The Influence of Casting Static Compaction Pressure on Carbonated Reactive Magnesia Cement (CRMC)-Based Mortars †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mixture Design and Production of Specimens

2.3. Assessment of the CRMC-Based Mortars Developed

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shi, C.; Qu, B.; Provis, J.L. Recent progress in low-carbon binders. Cem. Concr. Res. 2019, 122, 227–250. [Google Scholar] [CrossRef]

- Sonat, C.; Lim, C.H.; Liska, M.; Unluer, C. Recycling and reuse of reactive MgO cements–A feasibility study. Constr. Build. Mater. 2017, 157, 172–181. [Google Scholar] [CrossRef]

- Unluer, C.; Al-Tabbaa, A. Enhancing the carbonation of MgO cement porous blocks through improved curing conditions. Cem. Concr. Res. 2014, 59, 55–65. [Google Scholar] [CrossRef]

- Dung, N.T.; Lesimple, A.; Hay, R.; Celik, K.; Unluer, C. Formation of carbonate phases and their effect on the performance of reactive MgO cement formulations. Cem. Concr. Res. 2019, 125, 105894. [Google Scholar] [CrossRef]

- Liska, M.; Al-Tabbaa, A. Ultra-green construction: Reactive magnesia masonry products. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2009, 162, 185–196. [Google Scholar] [CrossRef]

- Grünhäuser Soares, E.; Castro-Gomes, J. Carbonation curing influencing factors of Carbonated Reactive Magnesia Cements (CRMC)–A review. J. Clean. Prod. 2021, 305, 17. [Google Scholar] [CrossRef]

- Humbert, P.S.; Castro-Gomes, J.P.; Savastano, H. Clinker-free CO2 cured steel slag based binder: Optimal conditions and potential applications. Constr Build. Mater. 2019, 210, 413–421. [Google Scholar] [CrossRef]

- Grünhäuser Soares, E.; Castro-Gomes, J.; Sitarz, M.; Zdeb, T.; Hager, I. The Immobilisation of Heavy Metals from Sewage Sludge Ash in CO2-Cured Mortars. Sustainability 2021, 13, 12893. [Google Scholar] [CrossRef]

- Grünhäuser Soares, E.; Castro-Gomes, J.; Sitarz, M.; Zdeb, T.; Hager, I.; Hassan, K.; Al-Kuwari, M.S. Feasibility for co-utilisation of Carbonated Reactive Magnesia Cement (CRMC) and industrial wastes in circular economy and CO2 mineralisation. Constr. Build. Mater. 2022, 323, 13. [Google Scholar] [CrossRef]

- Grünhäuser Soares, E.; Castro-Gomes, J. The role of biomass bottom ash in Carbonated Reactive Magnesia Cement (CRMC) for CO2 mineralisation. J. Clean Prod. 2022, 380, 135092. [Google Scholar] [CrossRef]

- Shand, M.A. The Chemistry and Technology of Magnesia; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006. [Google Scholar] [CrossRef]

- Jin, F.; Al-Tabbaa, A. Characterisation of different commercial reactive magnesia. Adv. Cem. Res. 2014, 26, 101–113. [Google Scholar] [CrossRef]

- Ma, H. Mercury intrusion porosimetry in concrete technology: Tips in measurement, pore structure parameter acquisition and application. J. Porous Mater. 2014, 21, 207–215. [Google Scholar] [CrossRef]

- Everett, D.H. Manual of Symbols and Terminology for Physicochemical Quantities and Units, Appendix II: Definitions, Terminology and Symbols in Colloid and Surface Chemistry. Pure Appl. Chem. 1972, 31, 577–638. [Google Scholar] [CrossRef]

- Dung, N.T.; Unluer, C. Carbonated MgO concrete with improved performance: The influence of temperature and hydration agent on hydration, carbonation and strength gain. Cem. Concr. Compos. 2017, 82, 152–164. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, D.; Ellis, B.R.; Li, V.C. Mechanical behavior of carbonated MgO-based Engineered Cementitious Composite (ECC) after high temperatures exposure. Cem. Concr. Compos. 2021, 124, 104255. [Google Scholar] [CrossRef]

- Hay, R.; Otchere, C.; Kashwani, G.; Celik, K. Recycling carbonated reactive magnesium cement (RMC) as a building material. J. Clean Prod. 2021, 320, 128838. [Google Scholar] [CrossRef]

- Dung, N.T.; Unluer, C. Improving the performance of reactive MgO cement-based concrete mixes. Constr. Build. Mater. 2016, 126, 747–758. [Google Scholar] [CrossRef]

- Unluer, C.; Al-Tabbaa, A. The role of brucite, ground granulated blastfurnace slag, and magnesium silicates in the carbonation and performance of MgO cements. Constr. Build. Mater. 2015, 94, 629–643. [Google Scholar] [CrossRef]

- Bhattacharjya, D.; Selvamani, T.; Mukhopadhyay, I. Thermal decomposition of hydromagnesite. J. Therm. Anal. Calorim. 2012, 107, 439–445. [Google Scholar] [CrossRef]

- Jauffret, G.; Morrison, J.; Glasser, F.P. On the thermal decomposition of nesquehonite. J. Therm. Anal. Calorim. 2015, 122, 601–609. [Google Scholar] [CrossRef]

- Tian, L.; Tahmasebi, A.; Yu, J. An experimental study on thermal decomposition behavior of magnesite. J. Therm. Anal. Calorim. 2014, 118, 1577–1584. [Google Scholar] [CrossRef]

- Thiery, M.; Villain, G.; Dangla, P.; Platret, G. Investigation of the carbonation front shape on cementitious materials: Effects of the chemical kinetics. Cem. Concr. Res. 2007, 37, 1047–1058. [Google Scholar] [CrossRef]

- Tu, Z.; Guo, M.Z.; Poon, C.S.; Shi, C. Effects of limestone powder on CaCO3 precipitation in CO2 cured cement pastes. Cem. Concr. Compos. 2016, 72, 9–16. [Google Scholar] [CrossRef]

- Qin, L.; Gao, X. Properties of coal gangue-Portland cement mixture with carbonation. Fuel 2019, 245, 1–12. [Google Scholar] [CrossRef]

- Bhagath Singh, G.V.P.; Sonat, C.; Yang, E.H.; Unluer, C. Performance of MgO and MgO–SiO2 systems containing seeds under different curing conditions. Cem. Concr. Compos. 2020, 108, 103543. [Google Scholar] [CrossRef]

- Khalil, A.; Sohn, S.; Celik, K. Thermal properties and stability of reactive magnesia cement. Constr. Build. Mater. 2021, 308, 125102. [Google Scholar] [CrossRef]

- Coleyshaw, E.E.; Crump, G.; Griffith, W. Vibrational spectra of the hydrated carbonate minerals ikaite, monohydrocalcite, lansfordite and nesquehonite. Spectrochim. Acta Part A 2003, 59, 2231–2239. [Google Scholar] [CrossRef]

- Kloprogge, J.T.; Martens, W.N.; Nothdurft, L.; Duong, L.V.; Webb, G.E. Low temperature synthesis and characterization of nesquehonite. J. Mater. Sci. Lett. 2003, 22, 825–829. [Google Scholar] [CrossRef]

- Nied, D.; Enemark-Rasmussen, K.; L’Hopital, E.; Skibsted, J.; Lothenbach, B. Properties of magnesium silicate hydrates (M-S-H). Cem. Concr. Res. 2016, 79, 323–332. [Google Scholar] [CrossRef]

| Raw Material | Oxide Composition | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Na2O | MgO | Al2O3 | SiO2 | P2O5 | SO3 | Cl- | K2O | CaO | TiO2 | MnO | Fe2O3 | |

| r-MgO | - | 93.3 | - | 1.6 | - | - | - | - | 3.5 | - | - | 1.6 |

| BFA | 1.6 | 5.7 | 20.3 | 35.1 | 2.4 | 2.7 | 0.5 | 8.9 | 14.9 | 0.7 | 0.7 | 6.3 |

| RS | 3.3 | 0.7 | 13.2 | 76.5 | - | - | - | 3.4 | 1.4 | - | - | 1.6 |

| Raw Material | Physical Properties | ||

|---|---|---|---|

| True Density (g/cm3) | Blaine Fineness (cm2/g) | LOI (%) at 1000 °C | |

| r-MgO | 3.0 | 6263 | 10.4 |

| BFA | 2.3 | 4029 | 7.5 |

| RS | 2.6 | - | 3.7 |

| Mixture Label | Raw Material (vol. %) | w/b | Static Compaction Pressure (MPa) | ||

|---|---|---|---|---|---|

| r-MgO | BFA | RS | |||

| M.P-10 | 10.0 | 15.0 | 75.0 | 0.41 | 10 |

| M.P-30 | 30 | ||||

| M.P-50 | 50 | ||||

| M.P-70 | 70 | ||||

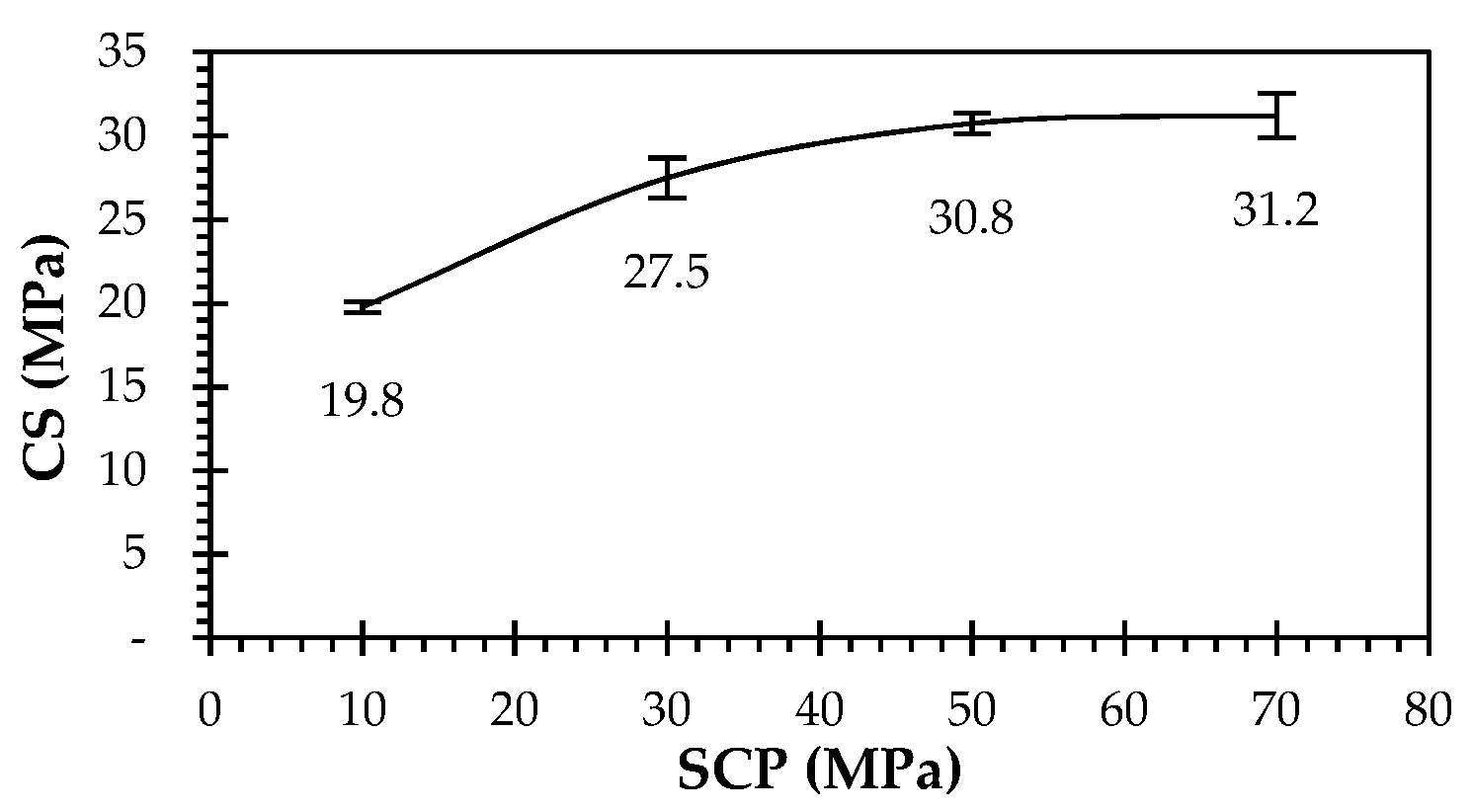

| Parameter | Mixture Label | ||||

|---|---|---|---|---|---|

| M.P-10 | M.P-30 | M.P-50 | M.P-70 | ||

| Compressive strength (MPa) | 19.79 | 27.50 | 30.75 | 31.21 | |

| Standard deviation (MPa) | 0.32 | 1.19 | 0.62 | 1.34 | |

| Compressive strength enhancement/weakening (%) comparing with | M.P-10 | − | 38.96 | 55.38 | 57.71 |

| M.P-30 | −28.04 | − | 11.82 | 13.49 | |

| M.P-50 | −35.64 | −10.57 | − | 1.50 | |

| M.P-70 | −36.59 | −11.89 | −1.47 | − | |

| Parameter | Mixture Label | ||||

|---|---|---|---|---|---|

| M.P-10 | M.P-30 | M.P-50 | M.P-70 | ||

| Porosity (%) | 22.34 | 18.99 | 16.90 | 15.80 | |

| Average pore diameter (µm) | 0.07 | 0.05 | 0.06 | 0.05 | |

| Critical diameter (µm) | 25.60 | 12.36 | 5.38 | 11.76 | |

| Bulk density at 14.50 psia (g/mL) | 2.11 | 2.08 | 2.11 | 2.13 | |

| Apparent (skeletal) density (g/mL) | 2.45 | 2.48 | 2.48 | 2.47 | |

| Pores typology (%) [14] | Mesopores (0.002−0.05 µm) | 19.44 | 23.64 | 22.11 | 22.03 |

| Macropores (0.05−10 µm) | 33.56 | 53.06 | 60.80 | 57.41 | |

| Air voids/cracks (≥10 µm) | 47.00 | 23.30 | 17.09 | 20.56 | |

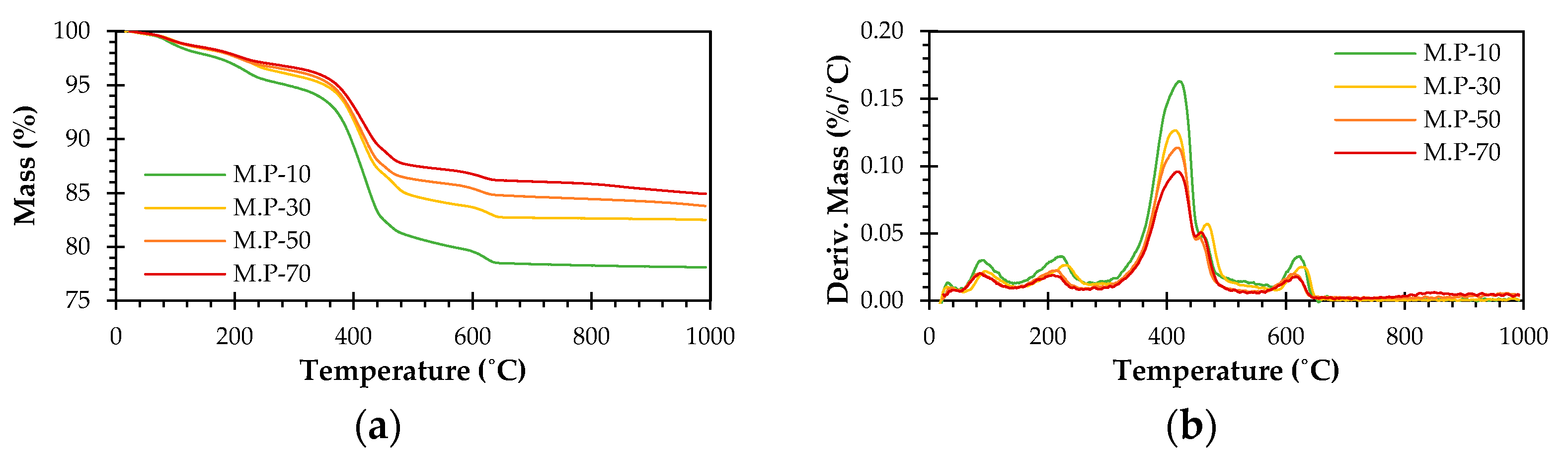

| Mixture Label | Mass Loss (%) in TG-DTG by Temperature Range | |||

|---|---|---|---|---|

| 25−300 °C | 300−550 °C | 550−1000 °C | ∑ | |

| M.P-10 | 5.19 | 14.63 | 2.09 | 21.92 |

| M.P-30 | 4.07 | 11.77 | 1.63 | 17.47 |

| M.P-50 | 3.66 | 10.41 | 2.10 | 16.17 |

| M.P-70 | 3.34 | 9.43 | 2.28 | 15.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grünhäuser Soares, E.; Castro-Gomes, J.; Magrinho, M. The Influence of Casting Static Compaction Pressure on Carbonated Reactive Magnesia Cement (CRMC)-Based Mortars. Mater. Proc. 2023, 13, 5. https://doi.org/10.3390/materproc2023013005

Grünhäuser Soares E, Castro-Gomes J, Magrinho M. The Influence of Casting Static Compaction Pressure on Carbonated Reactive Magnesia Cement (CRMC)-Based Mortars. Materials Proceedings. 2023; 13(1):5. https://doi.org/10.3390/materproc2023013005

Chicago/Turabian StyleGrünhäuser Soares, Erick, João Castro-Gomes, and Manuel Magrinho. 2023. "The Influence of Casting Static Compaction Pressure on Carbonated Reactive Magnesia Cement (CRMC)-Based Mortars" Materials Proceedings 13, no. 1: 5. https://doi.org/10.3390/materproc2023013005

APA StyleGrünhäuser Soares, E., Castro-Gomes, J., & Magrinho, M. (2023). The Influence of Casting Static Compaction Pressure on Carbonated Reactive Magnesia Cement (CRMC)-Based Mortars. Materials Proceedings, 13(1), 5. https://doi.org/10.3390/materproc2023013005