Properties of the Cement, Slag and Fly Ash Mixture Composition Corresponding to CEM II/C-M and CEM VI †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composition of Cement Mixtures and Measured Properties

3. Results and Discussion

3.1. Compressive Strength of the Cement Mortar Samples

3.2. Linear Changes in the Cement Paste Samples

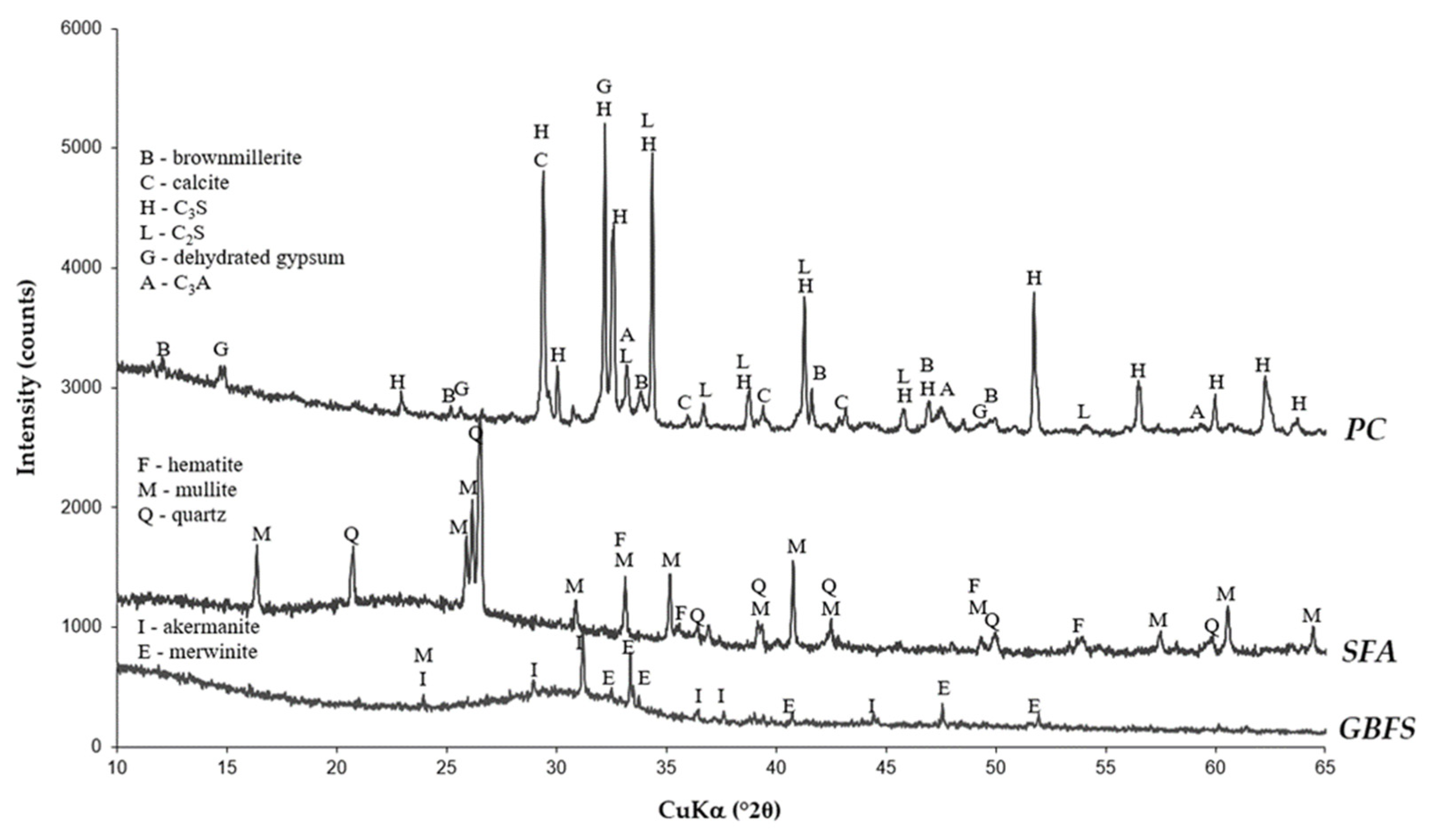

3.3. Phase Composition of the Cement Paste Samples

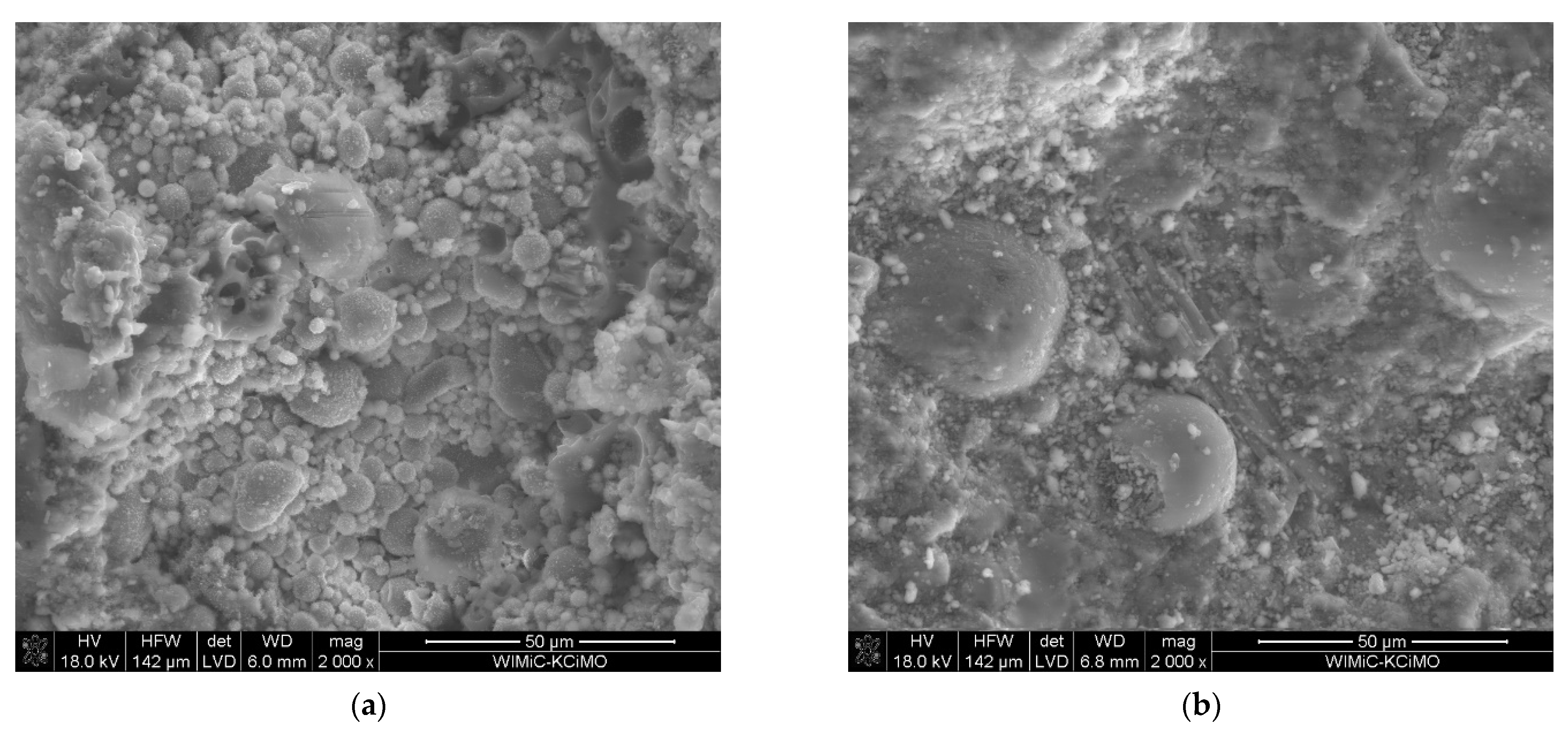

3.4. Microstructure of Cement Paste Samples

4. Conclusions

- According to requirements of the PN-EN 197-1 standard the 60PC-20GBFS-15SFA and 50PC-30GBFS-15SFA mixtures can be classified as CEM II/C-M (S-V) cements of the 32.5R and 32.5N strength classes, respectively, while the 40PC-40GBFS-15SFA mixture corresponds to the CEM VI (S-V) cement of the 32.5N strength class.

- Slight linear changes in the initial curing period of the cement pastes studied may be due to the disappearance of monocarboaluminates in favor of an increase in the amount of ettringite.

- Changes in the dynamics of the hydration process and an increase in the strength of the mortar may result in sealing the cement mortar microstructure with a compact C-S-H.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Andrew, R.; Peters, G. The Global Carbon Project’s fossil CO2 Emissions Dataset: 2021 Release; CICERO Center for International Climate Research: Oslo, Norway, 2021; Available online: https://zenodo.org/record/5569235/files/GCP%20fossilCO2%202021v34.pdf (accessed on 20 November 2022).

- Kurdowski, W. Chemistry of Cement and Concrete; Polish Scientific Publishers PWN: Warszawa, Poland, 2010. [Google Scholar]

- Bjegovic, D.; Strimer, N.; Serdar, M. Ecological aspects of concrete production. In Proceedings of the Second International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010; Zachar, J., Claisse, P., Naik, T.R., Ganjian, E., Eds.; UWM Center for By-Products Utlilization: Milwaukee, WI, USA, 2010; pp. 1483–1492. [Google Scholar]

- PN-EN 197-1; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. iTeh Standards: Warszawa, Poland, 2012.

- Giergiczny, Z. Fly ash and slag. Cem. Concr. Res. 2019, 124, 105826. [Google Scholar] [CrossRef]

- Król, A.; Giergiczny, Z.; Kuterasińska-Warwas, J. No TitleProperties of Concrete Made with Low-Emission Cements CEM II/C-M and CEM VI. Materials 2020, 13, 2257. [Google Scholar] [CrossRef] [PubMed]

- Deschner, F.; Winnefeld, F.; Lothenbach, B.; Seufert, S.; Schwesig, P.; Dittrich, S.; Goetz-Neunhoeffer, F.; Neubauer, J. Hydration of Portland cement with high replacement by siliceous fly ash. Cem. Concr. Res. 2012, 42, 1389–1400. [Google Scholar] [CrossRef]

- Sakai, E.; Miyahara, S.; Ohsawa, S.; Lee, S.H.; Daimon, M. Hydration of fly ash cement. Cem. Concr. Res. 2005, 35, 1135–1140. [Google Scholar] [CrossRef]

- Schuldyakov, K.V.; Kramar, L.Y.; Trofimov, B.Y. The properties of slag cement and its influence on the structure of the hardened cement paste. Procedia Eng. 2016, 150, 1433–1439. [Google Scholar] [CrossRef] [Green Version]

- Roy, D.M.; Malek, R.I. Hydration of slag cement. In Progress in Cement and Concrete: Mineral Admixtures in Cement and Concrete; ABI Books Pvt. Ltd.: Delhi, India, 1993; pp. 84–117. [Google Scholar]

- PN-EN 197-5; Cement—Part 5: Composition, Specifications and Conformity Criteria for Portland Composite-Cement and Composite Cement. iTeh Standards: Warszawa, Poland, 2021.

- PN-EN 196-1:2016; Methods of Testing Cement—Part 1: Determination of Strength. iTeh Standards: Warszawa, Poland, 2016.

- Wieczorek, M.; Pichniarczyk, P. Wpływ zmiennego stosunku popiołu lotnego krzemionkowego do granulowanego żużla wielkopiecowego na właściwości cementu. In Proceedings of the XI Konferencja „Dni Betonu: Tradycja i nowoczesność”, Wisła, Poland, 11–13 October 2021; Stowarzyszenie Producentów Cementu: Kraków, Poland, 2021; pp. 683–696. [Google Scholar]

| Parameter | PC | GBFS | SFA | G | |

|---|---|---|---|---|---|

| Chemical composition (%) | SiO2, Al2O3 Fe2O3 CaO MgO SO3 Na2O K2O TiO2 P2O5 Residue LOI Cl− Reactive SiO2 | 21.62 2.37 1.51 62.12 1.57 2.03 0.42 0.84 0.15 0.18 3.42 3.77 0.097 — | 36.25 8.68 0.23 42.70 8.22 1.51 0.57 0.39 0.41 0.03 0.92 0.10 0.014 — | 49.67 27.77 6.96 2.78 1.37 0.93 1.48 2.51 1.60 0.82 0.48 3.66 0.013 38.87 | 3.70 1.29 0.64 35.61 0.40 39.20 0.12 0.22 0.07 0.03 0.28 18.45 0.036 — |

| Density (g/cm3) | 3.04 | 2.89 | 2.11 | 1.49 | |

| Blaine surface area (cm2/g) | 3810 | 4120 | 2740 | 5250 | |

| Particle size distribution (%) (1) | D10, µm D50, µm D90, µm | 4.4 17.4 45.7 | 0.7 13.2 34.7 | 5.8 52.5 239.9 | 1.0 5.8 45.7 |

| Symbol | PC (%) | GBFS (%) | SFA (%) | G (%) | Cement Type According to the PN-EN 197-5 Standard [11] |

|---|---|---|---|---|---|

| 60PC-20GBFS-15SFA 50PC-30GBFS-15SFA 40PC-40GBFS-15SFA | 60 50 40 | 20 30 40 | 15 15 15 | 5 5 5 | CEM II/C-M (S-V) CEM II/C-M (S-V) CEM VI (S-V) |

| Cement Mixture | Compressive Strength (MPa) | ||

|---|---|---|---|

| 2 Days | 7 Days | 28 Days | |

| 60PC-20GBFS-15SFA 50PC-30GBFS-15SFA 40PC-40GBFS-15SFA | 13.73 9.85 6.34 | 23.49 19.75 17.69 | 41.73 40.13 37.68 |

| Cement Mixture | Length Changes (mm) | ||||||

|---|---|---|---|---|---|---|---|

| 1 Day | 2 Days | 3 Days | 4 Days | 5 Days | 6 Days | 7 Days | |

| 60PC-20GBFS-15SFA 50PC-30GBFS-15SFA 40PC-40GBFS-15SFA | 0.00 0.00 0.00 | −0.05 −0.09 −0.05 | −0.01 −0.01 −0.06 | −0.01 0.00 −0.04 | −0.01 0.00 −0.06 | −0.01 0.01 −0.05 | 0.00 0.00 −0.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tkaczewska, E.; Malata, G. Properties of the Cement, Slag and Fly Ash Mixture Composition Corresponding to CEM II/C-M and CEM VI. Mater. Proc. 2023, 13, 11. https://doi.org/10.3390/materproc2023013011

Tkaczewska E, Malata G. Properties of the Cement, Slag and Fly Ash Mixture Composition Corresponding to CEM II/C-M and CEM VI. Materials Proceedings. 2023; 13(1):11. https://doi.org/10.3390/materproc2023013011

Chicago/Turabian StyleTkaczewska, Ewelina, and Grzegorz Malata. 2023. "Properties of the Cement, Slag and Fly Ash Mixture Composition Corresponding to CEM II/C-M and CEM VI" Materials Proceedings 13, no. 1: 11. https://doi.org/10.3390/materproc2023013011

APA StyleTkaczewska, E., & Malata, G. (2023). Properties of the Cement, Slag and Fly Ash Mixture Composition Corresponding to CEM II/C-M and CEM VI. Materials Proceedings, 13(1), 11. https://doi.org/10.3390/materproc2023013011