Influence of Spent Fluid Catalytic Cracking Catalyst on the Properties of the New Binder Based on Fly Ash and Portland Cement †

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Characterization of the Binder Components

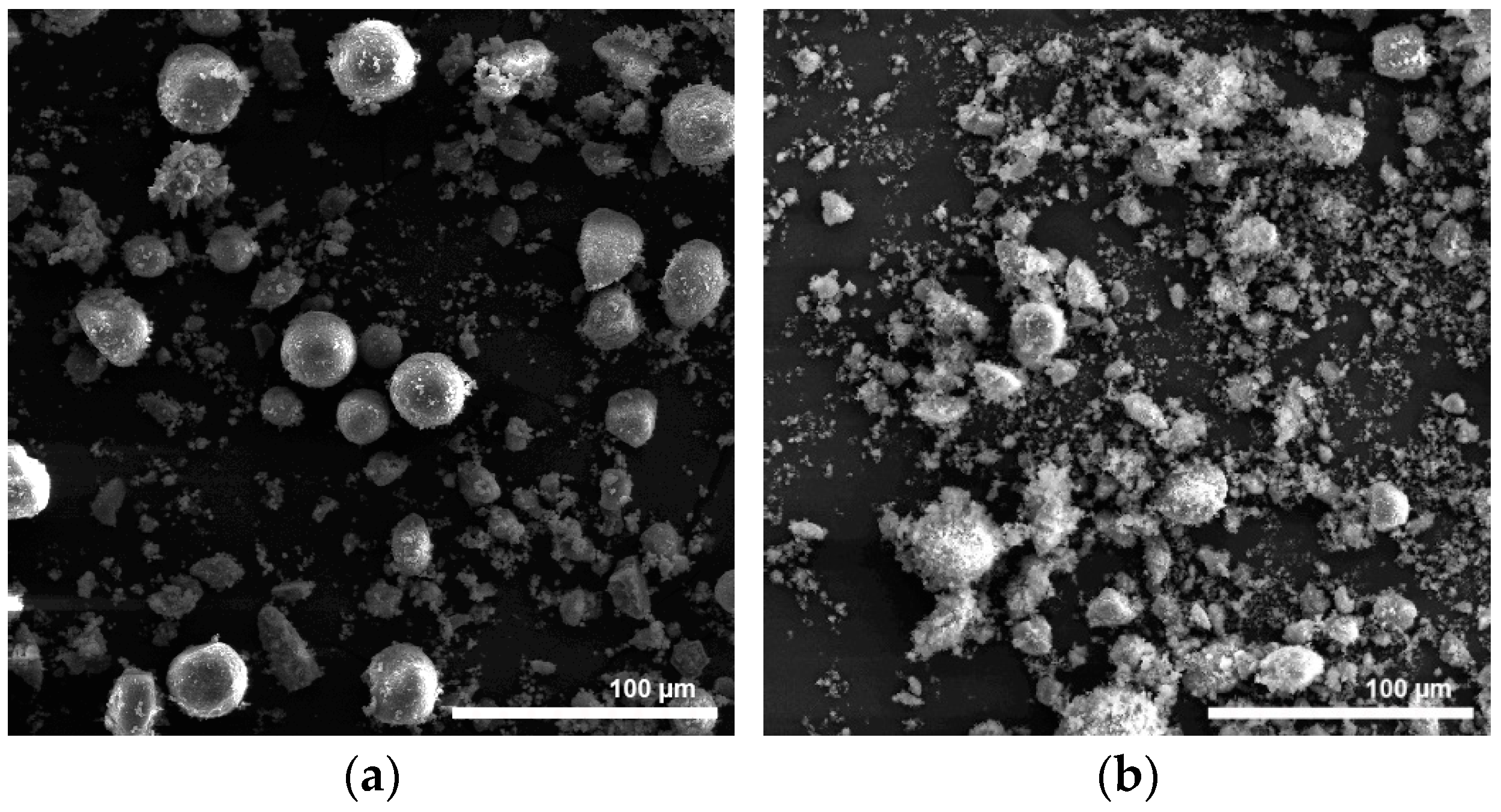

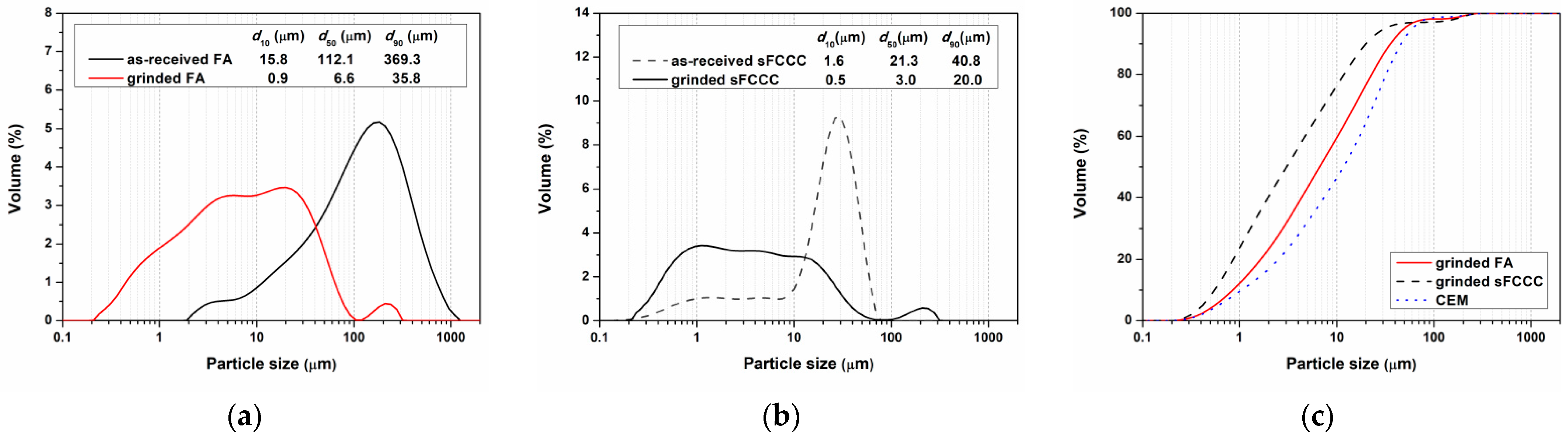

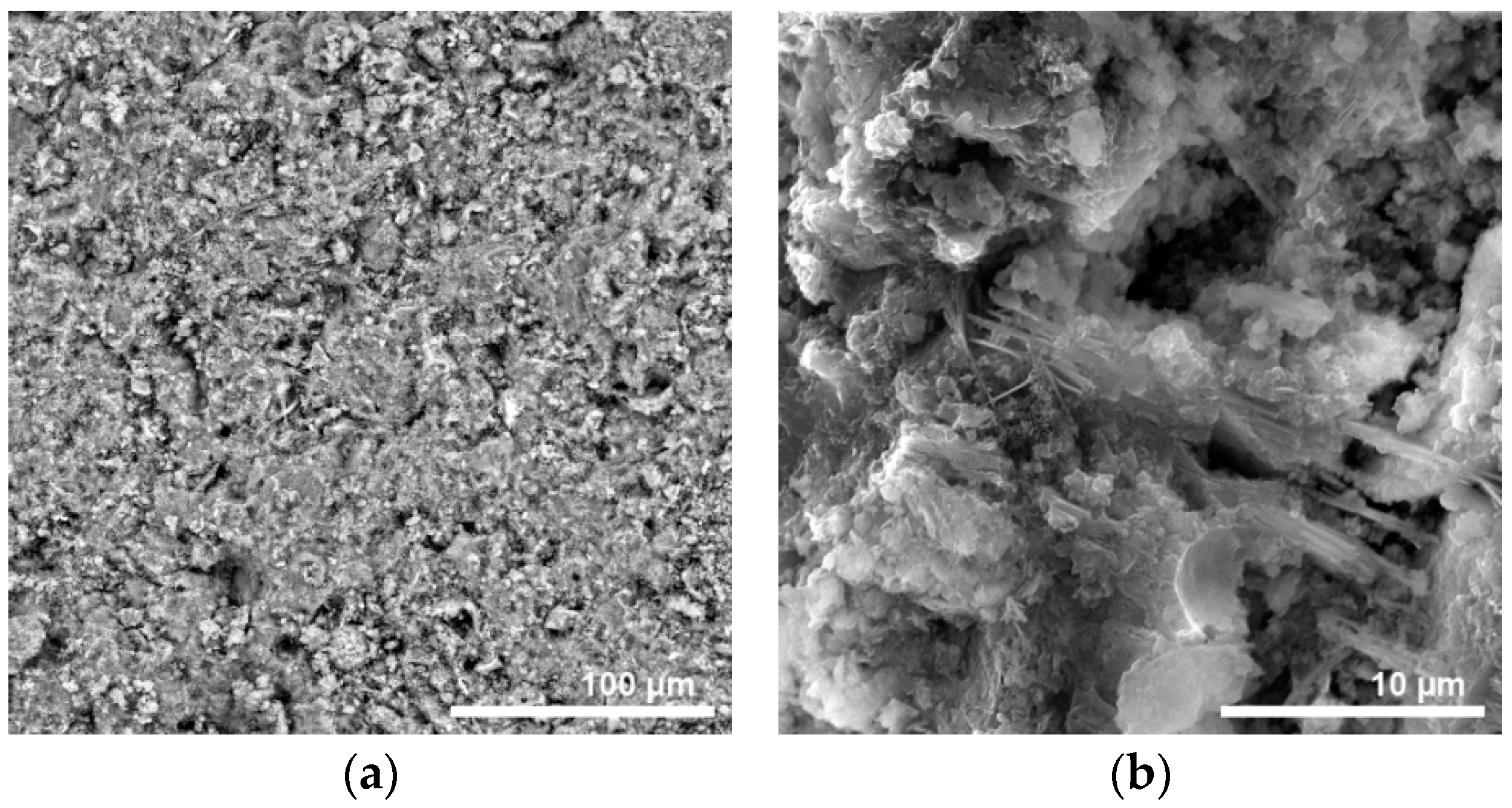

3.1.1. Effects of the Mechanical Activation on Morphology and Particle Size Distribution of FA and sFCCC

3.1.2. Chemical and Mineral Composition of the Binder Components

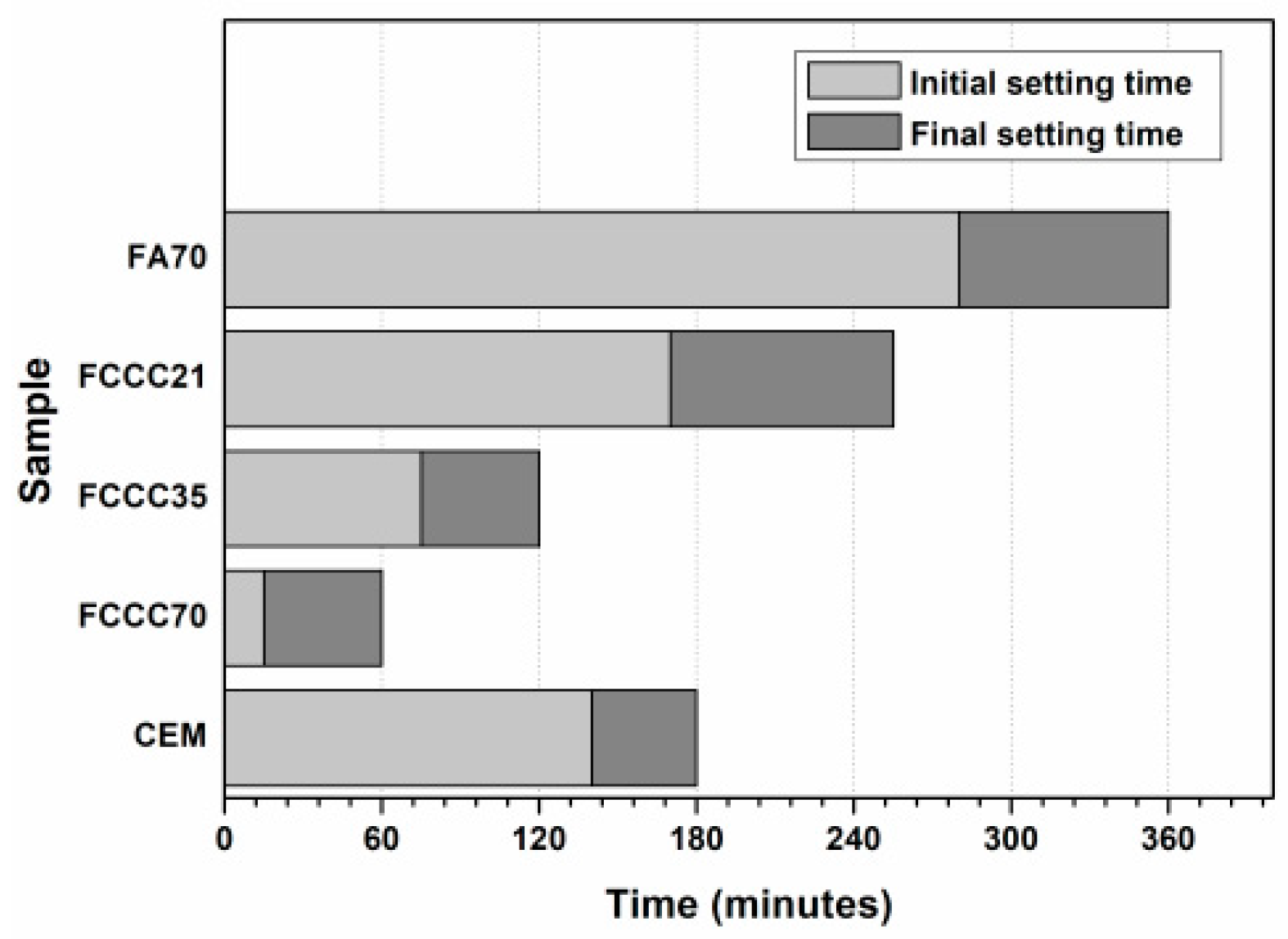

3.2. Influence of sFCCC on Setting Times of the New Binder

3.3. Compressive Strength of the New Binder

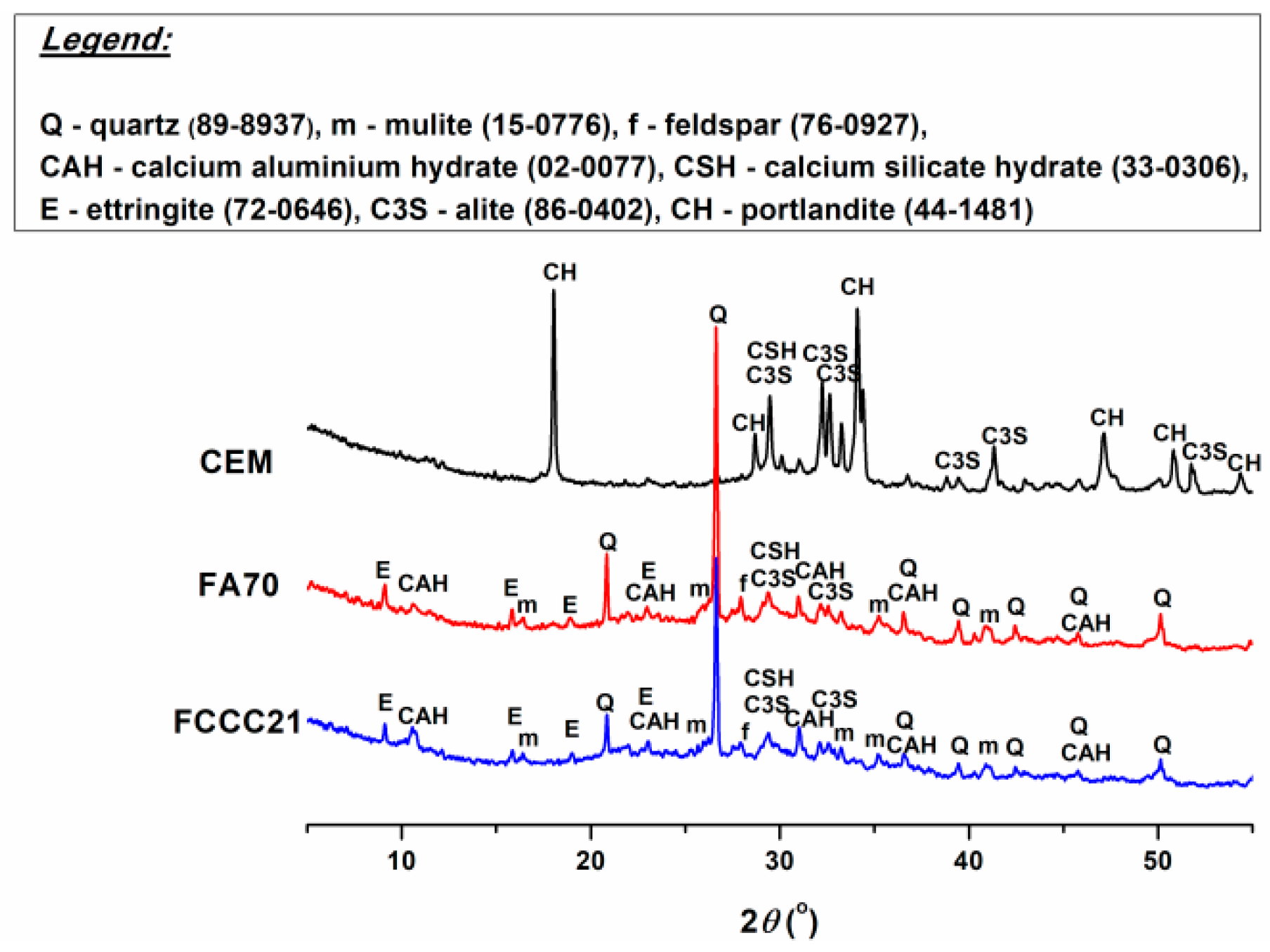

3.4. Mineral Composition and Microstructure of the New Binder

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alahrache, S.; Winnefeld, F.; Champenois, J.; Hesselbarth, F.; Lothenbach, B. Chemical activation of hybrid binders based on siliceous fly ash and Portland cement. Cem. Concr. Compos. 2016, 66, 10–23. [Google Scholar] [CrossRef]

- Wilinska, I.; Pacewska, B. Influence of selected activating methods on hydration processes of mixtures containing high and very high amount of fly ash. J. Therm. Anal. Calorim. 2018, 133, 823–843. [Google Scholar] [CrossRef]

- Alonso-Fariñas, B.; Rodríguez-Galán, M.; Arenas, C.; Arroyo Torralvo, F.; Leiva, C. Sustainable management of spent fluid catalytic cracking catalyst from a circular economy approach. Waste. Manag. 2020, 110, 10–19. [Google Scholar] [CrossRef] [PubMed]

- Wilińska, I.; Pacewska, B. Calorimetric and thermal analysis studies on the influence of waste aluminosilicate catalyst on the hydration of fly ash–cement paste. J. Therm. Anal. Calorim. 2014, 116, 689–697. [Google Scholar] [CrossRef]

- Payá, J.; Monzó, J.; Borrachero, M.V. Physical, chemical and mechanical properties of fluid catalytic cracking catalyst residue (FC3R) blended cements. Cem. Concr. Res. 2001, 31, 57–61. [Google Scholar] [CrossRef]

- Soriano, L.; Payá, J.; Monzó, J.; Borrachero, M.V.; Tashima, M.M. High strength mortars using ordinary Portland cement–fly ash–fluid catalytic cracking catalyst residue ternary system (OPC/FA/FCC). Constr. Build. Mater. 2016, 106, 228–235. [Google Scholar] [CrossRef]

- Da, Y.; He, T.; Wang, M.; Shi, C.; Xu, R.; Yang, R. The effect of spent petroleum catalyst powders on the multiple properties in blended cement. Constr. Build. Mater. 2020, 231, 117203. [Google Scholar] [CrossRef]

- Payá, J.; Monzó, J.; Borrachero, M.V. Fluid catalytic cracking catalyst residue (FC3R). An excellent mineral by-product for improving early strength development of cement mixtures. Cem. Concr. Res. 1999, 29, 1773–1779. [Google Scholar] [CrossRef]

- SRPS EN 196-3:2017; Methods of Testing Cement–Part 3: Determination of Setting Times and Soundness. Institute for Standardization of Serbia: Belgrade, Serbia, 2017.

- SRPS EN 196-1:2017; Methods of Testing Cement–Part 1: Determination of Strength. Institute for Standardization of Serbia: Belgrade, Serbia, 2017.

- SRPS EN 1015-3:2008; Methods of Test for Mortar for Masonry–Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). Institute for Standardization of Serbia: Belgrade, Serbia, 2008.

- Marjanović, N.; Komljenović, M.; Baščarević, Z.; Nikolić, V. Improving reactivity of fly ash and properties of ensuing geopolymers through mechanical activation. Constr. Build. Mater. 2014, 57, 151–162. [Google Scholar] [CrossRef]

- Marjanović, N.; Komljenović, M.; Baščarević, Z.; Nikolić, V. Comparison of two alkali-activated systems: Mechanically activated fly ash and fly ash-blast furnace slag blends. 7th Scientific-Technical Conference Material Problems in Civil Engineering (MATBUD’2015). Procedia Eng. 2015, 108, 231–238. [Google Scholar] [CrossRef] [Green Version]

- Pacewska, B.; Wilińska, I.; Bukowska, M.; Blonkowski, G.; Nocuñ-Wczelik, W. An attempt to improve the pozzolanic activity of waste aluminosilicate catalyst. J. Therm. Anal. Calorim. 2004, 77, 133–142. [Google Scholar] [CrossRef]

- Baščarević, Z.; Rakić, J.; Petrović, R. Possibility to use spent catalyst from fluid catalytic cracking process for geopolymer synthesis. In Proceedings of the (Tagungsband 1) Internationale Baustofftagung, IBAUSIL, Weimar, Germany, 12–14 September 2018. [Google Scholar]

- Musha, H.; Chandratilleke, G.R.; Chan, S.L.I.; Bridgwater, J.; Yu, A.B. Effects of Size and Density Differences on Mixing of Binary Mixtures of Particles. Powders Grains 2013 AIP Conf. Proc. 2013, 1542, 739–742. [Google Scholar] [CrossRef]

- ASTM C618-22; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohochen, PA, USA, 2022.

- Komljenović, M.; Baščarević, Z.; Bradić, V. Mechanical and microstructural properties of alkali-activated fly ash geopolymers. J. Hazard Mater. 2010, 181, 35–42. [Google Scholar] [CrossRef] [PubMed]

- Lam, L.; Wong, Y.L.; Poon, C.S. Degree of hydration and gel/space ratio of high-volume fly ash/cement systems. Cem. Concr. Res. 2000, 30, 747–756. [Google Scholar] [CrossRef]

- He, T.; Da, Y.; Xu, R.; Yang, R. Effect of multiple chemical activators on mechanical property of high replacement high calcium fly ash blended system. Constr. Build. Mater. 2019, 198, 537–545. [Google Scholar] [CrossRef]

| Binder | Composition (mass %) | Water/Binder Ratio | ||

|---|---|---|---|---|

| FA | sFCCC | CEM | ||

| CEM | 0 | 0 | 100 | 0.29 |

| FCCC70 | 0 | 70 | 30 | 0.47 |

| FCCC35 | 35 | 35 | 30 | 0.46 |

| FCCC21 | 49 | 21 | 30 | 0.45 |

| FA70 | 70 | 0 | 30 | 0.43 |

| Composition (mass %) | FA | sFCCC | CEM |

|---|---|---|---|

| LOI (1000 °C) | 2.69 | 5.55 | 2.54 |

| SiO2 | 61.51 | 41.97 | 20.17 |

| Al2O3 | 15.91 | 42.86 | 5.36 |

| Fe2O3 | 7.79 | 1.86 | 2.86 |

| CaO | 8.45 | 4.79 | 62.04 |

| MgO | 0.35 | 0.43 | 2.17 |

| SO3 | 0.19 | 0.10 | 3.38 |

| Na2O | 0.35 | 0.01 | 0.45 |

| K2O | 1.01 | 0.07 | 0.75 |

| P2O5 | 0.06 | 0.47 | - |

| TiO2 | 1.46 | 1.61 | - |

| SUM | 99.77 | 99.72 | 99.72 |

| Compressive Strength (MPa) | CEM | FA70 | FCCC21 |

|---|---|---|---|

| 2 days | 31.9 ± 0.9 | 6.0 ± 0.2 | 7.0 ± 0.2 |

| 7 days | 48.8 ± 0.6 | 15.0 ± 0.5 | 14.8 ± 0.3 |

| 28 days | 57.8 ± 2.1 | 32.9 ± 0.7 | 26.9 ± 0.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rakić, J.; Baščarević, Z. Influence of Spent Fluid Catalytic Cracking Catalyst on the Properties of the New Binder Based on Fly Ash and Portland Cement. Mater. Proc. 2023, 13, 8. https://doi.org/10.3390/materproc2023013008

Rakić J, Baščarević Z. Influence of Spent Fluid Catalytic Cracking Catalyst on the Properties of the New Binder Based on Fly Ash and Portland Cement. Materials Proceedings. 2023; 13(1):8. https://doi.org/10.3390/materproc2023013008

Chicago/Turabian StyleRakić, Jelena, and Zvezdana Baščarević. 2023. "Influence of Spent Fluid Catalytic Cracking Catalyst on the Properties of the New Binder Based on Fly Ash and Portland Cement" Materials Proceedings 13, no. 1: 8. https://doi.org/10.3390/materproc2023013008

APA StyleRakić, J., & Baščarević, Z. (2023). Influence of Spent Fluid Catalytic Cracking Catalyst on the Properties of the New Binder Based on Fly Ash and Portland Cement. Materials Proceedings, 13(1), 8. https://doi.org/10.3390/materproc2023013008