Artificial-Intelligence-Assisted Investigation of Quality and Yield of Cumene Production †

Abstract

1. Introduction

2. Materials and Methods

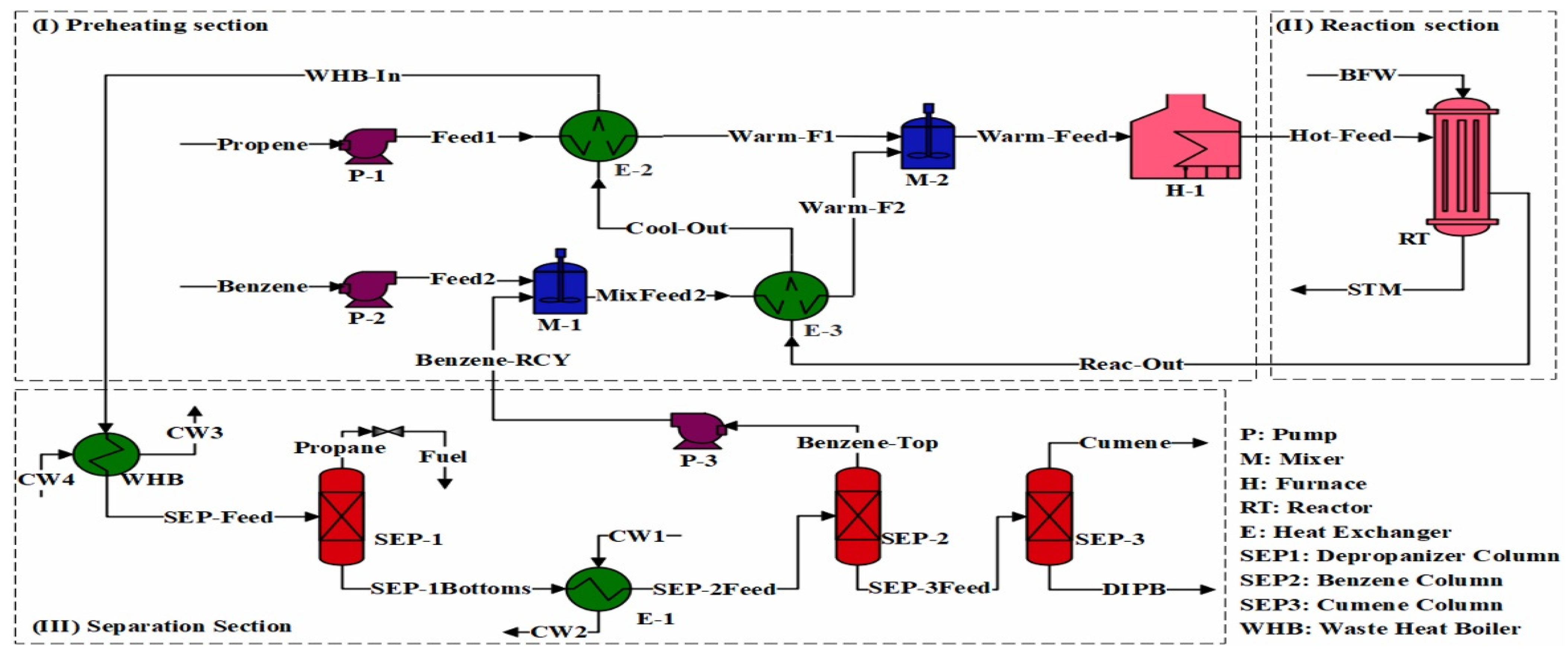

2.1. Process Description

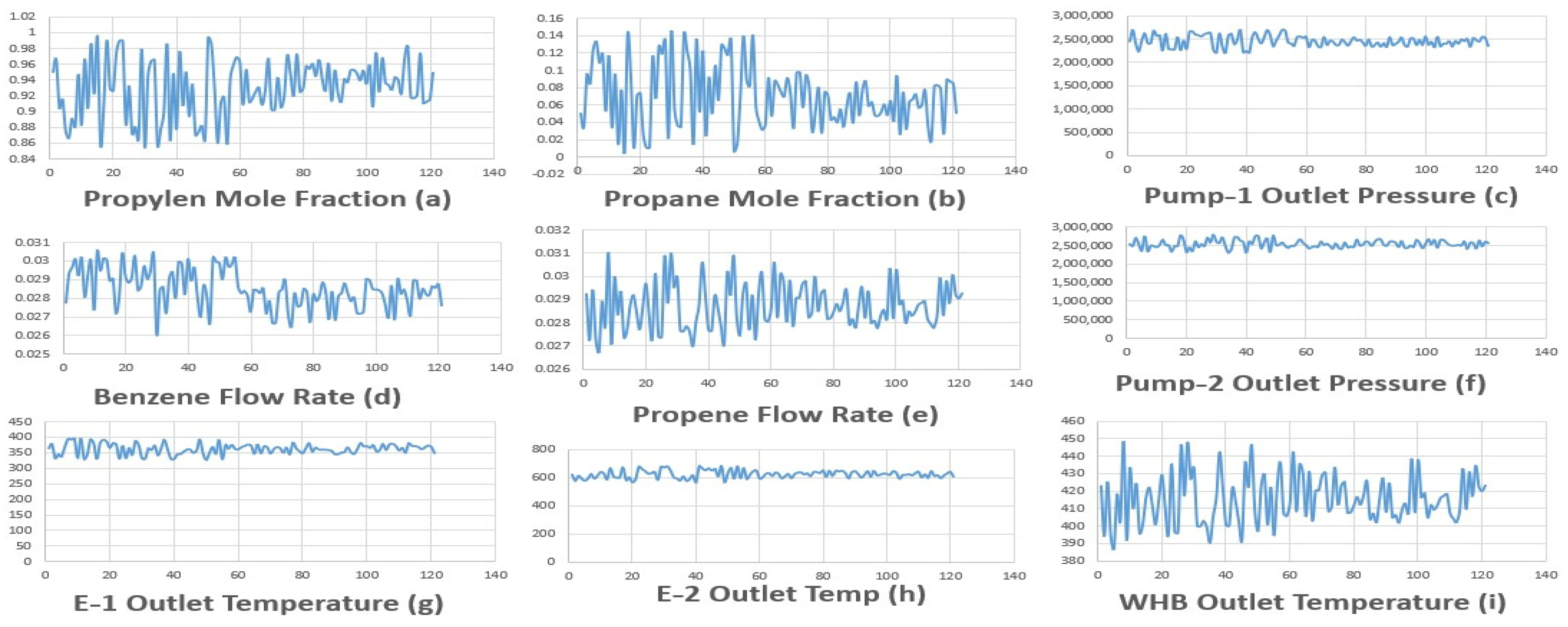

2.2. Artificial Neural Network

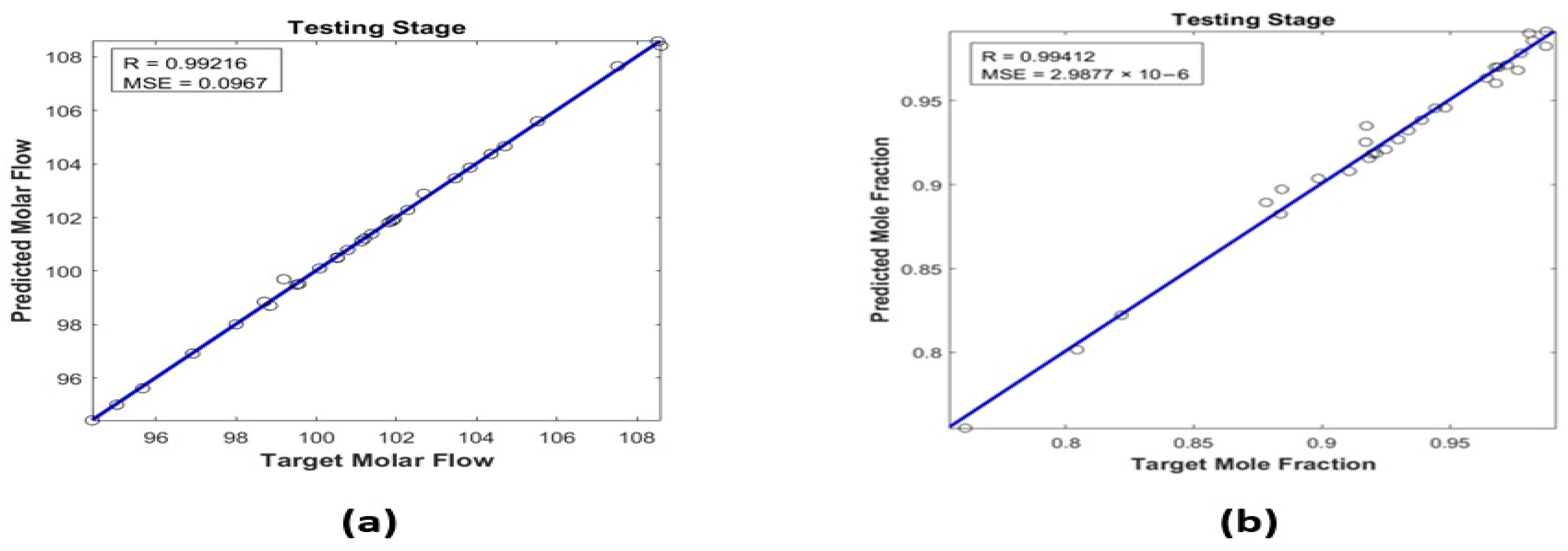

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ramazanov, K.R. Increase of efficiency of cumene process of receiving phenol and acetone. Eur. Sci. Technol. 2013, 775–786. [Google Scholar] [CrossRef]

- Samad, A.; Saghir, H.; Ahmad, I.; Ahmad, F.; Caliskan, H.J.E. Thermodynamic analysis of cumene production plant for identification of energy recovery potentials. Energy 2023, 270, 126840. [Google Scholar] [CrossRef]

- Alzubaidi, L.; Zhang, J.; Humaidi, A.J.; Al-Dujaili, A.; Duan, Y.; Al-Shamma, O.; Farhan, L. Review of deep learning: Concepts, CNN architectures, challenges, applications, future directions. J. Big Data 2021, 8, 1–74. [Google Scholar] [CrossRef] [PubMed]

- Sivaranjani, T.; Xavier, S.; Periandy, S. NMR, FT-IR, FT-Raman, UV spectroscopic, HOMO–LUMO and NBO analysis of cumene by quantum computational methods. J. Mol. Struct. 2015, 1083, 39–47. [Google Scholar] [CrossRef]

- Junqueira, P.G.; Mangili, P.V.; Santos, R.O.; Santos, L.S.; Prata, D.M. Economic and environmental analysis of the cumene production process using computational simulation. Chem. Eng. Process. Process Intensif. 2018, 130, 309–325. [Google Scholar] [CrossRef]

- Flegiel, F.; Sharma, S.; Rangaiah, G.P. Development and multiobjective optimization of improved cumene production processes. Mater. Manuf. Process. 2015, 30, 444–457. [Google Scholar] [CrossRef]

- Norouzi, H.; Hasani, M.; Haddadi-Sisakht, B.; Mostoufi, N.J. Economic design and optimization of zeolite-based cumene production plant. Chem. Eng. Commun. 2014, 201, 1270–1293. [Google Scholar] [CrossRef]

- Al-Shathr, A.; Shakor, Z.M.; Majdi, H.S.; AbdulRazak, A.A.; Albayati, T.M. Comparison between artificial neural network and rigorous mathematical model in simulation of industrial heavy naphtha reforming process. Catalysts 2021, 11, 1034. [Google Scholar] [CrossRef]

- Zhang, X.; Kano, M.; Matsuzaki, S. A comparative study of deep and shallow predictive techniques for hot metal temperature prediction in blast furnace ironmaking. Comput. Chem. Eng. 2019, 130, 106575. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ayub, A.; Zulkefal, M.; Sethi, H. Artificial-Intelligence-Assisted Investigation of Quality and Yield of Cumene Production. Mater. Proc. 2024, 17, 10. https://doi.org/10.3390/materproc2024017010

Ayub A, Zulkefal M, Sethi H. Artificial-Intelligence-Assisted Investigation of Quality and Yield of Cumene Production. Materials Proceedings. 2024; 17(1):10. https://doi.org/10.3390/materproc2024017010

Chicago/Turabian StyleAyub, Asad, Muhammad Zulkefal, and Hamza Sethi. 2024. "Artificial-Intelligence-Assisted Investigation of Quality and Yield of Cumene Production" Materials Proceedings 17, no. 1: 10. https://doi.org/10.3390/materproc2024017010

APA StyleAyub, A., Zulkefal, M., & Sethi, H. (2024). Artificial-Intelligence-Assisted Investigation of Quality and Yield of Cumene Production. Materials Proceedings, 17(1), 10. https://doi.org/10.3390/materproc2024017010