in LRFD bridge design specifications based on state-specific traffic environments. J. Bridge Eng. 2011, 16, 812–819. [Google Scholar]

- El-Sisi, A.; Hassanin, A.; Alsharari, F.; Galustanian, N.; Salim, H. Failure behavior of composite bolted joints. CivilEng 2022, 3, 1061–1076. [Google Scholar] [CrossRef]

- Galustanian, N.; El-Sisi, A.; Amer, A.; Elshamy, E.; Hassan, H. Review of the Structural Performance of Beams and Beam–Column Joints with Openings. CivilEng 2023, 4, 1233–1242. [Google Scholar] [CrossRef]

- Floyd, R.W.; Jeffery Volz, P.S.; Funderburg, C.K.; Amy McDaniel, M.S.; Trevor Looney, M.; Candidate Jake Choate, P.; Stephen Roswurm, C.; Connor Casey, C.; Raina Coleman, M.; Maranda Leggs, M.; et al. Evaluation of Ultra-High-Performance Concrete for Use in Bridge Connections and Repair; Oklahoma Department of Transportation: Oklahoma City, OK, USA, 2020.

- Bazaez, R.; Dusicka, P. Cyclic behavior of reinforced concrete bridge bent retrofitted with buckling restrained braces. Eng. Struct. 2016, 119, 34–48. [Google Scholar] [CrossRef]

- Aboukifa, M.; Moustafa, M.A.; Saiidi, M.S. Seismic response of precast bridge columns with composite non-proprietary UHPC filled ducts ABC connections. Compos. Struct. 2021, 274, 114376. [Google Scholar] [CrossRef]

- Saingam, P.; Sutcu, F.; Terazawa, Y.; Fujishita, K.; Lin, P.C.; Celik, O.C.; Takeuchi, T. Composite behavior in RC buildings retrofitted using buckling-restrained braces with elastic steel frames. Eng. Struct. 2020, 219, 110896. [Google Scholar] [CrossRef]

- Wang, W.W.; Dai, J.G.; Huang, C.K.; Bao, Q.H. Strengthening multiple span simply-supported girder bridges using post-tensioned negative moment connection technique. Eng. Struct. 2011, 33, 663–673. [Google Scholar] [CrossRef]

- Peggar, R. Two Integral Girder Connections for Precast Concrete Bridges in Seismic Regions Utilizing Extended Prestressing Strands. Master’s Thesis, Iowa State University, Ames, IA, USA, 2014. [Google Scholar]

- Holombo, J.; Priestly, M.J.N.; Seible, F. Continuity of precast prestressed spliced-girder bridges under seismic loads. PCI J. 2000, 45, 40–63. [Google Scholar]

- Hambly, E.C. Integral Bridges. Proc. Inst. Civ. Eng. Transp. 1997, 123, 30–38. [Google Scholar] [CrossRef]

- Caner, A. Behavior and design of link slabs for jointless bridge decks. PCI J. 1998, 43, 68–81. [Google Scholar]

- Burke, M.P. Design of integral concrete bridges. Concr. Int. 1993, 15, 37–42. [Google Scholar]

- Siros, K.A.; Spyrakos, C.C. Creep analysis of hybrid integral bridges. Transp. Res. Rec. 1995, 1476, 147–154. [Google Scholar]

- Kaar, P.H.; Kriz, L.B.; Hognestad, E. Precast-Prestressed Concrete Bridges: 1. Pilot Tests of Continuous Girders; Research and Development Laboratories, Portland Cement Association: Washington, DC, USA, 1960. [Google Scholar]

- Mattock, A.H.; Kaar, P.H. Precast-Prestressed Concrete Bridges 3: Further Tests of Continuous Girders; Research and Development Laboratories, Portland Cement Association: Washington, DC, USA, 1960. [Google Scholar]

- Mirmiran, A.; Kulkarni, S.; Miller, I.; Hastak, M.; Castrodale, I. Positive moment cracking in diaphragms of simple-span prestressed girders made continuous. Spec. Publ. 2001, 204, 117–134. [Google Scholar]

- Miller, R.A.; Castrodale, R.; Mirmiran, A.; Hastak, M.; Baseheart, T.M. Connections Between Simply Supported Concrete Beam Made Continuous. In Proceedings of the 2004 Concrete Bridge Conference Federal Highway, Charlotte, NC, USA, 17–18 May 2004. [Google Scholar]

- Demartini, C.J.; Heywood, R.J. Repair of the southern approach to the story bridge by elimination of the contraction joints. In Bridges: Part of the Transport System. Proceedings of the AUSTROADS Bridges Conference AUSTROADS; Queensland University of Technology: Brisbane, QLD, Australia; Queensland Department of Transport: Brisbane, QLD, Australia; Australian Road Research Board: Melbourne, VIC, Australia, 1991. [Google Scholar]

- Pierce, P. Jointless redecking. Civ. Eng. 1991, 61, 60–61. [Google Scholar]

- Missouri Department of Transportation. Engineering Policy Guide 751.31; Missouri Department of Transportation: Jefferson City, MO, USA, 2023.

- William, C.; Norman, C. Ultra-High Performance Concrete for Connections of Precast, Prestressed Girders Made Continuous for Live Load. Master’s Thesis, The University of Oklahoma, Norman, OK, USA, 2019. [Google Scholar]

- Freyermuth, C.L. Design of Continuous Highway Bridges with Precast, Prestressed Concrete Girders. PCI J. 1969, 14, 14–39. [Google Scholar] [CrossRef]

- Hanson, N.W. Precast-Prestressed Concrete Bridges: 2. Horizontal Shear Connections; Research and Development Laboratories, Portland Cement Association: Washington, DC, USA, 1960. [Google Scholar]

- Mattock, A.H. Precast-Prestressed Concrete Bridges. J. PCA Res. Dev. Lab. 1961, 6, 42–56. [Google Scholar]

- Galustanian, N.; Elshazli, M.T.; Elsisi, A.; Orton, S.L. Evaluating Rotational Restraint in Non-Integral Intermediate Bents with Closed Diaphragms. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=5169243 (accessed on 4 March 2025).

- Abdalla, O.A.; Ramirez, J.A.; Lee, R.H. Strand Debonding in Pretensioned Beams-Precast Prestressed Concrete Bridge Girders with Debonded Strands-Continuity Issues; Purdue University: West Lafayette, IN, USA, 1993. [Google Scholar]

- Clark, L.A.; Sugie, I. Serviceabiilty Limit State Aspects of Continuous Bridges Using Precast Concrete Beams. Struct. Eng. 1997, 75, 185–190. [Google Scholar]

- Salmons, J.R. End Connections of Pretensioned I-Beam Bridges; Federal Highway Administration: Washington, DC, USA, 1974.

- Thonstad, T.; Eberhard, M.O.; Stanton, J.F. Design of prestressed, jointed columns for enhanced seismic performance. Structures 2021, 33, 1007–1019. [Google Scholar] [CrossRef]

- Snyder, R.M. Seismic Performance of an I-Girder to Inverted-T Bent Cap Bridge Connection; Iowa State University: Ames, IA, USA, 2010. [Google Scholar]

- Tadros, M.K.; Ficenec, J.A.; Einea, A.; Holdsworth, S. A new technique to create continuity in prestressed concrete members. PRECAST/PRESTRESSED Concr. Inst. J. 1993, 38, 30–37. [Google Scholar] [CrossRef]

- Pang, J.B.K.; Steuck, K.P.; Cohagen, L.; Stanton, J.F.; Marc, O.E. Rapidly Constructible Large-Bar Precast Bridge-Bent Seismic Connection; Citeseer: Washington, DC, USA, 2008. [Google Scholar]

- Pang, J.B.K.; Eberhard, M.O.; Stanton, J.F. Large-bar connection for precast bridge bents in seismic regions. J. Bridge Eng. 2010, 15, 231–239. [Google Scholar] [CrossRef]

- Roy, S.S.; Sawab, J.; Zhou, T.; Wang, J.; Mo, Y.L.; Hsu, T.T.C. Experimental study on skew inverted-T bent caps with minimum traditional and skew transverse reinforcing. Eng. Struct. 2021, 230, 111653. [Google Scholar]

- Saber, A.; Alaywan, W. Full-scale test of continuity diaphragms in skewed concrete bridge girders. J. Bridge Eng. 2011, 16, 21–28. [Google Scholar] [CrossRef]

- Oz, Y.; Wang, J.; Roy, S.S.; Zhang, S.; Joshi, B.; Guo, Z.; Mo, Y.L.; Hsu, T.T.C. Finite-Element Simulation and Cost–Benefit Analysis of Full-Scale Skewed Inverted-T Bridge Caps with Traditional and Skew Reinforcements. J. Bridge Eng. 2022, 27, 4022046. [Google Scholar] [CrossRef]

- El-Ariss, B.; Mansour, M.; El-Maaddawy, T. Effects of web height reduction and skew angle variation on behavior of RC inverted T-beams. Buildings 2021, 11, 451. [Google Scholar] [CrossRef]

- Seibert, P.J.; Perry, V.H.; Corvez, D.; Seibert, P.J.; Perry, V.H. Performance Evaluation of Field Cast UHPC Connections for Precast Bridge Elements. In International Interactive Symposium on Ultra-High Performance Concrete; Iowa State University Digital Press: Ames, IA, USA, 2019. [Google Scholar]

- Hung, C.-C.; El-Tawil, S.; Chao, S.-H. A review of developments and challenges for UHPC in structural engineering: Behavior, analysis, and design. J. Struct. Eng. 2021, 147, 3121001. [Google Scholar] [CrossRef]

- Amran, M.; Huang, S.-S.; Onaizi, A.M.; Makul, N.; Abdelgader, H.S.; Ozbakkaloglu, T. Recent trends in ultra-high performance concrete (UHPC): Current status, challenges, and future prospects. Constr. Build. Mater. 2022, 352, 129029. [Google Scholar]

- Sharaky, I.A.; Ahmad, S.S.; El-Azab, A.M.; Khalil, H.S. Strength and mass loss evaluation of HSC with silica fume and nano-silica exposed to elevated temperatures. Arab. J. Sci. Eng. 2021, 47, 4187–4209. [Google Scholar] [CrossRef]

- El-Sisi, A.A.; Elkilani, A.M.; Salim, H.A. Investigation of the effect of crumb rubber on the static and dynamic response of reinforced concrete panels. Sustainability 2022, 14, 10810. [Google Scholar] [CrossRef]

- Liang, X.; Sritharan, S. Use of unstressed strands for connections of precast concrete members. PCI J. 2021, 66, 88–89. [Google Scholar]

- Tadros, M.K. Implementation of the Superstructure/Substructure Joint Details; Nebraska Department of Transportation: Lincoln, NE, USA, 2003.

- Tadros, M.K.; Martin, L.D. Design Aids for Threaded Rod Precast Prestressed Girder Continuity System; Nebraska Department of Transportation: Lincoln, NE, USA, 2007.

- Sun, C. High Performance Concrete Bridge Stringer System; The University of Nebraska-Lincoln: Lincoln, NE, USA, 2004. [Google Scholar]

- Cheng, Z. Seismic Performance of Accelerated Bridge Construction (ABC) Precast Bulb-Tee Girder-to-Bent Cap Connection; Iowa State University: Ames, IA, USA, 2015. [Google Scholar]

- Kurama, Y.C.; Sritharan, S.; Fleischman, R.B.; Restrepo, J.I.; Henry, R.S.; Cleland, N.M.; Ghosh, S.K.; Bonelli, P. Seismic-resistant precast concrete structures: State of the art. J. Struct. Eng. 2018, 144, 3118001. [Google Scholar] [CrossRef]

- Galustanian, N.; El-Sisi, A.E.; Panahshahi, N.; Orton, S.; Sobhy, A. Cyclic performance of RC frame joints with drilled openings. Structures 2024, 64, 106568. [Google Scholar]

- Ericson, A.C.; Warnes, C.E. Seismic Technology for Precast Concrete Systems; Concrete Industry Board Inc.: Kew Gardens, NY, USA, 1990. [Google Scholar]

- Nakaki, S.D. An overview of the PRESSS five-story precast test building. PCI J. 1999, 44, 26–29. [Google Scholar]

- Farrow, K.T.; Kurama, Y.C. SDOF demand index relationships for performance-based seismic design. Earthq. Spectra 2003, 19, 799–838. [Google Scholar]

- Priestley, M.J.N.; Sritharan, S.; Conley, J.R.; Pampanin, S. Preliminary results and conclusions from the PRESSS five-story precast concrete test building. PCI J. 1999, 44, 42–67. [Google Scholar]

- Priestley, M.J.N.; Tao, J.R. Seismic response of precast prestressed concrete frames with partially debonded tendons. PCI J. 1993, 38, 58–69. [Google Scholar] [CrossRef]

- Elawadi, A.; Orton, S.L.; Gopalaratnam, V.; Holt, J.; Lopez, M.D. Accuracy Evaluation of Prestressed Concrete Girder Camber in Missouri Bridges. J. Bridge Eng. 2022, 27, 04022119. [Google Scholar] [CrossRef]

- Vander Werff, J.R.; Snyder, R.; Sritharan, S.; Holombo, J. A cost-effective integral bridge system with precast concrete I-girders for seismic application. PCI J. 2015, 60, 76. [Google Scholar] [CrossRef]

- Caltrans. Seismic Design Criteria; California Department of Transportation: Sacramento, CA, USA, 2013.

- Burnell, K.; Restrepo, J.I.; Megally, S. Longitudinal testing of a precast post-tensioned bridge system. In Proceedings of the 20th US-Japan Workshop on Bridge Engineering, Public Works Research Institute of Japan, Washington, DC, USA, 3–9 October 2004. [Google Scholar]

- Sideris, P.; Aref, A.J.; Filiatrault, A. Large-scale seismic testing of a hybrid sliding-rocking posttensioned segmental bridge system. J. Struct. Eng. 2014, 140, 4014025. [Google Scholar] [CrossRef]

- Sideris, P.; Aref, A.J.; Filiatrault, A. Experimental seismic performance of a hybrid sliding–rocking bridge for various specimen configurations and seismic loading conditions. J. Bridge Eng. 2015, 20, 4015009. [Google Scholar] [CrossRef]

- Crespi, P.; Zucca, M.; Valente, M.; Longarini, N. Influence of corrosion effects on the seismic capacity of existing RC bridges. Eng. Fail. Anal. 2022, 140, 106546. [Google Scholar] [CrossRef]

- Guerrini, G.; Restrepo, J.I.; Massari, M.; Vervelidis, A. Seismic behavior of posttensioned self-centering precast concrete dual-shell steel columns. J. Struct. Eng. 2015, 141, 4014115. [Google Scholar] [CrossRef]

- Mander, J.B.; Cheng, C.-T. Seismic resistance of bridge piers based on damage avoidance design. In Seismic Resistance of Bridge Piers Based on Damage Avoidance Design; U.S. National Center for Earthquake Engineering Research: Buffalo, NY, USA, 1997; p. 109. [Google Scholar]

- Billington, S.L.; Yoon, J.K. Cyclic response of unbonded posttensioned precast columns with ductile fiber-reinforced concrete. J. Bridge Eng. 2004, 9, 353–363. [Google Scholar] [CrossRef]

- Palermo, A.; Pampanin, S.; Marriott, D. Design, modeling, and experimental response of seismic resistant bridge piers with posttensioned dissipating connections. J. Struct. Eng. 2007, 133, 1648–1661. [Google Scholar] [CrossRef]

- Marriott, D.; Pampanin, S.; Palermo, A. Quasi-static and pseudo-dynamic testing of unbonded post-tensioned rocking bridge piers with external replaceable dissipaters. Earthq. Eng. Struct. Dyn. 2009, 38, 331–354. [Google Scholar] [CrossRef]

- Marriott, D.; Pampanin, S.; Palermo, A. Biaxial testing of unbonded post-tensioned rocking bridge piers with external replacable dissipaters. Earthq. Eng. Struct. Dyn. 2011, 40, 1723–1741. [Google Scholar] [CrossRef]

- ElGawady, M.A.; Sha’Lan, A. Seismic behavior of self-centering precast segmental bridge bents. J. Bridge Eng. 2011, 16, 328–339. [Google Scholar] [CrossRef]

- Trono, W.; Jen, G.; Panagiotou, M.; Schoettler, M.; Ostertag, C.P. Seismic response of a damage-resistant recentering posttensioned-HYFRC bridge column. J. Bridge Eng. 2015, 20, 4014096. [Google Scholar] [CrossRef]

- Motaref, S.; Saiidi, M.S.; Sanders, D. Shake table studies of energy-dissipating segmental bridge columns. J. Bridge Eng. 2014, 19, 186–199. [Google Scholar] [CrossRef]

- Tazarv, M.; Saiidi, M.S. UHPC-filled duct connections for accelerated bridge construction of RC columns in high seismic zones. Eng. Struct. 2015, 99, 413–422. [Google Scholar] [CrossRef]

- Mashal, M.; Palermo, A. High-damage and low-damage seismic design technologies for accelerated bridge construction. Struct. Congr. 2015, 2015, 549–560. [Google Scholar]

- White, S.; Palermo, A. Quasi-static testing of posttensioned nonemulative column-footing connections for bridge piers. J. Bridge Eng. 2016, 21, 4016025. [Google Scholar] [CrossRef]

- Thonstad, T.; Mantawy, I.M.; Stanton, J.F.; Eberhard, M.O.; Sanders, D.H. Shaking table performance of a new bridge system with pretensioned rocking columns. J. Bridge Eng. 2016, 21, 4015079. [Google Scholar] [CrossRef]

- Tobolski, M.J.; Restrepo, J.I. Development of rocking column systems. In Proceedings of the Sixth National Seismic Conference on Bridges and Highways, Charleston, SC, USA, 28–30 July 2008. [Google Scholar]

- Cohagen, L.S.; Pang, J.B.K.; Eberhard, M.O.; Stanton, J.F. A Precast Concrete Bridge Bent Designed to Re-Center After an Earthquake: Draft Research Report, August 2008; Department of Transportation. Office of Research and Library Services: Washington, DC, USA, 2008.

- Restrepo, J.I.; Tobolski, M.J.; Matsumoto, E.E. Development of a Precast Bent Cap System for Seismic Regions; Transportation Research Board: Washington, DC, USA, 2011. [Google Scholar]

- Guerrini, G.; Restrepo, J. Seismic response of composite concrete-dual steel shell columns for accelerated bridge construction. In Proceedings of the 7th National Seismic Conference on Bridges and Highways, Oakland, CA, USA, 20–22 May 2013. [Google Scholar]

- Eberhard, M.O.; Stanton, J.F.; Haraldsson, O.S.; Finnsson, G.; Davis, P.M.; Schoettler, M.J. Development of a bridge bent system for rapid construction and enhanced seismic performance. In Proceedings of the 10th US National Conference on Earthquake Engineering, Anchorage, AK, USA, 21–25 July 2014; Earthquake Engineering Research Institute: Oakland, CA, USA, 2014. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Galustanian, N.; Elshazli, M.T.; Kaur, H.; Elsisi, A.; Orton, S. The Development of Continuous Connections for Multi-Span Precast Prestressed Girder Bridges: A Review. CivilEng 2025, 6, 16. https://doi.org/10.3390/civileng6020016

Galustanian N, Elshazli MT, Kaur H, Elsisi A, Orton S. The Development of Continuous Connections for Multi-Span Precast Prestressed Girder Bridges: A Review. CivilEng. 2025; 6(2):16. https://doi.org/10.3390/civileng6020016

Chicago/Turabian StyleGalustanian, Narek, Mohamed T. Elshazli, Harpreet Kaur, Alaa Elsisi, and Sarah Orton. 2025. "The Development of Continuous Connections for Multi-Span Precast Prestressed Girder Bridges: A Review" CivilEng 6, no. 2: 16. https://doi.org/10.3390/civileng6020016

APA StyleGalustanian, N., Elshazli, M. T., Kaur, H., Elsisi, A., & Orton, S. (2025). The Development of Continuous Connections for Multi-Span Precast Prestressed Girder Bridges: A Review. CivilEng, 6(2), 16. https://doi.org/10.3390/civileng6020016