Enhanced Mechanical Properties of CLAM by Zirconium Alloying and Thermo-Mechanical Processing

Abstract

1. Introduction

2. Materials and Experiments

2.1. Materials

2.2. Microstructure and Mechanical Property Tests

3. Results and Discussion

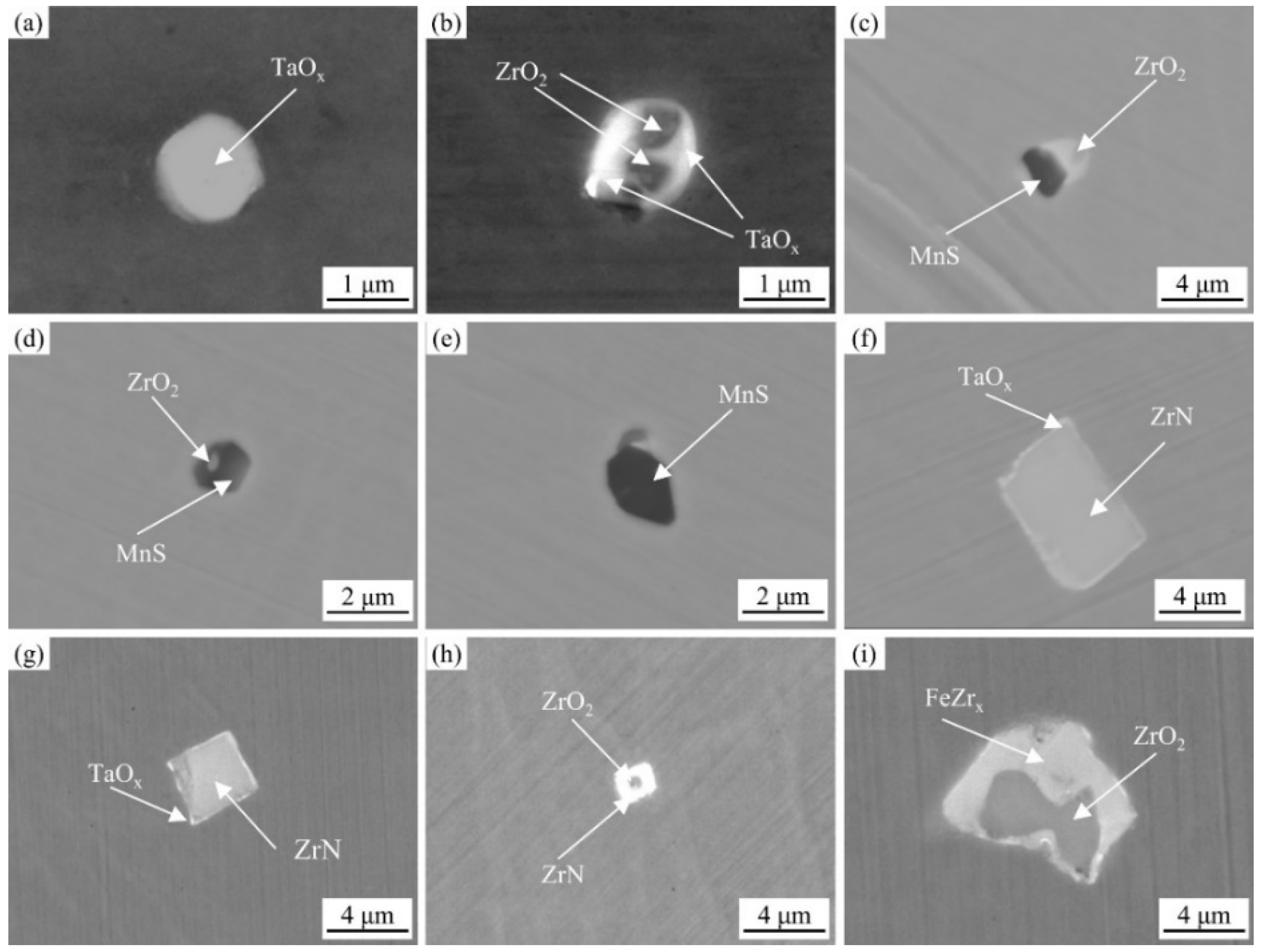

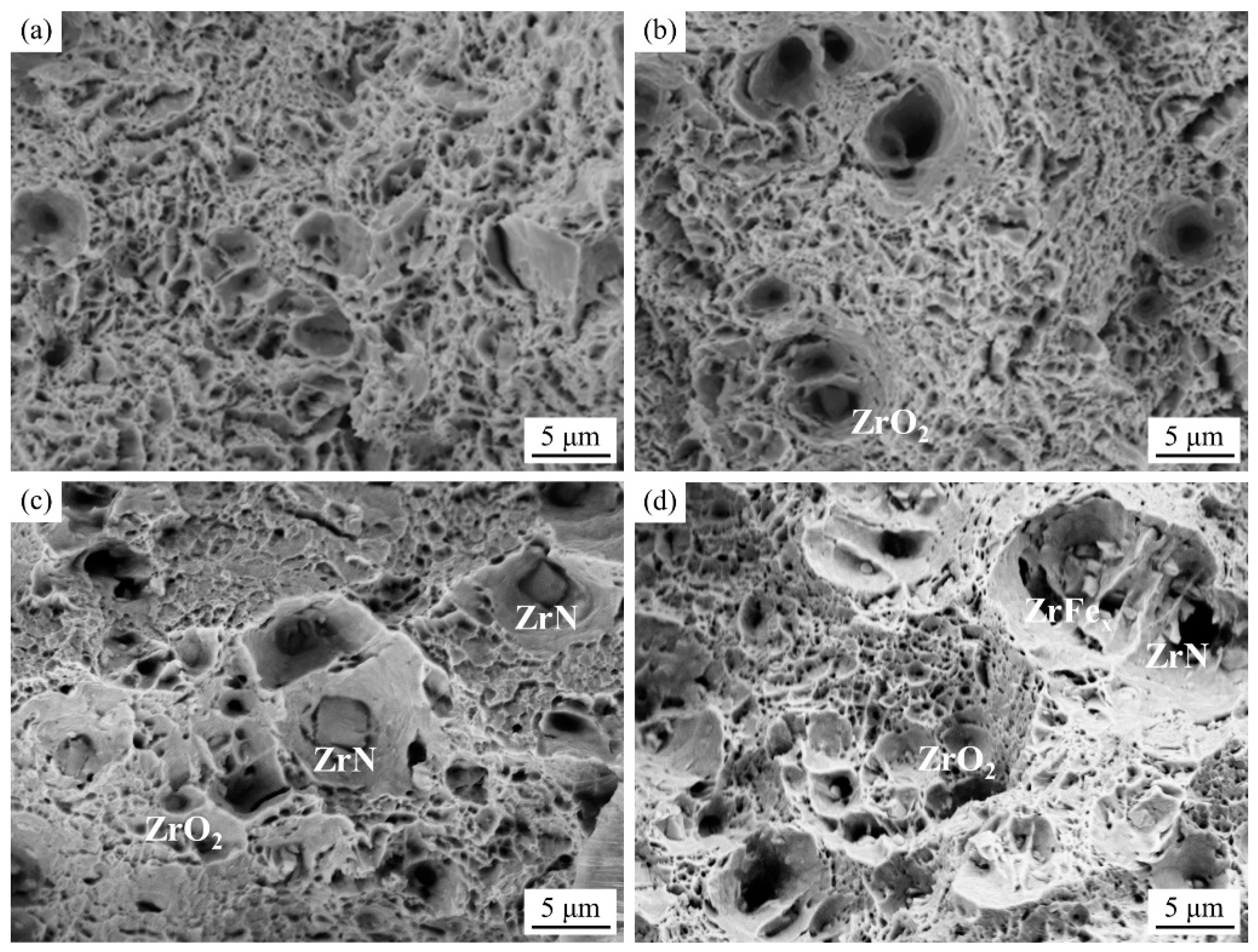

3.1. Inclusions in Ingots

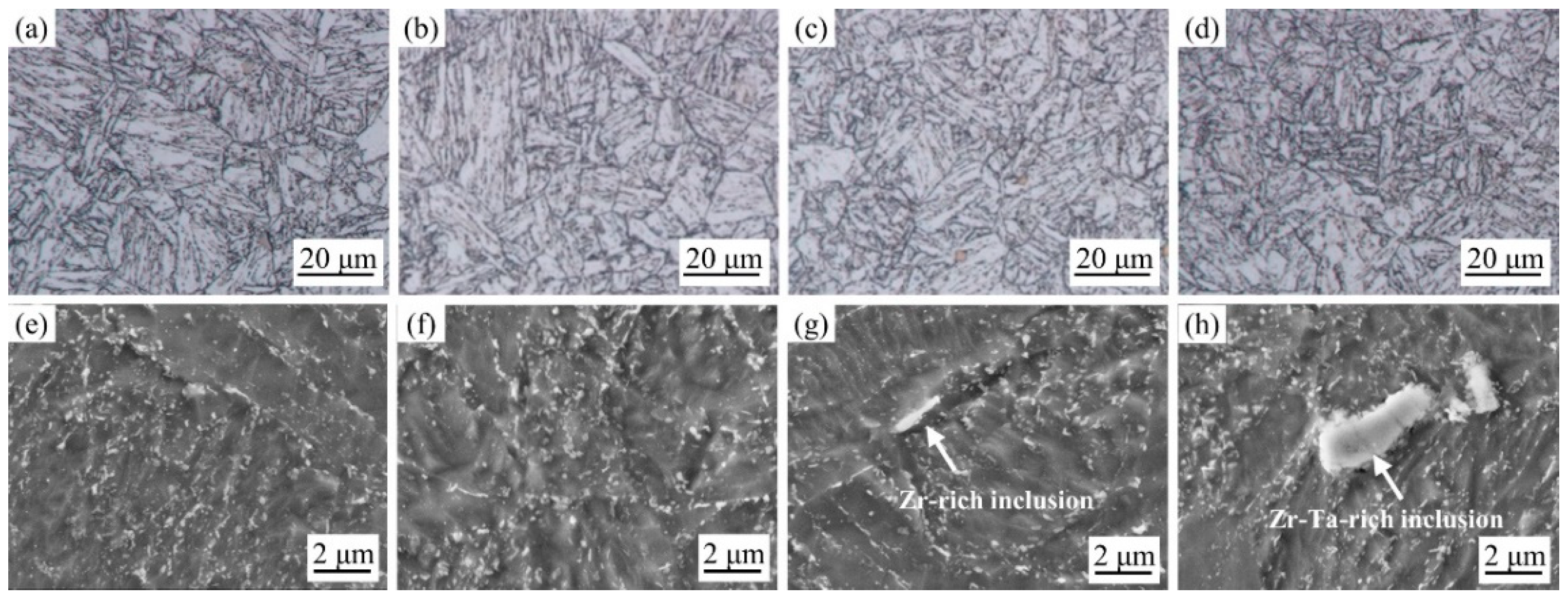

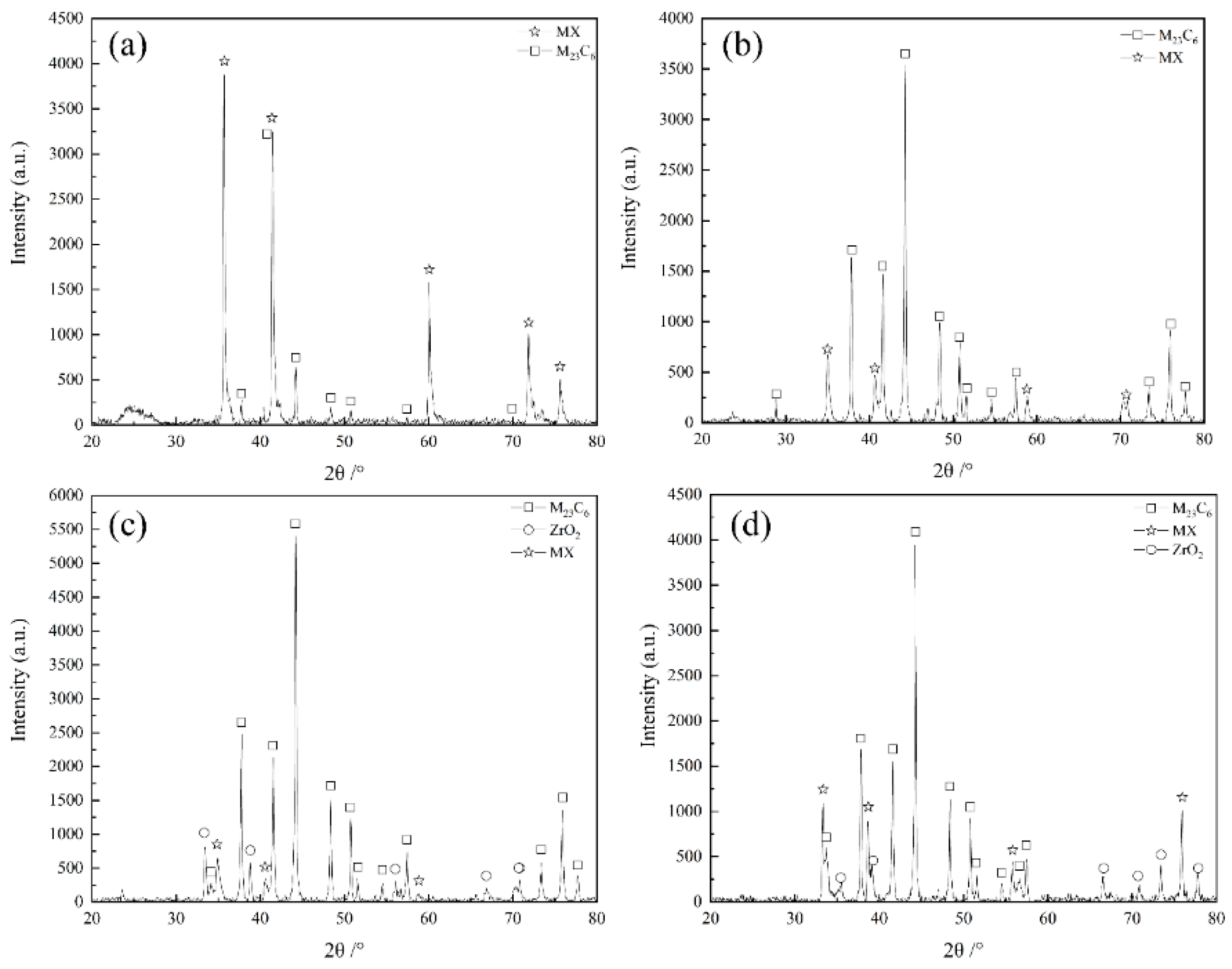

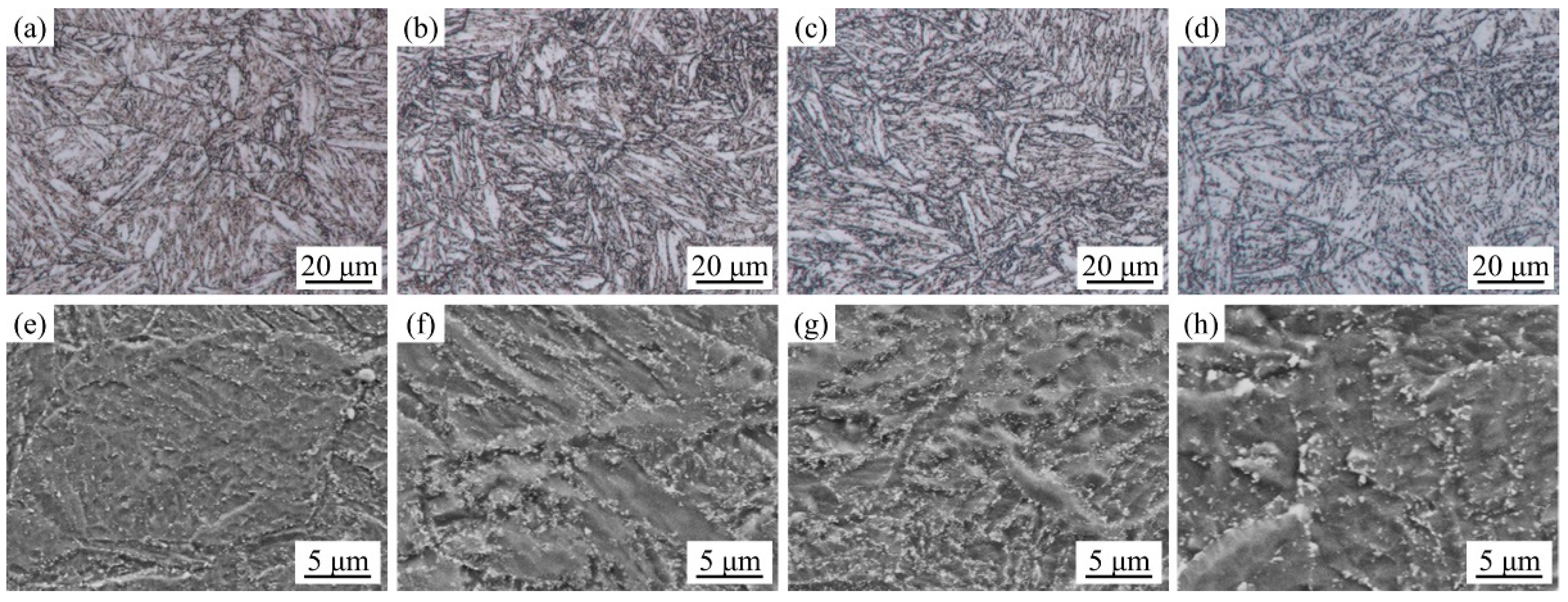

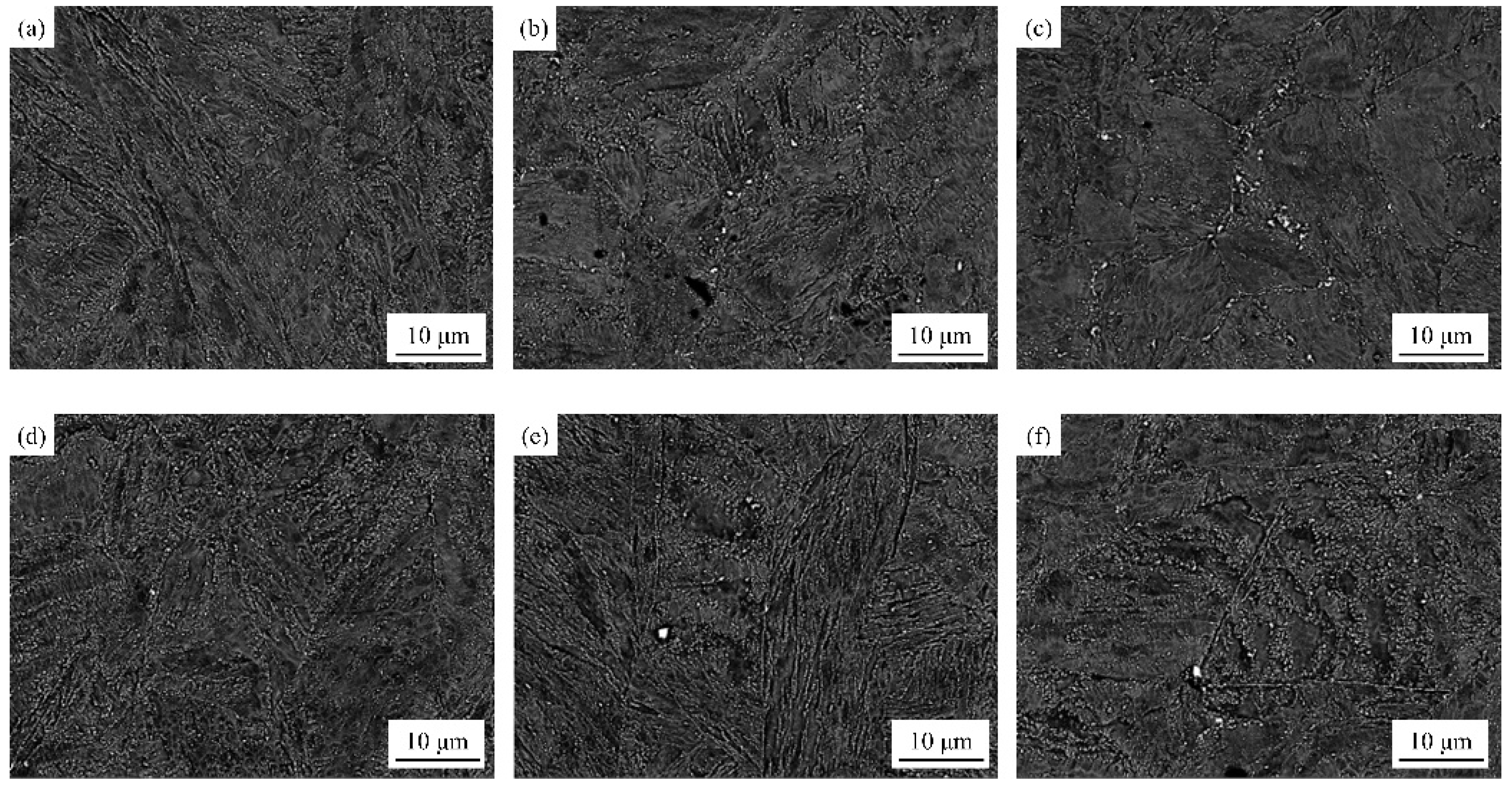

3.2. Microstructure of CLAM Steels with Zr

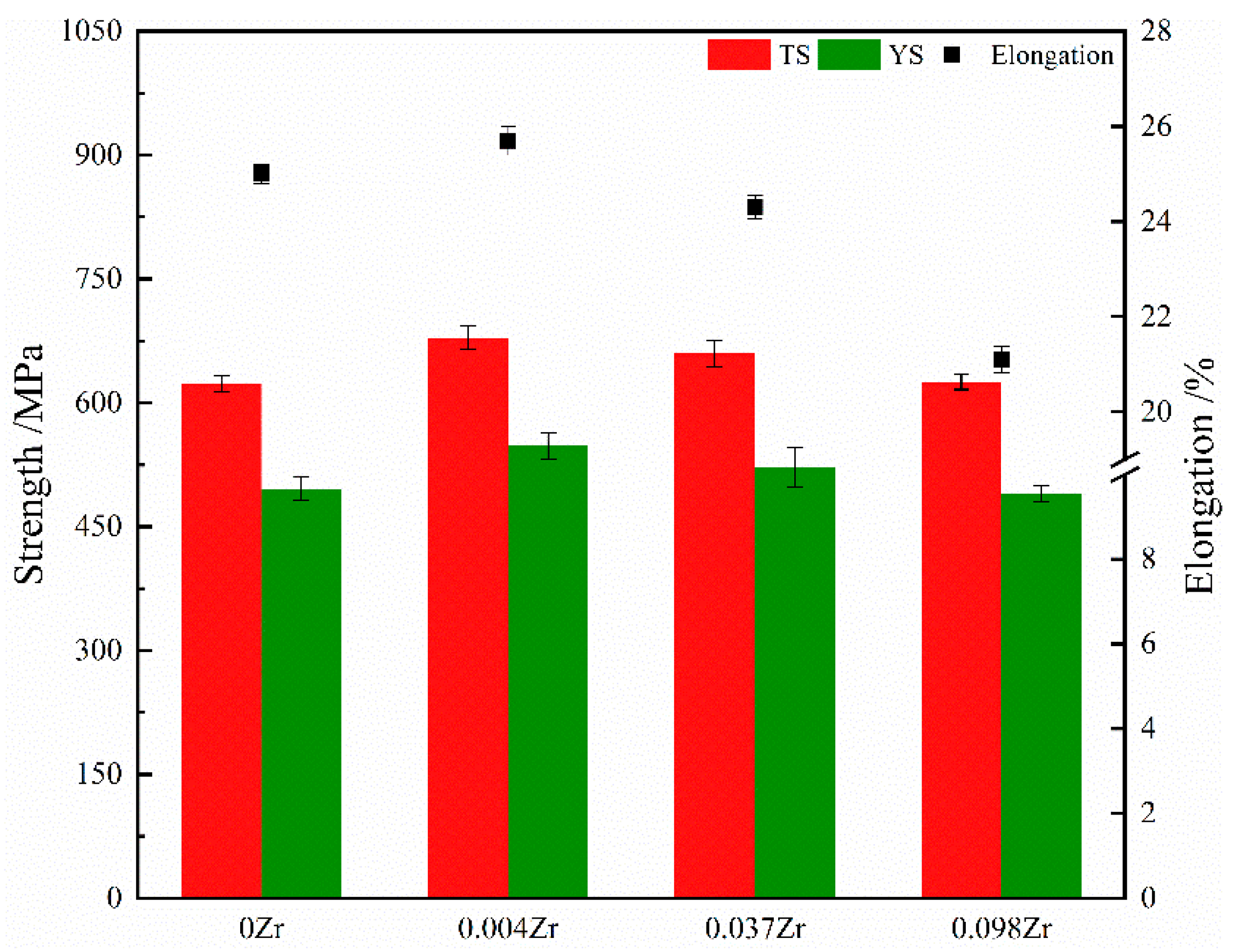

3.3. Mechanical Property of CLAM Steels with Zr

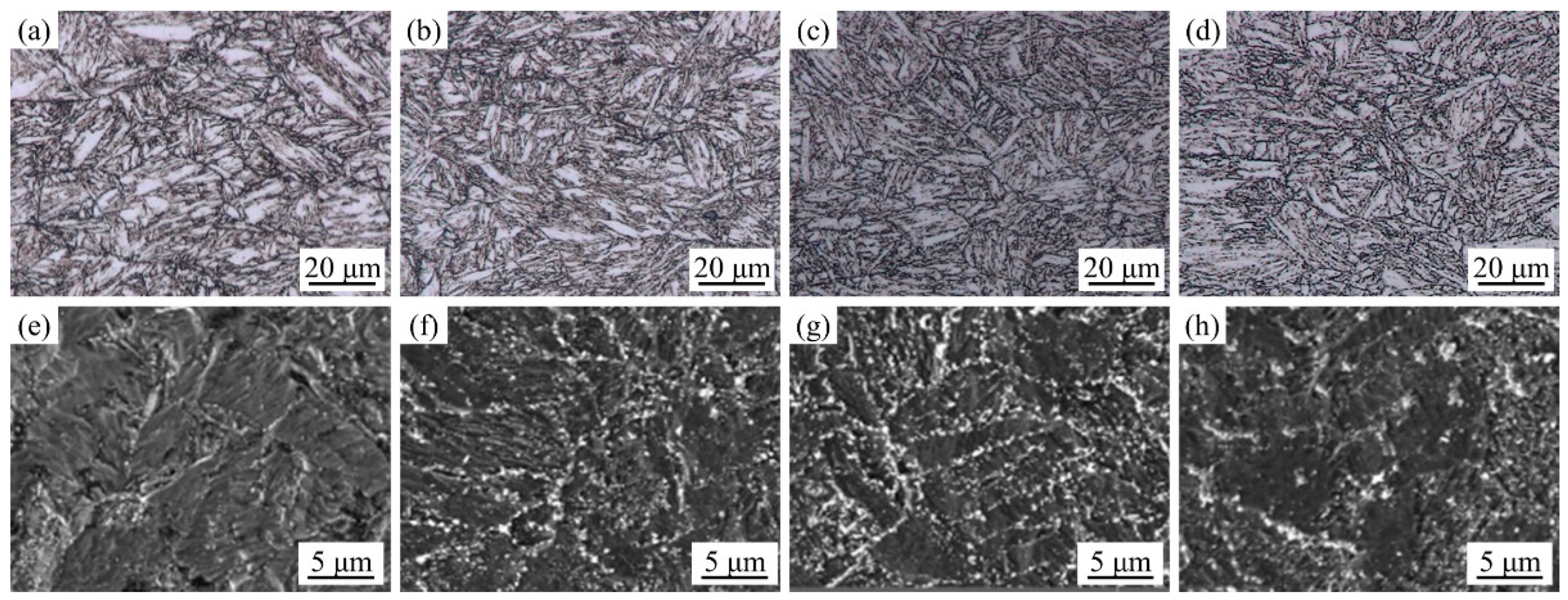

3.4. Influences of TMP on Microstructure and Mechanical Property

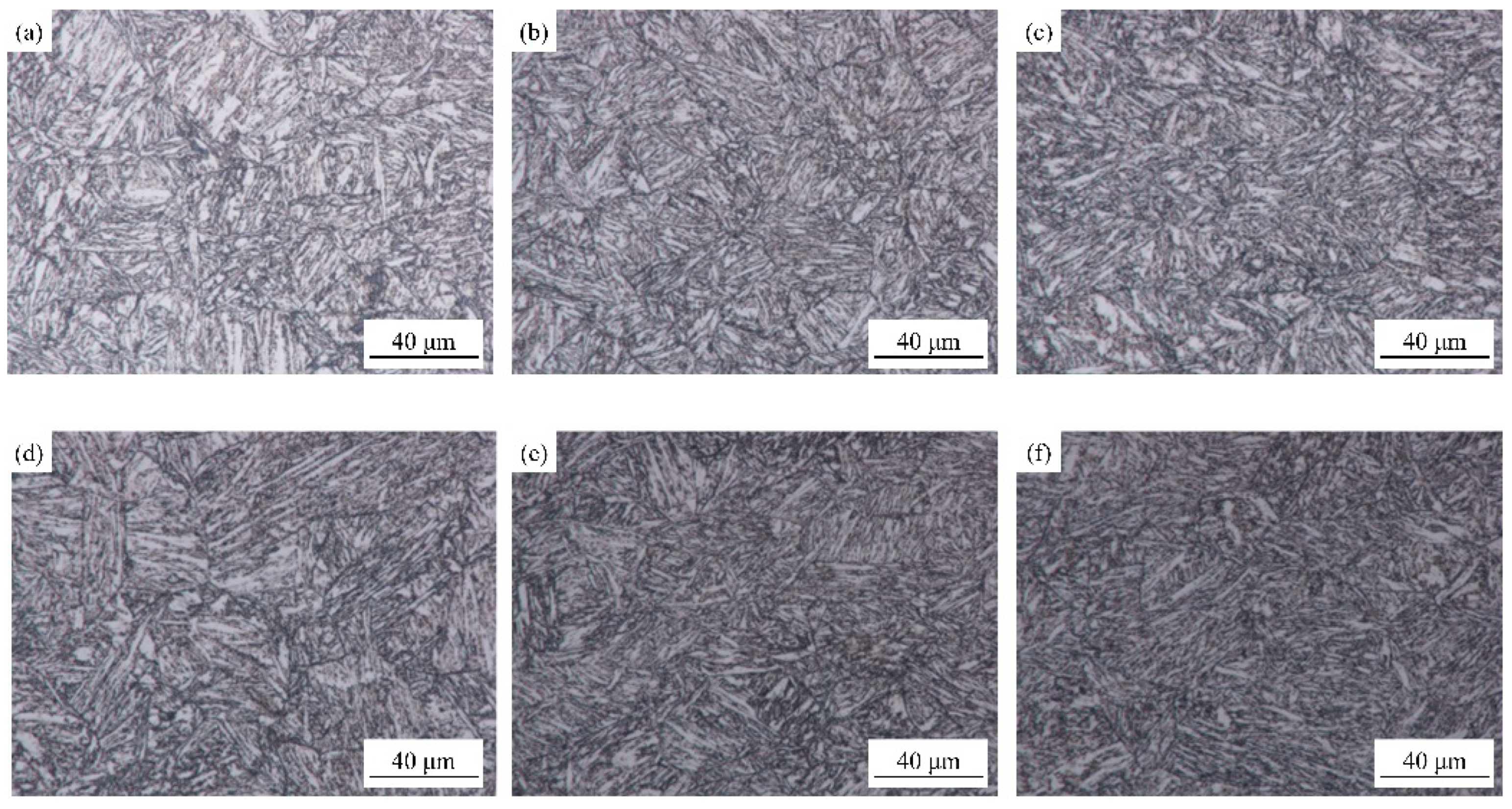

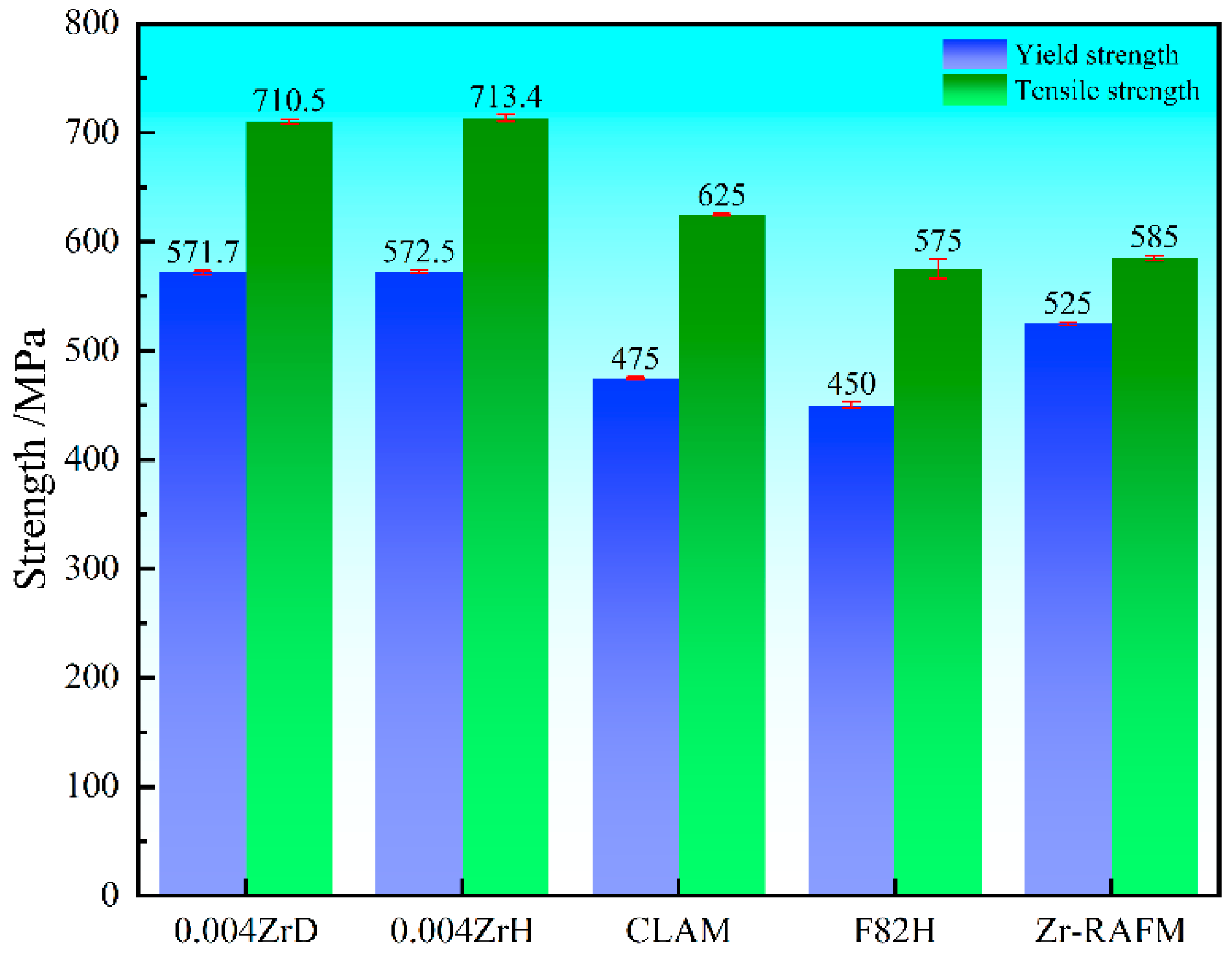

3.5. Effect of Aging on Microstructure and Mechanical Property

4. Conclusions

- (1)

- The inclusions in CLAM steel with Zr could be divided into fine simple particles and large complex particles. Typical simple particles include TaOx, MnS, and ZrN and complex particles were TaOx-ZrO2, ZrO2-MnS, TaOx-ZrN, and FeZrx-ZrO2. The higher the Zr content, the more complex the composition of inclusions in the alloy.

- (2)

- CLAM steel with 0.004% Zr (0.004Zr) had the highest yield strength, tensile strength, elongation, and impact energy at room temperature, which were 548.3 MPa, 679.4 MPa, 25.7%, and 253.9 J, respectively. The main precipitates in 0.004Zr steel were MX and M23C6. With the addition of Zr content in the alloys, the strength and toughness decreased due to the larger inclusions.

- (3)

- With the increase in tempering temperature, the yield strength and tensile strength of TMPed steels gradually decreased, while the elongation and impact energy gradually increased. The optimum yield strength and impact energy belonged to the 0.004ZrD and 0.004ZrH alloys. The yield strengths were 597.9 and 611.8 MPa, while the impact energies were 225.9 and 243.3 J, respectively.

- (4)

- During aging at 650 °C for 1500 h, the Laves phase precipitated and coarsened continuously, and the yield strength of 0.004ZrD and 0.004ZrH alloys decreased and then tended to stabilize. The yield strength of 0.004ZrD changed from 564.6 to 597.9 MPa, and the yield strength of 0.004ZrH changed from 570.2 to 611.8 MPa. TMP is a simple and practical industrial technique that could successfully enhance the mechanical properties of alloys.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nagasaka, T.; Ando, M.; Tanigawa, H.; Sakasegawa, H.; Tanaka, T.; Muroga, T.; Sagara, A. Tensile properties of F82H steel after aging at 400–650℃ for 1000–30,000 h. Fusion Eng. Des. 2017, 124, 1011–1014. [Google Scholar] [CrossRef]

- Qiu, G.X.; Zhan, D.P.; Cao, L.; Jiang, Z.H. Review on development of reduced activated ferritic/martensitic steel for fusion reactor. J. Iron Steel Res. Int. 2022, 29, 1343–1356. [Google Scholar] [CrossRef]

- Lindau, R.; Möslang, A.; Rieth, M.; Klimiankou, M.; Materna-Morris, E.; Alamo, A.; Tavassoli, A.-A.F.; Cayron, C.; Lancha, A.-M.; Fernandez, P.; et al. Present development status of EUROFER and ODS-EUROFER for application in blanket concepts. Fusion Eng. Des. 2005, 7579, 989–996. [Google Scholar] [CrossRef]

- Abe, F. Precipitate Design for creep strengthening of 9% Cr tempered martensitic steel for ultra-supercritical power plants. Sci. Technol. Adv. Mater. 2008, 9, 013002. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.J.; Huang, Q.Y.; Li, C.J.; Bo, H. Influence of non-metal inclusions on mechanical properties of CLAM steel. Fusion Eng. Des. 2009, 84, 1214–1218. [Google Scholar] [CrossRef]

- Liao, H.; Wang, X.; Yang, G.; Feng, Y.; Wang, P.; Feng, K. Recent progress of R&D activities on reduced activation ferritic/martensitic steel (CLF-1). Fusion Eng. Des. 2019, 147, 111235. [Google Scholar]

- Mazzone, G.; Aktaa, J.; Bachmann, C.; De Meis, D.; Frosi, P.; Gaganidze, E.; Di Gironimo, G.; Mariano, G.; Marzullo, D.; Porfiri, M.T.; et al. Choice of a low operating temperature for the DEMO EUROFER97 divertor cassette. Fusion Eng. Des. 2017, 124, 655–658. [Google Scholar] [CrossRef]

- Sakasegawa, H.; Tanigawa, H. Mechanical properties of F82H plates with different thicknesses. Fusion Eng. Des. 2016, 109–111, 1724–1727. [Google Scholar] [CrossRef]

- Klueh, R.L.; Sokolov, M.A. Mechanical properties of irradiated 9Cr-2WVTa steel with and without nickel. J. Nucl. Mater. 2007, 367, 102–106. [Google Scholar] [CrossRef]

- Rogozhkin, S.V.; Ageev, V.S.; Aleev, A.A.; Zaluzhnyi, A.G.; Leont’eva-Smirnova, M.V.; Nikitin, A.A. Tomographic atom-probe analysis of temperature-resistant 12%-chromium ferritic-martensitic steel EK-181. Phys. Met. Metallogr. 2009, 108, 579–585. [Google Scholar] [CrossRef]

- Chun, Y.B.; Lee, D.W.; Cho, S.; Rhee, C.K. Improvement of creep and impact resistance of reduced activation ferritic-martensitic steel by the addition of Zr. Mater. Sci. Eng. A 2015, 645, 286–291. [Google Scholar] [CrossRef]

- Guo, A.M.; Li, S.R.; Guo, J.; Li, P.H.; Ding, Q.F.; Wu, K.M.; He, X.L. Effect of zirconium addition on the impact toughness of the heat affected zone in a high strength low alloy pipeline steel. Mater. Charact. 2008, 59, 134–139. [Google Scholar] [CrossRef]

- Park, J.W.; Lee, K.K.; Jung, W.S. Elevated temperature deformation behavior of low carbon ZR-B steel. Scr. Mater. 2001, 44, 587–592. [Google Scholar] [CrossRef]

- Chun, Y.B.; Kang, S.H.; Lee, D.W.; Cho, S.; Jeong, Y.H.; Żywczak, A.; Rhee, C.K. Development of Zr-containing advanced reduced-activation alloy (ARAA) as structural material for fusion reactors. Fusion Eng. Des. 2016, 109–111, 629–633. [Google Scholar] [CrossRef]

- Tanigawa, H.; Gaganidze, E.; Hirose, T.; Ando, M.; Zinkle, S.; Lindau, R.; Diegele, E. Development of benchmark reduced activation ferritic/martensitic steels for fusion energy applications. Nucl. Fusion 2017, 57, 092004. [Google Scholar] [CrossRef]

- Zinkle, S.; Boutard, J.; Hoelzer, D.; Kimura, A.; Lindau, R.; Odette, G.; Rieth, M.; Tan, L.; Tanigawa, H. Development of next generation tempered and ODS reduced activation ferritic/martensitic steels for fusion energy applications. Nucl. Fusion 2017, 57, 092005. [Google Scholar] [CrossRef]

- Chun, Y.B.; Rhee, C.K.; Lee, D.W.; Park, Y.H. Enhanced high-temperature mechanical properties of ARAA by thermomechanical processing. Fusion Eng. Des. 2018, 136, 883–890. [Google Scholar] [CrossRef]

- Karasev, A.; Suito, H. Analysis of Size Distributions of Primary Oxide Inclusions in Fe-10 Mass Pct Ni-M (M=Si, Ti, Al, Zr, and Ce) Alloy. Metall. Mater. Trans. B 1999, 30, 259–270. [Google Scholar] [CrossRef]

- Zhou, J.H.; Shen, Y.F.; Jia, N. Strengthening mechanisms of reduced activation ferritic/martensitic steels: A review. Int. J. Miner. Metall. Mater. 2021, 28, 335–348. [Google Scholar] [CrossRef]

- Qiu, G.X.; Zhan, D.P.; Li, C.S.; Qi, M.; Jiang, Z.; Zhang, H. Effect of Y/Zr Ratio on Inclusions and Mechanical Properties of 9Cr-RAFM Steel Fabricated by Vacuum Melting. J. Mater. Eng. Perform. 2019, 28, 1067–1076. [Google Scholar] [CrossRef]

- Gurland, J.; Plateau, J. Mechanism of ductile rupture of metals containing inclusions. Copper Alloys 1963, 56, 442–454. [Google Scholar]

- Shi, Z.; Han, F. The microstructure and mechanical properties of micro-scale Y2O3 strengthened 9Cr steel fabricated by vacuum casting. Mater. Des. 2015, 66, 304–308. [Google Scholar] [CrossRef]

- Yan, W.; Hu, P.; Wang, W.; Zhao, L.; Shan, Y.; Yang, K. Effect of yttrium on mechanical properties of 9Cr-2WVTa low active martensite steel. Chin. J. Nucl. Sci. Eng. 2009, 29, 50–55. [Google Scholar]

- Hu, X.; Huang, L.; Yan, W.; Wang, W.; Sha, W.; Shan, Y.; Yang, K. Evolution of microstructure and changes of mechanical properties of CLAM steel after long-term aging. Mater. Sci. Eng. A 2013, 586, 253–258. [Google Scholar] [CrossRef]

- Qiu, G.X.; Zhan, D.P.; Cao, L.; Zhang, H.S. Effect of zirconium on inclusions and mechanical properties of China low activation martensitic steel. J. Iron Steel Res. Int. 2021, 28, 1168–1179. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | Cr | W | V | Ta | N | O | Zr | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0Zr | 0.06 | 0.1 | 0.45 | 9 | 1.5 | 0.2 | 0.15 | 0.0030 | 0.0043 | - | Bal. |

| 0.004Zr | 0.06 | 0.1 | 0.45 | 9 | 1.5 | 0.2 | 0.15 | 0.0025 | 0.0032 | 0.004 | Bal. |

| 0.037Zr | 0.06 | 0.1 | 0.45 | 9 | 1.5 | 0.2 | 0.15 | 0.0023 | 0.0018 | 0.037 | Bal. |

| 0.098Zr | 0.06 | 0.1 | 0.45 | 9 | 1.5 | 0.18 | 0.15 | 0.0022 | 0.0014 | 0.098 | Bal. |

| Process | Start Rolling Temperature | Finish Rolling Temperature | Normalizing | Tempering |

|---|---|---|---|---|

| A | 1150 °C | 950 °C | 1050 °C × 20 min | 760 °C × 90 min |

| B | 950 °C | 690 °C × 90 min | ||

| C | 725 °C × 90 min | |||

| D | 760 °C × 90 min | |||

| E | 795 °C × 90 min | |||

| F | 750 °C | 690 °C × 90 min | ||

| G | 725 °C × 90 min | |||

| H | 760 °C × 90 min | |||

| I | 795 °C × 90 min |

| Steel | Size Distribution/% | /μm | /10−4 | ||||

|---|---|---|---|---|---|---|---|

| <0.5 μm | 0.5–1.0 μm | 1.0–3.0 μm | 3.0–5.0 μm | >5 μm | |||

| 0Zr | 6.23 | 40.46 | 40.40 | 11.15 | 1.76 | 1.10 | 0.65 |

| 0.004Zr | 12.93 | 69.24 | 16.04 | 0.89 | 0.9 | 0.79 | 1.76 |

| 0.0037Zr | 0.37 | 49.63 | 42.62 | 6.07 | 1.31 | 1.35 | 2.53 |

| 0.0098Zr | 25.29 | 6.35 | 23.96 | 10.57 | 33.83 | 1.58 | 3.36 |

| Series | BCDE | FGHI | ||||||

|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | 690 | 725 | 760 | 795 | 690 | 725 | 760 | 795 |

| YS (MPa) | 863.9 | 691.6 | 597.9 | 537.3 | 869.6 | 713.1 | 611.8 | 508.2 |

| TS (MPa) | 965.7 | 814.7 | 726.8 | 679.3 | 992.2 | 832.0 | 730.0 | 661.3 |

| Elongation/% | 18.9 | 20.5 | 24.2 | 25.9 | 18.9 | 20.1 | 24.7 | 26.6 |

| Aging Time/h | Yield Strength/MPa | Tensile Strength/MPa | Elongation/% |

|---|---|---|---|

| 0 | 597.9 | 726.8 | 24.2 |

| 500 | 566.1 | 708.3 | 24.8 |

| 1000 | 564.6 | 699.8 | 25.3 |

| 1500 | 571.7 | 710.5 | 24.5 |

| Aging Time/h | Yield Strength/MPa | Tensile Strength/MPa | Elongation/% |

|---|---|---|---|

| 0 | 611.8 | 730.0 | 24.7 |

| 500 | 570.2 | 709.7 | 25.4 |

| 1000 | 580.2 | 708.5 | 25.9 |

| 1500 | 572.5 | 713.4 | 25.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhan, D.; Li, J.; Wang, D.; Zhang, H.; Qiu, G.; Yang, Y. Enhanced Mechanical Properties of CLAM by Zirconium Alloying and Thermo-Mechanical Processing. J. Nucl. Eng. 2023, 4, 127-141. https://doi.org/10.3390/jne4010009

Zhan D, Li J, Wang D, Zhang H, Qiu G, Yang Y. Enhanced Mechanical Properties of CLAM by Zirconium Alloying and Thermo-Mechanical Processing. Journal of Nuclear Engineering. 2023; 4(1):127-141. https://doi.org/10.3390/jne4010009

Chicago/Turabian StyleZhan, Dongping, Jihang Li, Dongwei Wang, Huishu Zhang, Guoxing Qiu, and Yongkun Yang. 2023. "Enhanced Mechanical Properties of CLAM by Zirconium Alloying and Thermo-Mechanical Processing" Journal of Nuclear Engineering 4, no. 1: 127-141. https://doi.org/10.3390/jne4010009

APA StyleZhan, D., Li, J., Wang, D., Zhang, H., Qiu, G., & Yang, Y. (2023). Enhanced Mechanical Properties of CLAM by Zirconium Alloying and Thermo-Mechanical Processing. Journal of Nuclear Engineering, 4(1), 127-141. https://doi.org/10.3390/jne4010009