Contribution to the Optimization of the Smelting Reduction of Nickeliferous Laterites, Based on the Recent Industrial Experience †

Abstract

:1. Introduction

2. Pyrometallurgical Processing of Greek Laterite Ores

3. Critical Parameters for the Optimization of the Smelting-Reduction Step

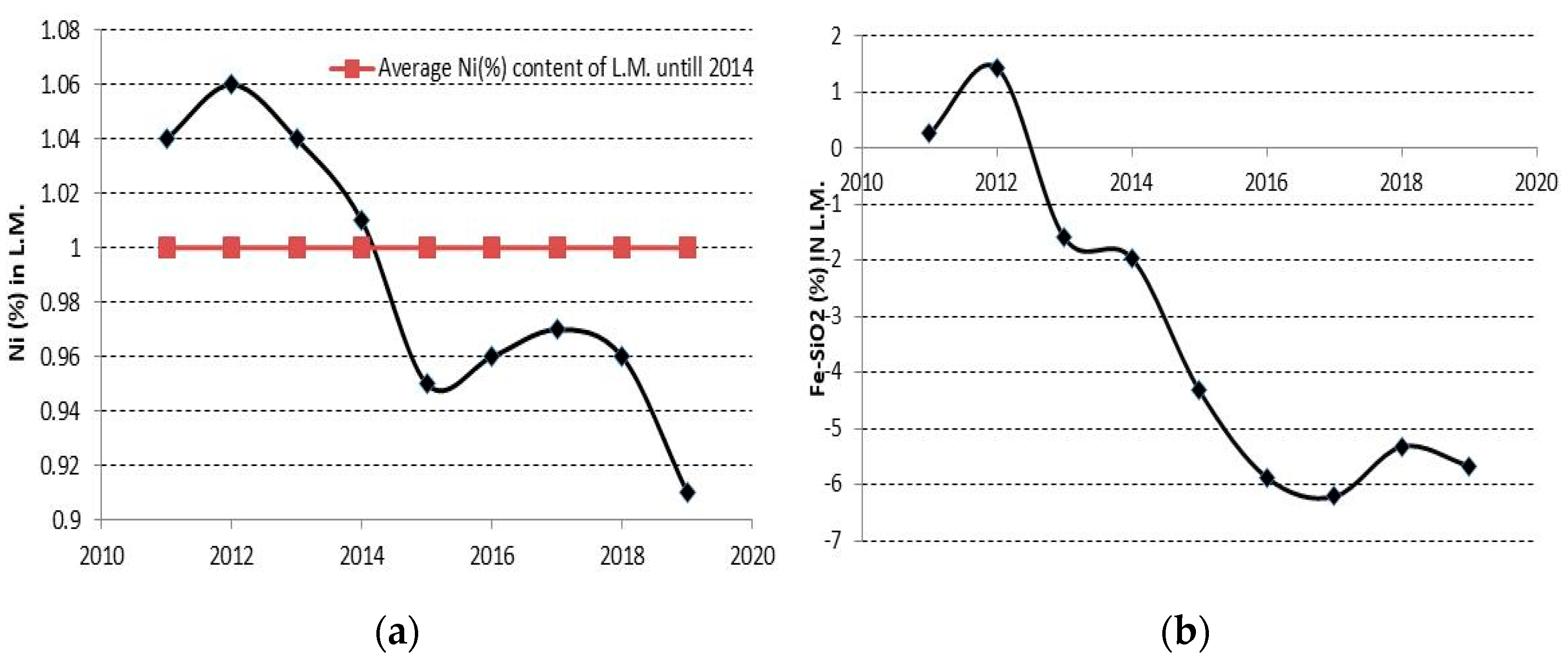

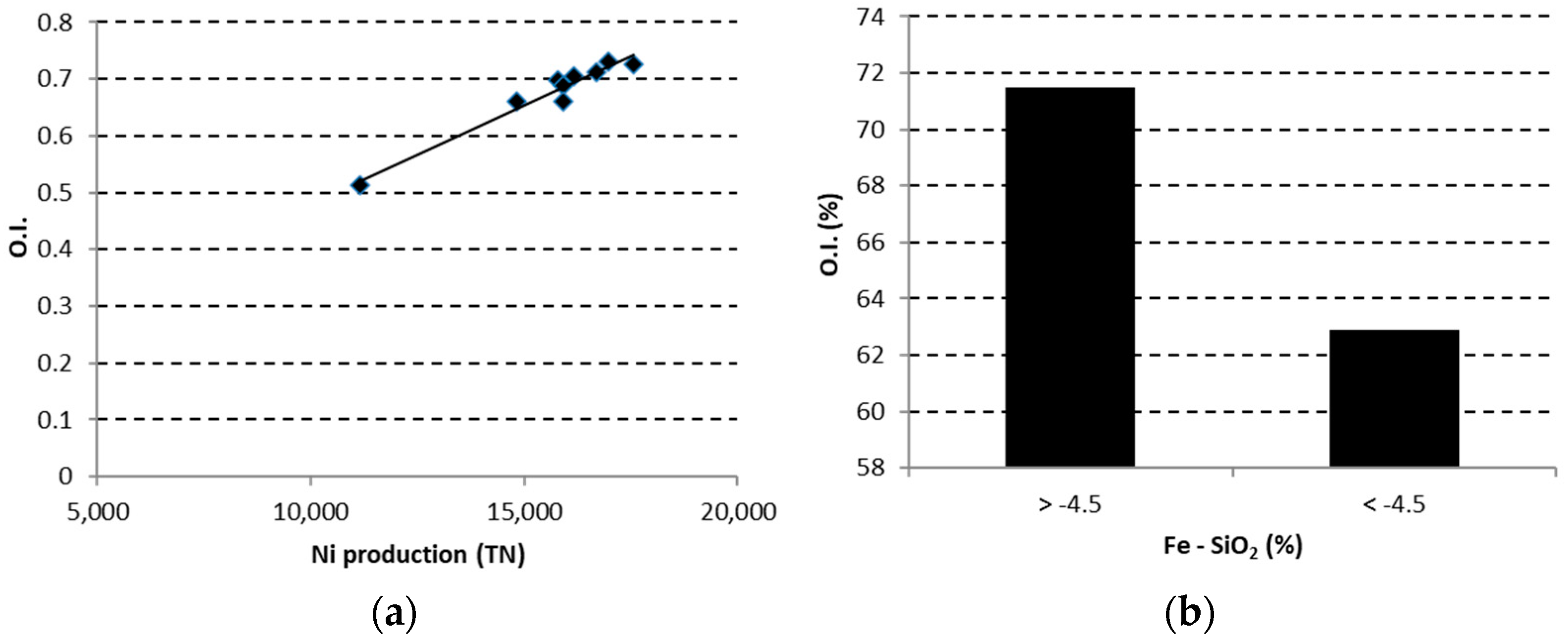

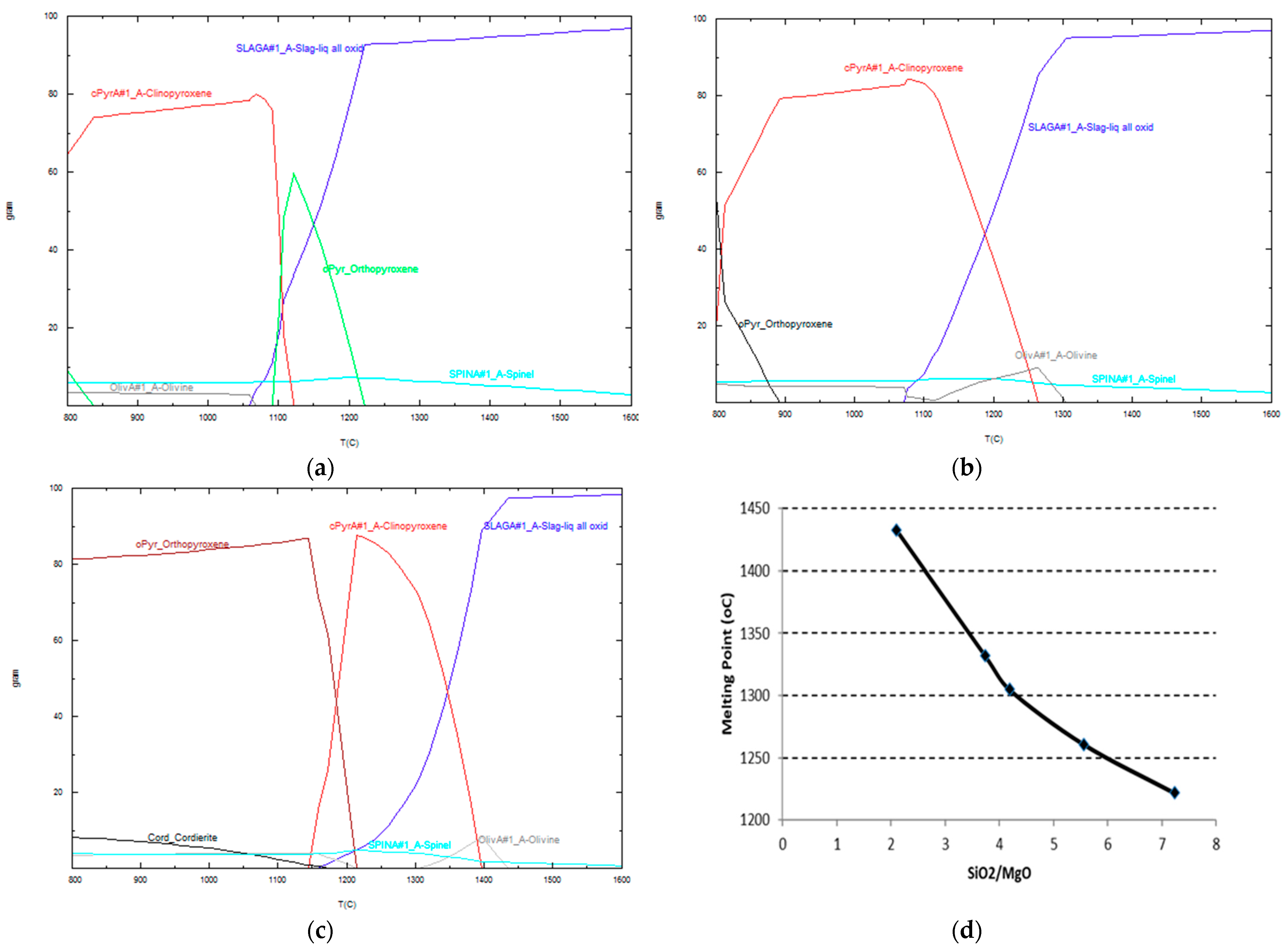

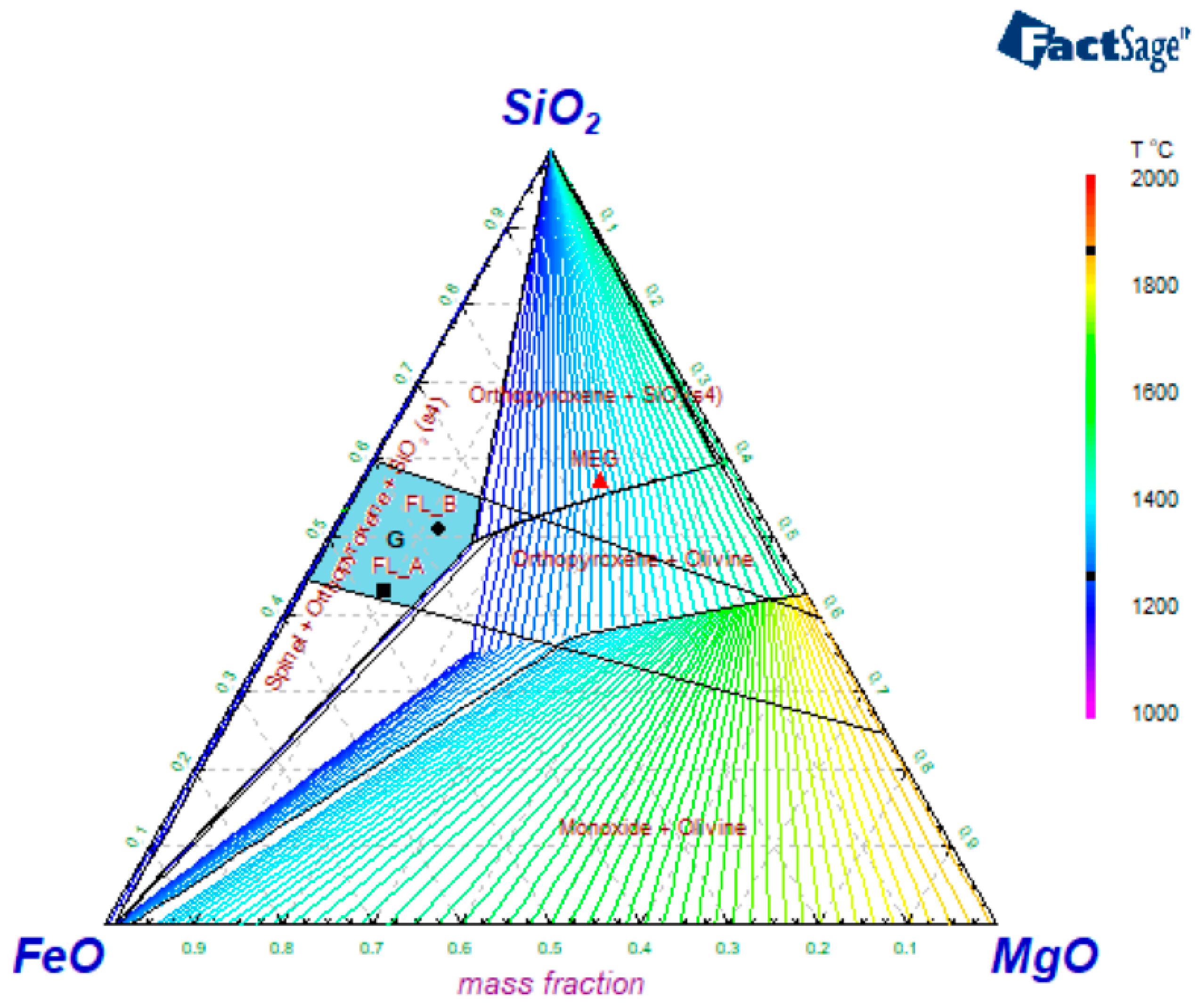

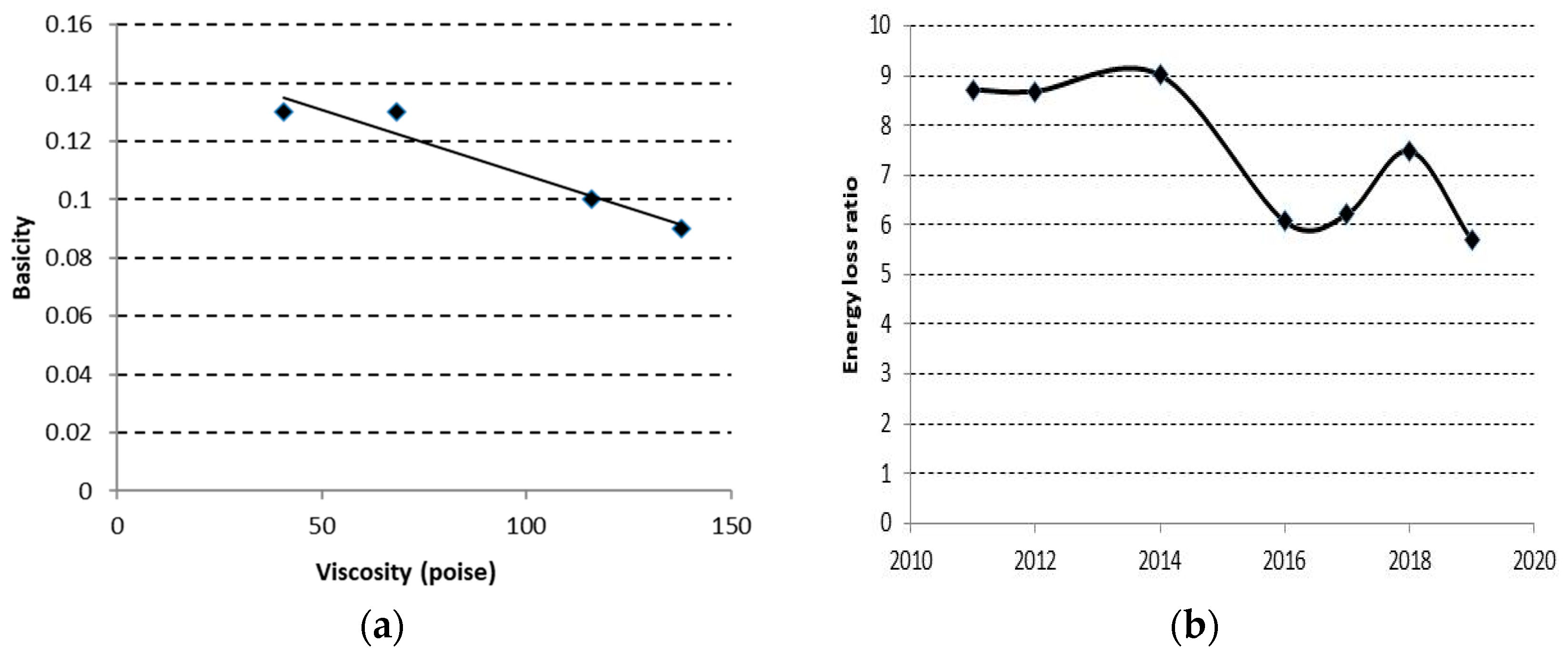

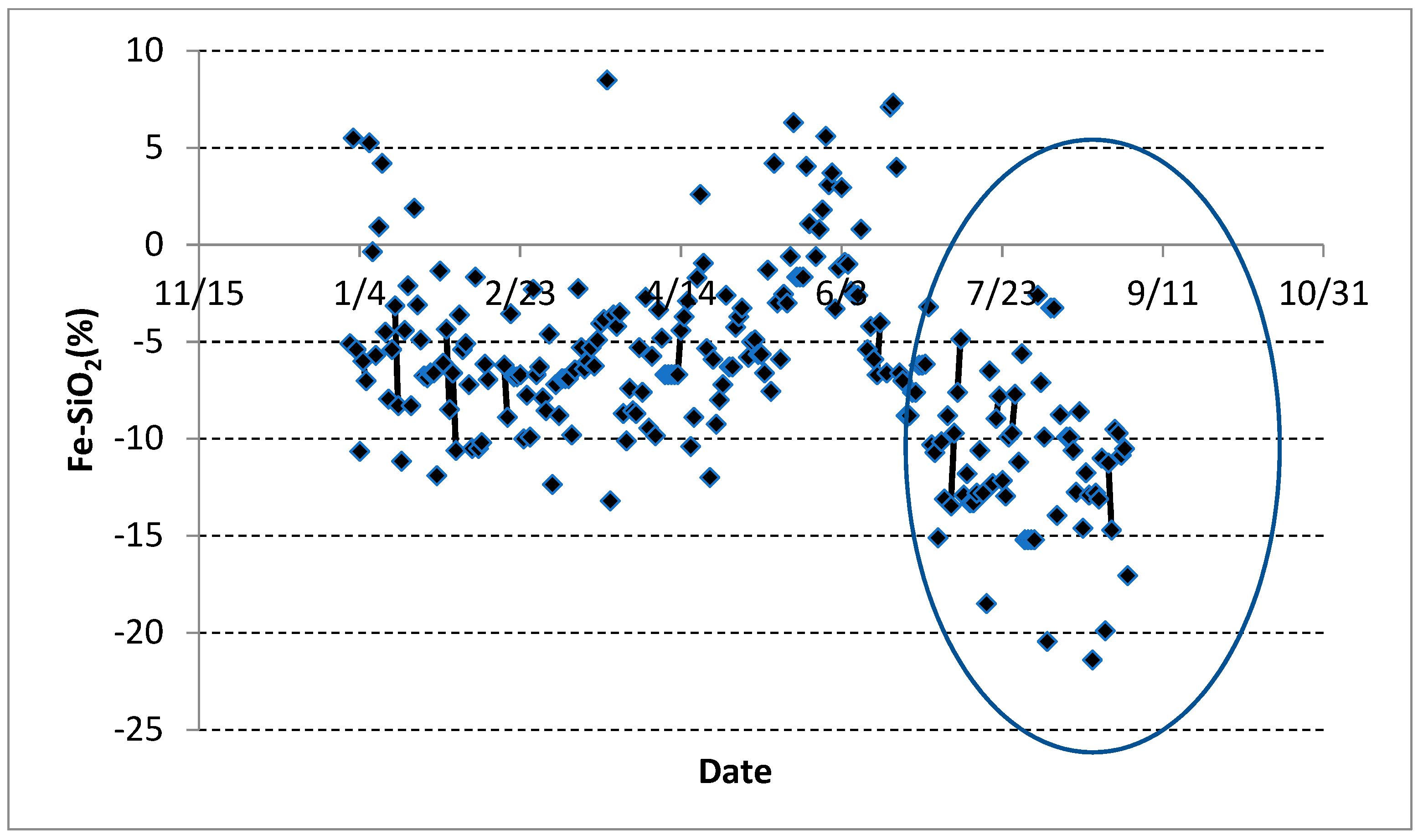

3.1. Laterite Ores

Uncontrolled E/F Operational Case Studies

3.2. Solid Fuels

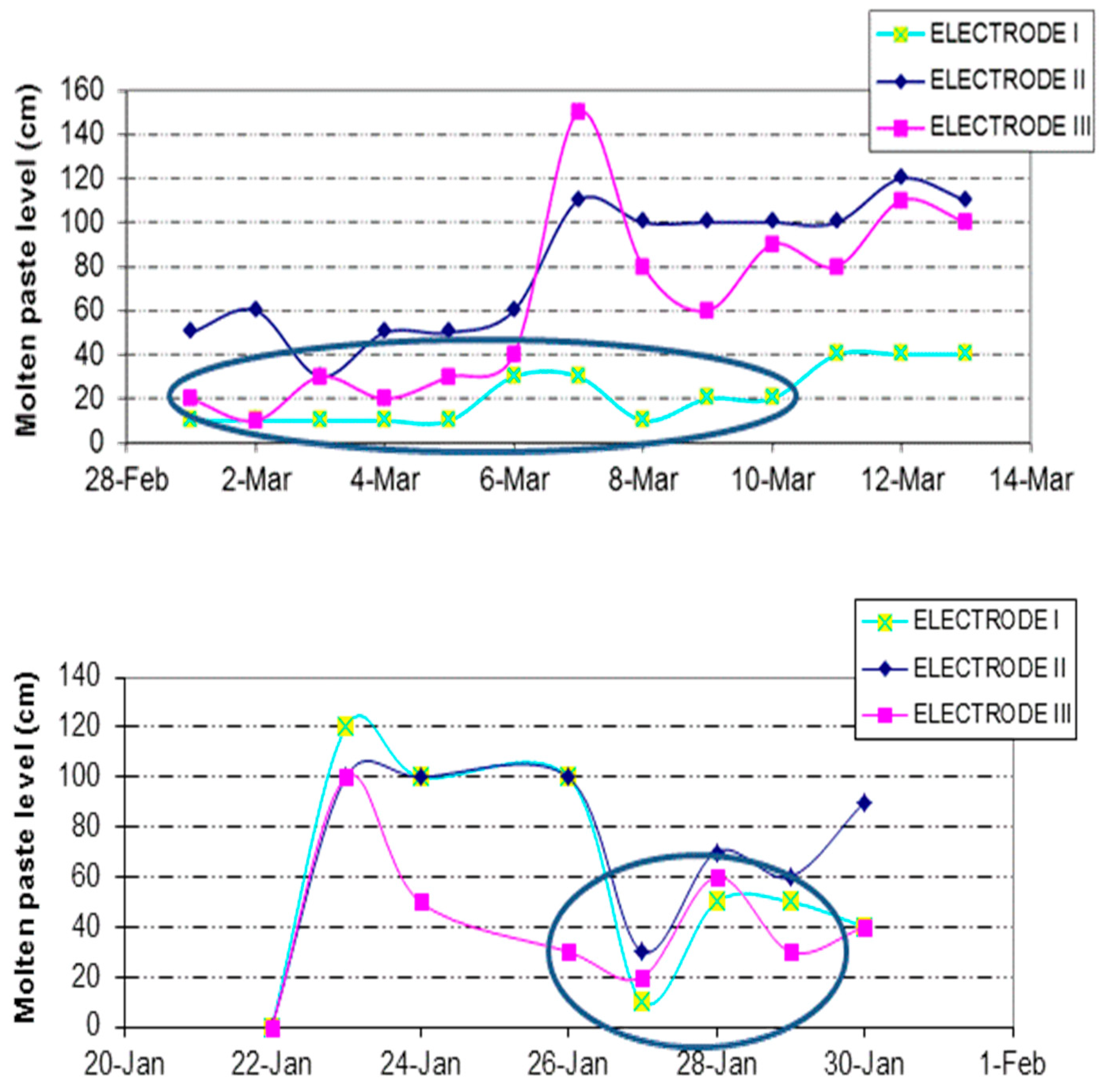

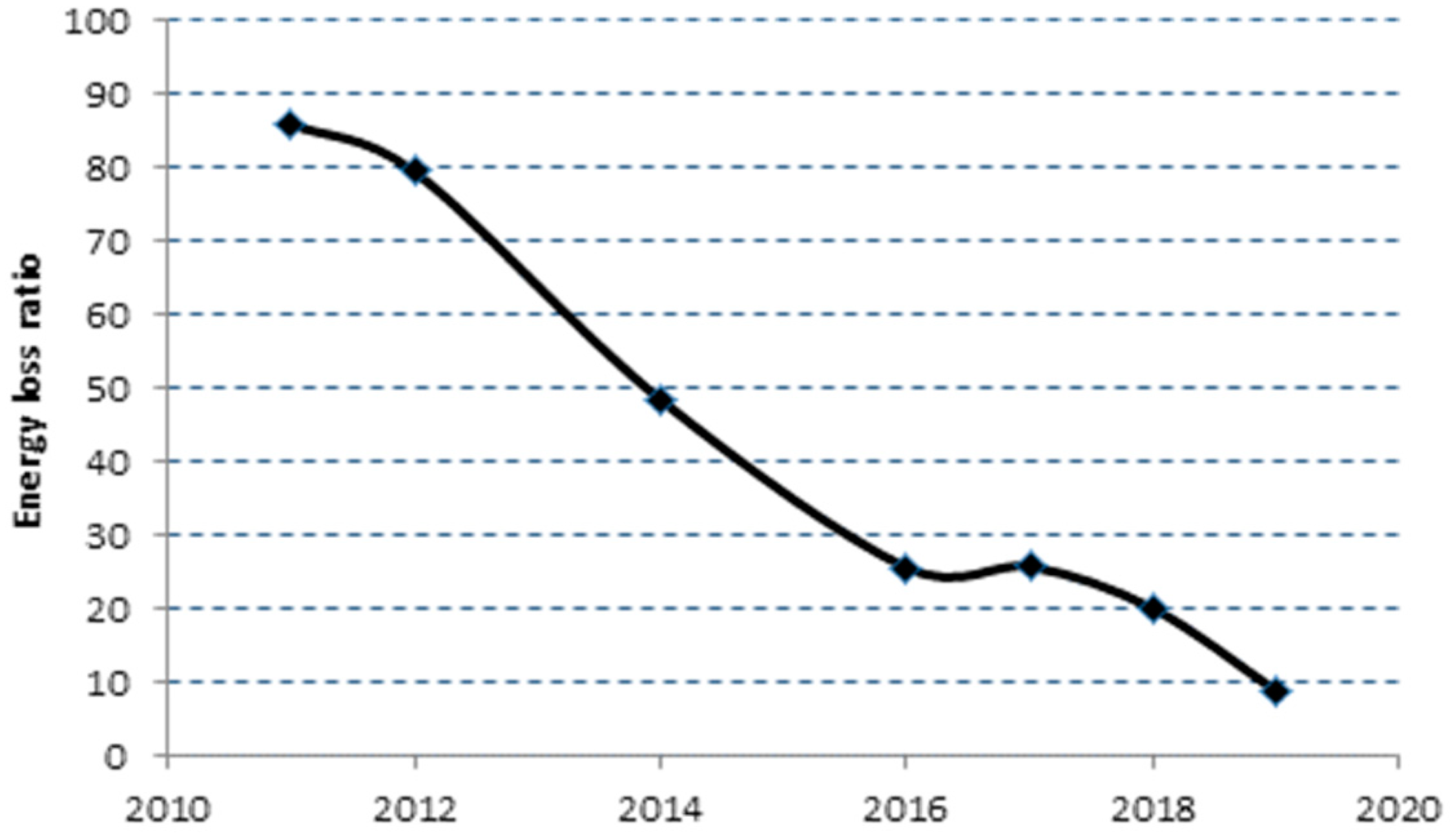

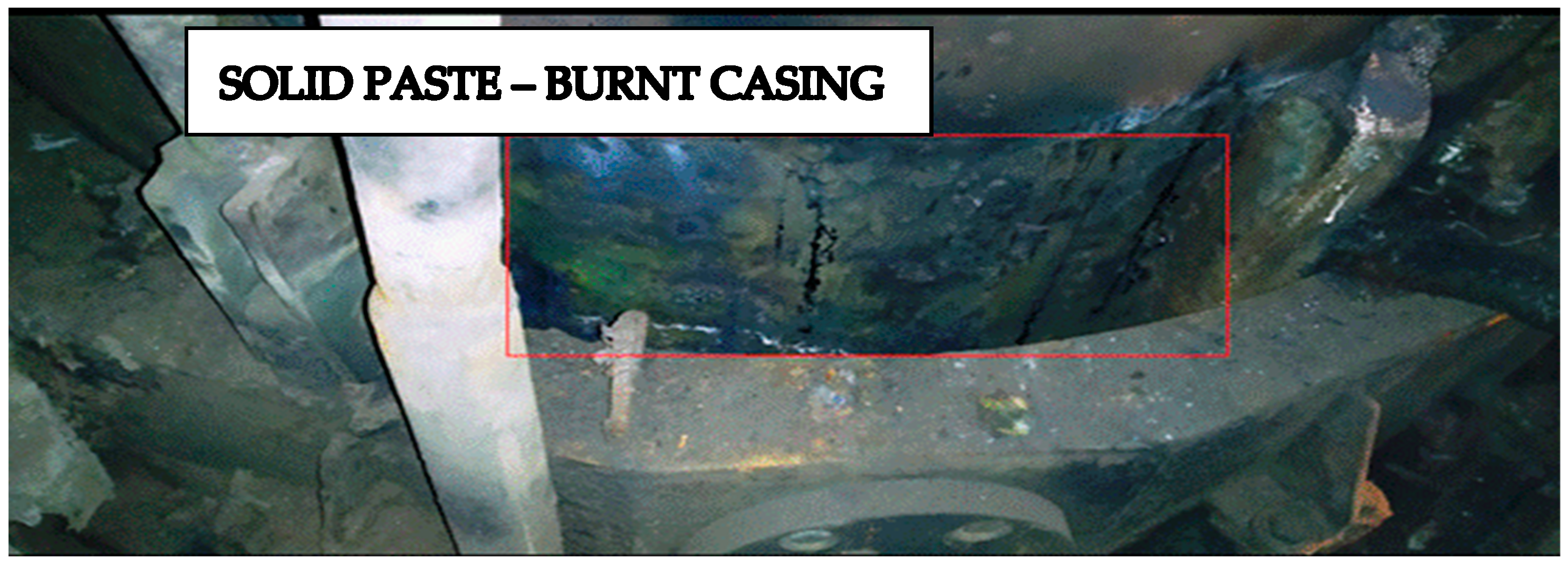

3.3. Electrode Paste Management

3.4. Maintenance

3.5. Human Resources and Knowledge Operationalization

- Experience retention of management: loss of experience results in productivity decreases and lack of a sustainable competitive advantage in the Greek Fe-Ni industry. Within this framework, incentives should be given to skilled and experienced workers to remain in metallurgy and to assure successful troubleshooting in difficult-to-handle situations;

- Tacit knowledge transfer through establishing meetings with supervisors, coaching of younger personnel and relationship-building interventions. There is an absolute need for skilled personnel capable of making critical metallurgical decisions;

- Establishment of standardization procedures for every single metallurgical process in order to ensure compatibility, safety, repeatability and quality. There were many cases where the lack of clearly described step-by-step procedures resulted in lost unit operation time, with respective losses in thousands of Euros;

- Introduction of modern ΙΤ systems, for thorough cost-monitoring management;

- Occupational safety education of the personnel, including safety seminars and establishment of modern on-the-job-training techniques.

4. Conclusions

- Supply the plant with high-Ni-grade (Ni% > 1.8% on a dry basis) imported laterite ores, with a participation of 35–40% to the laterite mixture. The aforementioned, in combination with the stable quality of critical raw materials, such as solid fuels and electrode paste, are the prerequisite for obtaining an operational index of 75% at least and a special energy consumption lower than 60 MWh/Tn Ni. Therefore, an updated detailed study of the proved domestic ore reserves is very important to confirm that a laterite feed with approximately 1.26% Ni content on a dry basis is possible to be practically obtained.

- A (SiO2/MgO) ratio lower than 3 by the use of foreign laterite ores results in a serious increase in the slag melting point, rendering the open-bath E/F operation very difficult. An (Fe-SiO2) relationship lower than −5 results in a serious increase in the slag viscosity, causing intensive slag foaming phenomena and operational problems, negatively affecting the productivity of the process.

- Retaining maintenance expenses at a stable level, based on industrial experience and the application of a shift from the philosophy of corrective maintenance to preventive maintenance is very essential. The lack of low-cost spare parts, mainly due to maintenance expense cuts, may result in a dramatic decrease in the E/F’s operational index and can be responsible for the occurrence of incidents that include risks for the personnel and the equipment.

- There is a need for the application of modern HR management tools and techniques, such as a tacit and explicit knowledge transfer management strategy, benchmarking, motivation policy, introduction of modern IT systems for maintenance cost monitoring management, health and safety training programs and non-stop promotion of a safety culture. The aforementioned should be incorporated in a holistic total quality long-term management plan.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fraser, J.; Anderson, J.; Lazuen, J.; Lu, Y.; Heathman, O.; Brewster, N.; Bedder, J.; Masson, O. Study on Future Demand and Supply Security of Nickel for Electric Vehicle Batteries; Publications Office of the European Union: Luxembourg, 2021; ISBN 978-92-76-29139-8. [Google Scholar]

- International Nickel Study Group, Lisbon. 26 April 2023. Available online: https://insg.org/wp-content/uploads/2023/04/pressrel_INSG-Press-Release-April_2023-kr9tr21a.pdf (accessed on 7 June 2023).

- Zevgolis, E.N.; Daskalakis, K. The Nickel production methods from laterites and the Greek Ferronickel production among them. Mater. Proc. 2021, 5, 104. [Google Scholar] [CrossRef]

- Zevgolis, E.N.; Zografidis, C.; Gaitanos, J.; Kostika, I.P.; Halikia, I. Energy requirements in nickeliferous laterite treatment. In Proceedings of the EPD Congress, San Antonio, TX, USA, 12–16 March 2006; pp. 487–496. [Google Scholar]

- Solar, M.Y.; Candy, I.; Wasmund, B. Selection of optimum ferronickel grade for smelting nickel laterites. CIM Bull. 2008, 101, 1–8. [Google Scholar]

- Shefik, I.; Gaitanos, I.; Tahiraj, N.; Rizaj, M.; Kongoli, F. Optimization of Technological FE-NI Production Process in NEWCO FERRONIKELI In Kosovo. In Fray International Symposium, Metals and Materials Processing in a Clean Environment; Florian, K., Ed.; FLOGEN: Mont-Royal, QC, Canada, 2013; Volume 1. [Google Scholar]

- Ma, Y.T.; Yang, P.; Lu, B.G.; Dou, Y.L.; Tian, J.K.; Guo, W.B.; Zhang, Z.Q.; Shen, Y.Y. Effect of FeO Content on Melting Characteristics and Structure of Nickel Slag. J. Min. Metall. B Metall. 2022, 58, 427–438. [Google Scholar] [CrossRef]

- Xueming, L.; Jie, Q.; Meng, L.; Mei, L.; Xuewei, L. Viscosity of SiO2-MgO-Al2O3-FeO Slag for Nickel Laterite Smelting Process. In Proceedings of the Fourteenth International Ferroalloys Congress: Energy Efficiency and Environmental Friendliness Are the Future of the Global Ferroalloy Industry, Kiev, Ukraine, 31 May–4 June 2015; pp. 561–566. [Google Scholar]

- Zevgolis, E.N.; Tzamtzis, A. The Role of Solid Fuels Used for Reduction in Rotary Kilns. Tech. Chron. Sci. J. Tech. Chamb. Greece 1987, 7, 5–19. [Google Scholar]

- Nikolaou, I. Current Trends and Prospects for Methods and Tools in Maintenance Management Systems. Bachelor’s Thesis, Department of Mechanical Engineering, University of West Attica, Aigario, Greece, 2021. [Google Scholar]

- Coetzee, J.C.; van Beek, W.S.B.; Buys, A. A practical knowledge management framework within the pyrometallurgical industry. J. S. Afr. Inst. Min. Metall. 2012, 112, 621–630. [Google Scholar]

- Requisite Organization International Institute. Challenges to Knowledge Operationalization: Example of Metallurgy Knowledge Operationalization at Metallurgical Operations. Available online: https://www.requisite.org/wp-content/uploads/2019/08/Metallurgical-Knowledge-Operationalization-by-ROII.pdf (accessed on 11 August 2023).

| Laterite Mixture (L.M.) | Ni (%) | Fe-SiO2 (%) | SiO2/MgO (%) |

|---|---|---|---|

| L.M.1: Ore A–Ore B–Ore C (%) = 65–25–10 (%) | 1.04 | 2.4 | 7.3 |

| L.M.2: Ore A–Ore B–Ore G * (%) = 45–25–30 (%) | 1.17 | −4.5 | 3.8 |

| L.M.3: Ore A–Ore B–Ore C (%) = 50–25–25 (%) | 0.96 | −7.1 | 4.8 |

| L.M.4: Ore A–Ore B–Ore C (%) = 45–25–30 (%) | 1.22 | −1.3 | 3.6 |

| L.M.5: Ore A–Ore B–Ore C (%) = 45–25–30 (%) | 1.25 | −0.4 | 3.3 |

| L.M.6: Ore A–Ore B–Ore D *–Ore G (%) = 45–15–10–30 (%) | 1.26 | 1.22 | 3.8 |

| L.M.7: Ore A–Ore B–Ore T *–Ore G (%) = 40–15–20–25 (%) | 1.26 | −1.7 | 4.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zografidis, C.; Betsis, K. Contribution to the Optimization of the Smelting Reduction of Nickeliferous Laterites, Based on the Recent Industrial Experience. Mater. Proc. 2023, 15, 61. https://doi.org/10.3390/materproc2023015061

Zografidis C, Betsis K. Contribution to the Optimization of the Smelting Reduction of Nickeliferous Laterites, Based on the Recent Industrial Experience. Materials Proceedings. 2023; 15(1):61. https://doi.org/10.3390/materproc2023015061

Chicago/Turabian StyleZografidis, Charalabos, and Konstantinos Betsis. 2023. "Contribution to the Optimization of the Smelting Reduction of Nickeliferous Laterites, Based on the Recent Industrial Experience" Materials Proceedings 15, no. 1: 61. https://doi.org/10.3390/materproc2023015061

APA StyleZografidis, C., & Betsis, K. (2023). Contribution to the Optimization of the Smelting Reduction of Nickeliferous Laterites, Based on the Recent Industrial Experience. Materials Proceedings, 15(1), 61. https://doi.org/10.3390/materproc2023015061