Impact of Coal Orthotropic and Hydraulic Fracture on Pressure Distribution in Coalbed Methane Reservoirs

Abstract

:1. Introduction

2. Method

3. Results and Discussion

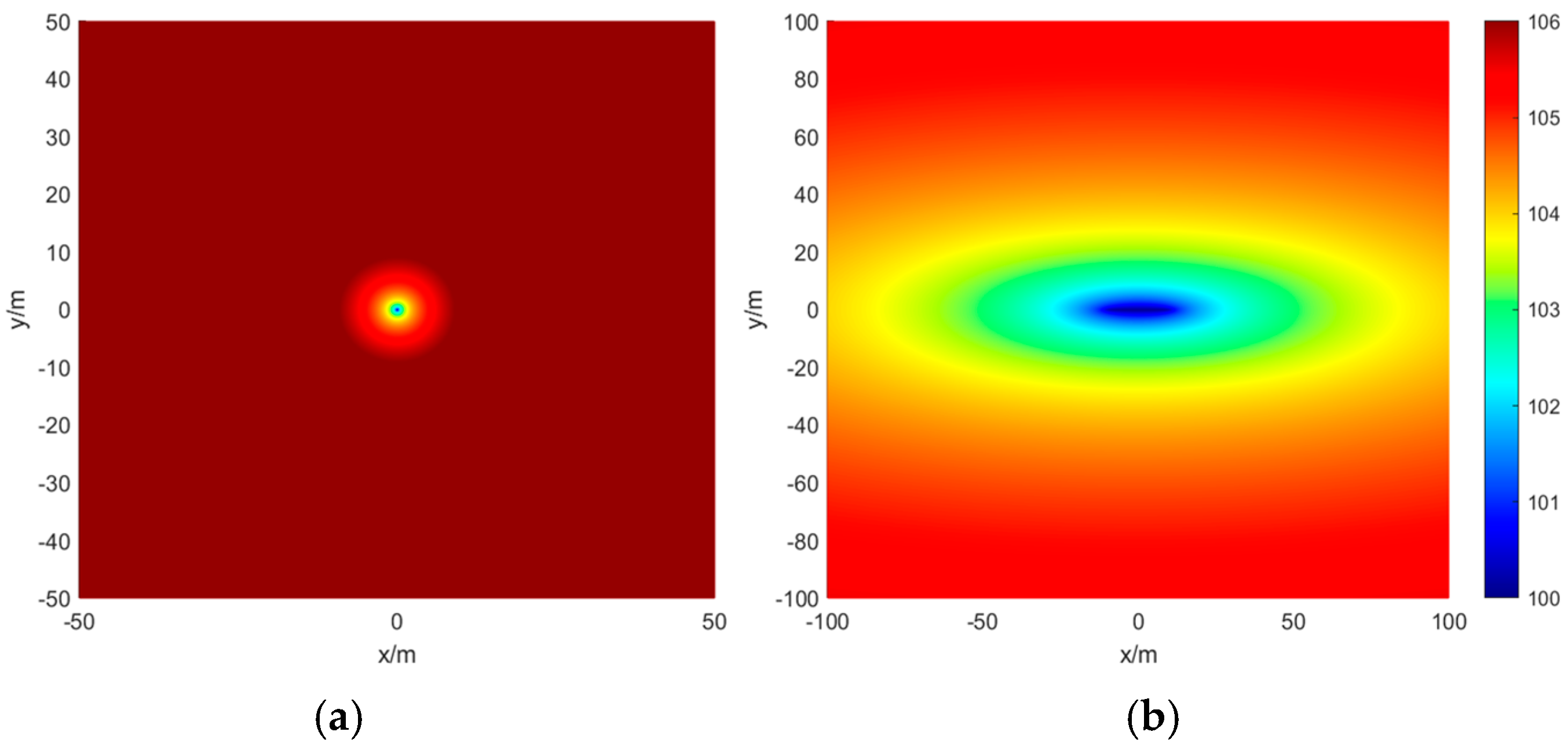

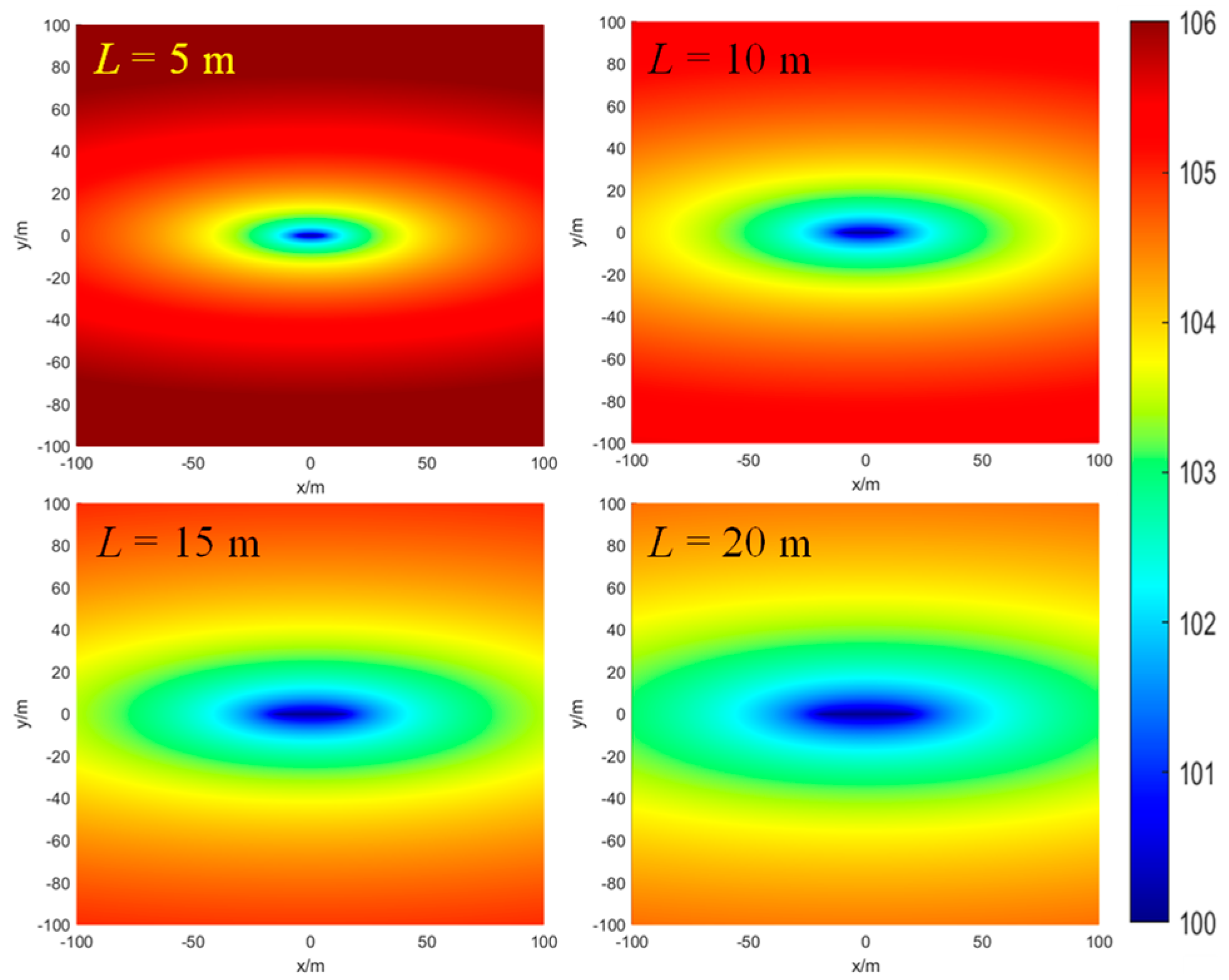

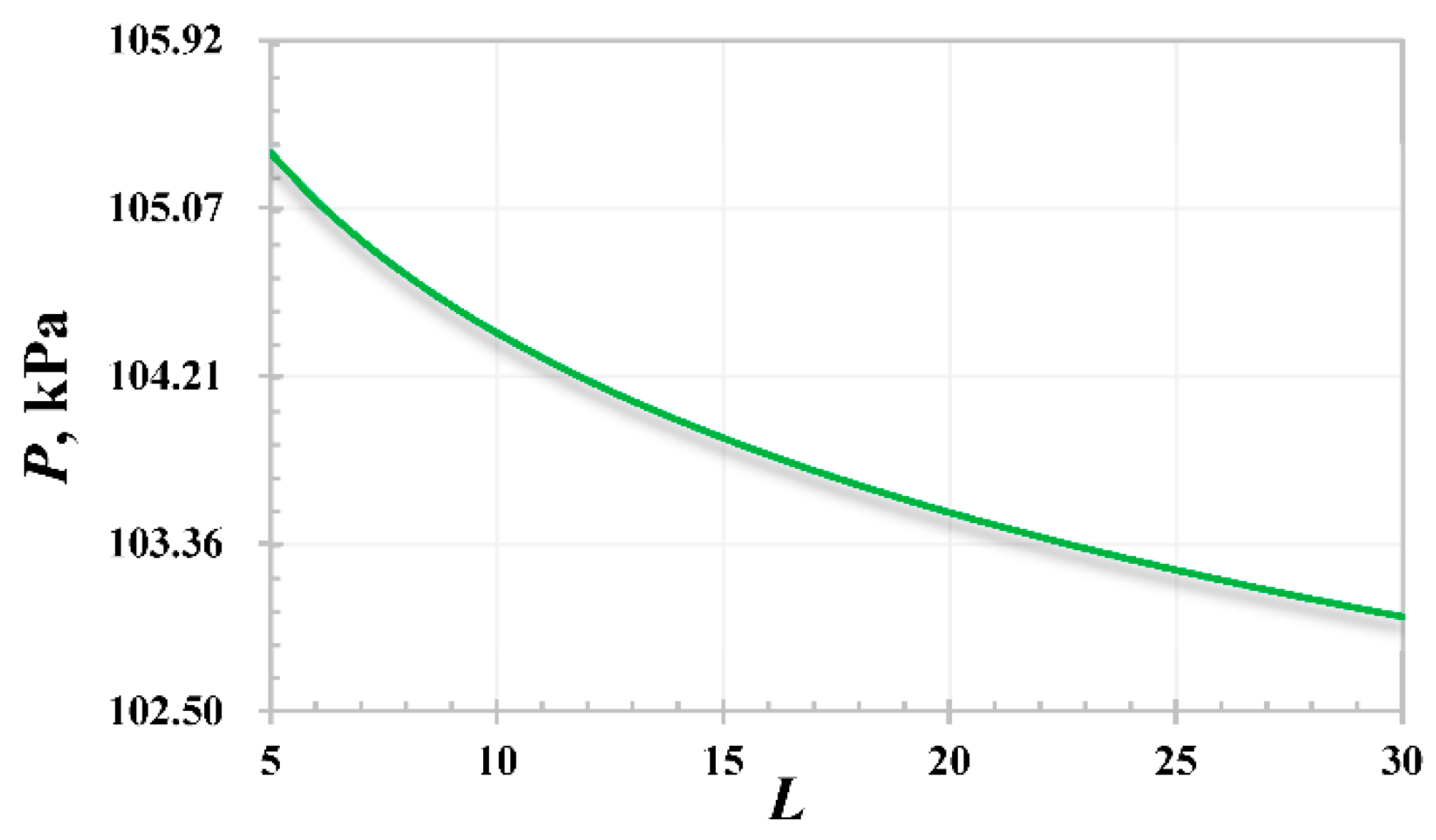

3.1. Impact of Fracture Length in Homogeneous Coal Seam

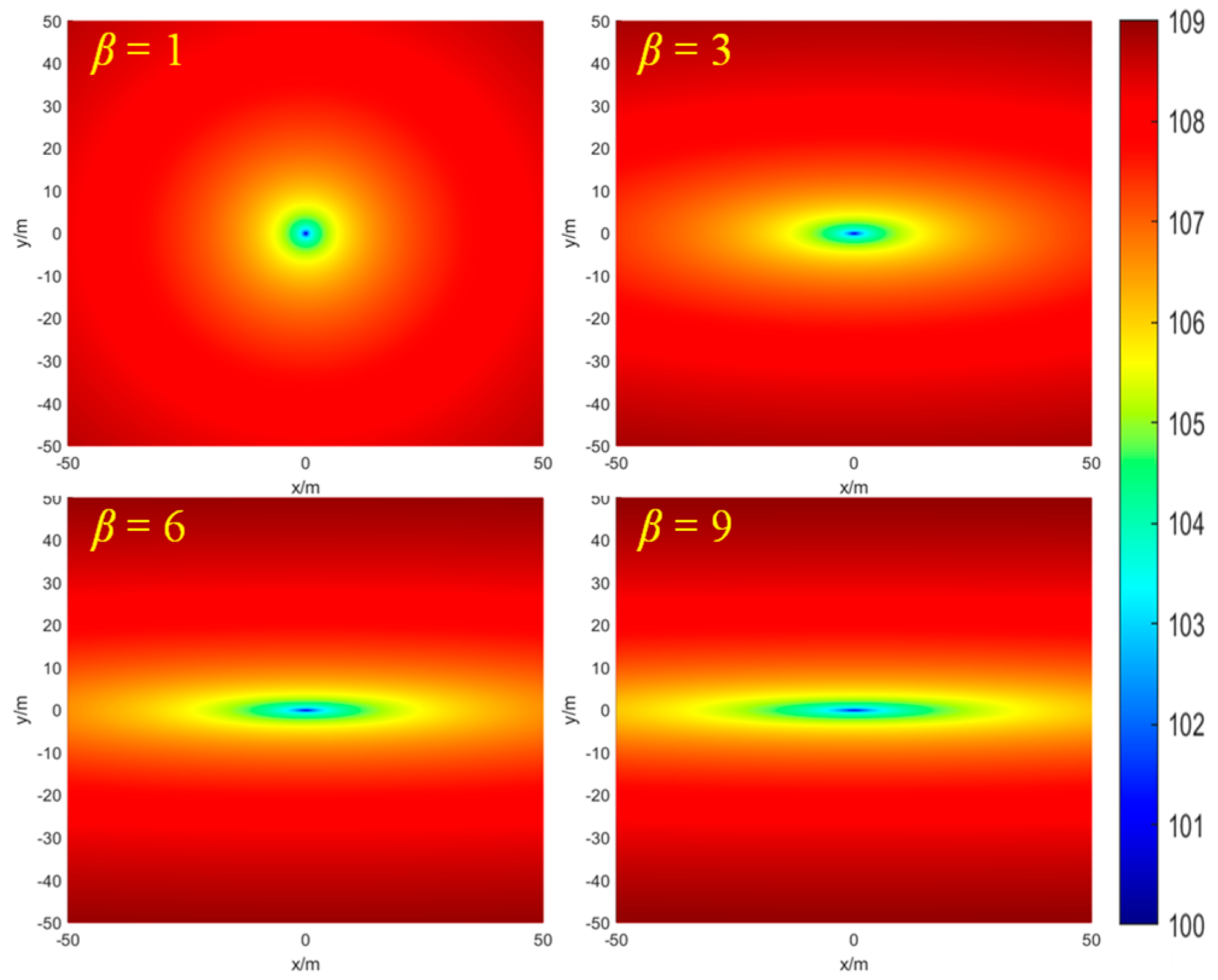

3.2. Impact of Heterogeneity for Unfractured Coal Seam

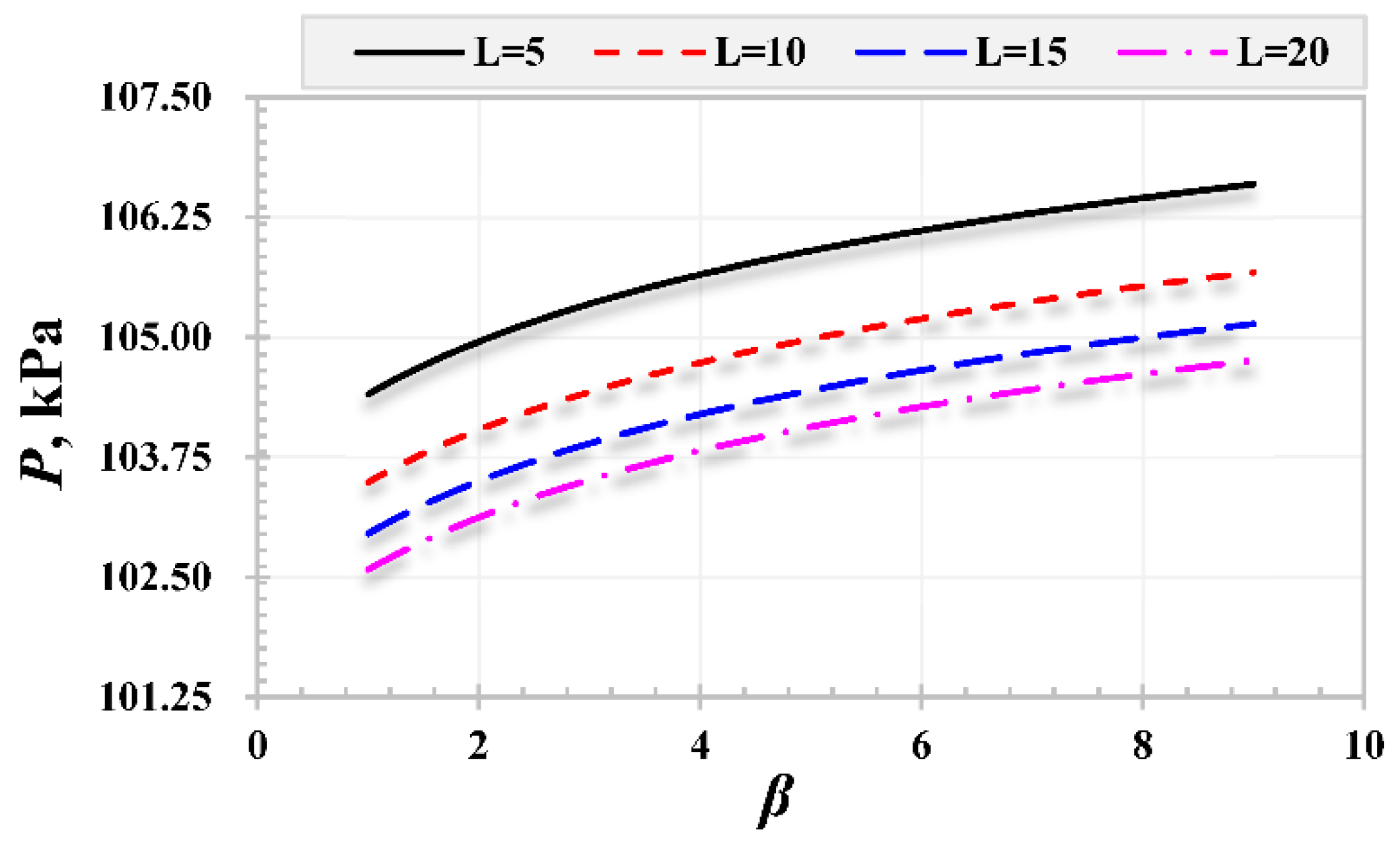

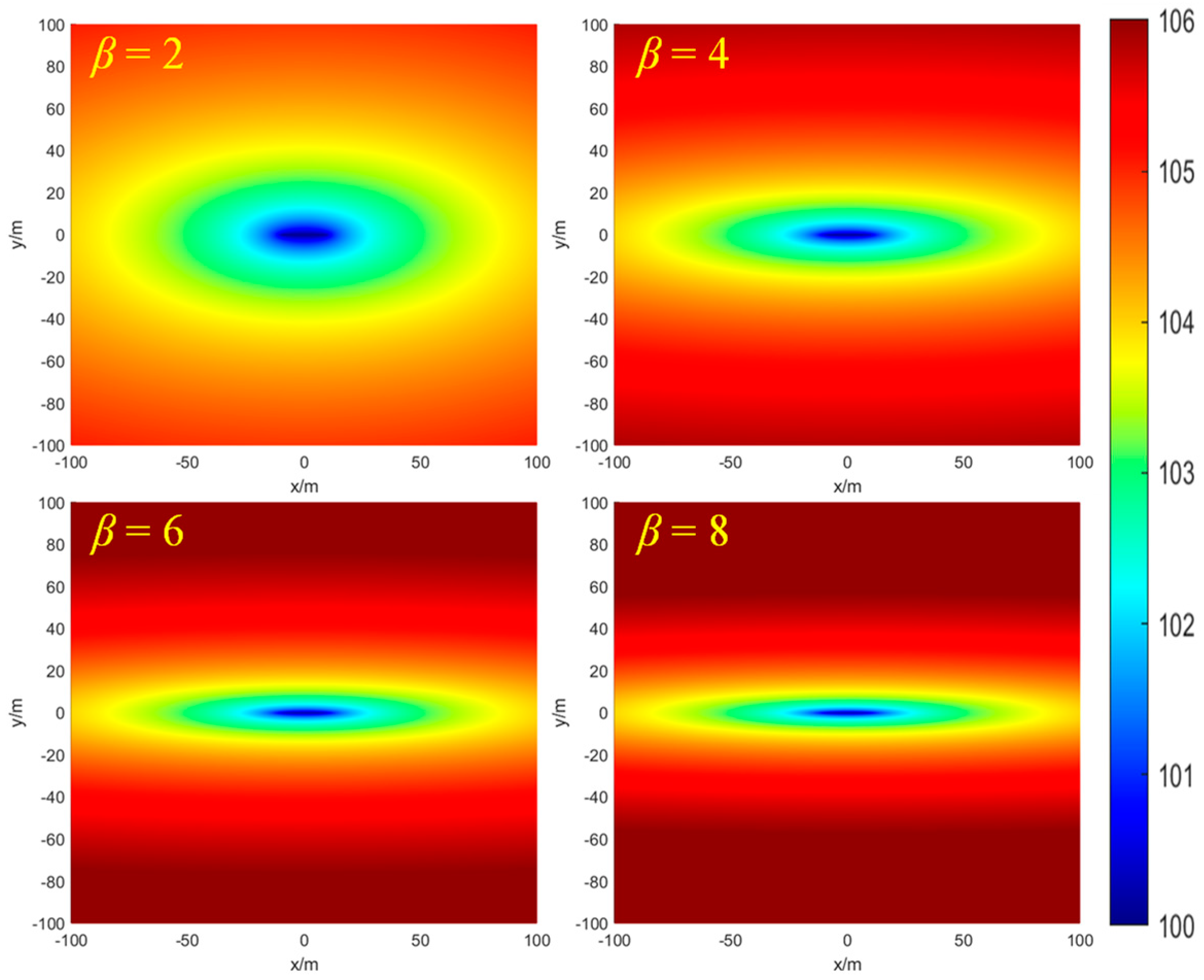

3.3. Impact of Simultaneous Change in Fracture Length and Anisotropy Coefficient

3.4. Impact of Fracturing Length for a Multi-Well Production Case in a Homogeneous Coal Seam

3.5. Impact of Anisotropy under the Condition of Multi-Well Production without Fracturing

3.6. Impact of Anisotropy under the Condition of Multi-Well Production with Fracturing

4. Conclusions

- (1)

- In the study of the pressure field distribution of a coal seam in a single borehole, under the condition of a constant anisotropy coefficient, fracturing can effectively reduce the pressure around the borehole and has a good pressure drop effect. In addition, the greater the half-length of the fracture, the better the effect of the coal seam’s pressure drop. When the fracture half-length is certain, heterogeneity can affect the CBM pressure around the borehole. With the increase in the anisotropy coefficient, the CBM pressure increases gradually.

- (2)

- In the homogeneous fractured coal seam with multiple wells, the pressure effect under the joint action of multiple wells is the same as that of a single borehole. Under the condition of constant homogeneity, with the increase in the fracturing half-length, the pressure of CBM decreases gradually, which has a good pressure drop effect and is more conducive to the extraction of CBM. In the multi-well heterogeneous fracturing coal seam, under the condition of constant heterogeneity, with the increase in fracturing half-length, the coal seam gas pressure gradually decreases, which has a good pressure drop effect and is more conducive to the extraction of coal seam gas.

- (3)

- The pressure distribution between the four wells shows significant non-uniformity in the multi-well CBM extraction. Therefore, there is an optimal hole layout mode to minimize the average pressure between the four wells and achieve better pumping effect.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, F.; Dai, K.; Zhou, Z.; Wang, Z. The Researching Progress and Problems of The Extraction of Coal and CBM. China Coalbed Methane 2010, 7, 45–47. [Google Scholar]

- Zhao, Z.; Dong, W.; Wei, G.; Shi, T. Numerical simulation study and application of hectometre borehole gas flowrate. J. Min. Saf. Eng. 2018, 35, 436–441. [Google Scholar]

- Xu, F.; Yan, X.; Lin, Z.; Li, S.; Xiong, X.; Yan, D.; Wang, H.; Zhang, S.; Xu, B.; Ma, X.; et al. Research progress and development direction of key technologies for efficient development of CBM in China. Coal Geol. Explor. 2022, 50, 2–8. [Google Scholar]

- Qin, Y.; Yuan, L.; Hu, Q.; Ye, J.; Hu, A.; Shen, B.; Cheng, Y.; He, X.; Zhang, S.; Li, G.; et al. Status and Development Orientation of Coal Bed Methane Exploration and Development Technology in China. Coal Sci. Technol. 2012, 40, 2–6. [Google Scholar]

- Wu, H. Study and practice on technology of three-zones linkage 3D CBM drainage in coal mining area. J. China Coal Soc. 2011, 36, 1312–1315. [Google Scholar]

- Yuan, L. Theory and Practice of Integrated Pillarless Coal Production and Methane Extraction in Multiseams of Low Permeability. China Coal Ind. Publ. House 2009, 11, 72–79. [Google Scholar]

- Yuan, L. Research on comprehensive mine gas prevention and control technology system in mine with com plicated geological conditions. Coal Sci. Technol. 2006, 34, 1–3. [Google Scholar]

- Cheng, Y.; Yu, Q. Development of Regional Gas Control Technology for Chinese Coalmines. J. Min. Saf. Eng. 2007, 24, 383–390. [Google Scholar]

- Zhao, Z. Gas Comprehensive Management on Mining Protective Seam in Full Mechanized Coal Face. Coal Technol. 2007, 26, 77–78. [Google Scholar]

- Cheng, Y.; Yu, Q.; Yuan, L.; Li, P.; Liu, Y.; Tong, F. Experimental Research of Safe and High-Efficient Exploitation of Coal and Pressure Relief Gas in Long Distance. J. China Univ. Min. Technol. 2004, 33, 133–136. [Google Scholar]

- Yuan, L. Concept of gas control and simultaneous extraction of coal and gas. China Coal 2010, 36, 5–12. [Google Scholar]

- Ji, H.; Li, Z.; Yang, Y.; Liu, Z.; Yang, J. Drainage radius measurement based on gas flow field. J. Min. Saf. Eng. 2013, 30, 917–921. [Google Scholar]

- Liang, B.; Yuan, X.; Sun, W. Seepage coupling model of in-seam gas extraction and its applications. J. China Univ. Min. Technol. 2014, 43, 208–212. [Google Scholar]

- Yin, G.; Li, M.; Li, S.; Li, W.; Yao, J.; Zhang, Q. 3D numerical simulation of gas drainage from boreholes based on solid-gas coupling model of coal containing gas. J. China Coal Soc. 2013, 38, 536–539. [Google Scholar]

- Lu, Y.; Shen, H.; Qin, B.; Zhang, L.; Ma, H.; Mao, T. Gas drainage radius and borehole distance along seam. J. Min. Saf. Eng. 2015, 32, 156–162. [Google Scholar]

- Cao, Y.; Long, S.; Li, X.; Hu, X.; Wang, C.; Wang, F. The Enlightenment from Comparative Studies of the Coalbed Methane (CBM) Development at Home and Abroad. Xinjiang Pet. Geol. 2014, 35, 109–112. [Google Scholar]

- Zhou, Y. Study on Surface Boreholes Extracting Gas from Gobs. Coal Technol. 2013, 32, 90–91. [Google Scholar]

- Hao, C.; Cheng, Y.; Wang, L.; Liu, H.; Shang, Z. A novel technology for enhancing CBM extraction: Hydraulic cavitating assisted fracturing. J. Nat. Gas Sci. Eng. 2019, 72, 103040. [Google Scholar] [CrossRef]

- Cheng, G.; Deng, B.; Liu, Y.; Chen, J.; Wang, K.; Zhang, D.; Li, M. Experimental investigation on the feasibility and efficiency of shear-fracturing stimulation for enhancing coal seam permeability. J. Nat. Gas Sci. Eng. 2020, 81, 103381. [Google Scholar] [CrossRef]

- Tang, Z.; Zhai, C.; Zou, Q.; Qin, L. Changes to coal pores and fracture development by ultrasonic wave excitation using nuclear magnetic resonance. Fuel 2016, 186, 571–578. [Google Scholar] [CrossRef]

- Yan, F.; Lin, B.; Zhu, C.; Shen, C.; Zou, Q.; Guo, C.; Liu, T. A novel ECBM extraction technology based on the integration of hydraulic slotting and hydraulic fracturing. J. Nat. Gas Sci. Eng. 2015, 22, 571–579. [Google Scholar] [CrossRef]

- Zuo, S.; Ge, Z.; Zhou, Z.; Wang, L.; Zhao, H. A Novel Hydraulic Mode to Promote Gas Extraction: Pressure Relief Technologies for Tectonic Regions and Fracturing Technologies for Nontectonic Regions. Energy Sci. Technol. 2019, 9, 1404. [Google Scholar] [CrossRef]

- Fan, M.; Wang, S. Study on the cleats in CBM development. Coal Geol. Explor. 1997, 25, 29–32. [Google Scholar]

- Wang, Y.; Liu, X.; Bai, J.; Xie, X. Experimental evaluation of anisotropy of coal permeability. Pet. Geol. Eng. 2016, 30, 92–94. [Google Scholar]

- Fu, H.; Qin, Y.; Jiang, B.; Wang, W.-F. Compress experiment of coal cleat and mathematical simulation of coal reservoir permeability. J. China Coal Soc. 2001, 26, 573–577. [Google Scholar]

- Wang, B.; Yan, X.; Yang, X. Production Prediction with the Consideration of the Orthotropic Permeability of Coal Seam. Sci. Technol. Eng. 2017, 17, 229–231. [Google Scholar]

- Feng, X.; Wang, S.; Yu, X.; Chang, L.; Zhang, K. Effect of effective stress on anisotropy of CBM reservoir. Saf. Coal Mines 2020, 51, 15–19. [Google Scholar]

- Song, H.; Lin, B.; Zhao, Y.; Kong, J.; Zha, W. Effect mechanism of anisotropy and heterogeneity on gas seepage during coal seam drainage. J. Xi’an Univ. Sci. Technol. 2019, 39, 461–468. [Google Scholar]

- Lou, Z.; Wang, K.; Zang, J.; Zhao, W.; Qin, B.; Kan, T. Effects of permeability anisotropy on coal mine methane drainage performance. J. Nat. Gas Sci. Eng. 2021, 86, 103733. [Google Scholar] [CrossRef]

- Wan, Y.; Pan, Z.; Tang, S.; Connell, L.D.; Down, D.D.; Camilleri, M. An experimental investigation of diffusivity and porosity anisotropy of a Chinese gas shale. J. Nat. Gas Sci. Eng. 2015, 23, 70–79. [Google Scholar] [CrossRef]

- Pan, Z.; Connell, L.D. Modelling of anisotropic coal swelling and its impact on permeability behavior for primary and enhanced CBM recovery. Int. J. Coal Geol. 2016, 28, 153–172. [Google Scholar]

- Zang, J.; Wang, K. A numerical model for simulating single-phase gas flow in anisotropic coal. J. Nat. Gas Sci. Eng. 2016, 28, 153–172. [Google Scholar] [CrossRef]

- Yuan, L. Theory of pressure-relieved gas extraction and technique system of integrated coal production and gas extraction. J. China Coal Soc. 2009, 34, 1–8. [Google Scholar]

| Parameters | Value | Unit |

|---|---|---|

| Bottom hole pressure | 100 | kPa |

| Production of gas | 0.5 | m3/min |

| X direction range | −100:0.1:100 | m |

| Y direction range | −100:0.1:100 | m |

| Thickness of the coal seam | 1 | m |

| Gas viscosity | 1 | mPa × s |

| Permeability of coal | 1 | mD |

| Shaft radius | 0.1 | m |

| The range of anisotropy coefficient | 1–9 | / |

| Parameters | Value | Unit |

|---|---|---|

| Bottom hole pressure | 100 | kPa |

| Production of gas | 0.5 | m3/min |

| X direction range | −100:0.1:100 | m |

| Y direction range | −100:0.1:100 | m |

| Thickness of the coal seam | 1 | m |

| Gas viscosity | 1 | mPa × s |

| Permeability of coal | 1 | mD |

| The range of fracturing half-length | 5–20 | m |

| The range of anisotropy coefficient | 1–9 | / |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Liu, Z.; Yan, S.; Yang, Y.; Zhou, Y.; Sun, Z. Impact of Coal Orthotropic and Hydraulic Fracture on Pressure Distribution in Coalbed Methane Reservoirs. Gases 2022, 2, 85-97. https://doi.org/10.3390/gases2030006

Li Y, Liu Z, Yan S, Yang Y, Zhou Y, Sun Z. Impact of Coal Orthotropic and Hydraulic Fracture on Pressure Distribution in Coalbed Methane Reservoirs. Gases. 2022; 2(3):85-97. https://doi.org/10.3390/gases2030006

Chicago/Turabian StyleLi, Yaohui, Zheng Liu, Shuhui Yan, Yaoxin Yang, Yu Zhou, and Zheng Sun. 2022. "Impact of Coal Orthotropic and Hydraulic Fracture on Pressure Distribution in Coalbed Methane Reservoirs" Gases 2, no. 3: 85-97. https://doi.org/10.3390/gases2030006

APA StyleLi, Y., Liu, Z., Yan, S., Yang, Y., Zhou, Y., & Sun, Z. (2022). Impact of Coal Orthotropic and Hydraulic Fracture on Pressure Distribution in Coalbed Methane Reservoirs. Gases, 2(3), 85-97. https://doi.org/10.3390/gases2030006