Application of CO2-Assisted Polymer Compression to Polylactic Acid and the Relationship between Crystallinity and Plasticization

Abstract

:1. Introduction

2. Materials and Methods

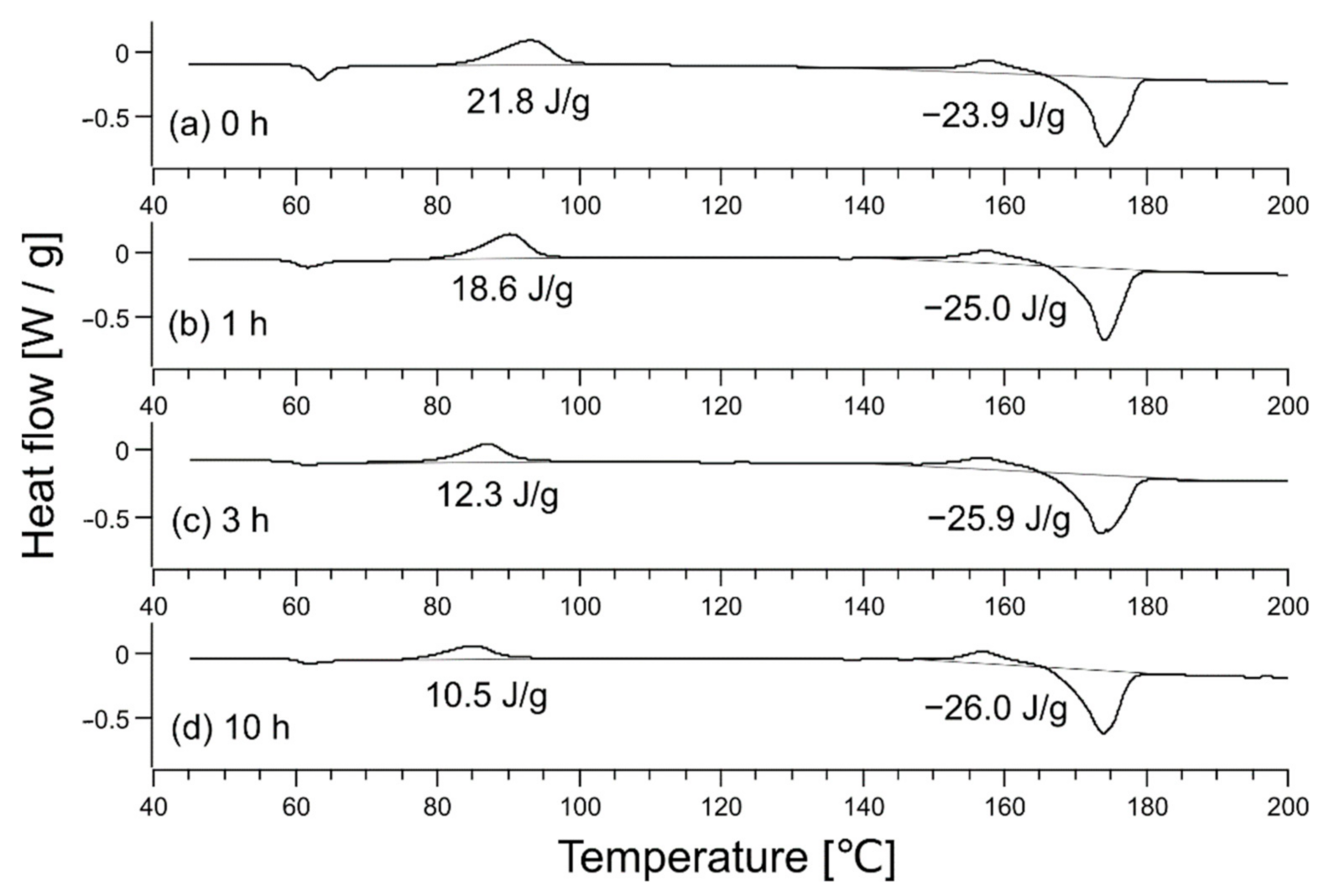

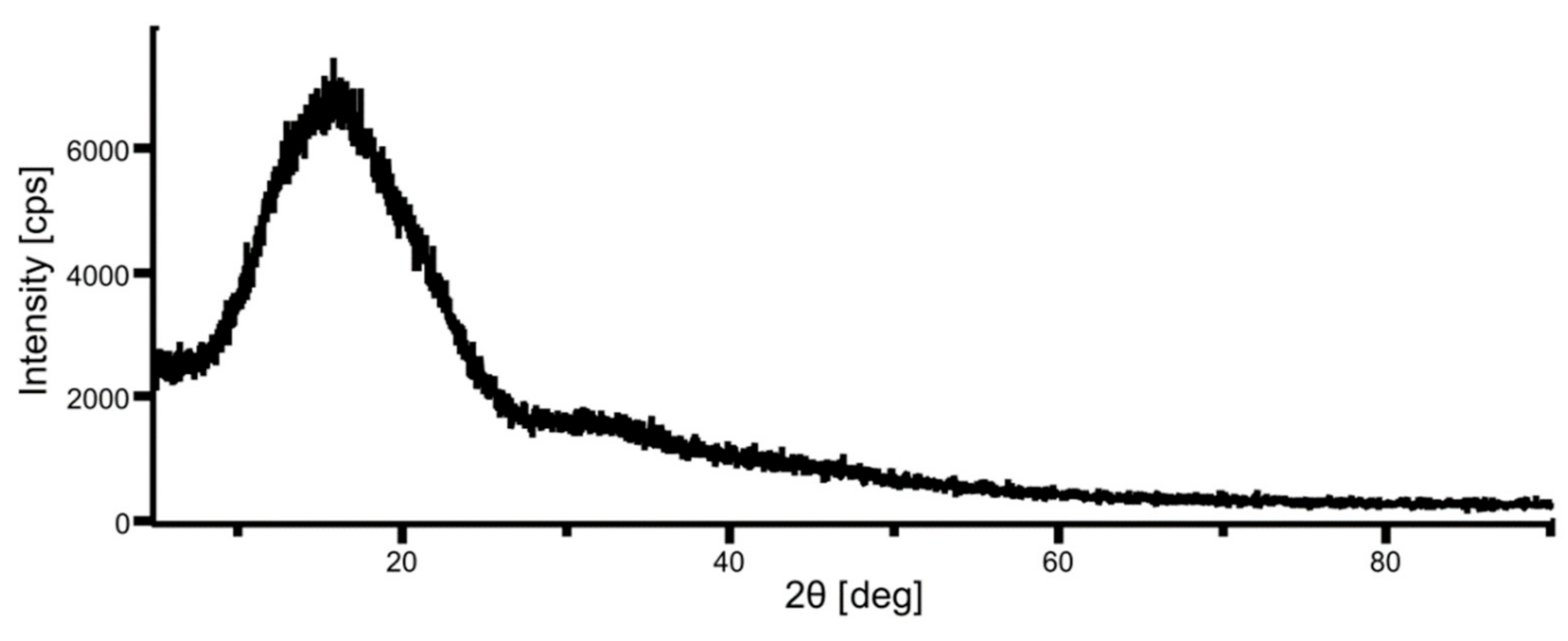

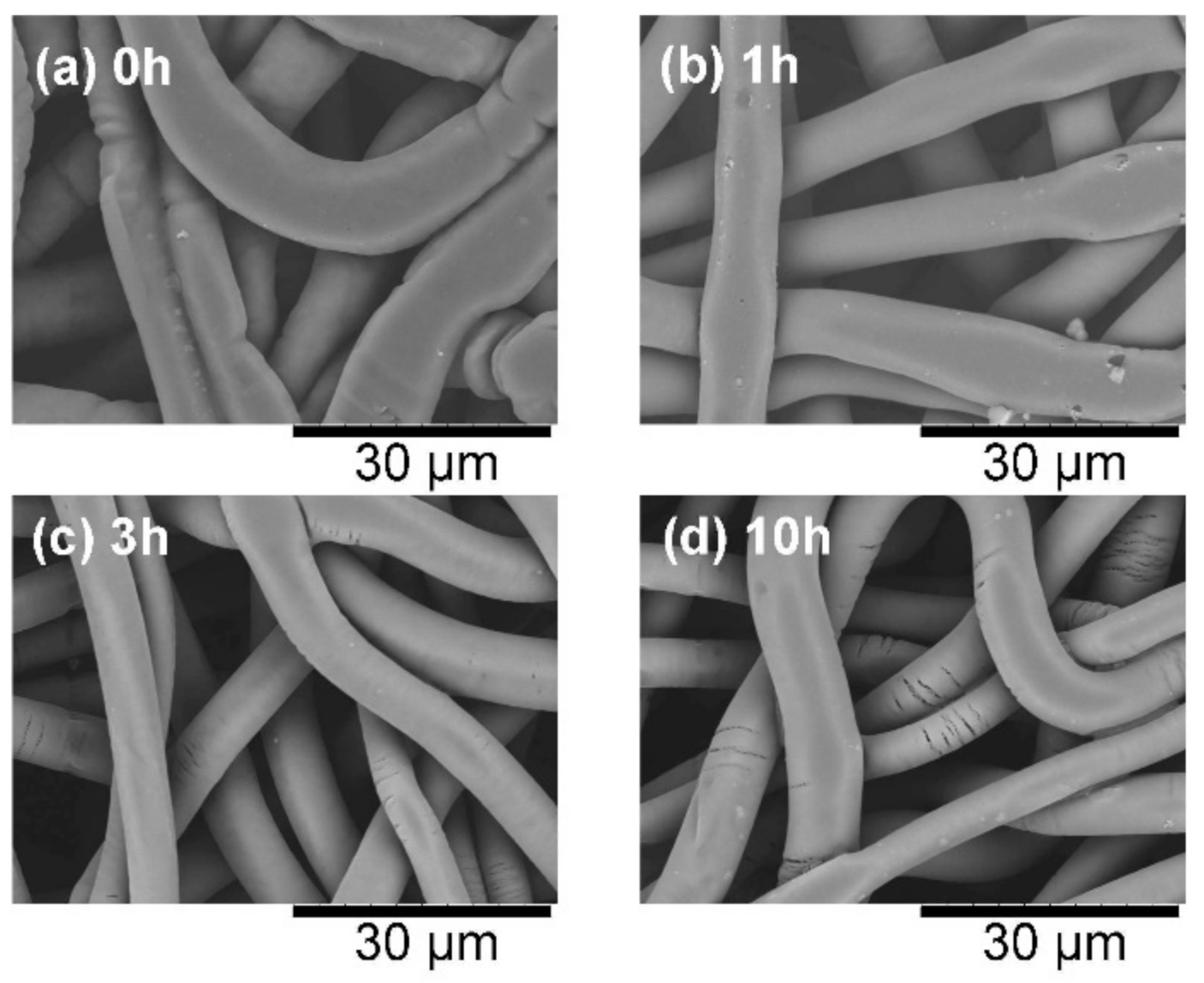

3. Results and Discussion

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- UN OWG. Introduction to the Proposal of the Open Working Group for the Sustainable Development Goals. Outcome Document as of 19.6.2014 (Online). 2014. Available online: https://sdgs.un.org/ (accessed on 13 April 2021).

- Shogren, R.; Wood, D.; Orts, W.; Glenn, G. Plant-based materials and transitioning to a circular economy. Sustain. Prod. Consum. 2019, 19, 194–215. [Google Scholar] [CrossRef]

- Inamuddin. Green Polymer Composites Technology: Properties and Applications; CRC Press: Boca Raton, FL, USA, 2019; ISBN 978-0367872557. [Google Scholar]

- Sin, L.T.; Tueen, B.S. Polylactic Acid: A Practical Guide for the Processing, Manufacturing, and Applications of PLA, 2nd ed.; William Andrew: Oxford, UK, 2019; ISBN 978-0128144725. [Google Scholar]

- Rojas, A.; Velásquez, E.; Garrido, L.; Galotto, M.J.; de Dicastillo, C.L. Design of active electrospun mats with single and core-shell structures to achieve different curcumin release kinetics. J. Food Eng. 2020, 273, 109900. [Google Scholar] [CrossRef]

- Velásquez, E.; Vidal, C.P.; Rojas, A.; Guarda, A.; Galotto, M.J.; de Dicastillo, C.L. Natural antimicrobials and antioxidants added to polylactic acid packaging films. Part I: Polymer processing techniques. Compr. Rev. Food Sci. Food Saf. 16. [CrossRef]

- Aizawa, T. A new method for producing porous polymer materials using carbon dioxide and a piston. J. Supercrit. Fluids 2018, 133, 38–41. [Google Scholar] [CrossRef]

- Koytsoumpa, E.K.; Bergins, C.; Kakaras, E. The CO2 economy: Review of CO2 capture and reuse technologies. J. Supercrit. Fluids 2018, 132, 3–16. [Google Scholar] [CrossRef]

- Aizawa, T. Fabrication of porosity-controlled polyethylene terephthalate porous materials using a CO2-assisted polymer compression method. RSC Adv. 2018, 8, 3061–3068. [Google Scholar] [CrossRef] [Green Version]

- Aizawa, T. Peel and penetration resistance of porous polyethylene terephthalate material produced by CO2-assisted polymer compression. Molecules 2019, 24, 1384. [Google Scholar] [CrossRef] [Green Version]

- Aizawa, T.; Wakui, Y. Correlation between the porosity and permeability of a polymer filter fabricated via CO2-assisted polymer compression. Membranes 2020, 10, 391. [Google Scholar] [CrossRef]

- Wakui, Y.; Aizawa, T. Analysis of sustained release behavior of drug-containing tablet prepared by CO2-assisted polymer compression. Polymers 2018, 10, 1405. [Google Scholar] [CrossRef] [Green Version]

- Aizawa, T. Process development of CO2-assisted polymer compression for high productivity: Improving equipment and the challenge of numbering-up. Technologies 2019, 7, 39. [Google Scholar] [CrossRef] [Green Version]

- Aizawa, T. Novel strategy for fabricating multi-layer porous membranes with varying porosity. ACS Omega 2020, 5, 24461–24466. [Google Scholar] [CrossRef] [PubMed]

- Aizawa, T. New design method for fabricating multilayer membranes using CO2-assisted polymer compression process. Molecules 2020, 25, 5786. [Google Scholar] [CrossRef]

- Kemmere, M.F.; Meyer, T. Supercritical Carbon Dioxide in Polymer Reaction Engineering; Wiley-VCH: Weinheim, Germany, 2005; ISBN 978-3527607051. [Google Scholar]

- Li, M.; Zhang, J.; Zou, Y.; Wang, F.; Chen, B.; Guan, L.; Wu, Y. Models for the solubility calculation of a CO2/polymer system: A review. Mater. Today Commun. 2020, 25, 1012772. [Google Scholar] [CrossRef]

- Lee, J.K.; Yao, S.X.; Li, G.M.; Jun, M.B.G.; Lee, P.C. Measurement methods for solubility and diffusivity of gases and supercritical fluids in polymers and its applications. Polym. Rev. 2017, 57, 695–747. [Google Scholar] [CrossRef]

- Gangapurwala, G.; Vollrath, A.; De San Luis, A.; Schubert, U.S. PLA/PLGA-based drug delivery systems produced with supercritical CO2-A green future for particle formulation? Pharmaceutics 2020, 12, 1118. [Google Scholar] [CrossRef] [PubMed]

- Villamil Jiménez, J.A.; Le Moigne, N.; Bénézet, J.-C.; Sauceau, M.; Sescousse, R.; Fages, J. Foaming of PLA composites by supercritical fluid-assisted processes: A review. Molecules 2020, 25, 3408. [Google Scholar] [CrossRef] [PubMed]

- Balaban, M.O.; Ferrentino, G. Dense Phase Carbon Dioxide: Food and Pharmaceutical Applications; Wiley-Blackwell: Ames, IA, USA, 2012; ISBN 978-0813806495. [Google Scholar]

- Drabek, J.; Zatloukal, M. Meltblown technology for production of polymeric microfibers/nanofibers: A review. Phys. Fluids 2019, 31, 091301. [Google Scholar] [CrossRef]

- Bruckmoser, K.; Resch, K. Effect of processing conditions on crystallization behavior and mechanical properties of poly(lactic acid) staple fibers. J. Appl. Polym. Sci. 2015, 132, 42432. [Google Scholar] [CrossRef]

- Fried, J.R. Polymer Science and Technology, 3rd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2014; ISBN 978-0137039555. [Google Scholar]

- Lim, L.-T.; Auras, R.; Rubino, M. Processing technologies for poly(lactic acid). Prog. Polym. Sci. 2008, 33, 820–852. [Google Scholar] [CrossRef]

- Young, R.J.; Lovell, P.A. Introduction to Polymers, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2011; ISBN 978-0849339295. [Google Scholar]

- Tomasko, D.L.; Li, H.; Liu, D.; Han, X.; Wingert, M.J.; Lee, L.J.; Koelling, K.W. A review of CO2 applications in the processing of polymers. Ind. Eng. Chem. Res. 2003, 42, 6431–6456. [Google Scholar] [CrossRef]

- Lian, Z.; Epstein, S.A.; Blenk, C.W.; Shine, A.D. Carbon dioxide-induced melting point depression of biodegradable semicrystalline polymers. J. Supercrit. Fluids 2006, 39, 107–117. [Google Scholar] [CrossRef]

| Sample | Heat-Treatment Time [h] | Thickness [mm] | Standard Deviation [mm] |

|---|---|---|---|

| 1A | 0 | 1.197 | 0.003 |

| 1B | 1 | 1.206 | 0.003 |

| 2A | 0 | 1.152 | 0.018 |

| 2B | 3 | 1.249 | 0.019 |

| 3A | 0 | 1.114 | 0.006 |

| 3B | 10 | 1.285 | 0.005 |

| 4A | 1 | 1.157 | 0.004 |

| 4B | 3 | 1.246 | 0.009 |

| 5A | 1 | 1.140 | 0.009 |

| 5B | 10 | 1.261 | 0.009 |

| 6A | 3 | 1.173 | 0.010 |

| 6B | 10 | 1.229 | 0.006 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aizawa, T. Application of CO2-Assisted Polymer Compression to Polylactic Acid and the Relationship between Crystallinity and Plasticization. Compounds 2021, 1, 75-82. https://doi.org/10.3390/compounds1020007

Aizawa T. Application of CO2-Assisted Polymer Compression to Polylactic Acid and the Relationship between Crystallinity and Plasticization. Compounds. 2021; 1(2):75-82. https://doi.org/10.3390/compounds1020007

Chicago/Turabian StyleAizawa, Takafumi. 2021. "Application of CO2-Assisted Polymer Compression to Polylactic Acid and the Relationship between Crystallinity and Plasticization" Compounds 1, no. 2: 75-82. https://doi.org/10.3390/compounds1020007

APA StyleAizawa, T. (2021). Application of CO2-Assisted Polymer Compression to Polylactic Acid and the Relationship between Crystallinity and Plasticization. Compounds, 1(2), 75-82. https://doi.org/10.3390/compounds1020007