Electrospun Nanofibers for Optimized Fiber-Shaped Wearable Sensors †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of PVDF Nanofibers through Electrospinning Process

2.2. Morphological Characterization and Physico-Chemcial Characterizations

3. Results and Discussion

3.1. Morphology

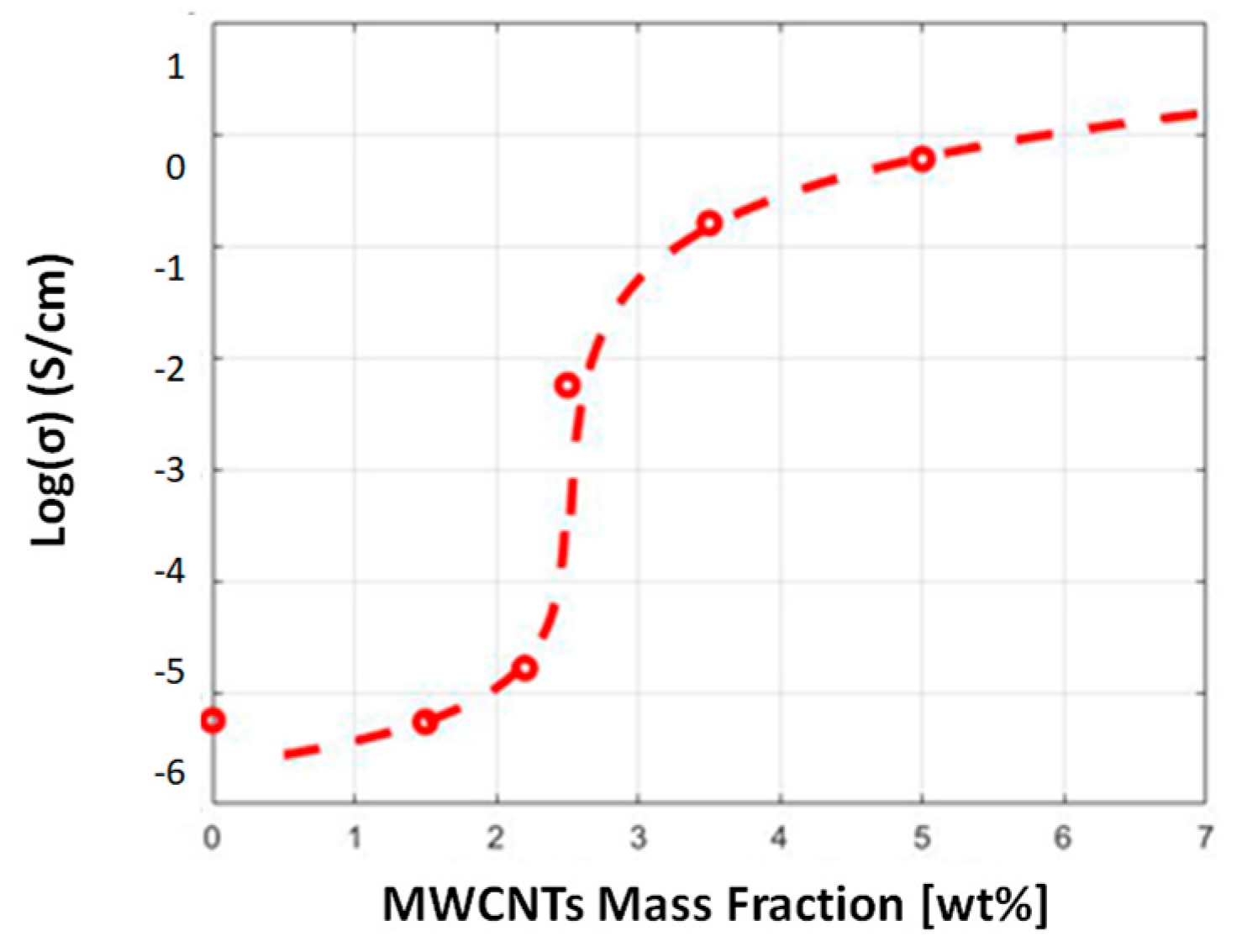

3.2. Electrical Characterization

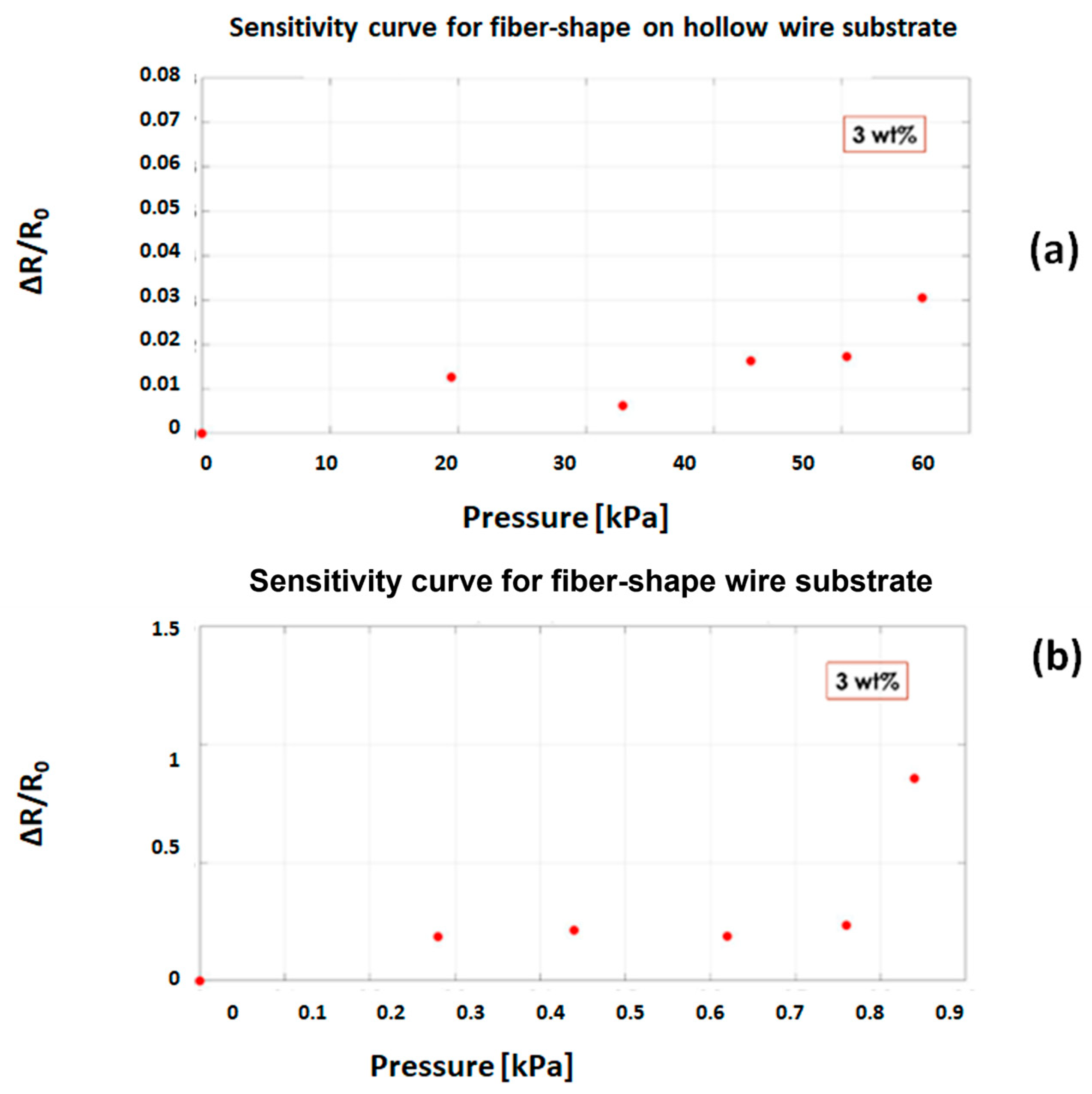

3.3. Piezoresistive Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Amjadi, M.; Kyung, K.U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Weng, W.; Chen, P.; He, S.; Sun, X.; Peng, H. Smart electronic textiles. Angew. Chem. Int. Ed. 2016, 55, 6140–6169. [Google Scholar] [CrossRef] [PubMed]

- Gong, S.; Cheng, W. One-Dimensional Nanomaterials for Soft Electronics. Adv. Electron. Mater. 2017, 3, 1600314. [Google Scholar] [CrossRef]

- Wang, Y.; Yokota, T.; Someya, T. Electrospun nanofiber-based soft electronics. NPG Asia Mater. 2021, 13, 22. [Google Scholar] [CrossRef]

- Verpoorten, E.; Massaglia, G.; Ciardelli, G.; Pirri, C.F.; Quaglio, M. Design and optimization of piezoresistive peo/pedot:Pss electrospun nanofibers for wearable flex sensors. Nanomaterials 2020, 10, 2166. [Google Scholar] [CrossRef] [PubMed]

- Verpoorten, E.; Massaglia, G.; Pirri, C.F.; Quaglio, M. Electrospun peo/pedot:Pss nanofibers for wearable physiological flex sensors. Sensors 2021, 21, 4110. [Google Scholar] [CrossRef] [PubMed]

- Nadaf, A.; Gupta, A.; Hasan, N.; Fauziya Ahmad, S.; Kesharwani, P.; Ahmad, F.J. Recent update on electrospinning and electrospun nanofibers: Current trends and their applications. RSC Adv. 2022, 12, 23808. [Google Scholar] [CrossRef] [PubMed]

- Fakharuddin, A.; Li, H.; Di Giacomo, F.; Zhang, T.; Gasparini, N.; Elezzabi, A.Y.; Mohanty, A.; Ramadoss, A.; Ling, J.K.; Soultati, A.; et al. Fiber-Shaped Electronic Devices. Adv. Energy Mater. 2021, 11, 2101443. [Google Scholar] [CrossRef]

- Massaglia, G.; Chiodoni, A.; Salvador, G.P.; Delmondo, L.; Munoz-Tabares, J.A.; Bocchini, S.; Sacco, A.; Bianco, S.; Saracco, G.; Quaglio, M. Defining the role of nanonetting in the electrical behaviour of composite nanofiber/nets. RSC Adv. 2017, 7, 38812–38818. [Google Scholar] [CrossRef]

- Yuan, H.; Zhou, Q.; Zhang, Y. Electrospun Nanofibers; Elsevier; The Textile Institute; Woodhead Publishing: Cambridge, UK, 2017; pp. 125–147. [Google Scholar]

- Fan, Q.; Qin, Z.; Gao, S.; Wu, Y.; Pionteck, J.; Mäder, E.; Zhu, M. The use of a carbon nanotube layer on a polyurethane multifilament substrate for monitoring strains as large as 400%. Carbon 2012, 50, 4085–4092. [Google Scholar] [CrossRef]

- Chen, L.; Chen, G.H.; Lu, L. Piezoresistive behavior study on fingersensing silicone rubber/graphite nanosheet nanocomposites. Adv. Funct. Mater. 2007, 17, 898–904. [Google Scholar] [CrossRef]

| wt% | σfinal (S/cm) |

|---|---|

| 0 | 5.62 × 10−7 |

| 1.5 | 5.45 × 10−7 |

| 2.2 | 1.65 × 10−6 |

| 2.5 | 5.62 × 10−4 |

| 3.5 | 1.59 × 10−2 |

| 5 | 5.96 × 10−2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Massaglia, G.; Quaglio, M. Electrospun Nanofibers for Optimized Fiber-Shaped Wearable Sensors. Mater. Proc. 2023, 14, 55. https://doi.org/10.3390/IOCN2023-14533

Massaglia G, Quaglio M. Electrospun Nanofibers for Optimized Fiber-Shaped Wearable Sensors. Materials Proceedings. 2023; 14(1):55. https://doi.org/10.3390/IOCN2023-14533

Chicago/Turabian StyleMassaglia, Giulia, and Marzia Quaglio. 2023. "Electrospun Nanofibers for Optimized Fiber-Shaped Wearable Sensors" Materials Proceedings 14, no. 1: 55. https://doi.org/10.3390/IOCN2023-14533

APA StyleMassaglia, G., & Quaglio, M. (2023). Electrospun Nanofibers for Optimized Fiber-Shaped Wearable Sensors. Materials Proceedings, 14(1), 55. https://doi.org/10.3390/IOCN2023-14533