Abstract

This article examines the impact of meteorological conditions represented by ambient temperature, ambient humidity, wind speed, and daily precipitation sum on the reliability of low-voltage cable lines. Cable line reliability is crucial to the stability and safety of power systems. Failure of cable lines can lead to power outages. This can cause serious economic and social consequences, as well as threaten human safety, especially in the public sector and critical infrastructure. In addition, any interruption of cable lines generates costs related to repairs, operational losses, and possible contractual penalties. This is why it is so important to investigate the causes of power equipment failures. Many power system failures are caused by weather factors. The main purpose of this article is to quantify the actual impact of weather conditions on the performance and reliability of power equipment in distribution networks. Reliability indicators (failure rate, failure duration, restoration rate, and failure coefficient) for low-voltage cable lines were calculated as a function of weather conditions. Empirical values of the indicators were determined based on many years of observations of power lines operating in the Polish power system. An analysis of the conformity of their empirical distribution with the assumed theoretical model was also conducted. By quantifying the impact of specific weather factors on the operation of power equipment, it becomes possible to identify the ranges in which failures are most likely.

1. Introduction

The distribution network is responsible for the distribution and delivery of electric power. Due to its position in the national power system and the role it plays, it is crucial for supplying consumers. It is an important link in the power system and significantly influences the quality, reliability, and security of electricity supply to end users. The distribution network includes high- (HV) and medium-voltage (MV) lines and stations with nominal voltages equal to or less than 110 kV, as well as low-voltage (LV) lines [1,2].

In Poland, the national distribution network comprises 34,517 km of lines and 1639 power stations at 110 kV, 322,377 km of lines and 274,088 MV power stations, and 507,227 km of low-voltage lines [3].

The low-voltage network is a distribution network that directly supplies electricity to individual consumers such as households, plants, companies, etc. The Distribution System Operator is responsible for the distribution of electricity in a given area. One of their main tasks is to minimize the occurrence of failures in the system [4].

Currently, almost all households in the country are electrified. Modern electricity consumers have very high demands regarding the continuity and quality of electricity supply. Electricity is considered the most important energy carrier in households. Any interruption in its supply affects many aspects of household life: it limits activities at home, forces temporary inactivity, causes disorganization, leads to irritation, causes economic and social losses, and can even threaten the health and life of the consumer. Recently, a significant number of people have been working remotely from their homes. In this case, power supply reliability not only affects how consumers spend their time but also primarily results in their inability to perform their professional work, which is associated with a loss of income [5,6,7,8].

The Distribution System Operator is also exposed to the effects of power outages. Power failures result in a loss of profit for the operator and expenses related to covering the costs of repairing the resulting failures. Additionally, failure to meet guaranteed supply standards is usually accompanied by refund payments to the consumer. These standards may concern the maximum time to restore supply, other than that specified by the Regulation of the Minister of Climate and Environment of 27 September 2022 [9] on the specific conditions for the functioning of the power system [10].

Therefore, ensuring the reliability of the power system is paramount, given the requirements of the modern economy and the expectations of individual customers. This situation underscores the necessity for continuous development and modernization of distribution power grids.

The continuity of electricity supply can be achieved through the high reliability of the components of the power system, as well as by selecting the appropriate configuration of power supply systems. Achieving this entails a deep understanding of equipment operational principles, necessitating equipment failure analyses and research on power equipment reliability. A key aspect is the knowledge of the reliability of the components of the transmission and distribution system and the devices supporting their operation [11,12,13,14].

The nature of damage to power systems indicates that it is primarily caused by random factors. Disturbances in power systems are caused by various factors related to the working conditions of system components and external factors (design errors, material defects of components, aging processes, component overloads, accidental or intentional human activity, and weather conditions) [15,16,17,18].

More than half of system failures are caused by atmospheric factors, which, progressing in a cascading manner, lead to a rapid escalation of system failures. Weather-related failure factors include, among others, extreme air temperatures (both low and high), snowstorms, lightning strikes, strong winds, natural disasters (storms, tornadoes, floods, droughts) [19,20,21,22].

In the Northern Hemisphere, there is a noticeable seasonal variability in the causes of power system failures. There is a clear tendency for power outages to occur in the summer and winter months. The reason for this correlation is the intensification of extreme weather conditions. Winter conditions are often associated with snowstorms or frost accumulating on power equipment, leading to severe mechanical damage and consequently emergency shutdowns. In contrast, high temperatures in the summer can cause numerous product failures because they degrade material properties, causing softening, melting, sublimation, evaporation, decreased viscosity, size changes, and thermal aging [1,4,23,24].

The impact of environmental conditions on overhead power equipment is widely described [11,25,26,27,28,29,30,31,32,33,34], while there is a lack of publications on its impact on indoor power equipment and cable lines [35,36,37,38,39].

An analysis of the frequency of failures in individual months of the year for low-voltage cable lines was conducted. Most failures of low-voltage cable lines occurred in the summer months (May–August) and the winter months (January, December). In the summer months, 41.11% of all failures occurred. In the winter period, 15.63% of all failures occurred. In the remaining months, the failure rate of low-voltage cable lines is below the average failure intensity [40].

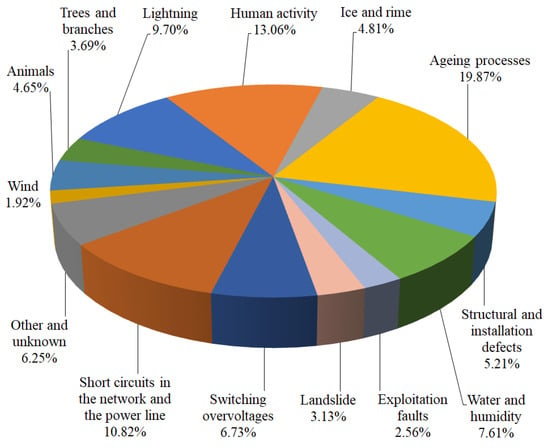

The most serious cause of low-voltage cable line failures is aging processes, which account for about 19.87% of all failures. The second most significant cause is human activity, resulting in about 13.06% of all failures. Seasonal causes that significantly impact the failure rate of low-voltage cable lines include lightning strikes and icing and rime. These were responsible for 9.70% and 4.81% of all failures, respectively. The percentage share of individual causes of low-voltage cable line failures in their total number is presented in Figure 1 [40].

Figure 1.

Percentage share of causes of low-voltage cable line failures [40].

Failures of power systems, due to their numerous causes, are an unavoidable phenomenon. Extreme weather events cannot be predicted and thus pose a serious threat to the operation of power systems. Therefore, power equipment, must be adapted to various environmental conditions (climate) due to their widespread occurrence [4,41,42,43,44,45,46,47].

2. Cable Lines as an Element of the Distribution Network

In Poland, a total of 880,216 km of power lines are in use: 596,086 km of overhead lines and 284,130 km of cable lines (which constitutes 32% of the total length of national power lines). Overhead lines, based on voltage level, are divided into: high voltage (HV + EHV), with a length of 49,661 km; medium voltage (MV), with a length of 225,032 km; and low voltage (LV), with a length of 321,393 km. Similarly, cable lines are divided into: HV + EHV (951 km in length), MV (97,345 km in length), and LV (185,834 km in length) [3].

According to the standard PN-EN 50160:2023-10 “Voltage Characteristics of Electricity Supplied by Public Distribution Networks” [48], low voltage has a nominal effective value of , medium voltage has a nominal effective value in the range of , and high voltage has a nominal effective value of .

In Poland, 65% of cable lines are low-voltage lines. The lengths of cable lines in various years in Poland are presented in Table 1.

Table 1.

Length of cable lines operated in the Polish power system [km] [3].

According to the PN-76/E-05125 standard [49], a cable line is defined as a multi-core cable or a bundle of single-core cables in a multi-phase arrangement, or several single-core or multi-core cables connected in parallel, including accessories, laid along a common route and connecting terminals of the same two electrical devices, either single-phase or multi-phase or single-pole or multi-pole. Cables can be laid in the ground, in cable channels, on walls, on structures, in pipes, suspended on carrying cables, etc. Cable lines are used where the installation of overhead lines is problematic and inadvisable due to dense development and high industrialization (this particularly applies to industrial plants and urban areas) [50].

Cables are conductors characterized by a special construction. Their structure includes the following layers: cores (made of aluminium or copper), insulation (paper, oil, gas, PVC, or polyethylene), filler (insulating material between the core insulation and the cable sheath), sheath (usually made of aluminium or PVC, seals the cable insulation, prevents moisture ingress, and prevents air bubbles in the insulation), armour (steel wires or tapes wound around the cable, protecting it from mechanical damage), and outer sheath (made of PVC or jute, protecting the armour from moisture). Depending on the cable’s purpose and location, some of these structural layers may be extended or omitted [4].

The main advantages of cable lines are their high reliability, relative independence from weather conditions, and low maintenance costs, while disadvantages are the high investment cost and the difficulty in locating and repairing damage [51].

In the national power system, overhead networks dominate. Buried cables are used only in large urban agglomerations for low- and medium-voltage power transmission. The disadvantage of overhead lines is their susceptibility to atmospheric and climatic conditions. The failure rate of overhead lines is highly dependent on frost, storms, gales, and snow. A significant influence on winter failures is rime, which is the weight load on conductors due to excessive icing. Meanwhile, cable networks are considered resistant to weather conditions. They are not affected by wind, frost, or snow. However, cable line approaches to poles and stations are exposed to these factors. Under the influence of climatic exposures, they can be damaged.

The primary goal of this paper is to quantify the actual impact of weather conditions on the performance and reliability of power equipment in distribution grids. While qualitative analyses indicate that weather factors do affect technical equipment, they do not reveal the strength of this influence. By determining the quantitative impact of specific weather factors on power equipment operation, it becomes possible to identify the ranges in which failures are most likely to occur. With this information and accurate weather forecasts, distribution grid managers can better prepare for increased failure rates—such as by deploying additional standby crews—potentially reducing the duration of outages.

3. Method of Analysis

Reliability studies can be conducted using three research methods: analytical, empirical, and statistical. Due to its highest accuracy, the statistical method was chosen for the study. This method involves using statistical data from the operation of power equipment.

Because weather factors affect the susceptibility of power equipment to damage and the time required to repair failures (sometimes even preventing the repair altogether), it was decided to analyse the impact of atmospheric factors on the failure intensity and repair (restoration) time of power equipment. Based on these analyses, failure rates and restoration intensity were determined.

Initially, the average failure intensity of individual devices was analysed. The theoretical relationship used to determine the average failure intensity is given by [25,32]:

where:

—observed number of failures in the time interval ∆t;

—sample size at the beginning of the observation period;

—sample size at the end of the observation period;

—total observation time.

The aim of this study is to correlate environmental conditions with intensity of damage λ. To achieve this, the Formula (1) was adjusted by introducing τ, the relative time of occurrence of a given climatic exposure over the considered time period . For clarity, the formulas are discussed using the example of climatic exposure, specifically temperature .

In order to determine the temperature characteristics of the intensity , it is necessary to determine the values of for successive ranges of temperature . For this purpose, in Equation (1), the number of failures , which occurred in the specific i-th interval of climatic exposure (temperature) and the duration of this interval of climatic exposure (temperature) are considered [25,32]:

where:

—number of failures that occurred during the time interval ;

—duration of climatic exposure (temperature) over the time period under consideration ;

—relative time of climatic exposure (temperature) occurrence in the considered time period [25,32]:

By determining the values of for subsequent intervals i, an empirical relationship between the failure intensity and climatic exposure (e.g., temperature) is obtained.

However, determining empirical values does not fully encompass the scope of the study, necessitating the determination of an approximation function (mathematical model) for this dependency.

The approximation function can be any mathematical function. For clarity and simplicity of notation, a polynomial is most frequently assumed as the approximation function in this work. Since in all cases the coefficients of the approximation function obtained for an order higher than the fourth are close to zero, the decision was made to approximate the function with a polynomial of at most the fourth order. The form of such a polynomial is as follows:

where:

i—climate exposure value;

a, b, c, d, e—coefficients of the approximation function.

In selected cases where polynomial approximation was characterized by excessively large errors, other types of functions were also considered as mathematical models, such as exponential, power, logarithmic, and their superpositions. For each of them, the model’s degree of fit to the empirical data was determined using the r-Pearson correlation coefficient. The coefficients of the approximation functions were estimated using Statistica software (version 13.3). Further studies aimed to determine the impact of individual climatic factors on the repair time (restoration time). Failures were sorted according to the considered climatic exposure, and in each interval, the average repair times were determined .

The failure removal time is also called the failure duration or restoration time and refers to the period during which equipment transitions from an unfit state back to a state of operable fitness. It is a crucial parameter for reliability analysis and evaluating the economic impact of failures, providing insight into the extent of the failure.

However, the determination of the empirical dependence does not fully encompass the scope of the study, necessitating the determination of an approximation function (mathematical model) for this dependency. It was developed based on the formula described earlier (Equation (4)), and in selected cases where polynomial approximation resulted in too large errors, other types of functions were also considered as mathematical models, such as exponential, power, logarithmic, and their superpositions.

The same methodology was applied in the analysis of the impact of other environmental factors.

In a further part of the study, assuming stationarity and ergodicity of the processes, the relationship between the reliability coefficient q and the given climatic exposure (e.g., temperature) was determined.

The relationship from which the reliability coefficient q can be calculated is as follows [25,32]:

Substituting the developed theoretical and empirical models of average damage intensity and average downtime into Equation (5), the relationship between the reliability coefficient and the specific climatic exposure (e.g., temperature T) is determined.

Another reliability indicator analysed is restoration intensity. The formula for determining the average restoration intensity takes the form [25,32,52]:

Substituting the developed theoretical and empirical models of average damage intensity and the reliability coefficient q into Equation (6), the relationship between the average repair intensity and the specific climatic exposure (e.g., temperature T) is determined.

To expedite calculations in the study, the Statistica (version 13.3) and Matlab (R2021a) software suites were utilized.

4. Statistical Data

The observation of the reliability of low-voltage cable lines spans over a period of ten years. During this time, 87,673 measurement points were recorded for each weather factor (ambient temperature, ambient humidity, wind speed, daily precipitation sum) at the Kielce-Suków meteorological station. Additionally, there were 1248 instances of failures in low-voltage cable lines in Kielce and surrounding areas. The meteorological statistical data were sourced from the Institute of Meteorology and Water Management, while the data on equipment failures came from the national electricity distribution company. At the beginning of the observation period, this company operated a total of 826 km of cable lines, which increased to 945 km by the end of the period. The lengths of the lines in each year of observation are shown in Table 2.

Table 2.

Total lengths of analysed LV cable lines in successive years of observation.

The lengths of low-voltage cable lines have increased in subsequent years of observation. This increase is attributed to the conversion of overhead lines to underground cables. It is the result of a series of modernization efforts undertaken by the Distribution System Operator to avoid or reduce the scale of network failures. During severe weather events, overhead electrical equipment is particularly vulnerable to their effects.

5. Analysis of the Impact of Weather Factors on the Reliability of Low-Voltage Cable Lines

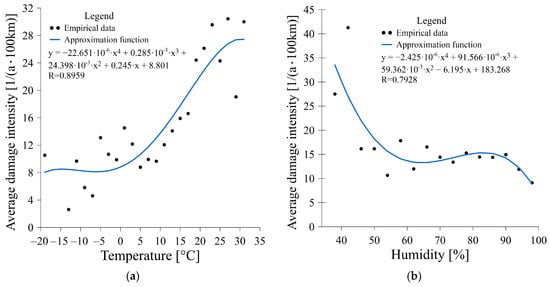

Figure 2 presents empirical data, approximation functions, and correlation coefficient R of the average damage intensity of LV cable lines depending on ambient temperature, ambient humidity, wind speed, and daily precipitation sum. Average damage intensity is expressed in one failure per year (a) over a distance of one hundred kilometers.

Figure 2.

Relationship of average failure intensity with ambient temperature (a), ambient humidity (b), wind speed (c), and daily precipitation sum (d) for low-voltage cable lines.

The premise of this article was to determine approximation functions for each phenomenon considered. In some cases, a very low correlation coefficient of the approximation function with empirical data was obtained. To enhance the models, a method was applied to remove individual outliers from the data samples. Outliers can negatively impact model fit, so identifying and removing them can result in a better fit. In order to identify them (outlier samples), the Median Absolute Deviation (MAD) method was used. To determine the model shown in Figure 2c, two samples were excluded as they were identified as outliers using the Median Absolute Deviation method.

The results of verifying hypotheses about the functional form of models for LV cable lines are included in Table 3.

Table 3.

Results of verifying the hypothesis regarding the functional form of the model depending on weather factors.

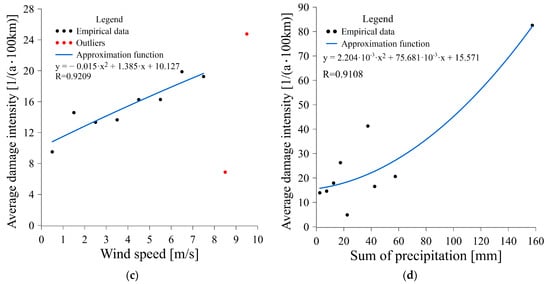

In Figure 3, empirical data, approximative functions, and correlation coefficient R of the average downtime of low-voltage cable failures are presented based on ambient temperature, ambient humidity, wind speed, and daily precipitation sum. To determine the models shown in Figure 3b and Figure 3d, respectively, four and two samples were excluded as they were identified as outliers using the Median Absolute Deviation method.

Figure 3.

Relationship of average downtime with ambient temperature (a), ambient humidity (b), wind speed (c), and daily precipitation (d) for low-voltage cable lines.

The results of verifying hypotheses about the functional form of models for LV cable lines are included in Table 4.

Table 4.

Results of verifying the hypothesis regarding the functional form of the model depending on weather factors.

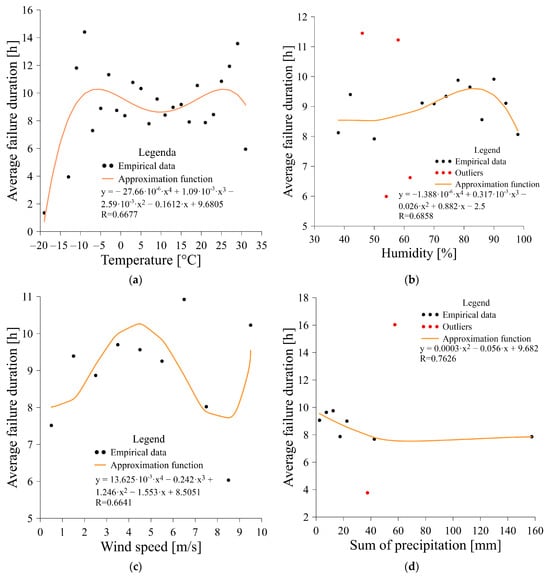

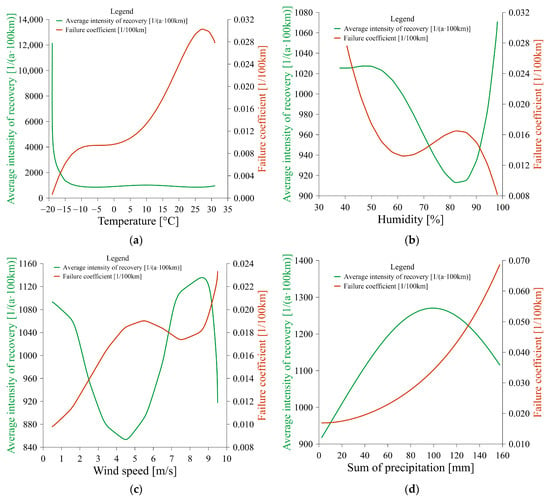

After inserting theoretical damage intensity functions and theoretical downtime models into Equations (5) and (6), models for the variability of reliability index and restoration intensity based on weather factors were obtained. These models for low-voltage cable lines are presented in Figure 4.

Figure 4.

Relationship between the average restoration intensity and the reliability coefficient with respect to ambient temperature (a), ambient humidity (b), wind speed (c), and daily precipitation (d) for low-voltage cable lines.

Empirical and theoretical values, calculated based on the implemented models of damage intensity, downtime duration, reliability coefficient, and restoration intensity shown in Figure 2a, Figure 3a, and Figure 4a, are summarized in Table 5.

Table 5.

Reliability indices, both empirical and theoretical, for low-voltage cable lines depending on ambient temperature.

The highest number of failures in low-voltage cable networks was observed in the temperature range from approximately −7 °C to around 27 °C. The relative occurrence time of these temperatures was also highest during the analysed observation period. These temperatures fall within the typical range experienced in Poland throughout the calendar year. The highest average failure intensity is observed for extreme temperatures, which have a low frequency of occurrence during the analysed period. For cable lines, the highest average failure intensity was recorded for a temperature of 27 °C, while the lowest was recorded for −13 °C. The longest failure duration was noted for temperatures of −9 °C () and 29 °C () and the lowest for −19 °C. The values for the average duration of failure are highest for temperature extremes that occur infrequently throughout the year. For cable lines, the highest value of occurs at 27 °C (), while the lowest value is recorded at the lowest temperature of the observation period, which is −19 °C (). For cable lines, the highest value of was recorded at −19 °C (the lowest temperature in the considered range), while the lowest value of was observed at −9 °C.

The empirical and theoretical values of the average failure rate, average repair time, failure rate coefficient, and average restoration rate, presented in Figure 2b, Figure 3b, and Figure 4b, are shown in Table 6.

Table 6.

Empirical and theoretical reliability indicators for low-voltage cable lines depending on ambient humidity.

The highest number of failures in low-voltage cable networks was observed in the humidity range from about 70% to about 94%. The highest value of average failure intensity occurs at a humidity of 42% for cable lines (). The lowest value of average failure intensity occurs at a humidity of 98% for cable lines (). The highest values of average failure duration occur for humidity of 46% () and 58% (), while the lowest () occurs at 54%. The failure coefficient reaches its highest value at a humidity of 42% and the lowest at 54% . The highest value of the average restoration intensity occurs at 54% humidity while the lowest occurs at 46%.

The empirical and theoretical values of the average failure rate, average repair time, failure rate coefficient, and average restoration rate, presented in Figure 2c, Figure 3c, and Figure 4c, are shown in Table 7.

Table 7.

Empirical and theoretical reliability indicators for low-voltage cable lines depending on wind speed.

The highest number of cable line failures was observed in the wind range of 1.5 m/s to 2.5 m/s. The highest average damage intensity () occurred at a wind speed of 9.5 m/s. The lowest value of average damage intensity occurred at 8.5 m/s (). The lowest value for the average duration of failure occurs at a wind speed of 8.5 m/s () and the highest at 6.5 m/s () and 9.5 m/s (). Minimum was recorded at 8.5 m/s and maximum at 9.5 m/s. The highest value of occurs for a significant wind speed of 8.5 m/s. This shows that, for cable lines, high windiness is not a factor that strongly influences their restoration. The lowest value of occurs at 6.5 m/s.

The empirical and theoretical values of the average failure rate, average repair time, failure rate coefficient, and average restoration rate, presented in Figure 2d, Figure 3d, and Figure 4d, are shown in Table 8.

Table 8.

Empirical and theoretical reliability indicators for low-voltage cable lines depending on daily sum of precipitation.

The highest number of failures in low-voltage cable lines was observed in the range of daily precipitation from 0 mm to 5 mm. The highest average damage intensity occurred at a daily precipitation of 157.5 mm and was The lowest average restoration intensity occurred for cable lines at 22.5 mm (). The highest failure duration was recorded for 57.5 mm (). The highest values for average failure times do not coincide with the ranges in which the most failures occurred. This may therefore lead to the conclusion that serious damage is caused when daily precipitation totals are high and that, in addition, the removal of this damage is hampered by heavy precipitation, all of which translates into an extended duration of failure. The shortest average failure durations for cable lines were recorded at 37.5 mm (). The minimum daily precipitation () was observed at 22.5 mm and the maximum at 157.5 m/s. The maximum average intensity of recovery is at 37.5 mm and the minimum is at 57.5 mm.

6. Discussion

Weather factors also affect the operation of low-voltage cable lines. Cable lines are often routed on overhead support structures, and in selected, few cases, they are conducted in a mixed underground/overhead manner (e.g., in situations where the line would have to pass through difficult terrain). In these cases, cable lines are exposed to direct atmospheric conditions. For high-voltage cable lines, a transition from cable to overhead line is made, but in medium- and low-voltage lines, due to lower costs, the cable is more often routed onto a support structure without changing the type of line. In this situation, cable lines are subject to atmospheric influences. In the context of icing and rime, this impact primarily concerns the sections where the cable is conducted overhead. In such a case, the effect of rime and ice is analogous to that of overhead lines [26]. Numerous failures of cable lines caused by icing occur at the approaches of cable lines to support structures and stations. In these situations, the failure results from moisture that has entered the cable terminations, which, upon significant temperature drops, turns into ice crystals, causing an uneven distribution of the electric field. Repeated cycles of this process eventually lead to insulation damage. It is also important to note the numerous instances of improper protection of protective ducts, allowing rainwater or groundwater to enter. When this water freezes, it leads to significant mechanical stresses that result in insulation damage. When it comes to the effects of high temperatures, besides direct heating from the sun, prolonged high temperatures affect cables that are buried too shallowly in the ground. This leads to soil drying, which hinders the dissipation of heat from the cable to the surroundings, resulting in an excessive increase in the temperature of its insulation. The impact of high temperatures on medium-voltage cables usually occurs at the exits from primary substations, where they are often overloaded and the high temperature further impedes their ability to dissipate heat to the ground. This situation mainly affects older types of cables. Newer types of cables (e.g., with XLPE insulation) are more resistant in such situations; however, due to the lack of data, this article does not analyse each type of cable separately but considers the entire population. Cable lines also suffer damage during low temperatures. Most often, damage occurs around joints and terminations where moisture enters and then freezes at low temperatures. Moisture freezing also occurs in cable insulation. Wind primarily affects overhead cable lines and their sections that are routed onto support structures. At low wind speeds (or lack thereof), mechanical damage is practically non-existent. However, it should be noted that in such situations, the natural cooling of the cable is significantly limited (especially at very high ambient temperatures). The situation is different at high wind speeds. The cooling of the overhead sections of the cable lines is significant due to the flow of large air masses. Unfortunately, in this situation, the amount of mechanical damage increases significantly. Wind can, of course, be both the cause of and a contributing factor to damage. Much cable damage is dependent on other damage, such as that to support structures. Many instances are caused by branches or entire trees falling due to strong winds. Damage to cable lines due to lightning strikes may indicate ineffective surge protection. According to cable line design principles, both ends of the cable, as well as any transition from an overhead line to a cable line, should be equipped with a set of surge arresters. If, in the aforementioned situation, lightning strikes lead to cable line damage, it can be inferred that the protection is ineffective.

7. Conclusions

This article discusses the impact of weather factors (ambient temperature, ambient humidity, wind speed, daily precipitation sum) on the performance of low-voltage power cable lines.

Based on the conducted research, it was found that low-voltage power cable lines are susceptible to meteorological conditions. It is possible to quantitatively determine their impact on the reliability of low-voltage power cable lines. This impact was determined by defining reliability indicators such as failure intensity, outage duration, renewal intensity, and reliability coefficient.

The reliability studies presented in the article were conducted using developed mathematical models. These models proved to be suitable tools for assessing the risk of damage to the considered power lines. The conducted reliability studies were based on data from over one thousand two hundred failures.

The developed models of the dependence of reliability indicators on weather factors will allow distribution network managers to prepare (for example, by mobilizing additional standby crews) for increased network failures caused by the forecasted meteorological phenomena. Understanding the failure rate of specific power equipment under given environmental conditions will facilitate quicker removal of anticipated failures and may inform future efforts to improve the design of specific equipment. Additionally, knowledge of the models can also be used to determine the conditions for optimal operation of electric distribution grids.

Author Contributions

Conceptualization, K.B. and A.Ł.C.; methodology, K.B. and A.Ł.C.; software, K.B.; validation, K.B. and A.Ł.C.; formal analysis, K.B. and A.Ł.C.; investigation, K.B. and A.Ł.C.; resources, K.B. and A.Ł.C.; data curation, K.B. and A.Ł.C.; writing—original draft preparation, K.B.; writing—review and editing, K.B.; visualization, K.B.; supervision, K.B. and A.Ł.C.; project administration, K.B. and A.Ł.C.; funding acquisition, K.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are from the Electricity Distribution Company of Poland and the Institute of Meteorology and Water Management in Poland. No consent to data sharing.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Dołęga, W. Efektywna transformacja krajowej sieci elektroenergetycznej. In Zeszyty Naukowe Instytutu Gospodarki Surowcami Mineralnymi i Energią Polskiej Akademii Nauk. Zagadnienia Surowców Energetycznych i Energii w Gospodarce Krajowej. Bezpieczeństwo Energetyczne Polski i UE w Świetle Obecnej Sytuacji Gospodarczej Świata; Stala-Szlugaj, K., Grudziński, Z., Eds.; Wydawnictwo IGSMiE PAN: Kraków, Poland, 2024; Volume 1, pp. 9–20. [Google Scholar]

- Dołęga, W. Bezpieczeństwo pracy krajowych sieci dystrybucyjnych. Przegląd Elektrotechniczny 2020, 3, 21–24. [Google Scholar] [CrossRef]

- Agencja Rynku Energii, S.A. Statystyka Elektroenergetyki Polskiej 2000–2021; Ministerstwo Klimatu i Środowiska Agencja Rynku Energii S.A.: Warszawa, Poland, 2001–2022. [Google Scholar]

- Wnukowska, B. Czynniki wpływające na niezawodność pracy sieci dystrybucyjnych. Zesz. Nauk. Coll. Witelona 2023, 48, 11–26. [Google Scholar] [CrossRef]

- Banasik, K.; Chojnacki, A.Ł. Economic effects of non-delivery of electricity to municipal and household consumers. Przegląd Elektrotechniczny 2018, 3, 181–187. [Google Scholar]

- Entress, R.M.; Stevens, K.A. Public values failure associated with Hurricane Ian power outages. Front. Sustain. Energy Policy 2023, 2, 1304673. [Google Scholar] [CrossRef]

- Rudnick, H. Impact of natural disasters on electricity supply. IEEE Power Energy Mag. 2011, 9, 22–26. [Google Scholar] [CrossRef]

- Yan, Q.; Dokic, T.; Kezunovic, M. Predicting impact of weather caused blackouts on electricity customers based on risk assessment. In Proceedings of the IEEE Power and Energy Society General Meeting (PESGM), Boston, MA, USA, 17–26 July 2016; pp. 1–5. [Google Scholar]

- Rozporządzenie Ministra Klimatu i Środowiska z dnia 27 września 2022 r. Zmieniające Rozporządzenie w Sprawie Szczegółowych Warunków Funkcjonowania Systemu Elektroenergetycznego. Available online: https://reference.globalspec.com/standard/3795734/p1366-d7-jan-2012 (accessed on 28 June 2024).

- Dubey, A. Preparing the Power Grid for Extreme Weather Events: Resilience Modeling and Optimization. In Women in Engineering and Science; Tietjen, J.S., Ilic, M.D., Bertling Tjernberg, L., Schulz, N.N., Eds.; Women in Power; Springer: Cham, Switzerland, 2023. [Google Scholar]

- Sozański, J. Niezawodność i Jakość Pracy Systemu Elektroenergetycznego; WNT: Warszawa, Polska, 1990. [Google Scholar]

- Ji, C.; Wei, Y.; Poor, H.V. Resilience of Energy Infrastructure and Services: Modeling, Data Analytics, and Metrics. Proc. IEEE 2017, 105, 1354–1366. [Google Scholar] [CrossRef]

- Brown, R.E. Electric Power Distribution Reliability; Marcel Dekker, Inc.: New York, NY, USA, 2002. [Google Scholar]

- IEEE Draft Guide for Electric Power Distribution Reliability Indices. In IEEE P1366/D7, January 2012; IEEE: Piscataway, NJ, USA, 6 March 2012; pp. 1–40.

- Mukherjee, S.; Nateghi, R.; Hastak, M. A multi-hazard approach to assess severe weather-induced major power outage risks in the U.S. Reliab. Eng. Syst. Saf. 2018, 175, 283–305. [Google Scholar] [CrossRef]

- Kankanala, P.; Das, S.; Pahwa, A. Adaboost+: An ensemble learning approach for estimating weather-related outages in distribution systems. IEEE Trans. Power Syst. 2014, 29, 359–367. [Google Scholar] [CrossRef]

- Kabir, E.; Guikema, S.D.; Quiring, S.M. Power outage prediction using data streams: An adaptive ensemble learning approach with a feature- and performance-based weighting mechanism. Risk Anal. 2023, 44, 686–704. [Google Scholar] [CrossRef]

- Cerruti, B.J.; Decker, S.G. A Statistical Forecast Model of Weather-Related Damage to a Major Electric Utility. J. Appl. Meteor. Climatol. 2011, 51, 191–204. [Google Scholar] [CrossRef][Green Version]

- Złotecka, D. Wpływ ekstremalnych zjawisk atmosferycznych na system elektroenergetyczny. Electr. Eng. 2018, 94, 87–98. [Google Scholar] [CrossRef]

- Chojnacki, A.Ł. Assessment of the Risk of Damage to 110 kV Overhead Lines Due to Wind. Energies 2021, 14, 556. [Google Scholar] [CrossRef]

- Hanif, S.; Mukherjee, M.; Poudel, S.; Yu, M.G.; Jinsiwale, R.A.; Hardy, T.D.; Reeve, H.M. Analyzing at-scale distribution grid response to extreme temperatures. Appl. Energy 2023, 337, 120886. [Google Scholar] [CrossRef]

- Potts, J.; Tiedmann, H.R.; Syephens, K.K.; Faust, K.M.; Castellanos, S. Enhancing power system resilience to extreme weather events: A qualitative assessment of winter storm Uri. Int. J. Disaster Risk Reduct. 2024, 103, 104309. [Google Scholar] [CrossRef]

- Sroka, K.; Złotecka, D. The risk of large blackout failures in power systems. Arch. Electr. Eng. 2019, 68, 411–426. [Google Scholar]

- Bernstein, A.; Bienstock, D.; Hay, D.; Uzunoglu, M.; Zussman, G. Power grid vulnerability to geographically correlated failures—Analysis and control implications. In Proceedings of the IEEE INFOCOM 2014—IEEE Conference on Computer Communications, Toronto, ON, Canada, 27 April–2 May 2014; pp. 2634–2642. [Google Scholar]

- Banasik, K.; Chojnacki, A.Ł.; Gębczyk, K.; Grąkowski, Ł. Influence of wind speed on the reliability of low-voltage overhead power lines. In Proceeding of the 2019 Progress in Applied Electrical Engineering (PAEE)—IEEE, Koscielisko, Poland, 17–21 June 2019; pp. 1–5. [Google Scholar]

- Zhou, Y.; Pahwa, A.; Yang, S.S. Modeling weather-related failures of overhead distribution lines. IEEE Trans. Power Syst. 2006, 21, 1683–1690. [Google Scholar] [CrossRef]

- Mitchell, J.W. Power line failures and catastrophic wildfires under extreme weather conditions. Eng. Fail. Anal. 2013, 35, 726–735. [Google Scholar] [CrossRef]

- Dzobo, O.; Tazvinga, H. Impact of Weather Conditions on Line Ampacity of Overhead Transmission Lines. In Proceedings of the 9th International Conference on Power and Energy Systems (ICPES), Perth, WA, Australia, 21–22 December 2019; pp. 1–5. [Google Scholar]

- Kolev, V.G.; Sulakov, S.I. The weather impact on the overhead line losses. In Proceedings of the 2017 15th International Conference on Electrical Machines, Drives and Power Systems (ELMA), Sofia, Bulgaria, 1–3 June 2017; pp. 119–123. [Google Scholar]

- Goncalves, A.; Marques, M.C.; Loureiro, S.; Nieto, R.; Liberato, M.L.R. Disruption risk analysis of the overhead power lines in Portugal. Energy 2023, 263 (Pt A), 125583. [Google Scholar]

- Hou, G.; Muraleetharan, K.K.; Panchalogaranjan, V.; Moses, P.; Javid, A.; Al-Dakheeli, H.; Bulut, R.; Campos, R.; Harvey, P.S.; Miller, G.; et al. Resilience assessment and enhancement evaluation of power distribution systems subjected to ice storms. Reliab. Eng. Syst. Saf. 2023, 230, 108964. [Google Scholar] [CrossRef]

- Banasik, K. Influence of Ambient Temperature on the Reliability of Overhead Power Lines with Bare Conductors. Energies 2024, 17, 3062. [Google Scholar] [CrossRef]

- Chojnacki, A.Ł. Modele niezawodnościowe izolowanych linii napowietrznych SN. Elektro Info 2016, 6, 69–73. [Google Scholar]

- Chojnacki, A.Ł. Modele niezawodnościowe linii napowietrznych SN z przewodami gołymi. Elektro Info 2016, 5, 20–24. [Google Scholar]

- Naigen, L.; Yong, Y.Z.; Heheng, L.; Xiaojun, P. Application Research on Online Power Cable Temperature Detection via Fiber Optics. Appl. Math. Nonlinear Sci. 2024, 9, 1–12. [Google Scholar] [CrossRef]

- Carer, P.; Briend, C. Weather Impact on Components Reliability: A Model for MV Electrical Networks. In Proceedings of the 10th International Conference on Probablistic Methods Applied to Power Systems, Rincon, PR, USA, 24–26 June 2008; pp. 1–7. [Google Scholar]

- van Dinter, R.; Rieken, S.; Leduc, P.; Netten, G.; Tekinerdogan, B.; Catal, C. Forecasting Partial Discharges of Cable Joints using Weather data. In Proceedings of the IEEE Conference on Artificial Intelligence (CAI), Santa Clara, CA, USA, 5–6 June 2023; pp. 30–31. [Google Scholar]

- Sturchio, A.; Fioriti, G.; Pompili, M.; Cauzillo, B. Failure rates reduction in SmartGrid MV underground distribution cables: Influence of temperaturę. In Proceedings of the AEIT Annual Conference—From Research to Industry: The Need for a More Effective Technology Transfer (AEIT), Trieste, Italy, 1 September 2014; pp. 1–6. [Google Scholar]

- Chojnacki, A.Ł. Porównanie wskaźników i właściwości niezawodnościowych przyłączy napowietrznych i kablowych nN. Pr. Inst. Elektrotechniki 2015, 250, 93–107. [Google Scholar] [CrossRef]

- Chojnacki, A.Ł.; Chojnacka, K.J. Niezawodność Elektroenergetycznych Sieci Dystrybucyjnych; Wydawnictwo Politechniki Świętokrzyskiej: Kielce, Poland, 2018. [Google Scholar]

- Gkika, A.V.; Zacharis, E.A.; Lekkas, E.L.; Lizios, S.G.; Parcharidis, I.A. Climate Change Adaptation Management Pathway for Overhead Electricity Pole Systems of Distribution Networks. In Proceedings of the 2nd World Conference on Sustainability, Energy and Environment, Berlin, Germany, 9–11 December 2022; pp. 49–83. [Google Scholar]

- Wang, Y.; Chen, C.; Wang, J.; Baldick, R. Research on Resilience of Power Systems Under Natural Disasters—A Review. IEEE Trans. Power Syst. 2016, 31, 1604–1613. [Google Scholar] [CrossRef]

- Panteli, M.; Mancarella, P. Modeling and Evaluating the Resilience of Critical Electrical Power Infrastructure to Extreme Weather Events. IEEE Syst. J. 2017, 11, 1733–1742. [Google Scholar] [CrossRef]

- Lee, S.M.; Chinthavali, S.; Bhusal, N.; Stenvig, N.; Tabassum, A.; Kuruganti, T. Quantifying the Power System Resilience of the US Power Grid Through Weather and Power Outage Data Mapping. IEEE Access 2024, 12, 5237–5255. [Google Scholar] [CrossRef]

- Dehghani, F.; Mohammadi, M.; Karimi, M. Age-dependent resilience assessment and quantification of distribution systems under extreme weather events. Int. J. Electr. Power Energy Syst. 2023, 150, 109089. [Google Scholar] [CrossRef]

- Atrigna, M.; Buonanno, A.; Carli, R.; Cavone, G.; Scarabaggio, P.; Valenti, M.; Dotoli, M. A Machine Learning Approach to Fault Prediction of Power Distribution Grids Under Heatwaves. IEEE Trans. Ind. Appl. 2023, 59, 4835–4845. [Google Scholar] [CrossRef]

- Coleman, N.; Esmalian, A.; Lee, C.; Gonzales, E.; Koirala, P.; Mostafavi, A. Energy inequality in climate hazards: Empirical evidence of social and spatial disparities in manager and hazard-induced power outages. Sustain. Cities Soc. 2023, 92, 104491. [Google Scholar]

- EN 50160:2023-10; Supply Voltage Parameters in Public Power Grids. Polish Committee for Standardization: Warsaw, Poland, 2023.

- PN-76/E-05125; Power and Signalling Cable Lines. Design and Construction. Polish Committee for Standardization: Warsaw, Poland, 2004.

- Kujszczyk, S. Elektroenergetyczne Sieci Rozdzielcze Tom 1; Wydawnictwo Naukowe PWN: Warszawa Polska, 1994. [Google Scholar]

- Stępień, J.C. Metody Analizy i Oceny Niezawodności Kablowych Układów Zasilających Średnich Napięć; Wydawnictwo Politechniki Świętokrzyskiej: Kielce, Polska, 2011. [Google Scholar]

- Bartáková, B.; Rychtera, M. Tropikalizacja Urządzeń Elektrycznych; Wydawnictwo Naukowo-Techniczne: Warszawa, Poland, 1960. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).