Review on Biomass Pyrolysis with a Focus on Bio-Oil Upgrading Techniques

Abstract

:1. Introduction

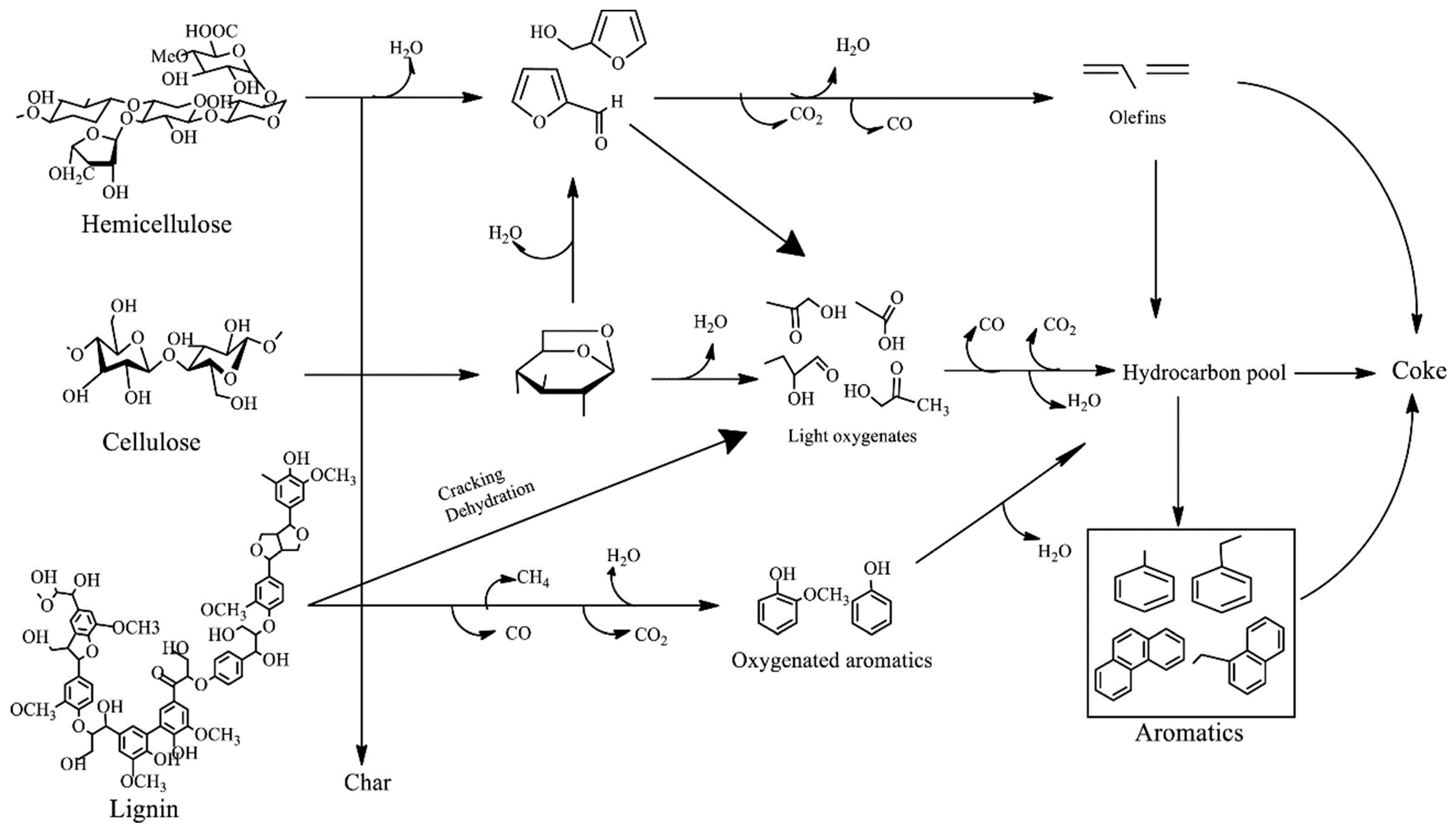

2. Bio-Oil

3. Biomass Pyrolysis Mechanism

4. Effect of Process Parameters on Bio-Oil Production

4.1. Temperature

4.2. Heating Rate

4.3. Pressure (Atmospheric or Vacuum)

4.4. Catalyst

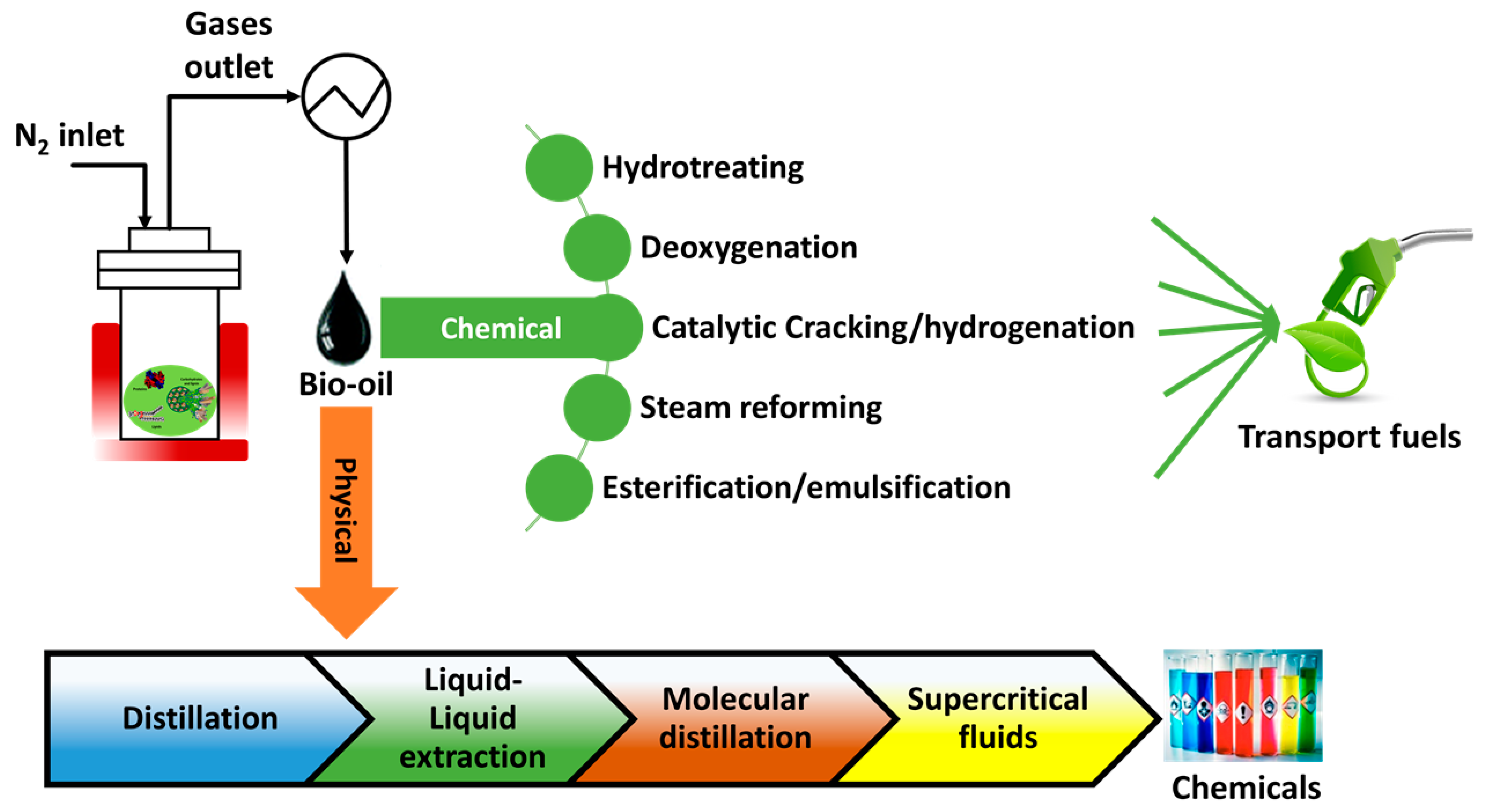

5. Bio-Oil Upgrading

5.1. Chemical Processes

5.1.1. Hydrotreating

5.1.2. Catalytic Cracking/ Hydrocracking

5.1.3. Steam Reforming

5.1.4. Esterification

5.2. Physical Processes

5.2.1. Distillation

5.2.2. Supercritical Fluid Extraction

5.2.3. Liquid–Liquid Extraction

5.2.4. Emulsification

6. Environmental and Economic Aspects of Bio-Oil

7. Applications of Upgraded Bio-Oil

8. Future Directions

- Enhancing the properties and yield of pyrolytic bio-oil by handling biomasses and different operating conditions.

- Exploring novel catalyst synthesis mainly in the field of bi-functional, multifunctional, and biochar-based catalysts to be used as upgrading catalysts of the bio-oil in an integrated system process.

- Understanding the behavior and kinetics of the mechanism reaction, including hydrotreating, catalytic cracking, steam reforming, and esterification.

- Improving economically and environmentally suitable technologies for valuable chemical extraction from bio-oil.

- Exploring spectral and chemical characterization of bio-oil, upgrading, and fractionation products using novel advances to understand several complexities of each upgrading technique.

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lennan, M.; Morgera, E. The Glasgow Climate Conference (COP26). Int. J. Mar. Coast. Law 2022, 37, 137–151. [Google Scholar] [CrossRef]

- Sun, X.; Liu, Z.; Shi, L.; Liu, Q. Pyrolysis of COVID-19 disposable masks and catalytic cracking of the volatiles. J. Anal. Appl. Pyrolysis 2022, 163, 105481. [Google Scholar] [CrossRef] [PubMed]

- Toscano Miranda, N.; Lopes Motta, I.; Maciel Filho, R.; Wolf Maciel, M.R. Sugarcane bagasse pyrolysis: A review of operating conditions and products properties. Renew. Sustain. Energy Rev. 2021, 149, 111394. [Google Scholar] [CrossRef]

- Lachos-Perez, D.; César Torres-Mayanga, P.; Abaide, E.R.; Zabot, G.L.; De Castilhos, F. Hydrothermal carbonization and Liquefaction: Differences, progress, challenges, and opportunities. Bioresour. Technol. 2022, 343, 126084. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y. Fractionation of Pyrolysis Liquids with Supercritical Carbon Dioxide. Ph.D. Thesis, Staats-und Universitätsbibliothek Hamburg Carl von Ossietzky, Hamburg, Germany, 2018. [Google Scholar]

- Lehto, J.; Oasmaa, A.; Solantausta, Y.; Kytö, M.; Chiaramonti, D. Review of fuel oil quality and combustion of fast pyrolysis bio-oils from lignocellulosic biomass. Appl. Energy 2014, 116, 178–190. [Google Scholar] [CrossRef]

- Yogalakshmi, K.N.K.; Sivashanmugam, P.; Kavitha, S.; Kannah, Y.; Varjani, S.; AdishKumar, S.; Kumar, G.B. Lignocellulosic biomass-based pyrolysis: A comprehensive review. Chemosphere 2022, 286, 131824. [Google Scholar] [CrossRef]

- De Jong, E.; Higson, A.; Walsh, P.; Wellisch, M. Task 42 Biobased Chemicals—Value Added Products from Biorefineries. 2011. Available online: https://www.ieabioenergy.com/blog/publications/bio-based-chemicals-value-added-products-from-biorefineries/ (accessed on 7 December 2022).

- Feng, Y.; Meier, D. Comparison of supercritical CO2, liquid CO2, and solvent extraction of chemicals from a commercial slow pyrolysis liquid of beech wood. Biomass Bioenergy 2016, 85, 346–354. [Google Scholar] [CrossRef]

- Feng, Y.; Meier, D. Extraction of value-added chemicals from pyrolysis liquids with supercritical carbon dioxide. J. Anal. Appl. Pyrolysis 2015, 113, 174–185. [Google Scholar] [CrossRef]

- Feng, Y.; Meier, D. Supercritical carbon dioxide extraction of fast pyrolysis oil from softwood. J. Supercrit. Fluids 2017, 128, 6–17. [Google Scholar] [CrossRef]

- Cheng, S.; Wei, L.; Julson, J.; Rabnawaz, M. Upgrading pyrolysis bio-oil through hydrodeoxygenation (HDO) using non-sulfided Fe-Co/SiO2 catalyst. Energy Convers. Manag. 2017, 150, 331–342. [Google Scholar] [CrossRef]

- Panwar, N.L.; Paul, A.S. An overview of recent development in bio-oil upgrading and separation techniques. Environ. Eng. Res. 2021, 26, 200382. [Google Scholar] [CrossRef]

- Fan, L.; Zhang, Y.; Liu, S.; Zhou, N.; Chen, P.; Cheng, Y.; Addy, M.; Lu, Q.; Omar, M.M.; Liu, Y.; et al. Bio-oil from fast pyrolysis of lignin: Effects of process and upgrading parameters. Bioresour. Technol. 2017, 241, 1118–1126. [Google Scholar] [CrossRef] [PubMed]

- Ali, N.; Saleem, M.; Shahzad, K.; Hussain, S.; Chughtai, A. Effect of operating parameters on production of bio-oil from fast pyrolysis of maize stalk in bubbling fluidized bed reactor. Polish J. Chem. Technol. 2016, 18, 88–96. [Google Scholar] [CrossRef]

- Choudhury, N.D.; Chutia, R.S.; Bhaskar, T.; Kataki, R. Pyrolysis of jute dust: Effect of reaction parameters and analysis of products. J. Mater. Cycles Waste Manag. 2014, 16, 449–459. [Google Scholar] [CrossRef]

- Varma, A.K.; Thakur, L.S.; Shankar, R.; Mondal, P. Pyrolysis of wood sawdust: Effects of process parameters on products yield and characterization of products. Waste Manag. 2019, 89, 224–235. [Google Scholar] [CrossRef] [PubMed]

- Puy, N.; Murillo, R.; Navarro, M.V.; López, J.M.; Rieradevall, J.; Fowler, G.; Aranguren, I.; García, T.; Bartrolí, J.; Mastral, A.M. Valorisation of forestry waste by pyrolysis in an auger reactor. Waste Manag. 2011, 31, 1339–1349. [Google Scholar] [CrossRef]

- Wang, Y.; Zeng, Z.; Tian, X.; Dai, L.; Jiang, L.; Zhang, S.; Wu, Q.; Wen, P.; Fu, G.; Liu, Y.; et al. Production of bio-oil from agricultural waste by using a continuous fast microwave pyrolysis system. Bioresour. Technol. 2018, 269, 162–168. [Google Scholar] [CrossRef]

- Li, H.; Wang, Y.; Zhou, N.; Dai, L.; Deng, W.; Liu, C.; Cheng, Y.; Liu, Y.; Cobb, K.; Chen, P.; et al. Applications of calcium oxide–based catalysts in biomass pyrolysis/gasification—A review. J. Clean. Prod. 2021, 291, 125826. [Google Scholar] [CrossRef]

- Singh, M.; Salaudeen, S.A.; Gilroyed, B.H.; Al-Salem, S.M.; Dutta, A. A review on co-pyrolysis of biomass with plastics and tires: Recent progress, catalyst development, and scaling up potential. Biomass Convers. Biorefinery 2021. [Google Scholar] [CrossRef]

- Ryu, H.W.; Kim, D.H.; Jae, J.; Lam, S.S.; Park, E.D.; Park, Y.K. Recent advances in catalytic co-pyrolysis of biomass and plastic waste for the production of petroleum-like hydrocarbons. Bioresour. Technol. 2020, 310, 123473. [Google Scholar] [CrossRef]

- Missau, J.; Bertuol, D.A.; Tanabe, E.H. Charcoal Briquetting: An Environmentally Friendly Destination for Waste Materials. Environ. Eng. Sci. 2021, 38, 841–853. [Google Scholar] [CrossRef]

- Missau, J.; Bertuol, D.A.; Tanabe, E.H. Highly efficient adsorbent for removal of Crystal Violet Dye from Aqueous Solution by CaAl/LDH supported on Biochar. Appl. Clay Sci. 2021, 214, 106297. [Google Scholar] [CrossRef]

- Kamali, M.; Sweygers, N.; Al-Salem, S.; Appels, L.; Aminabhavi, T.M.; Dewil, R. Biochar for soil applications-sustainability aspects, challenges and future prospects. Chem. Eng. J. 2022, 428, 131189. [Google Scholar] [CrossRef]

- Drugkar, K.; Rathod, W.; Sharma, T.; Sharma, A.; Joshi, J.; Pareek, V.K.; Ledwani, L.; Diwekar, U. Advanced separation strategies for up-gradation of bio-oil into value-added chemicals: A comprehensive review. Sep. Purif. Technol. 2022, 283, 120149. [Google Scholar] [CrossRef]

- Kumar, R.; Strezov, V. Thermochemical production of bio-oil: A review of downstream processing technologies for bio-oil upgrading, production of hydrogen and high value-added products. Renew. Sustain. Energy Rev. 2021, 135, 110152. [Google Scholar] [CrossRef]

- Pinheiro Pires, A.P.; Arauzo, J.; Fonts, I.; Domine, M.E.; Fernández Arroyo, A.; Garcia-Perez, M.E.; Montoya, J.; Chejne, F.; Pfromm, P.; Garcia-Perez, M. Challenges and opportunities for bio-oil refining: A review. Energy Fuels 2019, 33, 4683–4720. [Google Scholar] [CrossRef]

- Gupta, S.; Mondal, P.; Borugadda, V.B.; Dalai, A.K. Advances in upgradation of pyrolysis bio-oil and biochar towards improvement in bio-refinery economics: A comprehensive review. Environ. Technol. Innov. 2021, 21, 101276. [Google Scholar] [CrossRef]

- Hu, X.; Gholizadeh, M. Progress of the applications of bio-oil. Renew. Sustain. Energy Rev. 2020, 134, 110124. [Google Scholar] [CrossRef]

- Hansen, S.; Mirkouei, A.; Diaz, L.A. A comprehensive state-of-technology review for upgrading bio-oil to renewable or blended hydrocarbon fuels. Renew. Sustain. Energy Rev. 2020, 118, 109548. [Google Scholar] [CrossRef]

- Gollakota, A.R.K.; Reddy, M.; Subramanyam, M.D.; Kishore, N. A review on the upgradation techniques of pyrolysis oil. Renew. Sustain. Energy Rev. 2016, 58, 1543–1568. [Google Scholar] [CrossRef]

- Xiu, S.; Shahbazi, A. Bio-oil production and upgrading research: A review. Renew. Sustain. Energy Rev. 2012, 16, 4406–4414. [Google Scholar] [CrossRef]

- Amarasekara, A.S.; Reyes, C.D.G. Acidic ionic liquid catalyzed liquefactions of corn cobs and switchgrass in acetone: Analysis of bio-oils using LC-MS and GC-MS. J. Anal. Appl. Pyrolysis 2020, 145, 104752. [Google Scholar] [CrossRef]

- Chan, Y.H.; Loh, S.K.; Chin, B.L.F.; Yiin, C.L.; How, B.S.; Cheah, K.W.; Wong, M.K.; Loy, A.C.M.; Gwee, Y.L.; Lo, S.L.Y.; et al. Fractionation and extraction of bio-oil for production of greener fuel and value-added chemicals: Recent advances and future prospects. Chem. Eng. J. 2020, 397, 125406. [Google Scholar] [CrossRef]

- Zhou, Y.; Remón, J.; Gracia, J.; Jiang, Z.; Pinilla, J.L.; Hu, C.; Suelves, I. Toward developing more sustainable marine biorefineries: A novel ‘sea-thermal’ process for biofuels production from microalgae. Energy Convers. Manag. 2022, 270, 116201. [Google Scholar] [CrossRef]

- Su, G.; Ong, H.C.; Gan, Y.Y.; Chen, W.H.; Chong, C.T.; Ok, Y.S. Co-pyrolysis of microalgae and other biomass wastes for the production of high-quality bio-oil: Progress and prospective. Bioresour. Technol. 2022, 344, 126096. [Google Scholar] [CrossRef]

- Lyu, G.; Wu, S.; Zhang, H. Estimation and comparison of bio-oil components from different pyrolysis conditions. Front. Energy Res. 2015, 3, 28. [Google Scholar] [CrossRef]

- Seo, M.W.; Lee, S.H.; Nam, H.; Lee, D.; Tokmurzin, D.; Wang, S.; Park, Y.K. Recent advances of thermochemical conversieon processes for biorefinery. Bioresour. Technol. 2022, 343, 126109. [Google Scholar] [CrossRef]

- Oh, S.; Lee, J.; Lam, S.S.; Kwon, E.E.; Ha, J.M.; Tsang, D.C.W.; Ok, Y.S.; Chen, W.H.; Park, Y.K. Fast hydropyrolysis of biomass Conversion: A comparative review. Bioresour. Technol. 2021, 342, 126067. [Google Scholar] [CrossRef]

- Lee, D.J.; Lu, J.S.; Chang, J.S. Pyrolysis synergy of municipal solid waste (MSW): A review. Bioresour. Technol. 2020, 318, 123912. [Google Scholar] [CrossRef]

- Zhang, Q.; Chang, J.; Wang, T.; Xu, Y. Review of biomass pyrolysis oil properties and upgrading research. Energy Convers. Manag. 2007, 48, 87–92. [Google Scholar] [CrossRef]

- Czernik, S.; Bridgwater, A.V. Overview of applications of biomass fast pyrolysis oil. Energy Fuels 2004, 18, 590–598. [Google Scholar] [CrossRef]

- Agblevor, F.A.; Mante, O.; McClung, R.; Oyama, S.T. Co-processing of standard gas oil and biocrude oil to hydrocarbon fuels. Biomass Bioenergy 2012, 45, 130–137. [Google Scholar] [CrossRef]

- Peacocke, G.V.C.; Bridgwater, A.V. Ablative plate pyrolysis of biomass for liquids. Biomass Bioenergy 1994, 7, 147–154. [Google Scholar] [CrossRef]

- Peacocke, G.V.C.; Russell, P.A.; Jenkins, J.D.; Bridgwater, A.V. Physical properties of flash pyrolysis liquids. Biomass Bioenergy 1994, 7, 169–177. [Google Scholar] [CrossRef]

- Zerva, C.; Karakoulia, S.A.; Kalogiannis, K.G.; Margellou, A.; Iliopoulou, E.F.; Lappas, A.A.; Papayannakos, N.; Triantafyllidis, K.S. Hydrodeoxygenation of phenol and biomass fast pyrolysis oil (bio-oil) over Ni/WO3-ZrO2 catalyst. Catal. Today 2021, 366, 57–67. [Google Scholar] [CrossRef]

- Basu, P. Biomass Gasification and Pyrolysis: Practical design and theory; Academic press: Cambridge, MA, USA, 2012; Volume 5, ISBN 9780080878737. [Google Scholar]

- Zhang, J.; Zhang, X. The thermochemical conversion of biomass into biofuels. In Biomass, Biopolymer-Based Materials, and Bioenergy; Elsevier Ltd.: Amsterdam, The Netherlands, 2019; pp. 327–368. ISBN 9780081024263. [Google Scholar]

- Fahmy, T.Y.A.; Fahmy, Y.; Mobarak, F.; El-Sakhawy, M.; Abou-Zeid, R.E. Biomass pyrolysis: Past, present, and future. Environ. Dev. Sustain. 2020, 22, 17–32. [Google Scholar] [CrossRef]

- Tursi, A. A review on biomass: Importance, chemistry, classification, and conversion. Biofuel Res. J. 2019, 6, 962–979. [Google Scholar] [CrossRef]

- Gagić, T.; Perva-Uzunalić, A.; Knez, Ž.; Škerget, M. Hydrothermal Degradation of Cellulose at Temperature from 200 to 300 °C. Ind. Eng. Chem. Res. 2018, 57, 6576–6584. [Google Scholar] [CrossRef]

- Wang, S.; Dai, G.; Yang, H.; Luo, Z. Lignocellulosic biomass pyrolysis mechanism: A state-of-the-art review. Prog. Energy Combust. Sci. 2017, 62, 33–86. [Google Scholar] [CrossRef]

- Räisänen, U.; Pitkänen, I.; Halttunen, H.; Hurtta, M. Formation of the main degradation compounds from arabinose, xylose, mannose and arabinitol during pyrolysis. J. Therm. Anal. Calorim. 2003, 72, 481–488. [Google Scholar] [CrossRef]

- Kawamoto, H. Lignin pyrolysis reactions. J. Wood Sci. 2017, 63, 117–132. [Google Scholar] [CrossRef]

- Wang, Y.; Akbarzadeh, A.; Chong, L.; Du, J.; Tahir, N.; Awasthi, M.K. Catalytic pyrolysis of lignocellulosic biomass for bio-oil production: A review. Chemosphere 2022, 297, 134181. [Google Scholar] [CrossRef] [PubMed]

- Martins-Vieira, J.C.; Torres-Mayanga, P.C.; Lachos-Perez, D. Hydrothermal Processing of Lignocellulosic Biomass: An Overview of Subcritical and Supercritical Water Hydrolysis. Bioenergy Res. 2022. [Google Scholar] [CrossRef]

- Chen, D.; Cen, K.; Zhuang, X.; Gan, Z.; Zhou, J.; Zhang, Y.; Zhang, H. Insight into biomass pyrolysis mechanism based on cellulose, hemicellulose, and lignin: Evolution of volatiles and kinetics, elucidation of reaction pathways, and characterization of gas, biochar and bio-oil. Combust. Flame 2022, 242, 112142. [Google Scholar] [CrossRef]

- Galadima, A.; Muraza, O. In situ fast pyrolysis of biomass with zeolite catalysts for bioaromatics/gasoline production: A review. Energy Convers. Manag. 2015, 105, 338–354. [Google Scholar] [CrossRef]

- Hoang, A.T.; Ong, H.C.; Fattah, I.M.R.; Chong, C.T.; Cheng, C.K.; Sakthivel, R.; Ok, Y.S. Progress on the lignocellulosic biomass pyrolysis for biofuel production toward environmental sustainability. Fuel Process. Technol. 2021, 223, 106997. [Google Scholar] [CrossRef]

- Madadi, M.; Bakr, M.M.A.; Abdulkhani, A.; Zahoor; Asadollahi, M.A.; Sun, C.; Sun, F.; Abomohra, A.E.F. Alleviating lignin repolymerization by carbocation scavenger for effective production of fermentable sugars from combined liquid hot water and green-liquor pretreated softwood biomass. Energy Convers. Manag. 2022, 251, 114956. [Google Scholar] [CrossRef]

- Zhao, A.; Liu, S.; Yao, J.; Huang, F.; He, Z.; Liu, J. Characteristics of bio-oil and biochar from cotton stalk pyrolysis: Effects of torrefaction temperature and duration in an ammonia environment. Bioresour. Technol. 2022, 343, 126145. [Google Scholar] [CrossRef]

- Fu, J.; Liu, J.; Xu, W.; Chen, Z.; Evrendilek, F.; Sun, S. Torrefaction, temperature, and heating rate dependencies of pyrolysis of coffee grounds: Its performances, bio-oils, and emissions. Bioresour. Technol. 2022, 345, 126346. [Google Scholar] [CrossRef]

- Sohaib, Q.; Muhammad, A.; Younas, M. Fast pyrolysis of sugarcane bagasse: Effect of pyrolysis conditions on final product distribution and properties. Energy Sources Part A Recover. Util. Environ. Eff. 2017, 39, 184–190. [Google Scholar] [CrossRef]

- Lin, B.J.; Chen, W.H. Sugarcane bagasse pyrolysis in a carbon dioxide atmosphere with conventional and microwave-assisted heating. Front. Energy Res. 2015, 3, 4. [Google Scholar] [CrossRef]

- Tsai, W.T.; Lee, M.K.; Chang, Y.M. Fast pyrolysis of rice husk: Product yields and compositions. Bioresour. Technol. 2007, 98, 22–28. [Google Scholar] [CrossRef]

- Biswas, B.; Pandey, N.; Bisht, Y.; Singh, R.; Kumar, J.; Bhaskar, T. Pyrolysis of agricultural biomass residues: Comparative study of corn cob, wheat straw, rice straw and rice husk. Bioresour. Technol. 2017, 237, 57–63. [Google Scholar] [CrossRef]

- Alvarez, J.; Lopez, G.; Amutio, M.; Bilbao, J.; Olazar, M. Bio-oil production from rice husk fast pyrolysis in a conical spouted bed reactor. Fuel 2014, 128, 162–169. [Google Scholar] [CrossRef]

- Chen, Q.; Yang, R.; Zhao, B.; Li, Y.; Wang, S.; Wu, H.; Zhuo, Y.; Chen, C. Investigation of heat of biomass pyrolysis and secondary reactions by simultaneous thermogravimetry and differential scanning calorimetry. Fuel 2014, 134, 467–476. [Google Scholar] [CrossRef]

- Gonçalves, E.V.; Seixas, F.L.; de Souza Scandiuzzi Santana, L.R.; Scaliante, M.H.N.O.; Gimenes, M.L. Economic trends for temperature of sugarcane bagasse pyrolysis. Can. J. Chem. Eng. 2017, 95, 1269–1279. [Google Scholar] [CrossRef]

- Veses, A.; Aznar, M.; Martínez, I.; Martínez, J.D.; López, J.M.; Navarro, M.V.; Callén, M.S.; Murillo, R.; García, T. Catalytic pyrolysis of wood biomass in an auger reactor using calcium-based catalysts. Bioresour. Technol. 2014, 162, 250–258. [Google Scholar] [CrossRef] [PubMed]

- Fakayode, O.A.; Aboagarib, E.A.A.; Zhou, C.; Ma, H. Co-pyrolysis of lignocellulosic and macroalgae biomasses for the production of biochar—A review. Bioresour. Technol. 2020, 297, 122408. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Qin, J.; He, Q.; Wen, Y.; Huang, S.; Li, B.; Hu, J.; Zhou, N.; Zhou, Z. Torrefied herb residues in nitrogen, air and oxygen atmosphere: Thermal decomposition behavior and pyrolytic products characters. Bioresour. Technol. 2021, 342, 125991. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Wang, Z.; Li, J.; Yan, B.; Chen, G. Pyrolysis of food waste and food waste solid digestate: A comparative investigation. Bioresour. Technol. 2022, 354, 127191. [Google Scholar] [CrossRef]

- Akhtar, J.; Saidina Amin, N. A review on operating parameters for optimum liquid oil yield in biomass pyrolysis. Renew. Sustain. Energy Rev. 2012, 16, 5101–5109. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, B.; Shujaa Aldeen, A.; Mwenya, S.; Cheng, H.; Xu, Z.; Zhang, H. Enhancing production of hydrocarbon-rich bio-oil from biomass via catalytic fast pyrolysis coupled with advanced oxidation process pretreatment. Bioresour. Technol. 2022, 359, 127450. [Google Scholar] [CrossRef] [PubMed]

- Şensöz, S.; Demiral, I.; Gerçel, H.F. Olive bagasse (Olea europea L.) pyrolysis. Bioresour. Technol. 2006, 97, 429–436. [Google Scholar] [CrossRef]

- Morali, U.; Şensöz, S. Pyrolysis of hornbeam shell (Carpinus betulus L.) in a fixed bed reactor: Characterization of bio-oil and bio-char. Fuel 2015, 150, 672–678. [Google Scholar] [CrossRef]

- Bhoi, P.R.; Ouedraogo, A.S.; Soloiu, V.; Quirino, R. Recent advances on catalysts for improving hydrocarbon compounds in bio-oil of biomass catalytic pyrolysis. Renew. Sustain. Energy Rev. 2020, 121, 109676. [Google Scholar] [CrossRef]

- Xiong, Z.; Wang, Y.; Syed-Hassan, S.S.A.; Hu, X.; Han, H.; Su, S.; Xu, K.; Jiang, L.; Guo, J.; Berthold, E.E.S.; et al. Effects of heating rate on the evolution of bio-oil during its pyrolysis. Energy Convers. Manag. 2018, 163, 420–427. [Google Scholar] [CrossRef]

- Carrier, M.; Hugo, T.; Gorgens, J.; Knoetze, H. Comparison of slow and vacuum pyrolysis of sugar cane bagasse. J. Anal. Appl. Pyrolysis 2011, 90, 18–26. [Google Scholar] [CrossRef]

- Wan Mahari, W.A.; Nam, W.L.; Sonne, C.; Peng, W.; Phang, X.Y.; Liew, R.K.; Yek, P.N.Y.; Lee, X.Y.; Wen, O.W.; Show, P.L.; et al. Applying microwave vacuum pyrolysis to design moisture retention and pH neutralizing palm kernel shell biochar for mushroom production. Bioresour. Technol. 2020, 312, 123572. [Google Scholar] [CrossRef]

- Amutio, M.; Lopez, G.; Aguado, R.; Artetxe, M.; Bilbao, J.; Olazar, M. Effect of vacuum on lignocellulosic biomass flash pyrolysis in a conical spouted bed reactor. Energy Fuels 2011, 25, 3950–3960. [Google Scholar] [CrossRef]

- Jae, J.; Coolman, R.; Mountziaris, T.J.; Huber, G.W. Catalytic fast pyrolysis of lignocellulosic biomass in a process development unit with continual catalyst addition and removal. Chem. Eng. Sci. 2014, 108, 33–46. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, B.; Zhong, Z.; Ding, K.; Deng, A.; Min, M.; Chen, P.; Ruan, R. Catalytic fast co-pyrolysis of bamboo residual and waste lubricating oil over an ex-situ dual catalytic beds of MgO and HZSM-5: Analytical PY-GC/MS study. Energy Convers. Manag. 2017, 139, 222–231. [Google Scholar] [CrossRef]

- Wang, J.; Zhong, Z.; Ding, K.; Deng, A.; Hao, N.; Meng, X.; Ben, H.; Ruan, R.; Ragauskas, A.J. Catalytic fast pyrolysis of bamboo sawdust via a two-step bench scale bubbling fluidized bed/fixed bed reactor: Study on synergistic effect of alkali metal oxides and HZSM-5. Energy Convers. Manag. 2018, 176, 287–298. [Google Scholar] [CrossRef]

- Lappas, A.A.; Kalogiannis, K.G.; Iliopoulou, E.F.; Triantafyllidis, K.S.; Stefanidis, S.D. Catalytic pyrolysis of biomass for transportation fuels. Wiley Interdiscip. Rev. Energy Environ. 2012, 1, 285–297. [Google Scholar] [CrossRef]

- Chen, D.; Li, Y.; Deng, M.; Wang, J.; Chen, M.; Yan, B.; Yuan, Q. Effect of torrefaction pretreatment and catalytic pyrolysis on the pyrolysis poly-generation of pine wood. Bioresour. Technol. 2016, 214, 615–622. [Google Scholar] [CrossRef] [PubMed]

- Sun, T.; Li, Z.; Zhang, Z.; Wang, Z.; Yang, S.; Yang, Y.; Wang, X.; Liu, S.; Zhang, Q.; Lei, T. Fast corn stalk pyrolysis and the influence of catalysts on product distribution. Bioresour. Technol. 2020, 301, 122739. [Google Scholar] [CrossRef]

- Li, Y.; Yellezuome, D.; Liu, R.; Cai, J.; Gao, Y. Investigation of product selectivity and kinetics of poplar sawdust catalytic pyrolysis over bi-metallic Iron-Nickel/ZSM-5 catalyst. Bioresour. Technol. 2022, 349, 126838. [Google Scholar] [CrossRef]

- Tan, Y.L.; Abdullah, A.Z.; Hameed, B.H. Catalytic fast pyrolysis of durian rind using silica-alumina catalyst: Effects of pyrolysis parameters. Bioresour. Technol. 2018, 264, 198–205. [Google Scholar] [CrossRef]

- Limlamthong, M.; Yip, A.C.K. Recent advances in zeolite-encapsulated metal catalysts: A suitable catalyst design for catalytic biomass conversion. Bioresour. Technol. 2020, 297, 122488. [Google Scholar] [CrossRef]

- Ahmed, M.H.M.; Batalha, N.; Mahmudul, H.M.D.; Perkins, G.; Konarova, M. A review on advanced catalytic co-pyrolysis of biomass and hydrogen-rich feedstock: Insights into synergistic effect, catalyst development and reaction mechanism. Bioresour. Technol. 2020, 310, 123457. [Google Scholar] [CrossRef]

- Che, Q.; Yang, M.; Wang, X.; Yang, Q.; Chen, Y.; Chen, X.; Chen, W.; Hu, J.; Zeng, K.; Yang, H.; et al. Preparation of mesoporous ZSM-5 catalysts using green templates and their performance in biomass catalytic pyrolysis. Bioresour. Technol. 2019, 289, 121729. [Google Scholar] [CrossRef]

- Adam, J.; Blazsó, M.; Mészáros, E.; Stöcker, M.; Nilsen, M.H.; Bouzga, A.; Hustad, J.E.; Grønli, M.; Øye, G. Pyrolysis of biomass in the presence of Al-MCM-41 type catalysts. Fuel 2005, 84, 1494–1502. [Google Scholar] [CrossRef]

- Lu, Q.; Zhang, Z.F.; Dong, C.Q.; Zhu, X.F. Catalytic upgrading of biomass fast pyrolysis vapors with nano metal oxides: An analytical Py-GC/MS study. Energies 2010, 3, 1805–1820. [Google Scholar] [CrossRef]

- Zhang, H.; Zheng, J.; Xiao, R.; Jia, Y.; Shen, D.; Jin, B.; Xiao, G. Study on pyrolysis of pine sawdust with solid base and acid mixed catalysts by thermogravimetry-fourier transform infrared spectroscopy and pyrolysis-gas chromatography/mass spectrometry. Energy Fuels 2014, 28, 4294–4299. [Google Scholar] [CrossRef]

- Chang, R.; Zhu, L.; Jin, F.; Fan, M.; Liu, J.; Jia, Q.; Tang, C.; Li, Q. Production of bio-based p-xylene via catalytic pyrolysis of biomass over metal oxide-modified HZSM-5 zeolites. J. Chem. Technol. Biotechnol. 2018, 93, 3292–3301. [Google Scholar] [CrossRef]

- Cao, Z.; Niu, J.; Gu, Y.; Zhang, R.; Liu, Y.; Luo, L. Catalytic pyrolysis of rice straw: Screening of various metal salts, metal basic oxide, acidic metal oxide and zeolite catalyst on products yield and characterization. J. Clean. Prod. 2020, 269, 122079. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, Z.; Zhang, L.; Li, Q.; Li, C.; Chen, G.; Zhang, S.; Liu, Q.; Hu, X. Evolution of the functionalities and structures of biochar in pyrolysis of poplar in a wide temperature range. Bioresour. Technol. 2020, 304, 123002. [Google Scholar] [CrossRef] [PubMed]

- Stefanidis, S.D.; Kalogiannis, K.G.; Iliopoulou, E.F.; Lappas, A.A.; Pilavachi, P.A. In-situ upgrading of biomass pyrolysis vapors: Catalyst screening on a fixed bed reactor. Bioresour. Technol. 2011, 102, 8261–8267. [Google Scholar] [CrossRef]

- Li, Y.; Xing, B.; Ding, Y.; Han, X.; Wang, S. A critical review of the production and advanced utilization of biochar via selective pyrolysis of lignocellulosic biomass. Bioresour. Technol. 2020, 312, 123614. [Google Scholar] [CrossRef]

- Abu Bakar, M.S.; Titiloye, J.O. Catalytic pyrolysis of rice husk for bio-oil production. J. Anal. Appl. Pyrolysis 2013, 103, 362–368. [Google Scholar] [CrossRef]

- Auta, M.; Ern, L.M.; Hameed, B.H. Fixed-bed catalytic and non-catalytic empty fruit bunch biomass pyrolysis. J. Anal. Appl. Pyrolysis 2014, 107, 67–72. [Google Scholar] [CrossRef]

- Aysu, T. Catalytic pyrolysis of Eremurus spectabilis for bio-oil production in a fixed-bed reactor: Effects of pyrolysis parameters on product yields and character. Fuel Process. Technol. 2015, 129, 24–38. [Google Scholar] [CrossRef]

- Yorgun, S.; Şimşek, Y.E. Catalytic pyrolysis of Miscanthus × giganteus over activated alumina. Bioresour. Technol. 2008, 99, 8095–8100. [Google Scholar] [CrossRef] [PubMed]

- Rutkowski, P. Pyrolysis of cellulose, xylan and lignin with the K2CO 3 and ZnCl2 addition for bio-oil production. Fuel Process. Technol. 2011, 92, 517–522. [Google Scholar] [CrossRef]

- Sanna, A.; Vispute, T.P.; Huber, G.W. Hydrodeoxygenation of the aqueous fraction of bio-oil with Ru/C and Pt/C catalysts. Appl. Catal. B Environ. 2015, 165, 446–456. [Google Scholar] [CrossRef]

- Mu, W.; Ben, H.; Du, X.; Zhang, X.; Hu, F.; Liu, W.; Ragauskas, A.J.; Deng, Y. Noble metal catalyzed aqueous phase hydrogenation and hydrodeoxygenation of lignin-derived pyrolysis oil and related model compounds. Bioresour. Technol. 2014, 173, 6–10. [Google Scholar] [CrossRef] [PubMed]

- Jahromi, H.; Agblevor, F.A. Hydrodeoxygenation of Aqueous-Phase Catalytic Pyrolysis Oil to Liquid Hydrocarbons Using Multifunctional Nickel Catalyst. Ind. Eng. Chem. Res. 2018, 57, 13257–13268. [Google Scholar] [CrossRef]

- Cheng, S.; Wei, L.; Alsowij, M.R.; Corbin, F.; Julson, J.; Boakye, E.; Raynie, D. In situ hydrodeoxygenation upgrading of pine sawdust bio-oil to hydrocarbon biofuel using Pd/C catalyst. J. Energy Inst. 2018, 91, 163–171. [Google Scholar] [CrossRef]

- Baloch, H.A.; Nizamuddin, S.; Siddiqui, M.T.H.; Riaz, S.; Jatoi, A.S.; Dumbre, D.K.; Mubarak, N.M.; Srinivasan, M.P.; Griffin, G.J. Recent advances in production and upgrading of bio-oil from biomass: A critical overview. J. Environ. Chem. Eng. 2018, 6, 5101–5118. [Google Scholar] [CrossRef]

- Wang, S.; Guo, Z.; Cai, Q.; Guo, L. Catalytic conversion of carboxylic acids in bio-oil for liquid hydrocarbons production. Biomass Bioenergy 2012, 45, 138–143. [Google Scholar] [CrossRef]

- Kumar, A.; Chakraborty, J.P.; Singh, R. Bio-oil: The future of hydrogen generation. Biofuels 2017, 8, 663–674. [Google Scholar] [CrossRef]

- Remiro, A.; Ochoa, A.; Arandia, A.; Castaño, P.; Bilbao, J.; Gayubo, A.G. On the dynamics and reversibility of the deactivation of a Rh/CeO2–ZrO2 catalyst in raw bio-oil steam reforming. Int. J. Hydrog. Energy 2019, 44, 2620–2632. [Google Scholar] [CrossRef]

- Valle, B.; Aramburu, B.; Benito, P.L.; Bilbao, J.; Gayubo, A.G. Biomass to hydrogen-rich gas via steam reforming of raw bio-oil over Ni/La2O3-AAl2O3 catalyst: Effect of space-time and steam-to-carbon ratio. Fuel 2018, 216, 445–455. [Google Scholar] [CrossRef]

- Arregi, A.; Lopez, G.; Amutio, M.; Artetxe, M.; Barbarias, I.; Bilbao, J.; Olazar, M. Role of operating conditions in the catalyst deactivation in the in-line steam reforming of volatiles from biomass fast pyrolysis. Fuel 2018, 216, 233–244. [Google Scholar] [CrossRef]

- Chen, J.; Sun, J.; Wang, Y. Catalysts for Steam Reforming of Bio-oil: A Review. Ind. Eng. Chem. Res. 2017, 56, 4627–4637. [Google Scholar] [CrossRef]

- Rioche, C.; Kulkarni, S.; Meunier, F.C.; Breen, J.P.; Burch, R. Steam reforming of model compounds and fast pyrolysis bio-oil on supported noble metal catalysts. Appl. Catal. B Environ. 2005, 61, 130–139. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Otoikhian, K.S.; Ighalo, J.O. Steam Reforming of Biomass Pyrolysis Oil: A Review. Int. J. Chem. React. Eng. 2019, 17, 20180328. [Google Scholar] [CrossRef]

- Valle, B.; Aramburu, B.; Olazar, M.; Bilbao, J.; Gayubo, A.G. Steam reforming of raw bio-oil over Ni/La2O3-AAl2O3: Influence of temperature on product yields and catalyst deactivation. Fuel 2018, 216, 463–474. [Google Scholar] [CrossRef]

- Bizkarra, K.; Bermudez, J.M.; Arcelus-Arrillaga, P.; Barrio, V.L.; Cambra, J.F.; Millan, M. Nickel based monometallic and bimetallic catalysts for synthetic and real bio-oil steam reforming. Int. J. Hydrog. Energy 2018, 43, 11706–11718. [Google Scholar] [CrossRef]

- Wang, S.; Guo, X.; Wang, K.; Luo, Z. Influence of the interaction of components on the pyrolysis behavior of biomass. J. Anal. Appl. Pyrolysis 2011, 91, 183–189. [Google Scholar] [CrossRef]

- Liang, J.; Qian, Y.; Yuan, X.; Leng, L.; Zeng, G.; Jiang, L.; Shao, J.; Luo, Y.; Ding, X.; Yang, Z.; et al. Span80/Tween80 stabilized bio-oil-in-diesel microemulsion: Formation and combustion. Renew. Energy 2018, 126, 774–782. [Google Scholar] [CrossRef]

- Leng, L.; Li, H.; Yuan, X.; Zhou, W.; Huang, H. Bio-oil upgrading by emulsification/microemulsification: A review. Energy 2018, 161, 214–232. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, S.; Wang, X. Stability mechanism investigation of emulsion fuels from biomass pyrolysis oil and diesel. Energy 2014, 66, 250–255. [Google Scholar] [CrossRef]

- Lu, Q.; Yang, X.L.; Zhu, X.F. Analysis on chemical and physical properties of bio-oil pyrolyzed from rice husk. J. Anal. Appl. Pyrolysis 2008, 82, 191–198. [Google Scholar] [CrossRef]

- Zhang, X.S.; Yang, G.X.; Jiang, H.; Liu, W.J.; Ding, H.S. Mass production of chemicals from biomass-derived oil by directly atmospheric distillation coupled with co-pyrolysis. Sci. Rep. 2013, 3, srep01120. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Cui, H.; Wei, S.; Zhuo, S.; Wang, L.; Li, Z.; Yi, W. Separation of Biomass Pyrolysis Oil by Supercritical CO2 Extraction. Smart Grid Renew. Energy 2010, 1, 98–107. [Google Scholar] [CrossRef]

- Heng, L.; Zhang, H.; Xiao, J.; Xiao, R. Life Cycle Assessment of Polyol Fuel from Corn Stover via Fast Pyrolysis and Upgrading. ACS Sustain. Chem. Eng. 2018, 6, 2733–2740. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, G.; Brown, R.C. Life cycle assessment of the production of hydrogen and transportation fuels from corn stover via fast pyrolysis. Environ. Res. Lett. 2013, 8, 025001. [Google Scholar] [CrossRef]

- Peters, J.F.; Iribarren, D.; Dufour, J. Simulation and life cycle assessment of biofuel production via fast pyrolysis and hydroupgrading. Fuel 2015, 139, 441–456. [Google Scholar] [CrossRef]

- Iribarren, D.; Peters, J.F.; Dufour, J. Life cycle assessment of transportation fuels from biomass pyrolysis. Fuel 2012, 97, 812–821. [Google Scholar] [CrossRef]

- Wang, H.; Wang, L.; Shahbazi, A. Life cycle assessment of fast pyrolysis of municipal solid waste in North Carolina of USA. J. Clean. Prod. 2015, 87, 130–138. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, G.; Brown, R.C. Life cycle assessment of commodity chemical production from forest residue via fast pyrolysis. Int. J. Life Cycle Assess. 2014, 19, 1371–1381. [Google Scholar] [CrossRef]

- Dang, Q.; Yu, C.; Luo, Z. Environmental life cycle assessment of bio-fuel production via fast pyrolysis of corn stover and hydroprocessing. Fuel 2014, 131, 36–42. [Google Scholar] [CrossRef]

- Zhang, Y.; Brown, T.R.; Hu, G.; Brown, R.C. Techno-economic analysis of two bio-oil upgrading pathways. Chem. Eng. J. 2013, 225, 895–904. [Google Scholar] [CrossRef]

- Shemfe, M.B.; Gu, S.; Ranganathan, P. Techno-economic performance analysis of biofuel production and miniature electric power generation from biomass fast pyrolysis and bio-oil upgrading. Fuel 2015, 143, 361–372. [Google Scholar] [CrossRef]

- Carrasco, J.L.; Gunukula, S.; Boateng, A.A.; Mullen, C.A.; DeSisto, W.J.; Wheeler, M.C. Pyrolysis of forest residues: An approach to techno-economics for bio-fuel production. Fuel 2017, 193, 477–484. [Google Scholar] [CrossRef]

- van Schalkwyk, D.L.; Mandegari, M.; Farzad, S.; Görgens, J.F. Techno-economic and environmental analysis of bio-oil production from forest residues via non-catalytic and catalytic pyrolysis processes. Energy Convers. Manag. 2020, 213, 112815. [Google Scholar] [CrossRef]

- Shemfe, M.; Gu, S.; Fidalgo, B. Techno-economic analysis of biofuel production via bio-oil zeolite upgrading: An evaluation of two catalyst regeneration systems. Biomass Bioenergy 2017, 98, 182–193. [Google Scholar] [CrossRef]

- Veses, A.; Martínez, J.D.; Callén, M.S.; Murillo, R.; García, T. Application of upgraded drop-in fuel obtained from biomass pyrolysis in a spark ignition engine. Energies 2020, 13, 2089. [Google Scholar] [CrossRef]

- Rashid, U.; Nizami, A.-S.; Rehan, M. Waste Biomass Utilization for Value-added Green Products. Curr. Org. Chem. 2019, 23, 1497–1498. [Google Scholar] [CrossRef]

- Yang, S.I.; Hsu, T.C.; Wu, C.Y.; Chen, K.H.; Hsu, Y.L.; Li, Y.H. Application of biomass fast pyrolysis part II: The effects that bio-pyrolysis oil has on the performance of diesel engines. Energy 2014, 66, 172–180. [Google Scholar] [CrossRef]

- Pradhan, D.; Volli, V.; Singh, R.K.; Murgun, S. Co-pyrolysis behavior, engine performance characteristics, and thermodynamics of liquid fuels from mahua seeds and waste thermocol: A comprehensive study. Chem. Eng. J. 2020, 393, 124749. [Google Scholar] [CrossRef]

- Raguraman, D.; Kumar, A.; Prasanna Raj Yadav, S.; Patil, P.Y.; Samson Isaac, J.; Sowmya Dhanalakshmi, C.; Madhu, P.; Isaac Joshuaramesh Lalvani, J. Performance and Emission Characteristics of Pyrolysis Oil Obtained from Neem de Oiled Cake and Waste Polystyrene in a Compression Ignition Engine. Adv. Mater. Sci. Eng. 2021, 2021, 3728852. [Google Scholar] [CrossRef]

- Hu, X.; Mourant, D.; Gunawan, R.; Wu, L.; Wang, Y.; Lievens, C.; Li, C.Z. Production of value-added chemicals from bio-oil via acid catalysis coupled with liquid-liquid extraction. RSC Adv. 2012, 2, 9366–9370. [Google Scholar] [CrossRef]

- Ruiz, M.P.; Mijnders, J.; Tweehuysen, R.; Warnet, L.; van Drongelen, M.; Kersten, S.R.A.; Lange, J.P. Fully Recyclable Bio-Based Thermoplastic Materials from Liquefied Wood. ChemSusChem 2019, 12, 4395–4399. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Mahmood, N.; Ma, Z.; Zhu, M.; Wang, J.; Zheng, J.; Yuan, Z.; Wei, Q.; Xu, C. (Chunbao) Preparation and characterization of bio-polyol and bio-based flexible polyurethane foams from fast pyrolysis of wheat straw. Ind. Crops Prod. 2017, 103, 64–72. [Google Scholar] [CrossRef]

- Hu, X.; Nango, K.; Bao, L.; Li, T.; Mahmudul Hasan, M.D.; Li, C.Z. High yields of solid carbonaceous materials from biomass. Green Chem. 2019, 21, 1128–1140. [Google Scholar] [CrossRef]

- Sarkar, S.; Kumar, A. Large-scale biohydrogen production from bio-oil. Bioresour. Technol. 2010, 101, 7350–7361. [Google Scholar] [CrossRef]

- Yang, S.H.; Suciptan, T. Rheological behavior of Japanese cedar-based biobinder as partial replacement for bituminous binder. Constr. Build. Mater. 2016, 114, 127–133. [Google Scholar] [CrossRef]

| Properties/Elemental Composition (wt. %) | Bio-Oil | Heavy Petroleum-Derived Oil |

|---|---|---|

| HHV (MJ/kg) 1 | 16–19 | 40 |

| Viscosity (at 50 °C) (cP) | 40–100 | 180 |

| C | 54–58 | 85 |

| N | 0–0.2 | 0.3 |

| O | 35–40 | 1.0 |

| H | 5.5–7.0 | 11 |

| Ash | 0–0.2 | 0.1 |

| Water | 15–30 | 0.1 |

| Feedstock | Catalyst | Operating Conditions | Reactor Type | Bio-Oil Yields (wt. %) | Bio-Oil Composition | Ref. |

|---|---|---|---|---|---|---|

| Pinewood | Commercial spray-dried 40% ZSM-5 | 500–650 °C, catalyst to biomass ratio of 6, 5 slpm N2 fluidization flow rate, 550 g of bed mass, and 150 min of reaction time. | Bubbling fluidized-bed | - | Aromatic yield increased up to 15.5 carbon% with reducing gas velocities. | [84] |

| Rice husk | ZSM-5, Al-MCM-41, Al-MSU-F, and Brunei rice husk ash (BRHA) | Feedstock particle size: 355–849 µm; Primary reactor: 450 °C and heating rate of 25 °C/min; Secondary reactor: 490–540 °C | Fixed-bed pyrolysis rig | ZSM-5: 38.3 wt. % Al-MCM-41: 40.0 wt. % Al-MSU-F: 39.6 wt. % BRHA: 38.3 wt. % | ZSM-5 resulted in higher production of aromatic hydrocarbons and light phenols, whilst Al-MCM-41 reduced the acetic acid production. | [103] |

| Empty fruit bunch | K2CO3, Ca(OH)2, and MgO | 600 °C, 10 wt. % Ca(OH)2, and sweeping gas flow rate of 200 mL/min | Fixed-bed reactor | Ca(OH)2 provided the highest bio-oil yield (42.6%) | Higher content in phenolic compounds and lower acidic compounds was obtained in catalytic pyrolysis in comparison with a non-catalytic approach. | [104] |

| Eremurus spectabilis | Na2B4O7·10H2O, CaB3O4(OH)3·H2O, and NaCaB5O6(OH)6·5(H2O) | 350–550 °C; Heating rates of 10, 30, 50 °C/min | Fixed-bed tubular reactor | 38.1% including aqueous phase was achieved with NaCaB5O6(OH)6·5(H2O) | Bio-oils were reported to have high contents of monoaromatics, polyaromatics aliphatics, and oxygenated and nitrogenated organic products. | [105] |

| Miscanthus × giganteus | Al2O3 | 550 °C, heating rate of 10 °C and 50 °C/min, varying catalyst loading from 10 to 100%, and N2 flow rate from 50 to 200 cm3/min | Fixed-bed reactor | 51 wt. % was obtained when 60 wt. % catalyst and N2 flow rate of 50 °C/min were used. | Bio-oils were highly composed of oxygenated compounds. Higher aromatic content was found in the bio-oils produced via catalytic pyrolysis relative to nitrogen atmosphere-based pyrolysis. | [106] |

| Cellulose | K2CO3 and ZnCl2 | 450 °C, 5 g of feedstock, 10 wt. % catalyst, heating rate of 5 °C/min, argon flow of 40 dm3/h, and 1 h of reaction time. | Vertical Pyrex reactor | In the presence of catalysts: 36.4–41.4 wt. % In catalyst absence: 44.0 wt. %. | Lower oxygen content was found in bio-oils produced by K2CO3 and ZnCl2. K2CO3 led to an increased content of aliphatic hydrocarbons along with decreased yield of monocyclic aromatic hydrocarbons, phenols, and products with carboxyl groups. | [107] |

| Techniques | Operating Conditions | Reaction | Technique Feasibility | |

|---|---|---|---|---|

| Advantages | Challenges | |||

| Chemical processes to biofuel production | ||||

| Hydrotreating | Atmospheric pressure to 30 MPa and temperatures between 200 and 500 °C | Removal of oxygen in the bio-oil | Cost-competitive and route already marketed | Avoid the production of char, coke, and tar |

| Catalytic cracking | Intensive process: High temperature >350 °C and pressures (100–2000 Psi), Catalyst: zeolite | Dehydration, cracking of hydrocarbons, and production of larger molecules via C–C bonding and hydrogen | Light products similar to diesel and high conversion yields compared to gasoline fractions | Avoid reactor clogging and requires intensive process |

| Hydrocracking | Hydrogen under high temperatures (>400 °C) | |||

| Steam reforming | High temperatures (400–1000 °C), steam/carbon ratio (S/C > 3), and noble or non-noble metal catalysts | Catalytic steam reforming + water–gas shift | High yield of hydrogen or syngas (>90%) | Complicated process, requires steady and fully resistant reactors |

| Esterification | Employs polar alcohol-based solvents and catalysts | Esterification | Low cost, high grade biofuel, and removal of char particles | High energy for production is the most important challenge of these processes |

| Physical processes to chemical productions | ||||

| Distillation | (Atmospheric) 80–250 °C | No reaction | Production of alcohols, aldehydes, and acids | Avoid the polymerization reactions |

| (Vacuum) Low temperatures | Avoid polymerization reaction and degradation of thermally sensitive compounds | More expensive, energy intensive, and hard operation | ||

| (Molecular) High vacuum (<10−6 atmospheric pressure) | Low distillation temperature and heating rates and high efficiency of fractionation | |||

| Supercritical fluids | Mild conditions (T > 32 °C P > 100 bar) | Clean solvents and bio-oil with low viscosity and oxygen content | Energy intensive and hard operation system | |

| Liquid–liquid extraction | (Water extraction) Normal conditions (T and P) | Simple technique, increases the heating value and stability of bio-oil, and decreases the viscosity | Increases water/solvent content and decreases pH | |

| Emulsification | Warn conditions, surfactant, and co-surfactants | Emulsified with petroleum-based fuels | Classic and cost-effective route | High energy for production is the most important challenge of these processes |

| Biomass | Feed Rate (Dry MT/Day) | Boundary Limit | Functional Unit (FU) | GWP (kgCO2eq /FU) | Ref. | |

|---|---|---|---|---|---|---|

| Upgradation | Total Net GWP | |||||

| Corn stover | 25 | Cradle-to-grave | 1 MJ (of energy output) | 0.026 | 0.0444 | [136] |

| Corn stover | 2000 | Cradle-to-grave | 1 km (dist. traveled by vehicle) | 0.066 (gasoline) | 0.037 (gasoline) | [137] |

| 0.059 (diesel) | 0.015 (diesel) | |||||

| Poplar | 105 | Cradle-to-gate (ends at bio-oil upgradation unit) | 1 MJ (of bio-oil produced) | 0.039 | −0.036 | [139] |

| Poplar | 500 | Cradle-to-gate (ends at bio-oil transportation) | 1 MJ (of bio-oil produced) | 0.032 | −0.050 | [140] |

| MSW | 1620 | Cradle-to-grave | 1 kg (of MSW) | 0.286 | 1.250 | [141] |

| Forest residues | 2000 | Cradle-to-gate (ends at bio-oil upgradation unit) | 1 kg (of chemical produced) | 2.116 | −0.530 | [142] |

| Corn stover | 2 | Cradle-to-gate (ends at bio-oil transportation) | 1 MJ (of bio-oil produced) | 0.003 | 0.025 | [143] |

| Biomass | Feed Rate (Dry MT/Day) | Reactor | Plant Life (Years) | Upgradation Cost (Million USD)/MFSP (USD/GGE 1) | Total Capital Cost (Million USD) | Annual Operating Cost (Million USD) | Ref. | |

|---|---|---|---|---|---|---|---|---|

| Mixed wood | 2000 | Fluidized bed | 20 | P1 2 | 35/nr 3 | 130 | 111.5 | [149] |

| P2 4 | 58/nr | 155 | 88.3 | |||||

| Corn stover | P3 5 | 69/nr | 190 | 92.2 | ||||

| Pine wood | 61 | Bubbling fluidized bed | 20 | 10.95/6.25 | 18.8 | 7.01 | [145] | |

| Hog fuel | 2000 | Dual fluidized bed | 30 | 121/6.44 | 427 | 154 | [146] | |

| Eucalyptus residues | 2549 | Continuous rotary kiln reactor | 25 | 116.4/6.64 | 507.0 | 126.18 | [147] | |

| Pine wood | 61 | Bubbling fluidized bed reactor | 20 | R1 6 | 3.93/7.48 | 13.37 | 5.48 | [148] |

| R2 7 | 4.97/7.20 | 14.46 | 5.15 | |||||

| Biomass | Use | Main Findings | Ref. |

|---|---|---|---|

| Pine woodchips | Fuel Engine (application of 90/8/2 vol% of gasoline/ethanol/bio-oil) | Specific fuel consumption and electrical efficiency remained unaffected; less PAH, SO2, and CO emissions, but slightly more CO2 emissions. | [142] |

| Mallee biomass | Bio-based carbon material production (via polymerization of bio-oil and biochar) | 5-hydroxymethylfurfural and furfural are the best polymerizing agents for enhancing carbon material yield; biochar inclusion enhances hardness. | [150] |

| Coffee bean residues | In diesel engine (Span 80 and Tween 80 were used as emulsions; 5% and 10% (v/v) bio-oil were blended) | Emulsification property and water content of bio-oil slightly enhanced combustion characteristics; increased bio-oil fraction reduced heating value and NOx emissions, but increased delay in the ignition and dense smoke formation. | [144] |

| Wheat straw | Polyurethane foam production | Tensile strength: 80.0 kPa; resilience: 37%; potential to use as car cushions. | [149] |

| Cedar chips | Bio-binder production (to blend with asphalt binder) | Blending of bio-binder enhanced rutting resistance at high temperature; mixing of bio-binder up to 25% did not change complex shear modulus. | [152] |

| Mahua seeds | In diesel engine; 10% to 60% (v/v) of bio-oil were blended with pure diesel. | Brake thermal efficiency (from 30.9 to 27.1%) and NOx emissions were decreased, with an increase in the bio-oil fraction in the blend; application of up to 30% bio-oil in the blend was found preferable. | [145] |

| Mallee wood | Chemicals (methyl levulinate and levulinic acid) production | Sugar derivatives and aromatics fractions of bio-oil were effectively separated via extraction with water followed by chloroform. | [147] |

| Neem de-oiled cake (co-feed: polystyrene) | In diesel engine; 5%, 10%,15% and 20% (v/v) of bio-oil were blended with pure diesel. | Brake thermal efficiency declined for all blends; blending bio-oil up to 10% reflected the minimal impact on engine performance and emissions. | [146] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lachos-Perez, D.; Martins-Vieira, J.C.; Missau, J.; Anshu, K.; Siakpebru, O.K.; Thengane, S.K.; Morais, A.R.C.; Tanabe, E.H.; Bertuol, D.A. Review on Biomass Pyrolysis with a Focus on Bio-Oil Upgrading Techniques. Analytica 2023, 4, 182-205. https://doi.org/10.3390/analytica4020015

Lachos-Perez D, Martins-Vieira JC, Missau J, Anshu K, Siakpebru OK, Thengane SK, Morais ARC, Tanabe EH, Bertuol DA. Review on Biomass Pyrolysis with a Focus on Bio-Oil Upgrading Techniques. Analytica. 2023; 4(2):182-205. https://doi.org/10.3390/analytica4020015

Chicago/Turabian StyleLachos-Perez, Daniel, João Cláudio Martins-Vieira, Juliano Missau, Kumari Anshu, Odiri K. Siakpebru, Sonal K. Thengane, Ana Rita C. Morais, Eduardo Hiromitsu Tanabe, and Daniel Assumpção Bertuol. 2023. "Review on Biomass Pyrolysis with a Focus on Bio-Oil Upgrading Techniques" Analytica 4, no. 2: 182-205. https://doi.org/10.3390/analytica4020015

APA StyleLachos-Perez, D., Martins-Vieira, J. C., Missau, J., Anshu, K., Siakpebru, O. K., Thengane, S. K., Morais, A. R. C., Tanabe, E. H., & Bertuol, D. A. (2023). Review on Biomass Pyrolysis with a Focus on Bio-Oil Upgrading Techniques. Analytica, 4(2), 182-205. https://doi.org/10.3390/analytica4020015