Experimental Characterization of Cast Explosive Charges Used in Studies of Blast Effects on Structures

Abstract

:1. Introduction

1.1. Objectives

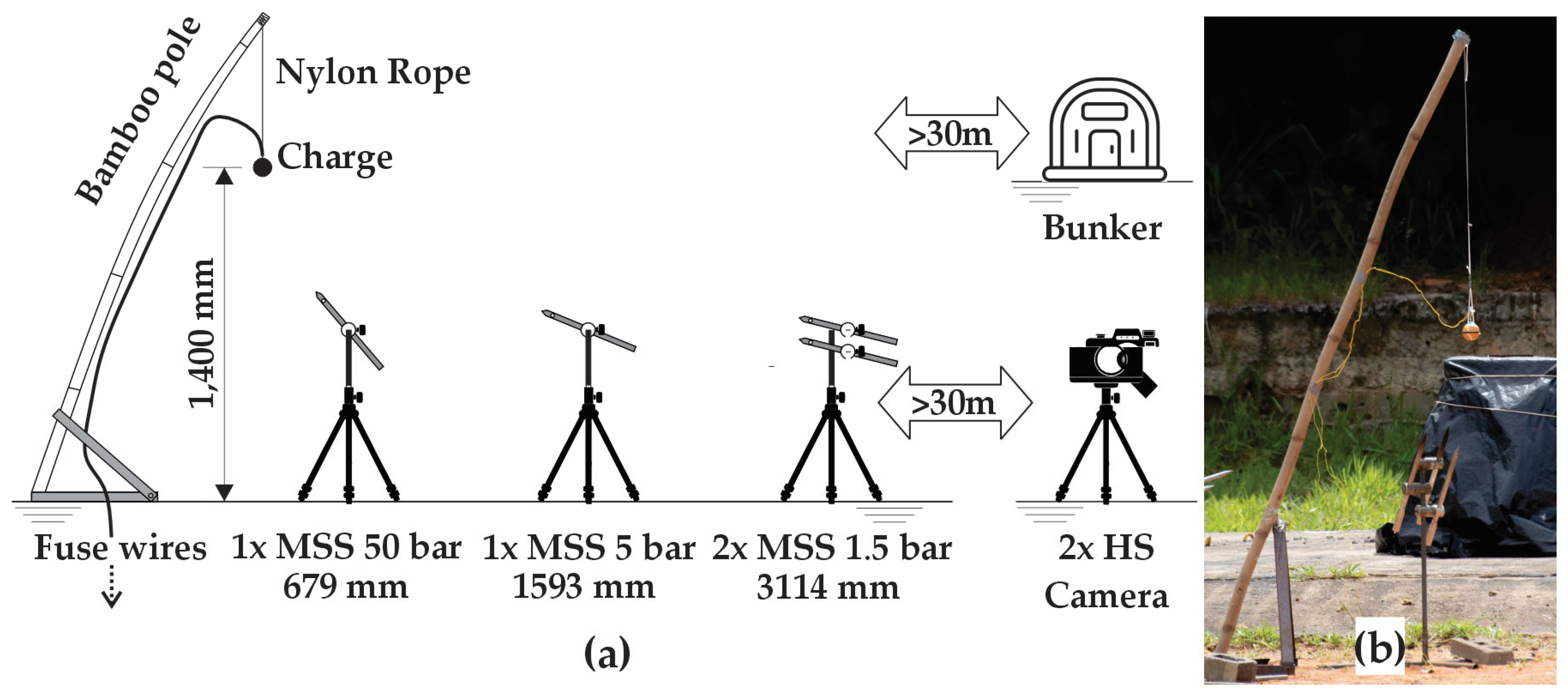

- Limited mass bare charges: The first requirement was to use small charges weighing up to 350 g and avoid any type of casing. This approach ensures that the blast effects remain within controlled parameters, preventing the generation of hazardous and unpredictable debris while reducing the costs associated with explosives. Under these conditions, a distance of 30 m from the detonation point was proven to be completely safe for both personnel and equipment during the tests. Another advantage of bare charges is the absence of interference from a casing, which allows for more accurate results of blast waves. The masses and dimensions of the charges can be adapted to meet each researcher’s specific needs, demanding adjustments to the safety zone.

- Spherical shape: The charges were loaded in a spherical shape with centrally initiated detonation. As demonstrated by [5], using other shapes, such as cylinders, results in variations in blast parameters at short-range distances compared to classical and validated references. Studies by Kinney and Graham [6] and Kingery and Bulmash [7] are widely recognized for their consideration of spherical shock waves and are used by organizations such as the United Nations [2], the U.S. Department of Defense [3], and the Brazilian Air Force [8] to predict blast effects. However, these studies are primarily applied to large-scale detonations, where the shape of the explosive is negligible relative to the distances involved. In small-scale academic tests with shorter distances, the shape of the charge can significantly affect the results [5].

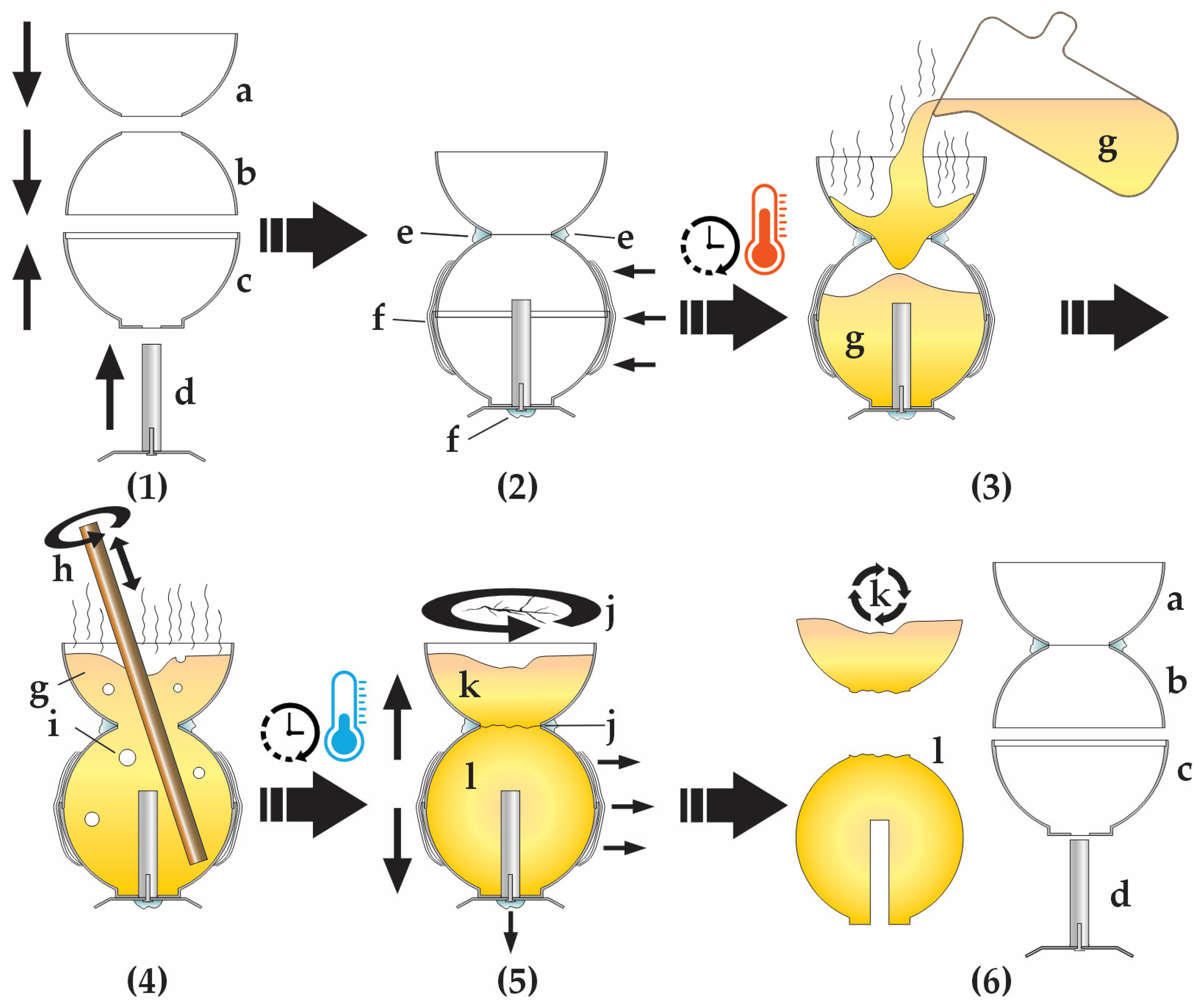

- Reduced costs: The method should utilize cost-effective, accessible, and removable molds to load the charges, rather than expensive machined metal molds, given the complexity of the spherical shape. The selected material for the molds was 0.7 mm-thick 1050 aluminum, fabricated into bipartite spherical molds that are commercially available and commonly used in paraffin candle production. The molds used in this research had a diameter of approximately 72 mm and a unit cost of less than one dollar. Other diameters and similar models are also available in retail stores, as illustrated in [9] (the example is very similar but not identical to the material purchased in Brazilian markets).

- Accessible Explosive: The selection of the explosive took into account several critical factors, including safety, cost, accessibility, power, castability, and the availability of well-established parameters. The explosives available to the research team that could meet these criteria included cast TNT, C4 (RDX + plasticizer), PBX (RDX or HMX + polymer), and cast Comp B (RDX + TNT + wax). C4 was deemed unsuitable due to its malleability, as it tends to lose its shape during testing. PBX was considered less ideal because it is more difficult to manufacture, more expensive, and available in a wide range of formulations. TNT and Comp B were ultimately determined to be the best options for this method due to their accessibility for defense research, ease of castability, well-established standards, safety profile, and good detonation power [10].

1.2. Experimental Tests and Analysis

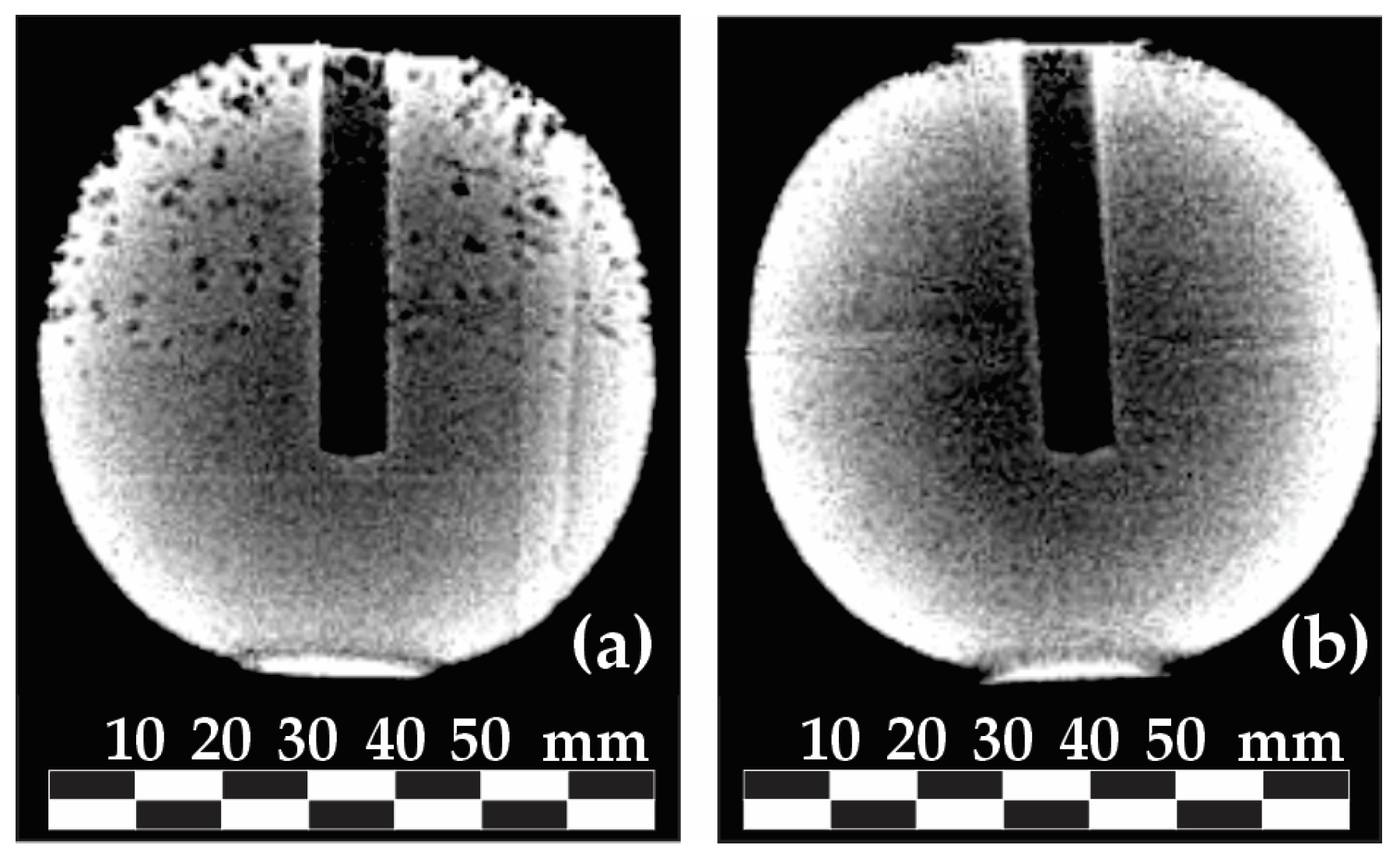

- X-ray analysis of all charges was conducted to investigate voids, cracks, or other mechanical problems, as TNT-based cast explosives may encounter these issues during solidification and crystallization, which could interfere with explosive performance [10];

- Measurement of the mass and density of the loaded explosive charges, demonstrating maintained load consistency with brief statistical analysis;

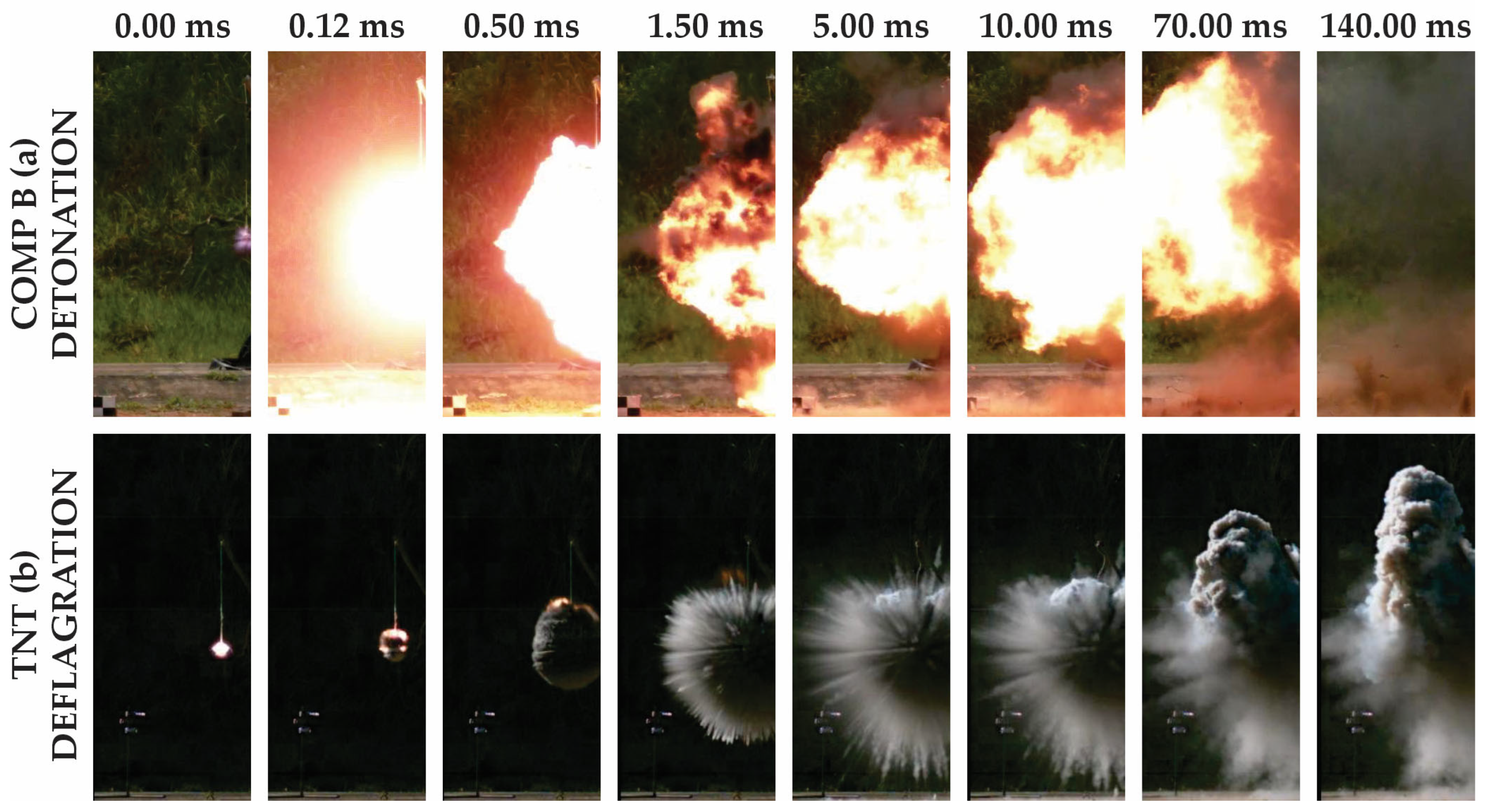

- Five detonation field tests were conducted for each type of explosive. All five Composition B charges detonated without incidents, while the TNT charges deflagrated, indicating that TNT was not effective for this type of loading and dimensions. The TNT initiation problem can be explained by the high critical diameter necessary for this explosive when not confined [11,12,13];

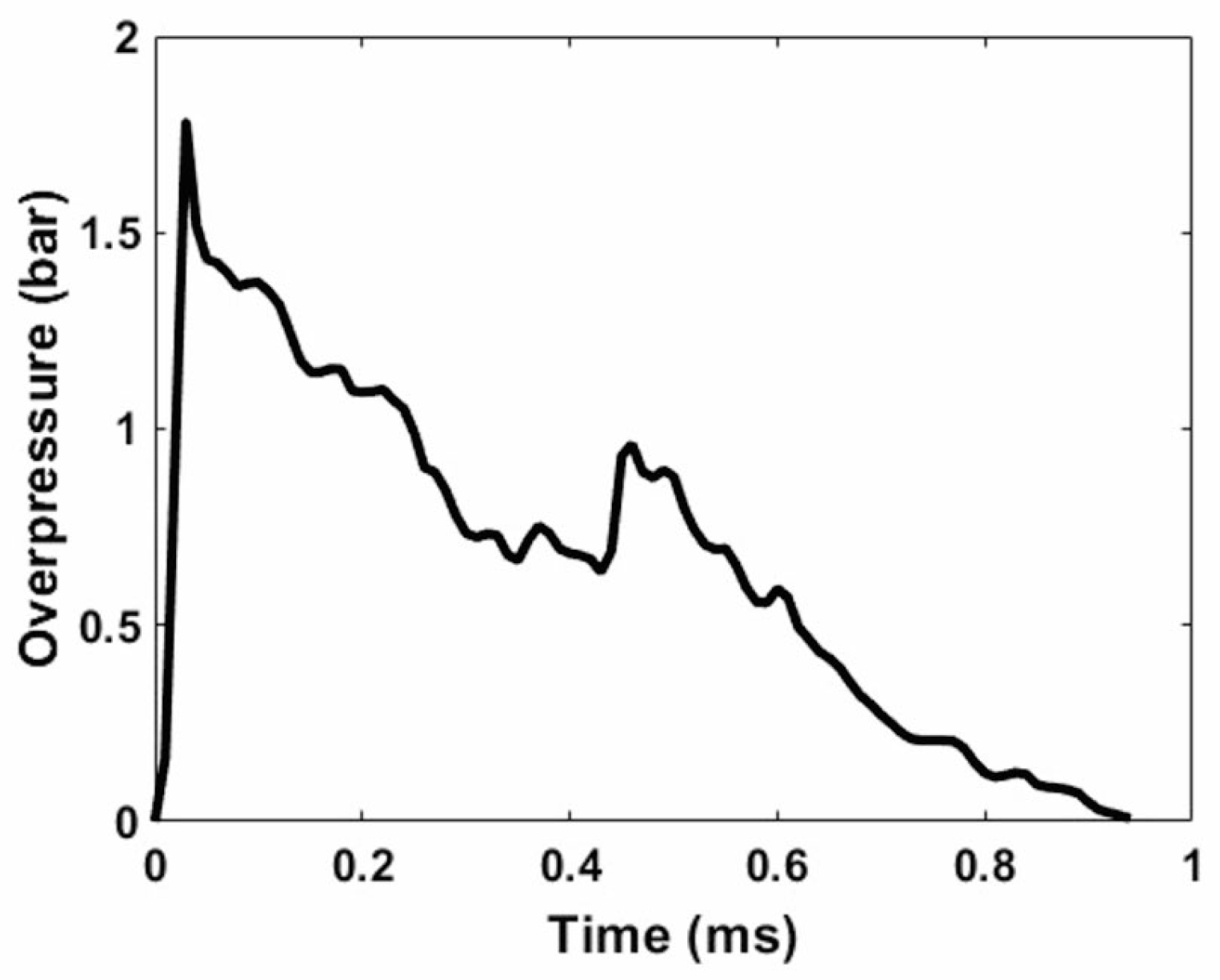

- Measurement of the atmospheric overpressures generated by the charges’ detonation using memorizing shock wave measuring systems in three different distances for each detonation test;

- TNT equivalence for pressure calculations of Composition B charges, compared with large-scale detonation events;

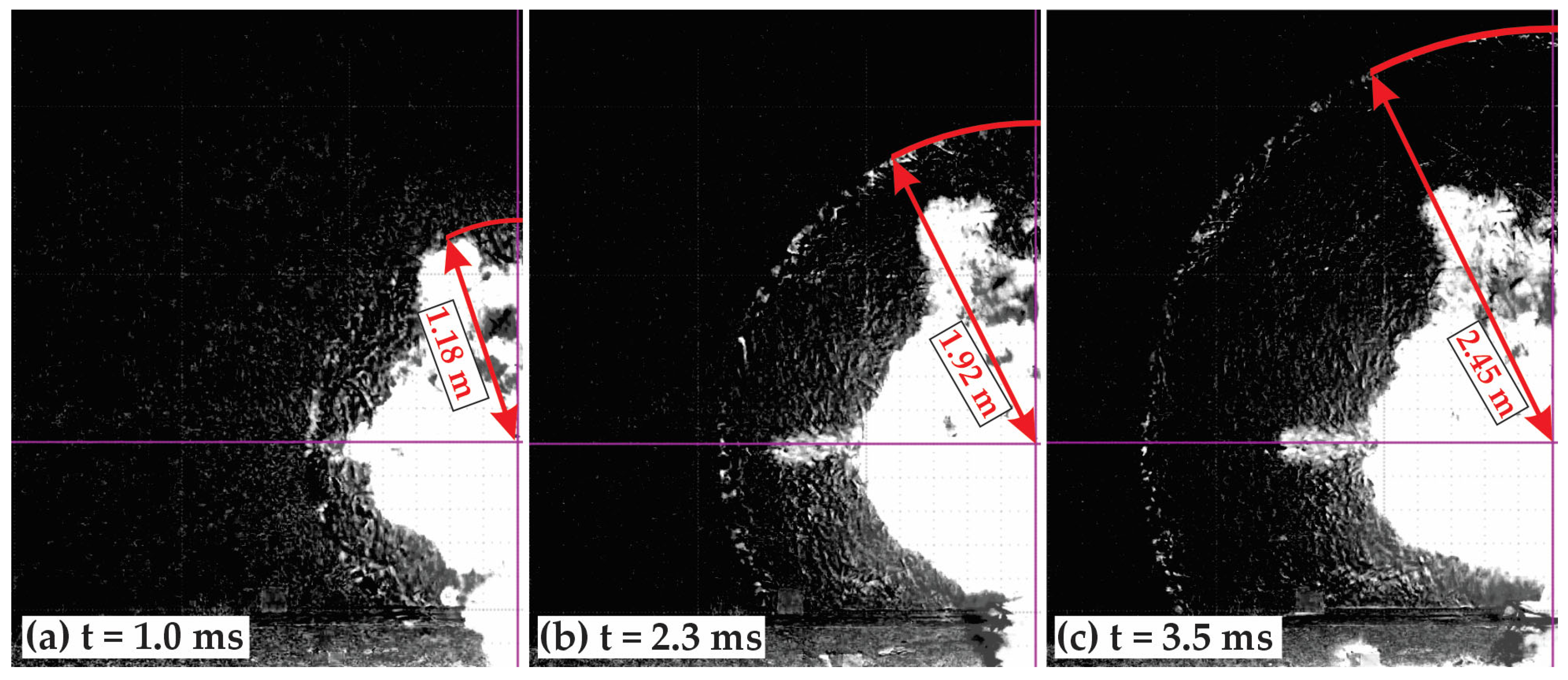

- Visual analysis of high-speed camera footage, comparing the effects of detonation and deflagration processes and examining the shock wave pattern of the Composition B charges;

- Other four specific detonation tests were conducted to characterize the detonation velocity of the charge;

- Chemical stability testing of three Comp B explosive samples, verifying whether the loading method introduced any hazardous contamination;

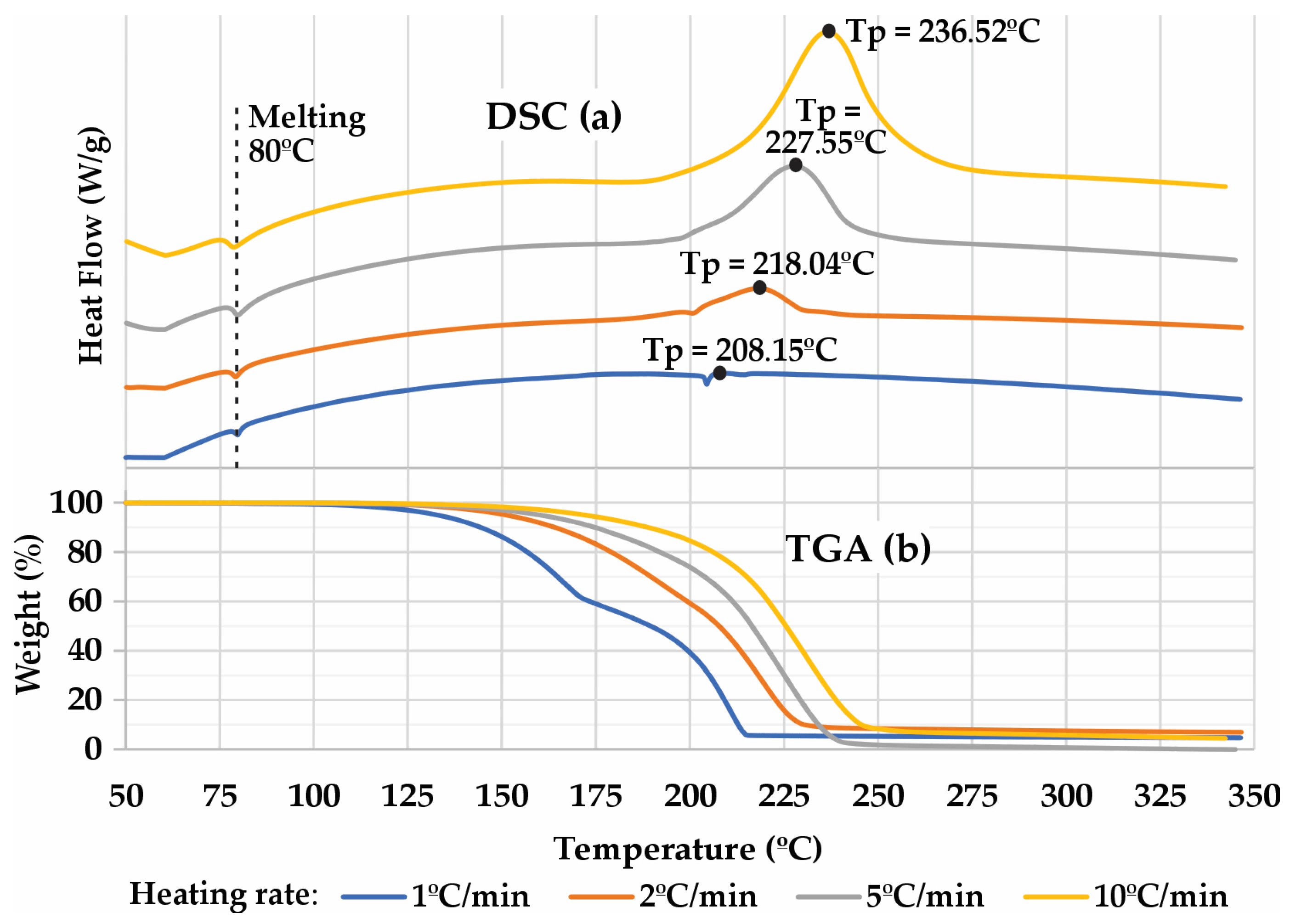

- Thermal analysis using differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) was conducted on four Composition B samples at four different heating rates: 1, 2, 5, and 10 °C/min. The degradation temperatures of the charges and other important parameters are presented;

- The activation energy of decomposition for the Composition B charges was calculated using two different methods and DSC results.

1.3. Positioning the Study in Modern Research

1.3.1. Blast Field Tests

1.3.2. Explosive Thermal Analysis

1.4. Contribution to Structural Analysis Field

2. Materials and Methods

2.1. Explosive Loading Method

2.2. Initial Inspections and Analysis

2.3. Field Detonation Tests

2.3.1. Blast Testing

2.3.2. Detonation Velocity Testing

2.3.3. TNT Equivalence

2.4. Laboratory Tests

2.4.1. Chemical Stability Test

2.4.2. DSC and TGA

2.4.3. Activation Energy Calculation

3. Results and Discussion

3.1. Initial Inspections and Analysis Results

3.2. Field Detonation Tests Results

3.2.1. Overpressure Measurements

3.2.2. TNT Equivalence Results

3.2.3. Detonation Shock Wave

3.2.4. Explosive Detonation Velocity Results

3.3. Laboratory Tests Results

3.3.1. Chemical Stability Test Results

3.3.2. DSC and TGA Results

3.3.3. Activation Energy

3.4. Illustrative Example of the Use of Charges in a Structural Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nazarian, A.; Presser, C. Forensic analysis methodology for thermal and chemical characterization of homemade explosives. Thermochim. Acta 2014, 576, 60–70. [Google Scholar] [CrossRef]

- United Nations. International Ammunition Technical Guidelines—IATG 01.08, 3rd ed.; United Nations: New York, NY, USA, 2021; Available online: https://unsaferguard.org/un-saferguard/guide-lines (accessed on 3 April 2025).

- USDOD. Structures to Resist the Effects of Accidental Explosions—UFC 3-340-02; United States Department of Defense (USDOD): Washington, DC, USA, 2008; p. 1943.

- Mendonça, F.B.; Urgessa, G.S.; Almeida, L.E.N.; Rocco, J.A.F.F. Damage diagram of blast test results for determining reinforced concrete slab response for varying scaled distance, concrete strength and reinforcement ratio. An. Acad. Bras. Ciênc. 2021, 93, e20200511. [Google Scholar] [CrossRef] [PubMed]

- Esparza, E.D. Spherical equivalency of cylindrical charges in free-air. In Proceedings of the 25th Department of Defense Explosives Safety Seminar, Anaheim, CA, USA, 18–20 August 1992; pp. 404–428. Available online: https://www.researchgate.net/publication/235193804_Spherical_Equivalency_of_Cylindrical_Charges_in_Free-Air (accessed on 3 April 2025).

- Kinney, G.F.; Graham, K.J. Explosive Shocks in Air, 2nd ed.; Springer Science+Business Media, LLC: New York, NY, USA, 1985; p. 269. Available online: https://link.springer.com/book/10.1007/978-3-642-86682-1 (accessed on 3 April 2025).

- Kingery, C.N.; Bulmash, G. Technical Report ARBRL TR-02555—Airblast Parameters from TNT Spherical Air Burst and Hemispherical Surface Burst; Aberdeen Proving Ground, Army Armament and Development Center, Ballistic Research Laboratory: Aberdeen, MD, USA, 1984. [Google Scholar]

- Mendonça, F.B.; Urgessa, G.S.; Domingues, M.G.; Iha, K.; Rocco, J.A.F.F. Efeitos do EPS na leitura de pico de pressão refletida em ensaio de campo com explosivo militar. Spectrum 2023, 24, 49–53. [Google Scholar] [CrossRef]

- Amazon Company. 12Pcs Semicircular Bath Molds Aluminum Alloy Half Ball Molds for Crafting Soaps Candles and Cakes for DIY Projects and Baking Supplies. Available online: https://www.amazon.com/IWOWHERO-Hemisphere-Steamer-Aluminum-Semicircle/dp/B0CN5T7RDG/ref=asc_df_B0CN5T7RDG?mcid=2b07c447b12c353989725ffce5404df0&hvocijid=10343000496065635276-B0CN5T7RDG-&hvexpln=73&tag=hyprod-20&linkCode=df0&hvadid=721245378154&hvpos=&hvn (accessed on 9 January 2025).

- USDOD. TM 9-1300-214—Military Explosives; United States Department of Defense (USDOD): Washington, DC, USA, 1984.

- Department of the Army. Explosive Trains; Department of the Army: Alexandria, VA, USA, 1974. [Google Scholar]

- Cooper, P.W. Explosives Engineering; Wiley-VCH: New York, NY, USA, 1997. [Google Scholar]

- Dobratz, B.M.; Crawford, P.C. LLNL Explosives Handbook: Properties of Chemical Explosives and Explosive Simulants; Lawrence Livermore National Laboratory—University of California: Livermore, CA, USA, 1985; p. 526. [Google Scholar]

- Zhang, P.; Cheng, Y.; Liu, Y.J.; Zhang, C.; Hou, H.; Wang, C. Experimental study on the dynamic response of foam-filled corrugated core sandwich panels subjected to air blast loading. Compos. Part B Eng. 2016, 106, 67–81. [Google Scholar] [CrossRef]

- Syed, Z.I.; Raman, S.N.; Ngo, T.; Pham, T. The failure behavior of reinforced concrete panels under far-field and near-field blast effects. Structures 2018, 14, 220–229. [Google Scholar] [CrossRef]

- Khan, R.; Farooq, S.H.; Usman, M. Blast loading response of reinforced concrete panels externally reinforced with steel strips. Infrastructures 2019, 4, 54. [Google Scholar] [CrossRef]

- Jamil, A.; Guan, Z.W.; Cantwell, W.J.; Zhang, X.F.; Langdon, G.S.; Wang, Q.Y. Blast response of aluminium/thermoplastic polyurethane sandwich panels—Experimental work and numerical analysis. Int. J. Impact Eng. 2019, 127, 31–40. [Google Scholar] [CrossRef]

- Mendonça, F.B.; Urgessa, G.S.; Augusto, A.S.; Rocco, J.A.F.F. Experimental records from blast tests of ten reinforced concrete slabs. CivilEng 2020, 1, 51–74. [Google Scholar] [CrossRef]

- Figuli, L.; Cekerevac, D.; Bedon, C.; Leitner, B. Numerical analysis of the blast wave propagation due to various explosive charges. Adv. Civ. Eng. 2020, 2020, 8871412. [Google Scholar] [CrossRef]

- Cui, Y.; Song, M.; Qu, Z.; Sun, S.; Zhao, J. Research on damage assessment of concrete-filled steel tubular column subjected to near-field blast loading. Shock Vib. 2020, 2020, 8883711. [Google Scholar] [CrossRef]

- Figuli, L.; Zvaková, Z.; Kavický, V.; Loveček, T. Dependency of the blast wave pressure on the amount of explosives. Symmetry 2021, 13, 1813. [Google Scholar] [CrossRef]

- Zu, X.; Chen, T.; Cai, Y.; Huang, Z.; Xiao, Q. Blast resistance of a masonry wall coated with a polyurea elastomer. Coatings 2022, 12, 1744. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, R.; Wang, X.; Lyu, P.; Ju, J.; Gao, F.; Yan, S. Study of blast mitigation performance and fracture mechanism of polyurea under contact explosion. Polymers 2022, 14, 3458. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, J.; Liu, F.; Mu, C.; Xia, M.; Yang, S. A research investigation into the impact of reinforcement distribution and blast distance on the blast resilience of reinforced concrete slabs. Materials 2023, 16, 4068. [Google Scholar] [CrossRef]

- Yue, Z.; Zhou, J.; Kong, X.; Xu, Y.; Chen, Y.; Wang, B.; Huang, Y.; Wang, P. Anti-blast performance of polyurea-coated concrete arch structures. Polymers 2023, 15, 1263. [Google Scholar] [CrossRef]

- Nazarian, A.; Presser, C. Forensic analysis methodology for thermochemical characterization of ANNM and ANFO homemade explosives. Thermochim. Acta 2015, 608, 65–75. [Google Scholar] [CrossRef]

- Nazarian, A.; Presser, C. Thermal and chemical kinetic characterization of multiphase and multicomponent substances by laser heating. Int. J. Heat Mass Transf. 2008, 51, 1365–1378. [Google Scholar] [CrossRef]

- Akhavan, J. The Chemistry of Explosives, 2nd ed.; TJ International Ltd.: Padstow, UK, 2001. [Google Scholar]

- Dimić, M.; Fidanovski, B.; Jelisavac, L.; Rodić, V. Analysis of the propellants-polymers compatibility by different test methods. Sci. Tech. Rev. 2017, 67, 13–19. [Google Scholar] [CrossRef]

- Zou, H.-M.; Chen, S.-S.; Li, X.; Jin, S.-H.; Niu, H.; Wang, F.; Chao, H.; Fang, T.; Shu, Q.-H. Preparation, thermal investigation and detonation properties of ε-CL-20-based polymer-bonded explosives with high energy and reduced sensitivity. Mater. Express 2017, 7, 199–208. [Google Scholar] [CrossRef]

- Lee, J.-S.; Hsu, C.-K.; Chang, C.-L. A study on the thermal decomposition behaviors of PETN, RDX, HNS and HMX. Thermochim. Acta 2002, 392–393, 173–176. [Google Scholar] [CrossRef]

- Junaid, A.; Qadeer, M.A. Thermal and kinetic studies of trinitrotoluene (TNT) and amatol vis-a-vis oxygen balance. Int. J. Sci. Eng. Res. 2017, 8, 850–855. Available online: https://www.ijser.org/researchpaper/Thermal-and-Kinetic-Studies-of-Trinitrotoluene-TNT-and-Amatol-Vis-a-Vis-Oxygen-Balance.pdf (accessed on 3 April 2025).

- Guo, J.; Chen, X.; Yu, Y.; Dong, J.; Zhang, J.; Meng, J.; Xin, C.; Wang, Z. Thermal hazard analysis of two non-ideal explosives based on ammonium perchlorate/ammonium nitrate and aluminium powder. Molecules 2024, 29, 2680. [Google Scholar] [CrossRef] [PubMed]

- Pawlus, K.; Stolarczyk, A.; Jarosz, T.; Polis, M.; Szydlo, K.; Hawełek, Ł.; Waśkiewicz, S.; Łapkowski, M. Energetic coordination compounds: Investigation of aliphatic ligands and development of prototype detonators. Int. J. Mol. Sci. 2024, 25, 8645. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.-H.; Yang, T.-M.; Li, J.-S.; Lu, K.-T.; Yeh, T.-F. Preliminary study on characteristics of NC/HTPB-based high-energy gun propellants. ChemEngineering 2022, 6, 80. [Google Scholar] [CrossRef]

- Li, J.-S.; Chen, J.-J.; Hwang, C.-C.; Lu, K.-T.; Yeh, T.-F. Study on thermal characteristics of TNT-based melt-cast explosives. Propellants Explos. Pyrotech. 2019, 44, 1270–1281. [Google Scholar] [CrossRef]

- Harris, J. Autoignition temperatures of military high explosives by differential thermal analysis. Thermochim. Acta 1976, 14, 183–199. [Google Scholar] [CrossRef]

- Phantom. PHANTOM VEO 640/VEO 440 High-Speed Camera Datasheet. 2024. Available online: https://www.phantomhighspeed.com/-/media/project/ameteksxa/visionresearch/documents/datasheets/web/ds_web-veo-640-440.pdf (accessed on 6 August 2024).

- Jeremić, R.; Bajić, Z. An approach to determining the TNT equivalent of high explosives. Sci. Tech. Rev. 2006, 56, 58–62. [Google Scholar]

- Panowicz, R.; Konarzewski, M.; Trypolin, M. Analysis of criteria for determining a TNT equivalent. J. Mech. Eng. 2017, 63, 666–672. [Google Scholar] [CrossRef]

- NATO. STANAG 4556—Explosives: Vacuum Stability Test; NATO—North Atlantic Treaty Organization: Brussels, Belgium, 1999. [Google Scholar]

- TA Instruments. SDT Q600 Specifications. 2010. Available online: https://www.tainstruments.com/wp-content/uploads/sdt.pdf (accessed on 6 November 2024).

- Kissinger, H.E. Reaction kinetics in differential thermal analysis. Anal. Chem. 1957, 29, 1702–1706. [Google Scholar] [CrossRef]

- Toan, N.T.; Nhan, P.D.; Phuong, V.H. Thermal decomposition and shelf-life of PETN and PBX based on PETN using thermal methods. Vietnam J. Sci. Technol. 2018, 56, 303–311. [Google Scholar] [CrossRef]

- Ozawa, T. A new method of analyzing thermogravimetric data. Bull. Chem. Soc. Jpn. 1965, 38, 1881–1886. [Google Scholar] [CrossRef]

- NATO. AASTP-1—Manual of NATO Safety Principles for the Storage of Military Ammunition and Explosives; NATO—North Atlantic Treaty Organization: Brussels, Belgium, 2010. [Google Scholar]

- Rigby, S.E.; Sielicki, P.W. An investigation of TNT equivalence of hemispherical PE4 charges. Eng. Trans. 2014, 62, 423–435. [Google Scholar] [CrossRef]

- Ohashi, K.; Kleine, H.; Takayama, K. Characteristics of blast waves generated by milligram charges. In Proceedings of the 23rd International Symposium on Shock Waves, Fort Worth, TX, USA, 22–27 July 2001; pp. 187–193. Available online: https://www.ifs.tohoku.ac.jp/jpn/shock-coe/papers/issw23/5489p.pdf (accessed on 3 April 2025).

- Lee, J.-S.; Hsu, C.-K. The thermal behaviors and safety characteristics of composition B explosive. Thermochim. Acta 2001, 367–368, 371–374. [Google Scholar] [CrossRef]

| TNT Explosive | Comp B Explosive | |||||

|---|---|---|---|---|---|---|

| Parameter | Average | Standard Deviation | Relative Amplitude | Average | Standard Deviation | Relative Amplitude |

| Volume (cm3) | 205.4 ± 0.7 | 1.03 | ±0.97% | 205.4 ± 0.7 | 1.03 | ±0.97% |

| Diameter (mm) | 71.4 ± 0.1 | 0.36 | ±0.98% | 71.4 ± 0.1 | 0.36 | ±0.98% |

| Mass (g) | 328 ± 2 | 4.66 | ±4.60% | 334 ± 1 | 2.74 | ±1.95% |

| Density (g/cm3) | 1.60 ± 0.01 | 0.02 | ±2.62% | 1.63 ± 0.01 | 0.01 | ±1.74% |

| Loaded Charges | 45 | 47 | ||||

| Discarded charges | 3 | 4 | ||||

| Viable charges | 42 | 43 | ||||

| Load Yield | 93% | 91% | ||||

| R (m) | Peak Overpressure by Test (bar) | Average (bar) | Reference (bar) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T4 | T5 | Ref. 1 | Ref. 2 | Ref. 3 | ||

| 0.68 | 12.3 | - | 11.2 | 12.1 | 12.0 | 11.9 ± 0.8 | 13.6 | 12.2 | 11.0 |

| 1.59 | 1.8 | 1.8 | 1.8 | 1.7 | - | 1.7 ± 0.1 | 2.0 | 1.8 | 1.6 |

| 3.11 | 0.49 | 0.45 | 0.45 | 0.46 | 0.47 | 0.46 ± 0.01 | 0.49 | 0.45 | 0.41 |

| 0.47 | 0.44 | 0.45 | 0.45 | 0.45 | |||||

| R (m) | TNT Equivalent by Test No. | Average | ||||

|---|---|---|---|---|---|---|

| T1 | T2 | T3 | T4 | T5 | ||

| 0.68 | 1.4 | - | 1.2 | 1.4 | 1.3 | 1.3 ± 0.1 |

| 1.59 | 1.3 | 1.4 | 1.4 | 1.2 | - | 1.3 ± 0.1 |

| 3.11 | 1.54 | 1.39 | 1.39 | 1.45 | 1.46 | 1.42 ± 0.04 |

| 1.47 | 1.36 | 1.40 | 1.39 | 1.37 | ||

| Global average | 1.38 ± 0.04 | |||||

| Reference [39] | 1.48 | |||||

| Reference [40] | 1.28 | |||||

| Reference [46] | 1.11 | |||||

| Test No. | ∆d (mm) | ∆t (μs) | Average VoD (mm/μs) |

|---|---|---|---|

| V1 | 35.2 | 4.7 | 7.5 ± 0.1 |

| V1 * | 35.2 | 4.70 | 7.49 ± 0.03 |

| V2 | 34.8 | 4.7 | 7.4 ± 0.1 |

| V3 | 30.0 | 4.0 | 7.5 ± 0.1 |

| V4 | 30.6 | 4.1 | 7.5 ± 0.1 |

| Global VoD average (mm/μs) | 7.5 ± 0.1 | ||

| Comparative reference to 6.1 g/cm3 density [13] | 7.67 | ||

| Sample No. | Sample Mass (g) | Volume of Gas (cm3/g) |

|---|---|---|

| 01 | 5.015 ± 0.0001 | 0.308 ± 0.001 |

| 02 | 5.004 ± 0.0001 | 0.324 ± 0.001 |

| 03 | 5.026 ± 0.0001 | 0.310 ± 0.001 |

| Average | 0.314 ± 0.009 | |

| Threshold for Stability [41] | ≤2.000 | |

| β | Tp | 1/Tp | ln (β/Tp2) | log (β) | ||

|---|---|---|---|---|---|---|

| Δ°C min−1 | ΔmK s−1 | °C | K | mK−1 | ln (mK−1 s−1) | log (mK s−1) |

| 1 | 16.67 | 208.15 | 481.30 | 2.08 | −9.54 | 1.22 |

| 2 | 33.33 | 218.04 | 491.19 | 2.04 | −8.89 | 1.52 |

| 5 | 83.33 | 227.55 | 500.70 | 2.00 | −8.01 | 1.92 |

| 10 | 166.67 | 236.52 | 509.67 | 1.96 | −7.35 | 2.22 |

| Kissinger Slope (kK) | −19.2696 | Kissinger Ea (kJ/mol) | 160.22 | |||

| Ozawa Slope (kK) | −8.7987 | Ozawa Ea (kJ/mol) | 160.18 | |||

| Reference [36] Ea (kJ/mol) | 149.90 | |||||

| Reference [37] Ea (kJ/mol) | 163.18 | |||||

| Reference [13] Ea (kJ/mol) | 180.30 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Augusto, A.S.; Urgessa, G.; Amorim, C.B.; Lopes Júnior, R.E.; Mendonça, F.B.; Rocco, J.A.F.F.; Iha, K. Experimental Characterization of Cast Explosive Charges Used in Studies of Blast Effects on Structures. CivilEng 2025, 6, 20. https://doi.org/10.3390/civileng6020020

Augusto AS, Urgessa G, Amorim CB, Lopes Júnior RE, Mendonça FB, Rocco JAFF, Iha K. Experimental Characterization of Cast Explosive Charges Used in Studies of Blast Effects on Structures. CivilEng. 2025; 6(2):20. https://doi.org/10.3390/civileng6020020

Chicago/Turabian StyleAugusto, Anselmo S., Girum Urgessa, Caio B. Amorim, Robison E. Lopes Júnior, Fausto B. Mendonça, José A. F. F. Rocco, and Koshun Iha. 2025. "Experimental Characterization of Cast Explosive Charges Used in Studies of Blast Effects on Structures" CivilEng 6, no. 2: 20. https://doi.org/10.3390/civileng6020020

APA StyleAugusto, A. S., Urgessa, G., Amorim, C. B., Lopes Júnior, R. E., Mendonça, F. B., Rocco, J. A. F. F., & Iha, K. (2025). Experimental Characterization of Cast Explosive Charges Used in Studies of Blast Effects on Structures. CivilEng, 6(2), 20. https://doi.org/10.3390/civileng6020020